Effect of Nano Ferrochrome Slag-Infused Polymer Matrix on Mechanical Properties of Bidirectional Carbon Fiber-Reinforced Polymer Composite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

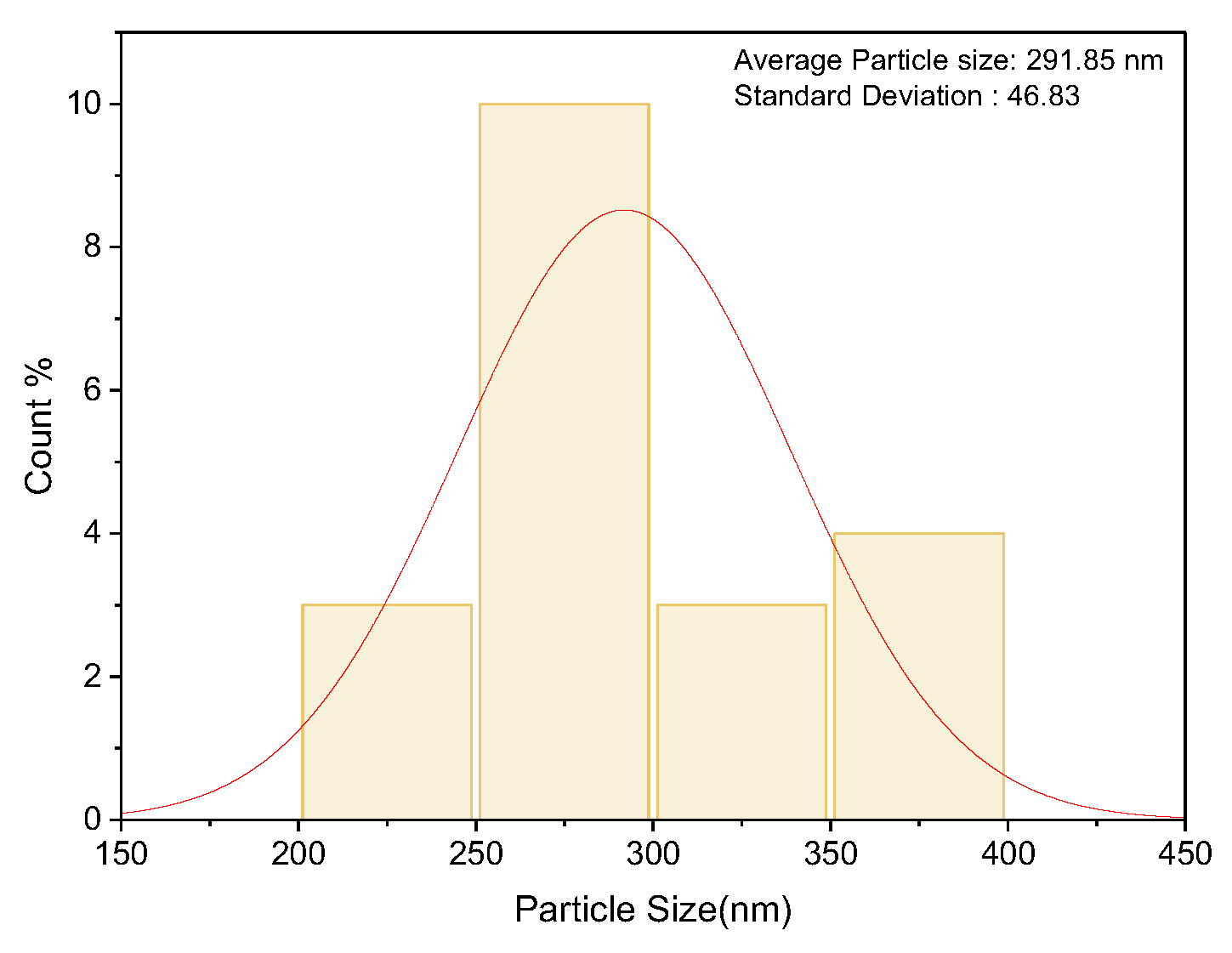

2.2. Preparation of Nanofillers

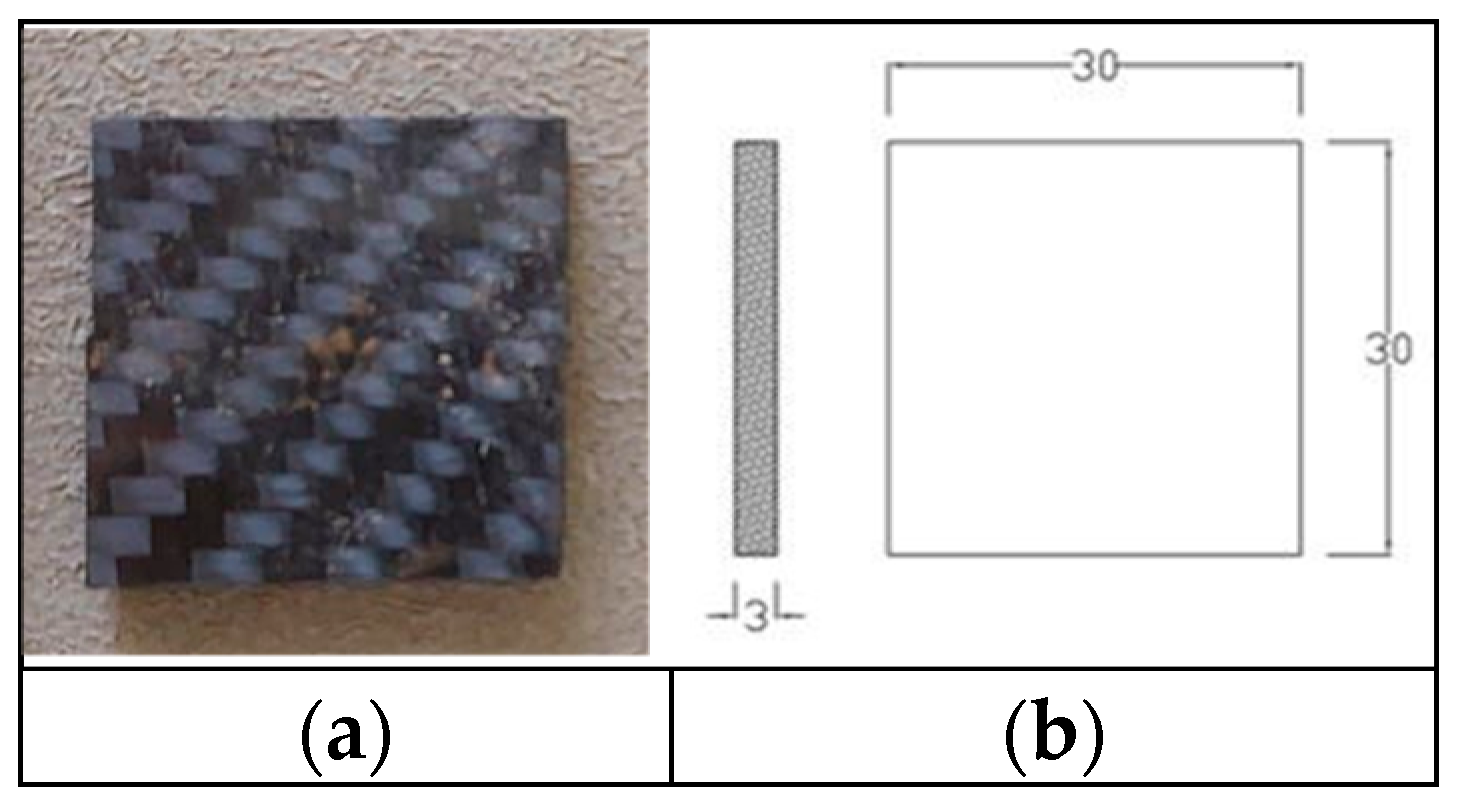

2.3. Composite Fabrication

2.4. Mechanical Testing

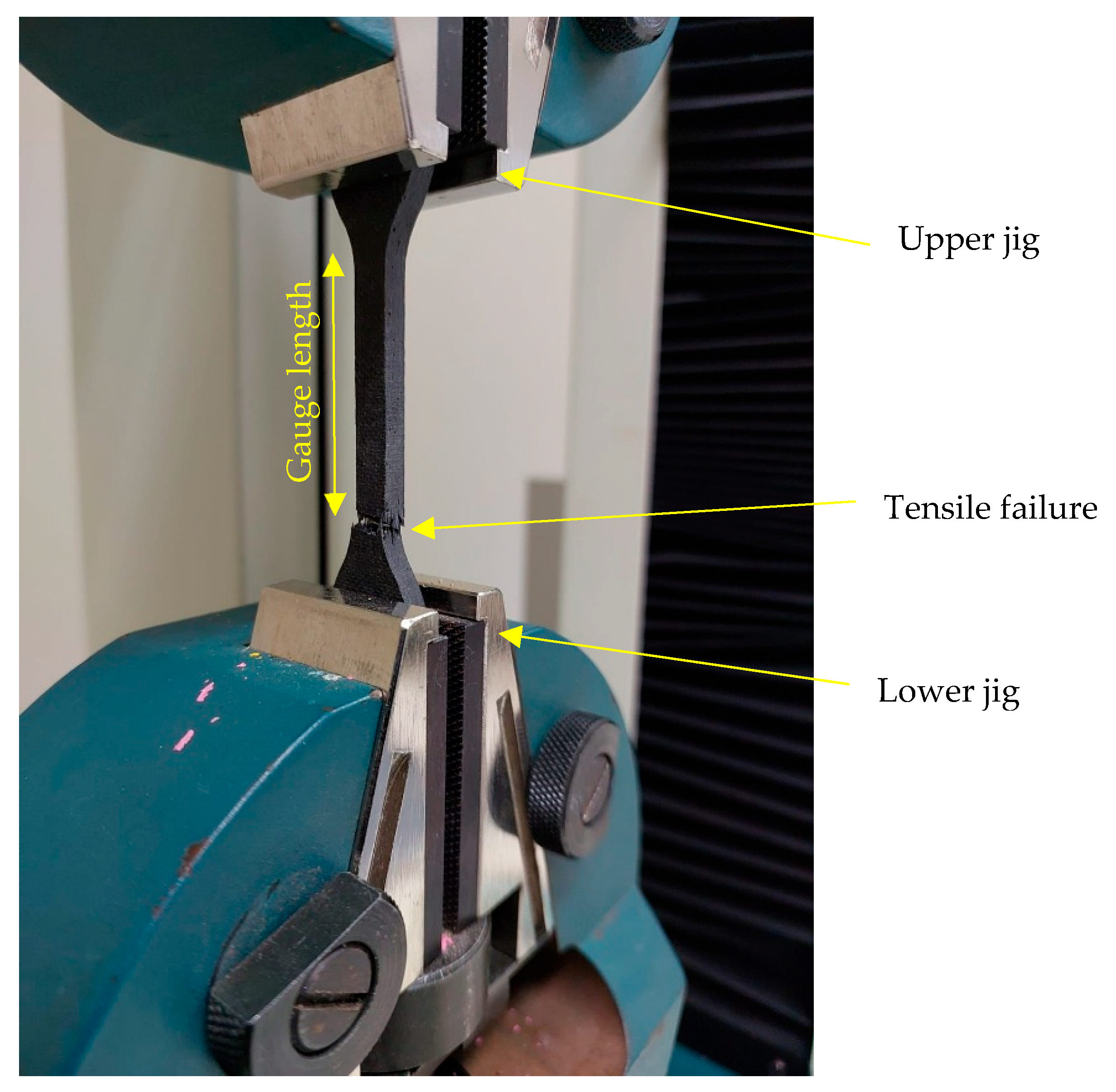

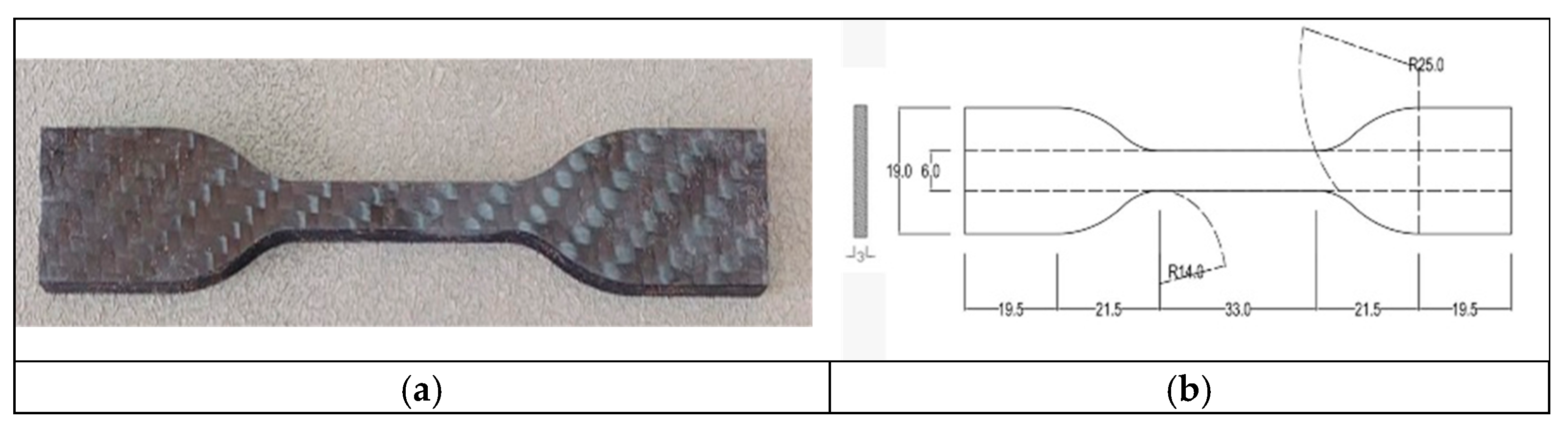

2.4.1. Tensile Test (ASTM D638)

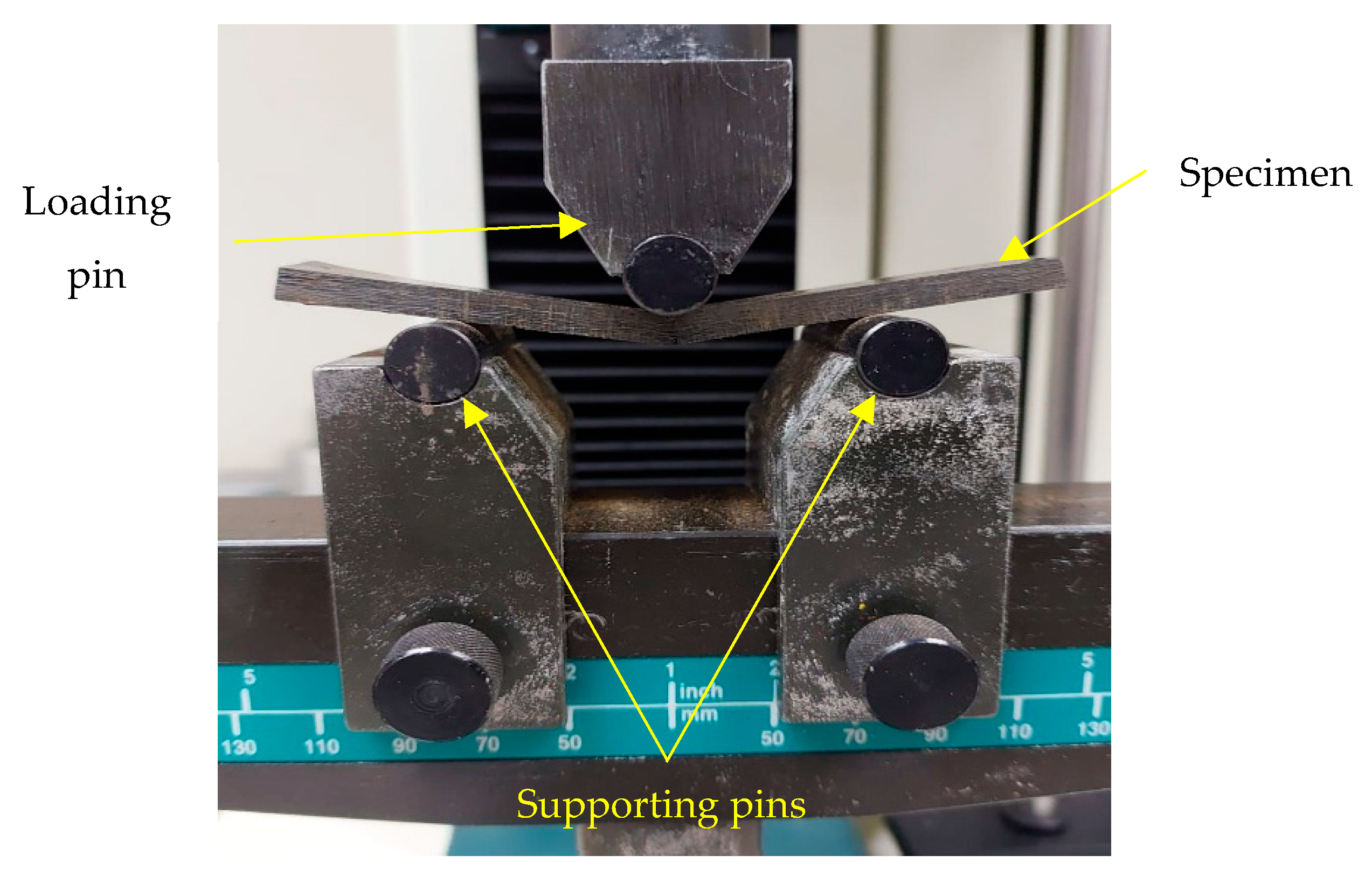

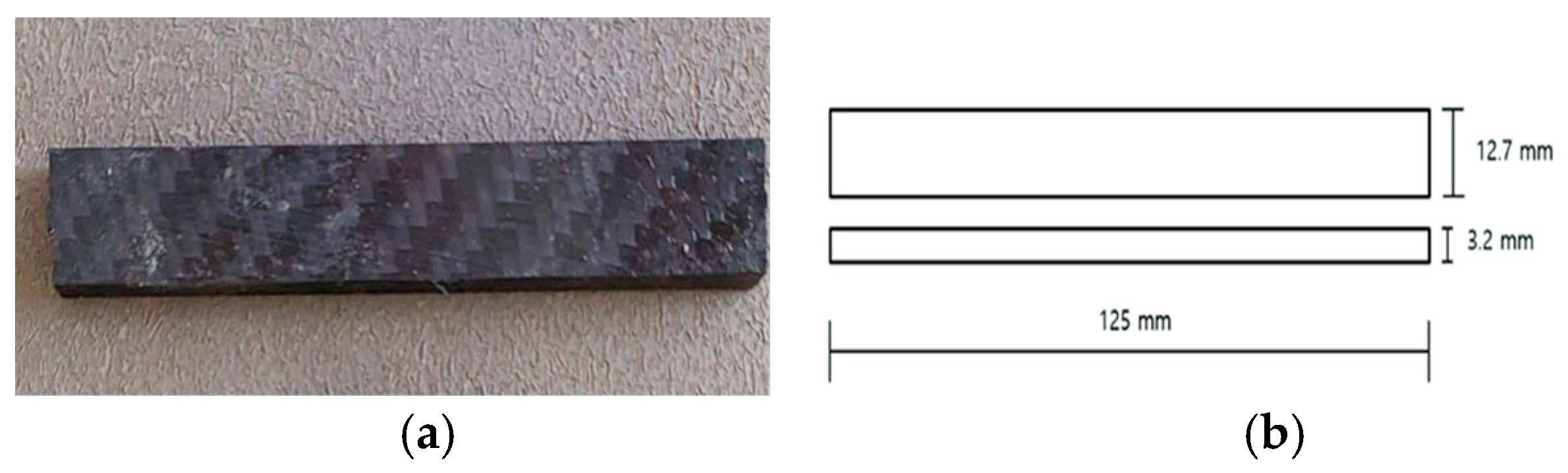

2.4.2. Flexural Test (ASTM D790)

2.4.3. Hardness Test (Shore D, ASTM D2240)

2.4.4. Impact Test (ISO 179)

3. Results and Discussion

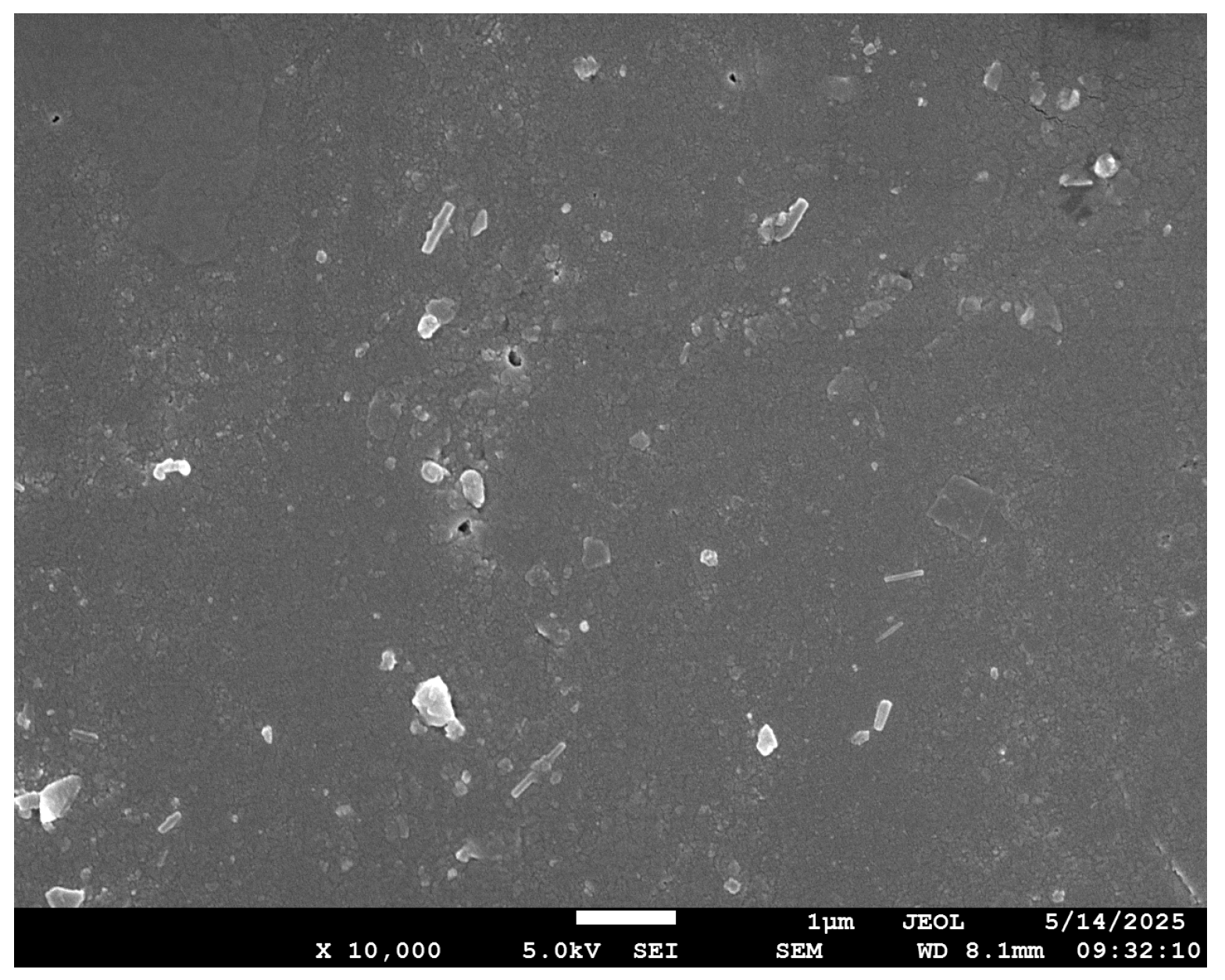

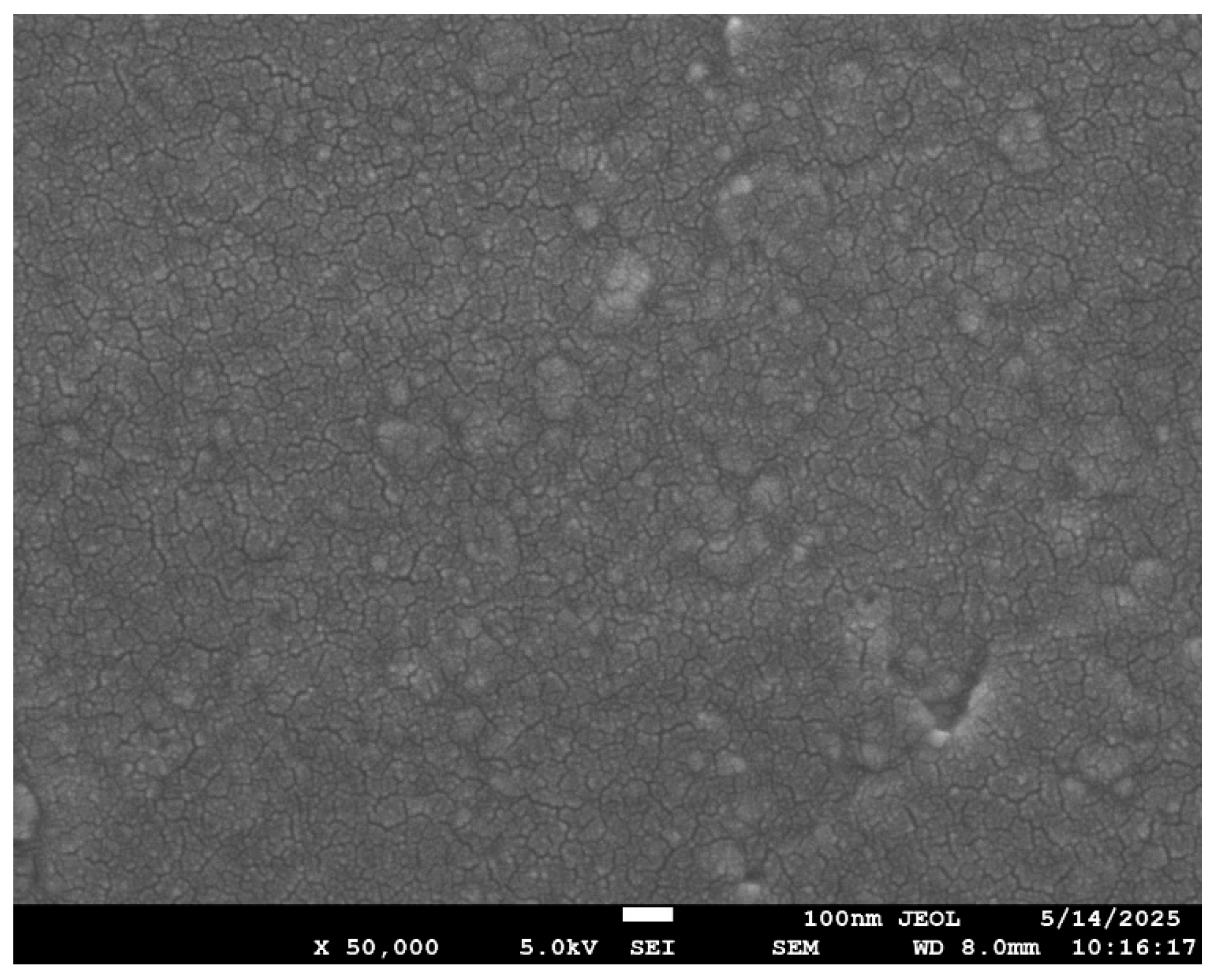

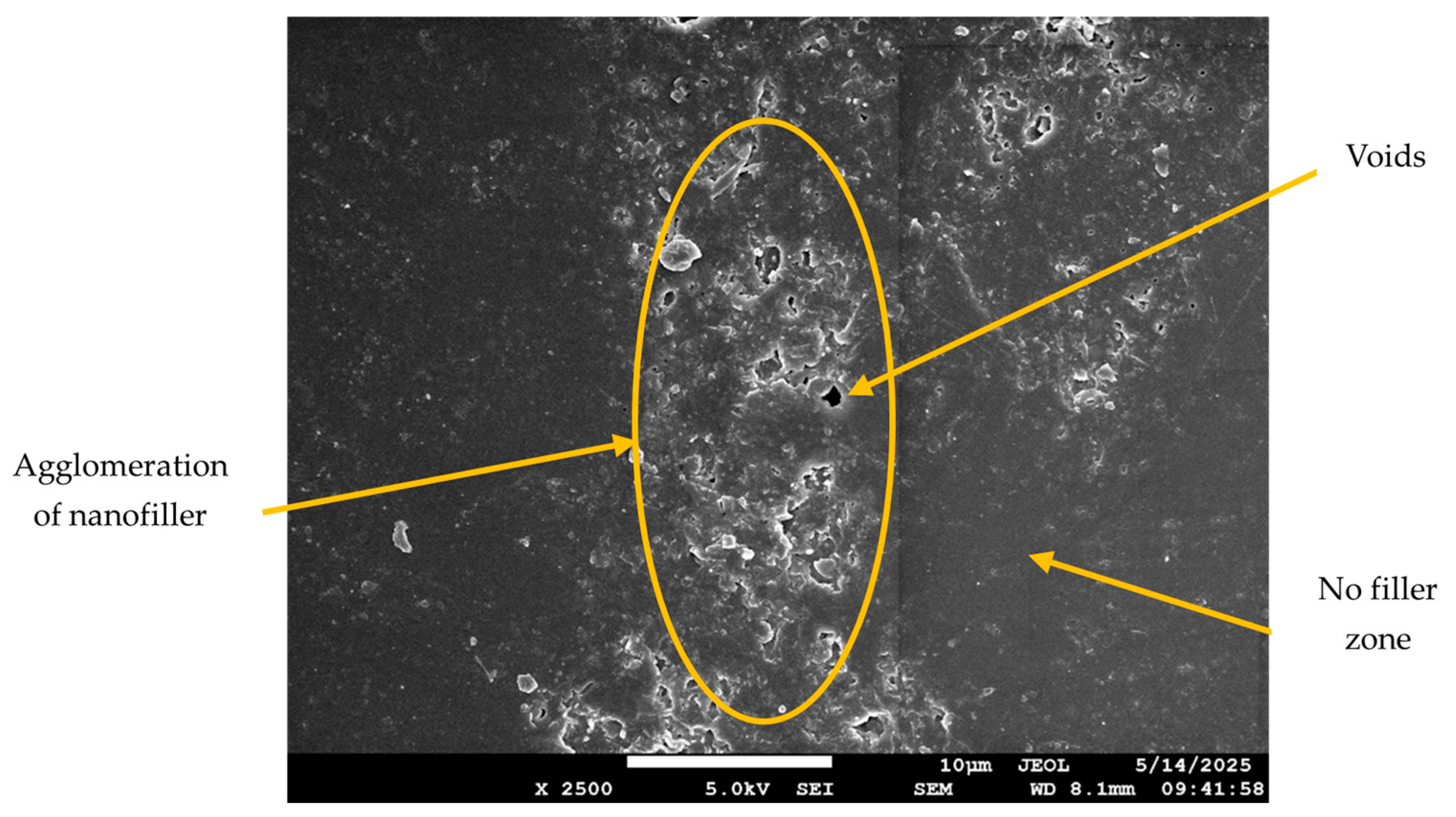

3.1. SEM Analysis

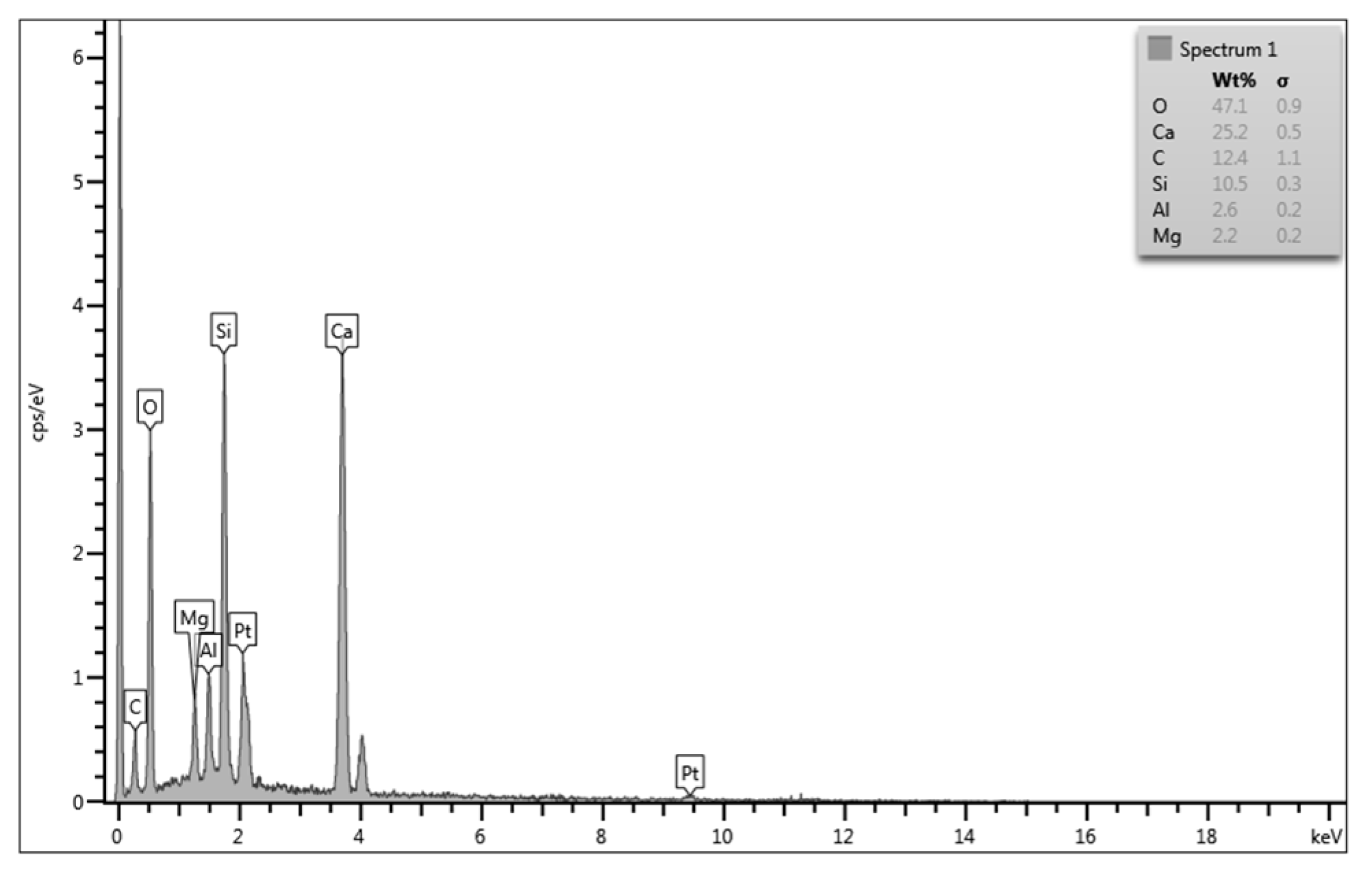

3.2. EDS Analysis

3.3. XRD Analysis

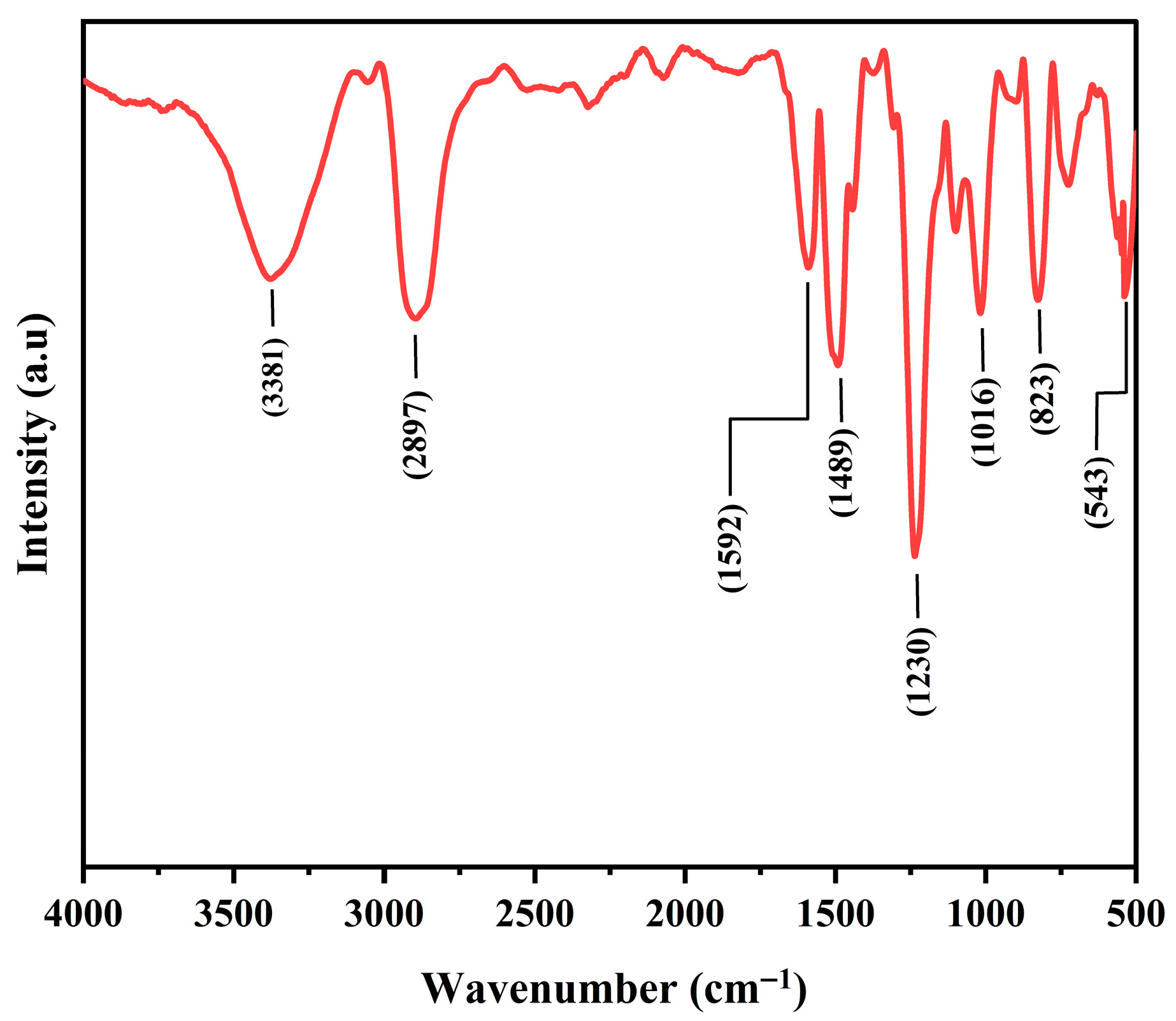

3.4. Fourier Transform Infrared Spectra (FTIR) Analysis

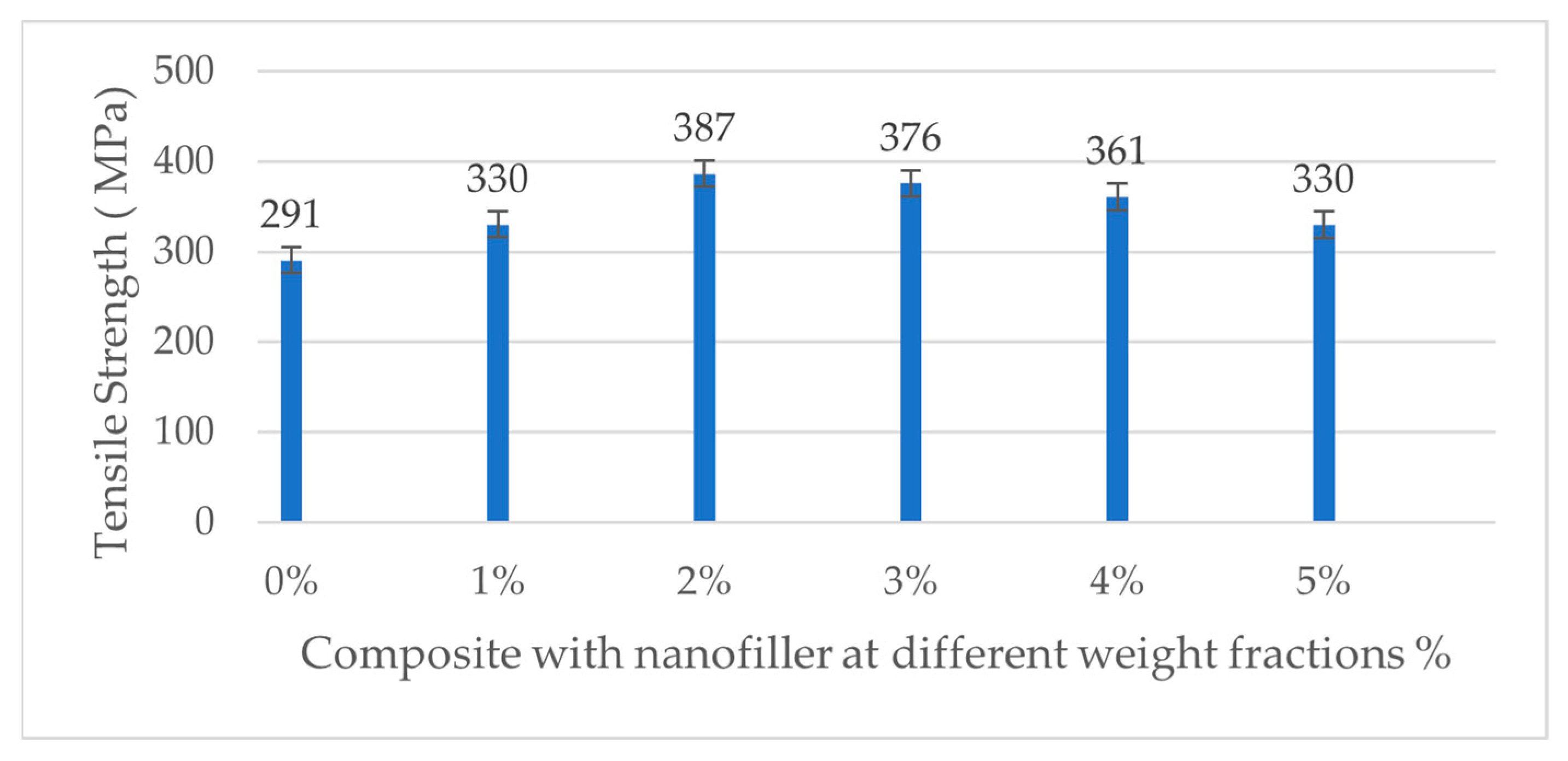

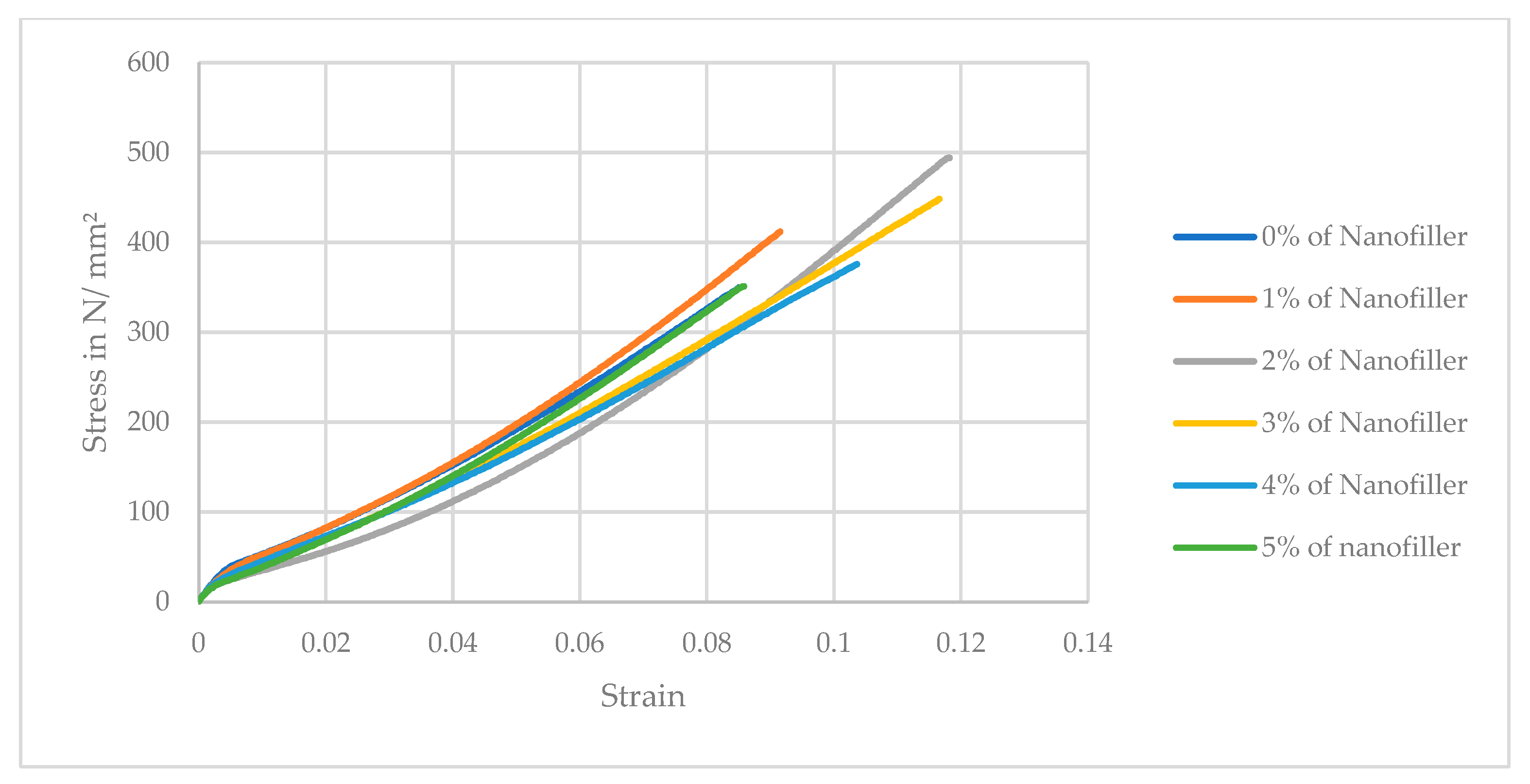

3.5. Tensile Strength

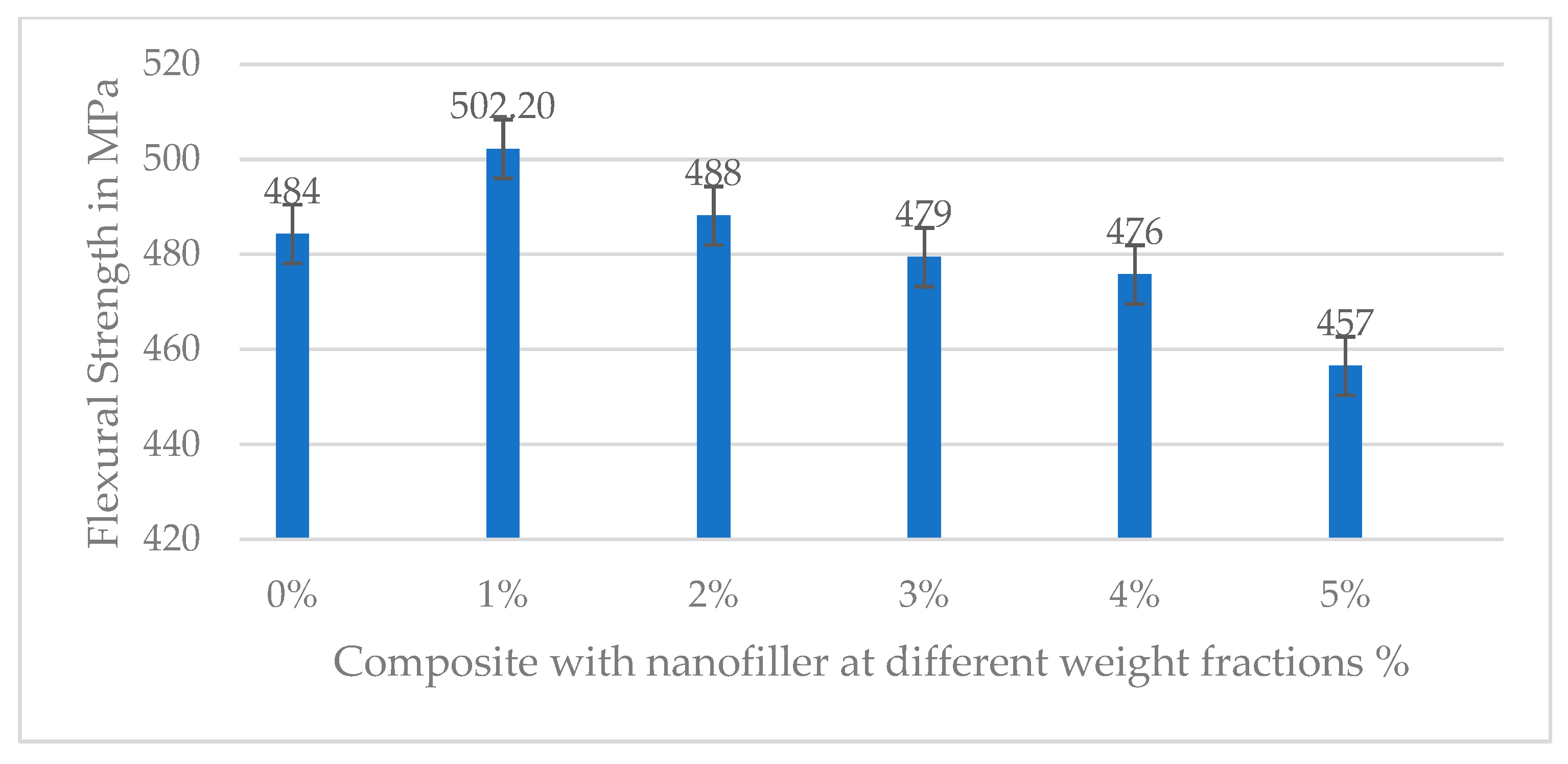

3.6. Flexural Strength

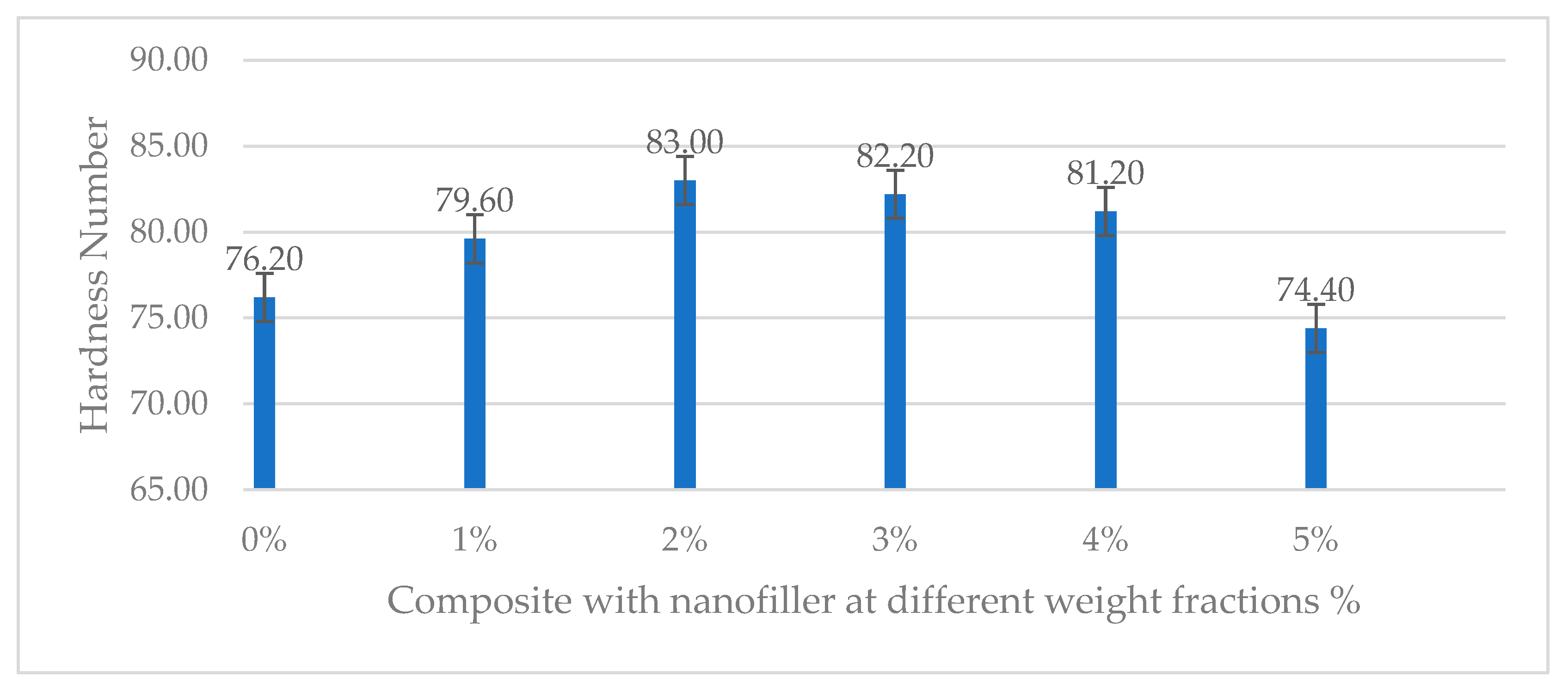

3.7. Hardness Results

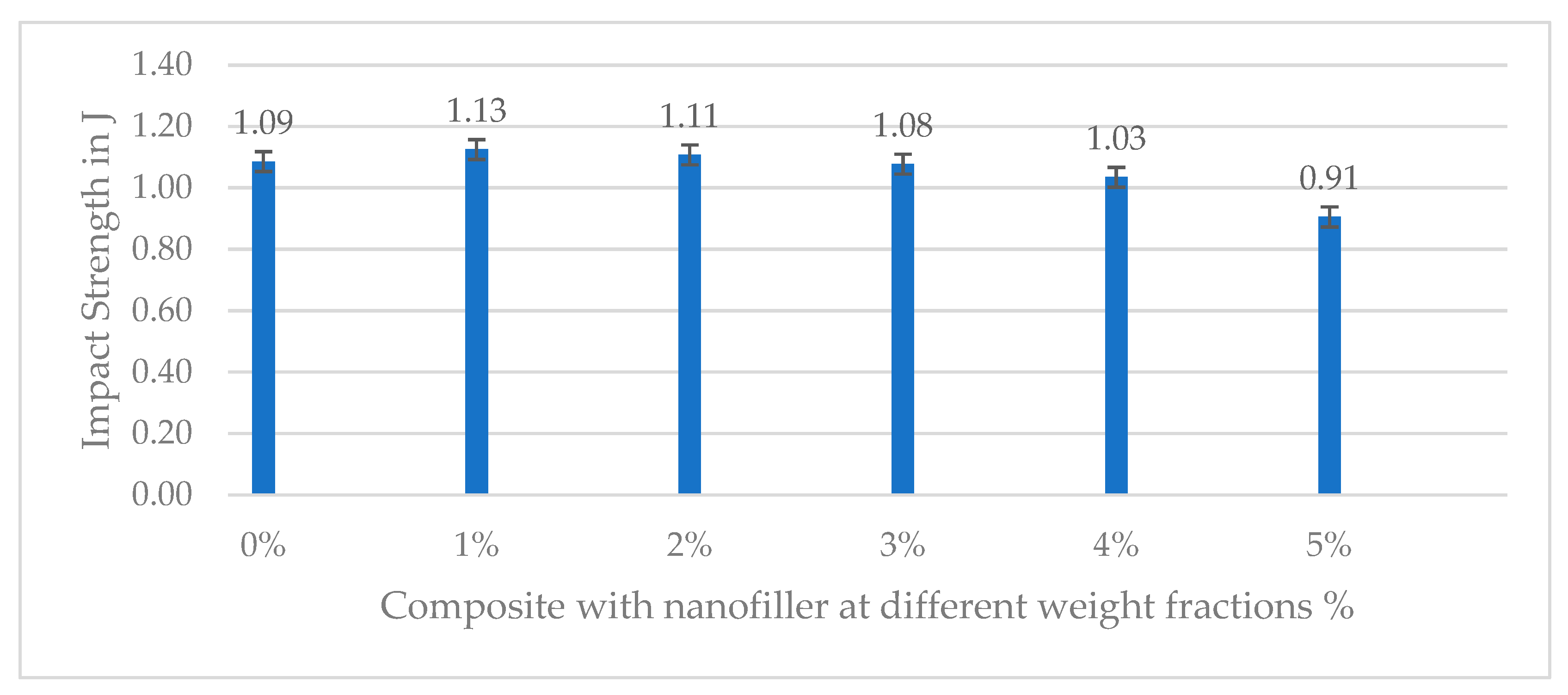

3.8. Impact Strength

4. Conclusions

- Mechanical characterization revealed that the incorporation of slag nanofillers at low concentrations (specifically 1–2 wt.%) led to moderate improvements in tensile and flexural strength, while also enhancing impact resistance and surface hardness.

- SEM analysis indicates uniform dispersion of nanofillers at low filler addition, whereas higher loading results in significant agglomeration and the presence of voids.

- Optimal performance was achieved at 2 wt.% for tensile strength (386.7 MPa) and hardness (83), and at 1 wt.% for flexural strength (502.2 MPa) and impact energy absorption (1.13 J). These enhancements are attributed to improved stress transfer, matrix stiffening, and potential crack-arresting mechanisms introduced by the well-dispersed hard ceramic phases within the ferrochrome slag.

- Beyond the optimum level (i.e., 1–2 wt.% filler addition), increasing the filler content above 1 wt.% for flexural and impact properties and above 2 wt.% for tensile and hardness resulted in a decline in performance. This reduction is due to poor dispersion, nanofiller agglomeration, and the formation of voids or weak interfaces that act as stress concentrators.

- Ferrochrome slag nanofillers offer a promising route for enhancing epoxy-based CFRP systems at the optimum filler addition. This approach not only improves mechanical performance but also supports sustainable engineering practices by reducing industrial waste and promoting material reuse.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.; Jiang, Y.; Chen, D.; Zhang, X.; Yan, P.; Wang, B.; Lin, Q. Strengthening Effect of the CFRP Method on Fire-Damaged Segments. Tunn. Undergr. Space Technol. 2024, 154, 105871. [Google Scholar] [CrossRef]

- Shahabaz, S.M.; Shetty, P.K.; Shetty, N.; Sharma, S.; Divakara Shetty, S.; Naik, N. Effect of Alumina and Silicon Carbide Nanoparticle-Infused Polymer Matrix on Mechanical Properties of Unidirectional Carbon Fiber-Reinforced Polymer. J. Compos. Sci. 2022, 6, 381. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Pulikkalparambil, H.; Rangappa, S.M.; Siengchin, S. Epoxy Composites; Wiley Online Library: New York, NY, USA, 2021; ISBN 3527824073. [Google Scholar]

- Weng, Y.; Liu, K.; Ou, Y.; Li, J.; Mao, D. Towards Developing Advanced CFRP with Simultaneously Enhanced Fracture Toughness and In-plane Properties via Interleaving CNT/PEI Hybrid Veils. Polym. Compos. 2024, 45, 12338–12348. [Google Scholar] [CrossRef]

- Han, Y.; Shi, Z.; Hua, C.; Sang, Y.; Gao, H.; Wang, Y. Analysis of Mechanical and Vibration Properties of Carbon Fiber Reinforced Polymer Matrix Composites with SiO2/Al2O3 Micron Particles. Polym. Compos. 2025, 46, 4800–4814. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H. Enhancing Adhesion Behaviour of Steel and CFRP Rebars in Al2O3 Nanoparticle-Reinforced Concrete: Insights from Experimental and Finite Element Analyses. Aust. J. Struct. Eng. 2025, 1–14. [Google Scholar] [CrossRef]

- Gupta, R.; Kumar, G.; Bisaria, H.; Zafar, S. Effect of Graphene Nanoparticles on Electrical, Mechanical and Viscoelastic Behavior of CFRP Multifunctional Multiscale Composites. Polym. Compos. 2025, 46, 6885–6899. [Google Scholar] [CrossRef]

- Kiran, M.D.; Lokesh Yadhav, B.R.; Babbar, A.; Kumar, R.; Sharath Chandra, H.S.; Shetty, R.P.; Sudeepa, K.B.; Sampath Kumar, L.; Kaur, R.; Meshel, Q.; et al. Alkahtani Tribological Properties of CNT-Filled Epoxy-Carbon Fabric Composites: Optimization and Modelling by Machine Learning. J. Mater. Res. Technol. 2024, 28, 2582–2601. [Google Scholar] [CrossRef]

- Shcherbakov, A.S.; Mostovoy, A.S.; Yakovlev, N.A.; Arzamastsev, S.V. Effect of Carbon Nanotube Functionalization on the Physicochemical and Mechanical Properties of Modified Fiber-Reinforced Composites Based on an Epoxy Resin. Russ. J. Appl. Chem. 2021, 94, 1080–1087. [Google Scholar] [CrossRef]

- Bunea, M. The Effect of Stacking Sequence on the Impact Response of Fabric Reinforced Epoxy Hybrid Composites. In Proceedings of the Patrimoniul Cultural de Ieri–Implicaţii în Dezvoltarea Societăţii Durabile de Mâine, Iasi, Romania, 26–27 September 2024; p. 102. [Google Scholar]

- Rashid, N.A.; Mahan, H.M.; Shabeeb, O.A. The Effect of Silicon-Carbide Additions on the Mechanical and Thermal Conductivity Properties of Fiber-Reinforced Epoxy Composites. Mater. Tehnol. 2024, 58, 793–799. [Google Scholar] [CrossRef]

- Ba-Gubair, A.-H.M.; Kok, C.K.; Lau, S.T.W.; Yaakob, Y. Effects of Loading and Silane Treatment of Alumina Nanoparticles in CFRP Composite. AIP Conf. Proc. 2024, 3240, 20020. [Google Scholar] [CrossRef]

- Bodduru, K.; Palanippan, S.K.; Siengchin, S.; Kassa, M.K.; Singh, L.K. Synergistic Effect of MXene-CNT as Effective Nanofillers for Enhancing the Vibration Properties of Honeycomb Cored Sandwich Composite Plates: An Experimental and Numerical Study. Polym. Compos. 2025, 46, 5938–5963. [Google Scholar] [CrossRef]

- Somashekar, D.G.; Eswaregowda, N.B.; Bheemappa, S. Adhesive Wear Characteristics of Mono and Hybrid CF/Ep Composite with Nano-HAP Filler. J. Met. Mater. Miner. 2024, 34, 2040. [Google Scholar] [CrossRef]

- Amal, O.P.; Murugan, V.S. Impact Strength of Hybrid Aluminum Sheet and Synthetic Reinforced Epoxy Composite-A Comparative Analysis. AIP Conf. Proc. 2024, 2853, 20083. [Google Scholar]

- Hang, M.; Wang, J.; Zhou, X.; Sun, M. Design and Study of Physical and Mechanical Properties of Concrete Based on Ferrochrome Slag and Its Mechanism Analysis. Buildings 2023, 13, 54. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Shoukry, H.; Khalil, I.S.; Nasir, S.; Hassan, H.F. Reuse of Waste Ferrochrome Slag in the Production of Mortar with Improved Thermal and Mechanical Performance. J. Mater. Civ. Eng. 2018, 30, 4018152. [Google Scholar] [CrossRef]

- Rajashekar, K.; Reddy, C.S. An Experimental Study on Use of Ferrochrome Slag Aggregate in Concrete Making. ICI J. 2015, 15, 25–29. [Google Scholar]

- Shahabaz, S.M.; Mehrotra, P.; Kalita, H.; Sharma, S.; Naik, N.; Noronha, D.J.; Shetty, N. Effect of Al2O3 and SiC Nano-Fillers on the Mechanical Properties of Carbon Fiber-Reinforced Epoxy Hybrid Composites. J. Compos. Sci. 2023, 7, 133. [Google Scholar] [CrossRef]

- Praneeth, H.R.; Patil, S.; Budavi, P.; Srinivas, G.S.; Usman, M.; Pasha, S. Study of Effect of Carbon Nanotube on Tensile, Impact and Flexural Properties of Carbon Fibre/Epoxy Reinforcement Polymer. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1248, 12088. [Google Scholar] [CrossRef]

- Agnihotri, S.N.; Thakur, R.K.; Singh, K.K. Influence of Nanoclay Filler on Mechanical Properties of CFRP Composites. Mater. Today Proc. 2022, 66, 1734–1738. [Google Scholar] [CrossRef]

- Raja, T.; Devarajan, Y.; Kailiappan, N. Study on Enhancing Mechanical and Thermal Properties of Carbon Fiber Reinforced Epoxy Composite through Zinc Oxide Nanofiller. Discov. Appl. Sci. 2024, 6, 566. [Google Scholar] [CrossRef]

- Hao, W.; Guoquan, L. Ferrite, Structure and Characteristic Of. In The ECPH Encyclopedia of Mining and Metallurgy; Springer: Berlin/Heidelberg, Germany, 2024; pp. 643–644. [Google Scholar]

- Mugivhi, F.F. Exploring Beneficial Uses of Ferrochrome Slag: A Case Study of a South African Ferrochrome Industry. Master’s Thesis, North-West University, Potchefstroom, South Africa, 2020. [Google Scholar]

- Shi, C. Steel Slag—Its Production, Processing, Characteristics, and Cementitious Properties. J. Mater. Civ. Eng. 2004, 16, 230–236. [Google Scholar] [CrossRef]

- Wu, B.; Chen, R.; Fu, R.; Agathopoulos, S.; Su, X.; Liu, H. Low Thermal Expansion Coefficient and High Thermal Conductivity Epoxy/Al2O3/T-ZnOw Composites with Dual-Scale Interpenetrating Network Structure. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105993. [Google Scholar] [CrossRef]

- Ma, B.; Zan, W.; Liu, K.; Mu, X.; Deng, C.; Huang, A. Preparation and Properties of Porous MgO Based Ceramics from Magnesite Tailings and Fused Magnesia. Ceram. Int. 2023, 49, 19072–19082. [Google Scholar] [CrossRef]

- Long, Z.; Pang, H.; Gao, S.; Yue, H.; Lan, X.; Peng, D.; Zhou, M. Improvement and Prediction Technology of the Water-Side Corrosion of Zirconium Alloy: The Developmental Tendency. J. Phys. Conf. Ser. 2024, 2821, 12016. [Google Scholar] [CrossRef]

- Khan, M.I.; Amari, A.; Mustafa, A.; Shoukry, H.; Ali, I.H.; Umoren, S.A.; Kumar, A.M. Synthesis, Characterization and Application of Ferrochrome Slag/Polyaniline Nanocomposite as Corrosion Protection Coatings for Carbon Steel. Int. J. Electrochem. Sci. 2018, 13, 7385–7396. [Google Scholar] [CrossRef]

- Jiao, M.; Rong, Z.; Zhang, L. A Critical Review of the Material Characteristics, Utilizations, Limitations, and Advanced Applications of Ferrochrome Slag. Constr. Build. Mater. 2024, 426, 136180. [Google Scholar] [CrossRef]

- Das, S.K.; Tripathi, A.K.; Kandi, S.K.; Mustakim, S.M.; Bhoi, B.; Rajput, P. Ferrochrome Slag: A Critical Review of Its Properties, Environmental Issues and Sustainable Utilization. J. Environ. Manag. 2023, 326, 116674. [Google Scholar] [CrossRef]

- Mishra, J.; Nanda, B.; Patro, S.K.; Das, S.K.; Mustakim, S.M. Strength and Microstructural Characterization of Ferrochrome Ash-and Ground Granulated Blast Furnace Slag-Based Geopolymer Concrete. J. Sustain. Metall. 2022, 8, 156–169. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A. Geopolymers vs. Cement Matrix Materials: How Nanofiller Can Help a Sustainability Approach for Smart Construction Applications—A Review. Nanomaterials 2021, 11, 2007. [Google Scholar] [CrossRef] [PubMed]

- Doğan, F.; Dehghanpour, H.; Subaşı, S.; Maraşlı, M. Characterization of Carbon Fiber Reinforced Conductive Mortars Filled with Recycled Ferrochrome Slag Aggregates. J. Sustain. Constr. Mater. Technol. 2022, 7, 145–157. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Zhang, J.; Mouritz, A.P.; Wang, C.H. Improving the Toughness and Electrical Conductivity of Epoxy Nanocomposites by Using Aligned Carbon Nanofibres. Compos. Sci. Technol. 2015, 117, 146–158. [Google Scholar] [CrossRef]

- ASTM D638; ASTM International Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D790; ASTM International Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D2240; ASTM International Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2015.

- ISO 179; Plastics—Determination of Charpy Impact Properties. International Organization for Standardization: Geneva, Switzerland, 2010.

- Gobetti, A.; Cornacchia, G.; Ramorino, G. Innovative Reuse of Electric Arc Furnace Slag as Filler for Different Polymer Matrixes. Minerals 2021, 11, 832. [Google Scholar] [CrossRef]

- Sathiya Narayanan, N.; Sai Venkat Mohan, D.; Abhinay, J.; Dinesh, T.; Satya Sai Surya Teja, V.; Praneeth, R. Effects on Microhardness, Tensile Strength, Deflection, and Drop Weight Impact Resistance with the Addition of Hybrid Filler Materials for Enhancing GFRP Composites. Sci. Rep. 2024, 14, 27524. [Google Scholar] [CrossRef]

- Huang, J.; Rodrigue, D. The Effect of Carbon Nanotube Orientation and Content on the Mechanical Properties of Polypropylene Based Composites. Mater. Des. 2014, 55, 653–663. [Google Scholar] [CrossRef]

- Aryaswara, L.G.; Kusni, M.; Wijanarko, D.; Muflikhun, M.A. Advanced Properties and Failure Characteristics of Hybrid GFRP-Matrix Thin Laminates Modified by Micro Glass Powder Filler for Hard Structure Applications. J. Eng. Res. 2025, 13, 142–155. [Google Scholar] [CrossRef]

| Type of Filler | Mechanical Properties | Loading Range | Enhancement | References |

|---|---|---|---|---|

| Alumina (Al2O3) | Tensile Strength | 1.75 wt.% | 29.54% | [2] |

| Flexural Strength | 31.76% | |||

| Impact | 47.51% | |||

| Hardness (HB) | 47 | |||

| Silicon carbide (SiC) | Tensile Strength | 1.25 wt.% | 25.75% | [19] |

| Flexural Strength | 12.79% | |||

| Impact | 30.45% | |||

| Hardness (HB) | 43 | |||

| Carbon nanotube (CNT) | Tensile Strength | 1 wt.% | 10.4% | [20] |

| Flexural Strength | 41.86% | |||

| Impact | 53.25% | |||

| Nanoclay | Tensile Strength | 2.50 wt.% | 10.4% | [21] |

| Flexural Strength | 41.86% | |||

| Zinc oxide (ZnO) | Tensile Strength | 15 g | 24% | [22] |

| Flexural Strength | 26% | |||

| Impact | 18% | |||

| Hardness (HRC) | 16 |

| Sample No. | Carbon Fiber Weight % | Epoxy Resin and Hardener Weight % | Nanofiller Weight % |

|---|---|---|---|

| 1 | 50% | 50% | 0% |

| 2 | 50% | 49% | 1% |

| 3 | 50% | 48% | 2% |

| 4 | 50% | 47% | 3% |

| 5 | 50% | 46% | 4% |

| 6 | 50% | 45% | 5% |

| Total Time (min) | No of Milling Cycles | Speed (Rpm) | Ball Material | No of Milling Balls Used |

|---|---|---|---|---|

| 105 | 7 cycles with 15 min on, 15 min off | 400 | Ceramics | Large-6 Medium-60 Small-600 |

| Count | Mean (nm) | Standard Deviation | Minimum (nm) | Median (nm) | Maximum (nm) |

|---|---|---|---|---|---|

| 20 | 291.85 | 46.83 | 5837 | 287 | 397 |

| Element | Weight % | Atomic % |

|---|---|---|

| Calcium (Ca) | 25.2 | 0.5 |

| Silicon (Si) | 10.5 | 0.3 |

| Aluminum (Al) | 2.6 | 0.2 |

| Magnesium (Mg) | 2.2 | 0.2 |

| Oxygen (O) | 47.1 | 0.9 |

| Carbon (C) | 12.4 | 1.1 |

| Composite | Tensile Strength (MPa) | Strength Gain % | |

|---|---|---|---|

| Average | Std. Dev. | ||

| Neat CFRP | 290.7 | 63.79 | - |

| 1% of Nanofiller | 330.3 | 19.69 | 13.60 |

| 2% of Nanofiller | 386.7 | 32.53 | 33.02 |

| 3% of Nanofiller | 375.8 | 21.54 | 29.26 |

| 4% of Nanofiller | 360.9 | 25.46 | 24.15 |

| 5% of Nanofiller | 330.0 | 18.37 | 13.51 |

| Composite | Flexural Strength (MPa) | Strength Gain % | |

|---|---|---|---|

| Average | Std. Dev. | ||

| Neat CFRP | 484.3 | 6.36 | - |

| 1% of Nanofiller | 502.2 | 10.32 | 3.70 |

| 2% of Nanofiller | 488.2 | 17.47 | 0.79 |

| 3% of Nanofiller | 479.4 | 5.94 | −1.01 |

| 4% of Nanofiller | 475.8 | 10.25 | −1.77 |

| 5% of Nanofiller | 456.5 | 12.02 | −5.74 |

| Composite | Hardness Number | Strength Gain % | |

|---|---|---|---|

| Average | Std. Dev. | ||

| Neat CFRP | 76.20 | 1.64 | |

| 1% of Nanofiller | 79.60 | 5.68 | 4.46 |

| 2% of Nanofiller | 83.00 | 3.87 | 8.92 |

| 3% of Nanofiller | 82.20 | 6.26 | 7.87 |

| 4% of Nanofiller | 81.20 | 9.13 | 6.56 |

| 5% of Nanofiller | 74.40 | 1.48 | −2.36 |

| Composite | Impact Strength (J) | Strength Gain % | |

|---|---|---|---|

| Average | Std. Dev. | ||

| Neat CFRP | 1.09 | 0.05 | - |

| 1% of Nanofiller | 1.13 | 0.02 | 3.62 |

| 2% of Nanofiller | 1.11 | 0.08 | 2.03 |

| 3% of Nanofiller | 1.08 | 0.07 | −0.77 |

| 4% of Nanofiller | 1.03 | 0.09 | −4.70 |

| 5% of Nanofiller | 0.91 | 0.08 | −16.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al mamari, S.S.; Julai, S.; Sabri, M.F.M.; Wilson Annamal, L.A.; Shahabaz, S.M. Effect of Nano Ferrochrome Slag-Infused Polymer Matrix on Mechanical Properties of Bidirectional Carbon Fiber-Reinforced Polymer Composite. Polymers 2025, 17, 2527. https://doi.org/10.3390/polym17182527

Al mamari SS, Julai S, Sabri MFM, Wilson Annamal LA, Shahabaz SM. Effect of Nano Ferrochrome Slag-Infused Polymer Matrix on Mechanical Properties of Bidirectional Carbon Fiber-Reinforced Polymer Composite. Polymers. 2025; 17(18):2527. https://doi.org/10.3390/polym17182527

Chicago/Turabian StyleAl mamari, Sultan Saif, Sabariah Julai, Mohd Faizul Mohd Sabri, Lenin Anselm Wilson Annamal, and S. M. Shahabaz. 2025. "Effect of Nano Ferrochrome Slag-Infused Polymer Matrix on Mechanical Properties of Bidirectional Carbon Fiber-Reinforced Polymer Composite" Polymers 17, no. 18: 2527. https://doi.org/10.3390/polym17182527

APA StyleAl mamari, S. S., Julai, S., Sabri, M. F. M., Wilson Annamal, L. A., & Shahabaz, S. M. (2025). Effect of Nano Ferrochrome Slag-Infused Polymer Matrix on Mechanical Properties of Bidirectional Carbon Fiber-Reinforced Polymer Composite. Polymers, 17(18), 2527. https://doi.org/10.3390/polym17182527