Investigation of Processing Conditions and Product Geometry in Out-Mold Decoration and Their Effects on Film Adhesion and Deformation

Abstract

1. Introduction

2. Experiment Setups

2.1. Sample-Preparation

2.2. Equipment

2.3. Methodology

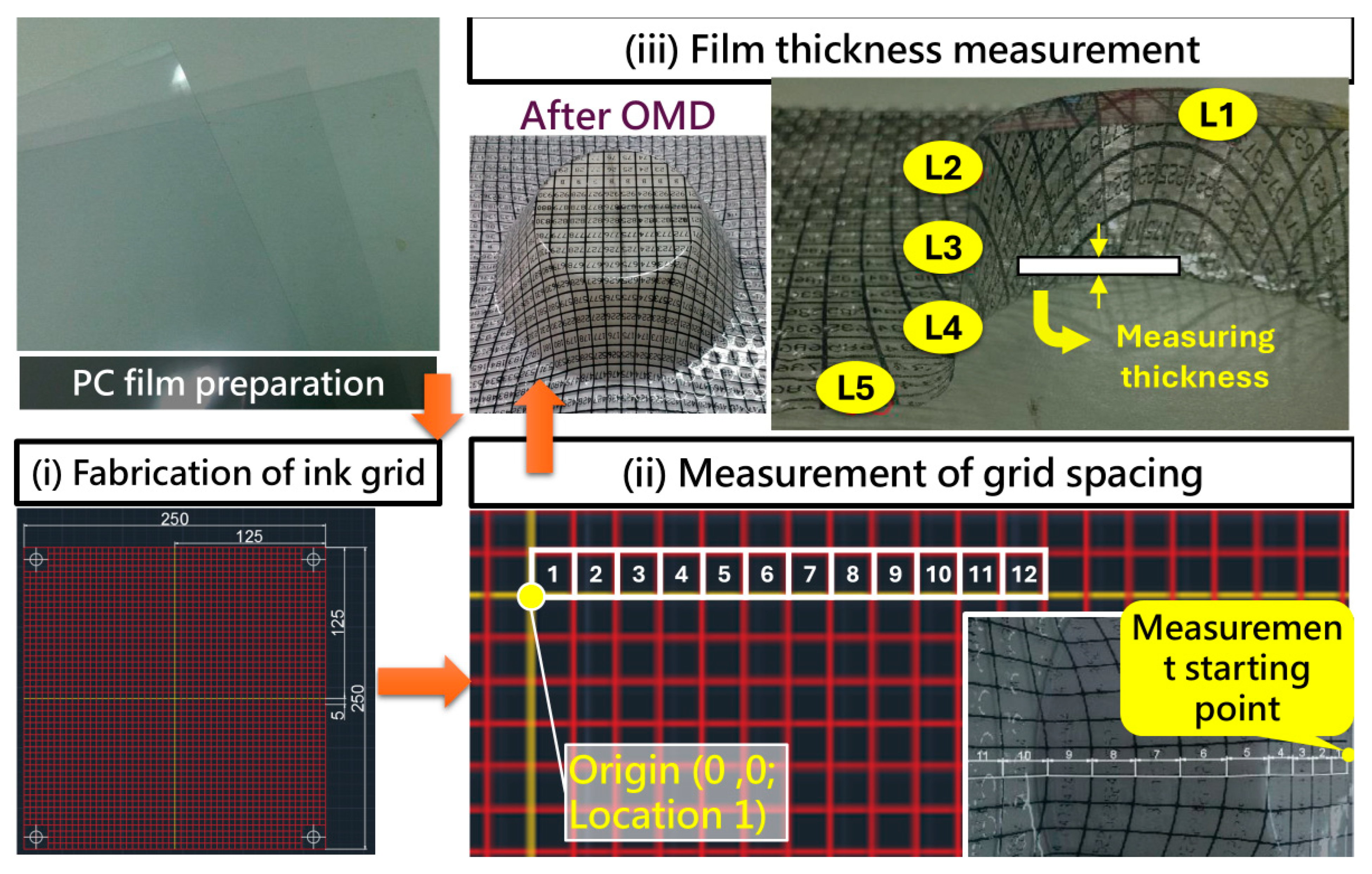

- After OMD forming, the spacing between the printed grid lines changed due to film stretching, which enabled quantitative assessment of strain distribution across different regions. The printed grid consisted of 50 cells, each measuring 5 × 5 mm, yielding an overall patterned area of 250 × 250 mm. This uniformly spaced grid provided stable and repeatable reference points for quantifying post-forming deformation, enabling precise evaluation of local strain and distortion across the film surface. As shown in Figure 4ii, grid-spacing measurements were performed sequentially along predetermined paths starting from a designated reference position. The actual spacing variations at each location were recorded using a precision vernier caliper (±0.02 mm resolution) to ensure accurate measurement of the deformed grid intervals. To determine deformation or strain, the measured grid spacing after forming was compared with the original undeformed grid spacing. The engineering strain for each grid segment was calculated as

- These data were used to construct strain distribution maps of the film after forming, thereby enabling analysis of how geometric parameters such as fillet radius, slope, and height affected the uniformity of film extension. In addition, film thickness was measured at five specific positions (L1 to L5), as shown in Figure 4iii. These positions covered regions ranging from high-curvature areas to relatively flat surfaces. Thickness measurements were obtained using a digital thickness gauge (Model MIT-DTG-S, accuracy ±0.01 mm; SEAT Industrial Co., Ltd., Qianzhen District, Kaohsiung City, Taiwan) to ensure precise detection of thickness variation in different regions. By comparing thickness values across these locations, it was possible to determine whether localized thinning occurred due to stress concentration during deformation.

- Thickness variation (%) in this study is calculated based on the relative change in film thickness before and after OMD forming, using the following expression:

3. Experiment Results and Discussion

3.1. Effect of Different Processing Conditions on the OMD Films After Forming

3.2. Effect of Different Product Geometry on the OMD Films After Forming

4. Conclusions

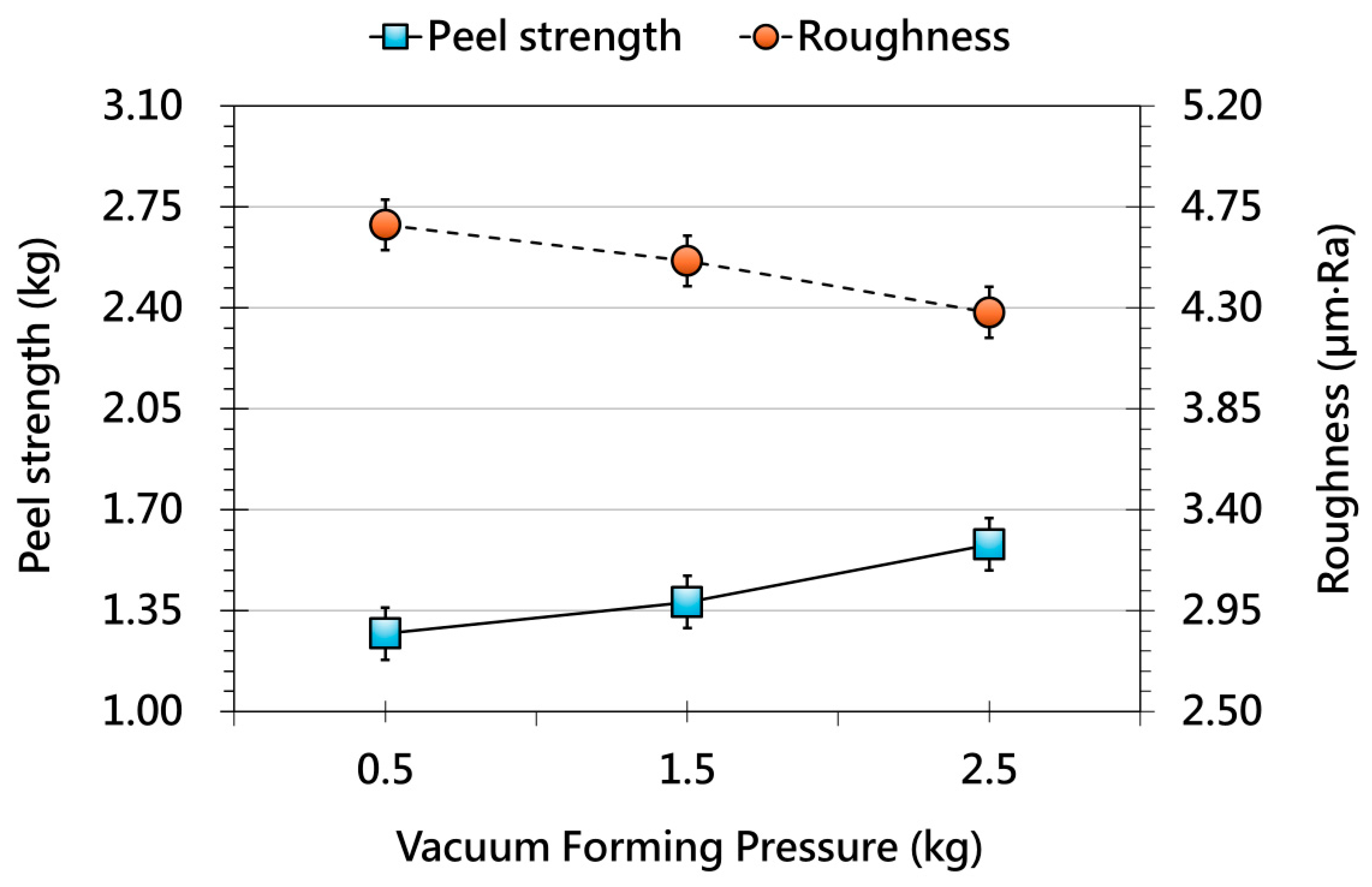

- This study demonstrated that the three key processing parameters—film preheating temperature, forming environment temperature, and vacuum forming pressure—exert distinct and non-linear effects on adhesion and surface quality. Increasing preheating temperature smooths the film but does not enhance adhesion, whereas higher environment temperature and vacuum pressure improve bonding and surface finish within safe operating limits.

- An optimized OMD processing window was identified at a film preheating temperature of 100 °C, a forming environment temperature of 90 °C, and a vacuum pressure of 2.5 kg. This coordinated setting yields superior adhesion, reduced roughness, and more stable elongation behavior.

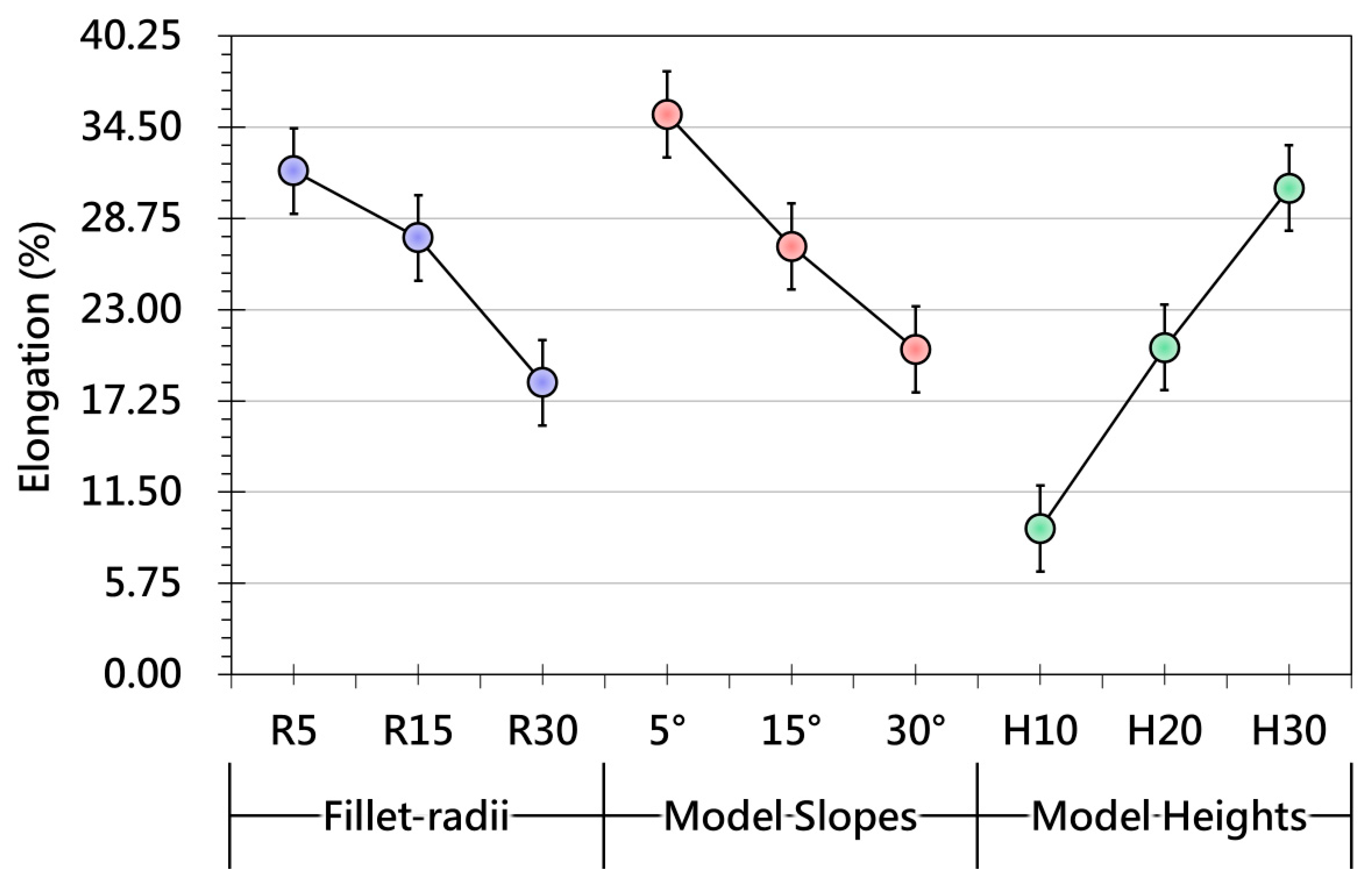

- Geometric factors including fillet radius, slope angle, and model height play a decisive role in film deformation. Small radii, steep slopes, and tall features intensify strain, enlarge grid-spacing changes, and increase thickness variation.

- Combined measurements of grid spacing and film thickness reveal consistent deformation hotspots at curvature transitions and elevated features, confirming that both global elongation and local strain accumulation govern OMD film behavior.

- The integration of processing-parameter control with geometric considerations establishes a practical framework for designing OMD components with high adhesion, uniform deformation, and improved visual quality, enabling more reliable decoration of complex 3D products.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Thi, T.B.N.; Yokoyama, A.; Hamanaka, S.; Kodama, K.; Yamashita, K.; Nonomura, C. Numerical and experimental evaluation of surface properties of embossed decorative injection-molded parts. Polym. Test. 2016, 53, 188–196. [Google Scholar] [CrossRef]

- You, H.; Ryu, T.; Oh, K.; Yun, M.H.; Kim, K.-J. Development of customer satisfaction models for automotive interior materials. Int. J. Ind. Ergon. 2016, 36, 323–330. [Google Scholar] [CrossRef]

- Gim, J.; Turng, L.-S. A review of current advancements in high surface quality injection molding: Measurement, influencing factors, prediction, and control. Polym. Test. 2022, 115, 107718. [Google Scholar] [CrossRef]

- Modrak, V.; Mandulak, J. Exploration of Impact of Technological Parameters on Surface Gloss of Plastic Parts. Procedia CIRP 2013, 12, 504–509. [Google Scholar] [CrossRef]

- Cele, H.M.; Ojijo, V.; Chen, H.; Kumar, S.; Land, K.; Joubert, T.; de Villiers, M.F.R.; Ray, S.S. Effect of nanoclay on optical properties of PLA/clay composite films. Polym. Test. 2014, 36, 24–31. [Google Scholar] [CrossRef]

- Oliveira, M.J.; Brito, A.; Costa, M.C. Gloss and Surface Topography of ABS: A Study on the influence of the Injedtion Molding Parameters. Polym. Eng. Science. 2006, 46, 1394–1401. [Google Scholar] [CrossRef]

- Wang, S. IMD vs. OMD: A New Way to Improve Efficiency in the Mold Industry. Industry Insights on Injection Molding and Decoration Technologies. 2025. Available online: https://www.linkedin.com/pulse/imd-vs-omd-new-way-improve-efficiency-mold-industry-sunny-wang-7gr3e/ (accessed on 3 December 2025).

- Zhigang, L. Study of multi-objective optimization of process parameters in film posting based on outside mold decoration. J. Elastomers Plast. 2018, 50, 634–655. [Google Scholar] [CrossRef]

- Hsiao, S.-W.; Yen, C.-H.; Lee, C.-H. Apply out-side mold decoration technique to Cosmetic Package Design. In Proceedings of the 2017 International Conference on Organizational Innovation, Bali, Indonesia, 21–23 July 2017. [Google Scholar] [CrossRef]

- Chang, H.-J.; Zhang, G.; Sun, Y.; Lu, S. Barrel rifling node offset detection and subsequent optimization based on thin film in-mold decoration characteristics of the Johnson–Cook model. Sci. Rep. 2024, 14, 24410. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.; Su, Z.; Guo, W.; Wang, H. Effects of injection moulding parameters on pattern performance of in-mould decorative product. Int. J. Manuf. Res. 2021, 16, 21–31. [Google Scholar] [CrossRef]

- Zhou, L.; Guo, W.; Wang, H.; Su, Z. Effects of injection molding parameters on pattern performance of in mold decorative product. Int. J. Manuf. Res. 2021, 16, 21–31. [Google Scholar] [CrossRef]

- Chang, H.-J.; Zhang, G.; Sun, Y.; Lu, S. A Node Detection Method Based on Johnson–Cook and Thin-Film IMD Characteristic Model Armor Damage Detection Repair and Subsequent Optimization. Polymers 2022, 14, 4540. [Google Scholar] [CrossRef]

- Chen, S.-C.; Huang, S.-T.; Lin, M.-C.; Chien, R.-D. Study on the thermoforming of PC films used for in-mold decoration. Int. Commun. Heat. Mass. 2008, 35, 967–973. [Google Scholar] [CrossRef]

- Ragoubi, A.; Ducloud, G.; Agazzi, A.; Dewailly, P.; Le, R. Modeling the Thermoforming Process of a Complex Geometry Based on a Thermo-Visco-Hyperelastic Model. J. Manuf. Mater. Process. 2024, 8, 33. [Google Scholar] [CrossRef]

- Riley, A. Plastics Manufacturing Processes for Packaging Materials. In Packaging Technology; Elsevier: Amsterdam, The Netherlands, 2012; pp. 310–360. [Google Scholar] [CrossRef]

- Shen, R.; Liu, T.; Liu, H.; Zou, X.; Gong, Y.; Guo, H. An Enhanced Vacuum-Assisted Resin Transfer Molding Process and Its Pressure Effect on Resin Infusion Behavior and Composite Material Performance. Polymers 2024, 16, 1386. [Google Scholar] [CrossRef] [PubMed]

- Neubauer, M.; Dannemann, M.; Herzer, N.; Schwarz, B.; Modler, N. Analysis of a Film Forming Process through Coupled Image Correlation and Infrared Thermography. Polymers 2022, 14, 1231. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Yu, Z.; Wei, W.; Meng, Z.; Mao, H.; Hua, L. Effect of film types on thermal response, cellular structure, forming defects and mechanical properties of combined in-mold decoration and microcellular injection molding parts. J. Mater. Sci. Technol. 2021, 92, 98–108. [Google Scholar] [CrossRef]

- Chen, S.-C.; Li, H.-M.; Huang, S.-T.; Wang, Y.-C. Effect of decoration film on mold surface temperature during in-mold decoration injection molding process. Int. Commun. Heat Mass Transfer. 2010, 37, 501–505. [Google Scholar] [CrossRef]

- De Paola, M.G.; Paletta, R.; Lopresto, C.G.; Lio, G.E.; De Luca, A.; Chakraborty, S.; Calabrò, V. Stability of Film-Forming Dispersions: Affects the Morphology and Optical Properties of Polymeric Films. Polymers 2021, 13, 1464. [Google Scholar] [CrossRef]

- Algieri, C.; Chakraborty, S.; Pal, U. Efficacy of Phase Inversion Technique for Polymeric Membrane Fabrication. J. Phase Change. Mater. 2021, 1. Available online: https://j-pcm.org/index.php/jpcm/article/view/10 (accessed on 17 July 2018).

- Westerman, S.; Sutherland, E.; Gardner, P.; Baig, N.; Critchley, C.; Hickey, C.; Mehigan, S.; Solway, A.; Zervos, Z. The design of consumer packaging: Effects of manipulations of shape, orientation, and alignment of graphical forms on consumers’ assessments. Food Qual. Prefer. 2013, 27, 8–17. [Google Scholar] [CrossRef]

- Celhay, F.; Boysselle, J.; Cohen, J. Food packages and communication through typeface design: The exoticism of exotypes. Food Qual. Prefer. 2015, 39, 167–175. [Google Scholar] [CrossRef]

- Rundh, B. Packaging design: Creating competitive advantage with product packaging. Br. Food J. 2009, 111, 988–1002. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D903; Standard Test Method for Peel or Stripping Strength of Adhesive Bonds. ASTM: West Conshohocken, PA, USA, 2025.

| Method | Film Preheating Temperatures (°C) | Forming Environment Temperature (°C) | Vacuum Forming Pressure (kg) |

|---|---|---|---|

| 1 | 100 | 60 | 1.5 |

| 2 | 110 | 60 | 1.5 |

| 3 | 120 | 60 | 1.5 |

| 4 | 100 | 30 | 1.5 |

| 5 | 100 | 60 | 1.5 |

| 6 | 100 | 90 | 1.5 |

| 7 | 100 | 60 | 0.5 |

| 8 | 100 | 60 | 1.5 |

| 9 | 100 | 60 | 2.5 |

| Film Preheating Temperatures (°C) | Peel Strength (kg) | Roughness (µm·Ra) | ||

| AVG. | ANOVA | AVG. | ANOVA | |

| 100 | 1.51 | 0.280% | 4.93 | 0.280% |

| 110 | 1.38 | 0.292% | 4.51 | 0.292% |

| 120 | 1.32 | 0.323% | 4.01 | 0.322% |

| Forming Environment Temperature (°C) | Peel strength (kg) | Roughness (µm·Ra) | ||

| AVG. | ANOVA | AVG. | ANOVA | |

| 30 | 1.38 | 0.337% | 4.51 | 0.337% |

| 60 | 2.36 | 0.354% | 4.42 | 0.354% |

| 90 | 2.78 | 0.359% | 4.11 | 0.359% |

| Vacuum Forming Pressure (kg) | Peel strength (kg) | Roughness (µm·Ra) | ||

| AVG. | ANOVA | AVG. | ANOVA | |

| 0.5 | 1.27 | 0.305% | 4.67 | 0.305% |

| 1.5 | 1.38 | 0.307% | 4.51 | 0.307% |

| 2.5 | 1.58 | 0.361% | 4.28 | 0.361% |

| Fillet- radii | Elongation (%) | Film-Thickness-Variation Rate (%) | ||||||||||

| L1 | L2 | L3 | L4 | L5 | ||||||||

| AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | |

| R5 | 31.74 | 0.280% | 13.3 | 0.292% | 20.5 | 0.292% | 33.3 | 0.290% | 40.1 | 0.292% | 46.7 | 0.272% |

| R15 | 27.52 | 0.292% | 12.2 | 0.294% | 18.4 | 0.294% | 32.2 | 0.296% | 34.2 | 0.298% | 36.7 | 0.292% |

| R30 | 18.39 | 0.323% | 2.3 | 0.332% | 10.2 | 0.327% | 18.7 | 0.344% | 23.3 | 0.323% | 26.7 | 0.310% |

| Model Slopes | Elongation (%) | Film-thickness-variation Rate (%) | ||||||||||

| L1 | L2 | L3 | L4 | L5 | ||||||||

| AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | |

| 5° | 35.31 | 0.337% | 8.1 | 0.339% | 20.8 | 0.339% | 26.7 | 0.336% | 33.1 | 0.337% | 36.1 | 0.321% |

| 15° | 26.99 | 0.354% | 10.1 | 0.356% | 20.4 | 0.356% | 23.4 | 0.356% | 30.2 | 0.297% | 32.2 | 0.348% |

| 30° | 20.5 | 0.359% | 13.3 | 0.361% | 14.7 | 0.360% | 20.7 | 0.359% | 20.3 | 0.352% | 25.3 | 0.377% |

| Model Heights | Elongation (%) | Film-thickness-variation Rate (%) | ||||||||||

| L1 | L2 | L3 | L4 | L5 | ||||||||

| AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | AVG. | ANOVA | |

| H10 | 9.21 | 0.305% | 7.5 | 0.318% | 15.6 | 0.318% | 20.8 | 0.340% | 24.2 | 0.297% | 26.7 | 0.300% |

| H20 | 20.62 | 0.307% | 8.2 | 0.309% | 22.6 | 0.309% | 27.6 | 0.313% | 29.4 | 0.316% | 30.1 | 0.295% |

| H30 | 30.67 | 0.361% | 14.2 | 0.364% | 23.1 | 0.364% | 26.2 | 0.368% | 30.6 | 0.363% | 32.2 | 0.350% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-L.; Huang, P.-W.; Hsu, S.-H.; Wu, J.-S. Investigation of Processing Conditions and Product Geometry in Out-Mold Decoration and Their Effects on Film Adhesion and Deformation. Polymers 2025, 17, 3239. https://doi.org/10.3390/polym17243239

Chen H-L, Huang P-W, Hsu S-H, Wu J-S. Investigation of Processing Conditions and Product Geometry in Out-Mold Decoration and Their Effects on Film Adhesion and Deformation. Polymers. 2025; 17(24):3239. https://doi.org/10.3390/polym17243239

Chicago/Turabian StyleChen, Hui-Li, Po-Wei Huang, Sheng-Hsun Hsu, and Jhong-Sian Wu. 2025. "Investigation of Processing Conditions and Product Geometry in Out-Mold Decoration and Their Effects on Film Adhesion and Deformation" Polymers 17, no. 24: 3239. https://doi.org/10.3390/polym17243239

APA StyleChen, H.-L., Huang, P.-W., Hsu, S.-H., & Wu, J.-S. (2025). Investigation of Processing Conditions and Product Geometry in Out-Mold Decoration and Their Effects on Film Adhesion and Deformation. Polymers, 17(24), 3239. https://doi.org/10.3390/polym17243239