Impact Absorption Behaviour of 3D-Printed Lattice Structures for Sportswear Applications

Abstract

1. Introduction

2. Materials and Methods

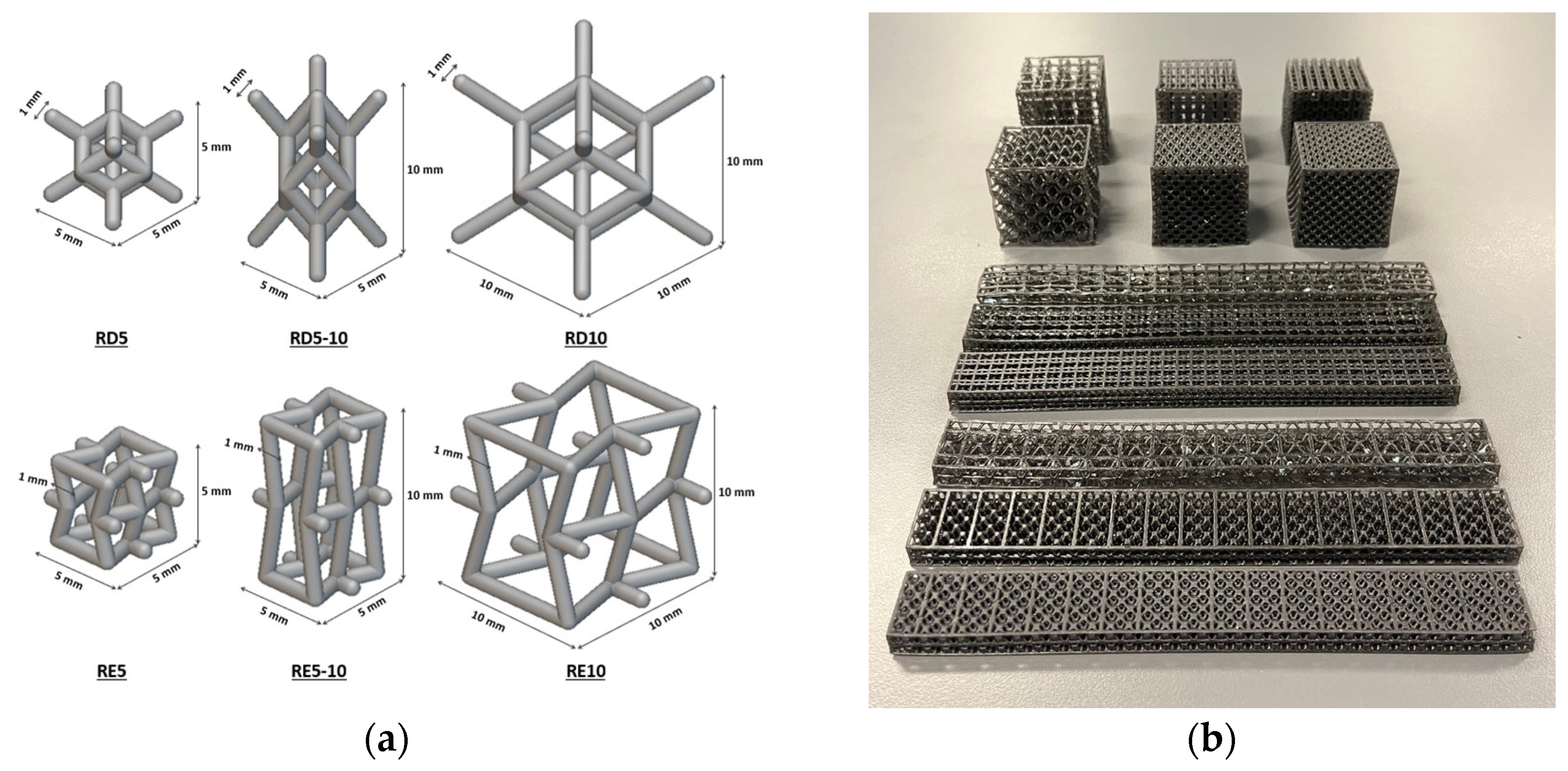

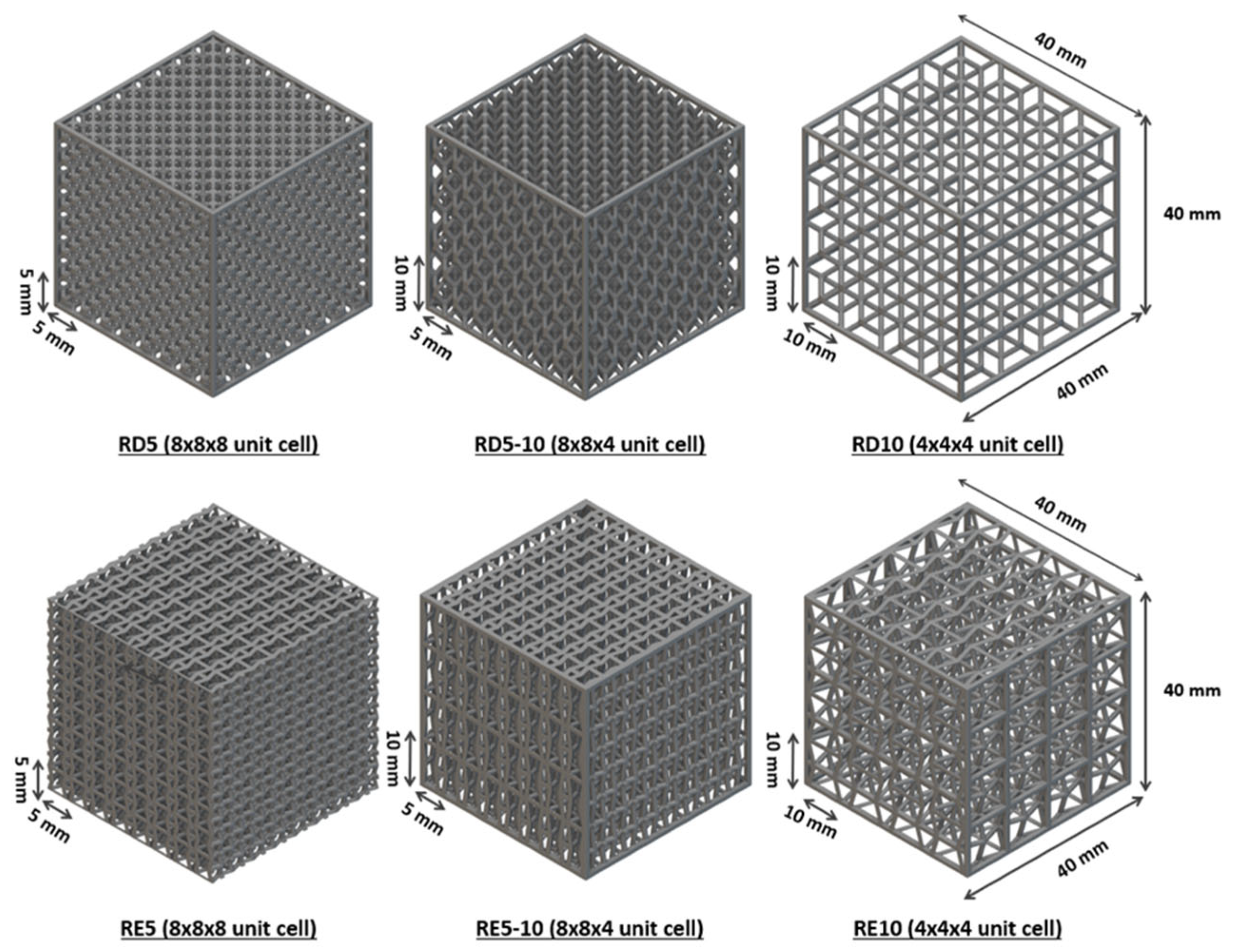

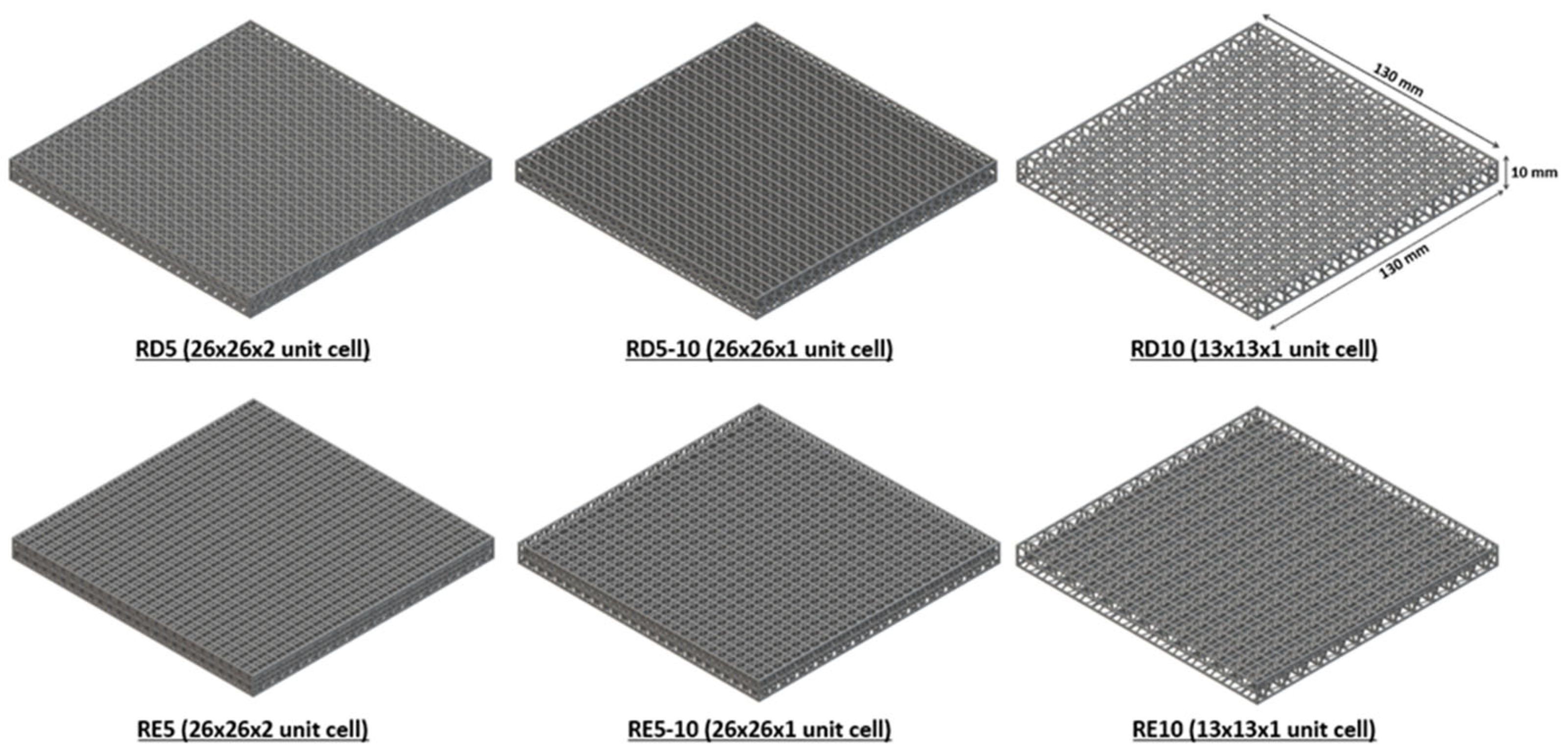

2.1. Lattice Design and Production

2.2. Experimental

2.2.1. Compression

2.2.2. Impact Force Reduction

2.2.3. Bending Test

3. Results and Discussion

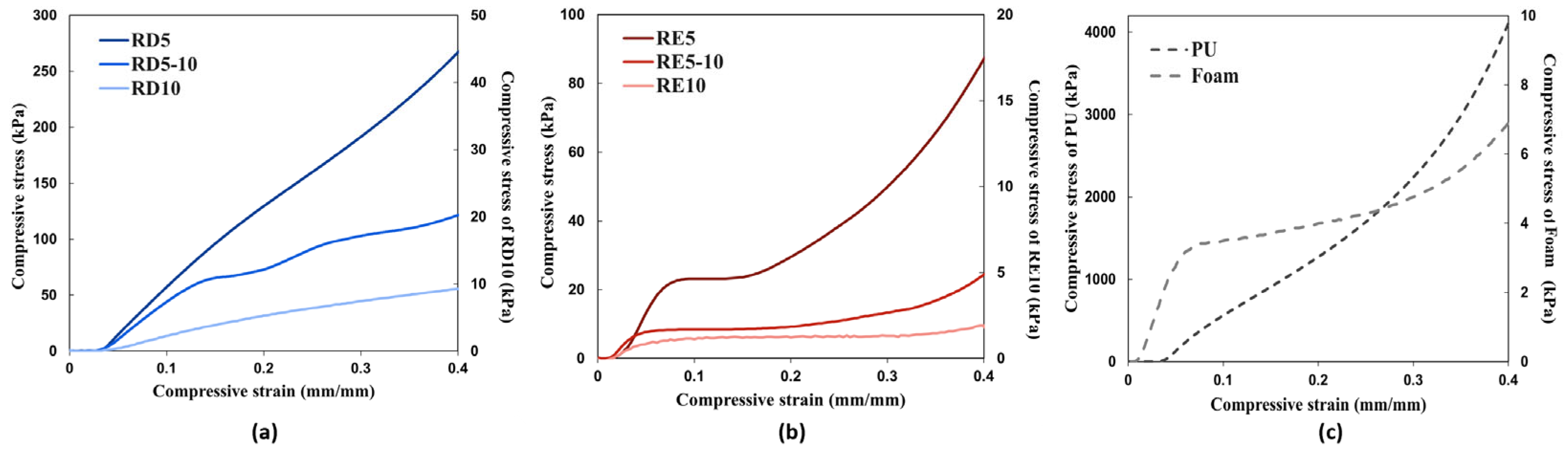

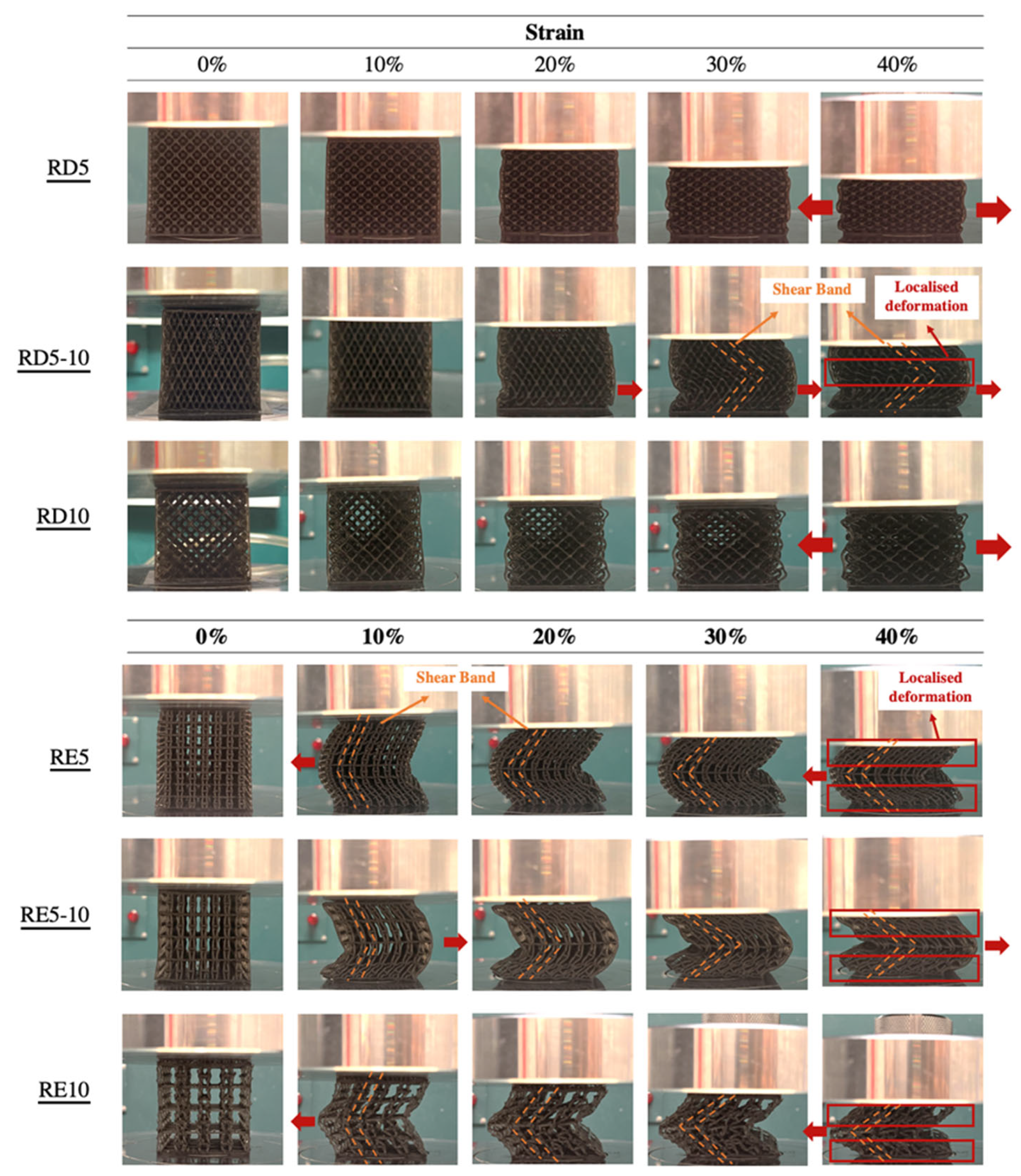

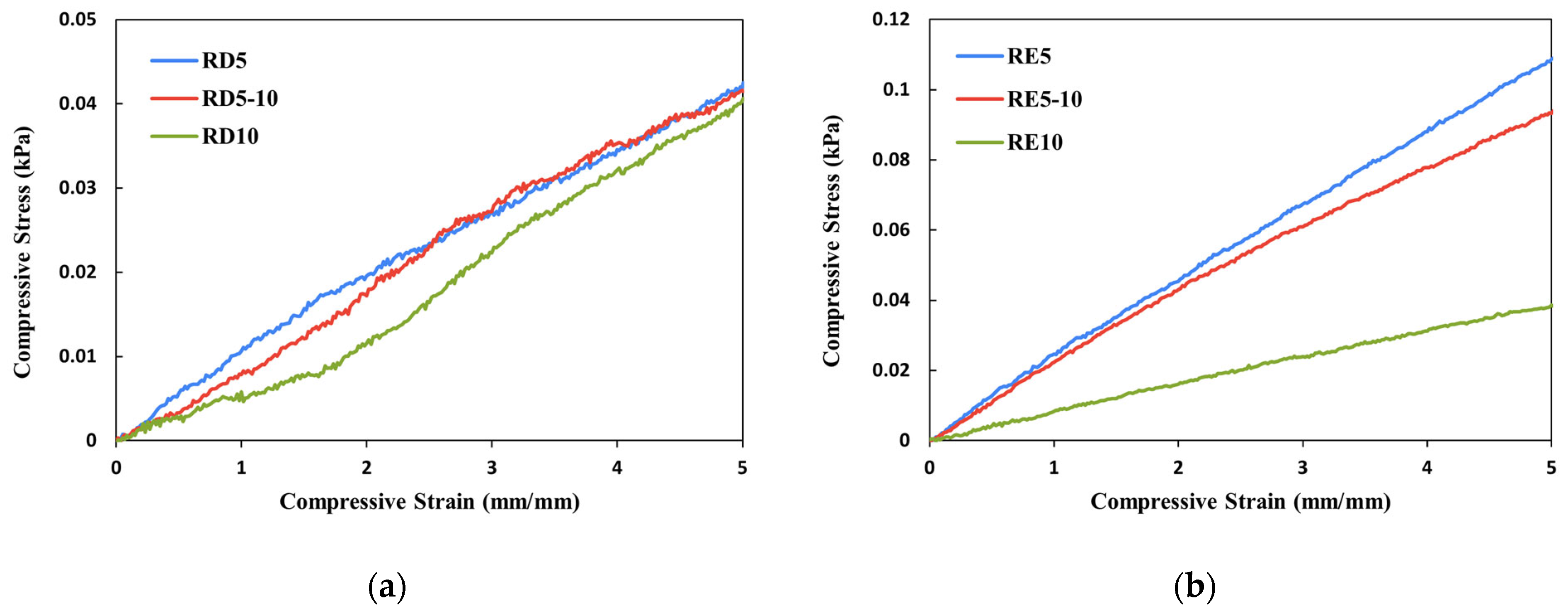

3.1. Compressive Behaviour

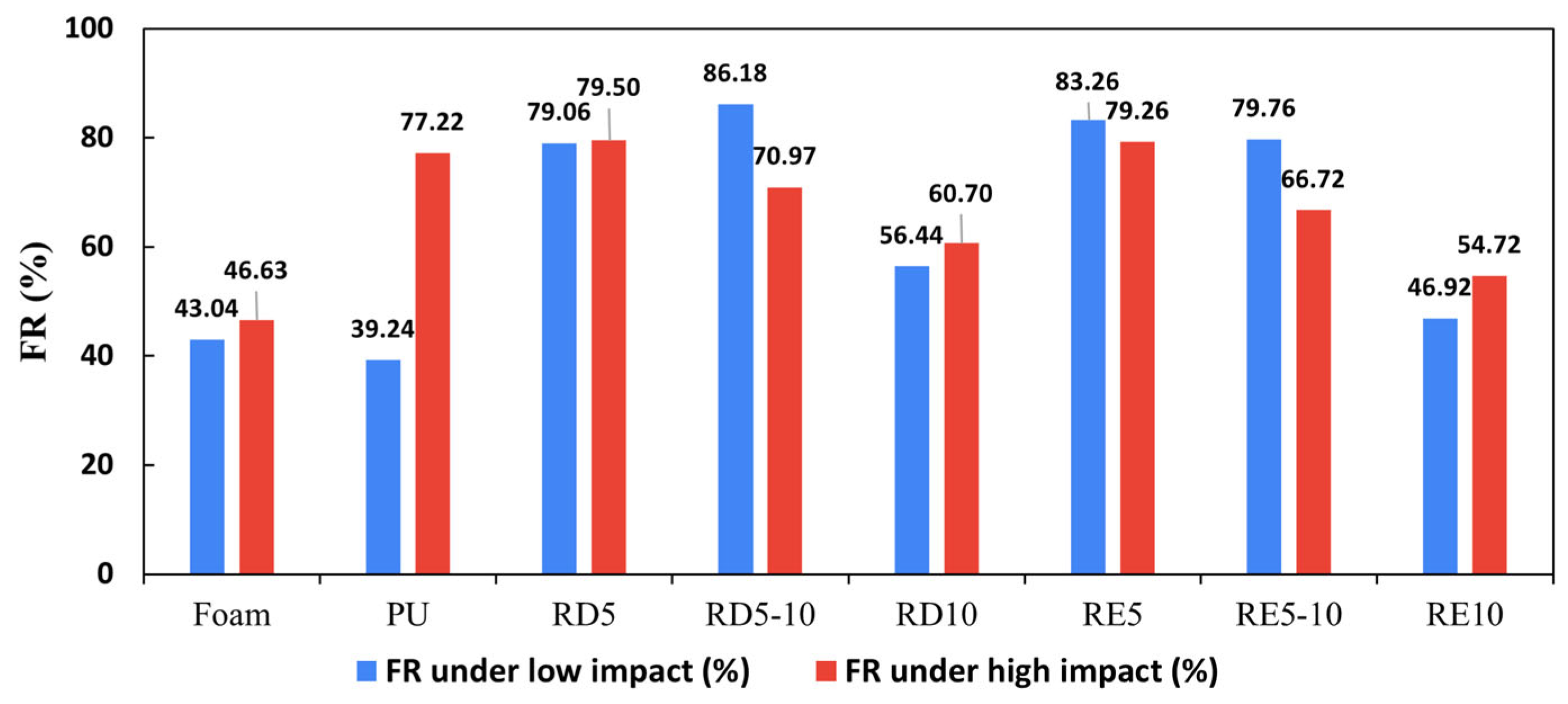

3.2. Impact Force Reduction

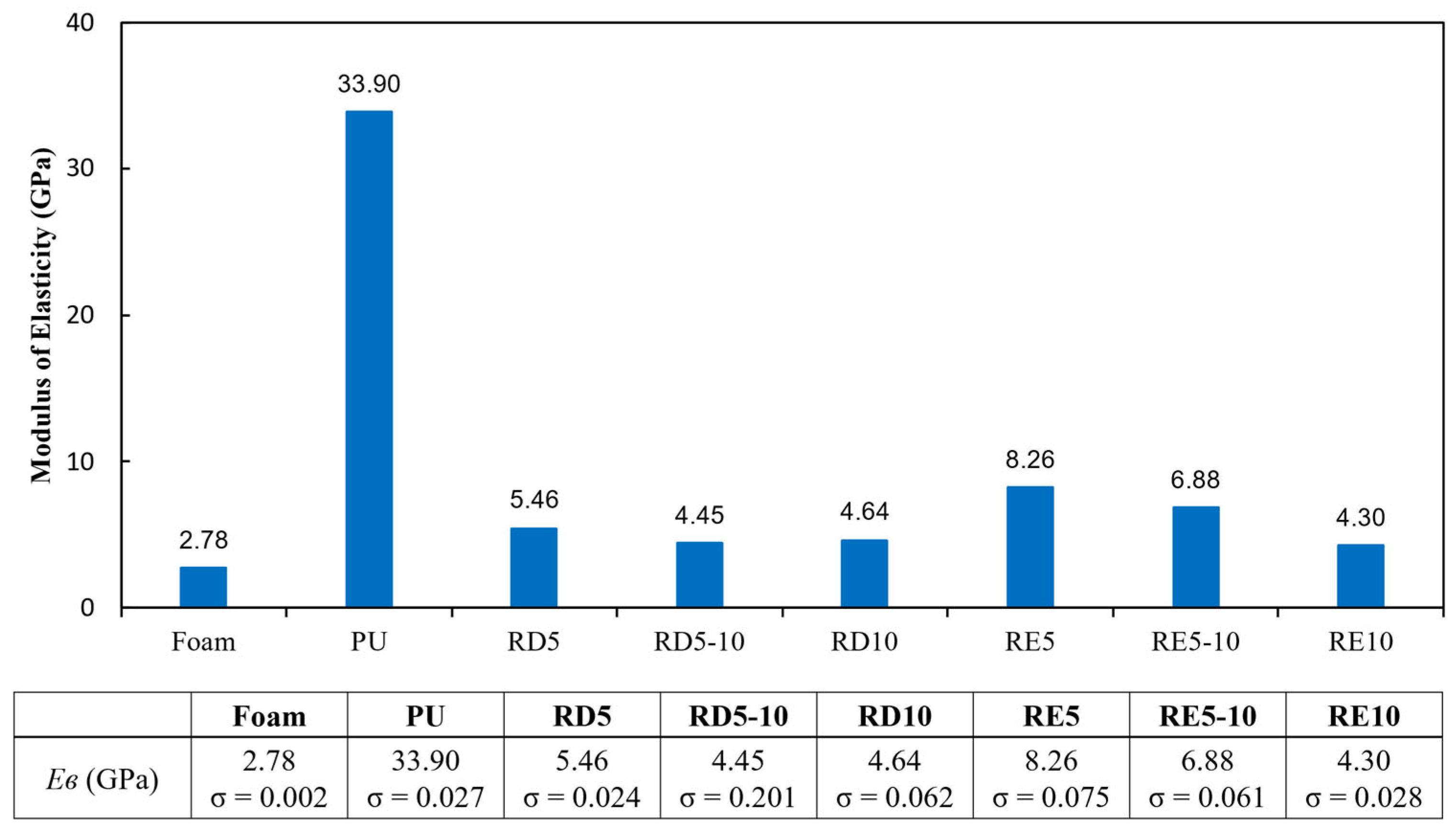

3.3. Bending Rigidity

4. Conclusions

- The RD structure exhibited significantly greater compressive strength and energy absorption capacity than the RE structure, with improvements ranging from 167% to 494%. The RD structure demonstrated uniform deformation under increasing loading, while the RE structure showed buckling and shifting without a negative Poisson’s effect. Both structures, however, had compressive strengths that were approximately 12.9 to 18 times higher than those of conventional foam material.

- In low-impact tests, RD5-10 and RE5 exhibited superior force reduction performance compared with conventional foam and PU, with enhancements of up to 2.2 and 2 times, respectively. Under high-impact conditions, only RD5 and RE5 performed slightly better than PU, achieving a 1.7 times improvement over foam.

- The RE structure exhibited greater flexural stiffness than the RD structure. No correlation was found between unit cell size, relative density, and flexural performance in the RD structure, whereas the rigidity of the RE structure increased as cell size decreased. Both structures showed significant flexibility improvements over rigid PU.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sewry, N.; Verhagen, E.; Lambert, M.; van Mechelen, W.; Viljoen, W.; Readhead, C.; Brown, J. Exercise-Based Interventions for Injury Prevention in Tackle Collision Ball Sports: A Systematic Review. Sports Med. 2017, 47, 1847–1857. [Google Scholar] [CrossRef]

- Gabbett, T.J. Changes in Physiological and Anthropometric Characteristics of Rugby League Players During a Competitive Season. J. Strength Cond. Res. 2005, 19, 400–408. [Google Scholar]

- Gabbett, T.J.; Jenkins, D.G.; Abernethy, B. Physical collisions and injury in professional rugby league match-play. J. Sci. Med. Sport 2011, 14, 210–215. [Google Scholar] [CrossRef]

- Gabbett, T.; Ryan, P. Tackling Technique, Injury Risk, and Playing Performance in High-Performance Collision Sport Athletes. Int. J. Sports Sci. Coach. 2009, 4, 521–533. [Google Scholar] [CrossRef]

- Link, M.S. Commotio cordis: Ventricular fibrillation triggered by chest impact–induced abnormalities in repolarization. Circ. Arrhythm. Electrophysiol. 2012, 5, 425–432. [Google Scholar] [CrossRef] [PubMed]

- Burger, N.; Lambert, M.I.; Viljoen, W.; Brown, J.; Readhead, C.; Hendricks, S. Tackle-related injury rates and nature of injuries in South African Youth Week tournament rugby union players (under-13 to under-18): An observational cohort study. BMJ Open 2014, 4, e005556. [Google Scholar] [CrossRef]

- Marshall, S.W.; Waller, A.E.; Loomis, D.P.; Feehan, M.; Chalmers, D.J.; Bird, Y.N.; Quarrie, K.L. Use of protective equipment in a cohort of rugby players. Med. Sci. Sports Exerc. 2001, 33, 2131–2138. [Google Scholar] [CrossRef]

- Velani, N.; Wilson, O.; Halkon, B.J.; Harland, A.R. Measuring the risk of sustaining injury in sport a novel approach to aid the re-design of personal protective equipment. Appl. Ergon. 2012, 43, 883–890. [Google Scholar] [CrossRef]

- Jenkins, M. Materials in Sports Equipment; Woodhead: Cambridge, UK, 2003. [Google Scholar]

- Dlugosch, S.; Hu, H.; Chan, A.C. Impact protective clothing in sport: Areas of application and level of utilization. Res. J. Text. Appar. 2012, 16, 18–28. [Google Scholar] [CrossRef]

- Tao, W.; Leu, M.C. Design of Lattice Structure for Additive Manufacturing; IEEE: New York, NY, USA, 2016; pp. 325–332. [Google Scholar]

- Totaro, G.; Gürdal, Z. Optimal design of composite lattice shell structures for aerospace applications. Aerosp. Sci. Technol. 2009, 13, 157–164. [Google Scholar] [CrossRef]

- Horn, T.J.; Harrysson, O.L.; Marcellin-Little, D.J.; West, H.A.; Lascelles, B.D.X.; Aman, R. Flexural properties of Ti6Al4V rhombic dodecahedron open cellular structures fabricated with electron beam melting. Addit. Manuf. 2014, 1, 2–11. [Google Scholar] [CrossRef]

- Wagner, M.A.; Lumpe, T.S.; Chen, T.; Shea, K. Programmable, active lattice structures: Unifying stretch-dominated and bending-dominated topologies. Extrem. Mech. Lett. 2019, 29, 100461. [Google Scholar] [CrossRef]

- Junio, R.F.P.; da Silveira, P.H.P.M.; Neuba, L.d.M.; Monteiro, S.N.; Nascimento, L.F.C. Development and applications of 3D printing-processed auxetic structures for high-velocity impact protection: A review. Eng 2023, 4, 903–940. [Google Scholar] [CrossRef]

- Sanami, M.; Ravirala, N.; Alderson, K.; Alderson, A. Auxetic materials for sports applications. Procedia Eng. 2014, 72, 453–458. [Google Scholar] [CrossRef]

- Hanna, B.; Adams, R.; Townsend, S.; Robinson, M.; Soe, S.; Stewart, M.; Burek, R.; Theobald, P. Auxetic metamaterial optimisation for head impact mitigation in American football. Int. J. Impact Eng. 2021, 157, 103991. [Google Scholar] [CrossRef]

- Alomar, Z.; Concli, F. A review of the selective laser melting lattice structures and their numerical models. Adv. Eng. Mater. 2020, 22, 2000611. [Google Scholar] [CrossRef]

- Cao, X.; Duan, S.; Liang, J.; Wen, W.; Fang, D. Mechanical properties of an improved 3D-printed rhombic dodecahedron stainless steel lattice structure of variable cross section. Int. J. Mech. Sci. 2018, 145, 53–63. [Google Scholar] [CrossRef]

- Zamani, M.H.; Heidari-Rarani, M.; Mirkhalaf, M. Design, optimization and additive manufacturing of an innovative bike helmet using auxetic metastructures. Int. J. Solids Struct. 2025, 310, 113240. [Google Scholar] [CrossRef]

- Mazur, E.; Shishkovsky, I. Additively Manufactured Hierarchical Auxetic Mechanical Metamaterials. Materials 2022, 15, 5600. [Google Scholar] [CrossRef]

- Critchley, R.; Hazael, R.; Bhatti, K.; Wood, D.; Peare, A.; Johnson, S.; Temple, T. Blast mitigation using polymeric 3D printed auxetic re-entrant honeycomb structures: A preliminary study. Int. J. Prot. Struct. 2022, 13, 469–486. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, B.; Wu, J.; Li, X.; Zhou, R. Research Progress on Helmet Liner Materials and Structural Applications. Materials 2024, 17, 2649. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; McMillan, M.; Sun, S.; Shidid, D.; Brandt, M. Mechanical properties of Ti6Al4V and AlSi12Mg lattice structures manufactured by Selective Laser Melting (SLM). In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 119–161. [Google Scholar]

- Xiao, L.; Song, W.; Wang, C.; Tang, H.; Fan, Q.; Liu, N.; Wang, J. Mechanical properties of open-cell rhombic dodecahedron titanium alloy lattice structure manufactured using electron beam melting under dynamic loading. Int. J. Impact Eng. 2017, 100, 75–89. [Google Scholar] [CrossRef]

- Nasim, M.; Hasan, M.J.; Galvanetto, U. Impact behavior of energy absorbing helmet liners with PA12 lattice structures: A computational study. Int. J. Mech. Sci. 2022, 233, 107673. [Google Scholar] [CrossRef]

- Zhang, L.; Kong, L.; Huang, G.; Zhou, W.; Jiang, H.; Zhao, P.; Jiang, B.; Xie, A.; Zhu, S.; Chen, Y. A Humanoid Robot Foot with a Lattice Structure for Absorbing Ground Impact Forces. In Intelligent Robotics and Applications; Springer: Singapore, 2023; pp. 380–391. [Google Scholar]

- Li, S.; Xu, Q.; Wang, Z.; Hou, W.; Hao, Y.; Yang, R.; Murr, L. Influence of cell shape on mechanical properties of Ti–6Al–4V meshes fabricated by electron beam melting method. Acta Biomater. 2014, 10, 4537–4547. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Ren, X.; Zhao, T.; Li, Y.; Xiao, D.; Fang, D. Numerical and theoretical analysis of the dynamic mechanical behaviour of a modified rhombic dodecahedron lattice structure. Int. J. Mech. Mater. Des. 2021, 17, 271–283. [Google Scholar] [CrossRef]

- Hu, L.; Luo, Z.; Zhang, Z.; Lian, M.; Huang, L. Mechanical property of re-entrant anti-trichiral honeycombs under large deformation. Compos. Part B Eng. 2019, 163, 107–120. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Remennikov, A.; Pei, L.Z.; Liu, J.; Wang, J.S.; Liao, X.W.; Yang, S. Quasi-static crushing behavior of novel re-entrant circular auxetic honeycombs. Compos. Part B Eng. 2020, 197, 108117. [Google Scholar] [CrossRef]

- Logakannan, K.P.; Ramachandran, V.; Rengaswamy, J.; Ruan, D. Dynamic performance of a 3D re-entrant structure. Mech. Mater. 2020, 148, 103503. [Google Scholar] [CrossRef]

- Fu, M.; Xu, O.; Hu, L.; Yu, T. Nonlinear shear modulus of re-entrant hexagonal honeycombs under large deformation. Int. J. Solids Struct. 2016, 80, 284–296. [Google Scholar] [CrossRef]

- Zahed, M.; Jouneghani, R.A.; Safarabadi, M. Reinforcement of 3D-printed re-entrant structures using additional supports under three-point bending, experimental and numerical analyses. Adv. Eng. Mater. 2024, 26, 2301252. [Google Scholar] [CrossRef]

- Korshunova, N.; Alaimo, G.; Hosseini, S.; Carraturo, M.; Reali, A.; Niiranen, J.; Auricchio, F.; Rank, E.; Kollmannsberger, S. Bending behavior of octet-truss lattice structures: Modelling options, numerical characterization and experimental validation. Mater. Des. 2021, 205, 109693. [Google Scholar] [CrossRef]

- Xiao, L.; Song, W.; Wang, C.; Liu, H.; Tang, H.; Wang, J. Mechanical behavior of open-cell rhombic dodecahedron Ti–6Al–4V lattice structure. Mater. Sci. Eng. A 2015, 640, 375–384. [Google Scholar] [CrossRef]

- Del Guercio, G.; Galati, M.; Saboori, A. Electron beam melting of Ti-6Al-4V lattice structures: Correlation between post heat treatment and mechanical properties. Int. J. Adv. Manuf. Technol. 2021, 116, 3535–3547. [Google Scholar] [CrossRef]

- ISO 3386-2:1997; Flexible Cellular Polymeric Materials—Determination of Stress-Strain Characteristics in Compression. ISO: Geneva, Switzerland, 1997.

- Dau, N.; Bir, C.; McCalley, E.; Halstead, D.; Link, M.S. Development of the NOCSAE standard to reduce the risk of commotio cordis. Circ. Arrhythm. Electrophysiol. 2024, 17, e011966. [Google Scholar] [CrossRef] [PubMed]

- ASTM D2632-15; Standard Test Method for Rubber Property—Resilience by Vertical Rebound. ASTM: West Conshohocken, PA, USA, 2024.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- McDonnell, B.; O’Hara, E.M.; Harrison, N.M. Simulation-driven-design of metal lattice structures for a target stress–strain curve. Mater. Des. 2024, 237, 112543. [Google Scholar] [CrossRef]

- Kechagias, S.; Karunaseelan, K.J.; Oosterbeek, R.N.; Jeffers, J.R. The coupled effect of aspect ratio and strut micro-deformation mode on the mechanical properties of lattice structures. Mech. Mater. 2024, 191, 104944. [Google Scholar] [CrossRef]

- Köhnen, P.; Haase, C.; Bültmann, J.; Ziegler, S.; Schleifenbaum, J.H.; Bleck, W. Mechanical properties and deformation behavior of additively manufactured lattice structures of stainless steel. Mater. Des. 2018, 145, 205–217. [Google Scholar] [CrossRef]

- Choi, H.G.; Park, K. Deformation behavior of re-entrant auxetic metamaterials considering shape transformation effects. J. Mech. Sci. Technol. 2023, 37, 6143–6151. [Google Scholar] [CrossRef]

- Nam, R.; Nam, D.; Naguib, H.E. Additive manufactured 3D re-entrant auxetic structures for enhanced impact resistance. Smart Mater. Struct. 2024, 33, 125021. [Google Scholar] [CrossRef]

- Rodriguez, V.M.; Grasso, M.; Zhao, Y.; Liu, H.; Deng, K.; Roberts, A.; Appleby-Thomas, G.J. Surface damage in woven carbon composite panels under orthogonal and inclined high-velocity impacts. J. Compos. Sci. 2022, 6, 282. [Google Scholar] [CrossRef]

- Zhang, X.G.; Jiang, W.; Zhang, Y.; Han, D.; Luo, C.; Zhang, X.Y.; Hao, J.; Xie, Y.M.; Ren, X. Bending performance of 3D re-entrant and hexagonal metamaterials. Thin-Walled Struct. 2023, 188, 110829. [Google Scholar] [CrossRef]

| Cell Structure | Sample | Unit Cell Size (L × W × H) (mm) | Mass of 40 × 40 × 40 mm3 Cubic (g) | Relative Density (%) |

|---|---|---|---|---|

| Rhombic dodecahedron (RD) | RD5 | 5 × 5 × 5 a = 1 | 20.33 | 31.45 |

| RD5-10 | 5 × 5 × 10 a = 2 | 15.21 | 23.53 | |

| RD10 | 10 × 10 × 10 a = 1 | 6.03 | 9.32 | |

| Re-entrant (RE) | RE5 | 5 × 5 × 5 a = 1 | 16.16 | 25.00 |

| RE5-10 | 5 × 5 × 10 a = 2 | 12.07 | 18.67 | |

| RE10 | 10 × 10 × 10 a = 1 | 4.58 | 7.08 |

| Tensile Strength (MPa) | Elongation at Break (%) | Tensile Modulus (MPa) | Tear Strength (kN/m) |

|---|---|---|---|

| 21.59 | 560 | 5.79 | 22.38 |

| Parameter | Market Sample | Non-Auxetic | Auxetic | |||||

|---|---|---|---|---|---|---|---|---|

| Foam | PU | RD5 | RD5-10 | RD10 | RE5 | R5-10 | RE10 | |

| Max. Compressive Stress (kPa) | 6.66 | 4083.20 | 260.05 | 120.46 | 10.46 | 86.12 | 24.36 | 1.67 |

| Standard Deviation | σ = 0.43 | σ = 33.86 | σ = 6.71 | σ = 0.84 | σ = 0.04 | σ = 0.08 | σ = 0.29 | σ = 0.24 |

| Energy Absorption Capacity (J/kg) | 20.55 | 532.81 | 151.32 | 109.73 | 21.36 | 54.79 | 22.23 | 5.30 |

| Standard Deviation | σ = 0.016 | σ = 0.067 | σ = 0.092 | σ = 0.076 | σ = 0.002 | σ = 0.0002 | σ = 0.003 | σ = 0.005 |

| Poisson’s Ratio | / | / | 0.16 | 0.22 | 0.50 | 0.50 | -0.42 | -1.27 |

| Standard Deviation | / | / | σ = 0.08 | σ = 0.33 | σ = 0.10 | σ = 0.42 | σ = 0.90 | σ = 0.58 |

| Market Sample | Non-Auxetic | Auxetic | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Foam | PU | RD5 | RD5-10 | RD10 | RE5 | R5-10 | RE10 | ||

| Low impact (500N) | Impact force (N) | 275.96 | 294.36 | 101.43 | 66.93 | 211.04 | 81.11 | 98.07 | 257.17 |

| Standard deviation | σ = 26.04 | σ = 7.11 | σ = 1.75 | σ = 1.13 | σ = 7.10 | σ = 1.11 | σ = 5.59 | σ = 15.66 | |

| FR (%) | 43.04 | 39.24 | 79.06 | 86.18 | 56.44 | 83.26 | 79.76 | 46.92 | |

| High impact (3300N) | Impact force (N) | 1759.35 | 750.95 | 675.76 | 956.91 | 1295.39 | 683.52 | 1096.95 | 1492.44 |

| Standard deviation | σ = 28.35 | σ = 13.41 | σ = 20.51 | σ = 13.10 | σ = 49.50 | σ = 14.86 | σ = 28.21 | σ = 20.67 | |

| FR (%) | 46.63 | 77.22 | 79.50 | 70.97 | 60.70 | 79.26 | 66.72 | 54.72 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, M.-k.; Hung, S.-c.; Yick, K.-l.; Sun, Y.; Yip, J.; Ng, S.-p. Impact Absorption Behaviour of 3D-Printed Lattice Structures for Sportswear Applications. Polymers 2025, 17, 2611. https://doi.org/10.3390/polym17192611

Chan M-k, Hung S-c, Yick K-l, Sun Y, Yip J, Ng S-p. Impact Absorption Behaviour of 3D-Printed Lattice Structures for Sportswear Applications. Polymers. 2025; 17(19):2611. https://doi.org/10.3390/polym17192611

Chicago/Turabian StyleChan, Mei-ki, Sik-cheung Hung, Kit-lun Yick, Yue Sun, Joanne Yip, and Sun-pui Ng. 2025. "Impact Absorption Behaviour of 3D-Printed Lattice Structures for Sportswear Applications" Polymers 17, no. 19: 2611. https://doi.org/10.3390/polym17192611

APA StyleChan, M.-k., Hung, S.-c., Yick, K.-l., Sun, Y., Yip, J., & Ng, S.-p. (2025). Impact Absorption Behaviour of 3D-Printed Lattice Structures for Sportswear Applications. Polymers, 17(19), 2611. https://doi.org/10.3390/polym17192611