Interphase-Resolved Performance in PA6/TiO2 Nanocomposite Fibers: Four-Phase Geometry Linking Structure to Mechanical and UV Protection

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Surface Modification

2.2. Fiber Preparation and Processing

2.3. Characterization Techniques

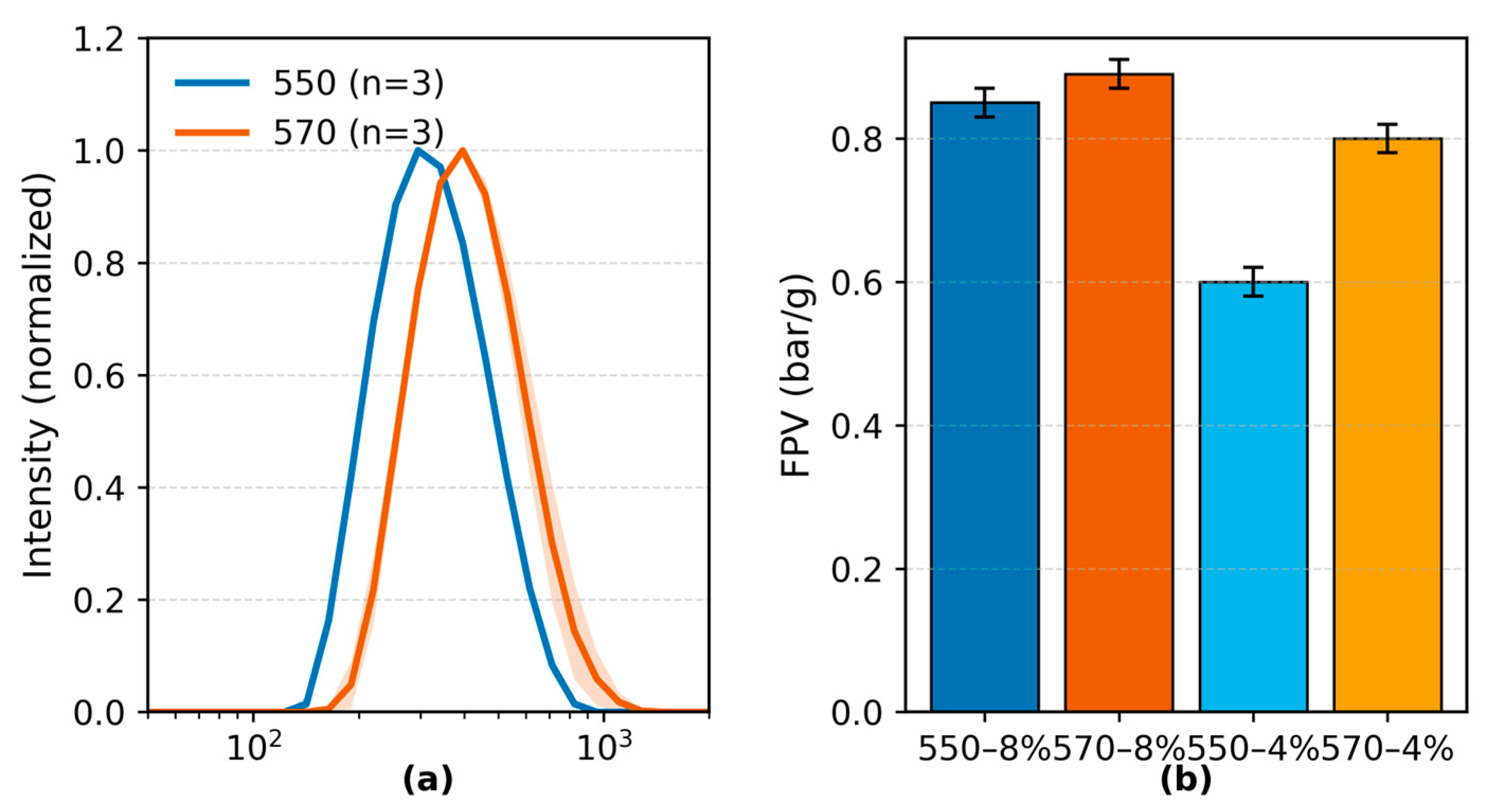

2.3.1. Dynamic Light Scattering (DLS)

2.3.2. Filter Pressure Value (FPV) Testing

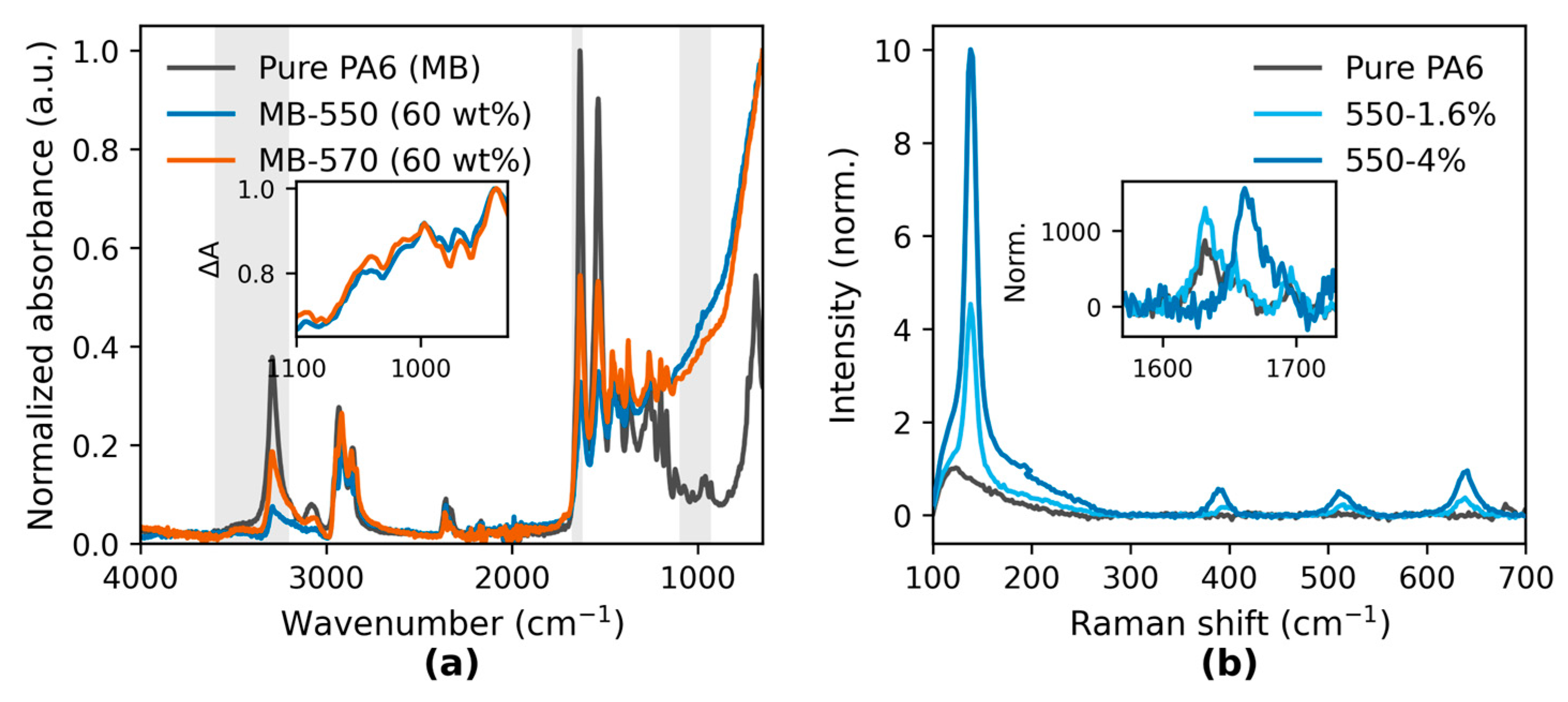

2.3.3. Fourier-Transform Infrared (FTIR) Spectroscopy

2.3.4. Raman Spectroscopy

2.3.5. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-Ray Spectroscopy (EDS)

2.3.6. Differential Scanning Calorimetry (DSC)

2.3.7. Synchrotron Small- and Wide-Angle X-Ray Scattering (SAXS/WAXS)

2.3.8. Dynamic Mechanical Analysis (DMA)

2.3.9. Rotational Rheology

2.3.10. Mechanical Testing

2.3.11. Ultraviolet Protection Factor (UPF)

2.3.12. Molecular Dynamics (MD) Simulations

2.3.13. Data Integration and Correlation Analysis

2.3.14. Generative AI Disclosure

3. Results

3.1. Nanoparticle Dispersion and Interfacial Chemistry

3.1.1. TiO2 Dispersion and Interfacial Modification

3.1.2. Chemical Interactions

3.2. Multi-Scale Structure and Crystallization Behavior

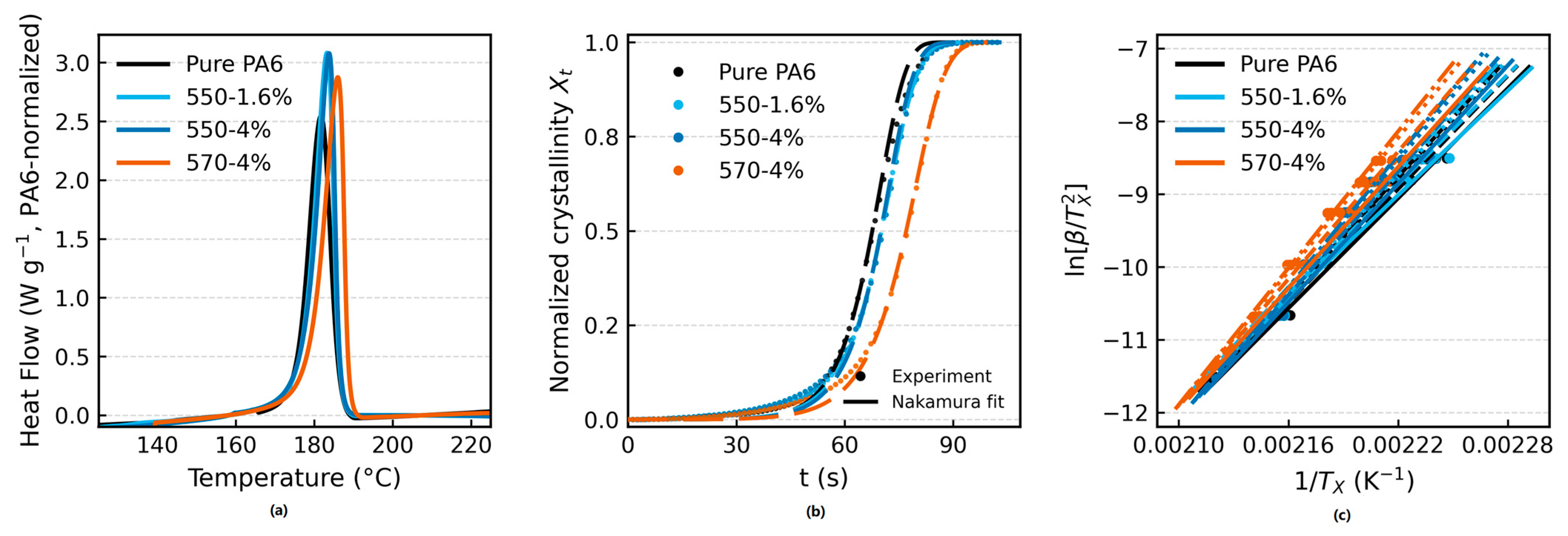

3.2.1. Non-Isothermal Crystallization Kinetics: Avrami–Nakamura and Isoconversional Analyses

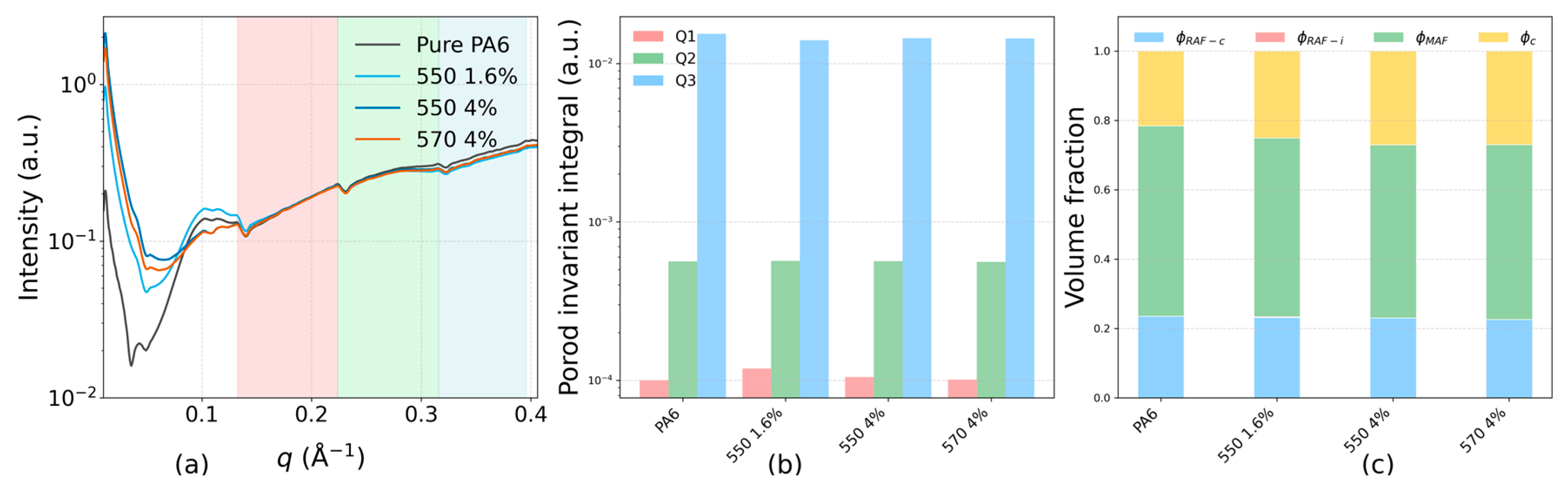

3.2.2. Rigid Amorphous Fraction (RAF) Quantification

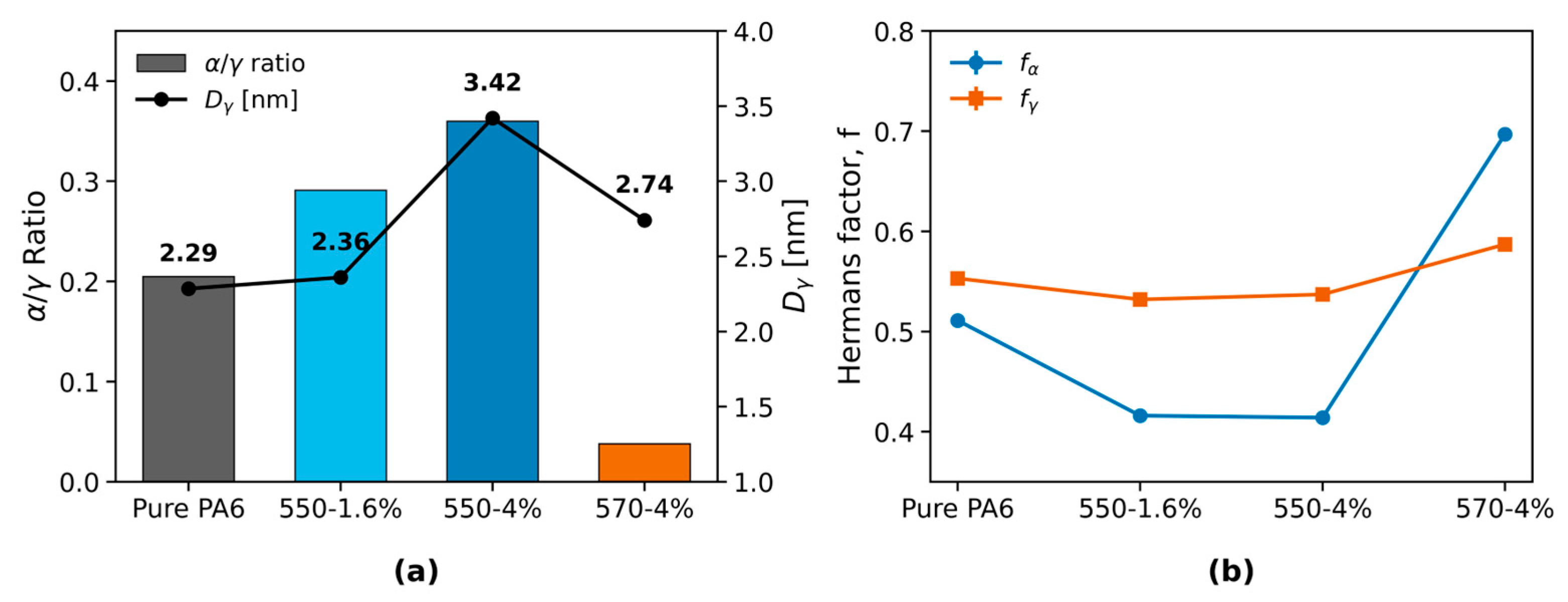

3.2.3. WAXS Analysis of Polymorphs and Orientation

3.3. Macroscopic Functional and Mechanical Performance

3.3.1. Stiffness and Strength

3.3.2. Flowability and UV Protection

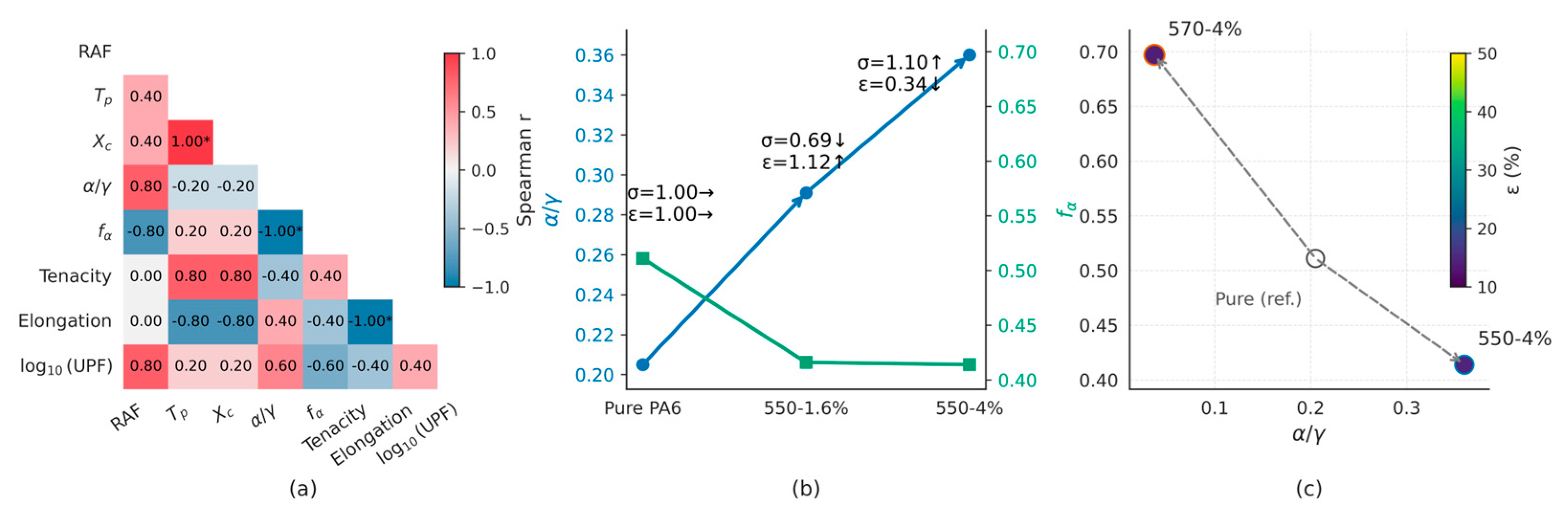

3.4. Interface–Structure–Performance Coupling

4. Discussion

4.1. Role of Interfacial Chemistry in RAF Redistribution

4.2. Influence of Interfacial RAF on Non-Isothermal Kinetics and Orientation

4.3. Structural States and Their Relation to Macroscopic Performance

4.4. Interfacial Regimes: Geometric Descriptors and Structural Outcomes

4.5. Geometry-Based Summary of RAF–Kinetics–Structure–Performance Relations

5. Conclusions

- Γi correlates with crystallization metrics (higher Tp, longer t1/2), while α/γ and f(α) provide orthogonal structural coordinates.

- “Compatibility” is described operationally as nucleation-compatibility and constraint-compatibility, consistent with RAF views.

- KH550 and KH570 yield distinct coupling routes (phase-fraction–dominated vs. orientation-dominated).

- Performance changes arise from redistribution and pathway choice, not from a net increase in RAF.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wunderlich, B. Reversible crystallization and the rigid–amorphous phase in semicrystalline macromolecules. Prog. Polym. Sci. 2003, 28, 383–450. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Righetti, M.C. Crystallization-induced formation of rigid amorphous fraction. Polym. Cryst. 2018, 1, e10023. [Google Scholar] [CrossRef]

- Strobl, G. From the melt via mesomorphic and granular crystalline layers to lamellar crystallites: A major route followed in polymer crystallization? Eur. Phys. J. E 2000, 3, 165–183. [Google Scholar] [CrossRef]

- Gambichler, T.; Laperre, J.; Hoffmann, K. The European standard for sun-protective clothing: EN 13758. J. Eur. Acad. Dermatol. Venereol. 2006, 20, 125–130. [Google Scholar] [CrossRef]

- Strobl, G. The Physics of Polymers: Concepts for Understanding Their Structures and Behavior; Springer: Berlin/Heidelberg, Germany, 2007; pp. 1–518. [Google Scholar]

- Strobl, G. Colloquium: Laws controlling crystallization and melting in bulk polymers. Rev. Mod. Phys. 2009, 81, 1287–1300. [Google Scholar] [CrossRef]

- Mo, Z. A Method for the Non-Isothermal Crystallization Kinetics of Polymers. Acta Polym. Sin. 2008, 656–661. [Google Scholar] [CrossRef]

- Cheng, S.Z.D.; Wunderlich, B. Thermal analysis of thermoplastic polymers. Thermochim. Acta 1988, 134, 161–166. [Google Scholar] [CrossRef]

- Jeziorny, A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by d.s.c. Polymer 1978, 19, 1142–1144. [Google Scholar] [CrossRef]

- Keller, A. A note on single crystals in polymers: Evidence for a folded chain configuration. Philos. Mag. 1957, 2, 1171–1175. [Google Scholar] [CrossRef]

- Porter, R.S. Macromolecular physics, volume 3—crystal melting, Bernhard Wunderlich, Academic Press, New York, 1980, 363 pp. Price: $42.50. J. Polym. Sci. Polym. Lett. Ed. 1980, 18, 824. [Google Scholar] [CrossRef]

- Cheng, S.Z.D. Phase Transitions in Polymers: The Role of Metastable States; Elsevier: Oxford, UK, 2008. [Google Scholar]

- Zhang, F.; Sherrell, P.C.; Luo, W.; Chen, J.; Li, W.; Yang, J.; Zhu, M. Organic/Inorganic Hybrid Fibers: Controllable Architectures for Electrochemical Energy Applications. Adv. Sci. 2021, 8, e2102859. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, X.; Sun, B.; Chen, L.; Xiang, H.; Zhu, M.; Chen, Z.; Wang, S.; Zhou, Z. Organic-inorganic hybrid material and multifunctional fibers. Sci. Sin. Technol. 2014, 44, 1137–1144. [Google Scholar] [CrossRef]

- Cazan, C.; Enesca, A.; Andronic, L. Synergic Effect of TiO2 Filler on the Mechanical Properties of Polymer Nanocomposites. Polymers 2021, 13, 2017. [Google Scholar] [CrossRef]

- Righetti, M.C.; Di Lorenzo, M.L.; Cinelli, P.; Gazzano, M. Temperature dependence of the rigid amorphous fraction of poly(butylene succinate). RSC Adv. 2021, 11, 25731–25737. [Google Scholar] [CrossRef]

- Chen, B.; Torkelson, J.M. Rigid amorphous fraction and crystallinity in cold-crystallized syndiotactic polystyrene: Characterization by differential scanning calorimetry. Polymer 2021, 230, 124044. [Google Scholar] [CrossRef]

- Benz, J.; Bonten, C. Rigid amorphous fraction as an indicator for polymer-polymer interactions in highly filled plastics. Polymers 2021, 13, 3349. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q. Polymer Condensation Process and Phase Transition; Higher Education Press: Beijing, China, 2016. [Google Scholar]

- Klonos, P.; Pissis, P. Effects of interfacial interactions and of crystallization on rigid amorphous fraction and molecular dynamics in polylactide/silica nanocomposites: A methodological approach. Polymer 2017, 112, 228–243. [Google Scholar] [CrossRef]

- Ma, Q.; Pyda, M.; Mao, B.; Cebe, P. Relationship between the rigid amorphous phase and mesophase in electrospun fibers. Polymer 2013, 54, 2544–2554. [Google Scholar] [CrossRef]

- Klonos, P.; Terzopoulou, Z.; Koutsoumpis, S.; Zidropoulos, S.; Kripotou, S.; Papageorgiou, G.Z.; Bikiaris, D.N.; Kyritsis, A.; Pissis, P. Rigid amorphous fraction and segmental dynamics in nanocomposites based on poly(l–lactic acid) and nano-inclusions of 1–3D geometry studied by thermal and dielectric techniques. Eur. Polym. J. 2016, 82, 16–34. [Google Scholar] [CrossRef]

- Shayestehfar, S.; Yazdanshenas, M.E.; Khajavi, R.; Rashidi, A.-S. Physical and mechanical properties of nylon 6/titanium dioxide micro and nano-composite multifilament yarns. J. Eng. Fibers Fabr. 2014, 9, 155892501400900319. [Google Scholar] [CrossRef]

- Cot, M.; Mijas, G.; Prieto-Fuentes, R.; Riba-Moliner, M.; Cayuela, D. The Influence of Titanium Dioxide (TiO2) Particle Size and Crystalline Form on the Microstructure and UV Protection Factor of Polyester Substrates. Polymers 2024, 16, 475. [Google Scholar] [CrossRef] [PubMed]

- Polinska, M.; Rozanski, A.; Kozanecki, M.; Galeski, A. Elastic modulus of the amorphous phase confined between lamellae: The role of crystalline component. Polymer 2023, 269, 125753. [Google Scholar] [CrossRef]

- Zhao, J.; Alsubhi, A.; Rastogi, S. Differences in thermal stability of Rigid Amorphous Fraction in nascent UHMWiPPs and its implication on lamellae thickening. Polymer 2025, 331, 128489. [Google Scholar] [CrossRef]

- Dalod, A.R.; Henriksen, L.; Grande, T.; Einarsrud, M.A. Functionalized TiO2 nanoparticles by single-step hydrothermal synthesis: The role of the silane coupling agents. Beilstein J. Nanotechnol. 2017, 8, 304–312. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Nguyen, T.-D.; Vu, D.-T.; Dinh, D.-P.; Nguyen, A.-H.; Ly, T.-N.-L.; Dao, P.-H.; Nguyen, T.-L.; Bach, L.-G.; Thai, H.; et al. Modification of Titanium Dioxide Nanoparticles with 3-(Trimethoxysilyl)propyl Methacrylate Silane Coupling Agent. J. Chem. 2020, 2020, 1381407. [Google Scholar] [CrossRef]

- Meroni, D.; Lo Presti, L.; Di Liberto, G.; Ceotto, M.; Acres, R.G.; Prince, K.C.; Bellani, R.; Soliveri, G.; Ardizzone, S. A Close Look at the Structure of the TiO2-APTES Interface in Hybrid Nanomaterials and Its Degradation Pathway: An Experimental and Theoretical Study. J. Phys. Chem. C 2017, 121, 430–440. [Google Scholar] [CrossRef]

- Chen, Q.; Li, F.; Zhai, Z.; Li, S.; Cai, Y.; Li, Q. Effect of Interfacial Compatibility on Mechanical Property of Polyamide 6 Modified by Polyborosiloxane. Polymers 2025, 17, 392. [Google Scholar] [CrossRef]

- Ludas Dujmic, A.; Radicic, R.; Ercegovic Razic, S.; Cingesar, I.K.; Glogar, M.; Jurov, A.; Krstulovic, N. Characterization of Melt-Spun Recycled PA 6 Polymer by Adding ZnO Nanoparticles during the Extrusion Process. Polymers 2024, 16, 1883. [Google Scholar] [CrossRef] [PubMed]

- Du, S.; Wei, Y.; Ahmed, S.; Zhou, F.; Tan, Y.; Li, Y.; Wang, M.; Chen, X.; Zhou, W. Enhanced thermal stability and UV resistance of polyamide 6 filament fabric via in-situ grafting with methyl methacrylate. Colloids Surf. A Physicochem. Eng. Asp. 2022, 651, 129371. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, Y.; Fan, X.; Lv, Y.; Wang, Z.; Zhang, X.; Liu, T. Macromolecular PEI-modified carbon nanotubes as multifunctional additives in controlling crystallization and enhancing comprehensive performance of polyamide 6 nanocomposites. Compos. Commun. 2024, 51, 102057. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, J.; Liu, M. Interphase in Polymer Nanocomposites. JACS Au 2022, 2, 280–291. [Google Scholar] [CrossRef]

- Buccella, M.; Dorigato, A.; Rizzola, F.; Caldara, M.; Fambri, L. Influence of the processing parameters on the dispersion and coloration behavior of a halogenated copper phthalocyanine-based masterbatch. Adv. Polym. Technol. 2018, 37, 778–785. [Google Scholar] [CrossRef]

- Wang, L.; Xie, G.; Mi, X.; Zhang, B.; Du, Y.; Zhu, Q.; Yu, Z. Surface-Modified TiO2@SiO2 Nanocomposites for Enhanced Dispersibility and Optical Performance to Apply in the Printing Process as a Pigment. ACS Omega 2023, 8, 20116–20124. [Google Scholar] [CrossRef]

- Zhu, R.; Yadama, V.; Liu, H.; Lin, R.J.T.; Harper, D.P. Fabrication and characterization of Nylon 6/cellulose nanofibrils melt-spun nanocomposite filaments. Compos. Part A Appl. Sci. Manuf. 2017, 97, 111–119. [Google Scholar] [CrossRef]

- Fu, S.; Sun, Z.; Huang, P.; Li, Y.; Hu, N. Some basic aspects of polymer nanocomposites: A critical review. Nano Mater. Sci. 2019, 1, 2–30. [Google Scholar] [CrossRef]

- EN 13900-5:2005; Pigments and Extenders—Methods of Dispersion and Assessment of Dispersibility in Plastics—Part 5: Determination by Filter Pressure Value Test. CEN: Brussels, Belgium, 2005.

- Kissinger, H.E. Reaction Kinetics in Differential Thermal Analysis. Anal. Chem. 1957, 29, 1702–1706. [Google Scholar] [CrossRef]

- Akahira, T.; Sunose, T. Method of determining activation deterioration constant of electrical insulating materials. Res. Rep. Chiba. Inst. Technol. (Sci. Technol.) 1971, 16, 22–31. [Google Scholar]

- Nakamura, K.; Watanabe, T.; Katayama, K.; Amano, T. Some aspects of nonisothermal crystallization of polymers. I. Relationship between crystallization temperature, crystallinity, and cooling conditions. J. Appl. Polym. Sci. 1972, 16, 1077–1091. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Pérez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 2011, 520, 1–19. [Google Scholar] [CrossRef]

- Huang, Y.-P.; Chen, T.-K.; Tang, J.-W.; Yeh, C.; Tien, C.-H. Effect of PET melt spinning on TiO2 nanoparticle aggregation and friction behavior of fiber surface. Ind. Eng. Chem. Res. 2007, 46, 5548–5554. [Google Scholar] [CrossRef]

- Ismail, M.A.; Yousef, E.A.; Nasr, G.M. Surface modification of montmorillonite—MMT nanofiller: How it affects both the rigid amorphous fraction (RAF) and the physical properties of polyamide 66. Polym. Bull. 2025, 82, 3553–3611. [Google Scholar] [CrossRef]

- Li, C.; Xia, Z.; Wu, L.; Xiong, Y.; Chen, W. Strain-Dependent Evolution of the Rigid Amorphous Fraction of Low-Density Polyethylene under Deformation. Macromolecules 2025, 58, 2320–2335. [Google Scholar] [CrossRef]

- Feigin, L.; Svergun, D.I. Structure Analysis by Small-Angle X-Ray and Neutron Scattering; Springer: Boston, MA, USA, 1987; Volume 1. [Google Scholar]

- Rambo, R.P.; Tainer, J.A. Characterizing flexible and intrinsically unstructured biological macromolecules by SAS using the Porod-Debye law. Biopolymers 2011, 95, 559–571. [Google Scholar] [CrossRef]

- Glatter, O. Small Angle X-Ray Scattering; Academic Press: London, UK, 1982. [Google Scholar]

- Hermans, P.; Weidinger, A. Quantitative x-ray investigations on the crystallinity of cellulose fibers. A background analysis. J. Appl. Phys. 1948, 19, 491–506. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Silvestre, C. Non-isothermal crystallization of polymers. Prog. Polym. Sci. 1999, 24, 917–950. [Google Scholar] [CrossRef]

- AATCC TM183; Transmittance or Blocking of Erythemally Weighted Ultraviolet Radiation through Fabrics. American Association of Textile Chemists and Colorists (AATCC): Research Triangle Park, NC, USA, 2020.

- Bhattacharjee, S. DLS and zeta potential—What they are and what they are not? J. Control. Release 2016, 235, 337–351. [Google Scholar] [CrossRef] [PubMed]

- Scientific, T.F. Filter Pressure Value Test (FPV test)—A New Standard to Examine Master Batches; Application Note LR49-e; Thermo Fisher Scientific: Waltham, MA, USA, 2007. [Google Scholar]

- Müller, A.R.K.; Rupp, H. Quality of Dispersion—Standardised: The Filter Pressure Value as an Evaluation Tool. Kunststoffe Int. 2004, 94, 70–73. [Google Scholar]

- Zhang, X. Applications of Kinetic Methods in Thermal Analysis: A Review. Eng. Sci. 2020, 14, 1–13. [Google Scholar] [CrossRef]

- Feng, T.; Xiu-Hong, L.; Yu-Zhu, W.; Chun-Ming, Y.; Ping, Z.; Jin-You, L.; Zeng, J.; Chun-Xia, H.; Wen-Qiang, H.; Xiao-Yun, L.; et al. Small angle X-ray scattering beamline at SSRF. Nucl. Sci. Tech. 2015, 26. [Google Scholar] [CrossRef]

- Kieffer, J.; Karkoulis, D. PyFAI, a versatile library for azimuthal regrouping. J. Phys. Conf. Ser. 2013, 425, 202012. [Google Scholar] [CrossRef]

- Xu, H.; Ince, B.S.; Cebe, P. Development of the crystallinity and rigid amorphous fraction in cold-crystallized isotactic polystyrene. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 3026–3036. [Google Scholar] [CrossRef]

- Ogle, J.; Powell, D.; Amerling, E.; Smilgies, D.-M.; Whittaker-Brooks, L. Quantifying multiple crystallite orientations and crystal heterogeneities in complex thin film materials. CrystEngComm 2019, 21, 5707–5720. [Google Scholar] [CrossRef]

- Marrink, S.J.; Risselada, H.J.; Yefimov, S.; Tieleman, D.P.; de Vries, A.H. The MARTINI force field: Coarse grained model for biomolecular simulations. J. Phys. Chem. B 2007, 111, 7812–7824. [Google Scholar] [CrossRef]

- Alessandri, R.; Barnoud, J.; Gertsen, A.S.; Patmanidis, I.; De Vries, A.H.; Souza, P.C.T.; Marrink, S.J. Martini 3 coarse-grained force field: Small molecules. Adv. Theory Simul. 2022, 5, 2100391. [Google Scholar] [CrossRef]

- Abraham, M.J.; Murtola, T.; Schulz, R.; Páll, S.; Smith, J.C.; Hess, B.; Lindahl, E. GROMACS: High performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 2015, 1-2, 19–25. [Google Scholar] [CrossRef]

- Mousavifard, S.M.; Ghermezcheshme, H.; Mirzaalipour, A.; Mohseni, M.; de With, G.; Makki, H. PolySMart: A general coarse-grained molecular dynamics polymerization scheme. Mater. Horiz. 2023, 10, 2281–2296. [Google Scholar] [CrossRef] [PubMed]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; in ’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Luo, C.; Kröger, M.; Sommer, J.-U. Molecular dynamics simulations of polymer crystallization under confinement: Entanglement effect. Polymer 2017, 109, 71–84. [Google Scholar] [CrossRef]

- Mortezazadeh, S.; Jamali, Y.; Naderi-Manesh, H.; Lyubartsev, A.P. Implicit solvent systematic coarse-graining of dioleoylphosphatidylethanolamine lipids: From the inverted hexagonal to the bilayer structure. PLoS ONE 2019, 14, e0214673. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.P.; Alessandri, R.; Dominguez, M.; Araya-Osorio, R.; Grunewald, L.; Borges-Araujo, L.; Wu, S.; Marrink, S.J.; Souza, P.C.T.; Mera-Adasme, R. Bartender: Martini 3 Bonded Terms via Quantum Mechanics-Based Molecular Dynamics. J. Chem. Theory Comput. 2024, 20, 5763–5773. [Google Scholar] [CrossRef]

- Reith, D.; Putz, M.; Muller-Plathe, F. Deriving effective mesoscale potentials from atomistic simulations. J. Comput. Chem. 2003, 24, 1624–1636. [Google Scholar] [CrossRef]

- Moore, T.C.; Iacovella, C.R.; McCabe, C. Derivation of coarse-grained potentials via multistate iterative Boltzmann inversion. J. Chem. Phys. 2014, 140, 224104. [Google Scholar] [CrossRef]

- Neese, F. The ORCA program system. WIREs Comput. Mol. Sci. 2011, 2, 73–78. [Google Scholar] [CrossRef]

- Riplinger, C.; Sandhoefer, B.; Hansen, A.; Neese, F. Natural triple excitations in local coupled cluster calculations with pair natural orbitals. J. Chem. Phys. 2013, 139, 134101. [Google Scholar] [CrossRef]

- Kendall, R.A.; Dunning, T.H.; Harrison, R.J. Electron affinities of the first-row atoms revisited. Systematic basis sets and wave functions. J. Chem. Phys. 1992, 96, 6796–6806. [Google Scholar] [CrossRef]

- Lu, T.; Chen, F. Multiwfn: A multifunctional wavefunction analyzer. J. Comput. Chem. 2012, 33, 580–592. [Google Scholar] [CrossRef] [PubMed]

- Wilkes, G.L. An overview of the basic rheological behavior of polymer fluids with an emphasis on polymer melts. J. Chem. Educ. 1981, 58, 880. [Google Scholar] [CrossRef]

- Sangroniz, L.; Fernández, M.; Santamaria, A. Polymers and rheology: A tale of give and take. Polymer 2023, 271, 125811. [Google Scholar] [CrossRef]

- Pissis, P.; Klonos, P.; Kyritsis, A. Interfacial effects in polymer nanocomposites studied by dielectric and thermal techniques. In Proceedings of the 2011—14th International Symposium on Electrets, Piscataway, NJ, USA, 28–31 August 2011; pp. 67–68. [Google Scholar]

- Keddie, J.L.; Jones, R.A.L.; Cory, R.A. Interface and surface effects on the glass-transition temperature in thin polymer films. Faraday Discuss. 1994, 98, 219–230. [Google Scholar] [CrossRef]

- Yu, D.; Wang, J.; Wang, G. Glass fiber treated with a glycine bridged silane coupling agent reinforcing polyamide 6(PA6): Effect of hydrogen bonding. RSC Adv. 2025, 15, 3331–3338. [Google Scholar] [CrossRef]

- Doi, M.; Edwards, S.F.; Edwards, S.F. The Theory of Polymer Dynamics; Oxford University Press: Oxford, UK, 1988; Volume 73. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- Landel, R.F.; Nielsen, L.E. Mechanical Properties of Polymers and Composites; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Allen, N.S.; Chirinis-Padron, A.; Henman, T.J. The photo-stabilisation of polypropylene: A review. Polym. Degrad. Stab. 1985, 13, 31–76. [Google Scholar] [CrossRef]

- Ward, I.M.; Sweeney, J. Mechanical Properties of Solid Polymers; Wiley Online Library: Chichester, UK, 1971; Volume 313. [Google Scholar]

- Forrest, J.A.; Dalnoki-Veress, K. The glass transition in thin polymer films. Adv. Colloid Interface Sci. 2001, 94, 167–195. [Google Scholar] [CrossRef]

- Blachnio, M.; Zienkiewicz-Strzalka, M.; Derylo-Marczewska, A.; Nosach, L.V.; Voronin, E.F. Chitosan-Silica Composites for Adsorption Application in the Treatment of Water and Wastewater from Anionic Dyes. Int. J. Mol. Sci. 2023, 24, 11818. [Google Scholar] [CrossRef] [PubMed]

| Sample ID | Silane Coupling Agent | TiO2 Content (wt%) | Draw Ratio |

|---|---|---|---|

| pure PA6 | None | 0 | 3.0 |

| PA6-1.6 wt% TiO2-KH550 | KH550 | 1.6 | 3.0 |

| PA6-4.0 wt% TiO2-KH550 | KH550 | 4.0 | 3.0 |

| PA6-4.0 wt% TiO2-KH570 | KH570 | 4.0 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Liu, P.; Ji, X.; Jiang, X.; Sun, B. Interphase-Resolved Performance in PA6/TiO2 Nanocomposite Fibers: Four-Phase Geometry Linking Structure to Mechanical and UV Protection. Polymers 2025, 17, 2551. https://doi.org/10.3390/polym17182551

Yu H, Liu P, Ji X, Jiang X, Sun B. Interphase-Resolved Performance in PA6/TiO2 Nanocomposite Fibers: Four-Phase Geometry Linking Structure to Mechanical and UV Protection. Polymers. 2025; 17(18):2551. https://doi.org/10.3390/polym17182551

Chicago/Turabian StyleYu, Hailong, Ping Liu, Xiaohuan Ji, Xiaoze Jiang, and Bin Sun. 2025. "Interphase-Resolved Performance in PA6/TiO2 Nanocomposite Fibers: Four-Phase Geometry Linking Structure to Mechanical and UV Protection" Polymers 17, no. 18: 2551. https://doi.org/10.3390/polym17182551

APA StyleYu, H., Liu, P., Ji, X., Jiang, X., & Sun, B. (2025). Interphase-Resolved Performance in PA6/TiO2 Nanocomposite Fibers: Four-Phase Geometry Linking Structure to Mechanical and UV Protection. Polymers, 17(18), 2551. https://doi.org/10.3390/polym17182551