Ascertaining the Anatomical Parameters and Chemical Composition of Luffa cylindrica Cellulosic Fibers for Their Plausibility in Pulp and Paper Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Collection of Materials

2.2. Determination of Chemical Composition

2.3. Fourier Transform Infrared Spectroscopy

2.4. Determination of Fiber Dimensions

2.5. Statistical Testing

2.6. Determination of Derived Indices of Fibers

3. Results and Discussion

3.1. Chemical Composition

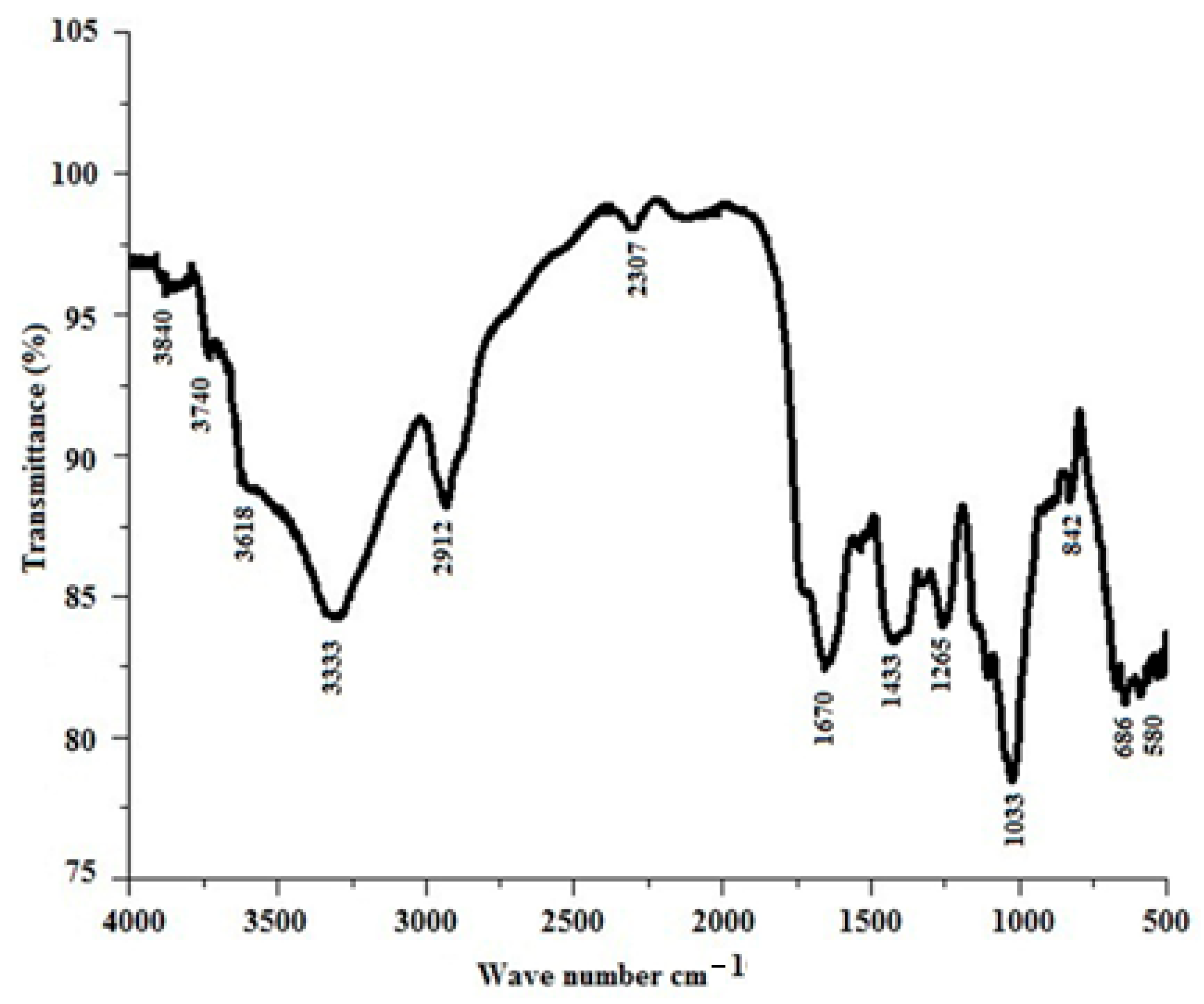

3.2. Fourier Transform Infrared Spectroscopy

3.3. Determination of Fiber Dimensions

3.3.1. Fiber Length

3.3.2. Fiber Diameter

3.3.3. Lumen Width

3.3.4. Fiber Cell Wall Thickness

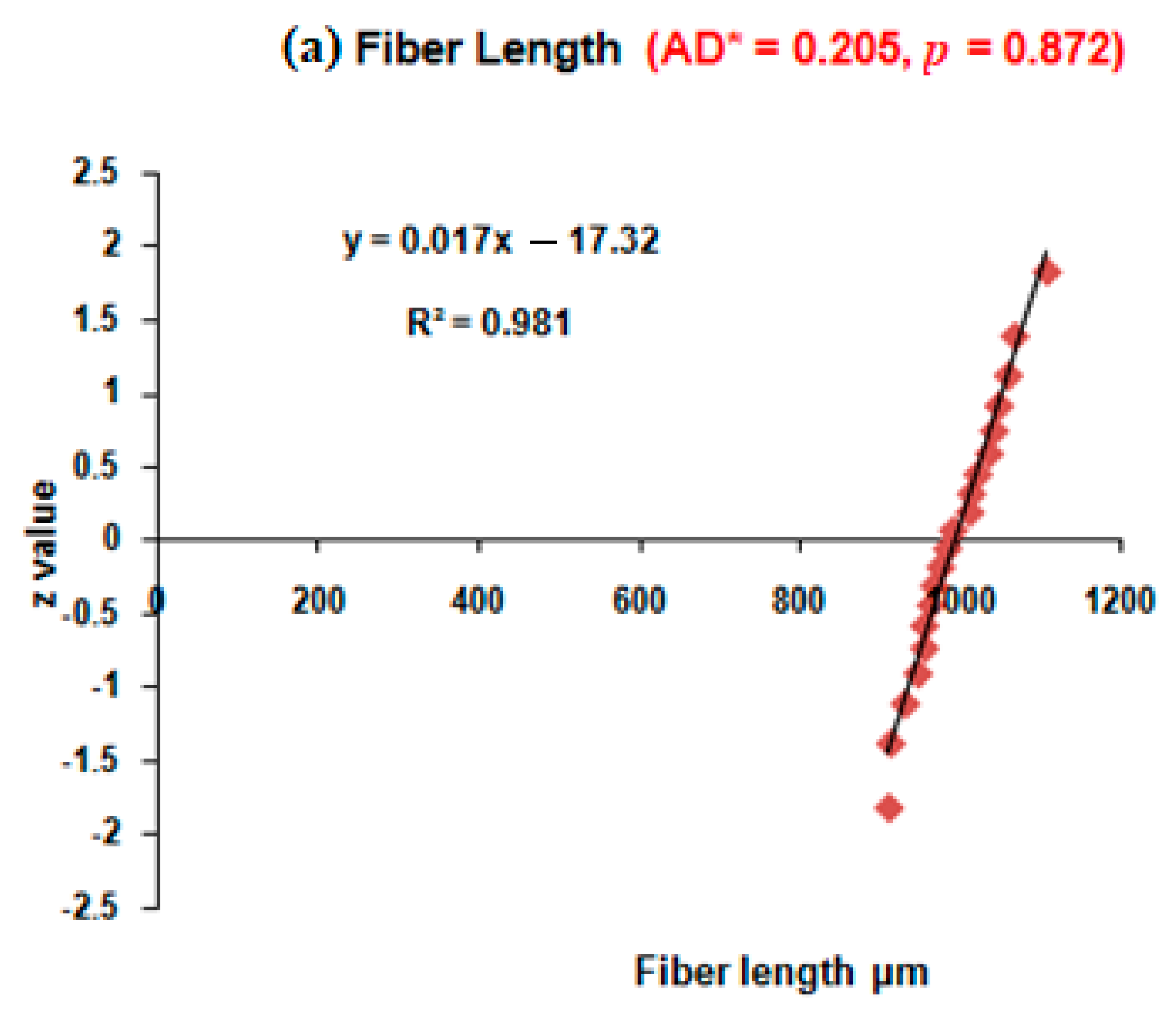

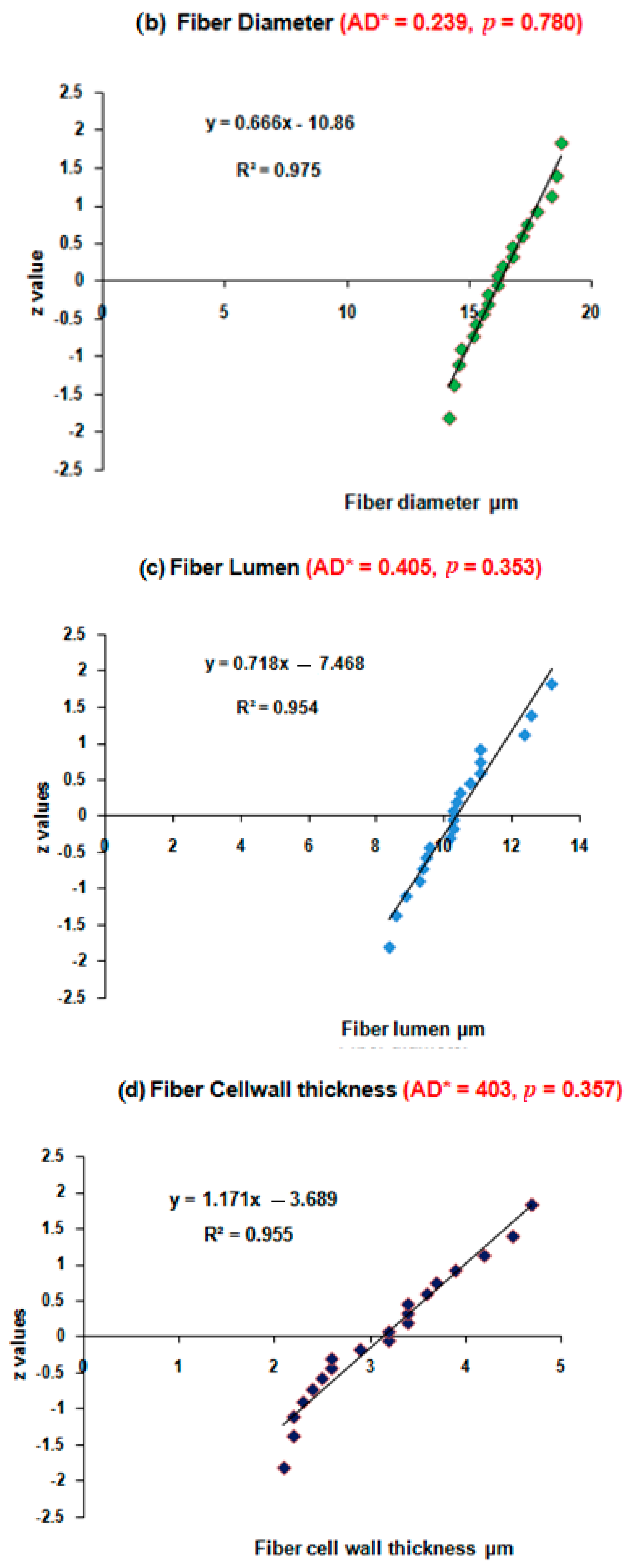

3.4. Statistical Testing

3.5. Derived Indices of Fibers

3.5.1. Runkel Ratio

3.5.2. Slenderness Ratio

3.5.3. Coefficient of Flexibility

3.5.4. Rigidity Coefficient

3.5.5. Luce’s Shape Factor

3.5.6. Solids Shape Factor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dutt, D.; Tyagi, C.H. Comparison of various eucalyptus species for their morphological, chemical, pulp and paper making characteristics. Indian J. Chem. Technol. 2011, 18, 145–151. [Google Scholar]

- Gopal, P.M.; Sivaram, N.M.; Barik, D. Paper industry wastes and energy generation from wastes. In Energy from Toxic Organic Waste for Heat and Power Generation; Woodhead Publishing: Cambridge, UK, 2019; pp. 83–97. [Google Scholar] [CrossRef]

- Available online: https://www.fao.org/forestry-fao/statistics/80938/en/ (accessed on 15 March 2025).

- Available online: https://ipmaindia.org/overview-2/ (accessed on 10 September 2025).

- Przybysz, K.; Małachowska, E.; Martyniak, D.; Boruszewski, P.; Iłowska, J.; Kalinowska, H.; Przybysz, P. Yield of pulp, dimensional properties of fibers, and properties of paper produced from fast growing trees and grasses. BioResources 2018, 13, 1372–1387. [Google Scholar] [CrossRef]

- Available online: www.resourcewise.com/blog/forest-products-blog/indias-pulp-and-paper-industry (accessed on 15 March 2025).

- Anthonio, F.; Antwi-Boasiako, C. The characteristics of fibres within coppiced and non-coppiced rosewood (Pterocarpus erinaceus Poir.) and their aptness for wood- and paper-based products. Pro Ligno 2017, 13, 27–39. [Google Scholar]

- Shakhes, J.; Marandi, M.A.; Zeinaly, F.; Saraian, A.; Saghafi, T. Tobacco residuals as promising lignocellulosic materials for pulp and paper industry. BioResources 2011, 6, 4481–4493. [Google Scholar] [CrossRef]

- Sadiku, N.A.; Oluyege, A.O.; Ajayi, B. Fibre dimension and chemical characterisation of naturally grown Bambusa vulgaris for pulp and paper production. J. Bamboo Ratt. 2016, 15, 33–43. [Google Scholar]

- Balasubramanian, N.; Balasubramanian, R. Turning Discarded Agricultural Remnants and PoultryWaste into Usable Hybrid Polymer Matrix Reinforcements: An Experimental Study. J. Compos. Sci. 2024, 8, 411. [Google Scholar] [CrossRef]

- Lukmandaru, G.; Zumaini, U.F.; Soeprijadi, D.; Nugroho, W.D.; Susanto, M. Chemical properties and fiber dimension of Eucalyptus pellita from the 2nd generation of progeny tests in Pelaihari, South Borneo, Indonesia. J. Korean Wood Sci. Technol. 2016, 44, 571–588. [Google Scholar] [CrossRef]

- Pirralho, M.; Flores, D.; Sousa, B.V.; Quilhó, T.; Knapic, S.; Pereira, H. Evaluation of papermaking potential of nine Eucalyptus species based on wood anatomical features. Ind. Crops Prod. 2014, 54, 327–334. [Google Scholar] [CrossRef]

- Ohshima, J.; Yokota, S.; Yoshizawa, N.; Ona, T. Examination of within-tree variations and the heights representing whole-tree values of derived wood properties for quasi-non-destructive breeding of Eucalyptus camaldulensis and Eucalyptus globulus as quality pulpwood. J. Wood Sci. 2005, 51, 102–111. [Google Scholar] [CrossRef]

- Sharma, A.K.; Dutt, D.; Upadhyaya, J.S.; Roy, T.K. Anatomical, morphological, and chemical characterization of Bambusa tulda, Dendrocalamus hamiltonii, Bambusa balcooa, Malocana baccifera, Bambusa arundinacea and Eucalyptus tereticornis. BioResources 2011, 6, 5062–5073. [Google Scholar] [CrossRef]

- Ibrahim, M.F.E.; Abdelazim, Y.A. Effect of growth rate on fiber characteristics of eucalyptus camaldulensis wood of coppice origin grown in White Nile State. Sudan J. Nat. Resour. Environ. Stud. 2015, 3, 14–23. [Google Scholar]

- Muniandy, S.K.; Sapuan, S.M.; Ilyas, R.A.; Azmi, A. Sugar Palm Lignocellulosic Fiber Reinforced Polymer Composite: A Review. J. Fibers Polym. Compos. 2022, 1, 1–19. [Google Scholar] [CrossRef]

- Asrat, T.H.; Bachheti, R.K.; Getachew, M.; Abate, L. Evaluation of pulp and paper making properties of Caesalpinia decapetela. Nord. Pulp Pap. Res. J. 2022, 37, 14–24. [Google Scholar] [CrossRef]

- NagarajaGanesh, B.; Rekha, B.; Mohanavel, V.; Ganeshan, P. Exploring the possibilities of producing pulp and paper from discarded lignocellulosic fibers. J. Nat. Fibers 2023, 20, 2137618. [Google Scholar] [CrossRef]

- Rekha, B.; NagarajaGanesh, B. X-ray diffraction: An efficient method to determine microfibrillar angle of dry and matured cellulosic fibers. J. Nat. Fibers 2022, 19, 3689–3696. [Google Scholar] [CrossRef]

- Tanobe, V.O.; Sydenstricker, T.H.; Munaro, M.; Amico, S.C. A comprehensive characterization of chemically treated Brazilian sponge-gourds (Luffa cylindrica). Polym. Test. 2005, 24, 474–482. [Google Scholar] [CrossRef]

- NagarajaGanesh, B.; Muralikannan, R. Extraction and characterization of lignocellulosic fibers from Luffa cylindrica fruit. Int. J. Polym. Anal. Charact. 2016, 21, 259–266. [Google Scholar] [CrossRef]

- Available online: https://content.ces.ncsu.edu/commercial-luffa-sponge-gourd-production (accessed on 1 April 2025).

- Available online: https://www.tridge.com/intelligences/sponge-gourd/export (accessed on 1 April 2025).

- Government of India’s Indian Horticulture Database (2019–2020). Available online: https://nhb.gov.in/StatisticsViewer.aspx?enc=MWoUJibk35dW2g36TUJWAoZqESmAYFi7h2irlsmjlINTcFl1rG/kLbq8ZQbWUvuM (accessed on 14 March 2025).

- Zobel, B.J.; Buijtenen, J.P.V. Wood variation and wood properties. In Wood Variation; Springer: Berlin, Germany, 1989. [Google Scholar]

- NagarajaGanesh, B.; Rekha, B. Intrinsic cellulosic fiber architecture and their effect on the mechanical properties of hybrid composites. Arch. Civ. Mech. Eng. 2020, 20, 125. [Google Scholar] [CrossRef]

- Anderson, T.W.; Darling, D.A. A Test of Goodness of Fit. J. Am. Stat. Assoc. 1954, 49, 765–769. [Google Scholar] [CrossRef]

- Luce, G.E. Transverse collapse of wood pulp fibers: Fiber models. In The Physics and Chemistry of Wood Pulp Fibers (Special Technical Association Publication, No. 8); Page, D.H., Ed.; Technical Association of the Pulp and Paper Industry: New York, NY, USA, 1970; pp. 278–281. [Google Scholar]

- Malan, F.S.; Gerischer, G.F.R. Wood property differences in South African grown Eucalyptus grandis trees of different growth stress intensity. Holzforschung 1987, 41, 331–335. [Google Scholar] [CrossRef]

- Rana, R.; Langenfeld-Heyser, R.; Finkeldey, R.; Polle, A. Functional anatomy of five endangered tropical timber wood species of the family Dipterocarpaceae. Trees 2009, 23, 512–529. [Google Scholar] [CrossRef]

- Afrifah, K.; Osei, L.; Ofosu, S. Suitability of Four Varieties of Cocos nucifera Husk in Ghana for Pulp and Paper Production. J. Nat. Fibers 2020, 19, 4654–4661. [Google Scholar] [CrossRef]

- NagarajaGanesh, B.; Rekha, B. Morphology and damage mechanism of lignocellulosic fruit fibers reinforced polymer composites: A comparative study. SN Appl. Sci. 2019, 1, 1250. [Google Scholar] [CrossRef]

- Kapun, T.; Zule, J.; Fabjan, E.; Hočevar, B.; Grilc, M.; Likozar, B. Engineered invasive plant cellulose fibers as resources for papermaking. Eur. J. Wood Wood Prod. 2022, 80, 501–514. [Google Scholar] [CrossRef]

- Enayati, A.A.; Hamzeh, Y.; Mirshokraiei, S.A.; Molaii, M. Papermaking potential of canola stalks. BioResources 2009, 4, 245–256. [Google Scholar] [CrossRef]

- Daud, Z.; Awang, H.; Mohd Kassim, A.S.; Mohd Hatta, M.Z.; Mohd Aripin, A. Cocoa pod husk and corn stalk: Alternative paper fibres study on chemical characterization and morphological structures. Adv. Mater. Res. 2014, 911, 331–335. [Google Scholar] [CrossRef]

- Kiaei, M.; Tajik, M.; Vaysi, R. Chemical and biometrical properties of plum wood and its application in pulp and paper production. Maderas Cienc. Tecnol. 2014, 16, 313–322. [Google Scholar] [CrossRef]

- Laftah, W.A.; Abdul Rahman, A.W. Pulping Process and the Potential of Using Non-Wood Pineapple Leaves Fiber for Pulp and Paper Production: A Review. J. Nat. Fibers 2016, 13, 85–102. [Google Scholar] [CrossRef]

- Rodríguez, A.; Sánchez, R.; Requejo, A.; Ferrer, A. Feasibility of rice straw as a raw material for the production of soda cellulose pulp. J. Clean. Prod. 2010, 18, 1084–1091. [Google Scholar] [CrossRef]

- NagarajaGanesh, B.; Rekha, B. Effect of mercerization on the physico-chemical properties of matured and seasoned Cocos nucifera fibers for making sustainable composites. Mater. Res. Express 2019, 6, 125102. [Google Scholar] [CrossRef]

- Pavithra, R.; Gunasekaran, S.; Sailatha, E.; Kamatchi, S. Investigations on Paper Making Raw Materials and Determination of Paper Quality by FTIR-UATR and UV-Vis DRS Spectroscopy. Int. J. Curr. Res. Acad. Rev. 2015, 3, 42–59. [Google Scholar]

- Tekleyohanis Hailemariam, T.; Woldeyes, B. Production and characterization of pulp and paper from flax straw. Sci. Rep. 2024, 14, 24300. [Google Scholar] [CrossRef]

- Ververis, C.; Georghiou, K.; Christodoulakis, N.; Santas, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 2004, 19, 245–254. [Google Scholar] [CrossRef]

- Khakifirooz, A.; Kiaei, M.; Sadegh, A.N.; Samariha, A.A. Studies on chemical properties and morphological characteristics of Iranian cultivated kenaf (Hibiscus cannabinus L.): A potential source of fibrous raw material for paper industry in Iran. Res. Crops 2012, 13, 715–720. [Google Scholar]

- Fonseca, A.D.S.; Mori, F.A.; Tonoli, G.H.D.; Junior, H.S.; Ferrari, D.L.; Miranda, I.P.D.A. Properties of an Amazonian vegetable fiber as a potential reinforcing material. Ind. Crops Prod. 2013, 47, 43–50. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, F.C.; Sun, R.C.; Lu, Q. Anatomy, ultrastructure and lignin distribution, in cell wall of Caragana korshinskii. Ind. Crops Prod. 2006, 24, 186–193. [Google Scholar] [CrossRef]

- Boadu, B.K.; Antwi-Boasiako, C.; Frimpong Mensah, K. Physical and mechanical properties of Klainedoxa gabonensis with engineering prospects. J. For. Res. 2017, 28, 629–636. [Google Scholar] [CrossRef]

- Afrifah, K.A.; Adjei-Mensah, E. Anatomical and chemical characterization of Alstonia boonei for pulp and paper production. Les/Wood 2021, 70, 5–18. [Google Scholar] [CrossRef]

- Wangaard, F.F. Contributions of hardwood fibres to the properties of kraft pulps. Tappi 1962, 45, 548–556. [Google Scholar]

- Sangumbe, M.V.L.; Pereira, M.; Carrillo, I.; Mendonça, R.T. An exploratory evaluation of the pulpability of Brachystegia spiciformis and Pericopsis angolensis from the Angolan Miombo woodlands. Maderas Cienc. Tecnol. 2018, 20, 183–198. [Google Scholar] [CrossRef]

- Ofosu, S.; Boadu, K.B.; Afrifah, K.A. Suitability of Chrysophyllum albidum from moist semi-deciduous forest in Ghana as a raw material for manufacturing paper-based products. J. Sustain. For. 2019, 39, 153–166. [Google Scholar] [CrossRef]

- Sharma, M.; Sharma, C.L.; Lama, D.D. Anatomical and fibre characteristics of some agro waste materials for pulp and paper making. Int. J. Agric. Sci. Res. 2015, 5, 155–162. [Google Scholar]

- Tembe, E.T.; Ekhuemelo, D.O.; Aondoaver, B.T. Assessment of fibre characteristics of Spondia mombin L. (Anacardiaceae) for pulp and paper production. FUDMA J. Sci. 2021, 5, 511–516. [Google Scholar] [CrossRef]

- Monga, S.; Naithani, S.; Thapliyal, B.P.; Tyagi, S.; Bist, M. Effect of morphological characteristics of indegeneous fibers (E. tereticornis and S. officinarum) and their impact on paper properties. Ippta J. 2017, 29, 1–5. [Google Scholar]

- Oluwadare, A.O.; Sotannde, O.A. The relationship between fiber characteristics and pulp-sheet properties of Leucaena leucocephala (Lam.) De Wit. Middle-East J. Sci. Res. 2007, 2, 63–68. [Google Scholar]

- Khantayanuwong, S.; Yimlamai, P.; Chitbanyong, K.; Wanitpinyo, K.; Pisutpiched, S.; Sungkaew, S.; Sukyai, P.; Puangsin, B. Fiber morphology, chemical composition, and properties of kraft pulping handsheet made from four Thailand bamboo species. J. Nat. Fibers 2023, 20, 2150924. [Google Scholar] [CrossRef]

- Mboumba, U.C.; Koyota, G.; Ikumi, N.E.; Ishiguri, F.; Naoto, H.A.; Ohshima, J.; Yokota, S. Anatomical characteristics, derived-wood, chemical, and kraft pulp properties of Acacia species grown in Gabon. Bull. Utsunomiya Univ. For. 2023, 30, 1–2. [Google Scholar]

- Available online: https://patents.google.com/patent/EP0791683A1/en (accessed on 13 April 2025).

- Available online: https://patents.google.com/patent/CN113201796A/en (accessed on 28 April 2025).

- NagarajaGanesh, B.; Rekha, B. Synergistic Behavior of Hybrid Polymer Composites Reinforced Using Raw and Chemically Treated Agricultural Residues and Poultry Leftovers. Preprints 2024, 2024060918. [Google Scholar] [CrossRef]

| Fiber Name | Holocellulose | Lignin | Ash Content | References |

|---|---|---|---|---|

| wt% | wt% | wt% | ||

| Eucalyptus grandis | 59.8 | 29.6 | 2.87 | [1] |

| Eucalyptus alba | 60.3 | 27.9 | 0.36 | [1] |

| Eucalyptus europhyllia | 64.2 | 26.5 | 0.98 | [1] |

| Reed | 77.9 | 18.7 | 3.9 | [8] |

| Paulownia | 75.4 | 20.5 | 0.21 | [8] |

| Canola stalk | 73.6 | 17.3 | 8.2 | [8] |

| Bamboosa vulgaris | 79.01 | 40.41 | 29.2 | [9] |

| Eucalyptus pellita | 71.07 | 25.5 | - | [11] |

| E. tereticornis | 66.5 | 28.2 | 1.12 | [1] |

| Ananas comosus | 82 | 5–12% | 1.1 | [37] |

| Softwood | 60–80 | 21–37 | <1 | [35] |

| Hardwood | 71–89 | 14–34 | <1 | [36] |

| Rice straw | 70.85 | 17.2 | 16.6 | [38] |

| Tobacco stalks | 67.79 | 18.9 | 6.86 | [8] |

| Luffa cylindrica | 82.4 | 11.2 | 0.63 | Current work |

| Wave Numbers (cm−1) | ||||||

|---|---|---|---|---|---|---|

| Eucalyptus Wood | Bagasse | Unbleached Wood Pulp | Bleached Wood Pulp | Flax Straw | Luffa cylindrica | Assignment |

| 3338 | 3338 | 3339 | 3337 | 3500–2900 | 3333 | O-H stretching vibration |

| 2892 | 2917 | 2898 | 2896 | 2911 | 2912 | C-H stretching |

| 1424 | 1423 | 1433 | 1426 | 1420–1430 | 1433 | C-H bending |

| 1231 | 1240 | 1249 | 1204 | 1230 | 1265 | Out of plane C-OH |

| 1031 | 1033 | 1031 | 1055 | 1066 | 1033 | C-OH bending |

| 896 | 896 | 897 | 897 | 900 | 842 | Glucosidic ring stretching |

| [40] | [40] | [40] | [40] | [41] | This work | References |

| S.No | Fiber Length | Fiber Diameter | Lumen Diameter | Cell Wall Thickness |

|---|---|---|---|---|

| µm | μm | μm | µm | |

| 1 | 956 | 15.2 | 9.3 | 2.9 |

| 2 | 984 | 16.2 | 9.5 | 3.4 |

| 3 | 964 | 14.7 | 10.3 | 2.3 |

| 4 | 1022 | 16.4 | 12.6 | 2.2 |

| 5 | 1014 | 16.2 | 10.2 | 3.2 |

| 6 | 1036 | 17.4 | 10.3 | 3.6 |

| 7 | 1012 | 18.6 | 14.2 | 2.4 |

| 8 | 956 | 15.3 | 11.1 | 2.3 |

| 9 | 976 | 15.8 | 8.9 | 3.4 |

| 10 | 932 | 16.8 | 10.8 | 3.2 |

| 11 | 912 | 14.6 | 11.1 | 2.1 |

| 12 | 948 | 14.4 | 9.4 | 2.5 |

| 13 | 914 | 14.2 | 10.4 | 2.2 |

| 14 | 1042 | 18.8 | 10.5 | 4.2 |

| 15 | 968 | 15.8 | 9.6 | 3.3 |

| 16 | 992 | 15.6 | 8.6 | 3.6 |

| 17 | 1068 | 17.8 | 12.4 | 2.6 |

| 18 | 1060 | 16.8 | 8.4 | 4.5 |

| 19 | 1048 | 17.2 | 10 | 3.7 |

| 20 | 1108 | 18.4 | 10.2 | 4.4 |

| Mean | 995.6 | 16.31 | 10.39 | 3.1 |

| Min | 912 | 14.2 | 8.4 | 2.1 |

| Max | 1108 | 18.8 | 14.2 | 4.5 |

| Range | 196 | 4.6 | 5.8 | 2.4 |

| STD | 53.92 | 1.40 | 1.41 | 0.76 |

| CV% | 5.42 | 8.58 | 13.57 | 24.52 |

| N | 20 | 20 | 20 | 20 |

| S | −403.940 | −404.578 | −412.037 | −409.828 |

| AD | 0.197 | 0.229 | 0.602 | 0.491 |

| AD* | 0.205 | 0.239 | 0.628 | 0.513 |

| p-Value | 0.872 | 0.781 | 0.102 | 0.194 |

| Fiber Name | Runkel Ratio | Slenderness Ratio% | Coefficient of Flexibility | Rigidity Ratio | Luce Shape Factor | Solids Factor 103 μm3 | References |

|---|---|---|---|---|---|---|---|

| Biden spilosa | 0.46 | 47.33 | 69.01 | - | 0.33 | - | [1] |

| Eupatorium odoratum | 0.52 | 42.3 | 65.81 | - | 0.50 | - | [1] |

| Tobacco stalk | 1.16 | 50.59 | 63.26 | - | - | - | [8] |

| Setaria glauca | 0.57 | 173.15 | 65.57 | 0.35 | 0.4 | 0.86 | [14] |

| Solanum torvum | 0.25 | 24.62 | 80.30 | - | 0.19 | - | [14] |

| Pinus kesiya | 0.22 | 49.04 | 81.74 | - | 0.19 | - | [14] |

| Cocos nucifera | 0.67 | 44.11 | 0.59 | 0.19 | 0.486 | 278.53 | [18] |

| Beema bamboo | 0.69–0.8 | 78.38–101.48 | 56.32–60.39 | - | - | - | [46] |

| Oxythenantera abyssinica | 0.6–0.76 | 82.37–93.92 | 59.75–60.66 | - | - | - | [46] |

| Chrysophyllum albidum | 0.55 | 46.9 | 0.64 | 0.177 | 0.41 | 346 | [50] |

| Saccharum officinarum | 2.479 | 69.77 | 29.12 | 0.722 | 84 | 634 | [53] |

| Eucalyptus tereticornis | 1.047 | 39.07 | 39.73 | 0.416 | 0.727 | 256 | [53] |

| Leucaena leucocephala | 0.59 | - | 0.63 | - | 0.41 | - | [54] |

| Bambusa. vulgaris | 2.82 | 88.96 ± 0.8 | 27 | - | - | - | [55] |

| B. longispiculata | 3.28 | 76.08 ± 3.5 | 24 | - | - | - | [55] |

| Dendro calamus | 3.39 | 91.17 ± 1.34 | 23.8 | - | - | - | [55] |

| Thyrsocalamus liang | 4.21 | 84.42 ± 0.55 | 19.8 | - | - | - | [55] |

| Debdro asper | 5.43 | 116.14 | 16 | - | - | - | [55] |

| Acacia mangium | 0.45 | 56.5 | 0.69 | 0.15 | 0.36 | 156 | [56] |

| Luffa cylindrica | 0.5977 | 61.04 | 0.637 | 0.19 | 0.42 | 157.36 | Current work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

NagarajaGanesh, B.; Rekha, B.; Krishna, M.G.; Ferozdheen, S.I.S.M. Ascertaining the Anatomical Parameters and Chemical Composition of Luffa cylindrica Cellulosic Fibers for Their Plausibility in Pulp and Paper Production. Polymers 2025, 17, 2643. https://doi.org/10.3390/polym17192643

NagarajaGanesh B, Rekha B, Krishna MG, Ferozdheen SISM. Ascertaining the Anatomical Parameters and Chemical Composition of Luffa cylindrica Cellulosic Fibers for Their Plausibility in Pulp and Paper Production. Polymers. 2025; 17(19):2643. https://doi.org/10.3390/polym17192643

Chicago/Turabian StyleNagarajaGanesh, Balasubramanian, Balasubramanian Rekha, Manoharan Gopi Krishna, and Syed Ibrahim Shaik Mohamed Ferozdheen. 2025. "Ascertaining the Anatomical Parameters and Chemical Composition of Luffa cylindrica Cellulosic Fibers for Their Plausibility in Pulp and Paper Production" Polymers 17, no. 19: 2643. https://doi.org/10.3390/polym17192643

APA StyleNagarajaGanesh, B., Rekha, B., Krishna, M. G., & Ferozdheen, S. I. S. M. (2025). Ascertaining the Anatomical Parameters and Chemical Composition of Luffa cylindrica Cellulosic Fibers for Their Plausibility in Pulp and Paper Production. Polymers, 17(19), 2643. https://doi.org/10.3390/polym17192643