Crashworthy Performance of Sustainable Filled Structures Using Recycled Beverage Cans and Eco-Friendly Multi-Cell Fillers

Abstract

1. Introduction

2. Materials and Processing

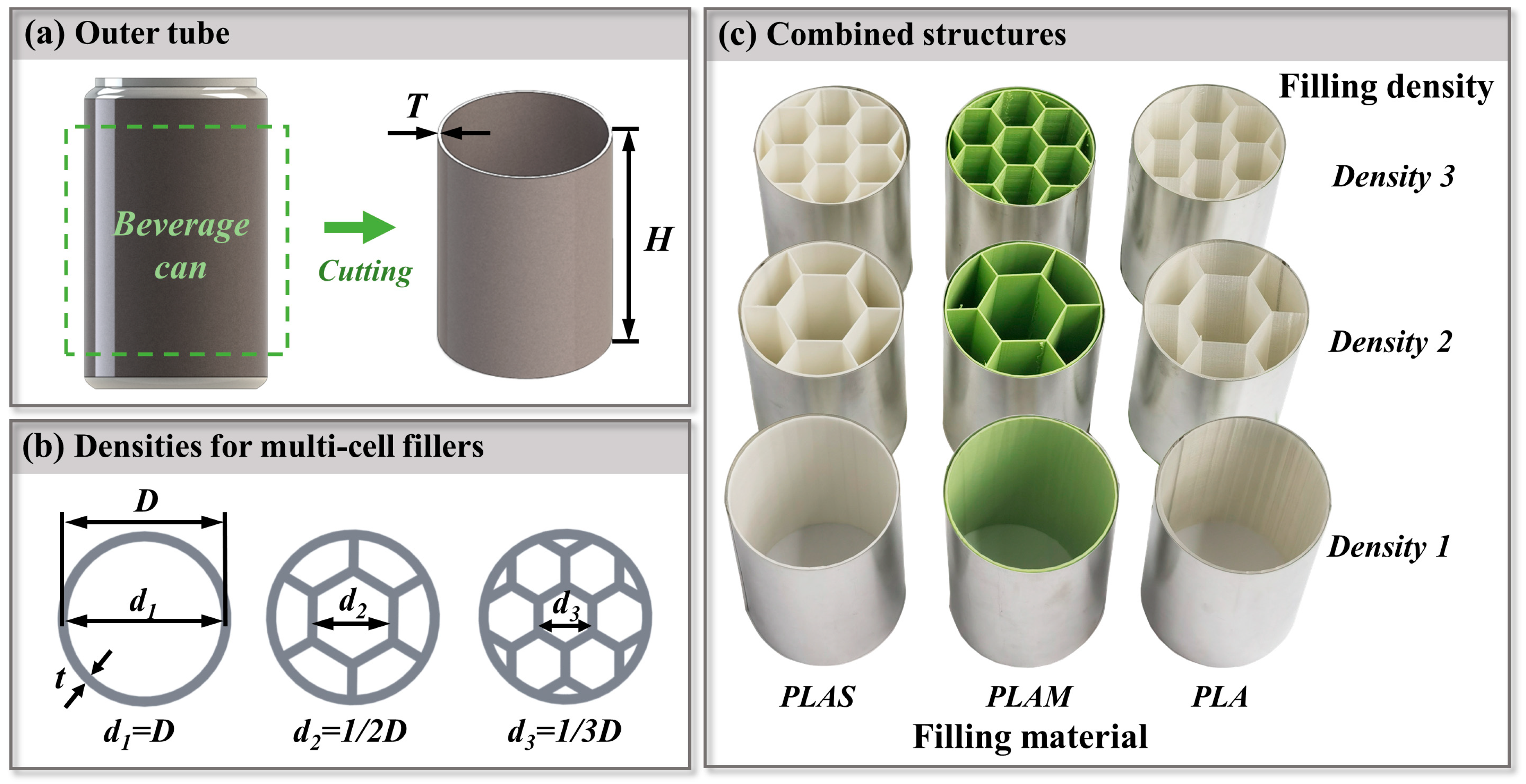

2.1. Specimen Preparation

2.2. Experimental Methods

2.3. Crashworthiness Criteria

3. Results and Discussion

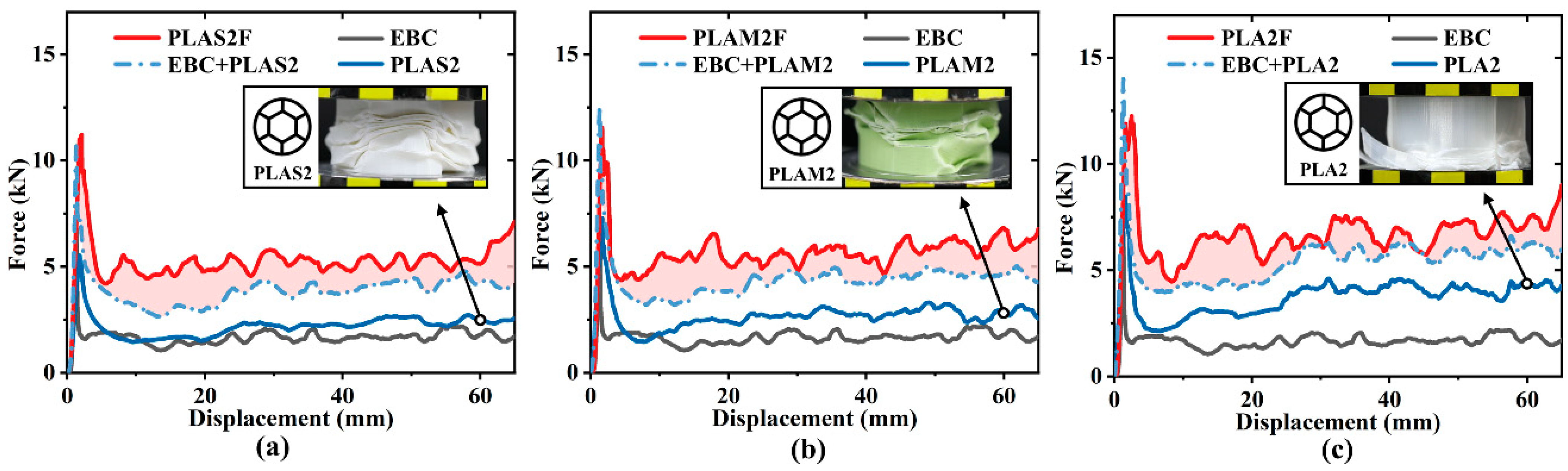

3.1. The Crushing Behavior of Filled Tubes

3.2. Quantified Evaluation

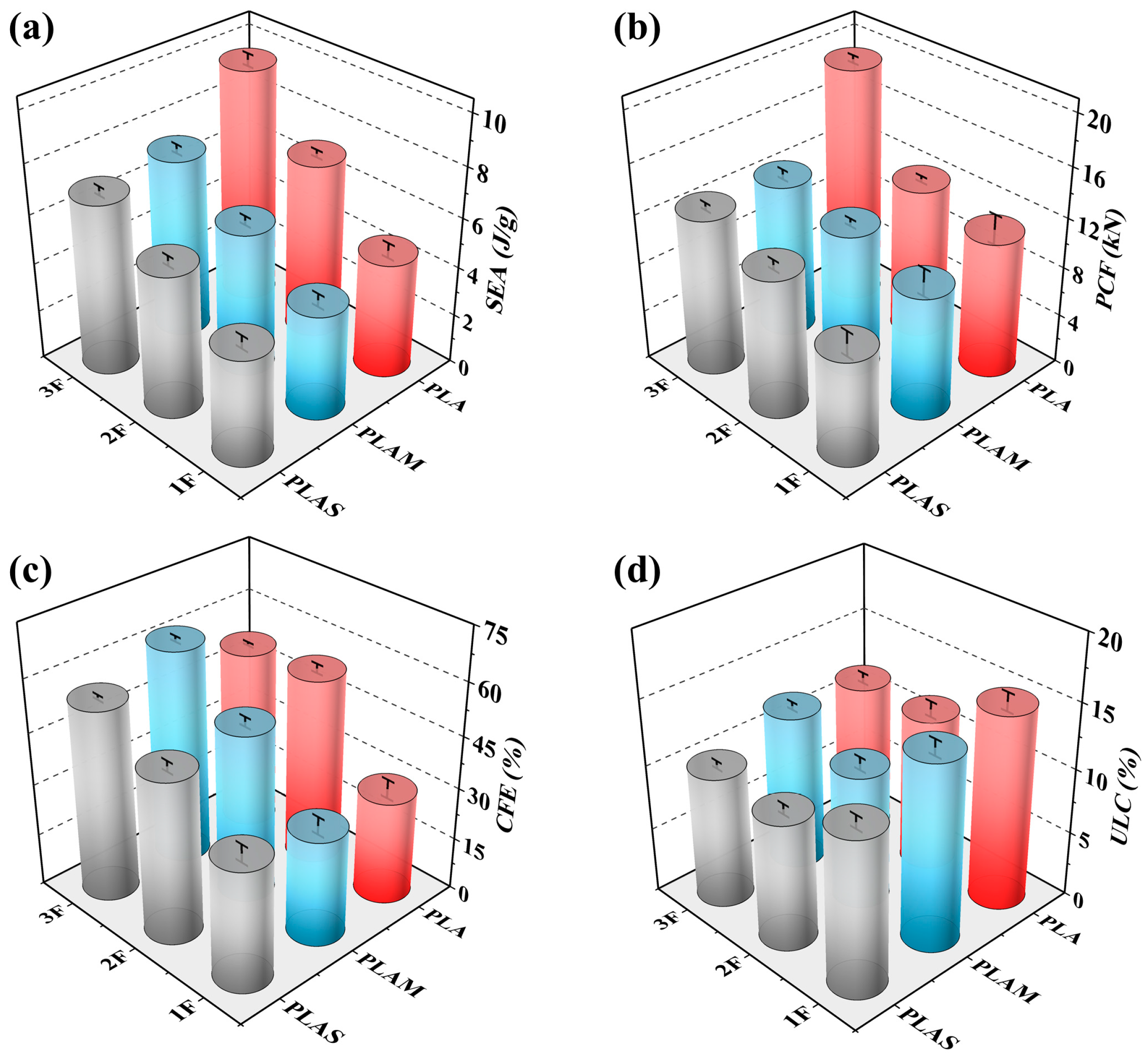

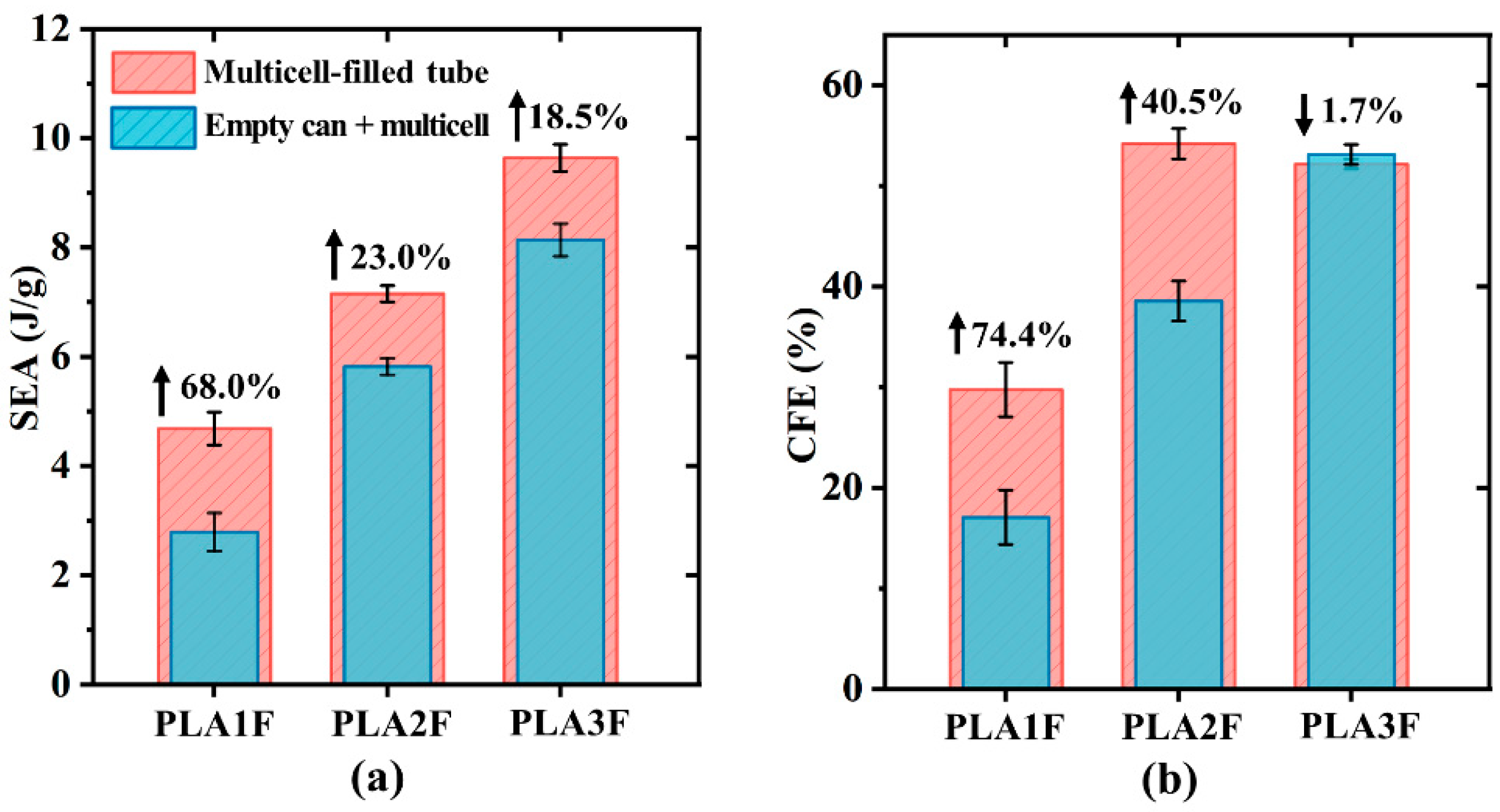

3.3. Interaction Between Empty Beverage Cans and Multi-Cell Fillers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, L.; Chen, Y.; Zheng, S.; Chang, M.; Chen, J. Upcycling discarded aluminum cans into nanoporous membranes as an eco-friendly and cost-effective strategy for fabricating polymer nanoarrays and self-cleaning surfaces. ACS Appl. Nano Mater. 2023, 6, 18558–18570. [Google Scholar] [CrossRef]

- Sondh, S.; Upadhyay, D.S.; Patel, S.; Patel, R.N. Strategic approach towards sustainability by promoting circular economy-based municipal solid waste management system—A review. Sustain. Chem. Pharm. 2024, 37, 101337. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Amin, M.B. Circular economy and sustainable practices in the food industry: A comprehensive bibliometric analysis. Clean. Responsible Consum. 2024, 14, 100206. [Google Scholar] [CrossRef]

- Palanivelu, S.; Van Paepegem, W.; Degrieck, J.; Reymen, B.; Ndambi, J.; Vantomme, J.; Kakogiannis, D.; Wastiels, J.; Van Hemelrijck, D. Close-range blast loading on empty recyclable metal beverage cans for use in sacrificial cladding structure. Eng. Struct. 2011, 33, 1966–1987. [Google Scholar] [CrossRef]

- Palanivelu, S.; Van Paepegem, W.; Degrieck, J.; De Pauw, S.; Vantomme, J.; Wastiels, J.; Kakogiannis, D.; Van Hemelrijck, D. Low velocity axial impact crushing performance of empty recyclable metal beverage cans. Int. J. Impact Eng. 2011, 38, 622–636. [Google Scholar] [CrossRef]

- Ousji, H.; Belkassem, B.; Pyl, L.; Vantomme, J. Air-blast loading on empty metallic beverage can used as sacrificial cladding: Experimental, analytical and numerical study. Eng. Struct. 2020, 204, 109979. [Google Scholar] [CrossRef]

- Zhang, X.W.; Yu, T.X. Energy absorption of pressurized thin-walled circular tubes under axial crushing. Int. J. Mech. Sci. 2009, 51, 335–349. [Google Scholar] [CrossRef]

- Hu, L.L.; Zeng, Z.H.; Yu, T.X. Axial crushing of pressurized cylindrical tubes. Int. J. Mech. Sci. 2016, 107, 126–135. [Google Scholar] [CrossRef]

- Liu, C.; Qi, G.; Li, P. Crashworthy characteristics of sustainable thin-walled tubes: A study on recycled beverage cans. Mech. Adv. Mater. Struct. 2022, 29, 3222–3236. [Google Scholar] [CrossRef]

- Chen, J.; Li, E.; Liu, W.; Mao, Y.; Hou, S. Sustainable composites with ultrahigh energy absorption from beverage cans and polyurethane foam. Compos. Sci. Technol. 2023, 239, 110047. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Liu, Y.; Ma, W.; Zhang, Z.; Zhao, C.; Yang, C. On the crush behavior and energy absorption of sustainable beverage cans and their polyurethane foam-filled structures: An experimental study. Materials 2024, 17, 2655. [Google Scholar] [CrossRef] [PubMed]

- Yao, R.; Pang, T.; Zhang, B.; Fang, J.; Li, Q.; Sun, G. On the crashworthiness of thin-walled multi-cell structures and materials: State of the art and prospects. Thin-Walled Struct. 2023, 189, 110734. [Google Scholar] [CrossRef]

- Sun, G.; Chen, D.; Zhu, G.; Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 2022, 172, 108760. [Google Scholar] [CrossRef]

- Guo, W.; Yang, L.; Xu, P.; Li, S.; Yan, W.; Shen, Z.; Yao, S.; Yang, C. Crashworthiness analysis of okra biomimetic corrugated multi-cellular structure. Int. J. Mech. Sci. 2024, 280, 109459. [Google Scholar] [CrossRef]

- Lin, P.; Zhang, Z.; Chen, Y.; Hu, D. Investigation of structural energy absorption performance in 3d-printed polymer (tough 1500 resin) materials with novel multilayer thin-walled sandwich structures inspired by peano space-filling curves. Polymers 2023, 15, 4068. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, X.; Huang, Z. Axial crushing of nylon and al/nylon hybrid tubes by fdm 3d printing. Compos. Struct. 2021, 256, 113055. [Google Scholar] [CrossRef]

- Tsang, H.H.; Raza, S. Impact energy absorption of bio-inspired tubular sections with structural hierarchy. Compos. Struct. 2018, 195, 199–210. [Google Scholar] [CrossRef]

- Ying, L.; Gao, T.; Hou, W.; Dai, M.; Han, X.; Jiang, D. On crashing behaviors of bio-inspired hybrid multi-cell al/cfrp hierarchical tube under quasi-static loading: An experimental study. Compos. Struct. 2021, 257, 113103. [Google Scholar] [CrossRef]

- Taib, N.A.B.; Rahman, M.R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bakri, M.K.B.; Julaihi, M.R.M.B.; Khan, A. A review on poly lactic acid (pla) as a biodegradable polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Akhrib, S.; Djellali, S.; Haddaoui, N.; Karimian, D.; Carraro, M. Biocomposites and poly (lactic acid) in active packaging: A review of current research and future directions. Polymers 2024, 17, 3. [Google Scholar] [CrossRef] [PubMed]

- Tănase, M.; Portoacă, A.I.; Diniță, A.; Brănoiu, G.; Zamfir, F.; Sirbu, E.; Călin, C. Optimizing mechanical properties of recycled 3d-printed pla parts for sustainable packaging solutions using experimental analysis and machine learning. Polymers 2024, 16, 3268. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-based 3d printing applications of pla composites: A review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Moradi, M.; Aminzadeh, A.; Rahmatabadi, D.; Hakimi, A. Experimental investigation on mechanical characterization of 3d printed pla produced by fused deposition modeling (fdm). Mater. Res. Express 2021, 8, 35304. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, L.; Yang, P.; Fang, J.; Li, W. Energy absorption of additively manufactured functionally bi-graded thickness honeycombs subjected to axial loads. Thin-Walled Struct. 2021, 164, 107810. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Khajepour, M.; Bayati, A.; Mirasadi, K.; Amin Yousefi, M.; Shegeft, A.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; et al. Advancing sustainable shape memory polymers through 4d printing of polylactic acid-polybutylene adipate terephthalate blends. Eur. Polym. J. 2024, 216, 113289. [Google Scholar] [CrossRef]

- Rebelo, H.B.; Lecompte, D.; Cismasiu, C.; Jonet, A.; Belkassem, B.; Maazoun, A. Experimental and numerical investigation on 3d printed pla sacrificial honeycomb cladding. Int. J. Impact Eng. 2019, 131, 162–173. [Google Scholar] [CrossRef]

- Alavi Nia, A.; Parsapour, M. Comparative analysis of energy absorption capacity of simple and multi-cell thin-walled tubes with triangular, square, hexagonal and octagonal sections. Thin-Walled Struct. 2014, 74, 155–165. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, Y.; Su, L.; Zhang, F.; Wu, C. Experimental and numerical study on mechanical behavior of hybrid multi-cell structures under multi-crushing loads. Thin-Walled Struct. 2022, 170, 108588. [Google Scholar] [CrossRef]

- Xiang, J.; Cheng, P.; Wang, K.; Wu, Y.; Rao, Y.; Peng, Y. Interlaminar and translaminar fracture toughness of 3d-printed continuous fiber reinforced composites: A review and prospect. Polym. Compos. 2024, 45, 3883–3900. [Google Scholar] [CrossRef]

- Xiang, J.; Wang, J.; Liu, Y.; Gao, H.; Tan, Q.; Wang, K.; Peng, Y. Effects of undulating printing paths on axial compressive behaviors of 3d-printed continuous fiber-reinforced multi-cell thin-walled structure. Eng. Struct. 2025, 325, 119353. [Google Scholar] [CrossRef]

- Zuo, X.; Guo, C.; Chen, W.; Wang, Y.; Zhao, J.; Lv, H. Influence of loading rate and temperature on the energy absorption of 3d-printed polymeric origami tubes under quasi-static loading. Polymers 2022, 14, 3859. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Li, S.; Long, H.; Dong, S.; Wang, K.; Peng, Y. Simulation analysis and optimization of 3d printed continuous carbon fiber reinforced composites. Compos. Struct. 2025, 355, 118840. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. Thin-walled corrugated structures: A review of crashworthiness designs and energy absorption characteristics. Thin-Walled Struct. 2020, 157, 106995. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, Y.; Lin, J.; Lu, Y. Theoretical analysis and crashworthiness optimization of hybrid multi-cell structures. Thin-Walled Struct. 2019, 142, 116–131. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, Q.; Lin, H.; Wang, J.; Wang, K.; Peng, Y.; Yao, S. Integrated design and additive manufacturing of lattice-filled multi-cell tubes. Compos. Sci. Technol. 2023, 243, 110252. [Google Scholar] [CrossRef]

- Pugsley, A. The large-scale crumpling of thin cylindrical columns. Q. J. Mech. Appl. Math. 1960, 13, 1–9. [Google Scholar] [CrossRef]

- Faraz, M.R.; Ahmadi, H.; Liaghat, G.; Vahid, S.; Razmkhah, O.; Tarafdar, A. Energy absorption assessment of bio-mimicked hybrid al/pp sandwich tube: Experimental and numerical investigation. Thin-Walled Struct. 2022, 181, 110116. [Google Scholar] [CrossRef]

- Guillow, S.R.; Lu, G.; Grzebieta, R.H. Quasi-static axial compression of thin-walled circular aluminium tubes. Int. J. Mech. Sci. 2001, 43, 2103–2123. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H. Axial crushing of circular multi-cell columns. Int. J. Impact Eng. 2014, 65, 110–125. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y.; Ahzi, S. Progressive collapse behaviors and mechanisms of 3d printed thin-walled composite structures under multi-conditional loading. Thin-Walled Struct. 2022, 171, 108810. [Google Scholar] [CrossRef]

- Sun, G.; Li, S.; Liu, Q.; Li, G.; Li, Q. Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled cfrp tubes. Compos. Struct. 2016, 152, 969–993. [Google Scholar] [CrossRef]

- Wang, K.; Gao, H.; Wang, J.; Wang, D.; Wen, W.; Peng, Y.; Yu, T. Modular assembly for multicell structures with designable energy absorption characteristics. Mech. Adv. Mater. Struct. 2024, 31, 11147–11157. [Google Scholar] [CrossRef]

- Nikkhah, H.; Baroutaji, A.; Kazancı, Z.; Arjunan, A. Evaluation of crushing and energy absorption characteristics of bio-inspired nested structures. Thin-Walled Struct. 2020, 148, 106615. [Google Scholar] [CrossRef]

| Materials | Density (g/cm3) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| PLA | 1.20 | 65.0 | 8 |

| PLAM | 1.33 | 42.0 | 50 |

| PLAS | 1.25 | 34.3 | 90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Xiang, J.; Lu, J.; Tan, Q.; Addiego, F.; Peng, Y.; Wang, K. Crashworthy Performance of Sustainable Filled Structures Using Recycled Beverage Cans and Eco-Friendly Multi-Cell Fillers. Polymers 2025, 17, 315. https://doi.org/10.3390/polym17030315

Gao H, Xiang J, Lu J, Tan Q, Addiego F, Peng Y, Wang K. Crashworthy Performance of Sustainable Filled Structures Using Recycled Beverage Cans and Eco-Friendly Multi-Cell Fillers. Polymers. 2025; 17(3):315. https://doi.org/10.3390/polym17030315

Chicago/Turabian StyleGao, Huijing, Jiangyang Xiang, Junyu Lu, Qianbing Tan, Frédéric Addiego, Yong Peng, and Kui Wang. 2025. "Crashworthy Performance of Sustainable Filled Structures Using Recycled Beverage Cans and Eco-Friendly Multi-Cell Fillers" Polymers 17, no. 3: 315. https://doi.org/10.3390/polym17030315

APA StyleGao, H., Xiang, J., Lu, J., Tan, Q., Addiego, F., Peng, Y., & Wang, K. (2025). Crashworthy Performance of Sustainable Filled Structures Using Recycled Beverage Cans and Eco-Friendly Multi-Cell Fillers. Polymers, 17(3), 315. https://doi.org/10.3390/polym17030315