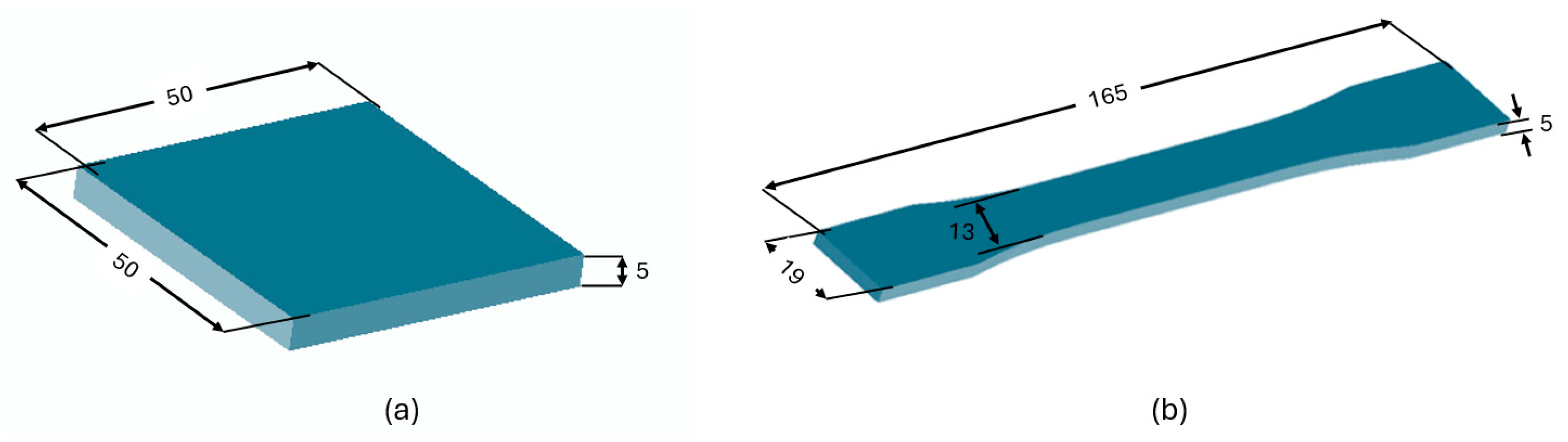

3.1. Experimental and Statistical Investigation

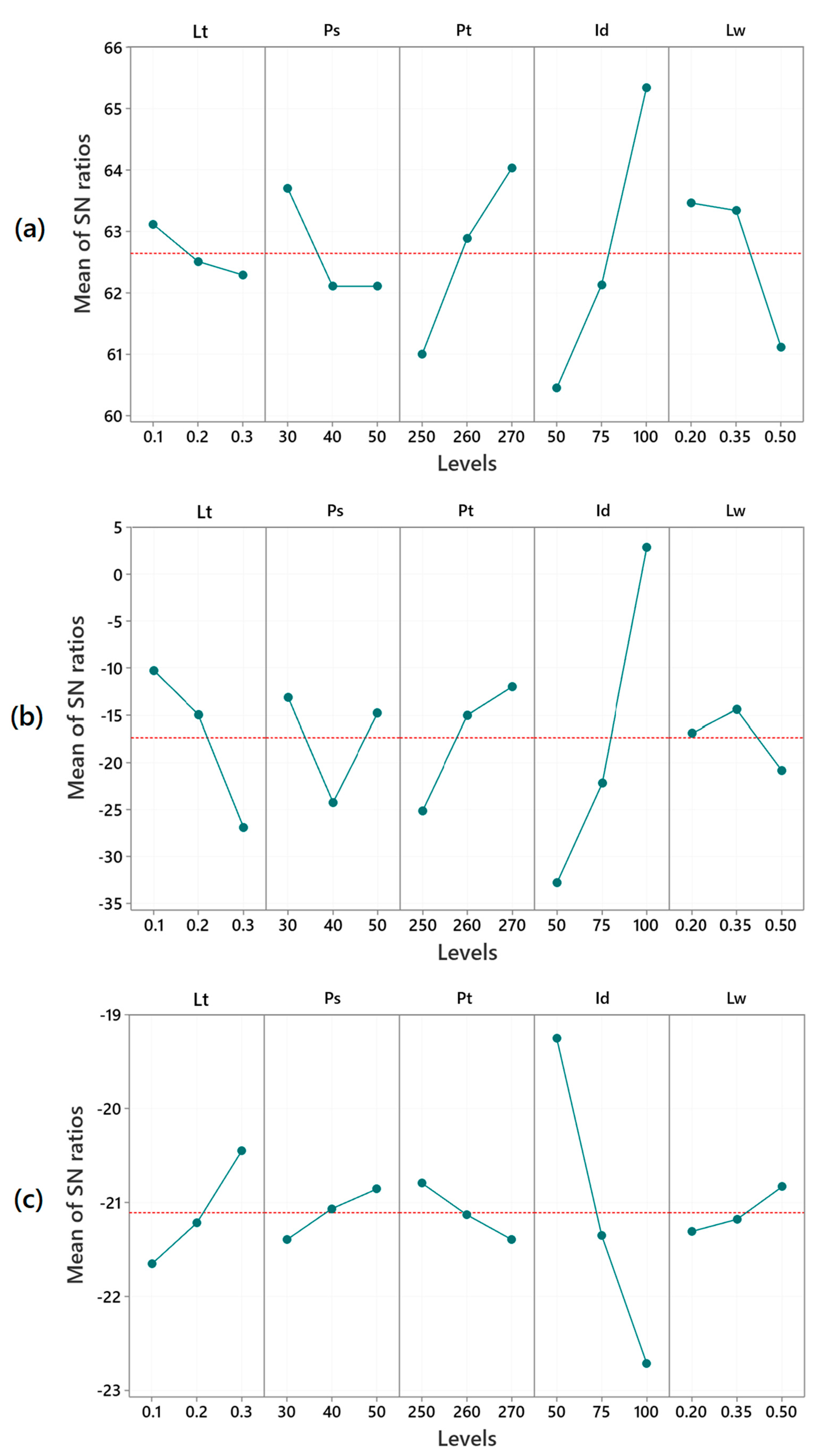

This study examines the influence of five variable 3D printing parameters on the protective performance of PC samples. The SN ratios are detailed in

Table 3 and illustrated in

Figure 2. Moreover, the data used in this study can be found in the table provided in

Supplementary Table S1. According to results, specimen 7 exhibited the highest toughness (2418.25 kJ/m

3) and the best stab protective performance, as so the lowest stab penetration depth of only 0.02 mm. In contrast, specimen 27 had the lightest armor panel weight at 7.67 g.

The detailed results of the Taguchi analysis for toughness are summarized in

Table 4. Higher toughness values were observed at lower levels of Lt and Lw, while higher levels of Pt and Id had a positive impact on toughness. However, setting Ps at 40 or 50 mm/s had no effect on toughness. The optimal printing parameters for the highest toughness was identified as Lt at 0.1 mm, Ps at 30 mm/min, Pt at 270 °C, Id at 100%, and Lw at 0.2 mm, or shortly Lt

1Ps

1Pt

3Id

3Lw

1.

As shown in

Table 5, the results of ANOVA indicate that all parameters, except Lt, had a statistically significant effect on toughness, as evidenced by their

p-values below 0.05. The mathematical model used to predict the toughness of specimens is given in Equation (3). The model also demonstrated high precision with an R

2 value of 93.92%.

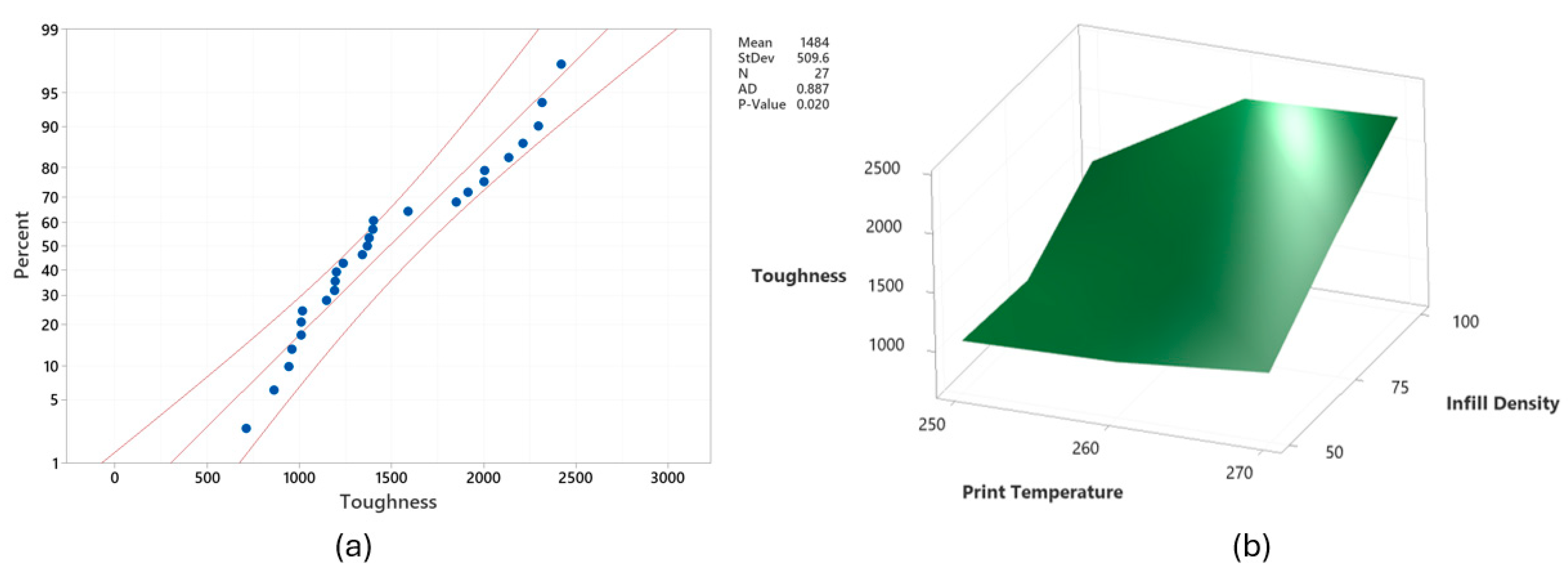

Moreover, as seen in

Figure 3a, the data were mostly within the probability limits. The ANOVA findings aligned with the Taguchi analysis results. Among the process parameters, Id was the most influential, contributing 52.58% to the toughness, followed by Pt at 21.46%. This is likely because higher Id led to denser structures with fewer voids, while elevated Pt improved layer adhesion, collectively enhancing the toughness of the 3D-printed parts. This relationship is further demonstrated in

Figure 3b. These findings align with the literature, where increased Id reduces void formation, and higher Pt strengthens interlayer bonding, improving mechanical integrity and toughness [

33,

47,

48,

49]. Additionally, Lw and Ps exhibited notable contributions of 10.94% and 8.11%, respectively. However, Lt had a minimal effect on toughness, contributing only 0.84%. Given that toughness is highly dependent on bonding quality and structural integrity, variations in Lt within the tested range likely did not significantly affect layer adhesion or stress distribution, both of which are critical to toughness [

50].

Since the optimal printing parameters for maximizing toughness were not included in the initial L27 design, a new set of tensile specimens was fabricated using the optimal printing parameters and tested. These specimens achieved a toughness value of 2664.39 kJ/m3, reflecting an approximately 10% improvement over the highest values recorded for specimen 7.

Figure 4 compares the mechanical behavior of specimens 7 and 27, providing insights into their stress–strain characteristics (

Figure 4a) and fracture surfaces. Specimens with higher Id exhibited more ductile fractures, as seen with specimen 7, which had the highest toughness. As seen in

Figure 4b, its fracture surface displayed uniform plastic deformation (as also witnessed from the necking in specimen 7), suggesting a well-distributed internal structure that allowed for substantial elongation before failure. In contrast, specimen 27 exhibited brittle fracture behavior, with sharper and irregular breakage patterns as demonstrated in

Figure 4c. The abrupt failure and lack of plastic deformation indicated weaker interlayer bonding or a more fragile internal structure, likely leading to premature crack propagation and sudden failure. These differences highlight the critical role of Id in the mechanical performance of 3D-printed parts. The findings suggest that optimizing printing parameters can enhance toughness and reliability, particularly for applications requiring durability and resistance to mechanical stress.

Table 6 presents the detailed SN ratios for stab impact protection based on the Taguchi results. The optimal printing parameters, identified by the minimum stab penetration, were Lt

1Ps

1Pt

3Id

3Lw

2, corresponding to Lt: 0.1 mm, Ps: 30 mm/s, Pt: 270 °C, Id: 100%, and Lw: 0.35 mm. Further, higher levels of Pt and Id improved stab protection, while reducing Lt had a similar effect. For Ps, levels 1 and 3 yielded comparable results, whereas level 2 had the least impact. Regarding Lw, printing at level 2 provided the highest stab protection.

The ANOVA results for stab impact protection are presented in

Table 7, with an R

2 value of 89%, indicating an acceptable level of accuracy. Moreover, the mathematical model used to predict the stab penetration depth of specimens is given in Equation (4).

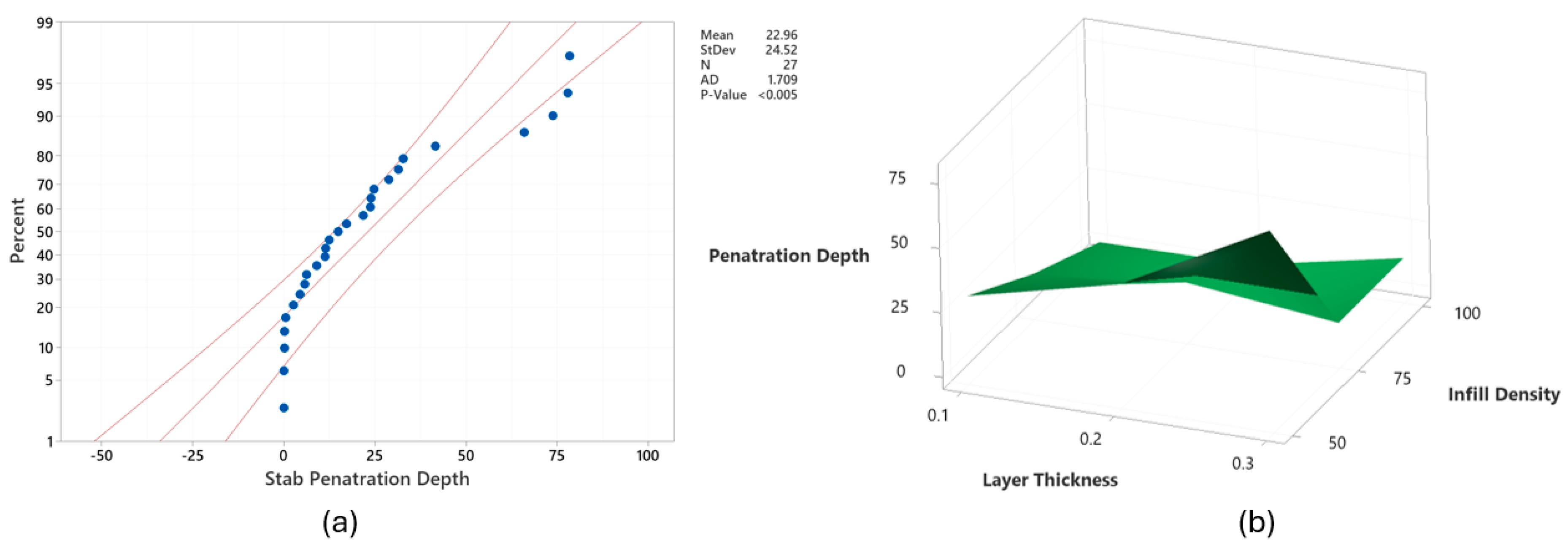

Figure 5a shows the probability plot for stab penetration depth, with the data predominantly falling within the probability limits, exhibiting a moderate level of scatter around the fitted line. The findings indicated that Lt, Ps, and Id were statistically significant factors with contributions of 10.52%, 7.96%, and 62.20%, respectively. The Taguchi and ANOVA results have shown that Id was the most important factor for the stab protection capability of 3D-printed textiles. This finding is comparable to the existing literature [

49,

51,

52,

53,

54,

55]. This is because increasing Id reduces voids and porosity by increasing material density, which, in turn, enhances impact resistance as more material absorbs and distributes the impact force. Being the two most influential print parameters, the effect of Lt and Id on stab penetration depth is demonstrated in

Figure 5b.

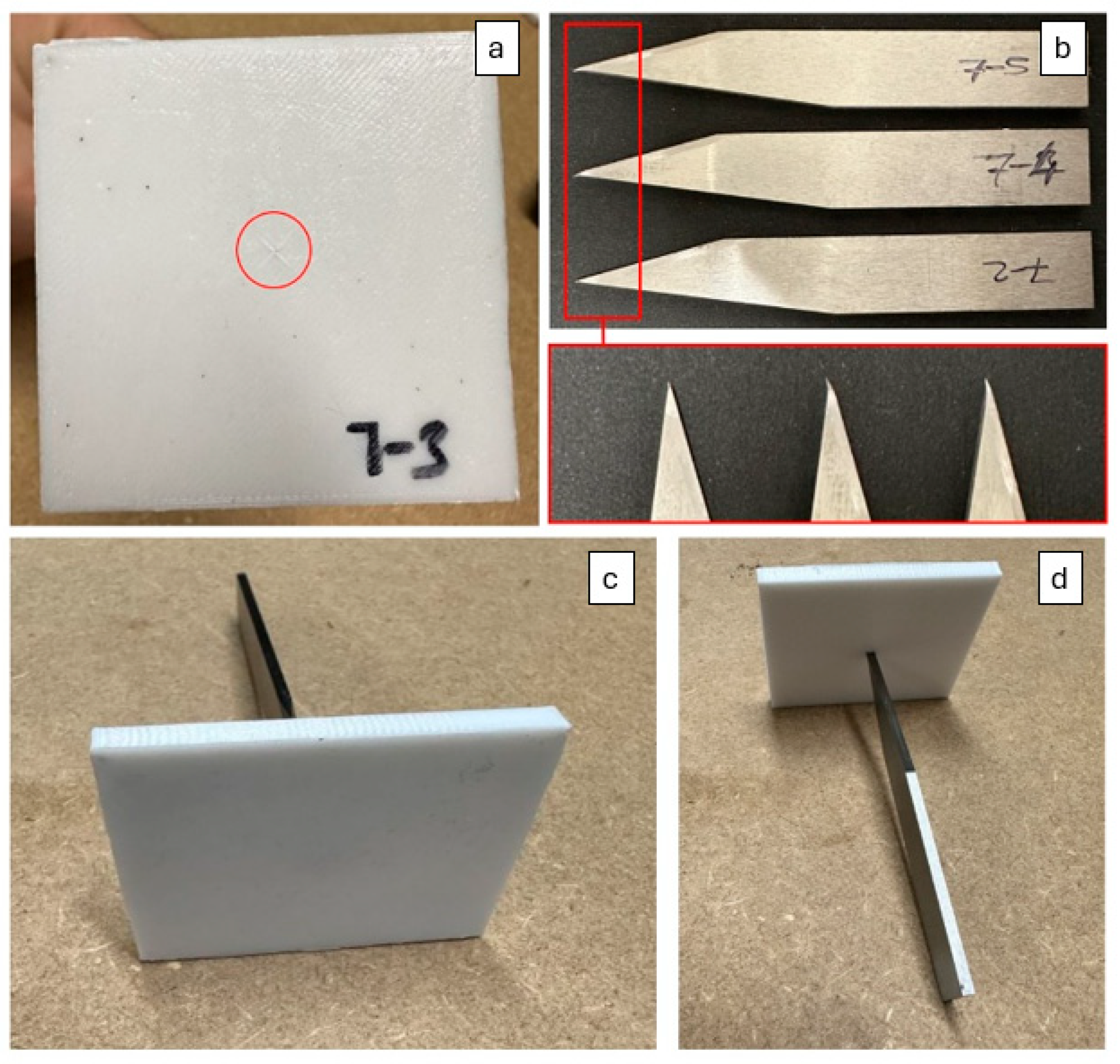

The results showed that specimen 7 had the lowest mean stab penetration depth of 0.02 mm, which is barely visible as seen in

Figure 6a. This performance not only surpasses the UK HOSDB standard threshold of 8 mm [

15] but also far exceeds the requirements of the US National Institute of Justice standard for stab-resistant armor, which specifies a maximum allowable penetration threshold of 7 mm for Level 1 protection [

56], thereby demonstrating exceptional robustness and broad international relevance. Their effectiveness was further demonstrated by damage to the knife tips used in testing (

Figure 6b).

Moreover, a new set of armor panels, fabricated using optimized print parameters, exhibited no penetration (

Figure 6c,d). However, this improvement resulted in an 8.25% increase in 3D-printed armor panel weight compared to specimen 7. Although this additional weight is relatively modest, it may influence wearer comfort, especially during extended use, where factors such as mobility and fatigue are critical. In practical applications, even small increases in armor weight can affect operational performance. This underscores the importance of not only maximizing protective performance (e.g., minimizing penetration depth) but also ensuring ergonomic suitability (e.g., minimizing armor weight) when designing 3D-printed stab-resistant armor.

Throughout history, the two major requirements of body armor, protection and comfort, have always been in conflict [

57]. Research confirms that the torso region that body armor covers is particularly vulnerable due to its role in shielding vital organs, such as the heart and lungs [

58]. Among the factors influencing wearer comfort, armor weight is the most critical, necessitating a systematic investigation into how 3D printing parameters affect panel weight optimization. The detailed SN ratios for armor panel weight are presented in

Table 8. Increases in Lt, Ps, and Lw reduced armor panel weight, while decreasing Pt and Id led to lighter panels. The optimal parameter set for minimizing armor panel weight was identified as Lt

3Ps

3Pt

1Id

1Lw

3, corresponding to Lt: 0.3 mm, Ps: 50 mm/min, Pt: 250 °C, Id: 50%, and Lw: 0.5 mm.

As seen in

Figure 7a, the data regarding armor panel weight was in the probability limits with a few exceptions. The ANOVA model, presented in

Table 9, demonstrated high statistical precision with an R

2 value of 98.99%. Furthermore, the mathematical model used to predict the armor panel weight of specimens is given in Equation (5).

All printing parameters had a statistically significant impact on armor panel weight, as indicated by

p-values less than 0.05. Among them, Id was identified as the most influential factor, contributing 82.17%, followed by Lt with a smaller effect of 10.21%. The relationship between Id and Lt in relation to armor panel weight is demonstrated in

Figure 7b. However, the remaining parameters had minimal impact on armor panel weight. A new set of armor panels using optimal printing parameters for weight reduction was fabricated, but not stab tested, as significantly minimizing panel weight would lead to a dramatic increase in stab penetration depth, compromising protection.

Moreover, it is widely known that the toughness and impact resistance of materials are related. However, in the context of 3D-printed armor, this relationship still requires confirmation due to the nature of stabbing, which involves indentation, penetration, and perforation [

59]. The Pearson correlation method revealed a strong correlation between toughness and impact resistance, with an r value of 0.550, which was statistically significant, as confirmed by a

p-value of 0.003.

As observed from the statistical analysis, Id was the most significant contributor to all investigated responses. This is because higher Id creates denser structures with fewer voids and internal porosities, improving interlayer bonding [

36]. This enhances energy absorption and impact resistance by optimizing load distribution and reducing localized deformation, as more material resists applied loads and impacts. Therefore, the SEM images presented in

Figure 8 were analyzed to evaluate the effect of these parameters. As seen in

Figure 8a,b, which show specimens 7 and 1 with 100% and 50% Id, respectively, the 100% Id specimen exhibited a structure closer to that of injection molding, with fewer porosities compared to the 50% Id specimen, which showed significant porosity. Both the statistical analysis and morphological investigation confirm that higher Id produces denser parts with fewer internal porosities and stronger interlayer fusion, thereby improving mechanical and protective performance by providing more material to resist impacts. However, increasing Id also affects material consumption and, consequently, increases the overall part weight, highlighting the need for optimization. Future research should therefore focus on balancing protective performance and weight in 3D-printed protective textiles to achieve an optimal trade-off. Moreover, as demonstrated by the red circle in

Figure 8a, the increased Pt of specimen 7 (printed at 270 °C) compared to specimen 1 (printed at 250 °C) caused increased material flow due to higher liquidity. This affected internal bonding and homogeneity.

Figure 8c,d compare the effect of Lw on specimens 7 and 27, respectively. A lower Lw resulted in a denser structure with minimal gaps between layers, whereas a larger Lw led to significant gaps (highlighted by the red ellipse in

Figure 8d) due to insufficient interlayer bonding, negatively impacting the overall performance of these structures.

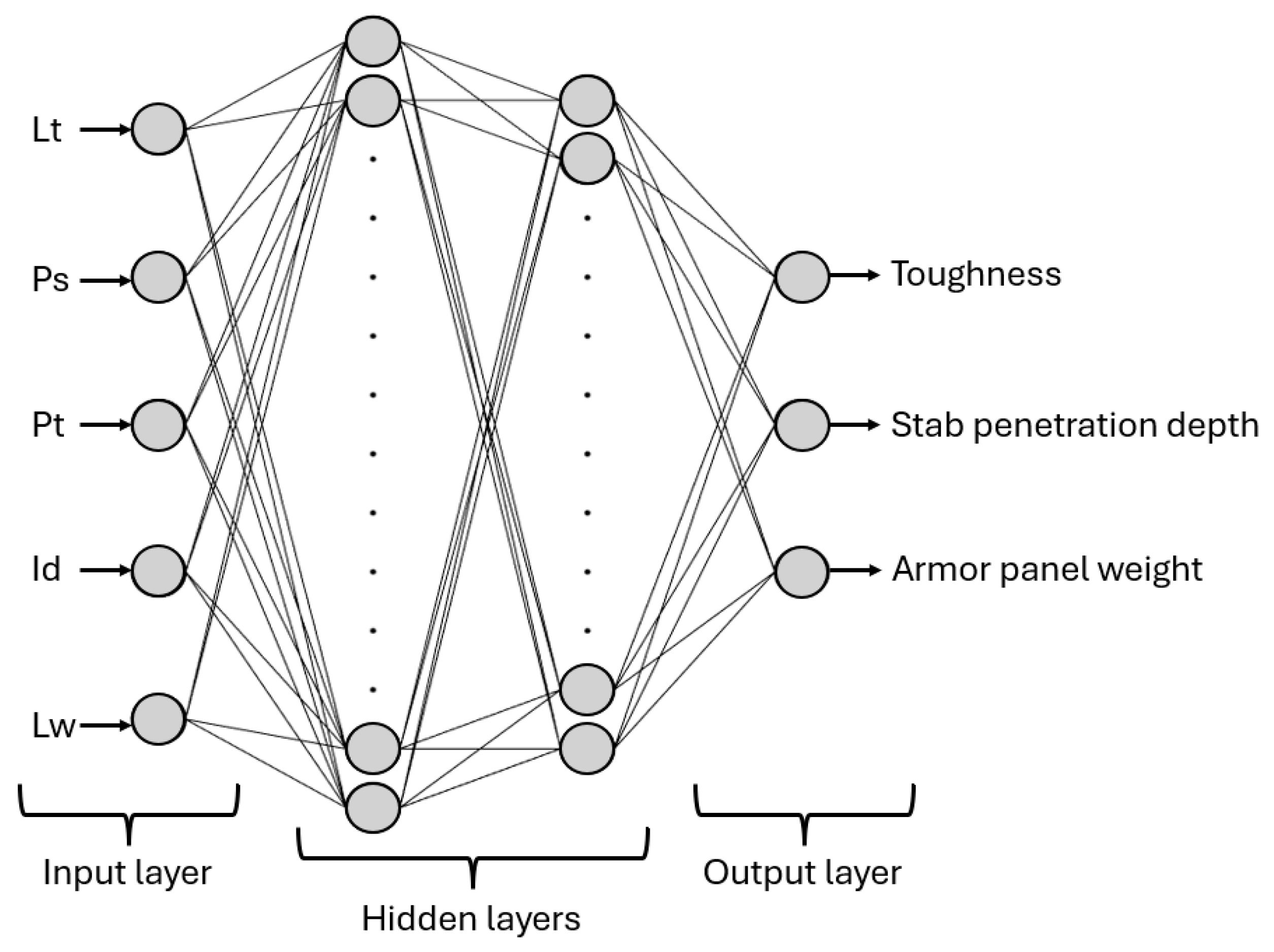

3.2. ANN Results

Among the tested ANN models with different topologies, as described in

Section 2.4, the best performance was obtained with two hidden layers containing 14 and 12 neurons, respectively. This topology was selected based on its minimum performance function value of 0.0061935, which can be considered effectively equivalent to zero. The resulting 5-14-12-3 ANN architecture is illustrated in

Figure 9.

Furthermore, the performance of the ANN model, assessed through linear regression, is illustrated in

Figure 10. Overall, the model exhibited excellent performance in predicting toughness, stab penetration depth, and armor panel weight, with an R

2 value of 0.97142. The R

2 values recorded for training, validation, and testing were 0.97391, 0.96065, and 0.97214, respectively. Additionally, the MSE values for the best-fit ANN structure were 0.0048, 0.0059, and 0.0047 for training, validation, and testing.

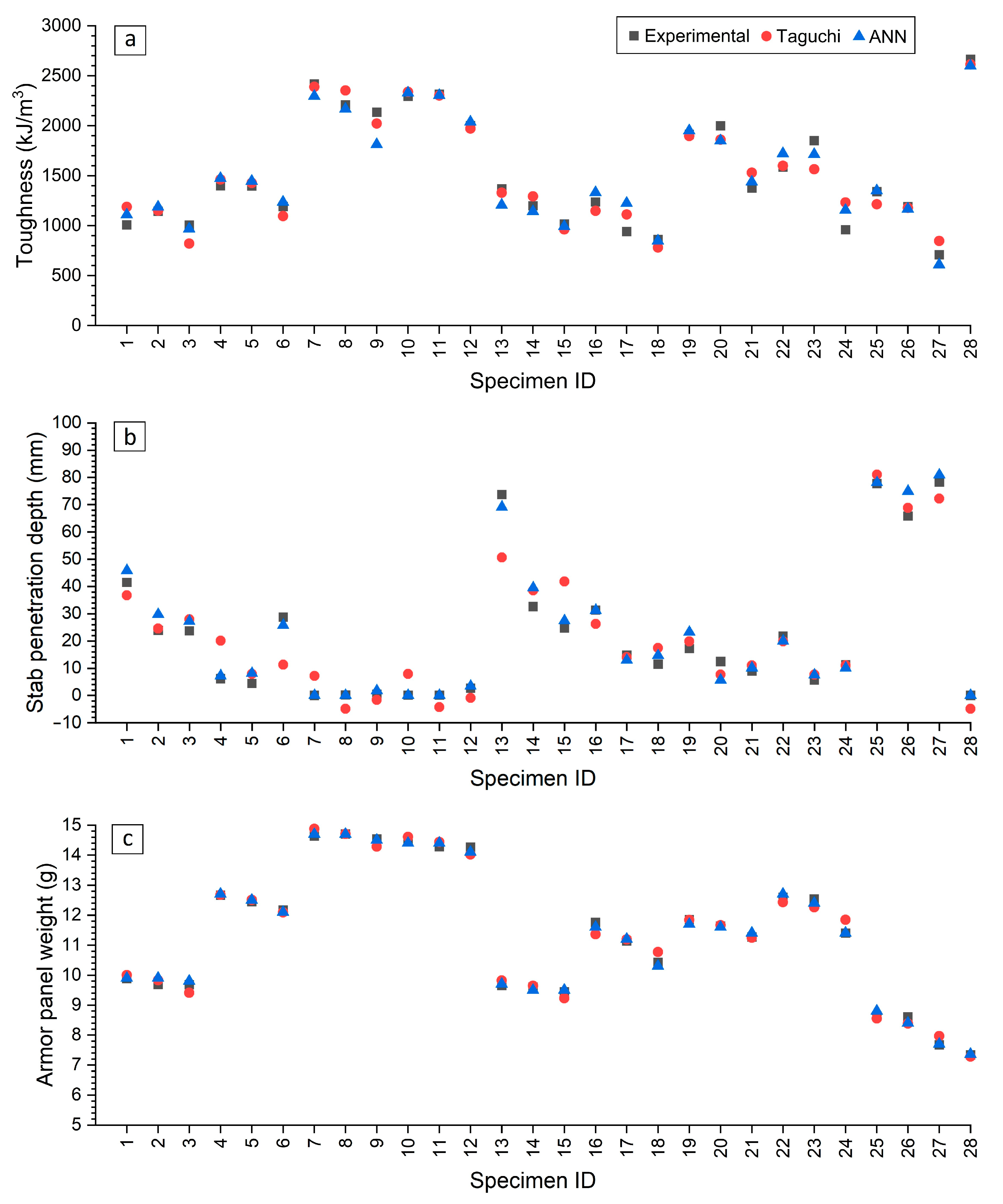

To further assess the performance of the developed ANN in predicting the outputs investigated, a comparison with experimental and Taguchi results was conducted by evaluating the percentage error. The results, shown in

Figure 11, reveal that the ANN model outperformed the Taguchi method, primarily due to its ability to capture the nonlinear relationships within the process. The ANN model predicted toughness and armor panel weight with similar accuracy as the Taguchi method, with only around 5% error from the experimental data, closely aligning with the experimental results as illustrated in

Figure 11a,c. However, the ANN model demonstrated an 8 times better performance in predicting stab penetration depth compared to the Taguchi method, as seen in

Figure 11b, where the experimental and ANN results were nearly identical, while the Taguchi results exhibited negative values, which are physically impossible. In summary, the ANN model exhibited similar performance in accurately predicting the results as the Taguchi method. This is because the ANN, being a non-linear data-driven model, was able to represent more complex parameter–response relationships, which explains its superior predictive accuracy. These methods should therefore be seen as complementary: Taguchi provides a structured and efficient experimental framework, while the ANN extends the analysis by modeling non-linearities in the data.

It is important to note that although ANNs are sometimes considered black-box models, in this study, the ANN was used not merely as an evaluation tool but as a predictive tool complementary to Taguchi and statistical analysis. The predictions were compared against experimental outcomes and validated through morphological observations, ensuring consistency with physical mechanisms. Thus, the ANN served as both a predictive and comparative tool in this study, paving the way for future research on its suitability to predict the performance of 3D-printed parts.