Sustainable Valorisation of End-of-Life Tyres Through Pyrolysis-Derived Recovered Carbon Black in Polymer Composites

Abstract

1. Introduction

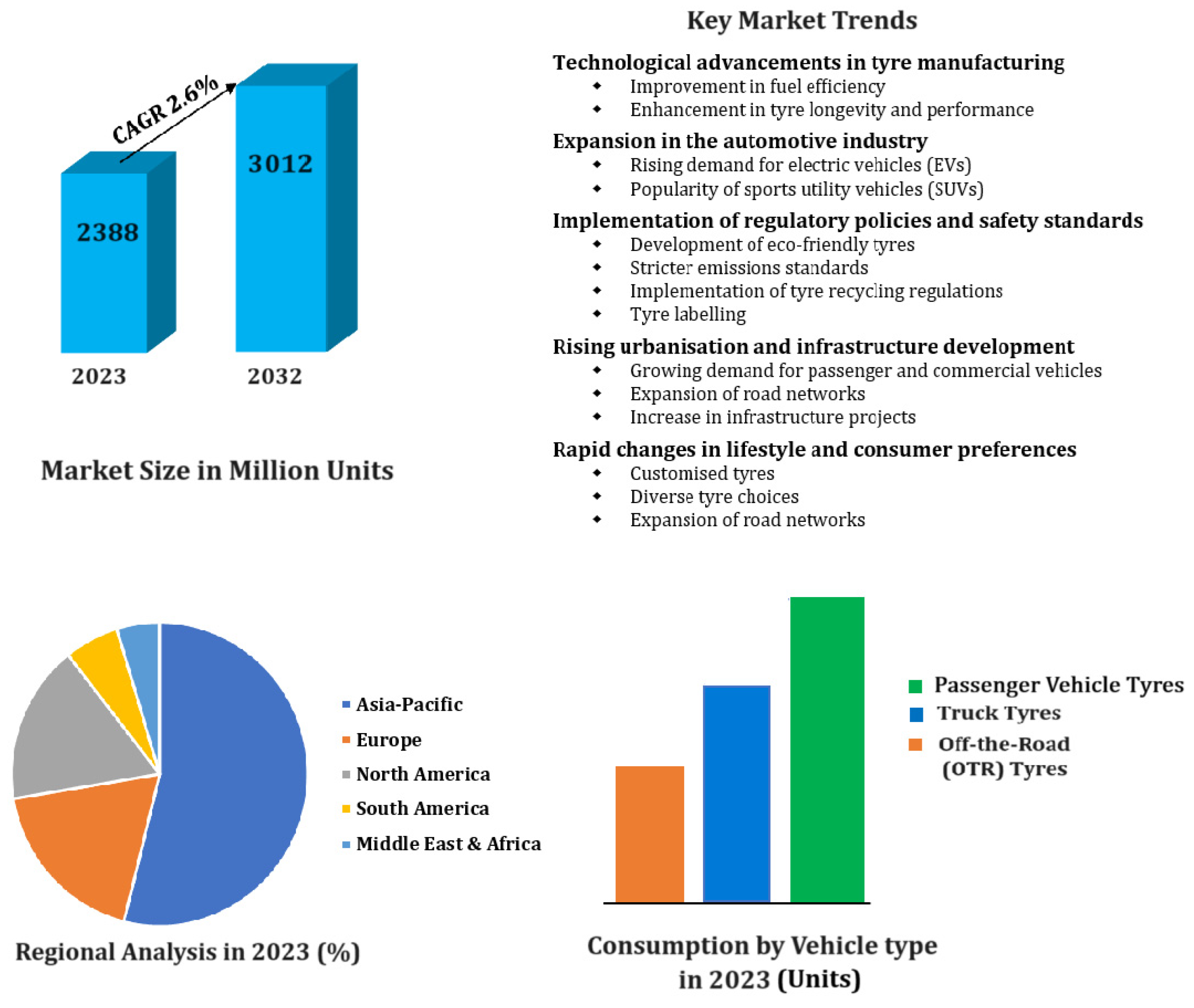

1.1. Global Tyre Market Analysis: From Market Growth to EOLTs Creation

1.2. Navigating the Risks of EOLTs

- Prolonged exposure of unused tyres to the environment could make them a breeding ground for insects, thus increasing vector-borne disease threats to human beings.

- The open accumulation of waste tyres represents a potential fire risk in the event of ignition. In the case of fires, they release toxic gases, heavy metals, and hydrocarbons, leading to major pollution of soil, air, and groundwater [7].

- The bulkiness and non-biodegradability of the waste tyres are additional burdens to landfill management because of the limitation on landfill space [8].

1.3. Review Focus and Framework

- Virgin carbon black (vCB): produced through the incomplete combustion of fossil fuel-derived petroleum feedstocks.

- Recovered carbon black (rCB): generated from the pyrolysis of EOLTs, significantly reducing CO2 emissions by about 80% compared to vCB.

- Sustainable carbon black (sCB): a forward-looking carbon black production produced from oil derived via advanced EOLT pyrolysis in a furnace reactor.

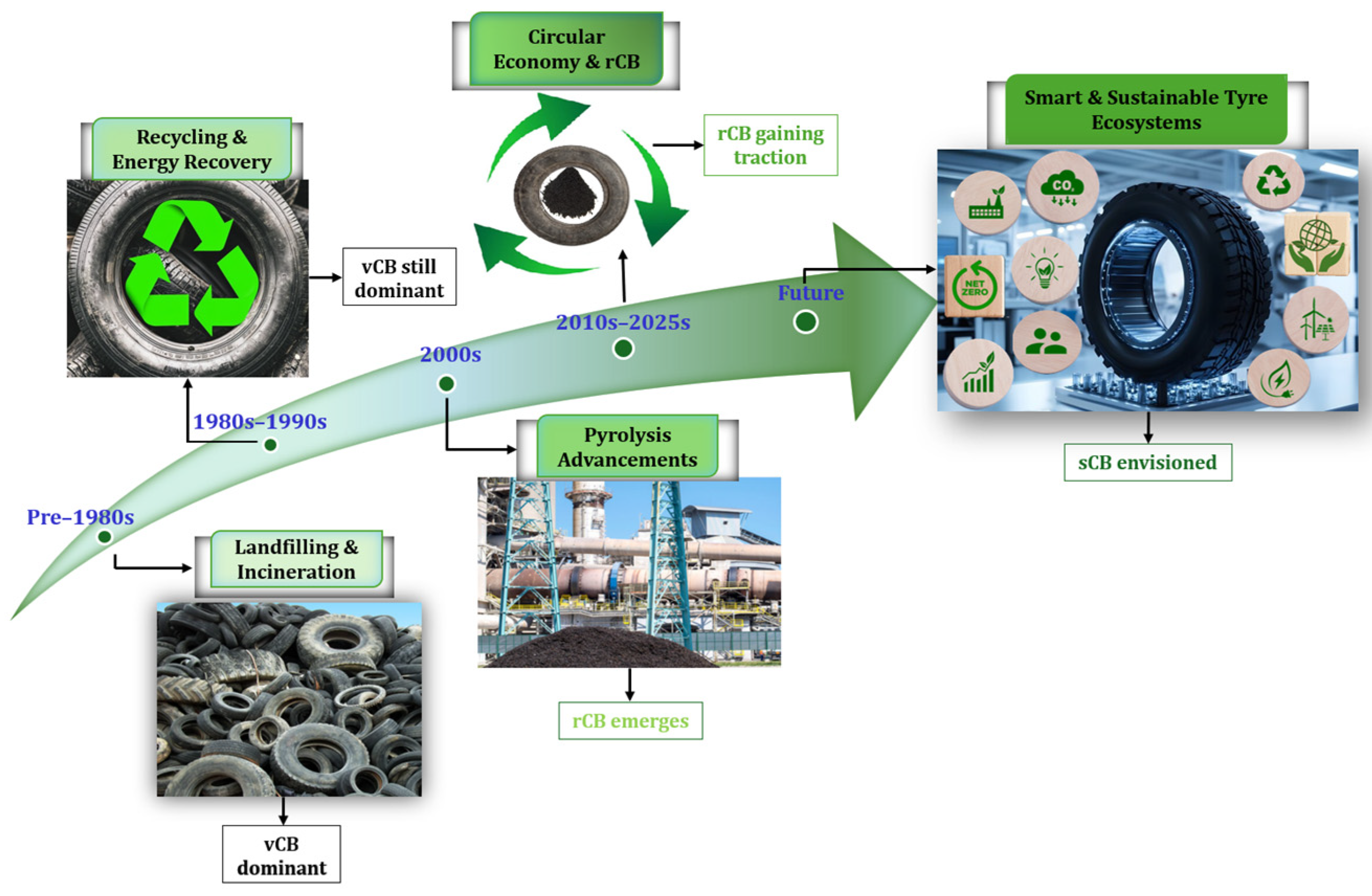

- Pre 1980s: Landfilling and incineration dominated as disposal methods of EOLTs, with virgin carbon black (vCB) as the standard filler in tyre production.

- From 1980s to 1990s: Recycling and energy recovery practices emerged, but fossil-based vCB remained the primary material.

- The 2000s: Pyrolysis technology began to mature, producing rCB as a viable alternative and enabling the conversion of tyre waste into fuels and materials.

- From 2010s to the present: rCB gained traction globally, driven by circular economy policies, industrial partnerships, and urgent environmental goals. In Europe, the 2006 Extended Producer Responsibility (EPR) scheme significantly increased EOLT collection rates (up to 95% by 2019), creating reliable feedstock for pyrolysis. rCB production now plays a critical role in decarbonising the tyre value chain—reducing emissions from 10 kg CO2 per kg of vCB to only 2 kg CO2 for rCB. The EU’s July 2024 ban on carbon black imports from Russia further emphasised the strategic importance of local, sustainable alternatives like rCB.

- Future: Sustainable carbon black (sCB) is envisioned as the outcome of next-generation innovations in tyre recycling. These are superior pyrolysis units for emission-free material recycling, rubber devulcanization for full recyclability, and bio-based materials for replacing synthetics. Plus, recycling rubber is increasingly employed in high-performance uses, while AI-tracking and smart solutions facilitate closed-loop recycling and supply chain traceability.

2. EOLT Management Pathways

2.1. Re-Use

2.1.1. Retreading

2.1.2. Refurbishment

2.2. Recycling

2.3. Energy Recovery

2.4. Pyrolysis

2.5. Disposal

2.5.1. Stockpiles

2.5.2. Landfill

2.5.3. Onsite Disposal

2.5.4. Dispersed Dumping

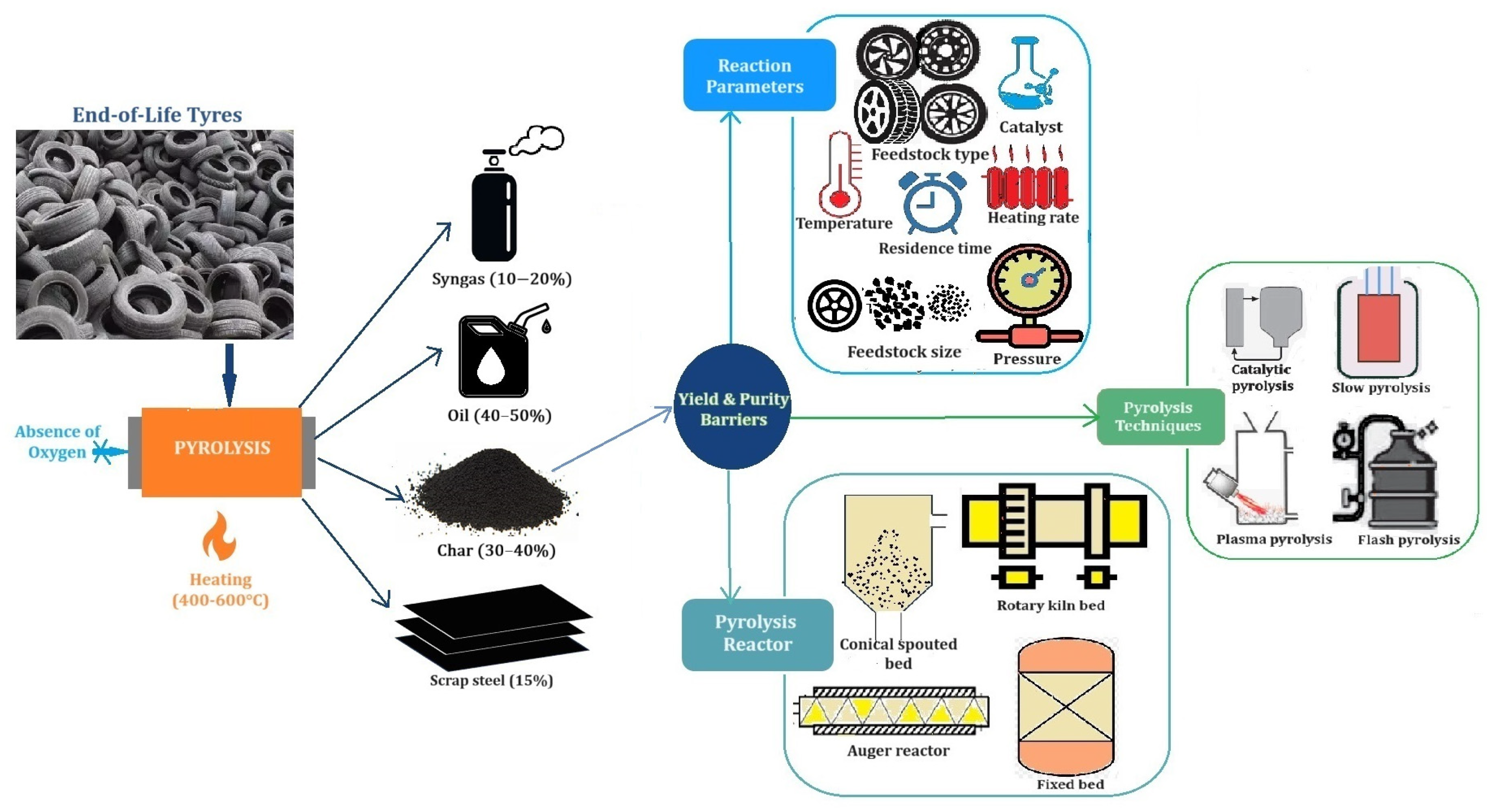

3. Pyrolysis of End-of-Life Tyres

- A 90% reduction in human toxicity potential (HTP) and ozone layer depletion potential (ODP);

- An 84% reduction in abiotic depletion potential (ADP) of fossil fuels and minerals;

- A reduction of 2.5 kg of CO2 emissions per kg of virgin carbon black produced [5].

Challenges and Considerations in Scaling up EOLT Pyrolysis

- Standardisation of pretreatment procedures: Establishing a standard pretreatment procedure for EOLTs is essential to achieve the optimal feedstock size for the pyrolysis reactor and ensure consistency in the output quality.

- Upgrading TDPs: Developing processes to upgrade the TDPs, especially oil and rCB, to establish stable and profitable markets.

- Supply chain coordination: Ensuring a steady supply of tyres is complicated due to the need to coordinate collection from multiple locations and manage the associated transportation costs.

- Obtaining necessary work approvals and environmental permissions;

- Creating detailed commissioning and operating guidelines;

- Providing adequate training for staff members;

4. Pyrolysis of Tyre-Derived Products

4.1. Scrap Steel or Steel Wire

4.2. Syngas or Tyre-Derived Pyrolysis Gas (TPG)

4.3. Oil or Tyre-Derived Pyrolysis Oil (TPO)

4.4. Char or Tyre-Derived Pyrolysis Char (TPC)

5. New Classification of Carbon Black

- Goal 9: Build resilient infrastructure, promote inclusive and sustainable industrialisation, foster innovation to deal with environmental challenges, enhance sustainability in industrial practices, and reduce waste.

- 2.

- Goal 12: Ensure sustainable consumption and production patterns.

- 3.

- Goal 13: Take urgent action to combat climate change and its impacts. This classification can be an extension of a future-based classification.

- Virgin carbon black (vCB), also known as traditional or commercial CB.

- Recovered carbon black (rCB).

- Sustainable carbon black (sCB).

5.1. Virgin Carbon Black (vCB)

5.2. Recovered Carbon Black (rCB)

5.3. Sustainable Carbon Black (sCB)

6. Composite Materials

6.1. Evolution of Reinforcements in Polymer Composites

6.2. Carbon-Based Polymer Composites

6.3. Scope of rCB/Polymer Composites

7. SWOT Analysis

8. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EOLTs | End-of-life tyres |

| TDPs | Tyre-derived products |

| rCB | Recovered carbon black |

| CB | Commercial carbon black |

| vCB | Virgin carbon black |

| sCB | Sustainable carbon black |

| CAGR | Compound annual growth rate |

| OTR | Off-the-road |

| EPR | Extended Producer Responsibility |

| TDA | Tyre Derived Aggregate |

| TDF | Tyre-derived fuel |

| HHV | High heating value |

| HTP | Human toxicity potential |

| ADP | Abiotic depletion potential |

| TPO | Tyre Pyrolysis Oil |

| TPC | Tyre-derived pyrolysis char |

| SDGs | Sustainable Development Goals |

| PEDOT | poly(3,4-ethylenedioxythiophene) |

| PEEK | Polyetheretherketone |

| PTFE | Polytetrafluoroethylene |

| HDPE | High-Density Polyethylene |

| PEI | Poly(ethylenimine) |

| PAN | Poly(acrylonitrile) |

| PAB | Poly(acrylonitrile-co-butadiene) |

| CF | Carbon fibres |

| CNTs | Carbon nanotubes |

| XRF | X-ray fluorescence |

| XRD | X-ray diffraction |

| FTIR | Fourier transform infrared spectroscopy |

| SEM | Scanning electron microscopy |

| BET | Brunauer–Emmett–Teller |

| PSD | Particle size distribution |

| SBET | Specific surface area |

| ASTM | American Society for Testing and Materials |

| LCC | Life-cycle cost |

References

- Antoniou, N.; Stavropoulos, G.; Zabaniotou, A. Activation of End of Life Tyres Pyrolytic Char for Enhancing Viability of Pyrolysis—Critical Review, Analysis and Recommendations for a Hybrid Dual System. Renew. Sustain. Energy Rev. 2014, 39, 1053–1073. [Google Scholar] [CrossRef]

- IMARC. Tire Market Report by Design, End-Use, Vehicle Type, Distribution Channel, Season, and Region 2024–2032. Available online: https://www.researchandmarkets.com/reports/5936421/tire-market-report-design-end-use-vehicle#product--toc (accessed on 1 February 2025).

- TSA. Australian Tyre Consumption and Recovery—2022–2023. Available online: https://www.tyrestewardship.org.au/tools-and-resources/tyre-consumption-recovery (accessed on 16 March 2024).

- Genever, M.; O’Farrell, K.; Randell, P.; Rebbechi, O. National Market Development Strategy for Used Tyres; Randell Environmental Consulting, Reincarnate and Envisage: Castlemaine, VIC, Australia, 2017. [Google Scholar]

- Contec Australia. Tire Waste Statistics in 2024. Available online: https://contec.tech/tire-waste-statistics-in-2024/ (accessed on 26 August 2024).

- Kibria, M.A.; Thomas, B.S.; Bhattacharya, M.; Bhattacharya, S. Processing of Metal-Free End-of-Life Tyres (Eolts) to Fuels and Products: An Experimental Study with Process Simulation and Economic Analysis from an Australian Perspective. Clean Technol. Environ. Policy 2024, 26, 4215–4229. [Google Scholar] [CrossRef]

- Gao, N.; Wang, F.; Quan, C.; Santamaria, L.; Lopez, G.; Williams, P.T. Tire Pyrolysis Char: Processes, Properties, Upgrading and Applications. Prog. Energy Combust. Sci. 2022, 93, 101022. [Google Scholar] [CrossRef]

- Boota, M.; Paranthaman, M.P.; Naskar, A.K.; Li, Y.; Akato, K.; Gogotsi, Y. Waste Tire Derived Carbon-Polymer Composite Paper as Pseudocapacitive Electrode with Long Cycle Life. ChemSusChem 2015, 8, 3576–3581. [Google Scholar] [CrossRef]

- ASTM D8178-24; Standard Terminology Relating to Recovered Carbon Black (rCB). ASTM International: Conshohocken, PA, USA, 2025. Available online: www.astm.org/d8178-24.html (accessed on 20 November 2024).

- Campuzano, F.; Martínez, J.D.; Agudelo Santamaría, A.F.; Sarathy, S.M.; Roberts, W.L. Pursuing the End-of-Life Tire Circularity: An Outlook Toward the Production of Secondary Raw Materials from Tire Pyrolysis Oil. Energy Fuels 2023, 37, 8836–8866. [Google Scholar] [CrossRef]

- Afash, H.; Ozarisoy, B.; Altan, H.; Budayan, C. Recycling of Tire Waste Using Pyrolysis: An Environmental Perspective. Sustainability 2023, 15, 14178. [Google Scholar] [CrossRef]

- Han, W.; Han, D.; Chen, H. Pyrolysis of Waste Tires: A Review. Polymers 2023, 15, 1604. [Google Scholar] [CrossRef]

- WBCSD. Managing End-of-Life Tires. Available online: https://docs.wbcsd.org/2018/02/TIP/End_of_Life_Tires-Full-Report.pdf (accessed on 16 May 2024).

- Pascal, S.; Plessis, S. Evaluating the Path to a Sustainable Tire Industry: Unlocking the Potential of Recovered Carbon Black. Available online: https://www.emerton.co/news/evaluating-the-path-to-a-sustainable-tire-industry-unlocking-the-potential-of-recovered-carbon-black# (accessed on 15 August 2024).

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in Used Tyres Management in the European Union: A Review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef]

- Bansal, P.N.; Kapgate, D.B. Tyre Waste Management: Where We Are & Where We Are Headed. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 134–151. [Google Scholar] [CrossRef]

- Fletcher, R.; Wilson, H. The Role of Pyrolysis in the Disposal of Waste Tyres. Resour. Conserv. Recycl. 1981, 5, 333–342. [Google Scholar] [CrossRef]

- Araki, T.; Niikawa, K.; Hosoda, H.; Nishizaki, H.; Mitsui, S.; Endoh, K.; Yoshida, K. Development of Fluidized-Bed Pyrolysis of Waste Tires. Resour. Conserv. Recycl. 1979, 3, 155–164. [Google Scholar] [CrossRef]

- Kaksonen, A.H.; Gazeau, B.; Caceres Ruiz, A.M.; Cheng, K.Y.; Minunno, R.; Zaman, A.; Boxall, N. Best Practice Case Studies for Increasing Value Recovery from End-of-Life Tyres and Conveyor Belts; National Environmental Science Program: Canberra, Australia, 2024. [Google Scholar]

- Hyder, V. Study into Domestic and International Fate of End-of-Life Tyres; Department for Environmental Protection, Australian Government: Melbourne, VIC, Australia, 2012. [Google Scholar]

- Nkosi, N.; Nhubu, T.; Mthombeni, N.H. An Inventory Analysis of Waste Tyre Generation and Management in South Africa. Waste Manag. 2025, 194, 353–365. [Google Scholar] [CrossRef]

- Kay, E.; Laman, J. A Review of Scrap Tire Disposal Processes; 790301; SAE: Warrendale, PA, USA, 1979. [Google Scholar] [CrossRef]

- Eco Green Equipment. The Complete History of Tire Recycling. Available online: https://ecogreenequipment.com/the-complete-history-of-tire-recycling/ (accessed on 10 April 2025).

- Eco Green Equipment. The Future of End-of-Life Tire Recycling in 2025 and Beyond. Available online: https://ecogreenequipment.com/the-future-of-end-of-life-tire-recycling-in-2025-and-beyond/ (accessed on 10 April 2025).

- Ławińska, O.; Korombel, A.; Zajemska, M. Pyrolysis-Based Municipal Solid Waste Management in Poland—Swot Analysis. Energies 2022, 15, 510. [Google Scholar] [CrossRef]

- Leandri, P.; Rocchio, P.; Losa, M. A Swot Analysis of Innovative High Sustainability Pavement Surfaces Containing Crumb Rubber Modifier. Road Mater. Pavement Des. 2020, 21, S103–S122. [Google Scholar] [CrossRef]

- Costa, S.M.R.; Fowler, D.; Carreira, G.A.; Portugal, I.; Silva, C.M. Production and Upgrading of Recovered Carbon Black from the Pyrolysis of End-of-Life Tires. Materials 2022, 15, 2030. [Google Scholar] [CrossRef]

- ETRMA. European Tyre and Rubber Manufacturers’ Association. Available online: https://www.etrma.org/key-topics/circular-economy/ (accessed on 10 August 2024).

- Randell, P.; Baker, B.; O’Farrell, K. Used Tyres Supply Chain and Fate Analysis; Randell Environmental Consulting: Castlemaine, VIC, Australia, 2020. [Google Scholar]

- TSA. Tsa Report Demystifies Pyrolysis and Gasification of Waste Tyres. Available online: https://www.tyrestewardship.org.au/news-and-insights/tsa-report-demystifies-pyrolysis-and-gasification-of-waste-tyres (accessed on 3 March 2024).

- Khan, W.; Shyamal, D.S.; Kazmi, A.A. Management of End-of-Life Tyres in India: Current Practices, Regulatory Framework, Challenges, and Opportunities. J. Mater. Cycles Waste Manag. 2024, 26, 1310–1325. [Google Scholar] [CrossRef]

- Cardona-Uribe, N.; Betancur, M.; Martínez, J.D. Towards the Chemical Upgrading of the Recovered Carbon Black Derived from Pyrolysis of End-of-Life Tires. Sustain. Mater. Technol. 2021, 28, e00287. [Google Scholar] [CrossRef]

- Han, J.; Li, W.; Liu, D.; Qin, L.; Chen, W.; Xing, F. Pyrolysis Characteristic and Mechanism of Waste Tyre: A Thermogravimetry-Mass Spectrometry Analysis. J. Anal. Appl. Pyrolysis 2018, 129, 1–5. [Google Scholar] [CrossRef]

- Maga, D.; Aryan, V.; Blömer, J. A Comparative Life Cycle Assessment of Tyre Recycling Using Pyrolysis Compared to Conventional End-of-Life Pathways. Resour. Conserv. Recycl. 2023, 199, 107255. [Google Scholar] [CrossRef]

- Sathiskumar, C.; Karthikeyan, S. Recycling of Waste Tires and Its Energy Storage Application of by-Products –A Review. Sustain. Mater. Technol. 2019, 22, e00125. [Google Scholar] [CrossRef]

- de Marco Rodriguez, I.; Laresgoiti, M.F.; Cabrero, M.A.; Torres, A.; Chomón, M.J.; Caballero, B. Pyrolysis of Scrap Tyres. Fuel Process. Technol. 2001, 72, 9–22. [Google Scholar] [CrossRef]

- Seng-eiad, S.; Jitkarnka, S. Untreated and Hno3-Treated Pyrolysis Char as Catalysts for Pyrolysis of Waste Tire: In-Depth Analysis of Tire-Derived Products and Char Characterization. J. Anal. Appl. Pyrolysis. 2016, 122, 151–159. [Google Scholar] [CrossRef]

- TSA. Pyrolysis of End-of-Life Tyres. Available online: https://www.tyrestewardship.org.au/tools-and-resources/pyrolysis-of-end-of-life-tyres (accessed on 9 September 2024).

- Hoang, A.T.; Nguyen, T.H.; Nguyen, H.P. Scrap Tire Pyrolysis as a Potential Strategy for Waste Management Pathway: A Review. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 46, 6305–6322. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Januszewicz, K.; Kosakowski, W. Efficiency and Proportions of Waste Tyre Pyrolysis Products Depending on the Reactor Type—A Review. J. Anal. Appl. Pyrolysis 2019, 140, 25–53. [Google Scholar] [CrossRef]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste Tyre Pyrolysis—A Review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Zerin, N.H.; Rasul, M.G.; Jahirul, M.I.; Sayem, A.S.M. End-of-Life Tyre Conversion to Energy: A Review on Pyrolysis and Activated Carbon Production Processes and Their Challenges. Sci. Total Environ. 2023, 905, 166981. [Google Scholar] [CrossRef]

- Contect Australia. Tire Recycling Pyrolysis: Pros and Cons, Explained. Available online: https://contec.tech/tire-recycling-pyrolysis-pros-and-cons-explained/ (accessed on 26 August 2024).

- FactMR. Steel Scrap Market Outlook (2023 to 2033). Available online: https://www.factmr.com/report/steel-scrap-market (accessed on 28 August 2024).

- Tsipa, P.C.; Phiri, M.M.; Iwarere, S.A.; Mkhize, N.M.; Phiri, M.J.; Hlangothi, S.P. The Effect of Pre-Pyrolysis Chemical Treatment of Waste Tyre Rubber Crumbs: Comparison between Pre-Treated and Conventional Waste Tyre-Derived Oil. J. Chem. Technol. Biotechnol. 2023, 98, 1279–1289. [Google Scholar] [CrossRef]

- Sanchis, A.; Veses, A.; Martinez, J.D.; Lopez, J.M.; Garcia, T.; Murillo, R. The Role of Temperature Profile During the Pyrolysis of End-of-Life-Tyres in an Industrially Relevant Conditions Auger Plant. J. Environ. Manag. 2022, 317, 115323. [Google Scholar] [CrossRef]

- Contec Australia. Products. Available online: https://contec.tech/products/ (accessed on 26 August 2024).

- Waverly Carbon. Recovered Carbon Black. Available online: https://www.waverlycarbon.com/carbon-black/ (accessed on 26 August 2024).

- Xu, J.; Yu, J.; Xu, J.; Sun, C.; He, W.; Huang, J.; Li, G. High-Value Utilization of Waste Tires: A Review with Focus on Modified Carbon Black from Pyrolysis. Sci. Total Environ. 2020, 742, 140235. [Google Scholar] [CrossRef]

- Williams, P.T. Pyrolysis of Waste Tyres: A Review. Waste Manag. 2013, 33, 1714–1728. [Google Scholar] [CrossRef] [PubMed]

- Min, A.; Harris, A. Influence of Carbon Dioxide Partial Pressure and Fluidization Velocity on Activated Carbons Prepared from Scrap Car Tyre in a Fluidized Bed. Chem. Eng. Sci. 2006, 61, 8050–8059. [Google Scholar] [CrossRef]

- Jin, Y.; Yan, J.; Gu, J.; Cen, K. Configuration of Pyrolytic Chars from Waste Tires in Fluidized Bed Reactor. Huan Jing Ke Xue Huanjing Kexue 2004, 25, 159–162. [Google Scholar]

- Fang, H.; Hou, Z.; Shan, L.; Cai, X.; Xin, Z. Influence of Pyrolytic Carbon Black Derived from Waste Tires at Varied Temperatures within an Industrial Continuous Rotating Moving Bed System. Polymers 2023, 15, 3460. [Google Scholar] [CrossRef] [PubMed]

- CORDIS-EU. Recycling Shredded Used Tyres and Rubber Waste into Personalized Recovered Carbon Black to Limit Use of Fossil Fuels and Carbon Dioxide Emission. Available online: https://cordis.europa.eu/project/id/101009283 (accessed on 26 August 2024).

- ICBA. Carbon Black User’s Guide; International Carbon Black Association: New Orleans, LA, USA, 2016. [Google Scholar]

- Recovered Carbon Black. Applications. Available online: https://recovered-carbon-black.com/en/ (accessed on 25 July 2024).

- bin Samsuri, A. Evaluation of Recycled Carbon Black (R-Cb) Based on Styrene Butadiene Rubber, Natural Rubber and Nitrile Rubber Compounds. In Application and Characterization of Rubber Materials; IntechOpen: London, UK, 2022. [Google Scholar]

- Karagiannidis, A.; Kasampalis, T. Resource Recovery from End-of-Life Tyres in Greece: A Field Survey, State-of-Art and Trends. Waste Manag. Res. 2010, 28, 520–532. [Google Scholar] [CrossRef] [PubMed]

- Goksal, F.P. An Economic Analysis of Scrap Tire Pyrolysis, Potential and New Opportunities. Heliyon 2022, 8, e11669. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Xu, J.; Li, Z.; He, W.; Huang, J.; Xu, J.; Li, G. Upgrading Pyrolytic Carbon-Blacks (Cbp) from End-of-Life Tires: Characteristics and Modification Methodologies. Front. Environ. Sci. Eng. 2019, 14, 19. [Google Scholar] [CrossRef]

- Tang, H.; Hu, H.; Li, A.; Yi, B.; Li, X.; Yao, D.; Yao, H.; Yuan, H. Removal of Impurities from Waste Tire Pyrolysis Char Using the Molten Salt Thermal Treatment. Fuel 2021, 301, 121019. [Google Scholar] [CrossRef]

- Zhong, R.; Xu, J.; Hui, D.; Bhosale, S.S.; Hong, R. Pyrolytic Preparation and Modification of Carbon Black Recovered from Waste Tyres. Waste Manag. Res. 2020, 38, 35–43. [Google Scholar] [CrossRef]

- Martínez, J.D.; Cardona-Uribe, N.; Murillo, R.; García, T.; López, J.M. Carbon Black Recovery from Waste Tire Pyrolysis by Demineralization: Production and Application in Rubber Compounding. Waste Manag. 2019, 85, 574–584. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Jones, I.; Zhu, M.; Zhang, Z.; Preciado-Hernandez, J.; Zhang, D. Pore Development During Co2 and Steam Activation of a Spent Tyre Pyrolysis Char. Waste Biomass Valorization 2021, 12, 2097–2108. [Google Scholar] [CrossRef]

- López, F.; Centeno, T.; Rodríguez, O.; Alguacil, F. Preparation and Characterization of Activated Carbon from the Char Produced in the Thermolysis of Granulated Scrap Tyres. J. Air Waste Manag. Assoc. 2013, 63, 534–544. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Dong, H.; Hao, X.; Liu, Y.; Tang, D.; Zhao, H.; Zhou, W.; Sun, C.; Zhang, L. Enhanced Fatigue Resistance of Plasma Modified Pyrolysis Carbon Black Filled Natural Rubber Composites. Appl. Surf. Sci. 2024, 643, 158707. [Google Scholar] [CrossRef]

- TRIF, C.M. Rubber Composition Containing Recycled Carbon Black for Tires. International Patent Application No. PCT/US2022/078899, 4 May 2023. [Google Scholar]

- United Nations. The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 2 August 2024).

- Weibold. Weibold Academy: Astm Committee D36 Advances Standards for rCB. 2024. Available online: https://weibold.com/weibold-academy-astm-committee-d36-advances-standards-for-rcb (accessed on 26 August 2024).

- BlackCycle. Orion Engineered Carbons Is Moving Forward on the Road to Sustainability: Creation of Sn234 Able to Be Used as a Drop-in to a Conventional N234—November 2022. Available online: https://blackcycle-project.eu/orion-engineered-carbons-is-moving-forward-on-the-road-to-sustainability-creation-of-sn234-able-to-be-used-as-a-drop-in-to-a-conventional-n234/ (accessed on 28 August 2024).

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A Review on Natural Fiber Reinforced Composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Biswal, T.; BadJena, S.K.; Pradhan, D. Synthesis of Polymer Composite Materials and Their Biomedical Applications. Mater. Today Proc. 2020, 30, 305–315. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S.; Kroll, L. Lightweight Polymer Composite Structures: Design and Manufacturing Techniques; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2021. [Google Scholar]

- Patel, V.K.; Kant, R.; Chauhan, P.S.; Bhattacharya, S. Trends in Applications of Polymers and Polymer Composites; AIP: Melville, NY, USA, 2022. [Google Scholar]

- Aliyeva, N.; Sas, H.S.; Okan, B.S. Revolutionizing Transportation Composite Structures: Lightweight, Sustainable, and Multi-Scale Hybrid Design through Waste Tire-Driven Graphene, Hemp Fiber, and Bio-Based Overmoulding. J. Thermoplast. Compos. Mater. 2024, 37, 2987–3011. [Google Scholar] [CrossRef]

- Sasikumar, K.; Manoj, N.R.; Mukundan, T.; Rahaman, M.; Khastgir, D. Mechanical Properties of Carbon-Containing Polymer Composites. In Carbon-Containing Polymer Composites; Polymer and Composite Materials; Springer: Berlin/Heidelberg, Germany, 2019; pp. 125–157. [Google Scholar]

- Yang, H.; Gong, J.; Wen, X.; Xue, J.; Chen, Q.; Jiang, Z.; Tian, N.; Tang, T. Effect of Carbon Black on Improving Thermal Stability, Flame Retardancy and Electrical Conductivity of Polypropylene/Carbon Fiber Composites. Compos. Sci. Technol. 2015, 113, 31–37. [Google Scholar] [CrossRef]

- Norris, C.; Hale, M.; Bennett, M. Pyrolytic Carbon: Factors Controlling in-Rubber Performance. Plast. Rubber Compos. 2014, 43, 245–256. [Google Scholar] [CrossRef]

- Urrego-Yepes, W.; Cardona-Uribe, N.; Vargas-Isaza, C.A.; Martínez, J.D. Incorporating the Recovered Carbon Black Produced in an Industrial-Scale Waste Tire Pyrolysis Plant into a Natural Rubber Formulation. J. Environ. Manag. 2021, 287, 112292. [Google Scholar] [CrossRef]

- da Luz, F.; Garcia Filho, F.; del-Río, M.; Nascimento, L.; Pinheiro, W.; Monteiro, S. Graphene-Incorporated Natural Fiber Polymer Composites: A First Overview. Polymers 2020, 12, 1601. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.; Mahat, A.M.; Lee, C.L.; Aisyah, H.A.; et al. Fabrication, Functionalization, and Application of Carbon Nanotube-Reinforced Polymer Composite: An Overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef] [PubMed]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent Applications of Carbon-Based Composites in Defence Industry: A Review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Shahamatifard, F.; Rodrigue, D.; Mighri, F. Thermal and Mechanical Properties of Carbon-Based Rubber Nanocomposites: A Review. Plast. Rubber Compos. 2023, 52, 483–505. [Google Scholar] [CrossRef]

- Geier, N.; Xu, J.; Poór, D.I.; Dege, J.H.; Davim, J.P. A Review on Advanced Cutting Tools and Technologies for Edge Trimming of Carbon Fibre Reinforced Polymer (Cfrp) Composites. Compos. Part B Eng. 2023, 266, 111037. [Google Scholar] [CrossRef]

- Erkmen, B.; Bayram, G. Improvement in Mechanical, Electrical, and Shape Memory Properties of the Polystyrene-Based Carbon Fiber-Reinforced Polymer Composites Containing Carbon Nanotubes. J. Appl. Polym. Sci. 2021, 138, 50541. [Google Scholar] [CrossRef]

- Ojha, S.; Acharya, S.K.; Raghavendra, G. Mechanical Properties of Natural Carbon Black Reinforced Polymer Composites. J. Appl. Polym. Sci. 2015, 132, 41211. [Google Scholar] [CrossRef]

- Dwivedi, C.; Manjare, S.; Rajan, S.K. Recycling of Waste Tire by Pyrolysis to Recover Carbon Black: Alternative & Environment-Friendly Reinforcing Filler for Natural Rubber Compounds. Compos. Part B Eng. 2020, 200, 108346. [Google Scholar] [CrossRef]

- Karabörk, F.; Tıpırdamaz, S. Influence of Pyrolytic Carbon Black and Pyrolytic Oil Made from Used Tires on the Curing and (Dynamic) Mechanical Properties of Natural Rubber (Nr)/Styrene-Butadiene Rubber (Sbr) Blends. Express Polym. Lett. 2016, 10, 72–82. [Google Scholar] [CrossRef]

- Sagar, M.; Nibedita, K.; Manohar, N.; Kumar, K.R.; Suchismita, S.; Pradnyesh, A.; Reddy, A.B.; Sadiku, E.R.; Gupta, U.; Lachit, P.; et al. A Potential Utilization of End-of-Life Tyres as Recycled Carbon Black in Epdm Rubber. Waste Manag. 2018, 74, 110–122. [Google Scholar] [CrossRef]

- Saul, C.L. Valorisation of Pyrolytic Tyre Char as Filler in Polypropylene; Stellenbosch University: Stellenbosch, South Africa, 2019. [Google Scholar]

- Sunali, S.; Mago, J.; Negi, A.; Pant, K.K.; Fatima, S. Acoustical, Vibrational, and Thermal Investigations of Pyrolytic Carbon Black Reinforced Natural Rubber Composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 1047–1424. [Google Scholar] [CrossRef]

- ASTM D1765-23b; Standard Classification System for Carbon Blacks Used in Rubber Products. Available online: https://www.astm.org/d1765-23b.html (accessed on 3 September 2024).

- Ismawi, D.H.A.; Zaeimoedin, T.Z.; Saad, C.S.M. Recovered Carbon Black (rCB) from Waste Tyres: Effect on Mechanical Properties of Rubber Compound. In Proceedings of the Conference Malaysian Science and Technology Congress (MSTC 2010), Kuala Lumpur, Malaysia, 9–11 November 2010; pp. 9–11. [Google Scholar]

- Berki, P.; Göbl, R.; Karger-Kocsis, J. Structure and Properties of Styrene-Butadiene Rubber (Sbr) with Pyrolytic and Industrial Carbon Black. Polym. Test. 2017, 61, 404–415. [Google Scholar] [CrossRef]

- Jie, Z.; Shengji, W.; Tianming, Y.; Zhengmiao, X. Modified Pyrolytic Carbon Black from Scrap Tires and Its Reinforcement Performance in Natural Rubber. In Proceedings of the 2011 International Conference on Computer Distributed Control and Intelligent Environmental Monitoring, Changsha, China, 19–20 February 2011; pp. 472–475. [Google Scholar]

- Hussain, N.I.A.M.; Bonnia, N.N.; Hirzin, R.S.F.N.; Ali, E.S.; Ratim, S. Preparation of Castor-Based Polyurethane Composites Filled with Waste Carbon Tyres (Wct) as Grouting Material. J. Technol. 2020, 82, 59–66. [Google Scholar] [CrossRef]

- Sharma, A.; Sawant, R.J.; Sharma, A.; Joshi, J.B.; Jain, R.K.; Kasilingam, R. Valorisation of End-of-Life Tyres for Generating Valuable Resources under Circular Economy. Fuel 2022, 314, 123138. [Google Scholar] [CrossRef]

| Treatment Method | Key Effects | Quantitative Outcomes | Source |

|---|---|---|---|

| Molten salt thermal treatment (Na2CO3–NaOH) | Removes inorganic ash and sulphur; breaks agglomerates; improves particle uniformity | >80% ash removal and >70% S removal at ≈400 °C; 71–83% char recovery | [61] |

| Acid washing—HNO3 (5 M) | Demineralisation; increases surface acidity (–COOH); preserves pore structure | Increased carboxyl (–COOH) groups on the char’s surface enhanced its acidity by 57.8% and reduced the sulphur content | [37] |

| Acid washing—HCl (rinsing) | Demineralisation; lowers ash; improves mechanical properties in rubber compounds | Ash content reduced from 22.5% to 8.4% and tensile stress increased by ≈2.2 MPa at 300% strain. | [62] |

| Acid/alkali sequential demineralisation (HNO3 + NaOH, etc.) | Strong ash reduction; improves BET and particle size after milling | Ash content reduced from 16.24% to 1.95%; BET surface area increased from 58.9 to 80.22 m2/g; particle size decreased from 153.2 to 38.5 µm | [63] |

| Thermal activation (CO2 and steam at high temperature 900 °C) | Develops porosity and raises the BET strongly | Steam activation improves carbon conversion by 30–70% over CO2; surface area: steam 666.6 m2/g; CO2 434.5 m2/g | [64] |

| Chemical activation (KOH, CO2) and Acid treatments (HNO3/H2SO4 & HNO3/H2O | Creates microporosity; achieves very high BET surface area | Acid treatments removed ~70% of impurities and increased the BET surface area to 38–57 m2/g; the BET surface area is 720 m2/g after CO2 activation and 242 m2/g after KOH activation. | [65] |

| Plasma treatment (O2, Ar glow discharge) | Adds oxygen-containing groups; improves dispersion and mechanical properties | O/C ratio and XPS O-peak intensities increased 10–30%; fatigue/wear resistance improved by 15–25% | [66] |

| Silane grafting/coupling agents (e.g., 3-aminopropyltriethoxysilane) | Improves bonding with polar polymers (PP, silica/CB blends); restores mechanical properties | Up to 300% increase in tensile strength and modulus compared to untreated char | [67] |

| Graft polymerization/covalent functionalisation (–COOH, –NH2 grafts) | Adds functional groups; improves compatibility; reduces hysteresis in elastomers | Mechanical recovery and dispersion improved by approximately 10–40% | [27] |

| rCB Name in Paper | Polymer Matrix | Properties Analysed | Compared Commercial CB Grades | Reference |

|---|---|---|---|---|

| Recovered carbon black (rCB) | Nitrile butadiene rubber (NBR) | Tensile properties and curing characteristics | N774 and N660 | [93] |

| Pyrolytic carbon black (PCB) | Vulcanised rubber | Extend stress, tensile strength at break, and elongation ratio | - | [95] |

| Pyrolysis carbon black (pCB) | Styrene butadiene rubber (SBR) | Elastic modulus and filler dispersion | N772, N550, N330, N234, and N115 | [78] |

| Waste tyre-derived carbon | Polyaniline (PANI) | Pseudocapacitive electrode properties like capacitance and cycle life | - | [8] |

| Pyrolytic carbon black (CBp) | Natural rubber (NR)/styrene–butadiene rubber (SBR) blends | Curing properties, tensile strength, elongation at break, modulus, tear strength, hardness, and dynamic mechanical properties | N550 | [88] |

| Pyrolytic carbon black (pCB) | Styrene–butadiene rubber (SBR) | Dispersion, cure behaviour, dynamic mechanical, thermal behaviour, and tensile mechanical and fracture mechanical properties | N330 | [94] |

| Recycled carbon black (rCB) | Ethylene–propylene–diene rubber (EPDM) | Hardness, tensile strength, elongation at break, and tear strength | N550 | [89] |

| Pyrolytic tyre char | Polypropylene | Tensile properties, impact strength, and degradation stability | - | [90] |

| Recovered carbon black (rCB) | Natural rubber (NR) | Tensile strength and elongation at break | N330 | [87] |

| Waste carbon tyres (WCTs) | Castor-based polyurethane (CPUC) | Physical, rheological, mechanical, morphological and thermal properties | - | [96] |

| Recovered carbon black (rCB) | Natural rubber (NR) | Rheological, thermal, structural, and mechanical properties | N550 | [79] |

| Tyre-recovered carbon black (Tyre rCB) | Styrene–butadiene rubber | Tear strength, tensile strength, hardness, and elasticity | - | [97] |

| Pyrolytic carbon black (PCB) | Natural rubber | Thermal conductivity, vibration damping, and sound transmission loss | - | [91] |

| Strengths | Weaknesses |

|---|---|

| Perception of end-of-life tyres (EOLTs) as valuable resources rather than waste. Sustainable alternative to virgin carbon black (vCB), reducing fossil resource depletion. Cost-effective and eco-friendly material derived from pyrolysis of EOLTs. Supports a circular economy and corporate sustainability goals. Versatile applications in polymers such as NBR, SBR, NR, polypropylene, etc. | Quality inconsistency due to feedstock variability and impurities (e.g., ash and silica). Lack of standardised testing and classification systems for rCB. Technological immaturity of pyrolysis processes, primarily focused on oil recovery. Challenges in the collection, transportation, and refining of EOLTs to meet demand. Lower reinforcing performance compared to commercial CB grades. |

| Opportunities | Threats |

| Increasing global focus on EOLT management and regulations to reduce stockpiles and illegal dumping. Volatility in oil prices makes rCB a competitive alternative to vCB. Development of new markets in construction, automotive, and consumer goods. Advance pyrolysis technology and standardisation efforts. | Slow industry adoption due to long qualification timelines. Competition with vCB and other sustainable fillers. Concerns about cost competitiveness * if rCB quality is not consistently improved. Regulatory hurdles and certification requirements for rCB products. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banala, D.; Sabri, Y.; Choudhury, N.R.; Parthasarathy, R. Sustainable Valorisation of End-of-Life Tyres Through Pyrolysis-Derived Recovered Carbon Black in Polymer Composites. Polymers 2025, 17, 2771. https://doi.org/10.3390/polym17202771

Banala D, Sabri Y, Choudhury NR, Parthasarathy R. Sustainable Valorisation of End-of-Life Tyres Through Pyrolysis-Derived Recovered Carbon Black in Polymer Composites. Polymers. 2025; 17(20):2771. https://doi.org/10.3390/polym17202771

Chicago/Turabian StyleBanala, Dharanija, Ylias Sabri, Namita Roy Choudhury, and Rajarathinam Parthasarathy. 2025. "Sustainable Valorisation of End-of-Life Tyres Through Pyrolysis-Derived Recovered Carbon Black in Polymer Composites" Polymers 17, no. 20: 2771. https://doi.org/10.3390/polym17202771

APA StyleBanala, D., Sabri, Y., Choudhury, N. R., & Parthasarathy, R. (2025). Sustainable Valorisation of End-of-Life Tyres Through Pyrolysis-Derived Recovered Carbon Black in Polymer Composites. Polymers, 17(20), 2771. https://doi.org/10.3390/polym17202771