Mineral Filler Hybridization in Recycled Polyethylene Terephthalate

Abstract

1. Introduction

2. Methodology

2.1. Materials

2.2. Specimen Preparation

2.3. Method of Testing

2.3.1. Density

2.3.2. Mechanical Tests

2.3.3. Dynamic Mechanical Analysis (DMA)

2.3.4. Thermal Tests

2.3.5. Morphology of Composites

3. Results

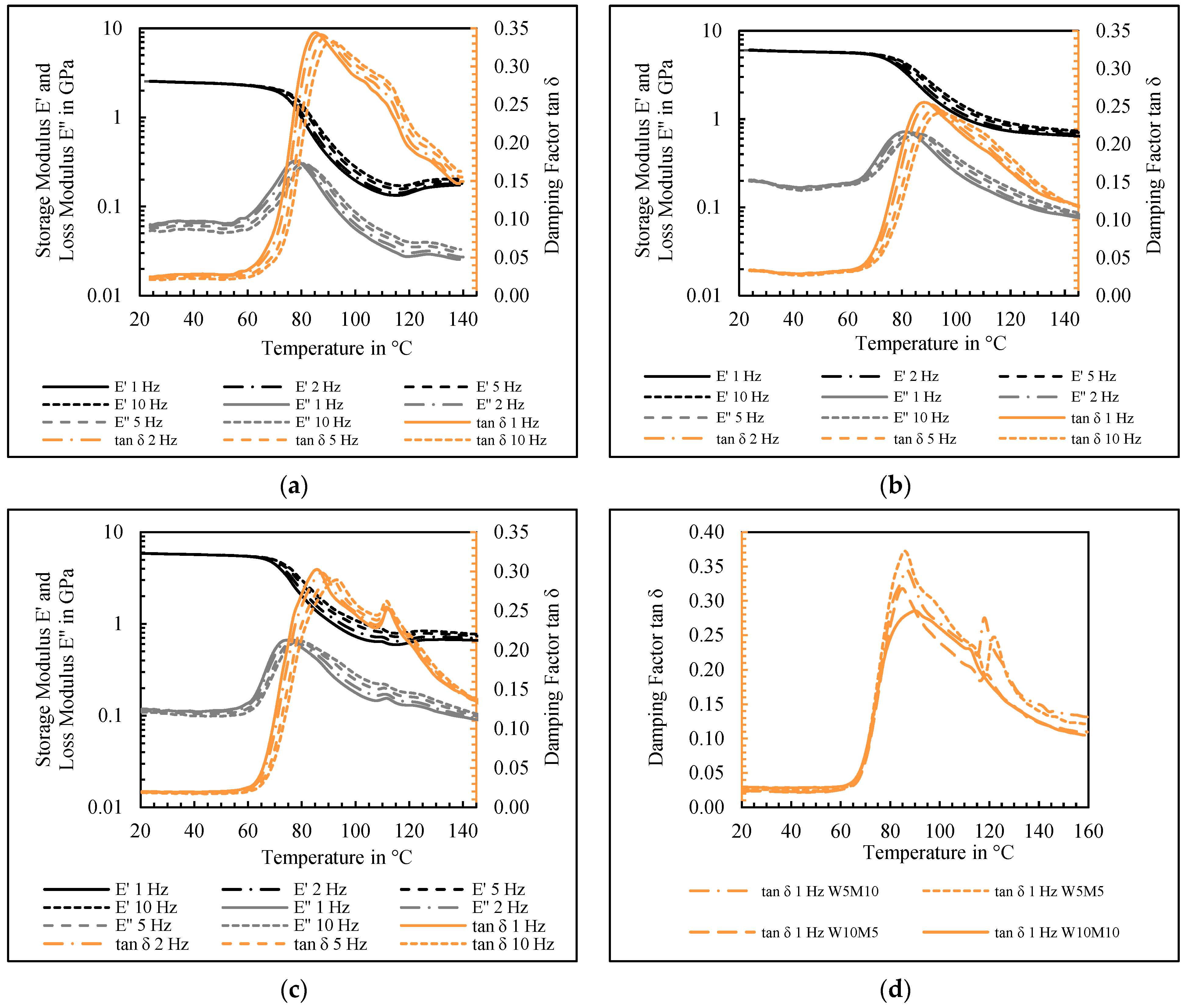

3.1. Thermal Properties

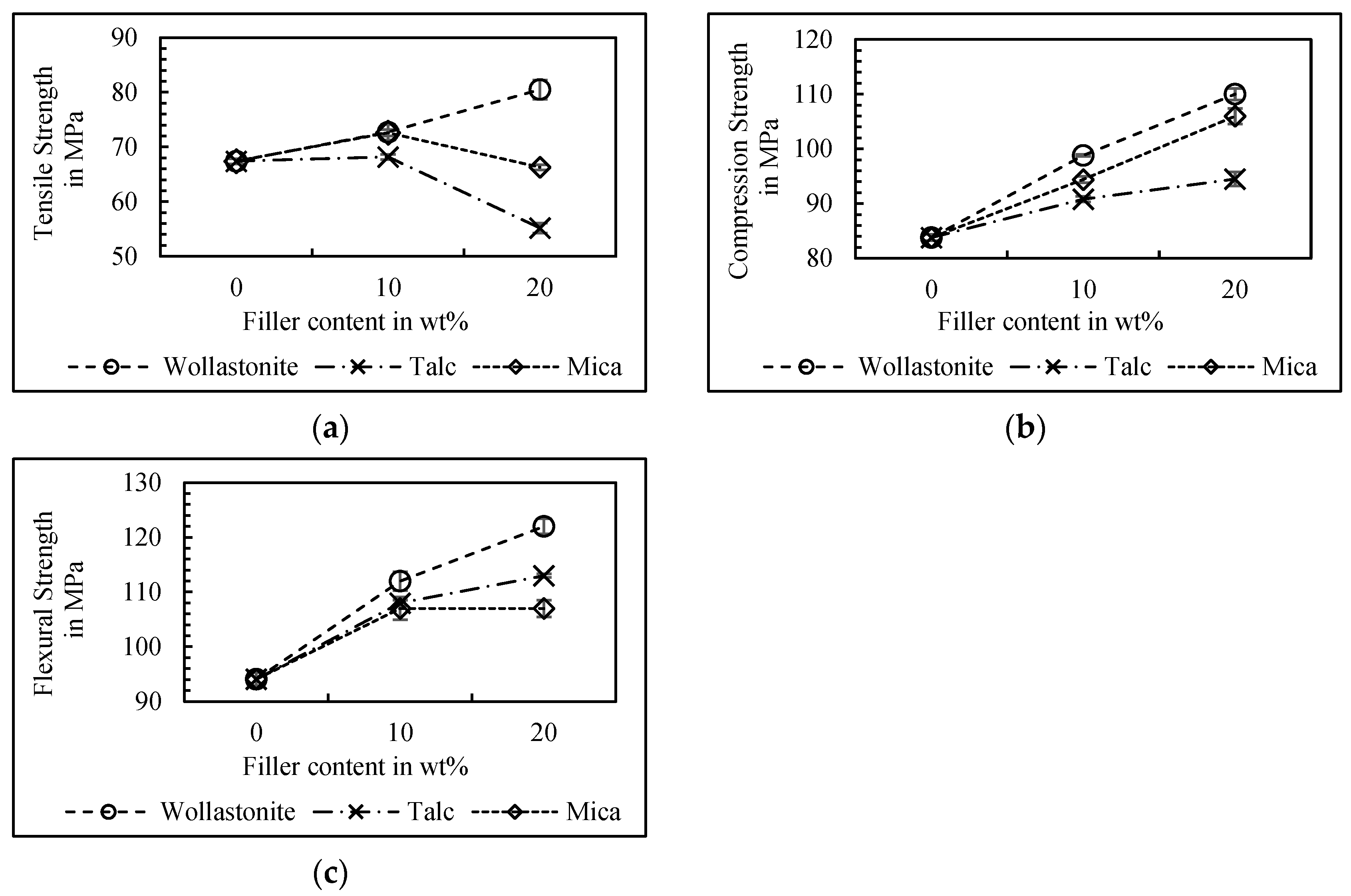

3.2. Mechanical Properties

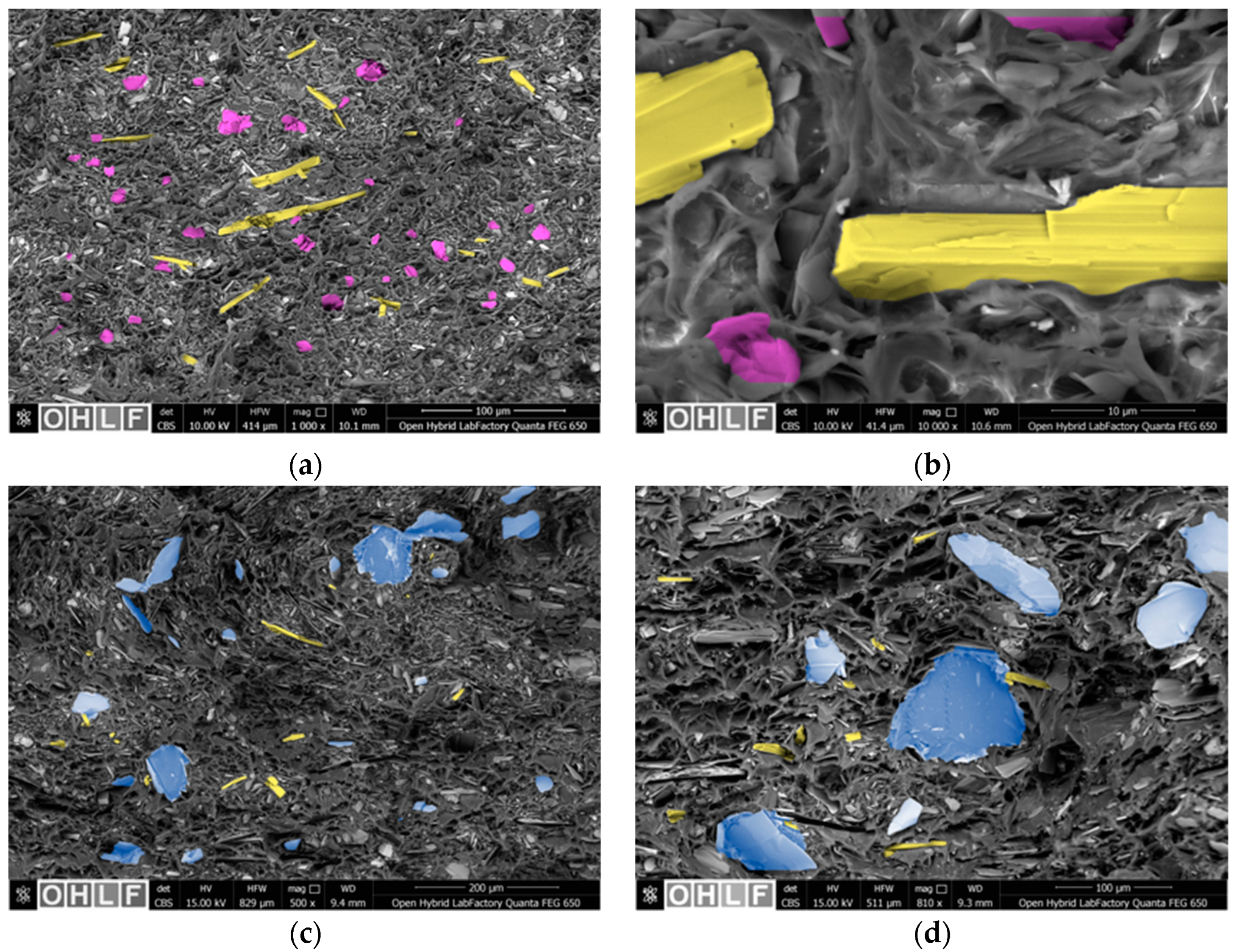

3.3. Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DMA | Dynamic mechanical analysis |

| DSC | Differential scanning calorimetry |

| HDT | Heat distortion temperature |

| MAF | Mobile amorphous fractions |

| PA | Polyamide |

| PET | Polyethylene terephthalate |

| RAF | Rigid amorphous fractions |

| RPET | Recycled polyethylene terephthalate |

| SEM | Scanning electron microscope |

| SSP | Solid-state polymerization |

References

- Cruz, S.A.; Zanin, M. PET recycling: Evaluation of the solid state polymerization process. J. Appl. Polym. Sci. 2006, 99, 2117–2123. [Google Scholar] [CrossRef]

- Pinter, E.; Welle, F.; Mayrhofer, E.; Pechhacker, A.; Motloch, L.; Lahme, V.; Grant, A.; Tacker, M. Circularity Study on PET Bottle-To-Bottle Recycling. Sustainability 2021, 13, 7370. [Google Scholar] [CrossRef]

- EFSA CEP Panel (EFSA Panel on Food Contact Materials, Enzymes and Processing Aids); Lambré, C.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Mengelers, M.; et al. Safety assessment of the process Lietpak, based on the EREMA MPR technology, used to recycle post-consumer PET into food contact materials. EFSA J. 2024, 22, e8609. [Google Scholar] [CrossRef] [PubMed]

- EFSA CEP Panel (EFSA Panel on Food Contact Materials, Enzymes and Processing Aids); Lambré, C.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Mengelers, M.; et al. Safety assessment of the process Reciclar, based on the EREMA Basic technology, used to recycle post-consumer PET into food contact materials. EFSA J. 2024, 22, e8518. [Google Scholar] [CrossRef] [PubMed]

- Grant, A.; Lahme, V.; Connock, T.; Lugal, L. How Circular Is PET? Eunomia Research and Consulting, Zero Waste Europe. 2022. Available online: https://zerowasteeurope.eu/library/how-circular-is-pet/ (accessed on 2 April 2024).

- Proposal for a Regulation on Circularity Requirements for Vehicle Design and on Management of End-of-Life Vehicles Amending Directive 2000/53/EC on End-of-Life Vehicles of the European Parliament. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_3819 (accessed on 3 April 2024).

- Mitalova, Z.; Dupláková, D.; Mital, D. Application of Recycled Plastics in Automotive Industry: A short review. SAR J. Sci. Res. 2022, 5, 200–205. [Google Scholar] [CrossRef]

- Hirschberg, V.; Rodrigue, D. Recycling of polyamides: Processes and conditions. J. Polym. Sci. 2023, 61, 1937. [Google Scholar] [CrossRef]

- Karthik, G.; Balaji, K.V.; Venkateshwara, R.; Rahul, B. Eco-Friendly Recycled PET (Polyethylene Terephthalate) Material for Automotive Canopy Strip Application; SAE Technical Paper; SAE: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Giraldi, A.D.M.; Bartoli, J.; Velasco, J.; Mei, L. Glass fibre recycled poly(ethylene terephthalate) composites: Mechanical and thermal properties. Polym. Test. 2005, 24, 507–512. [Google Scholar] [CrossRef]

- Monti, M.; Scrivani, M.T.; Kociolek, I.; Larsen, Å.G.; Olafsen, K.; Lambertini, V. Enhanced Impact Strength of Recycled PET/Glass Fiber Composites. Polymers 2021, 13, 1471. [Google Scholar] [CrossRef] [PubMed]

- Mondadori, N.M.L.; Nunes, R.C.R.; Canto, L.B.; Zattera, A.J. Composites of recycled PET reinforced with short glass fiber. J. Thermoplast. Compos. Mater. 2012, 25, 747–764. [Google Scholar] [CrossRef]

- Almahri, G.; Madi, K.; Alkaabi, F.; Badran, Y.; Shehadeh, K.; ElHassan, A.; Ahmed, W.; Alzahmi, S. Characterization of Hybrid FRP Composite Produced from Recycled PET and CFRP. Polymers 2023, 15, 2946. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Suwannachot, S.; Larpkasemusk, A. Recycled poly(ethylene terephthalate)/polypropylene/wollastonite composites using PP-g-MA as compatibilizer: Mechanical, thermal and morphological properties. J. Met. Mater. Miner. 2018, 28, 115–123. [Google Scholar]

- Kunimune, N.; Hamada, H.; Leong, W.Y.; Thumsorn, S.; Ogazi-Onyemaechi, B. Fracture Characteristics of talc-filled toughened recycled Polyethylene Terephthalate. In Proceedings of the 11th Japan International Sampe Symposium & Exhibition, Tokyo, Japan, 25–27 November 2009; Volume 11. [Google Scholar] [CrossRef]

- Deshmukh, S.P.; Rao, A.C. Mica Filled PVC Composites: Performance enhancement in dielectric and mechanical properties with treated/untreated Mica of different particle size and different concentration. J. Miner. Mater. Charact. Eng. 2012, 11, 169–181. [Google Scholar] [CrossRef]

- Kráčalík, M.; Studenovský, M.; Mikešová, J.; Sikora, A.; Thomann, R.; Friedrich, C.; Fortelný, I.; Šimoník, J. Recycled PET nanocomposites improved by silanization of organoclays. J. Appl. Polym. Sci. 2007, 106, 926–937. [Google Scholar] [CrossRef]

- Ronkay, F.; Czigány, T. Development of composites with recycled PET matrix. Polym. Adv. Technol. 2006, 17, 830–834. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, Y.; Zhang, M.; Li, L.; Ma, L.; Sun, Y.; Wang, W. A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids. Polymers 2022, 14, 2376. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Bedi, R.; Kaith, B.S. Composite materials based on recycled polyethylene terephthalate and their properties—A comprehensive review. Compos. Part B Eng. 2021, 219, 108928. [Google Scholar] [CrossRef]

- Balow, M.J.; Fuccella, D.C. Hybridization of Reinforcement to Optimize Part Performance and Molding in Reinforced Thermoplastics. Polym. Plast. Technol. Eng. 1983, 20, 23–33. [Google Scholar] [CrossRef]

- Morelli, C.L.; Pouzada, A.S.; Sousa, J. Influence of Hybridization of Glass Fiber and Talc on the Mechanical Performance of Polypropylene Composites. J. Appl. Polym. Sci. 2009, 114, 3592–3601. [Google Scholar] [CrossRef]

- Himani, J.; Purnima, J. Development of glass fiber, wollastonite reinforced polypropylene hybrid composite: Mechanical properties and morphology. Mater. Sci. Eng. A 2010, 527, 1946–1951. [Google Scholar] [CrossRef]

- Kodal, M.; Erturk, S.; Sanli, S.; Ozkoc, G. Properties of talc/wollastonite/polyamide 6 hybrid composites. Polym. Compos. 2015, 36, 739–746. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R. Dynamic Mechanical Properties of Sugar Palm/Glass Fiber Reinforced Thermoplastic Polyurethane Hybrid Composites. Polym. Compos. 2019, 40, 1329–1334. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Cantero, G.; Llano-Ponte, R.; Valea, A.; Mondragon, I. Mechanical properties of flax fibre/polypropylene composites. Influence of fibre/matrix modification and glass fibre hybridization. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1637–1644. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Rozman, H.D.; Tay, G.S.; Kumar, R.N.; Abusamah, A.; Ismail, H.; Mohd Ishak, Z.A. Polypropylene–oil palm empty fruit bunch-glass fibre hybrid composites: A preliminary study on the flexural and tensile properties. Eur. Polym. J. 2001, 37, 1283–1291. [Google Scholar] [CrossRef]

- Czigány, T. Discontinuous Basalt Fiber-Reinforced Hybrid Composites. In Polymer Composites; Springer: Boston, MA, USA, 2005. [Google Scholar] [CrossRef]

- Kuciel, S.; Mazur, K. Novel hybrid composite based on bio-PET with basalt/carbon fibre. IOP Conf. Ser. Mater. Sci. Eng. 2019, 634, 012009. [Google Scholar] [CrossRef]

- DIN EN ISO 527-2:2024; Plastcs—Determination of Tensile Propertes—Part 2: Test Conditions for Moulding and Extrusion Plastics. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2024.

- DIN EN ISO 294-2:2018; Plastcs—Injection Moulding of Test Specimens of Thermoplastic Materils—Part 2: Small Tensile Bars. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2018.

- DIN EN ISO 20028-2:2017; Plastcs—Thermoplastic Polyester (TP) Moulding and Extrusion Materils—Part 2: Preparation of Test Specimens and Determination of Properties. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2017.

- DIN EN ISO 1183-1:2019; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2019.

- DIN EN ISO 291:2008; Plastics—Standard Atmospheres for Conditioning and Testing. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2008.

- DIN EN ISO 604:2003; Plastics—Determination of Compressive Properties. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2003.

- DIN EN ISO 178:2019; Plastics—Determination of Flexural Properties. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2019.

- Bashir, M.A. Use of Dynamic Mechanical Analysis (DMA) for Characterizing Interfacial Interactions in Filled Polymers. Solids 2021, 2, 108–120. [Google Scholar] [CrossRef]

- DIN EN ISO 75-2:2013; Plastics—Determination of Temperature of Deflection Under Load—Part 2: Plastics and Ebonite. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2013.

- DIN EN ISO 11357-1:2023; Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles. DIN Media GmbH: Berlin, Germany; Viena, Austria; Zurich, Switzerland, 2023.

- Masmoudi, F.; Fenouillot, F.; Mehri, A.; Jaziri, M.; Ammar, E. Characterization and quality assessment of recycled post-consumption poly(ethylene terephthalate) (PET). Environ. Sci. Pollut. Res. Int. 2018, 25, 23307–23314. [Google Scholar] [CrossRef] [PubMed]

- Takemori, M.T. Towards an understanding of the heat distortion temperature of thermoplastics. Polym. Eng. Sci. 1979, 19, 1104–1109. [Google Scholar] [CrossRef]

- Benz, J.; Bonten, C. Rigid Amorphous Fraction as an Indicator for Polymer-Polymer Interactions in Highly Filled Plastics. Polymers 2021, 13, 3349. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. The role of crystalline, mobile amorphous and rigid amorphous fractions in the performance of recycled poly (ethylene terephthalate) (PET). Polym. Degrad. Stab. 2012, 97, 98–107. [Google Scholar] [CrossRef]

- Chen, B.; Torkelson, J.M. Rigid amorphous fraction and crystallinity in cold-crystallized syndiotactic polystyrene: Characterization by differential scanning calorimetry. Polymer 2021, 230, 124044. [Google Scholar] [CrossRef]

- Dasari, A.; Sarang, S.; Misra, R.D.K. Strain rate sensitivity of homopolymer polypropylenes and micrometric wollastonite-filled polypropylene composites. Mater. Sci. Eng. A 2004, 368, 191–204. [Google Scholar] [CrossRef]

| Nominal Filler Content (wt%) | Composite Description (vol%) | |||

|---|---|---|---|---|

| Wollastonite (d50 = 30 µm) | Mica (d50 = 44 µm) | Talc (d50 = 2.7 µm) | Hybrids | |

| 10 | RPET/W10 (4.90) | RPET/M10 (5.12) | RPET/T10 (5.31) | RPET/W5/T5 (4.78) RPET/W5/M5 (4.75) |

| 15 | - | - | - | RPET/W5/M10 (7.59) RPET/W10/T5 (7.61) RPET/W10/M5 (7.58) |

| 20 | RPET/W20 (10.61) | RPET/M20 (10.90) | RPET/T20 (10.77) | RPET/W10/M10 (10.59) RPET/W10/T10 (10.77) |

| Description | Crystallinity (%) | Tm (°C) | HDT (°C) |

|---|---|---|---|

| RPET | 20.68 | 247.9 | 68.4 |

| RPET/W10 | 28.03 | 251.4 | 79.2 |

| RPET/M10 | 29.36 | 251.9 | 76.6 |

| RPET/T10 | 29.48 | 249.9 | 83.9 |

| RPET/W20 | 29.19 | 251.5 | 84.6 |

| RPET/M20 | 30.84 | 251.4 | 84.9 |

| RPET/T20 | 27.80 | 250.5 | 93.6 |

| Description | Density (g/cm3) | Tensile Modulus (GPa) | Compression Modulus (GPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|

| RPET | 1.357 ± 0.000 | 3.250 ± 0.129 | 3.010 ± 0.134 | 2.590 ± 0.030 |

| RPET/W10 | 1.444 ± 0.001 | 4.330 ± 0.061 | 4.560 ± 0.149 | 3.880 ± 0.106 |

| RPET/M10 | 1.440 ± 0.009 | 4.450 ± 0.111 | 4.810 ± 0.131 | 3.990 ± 0.116 |

| RPET/T10 | 1.445 ± 0.003 | 4.210 ± 0.066 | 4.400 ± 0.206 | 3.990 ± 0.071 |

| RPET/W20 | 1.527 ± 0.003 | 5.920 ± 0.033 | 6.470 ± 0.279 | 5.260 ± 0.106 |

| RPET/M20 | 1.526 ± 0.002 | 6.210 ± 0.288 | 6.730 ± 0.337 | 5.930 ± 0.113 |

| RPET/T20 | 1.523 ± 0.001 | 5.820 ± 0.157 | 6.050 ± 0.197 | 5.540 ± 0.042 |

| Nominal (wt%) Filler Content | Description | Density (g/cm3) | Tensile Modulus (GPa) | Tensile Strength (MPa) | Compression Modulus (GPa) | Compression Strength (MPa) | Flexural Modulus (GPa) | Flexural Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| 10 | RPET/W5/M5 RPET/W5/T5 | 1.438 ± 0.001 1.444 ± 0.002 | 3.910 ± 0.217 3.810 ± 0.053 | 74.5 ± 0.8 75.0 ± 0.4 | 4.390 ± 0.115 4.240 ± 0.343 | 96.1 ± 0.5 96.6 ± 0.8 | 3.690 ± 0.117 3.720 ± 0.163 | 109 ± 1.9 116 ± 0.8 |

| 15 | RPET/W5/M10 RPET/W10/T5 RPET/W10/M5 | 1.478 ± 0.001 1.509 ± 0.002 1.481 ± 0.004 | 4.850 ± 0.165 5.190 ± 0.145 4.670 ± 0.242 | 75.5 ± 0.2 78.8 ± 0.3 77.5 ± 0.7 | 5.010 ± 0.376 5.430 ± 0.152 4.870 ± 0.186 | 101 ± 1.0 105 ± 0.5 101 ± 1.2 | 4.600 ± 0.171 4.780 ± 0.162 4.210 ± 0.128 | 110 ± 2.1 123 ± 0.6 116 ± 0.3 |

| 20 | RPET/W10/M10 RPET/W10/T10 | 1.509 ± 0.001 1.543 ± 0.002 | 5.640 ± 0.166 5.950 ± 0.180 | 79.3 ± 0.9 79.0 ± 0.9 | 5.590 ± 0.351 6.160 ± 0.175 | 106 ± 1.0 107 ± 1.7 | 5.200 ± 0.204 5.710 ± 0.236 | 117 ± 0.9 122 ± 1.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Droß, M.; Ehleben, M.; Dröder, K. Mineral Filler Hybridization in Recycled Polyethylene Terephthalate. Polymers 2025, 17, 259. https://doi.org/10.3390/polym17030259

Droß M, Ehleben M, Dröder K. Mineral Filler Hybridization in Recycled Polyethylene Terephthalate. Polymers. 2025; 17(3):259. https://doi.org/10.3390/polym17030259

Chicago/Turabian StyleDroß, Marcel, Max Ehleben, and Klaus Dröder. 2025. "Mineral Filler Hybridization in Recycled Polyethylene Terephthalate" Polymers 17, no. 3: 259. https://doi.org/10.3390/polym17030259

APA StyleDroß, M., Ehleben, M., & Dröder, K. (2025). Mineral Filler Hybridization in Recycled Polyethylene Terephthalate. Polymers, 17(3), 259. https://doi.org/10.3390/polym17030259