Sustainable Cellulose- and Pectin-Rich Triboelectric Nanogenerator for Mechanical Energy Harvesting and Self-Powered Humidity Sensing

Abstract

1. Introduction

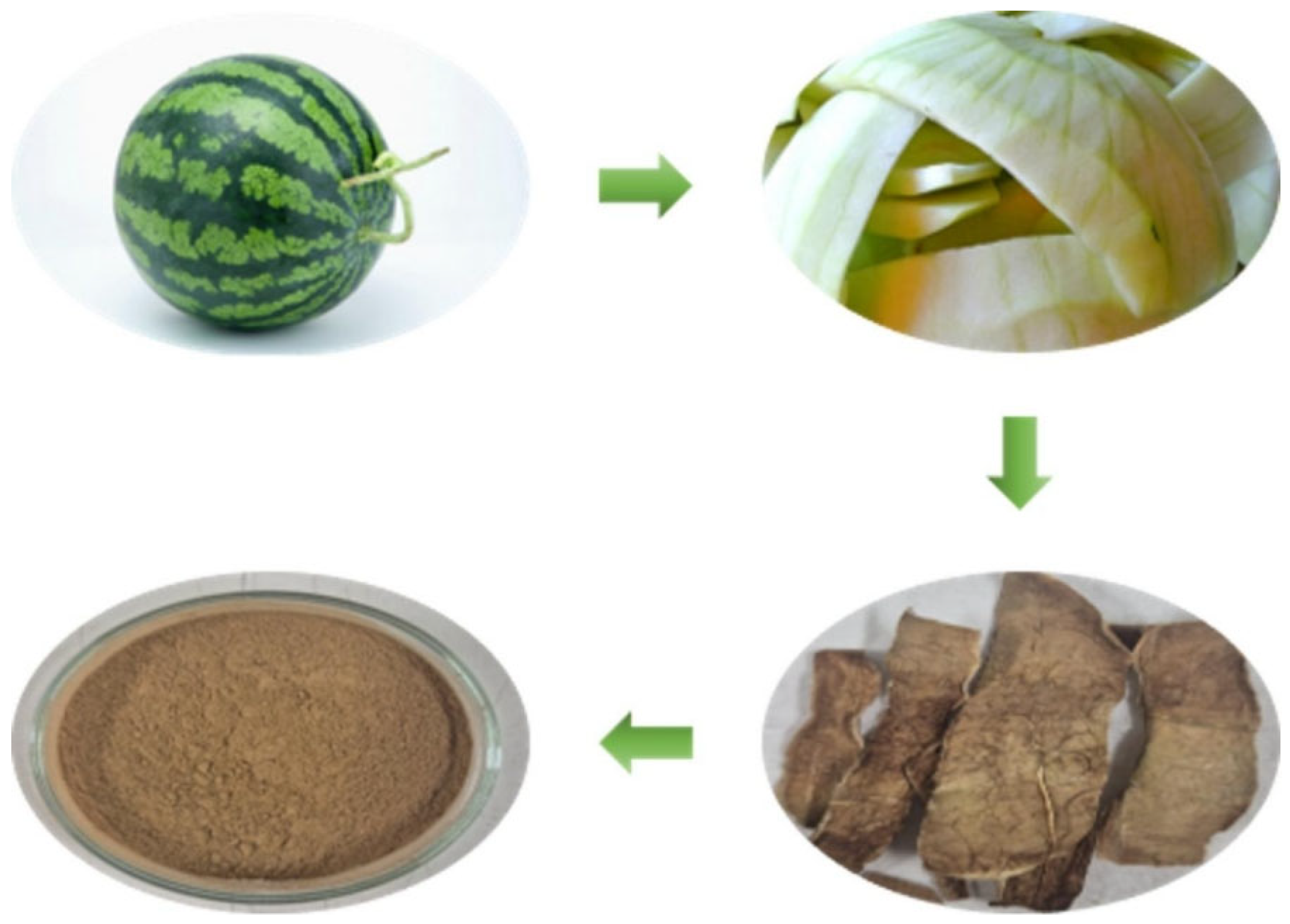

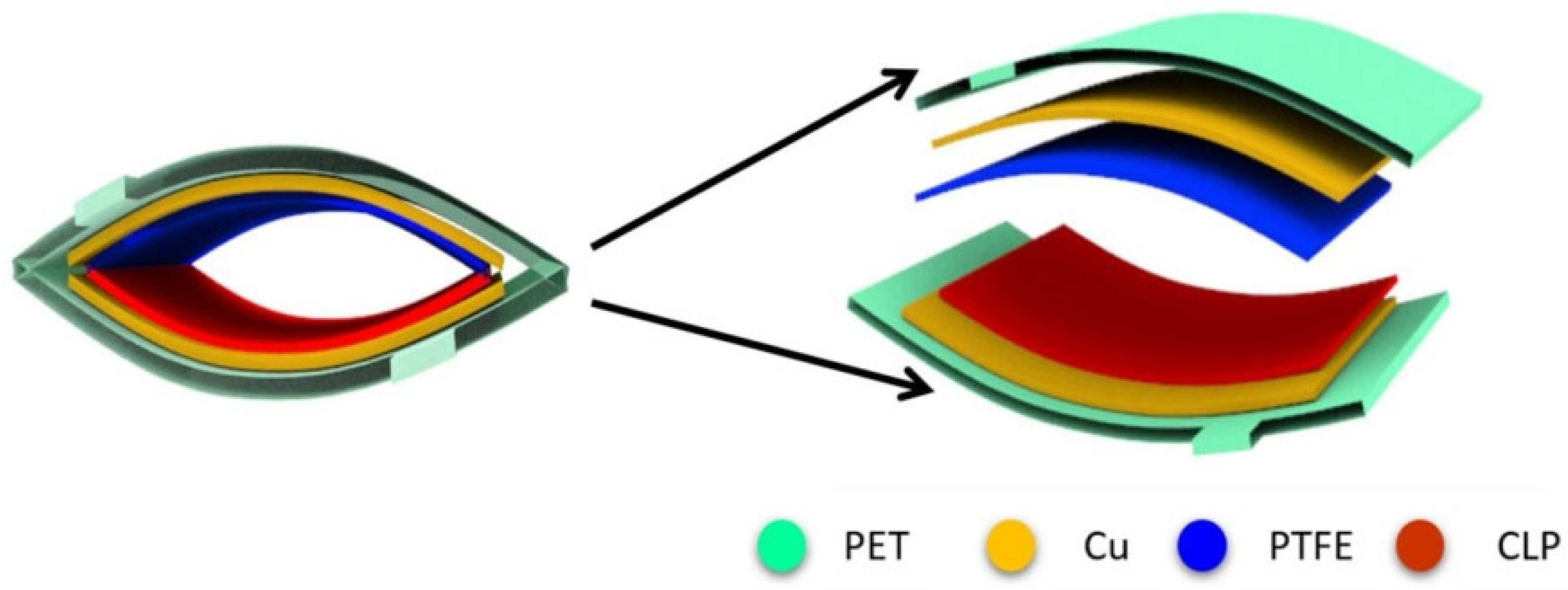

2. Materials and Methods

3. Results

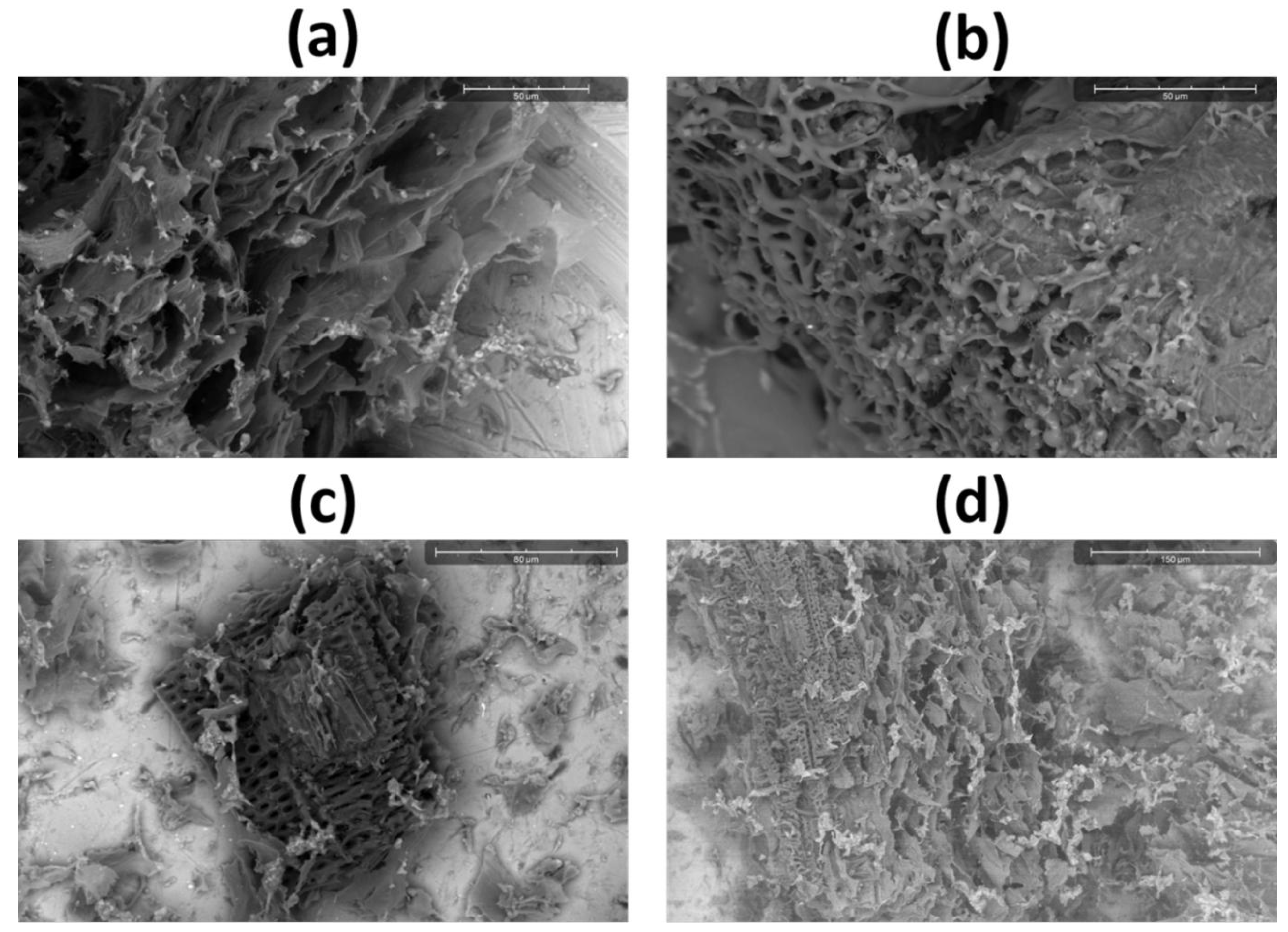

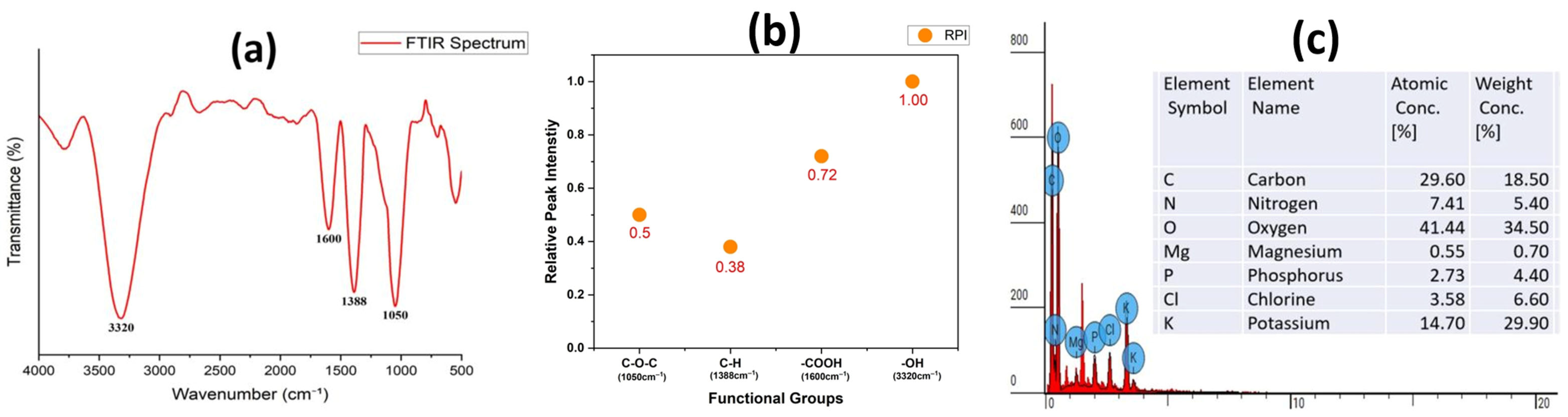

3.1. Morphological and Chemical Characterization

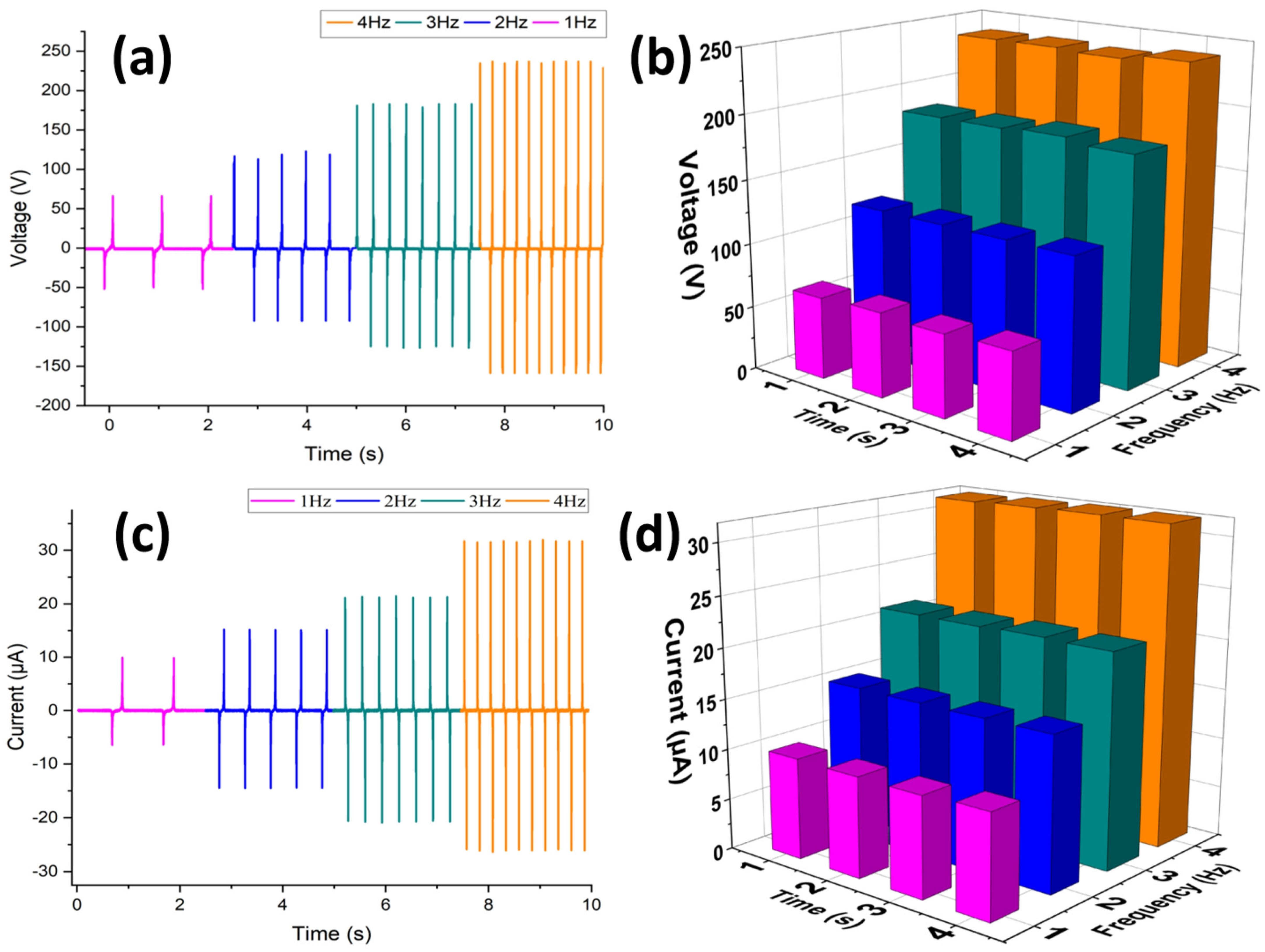

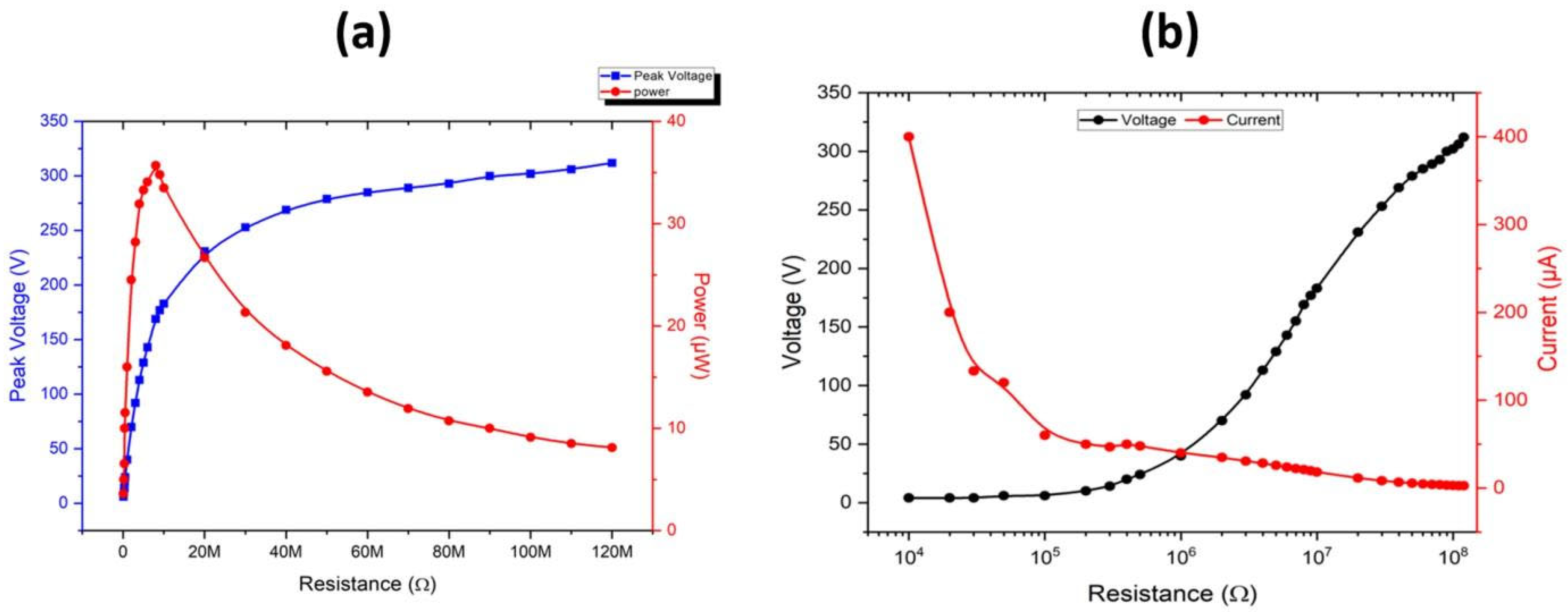

3.2. Electrical Output Performance of CLP-TENG

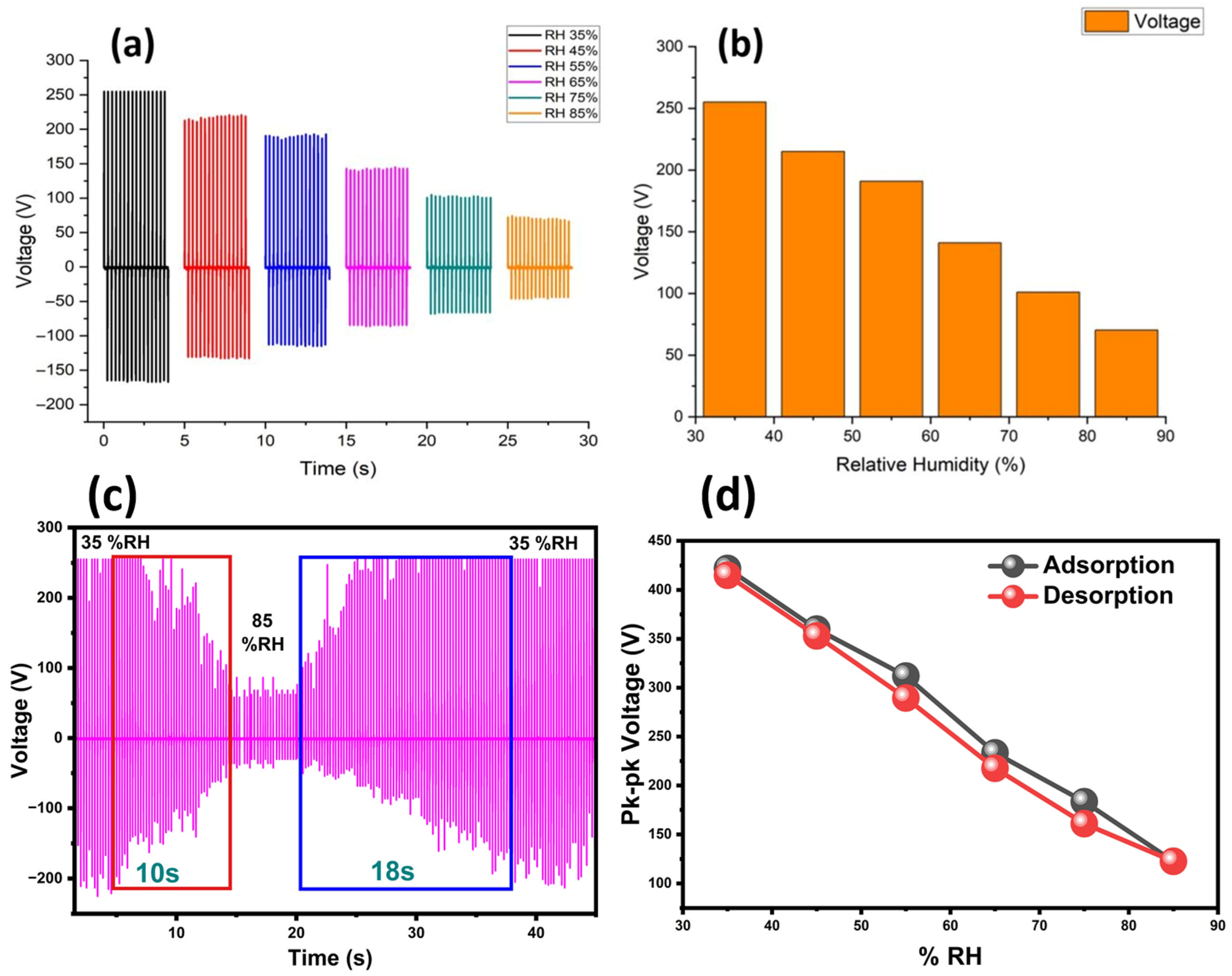

3.3. Humidity Sensing Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adewumi, A.; Olu-lawal, K.A.; Okoli, C.E.; Usman, F.O.; Usiagu, G.S. Sustainable Energy Solutions and Climate Change: A Policy Review of Emerging Trends and Global Responses. World J. Adv. Res. Rev. 2023, 21, 408–420. [Google Scholar] [CrossRef]

- Rahul, T.P.; Sreekanth, P.S.R. Synergies in Materials and Manufacturing: A Review of Composites and 3D Printing for Triboelectric Energy Harvesting. J. Compos. Sci. 2025, 9, 386. [Google Scholar] [CrossRef]

- Kumar, G.; Vyas, S.; Sharma, S.N.; Dehalwar, K. Challenges of Environmental Health in Waste Management for Peri-Urban Areas. In Sustainable Development Goals Series; Springer: Berlin/Heidelberg, Germany, 2024; Volume Part F3313, pp. 149–168. [Google Scholar]

- Khan, S.A.; Ahmed, M.A.; Baig, M.M.; Rehman, M.M.; Yang, Y.; Lee, S.G.; Choi, J.W.; Kim, W.Y. 3D Hierarchical Microcubic Morphological Composite and Its Application for Bi-Functional Humidity/Pressure Sensing in TENG Architecture. Chem. Eng. J. 2024, 485, 149660. [Google Scholar] [CrossRef]

- Rehman, M.M.; Khan, M.; Mutee ur Rehman, H.M.; Saqib, M.; Iqbal, S.; Lim, S.S.; Park, K.H.; Kim, W.Y. A Sustainable and Flexible Carbon Paper-Based Multifunctional Human–Machine Interface (HMI) Sensor. Polymers 2025, 17, 98. [Google Scholar] [CrossRef]

- Rahman, S.A.; Khan, S.A.; Iqbal, S.; Rehman, M.M.; Kim, W.Y. Eco-Friendly, High-Performance Humidity Sensor Using Purple Sweet-Potato Peel for Multipurpose Applications. Chemosensors 2023, 11, 457. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, M.M.; Khan, S.A.; Saqib, M.; Kim, W.Y. Characterization and Performance Evaluation of Fully Biocompatible Gelatin-Based Humidity Sensor for Health and Environmental Monitoring. Front. Mater. 2023, 10, 1233136. [Google Scholar] [CrossRef]

- Mutee ur Rehman, H.M.; Khan, M.; Rehman, M.M.; Khan, S.A.; Kim, W.Y. High-Performance Humidity Sensor for Multipurpose Applications by Recycling of Potato Peel Bio-Waste. Sens. Actuators A Phys. 2022, 343, 113662. [Google Scholar] [CrossRef]

- Mutee Ur Rehman, H.M.; Rehman, M.M.; Saqib, M.; Ali Khan, S.; Khan, M.; Yang, Y.; Kim, S.; Rahman, S.A.; Kim, W.-Y. Highly Efficient and Wide Range Humidity Response of Biocompatible Egg White Thin Film. Nanomaterials 2021, 11, 1815. [Google Scholar] [CrossRef]

- Ufitikirezi, J.d.D.M.; Filip, M.; Ghorbani, M.; Zoubek, T.; Olšan, P.; Bumbálek, R.; Strob, M.; Bartoš, P.; Umurungi, S.N.; Murindangabo, Y.T.; et al. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. Sustainability 2024, 16, 3617. [Google Scholar] [CrossRef]

- Selvaraj, Y.; Jayasingha, L.; Amarasinghe, G.; Jayanetti, S. Sustainable Micro Energy Harvesting Using Cryogenically Processed Bio-Waste Natural Human Hair as a Triboelectric Material. J. Electrostat. 2025, 138, 104183. [Google Scholar] [CrossRef]

- Lin, M.-F.; Chang, P.-Y.; Lee, C.-H.; Wu, X.-X.; Jeng, R.-J.; Chen, C.-P. Biowaste Eggshell Membranes for Bio-Triboelectric Nanogenerators and Smart Sensors. ACS Omega 2023, 8, 6699–6707. [Google Scholar] [CrossRef]

- Tharuman, S.; Chen, S.-M. Sustainable Energy from Nature: Biocompatible next-Generation Triboelectric Nanogenerators and Waste-Recycling Approach. J. Power Sources 2025, 640, 236683. [Google Scholar] [CrossRef]

- Vikram, L.S.; Potu, S.; Durga Prasad Kasireddi, A.K.; Khanapuram, U.K.; Divi, H.; Rajaboina, R.K. Biowaste Sea Shells-Based Triboelectric Nanogenerator: Sustainable Approach for Efficient Mechanical Energy Harvesting. Energy Technol. 2025, 13, 2401333. [Google Scholar] [CrossRef]

- Hasan, J.; Tonni, M.M.S.; Hossain, L.; Kamaruzzaman; Rana, S.M.S. Transforming Bio-Waste Into Low-Cost Green Triboelectric Nanogenerator for Biomechanical Energy Harvesting and Self-Powered Sensors. Adv. Mater. Technol. 2025; early view. [Google Scholar] [CrossRef]

- Chang, P.-Y.; Huang, T.-Y.; Yang, C.-H.; Lee, C.-H.; Jeng, R.-J.; Chen, C.-P.; Lin, M.-F. Leveraging Bio-Waste Onion Skin for High-Performance Triboelectric Nanogenerators. Chem. Eng. J. 2025, 506, 160136. [Google Scholar] [CrossRef]

- Motora, K.G.; Wu, C.-M.; Jose, C.R.M. Boosting the Triboelectric Performances of Biowaste Chitosan Keratin Triboelectric Nanogenerator Using Carbon Composite Film as Charge Storage and Charge Recombination Blocking Intermediate Layer. Chem. Eng. J. 2024, 492, 152413. [Google Scholar] [CrossRef]

- Motora, K.G.; Wu, C.; Jose, C.R.M.; Rani, G.M. Waste-to-Energy: Development of a Highly Efficient Keratin Enhanced Chitosan Bio-Waste-Derived Triboelectric Nanogenerator for Energy Harvesting and Real Applications. Adv. Funct. Mater. 2024, 34, 2315069. [Google Scholar] [CrossRef]

- Hou, X.; Ren, P.; Guo, Z.; Tian, W.; Wang, Y.; Fan, B.; Chen, H.; Chen, Z.; Jin, Y. Triboelectric Nanogenerators and Supercapacitors Based on Biowaste-Derived Porous Carbon for Efficient Energy Harvesting and Storage. J. Power Sources 2025, 649, 237422. [Google Scholar] [CrossRef]

- Cheedarala, R.K.; Kurumbala, A.M.; Chidambaram, R.R. Eco-Friendly Sand Blasted Polyvinyl Alcohol-Chitosan (PvOH-CN) Biofilm for Harvesting High-Density TENG Mechanical Energy through Contact-Separation Mode. Chem. Eng. J. 2025, 522, 168263. [Google Scholar] [CrossRef]

- Shi, W.; Wang, X.; Diao, W.; Liu, G.; Cao, Y. Effect of Pump Voltage on Triboelectric Properties and Air Breakdown of Sliding-Mode Triboelectric Nanogenerator. Nano Energy 2025, 137, 110758. [Google Scholar] [CrossRef]

- Li, Z.; Cui, B.; Guo, H.; Gong, Y.; Yang, C.; Zhang, Q.; Li, X.; Peng, Y.; Wang, J. Frequency Influence on Freestanding-Mode Triboelectric Nanogenerators. Chem. Eng. J. 2025, 511, 162060. [Google Scholar] [CrossRef]

- Qing, W.; Yan, W.; Zhou, Y.; Zhou, Q.; Wang, Q.; Zhu, Y.; Wei, K.; Zhao, L.; Zou, H.; Liu, S. Flexible Single-Electrode Triboelectric Sensor Array for Material Recognition and Trajectory Tracking. Chem. Eng. J. 2025, 525, 170266. [Google Scholar] [CrossRef]

- Wang, L.; Yu, J.; Wang, P.; Yang, L.; Yu, X.; Qiu, J.; Tan, K.; Tang, Y.; Guo, Y. Intelligent Online Sensing of Lubricating Oil Debris via Dual-Electrode Oil-Driven Triboelectric Nanogenerator. Chem. Eng. J. 2025, 503, 158413. [Google Scholar] [CrossRef]

- Iqbal, S.; Muqeet Rehman, M.; Abbas, Z.; Sardar, S.A.; Saqib, M.; Yang, Y.; Kim, W.Y. High Performance Triboelectric Nanogenerator Based on Metal–Organic Framework Composites for IoT-Assisted Wireless Healthcare Monitoring. Energy Environ. Mater. 2025, 8, e70010. [Google Scholar] [CrossRef]

- Khan, S.A.; Rehman, M.M.; Ameen, S.; Saqib, M.; Khan, M.; Kim, W.Y. High Performance Triboelectric Nanogenerator Based on Purified Chitin Nanopaper for the Applications of Self-Powered Humidity Sensing, Gait Monitoring, and Hyperhidrosis Sensor. Sustain. Mater. Technol. 2024, 40, e00867. [Google Scholar] [CrossRef]

- Sarkar, L.; Mondal, M.; Bhattacharyya, T.K. From Natural Abundant Silk to TENG; from Biowaste to Carbon Supercap: A Natural Sustainable Approach of Active Energy Storage. J. Energy Storage 2024, 97, 112641. [Google Scholar] [CrossRef]

- Prasanwong, C.; Harnchana, V.; Thongkrairat, P.; Pimanpang, S.; Jarernboon, W.; Thongbai, P.; Pimsawat, A.; Van Huynh, N.; Amornkitbamrung, V.; Treetong, A.; et al. Photoinduced Charge Generation of Nanostructured Carbon Derived from Human Hair Biowaste for Performance Enhancement in Polyvinylidene Fluoride Based Triboelectric Nanogenerator. J. Colloid Interface Sci. 2024, 665, 720–732. [Google Scholar] [CrossRef]

- Saqib, M.; Rehman, M.M.; Khan, M.; Iqbal, S.; Ali, A.U.; Siddiqui, G.U.; Kim, W.Y. Adaptable Self-Powered Humidity Sensor Based on a Highly Permeable, Hierarchically Fibrous, and Chaotically Textured Sustainable Biowaste. Sustain. Mater. Technol. 2025, 44, e01374. [Google Scholar] [CrossRef]

- Saqib, M.; Khan, S.A.; Khan, M.; Iqbal, S.; Rehman, M.M.; Kim, W.Y. Self-Powered Humidity Sensor Driven by Triboelectric Nanogenerator Composed of Bio-Wasted Peanut Skin Powder. Polymers 2024, 16, 790. [Google Scholar] [CrossRef]

- Rehman, H.M.M.U.; Prasanna, A.P.S.; Rehman, M.M.; Khan, M.; Kim, S.-J.; Kim, W.Y. Edible Rice Paper-Based Multifunctional Humidity Sensor Powered by Triboelectricity. Sustain. Mater. Technol. 2023, 36, e00596. [Google Scholar] [CrossRef]

- He, Z.; Nie, G.; You, T.; Qiao, Y.; Li, Y.; Huang, Y. Transformation of Household Waste-Watermelon Rind into High-Performance Adsorbents: A Low-Cost and Green Strategy for Dye Removal. Colloids Surf. A Physicochem. Eng. Asp. 2025, 725, 137589. [Google Scholar] [CrossRef]

- Sangwan, K.; Garhwal, R.; Sorout, S.; Mehra, R.; Bhardwaj, A.; Pal, Y.; Nayan, V.; Kumar, H. Physico-Chemical, Functional, Thermal, Dielectric and Surface Characteristics of Freeze-Dried Watermelon Rind Powder. Ann. Agri-Bio Res. 2024, 29, 136–145. [Google Scholar]

- Pérez, J.; Gómez, K.; Vega, L. Optimization and Preliminary Physicochemical Characterization of Pectin Extraction from Watermelon Rind (Citrullus lanatus) with Citric Acid. Int. J. Food Sci. 2022, 2022, 3068829. [Google Scholar] [CrossRef] [PubMed]

- Azubuike, C.P.; Adedokun, A.R.; Oseni, B.A.; Ologunagba, M.; Madu, S.J. Characterization of Physicochemical Properties of Microcrystalline and Nanocrystalline Cellulose Powders Derived from Citrullus lanatus Peels for Potential Pharmaceutical Applications. Am. J. Pharmacother. Pharm. Sci. 2025, 4, 2. [Google Scholar] [CrossRef]

- Majid, M.; Fallah-Joshaqani, S.; Dalvi-Isfahan, M.; Hamdami, R. Comparison of Conventional and Microwave-Assisted Extraction of Pectin from Watermelon Rind. J. Polym. Environ. 2023, 31, 3363–3371. [Google Scholar] [CrossRef]

- Ben Romdhane, M.; Bouallegue, A.; Bourhia, M.; Bougatef, A.; Salamatullah, A.M.; Ellouz-Chaabouni, S.; Haddar, A. Watermelon Rind Dietary Fibers as Natural Source to Enhance Texture of Wheat Bread. Foods 2024, 13, 2909. [Google Scholar] [CrossRef]

- Lochan Aryal, R.; Thapa, A.; Raj Poudel, B.; Raj Pokhrel, M.; Dahal, B.; Paudyal, H.; Nath Ghimire, K. Effective Biosorption of Arsenic from Water Using La(III) Loaded Carboxyl Functionalized Watermelon Rind. Arab. J. Chem. 2022, 15, 103674. [Google Scholar] [CrossRef]

- Mamiru, D.; Gonfa, G. Extraction and Characterization of Pectin from Watermelon Rind Using Acetic Acid. Heliyon 2023, 9, e13525. [Google Scholar] [CrossRef]

- Gladvin, G.; Sudhaakr, G.; Swathi, V.; Santhisri, K.V. Mineral and Vitamin Compositions Contents in Watermelon Peel (Rind). Int. J. Curr. Microbiol. Appl. Sci. 2017, 5, 129–133. [Google Scholar]

- Jeong, W.; Song, J.; Bae, J.; Nandanapalli, K.R.; Lee, S. Breathable nanomesh humidity sensor for real-time skin humidity monitoring. ACS Appl. Mater. Interfaces 2019, 11, 44758–44763. [Google Scholar] [CrossRef]

- Zhao, Q.; Jiang, Y.; Yuan, L.; Yuan, Z.; Zhang, B.; Liu, B.; Zhang, M.; Huang, Q.; Duan, Z.; Tai, H. Hydrophilic hyaluronic acid-induced crumpling of Nb2CTx nanosheets: Enabling fast humidity sensing based on primary battery. Sens. Actuators B Chem. 2023, 392, 134082. [Google Scholar] [CrossRef]

- Jang, J.; Kang, K.; Raeis-Hosseini, N.; Ismukhanova, A.; Jeong, H.; Jung, C.; Kim, B.; Lee, J.-Y.; Park, I.; Rho, J. Self-powered humidity sensor using chitosan-based plasmonic metal-hydrogel-metal filters. Adv. Opt. Mater. 2020, 8, 1901932. [Google Scholar] [CrossRef]

- Liu, B.-H.; Xie, G.-Z.; Li, C.-Z.; Wang, S.; Yuan, Z.; Duan, Z.-H.; Jiang, Y.-D.; Tai, H.-L. A chitosan/amido-graphene oxide-based self-powered humidity sensor enabled by triboelectric effect. Rare Met. 2021, 40, 1995–2003. [Google Scholar] [CrossRef]

- Li, X.; Qian, S.; Yan, K.; Zhu, Y.; Pang, Z.; Yang, J.; Li, M.; Chronakis, I.S. Self-powered humidity sensor based on polypyrrole modified melamine aerogel. Mater. Lett. 2020, 277, 128281. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Akhtar, F.; Iqbal, S.; Rehman, M.M.; Kim, W.Y. Sustainable Cellulose- and Pectin-Rich Triboelectric Nanogenerator for Mechanical Energy Harvesting and Self-Powered Humidity Sensing. Polymers 2025, 17, 3130. https://doi.org/10.3390/polym17233130

Kim S, Akhtar F, Iqbal S, Rehman MM, Kim WY. Sustainable Cellulose- and Pectin-Rich Triboelectric Nanogenerator for Mechanical Energy Harvesting and Self-Powered Humidity Sensing. Polymers. 2025; 17(23):3130. https://doi.org/10.3390/polym17233130

Chicago/Turabian StyleKim, Seongwan, Farhan Akhtar, Shahzad Iqbal, Muhammad Muqeet Rehman, and Woo Young Kim. 2025. "Sustainable Cellulose- and Pectin-Rich Triboelectric Nanogenerator for Mechanical Energy Harvesting and Self-Powered Humidity Sensing" Polymers 17, no. 23: 3130. https://doi.org/10.3390/polym17233130

APA StyleKim, S., Akhtar, F., Iqbal, S., Rehman, M. M., & Kim, W. Y. (2025). Sustainable Cellulose- and Pectin-Rich Triboelectric Nanogenerator for Mechanical Energy Harvesting and Self-Powered Humidity Sensing. Polymers, 17(23), 3130. https://doi.org/10.3390/polym17233130