Enhanced Dielectric Performance in PVDF-Based Composites by Introducing a Transition Interface

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

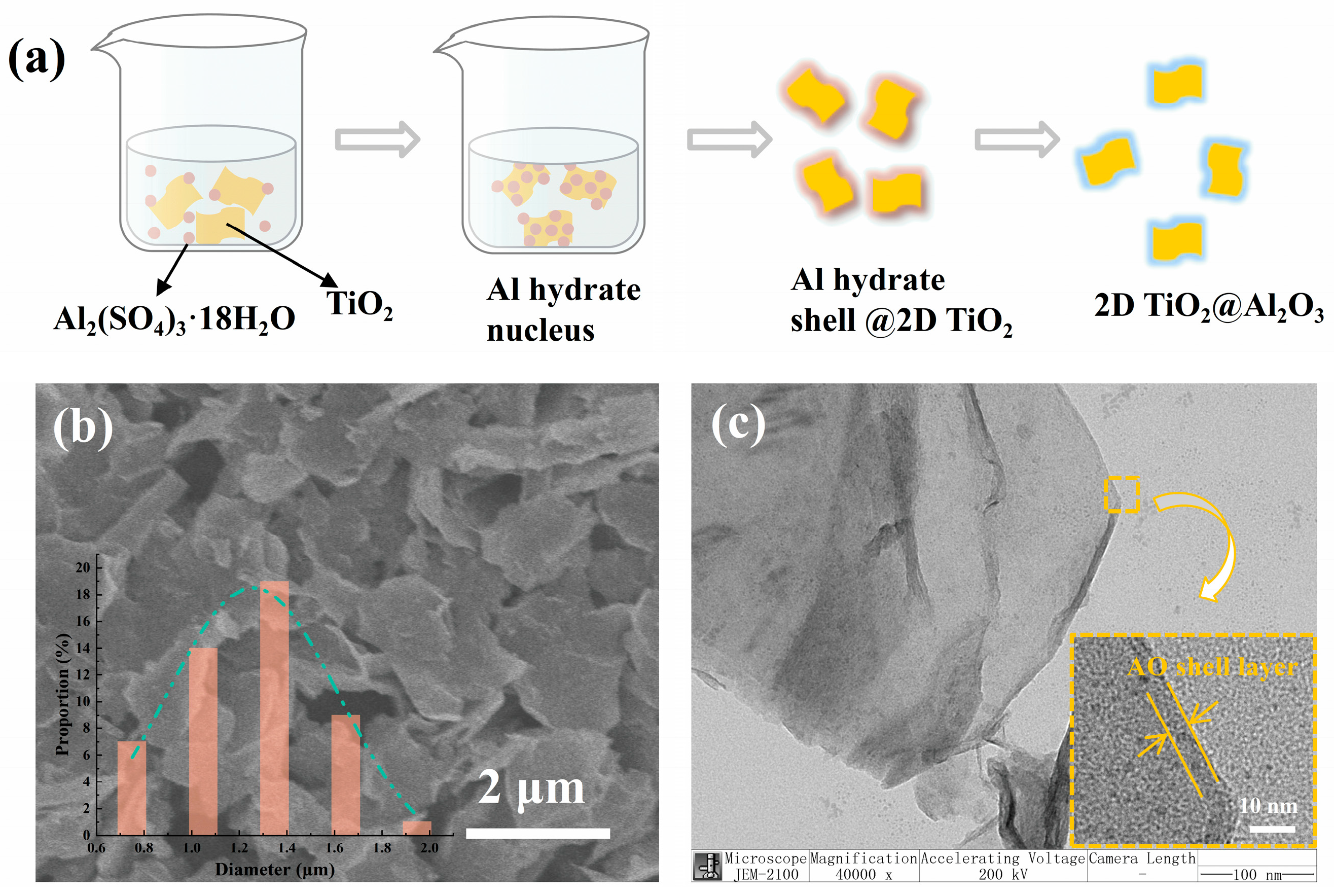

2.2. Preparation of TO@AO Nanosheets

2.3. Fabrication of PVDF/TO@AO Composite Films

2.4. Characterization

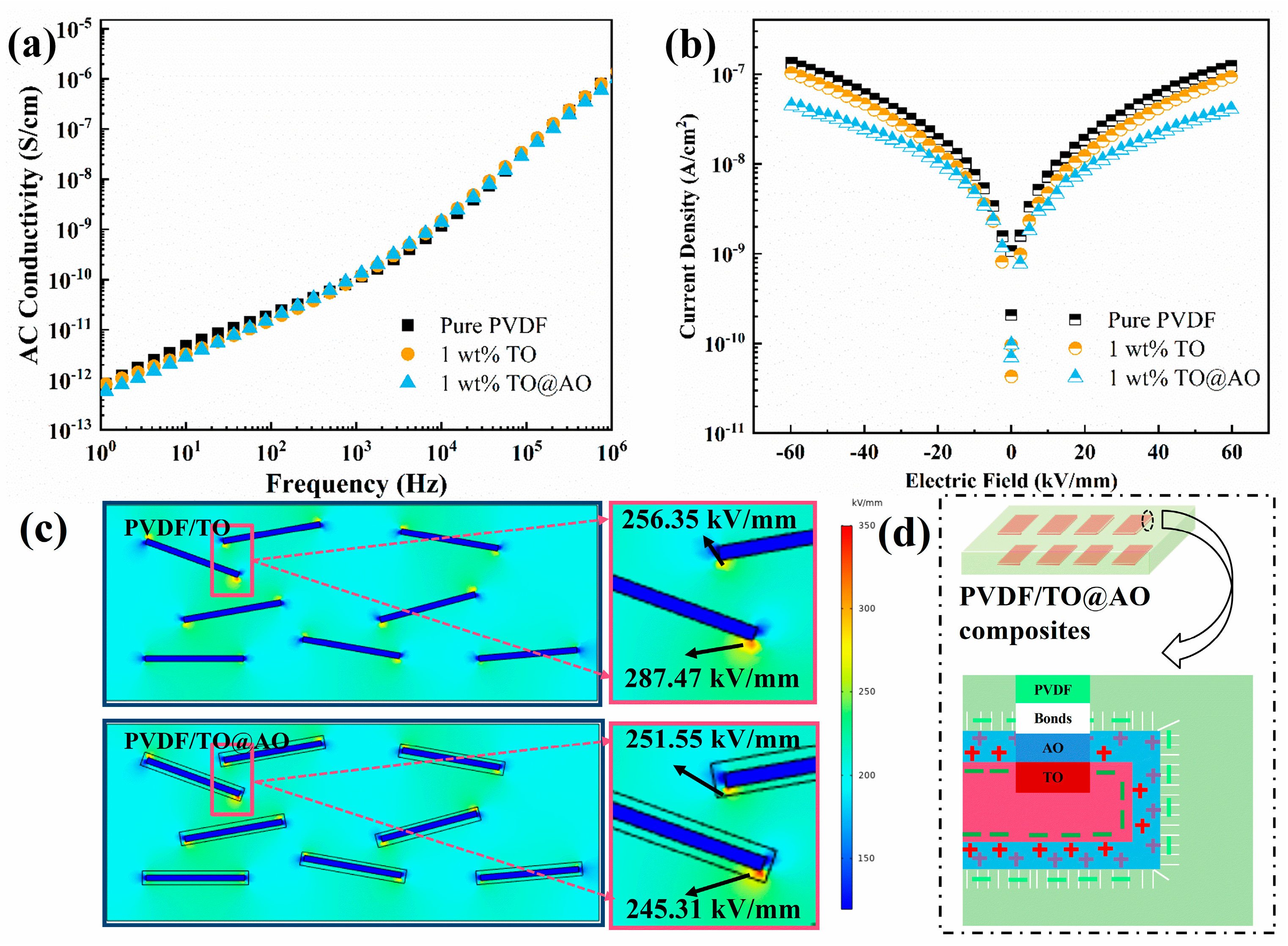

2.5. Finite Element Method (FEM) Simulations

3. Results

3.1. Characterization of TO@AO Nanosheets

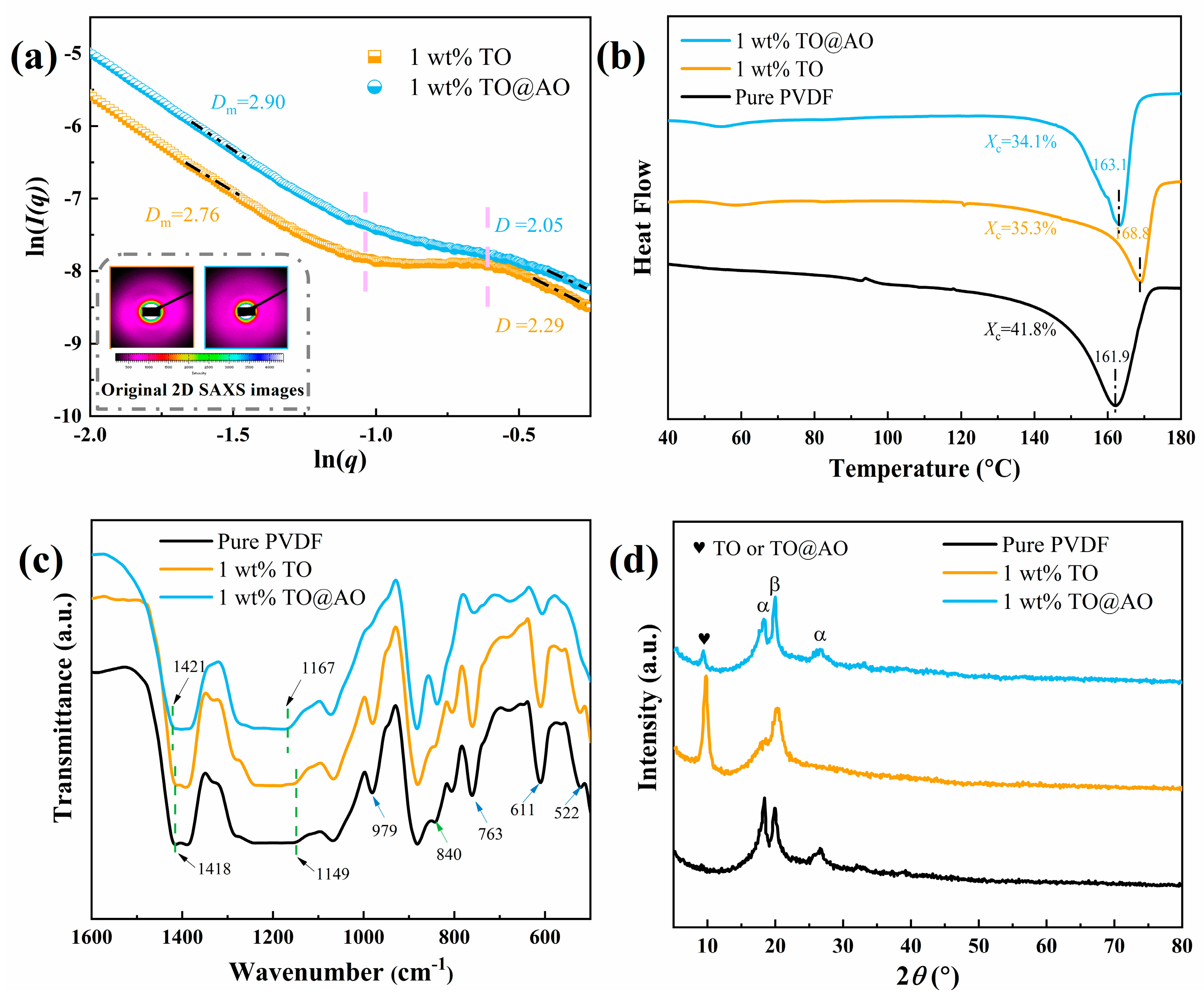

3.2. Characterization of PVDF/TO@AO Composites

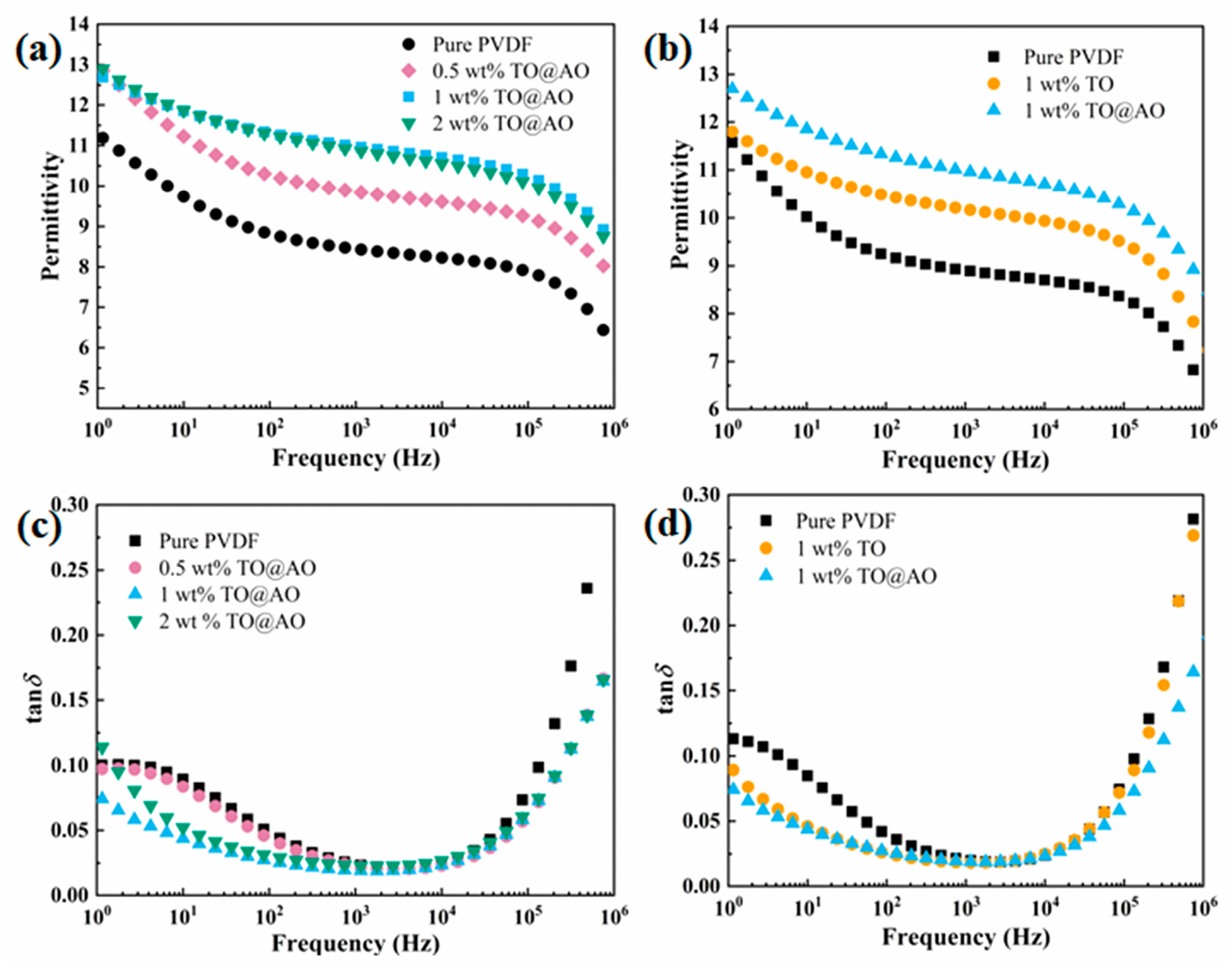

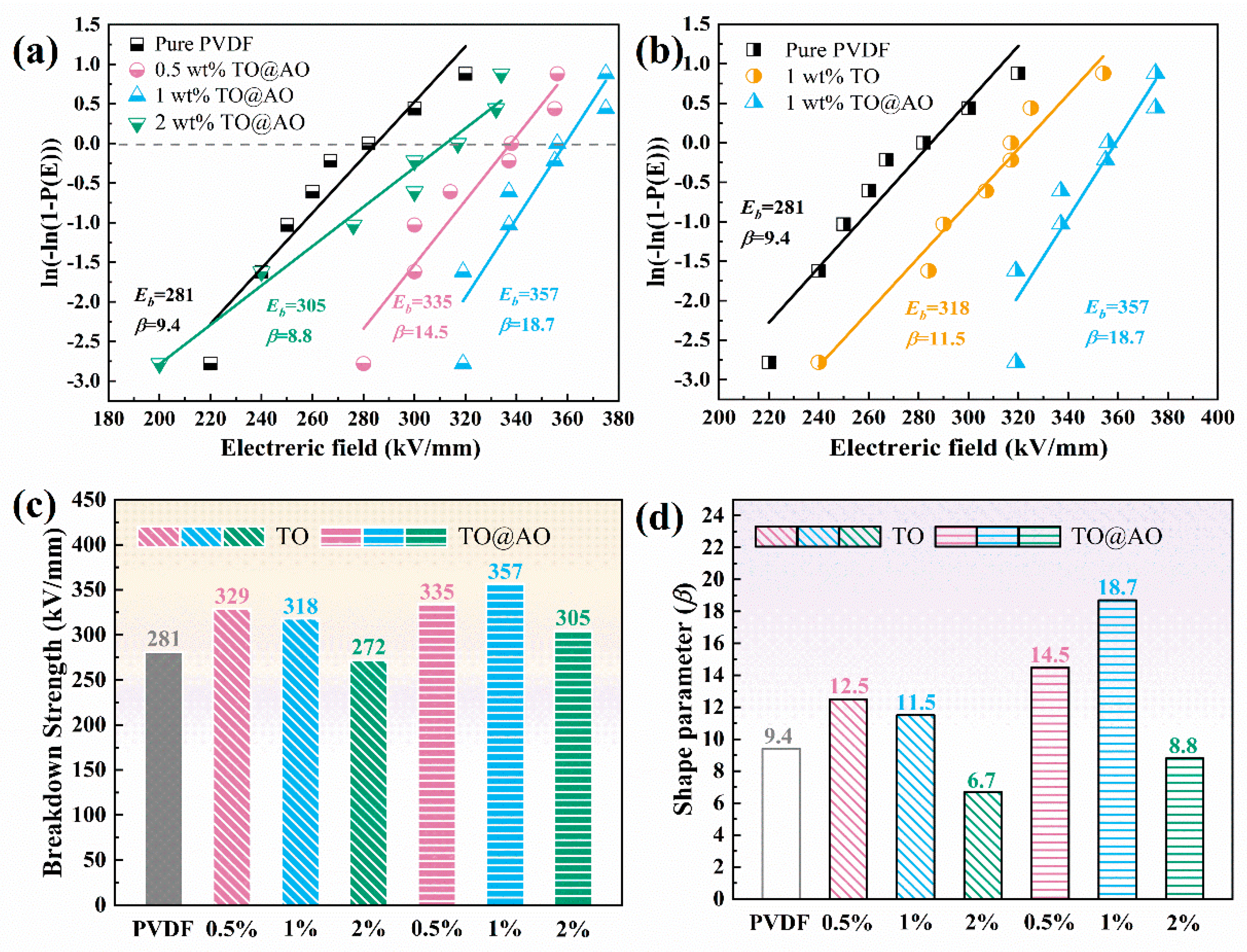

3.3. Dielectric Properties of PVDF/TO@AO Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hussain, A.; Jabeen, N.; Tabassum, A.; Ali, J. 3D-printed conducting polymers for solid oxide fuel cells. In 3D Printed Conducting Polymers; CRC Press: Boca Raton, FL, USA, 2024; pp. 179–195. [Google Scholar]

- Yue, D.; Feng, Y.; Liu, X.X.; Yin, J.H.; Zhang, W.C.; Guo, H.; Su, B.; Lei, Q.Q. Prediction of Energy Storage Performance in Polymer Composites Using High-Throughput Stochastic Breakdown Simulation and Machine Learning. Adv. Sci. 2022, 9, e2105773. [Google Scholar] [CrossRef] [PubMed]

- Behera, R.; Elanseralathan, K. A review on polyvinylidene fluoride polymer based nanocomposites for energy storage applications. J. Energy Storage 2022, 48, 103788. [Google Scholar] [CrossRef]

- Amin, K.; Ashraf, N.; Mao, L.; Faul, C.F.; Wei, Z. Conjugated microporous polymers for energy storage: Recent progress and challenges. Nano Energy 2021, 85, 105958. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.H.; Ariga, K. Redox-active polymers for energy storage nanoarchitectonics. Joule 2017, 1, 739–768. [Google Scholar] [CrossRef]

- Dang, Z.; Lin, Y.; Yuan, Q.; Li, X.; Zhang, Y.; Ma, Y.; Wang, Y.; Yang, Q.; Wang, Y.; Yang, H. Ultrahigh Dielectric Energy Density and Efficiency in PEI-Based Gradient Layered Polymer Nanocomposite. Adv. Funct. Mater. 2024, 34, 2406148. [Google Scholar] [CrossRef]

- Xie, X.; Yang, C.; Qi, X.-d.; Yang, J.-h.; Zhou, Z.-w.; Wang, Y. Constructing polymeric interlayer with dual effects toward high dielectric constant and low dielectric loss. Chem. Eng. J. 2019, 366, 378–389. [Google Scholar] [CrossRef]

- Thakur, Y.; Zhang, B.; Dong, R.; Lu, W.; Iacob, C.; Runt, J.; Bernholc, J.; Zhang, Q. Generating high dielectric constant blends from lower dielectric constant dipolar polymers using nanostructure engineering. Nano Energy 2017, 32, 73–79. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, J.; Yan, S.; Shen, Z.; Dong, L.; Zhang, S.; Zhang, X.; Nan, C.W. Ultrahigh energy density in continuously gradient-structured all-organic dielectric polymer films. Adv. Funct. Mater. 2022, 32, 2200848. [Google Scholar] [CrossRef]

- Luo, H.; Wang, F.; Guo, R.; Zhang, D.; He, G.; Chen, S.; Wang, Q. Progress on polymer dielectrics for electrostatic capacitors application. Adv. Sci. 2022, 9, 2202438. [Google Scholar] [CrossRef]

- Feng, Y.; Zhou, Y.; Zhang, T.; Zhang, C.; Zhang, Y.; Zhang, Y.; Chen, Q.; Chi, Q. Ultrahigh discharge efficiency and excellent energy density in oriented core-shell nanofiber-polyetherimide composites. Energy Storage Mater. 2020, 25, 180–192. [Google Scholar] [CrossRef]

- Arjmand, M.; Sundararaj, U. Impact of BaTiO3 as insulative ferroelectric barrier on the broadband dielectric properties of MWCNT/PVDF nanocomposites. Polym. Compos. 2016, 37, 299–304. [Google Scholar] [CrossRef]

- Zuo, P.; Jiang, J.; Wang, R.; Chen, D.; Lin, J.; Chen, Y.; Wang, X.; Zhuang, Q. Poly (ether imide) Nanocomposites with BaTiO3@TiO2@SiO2 or BaTiO3@SiO2@TiO2 Fillers Improve Energy Storage Capacity and Dielectric Thermal Stability. ACS Appl. Nano Mater. 2023, 6, 18381–18393. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Feng, Y.; Zhang, T.; Chen, Q.; Chi, Q.; Liu, L.; Li, G.; Cui, Y.; Wang, X. Excellent energy storage performance and thermal property of polymer-based composite induced by multifunctional one-dimensional nanofibers oriented in-plane direction. Nano Energy 2019, 56, 138–150. [Google Scholar] [CrossRef]

- Wen, R.; Guo, J.; Zhao, C.; Liu, Y. Nanocomposite capacitors with significantly enhanced energy density and breakdown strength utilizing a small loading of monolayer titania. Adv. Mater. Interfaces 2018, 5, 1701088. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Feng, Y.; Zhang, T.; Chen, Q.; Chi, Q.; Liu, L.; Wang, X.; Lei, Q. Energy storage enhancement of P (VDF-TrFE-CFE)-based composites with double-shell structured BZCT nanofibers of parallel and orthogonal configurations. Nano Energy 2019, 66, 104195. [Google Scholar] [CrossRef]

- Wang, G.; Deng, Y.; Xiang, Y.; Guo, L. Fabrication of radial ZnO nanowire clusters and radial ZnO/PVDF composites with enhanced dielectric properties. Adv. Funct. Mater. 2008, 18, 2584–2592. [Google Scholar] [CrossRef]

- He, D.; Wang, Y.; Song, S.; Liu, S.; Luo, Y.; Deng, Y. Polymer-based nanocomposites employing Bi2S3@SiO2 nanorods for high dielectric performance: Understanding the role of interfacial polarization in semiconductor-insulator core-shell nanostructure. Compos. Sci. Technol. 2017, 151, 25–33. [Google Scholar] [CrossRef]

- Feng, M.; Chi, Q.; Feng, Y.; Zhang, Y.; Zhang, T.; Zhang, C.; Chen, Q.; Lei, Q. High energy storage density and efficiency in aligned nanofiber filled nanocomposites with multilayer structure. Compos. Part B Eng. 2020, 198, 108206. [Google Scholar] [CrossRef]

- Pan, Z.; Yao, L.; Zhai, J.; Shen, B.; Liu, S.; Wang, H.; Liu, J. Excellent energy density of polymer nanocomposites containing BaTiO3@Al2O3 nanofibers induced by moderate interfacial area. J. Mater. Chem. A 2016, 4, 13259–13264. [Google Scholar] [CrossRef]

- Sun, L.; Shi, Z.; He, B.; Wang, H.; Liu, S.; Huang, M.; Shi, J.; Dastan, D.; Wang, H. Asymmetric trilayer all-polymer dielectric composites with simultaneous high efficiency and high energy density: A novel design targeting advanced energy storage capacitors. Adv. Funct. Mater. 2021, 31, 2100280. [Google Scholar] [CrossRef]

- Huang, Q.; Luo, H.; Chen, C.; Zhou, X.; Zhou, K.; Zhang, D. Enhanced energy density in P (VDF-HFP) nanocomposites with gradient dielectric fillers and interfacial polarization. J. Alloys Compd. 2017, 696, 1220–1227. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Feng, Y.; Yin, J. Recent progress in polymer/two-dimensional nanosheets composites with novel performances. Prog. Polym. Sci. 2022, 126, 101505. [Google Scholar] [CrossRef]

- Shen, X.; Zheng, Q.; Kim, J.-K. Rational design of two-dimensional nanofillers for polymer nanocomposites toward multifunctional applications. Prog. Mater. Sci. 2021, 115, 100708. [Google Scholar] [CrossRef]

- Chen, J.; Wang, X.; Yu, X.; Yao, L.; Duan, Z.; Fan, Y.; Jiang, Y.; Zhou, Y.; Pan, Z. High dielectric constant and low dielectric loss poly (vinylidene fluoride) nanocomposites via a small loading of two-dimensional Bi2Te3@ Al2O3 hexagonal nanoplates. J. Mater. Chem. C 2018, 6, 271–279. [Google Scholar] [CrossRef]

- Chen, J.; Wang, X.; Yu, X.; Fan, Y.; Duan, Z.; Jiang, Y.; Yang, F.; Zhou, Y. Significantly improved dielectric performances of nanocomposites via loading two-dimensional core-shell structure Bi2Te3@SiO2 nanosheets. Appl. Surf. Sci. 2018, 447, 704–710. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, Q.; Yao, L.; Huang, S.; Xing, S.; Liu, J.; Chen, J.; Zhai, J. Simultaneously enhanced discharge energy density and efficiency in nanocomposite film capacitors utilizing two-dimensional NaNbO3@Al2O3 platelets. Nanoscale 2019, 11, 10546–10554. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Liu, X.; Feng, Y.; Li, J.; Li, Y.; Zhao, H.; Yue, D.; Yin, J. Adjusting the energy gap and interface effect of titania nanosheets synergistically enhances the energy storage performance of PVDF-based composites. J. Mater. Chem. C 2022, 10, 2128–2138. [Google Scholar] [CrossRef]

- He, D.; Wang, Y.; Chen, X.; Deng, Y. Core–shell structured BaTiO3@Al2O3 nanoparticles in polymer composites for dielectric loss suppression and breakdown strength enhancement. Compos. Part A Appl. Sci. Manuf. 2017, 93, 137–143. [Google Scholar] [CrossRef]

- Sharma, M.; Madras, G.; Bose, S. Cooperativity and Structural Relaxations in PVDF/PMMA Blends in the Presence of MWNTs: An Assessment through SAXS and Dielectric Spectroscopy. Macromolecules 2014, 47, 1392–1402. [Google Scholar] [CrossRef]

- Liu, X.; Nie, T.; Li, Y.; Li, J.; Wang, T.; Feng, Y.; Yue, D.; Yin, J. Nanocomposites induced by two-dimensional titanium carbide nanosheets for highly efficient energy storage. Polym. Test. 2020, 89, 106712. [Google Scholar] [CrossRef]

- Ren, X.; Meng, N.; Yan, H.; Bilotti, E.; Reece, M.J. Remarkably enhanced polarisability and breakdown strength in PVDF-based interactive polymer blends for advanced energy storage applications. Polymer 2019, 168, 246–254. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Feng, Y.; Chen, D.; Li, Y.; Yue, D.; Huang, B.; Yin, J. Constructing bidirectional-matched interface between polymer and 2D nanosheets for enhancing energy storage performance of the composites. Energy Storage Mater. 2023, 54, 605–614. [Google Scholar] [CrossRef]

- Sharma, M.; Madras, G.; Bose, S. Contrasting Effects of Graphene Oxide and Poly(ethylenimine) on the Polymorphism in Poly(vinylidene fluoride). Cryst. Growth Des. 2015, 15, 3345–3355. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, L.; Liu, S.; Guan, F.; Jiang, M.; Li, Y.; Yue, D.; Li, J.; Liu, X.; Feng, Y. Enhancing the dielectric properties of polyimide-based composites with donor-doped SiO2. J. Alloys Compd. 2023, 950, 169760. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, M.; Guan, F.; Liu, S.; Wang, L.; Li, Y.; Yue, D.; Li, J.; Liu, X.; Feng, Y. Influence of the acceptor-fillers on the dielectric properties of polyimide composites. Polym. Test. 2023, 122, 108025. [Google Scholar] [CrossRef]

- Pan, Z.; Zhai, J.; Shen, B. Multilayer hierarchical interfaces with high energy density in polymer nanocomposites composed of BaTiO3@TiO2@Al2O3 nanofibers. J. Mater. Chem. A 2017, 5, 15217–15226. [Google Scholar] [CrossRef]

- Yang, P.; Li, L.; Yuan, H.; Wen, F.; Zheng, P.; Wu, W.; Zhang, L.; Wang, G.; Xu, Z. Significantly enhanced energy storage performance of flexible composites using sodium bismuth titanate based lead-free fillers. J. Mater. Chem. C 2020, 8, 14910–14918. [Google Scholar] [CrossRef]

- Guo, R.; Luo, H.; Yan, M.; Zhou, X.; Zhou, K.; Zhang, D. Significantly enhanced breakdown strength and energy density in sandwich-structured nanocomposites with low-level BaTiO3 nanowires. Nano Energy 2021, 79, 105412. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, J.; Yuan, Q.; Niu, Y.; Bai, Y.; Wang, H. Significantly enhanced breakdown strength and energy density in sandwich-structured barium titanate/poly (vinylidene fluoride) nanocomposites. Adv. Mater. 2015, 27, 6658–6663. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; Li, K.; Liu, X.; Li, Y.; Yin, J.; Hong, L.; Qin, Q. Enhanced Dielectric Performance in PVDF-Based Composites by Introducing a Transition Interface. Polymers 2025, 17, 137. https://doi.org/10.3390/polym17020137

Zhu C, Li K, Liu X, Li Y, Yin J, Hong L, Qin Q. Enhanced Dielectric Performance in PVDF-Based Composites by Introducing a Transition Interface. Polymers. 2025; 17(2):137. https://doi.org/10.3390/polym17020137

Chicago/Turabian StyleZhu, Congcong, Kun Li, Xiaoxu Liu, Yanpeng Li, Jinghua Yin, Lu Hong, and Qibing Qin. 2025. "Enhanced Dielectric Performance in PVDF-Based Composites by Introducing a Transition Interface" Polymers 17, no. 2: 137. https://doi.org/10.3390/polym17020137

APA StyleZhu, C., Li, K., Liu, X., Li, Y., Yin, J., Hong, L., & Qin, Q. (2025). Enhanced Dielectric Performance in PVDF-Based Composites by Introducing a Transition Interface. Polymers, 17(2), 137. https://doi.org/10.3390/polym17020137