Effect of Thickness on the Uniaxial Compression Failure Behavior of CFRP Laminates

Abstract

1. Introduction

2. Experimental Methodologies

2.1. Specimen Preparation

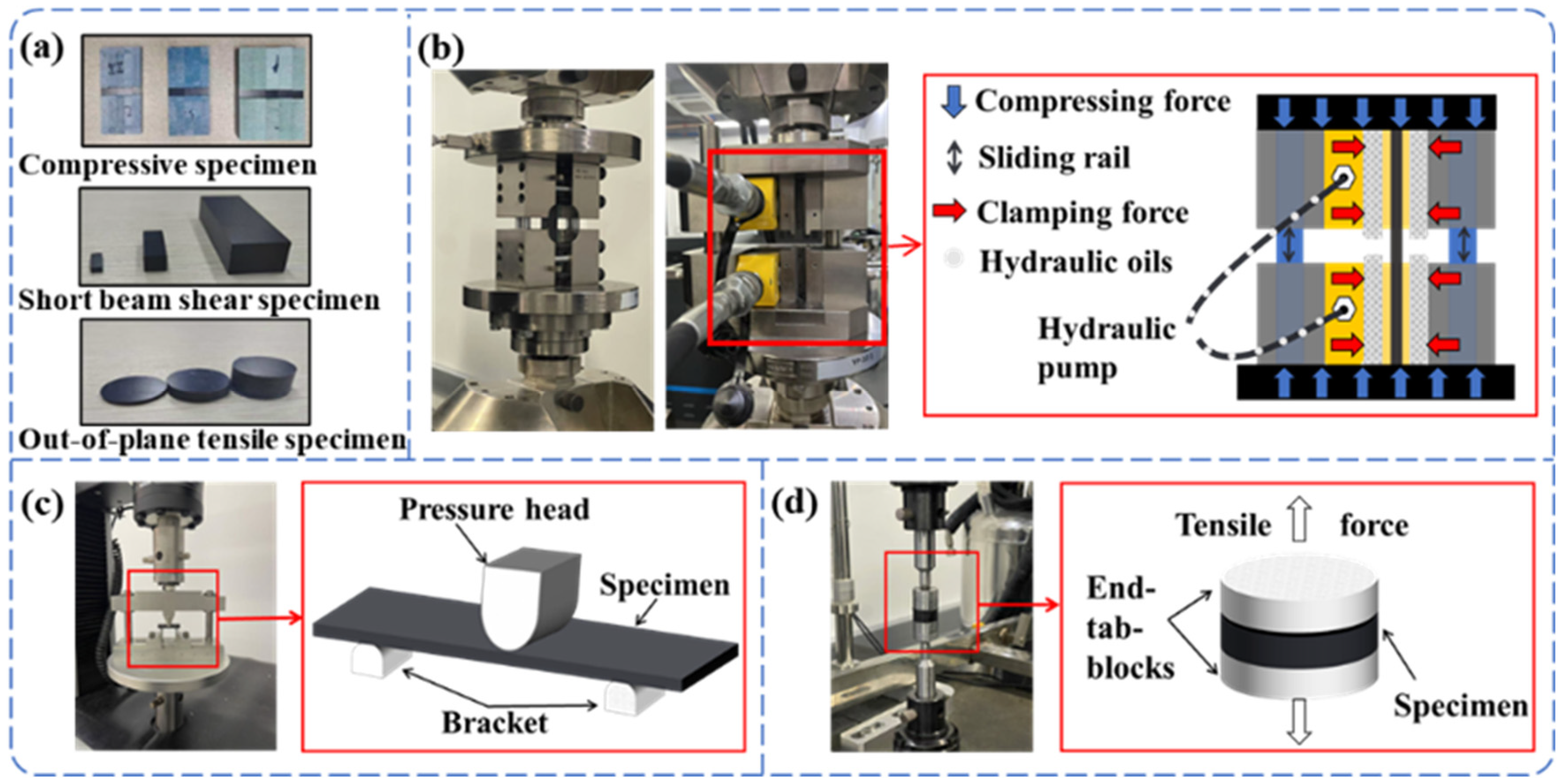

2.2. Test Methods

2.2.1. Uniaxial Compression Test

2.2.2. Interlaminar Shear Test

2.2.3. Out-of-Plane Tensile Test

2.3. Characterization Methods

3. Results and Discussion

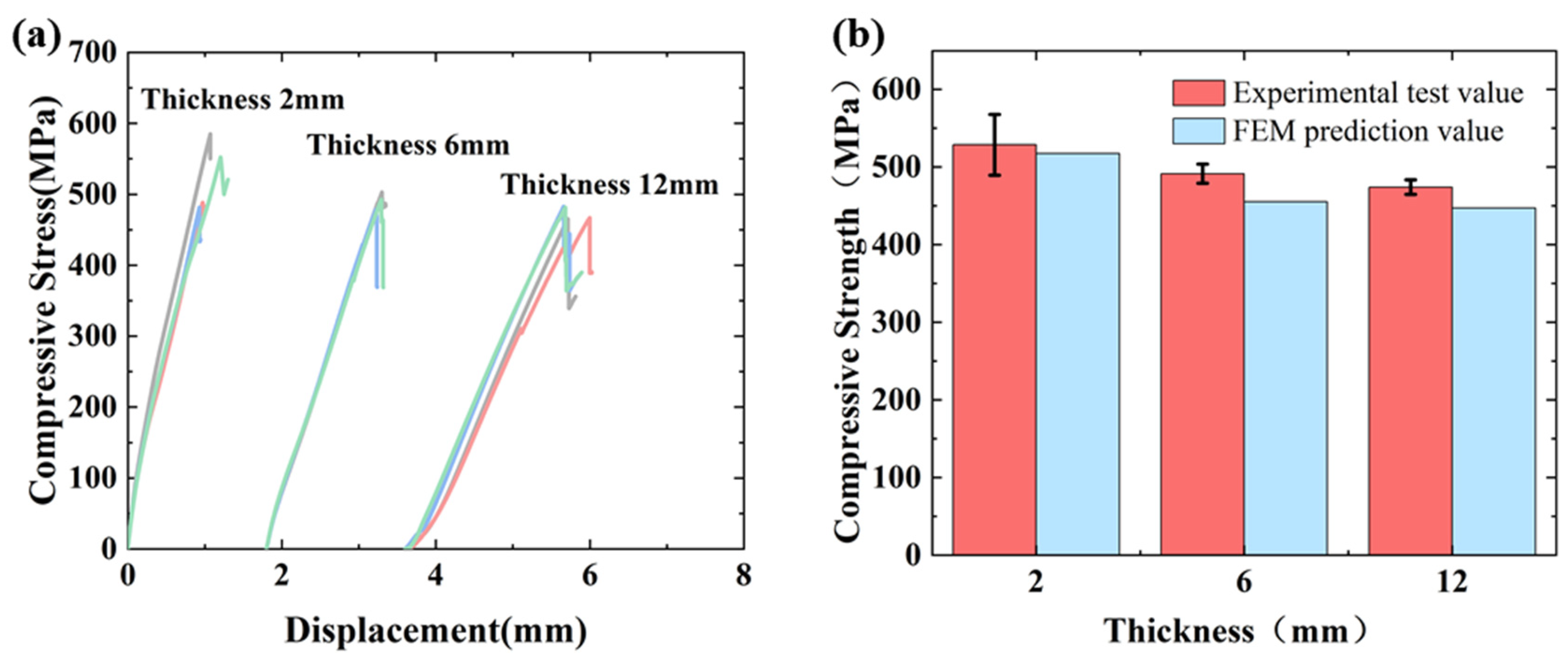

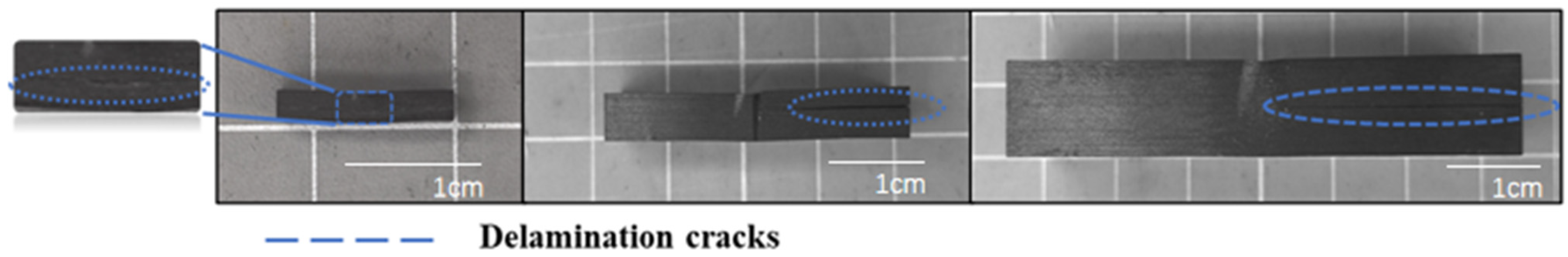

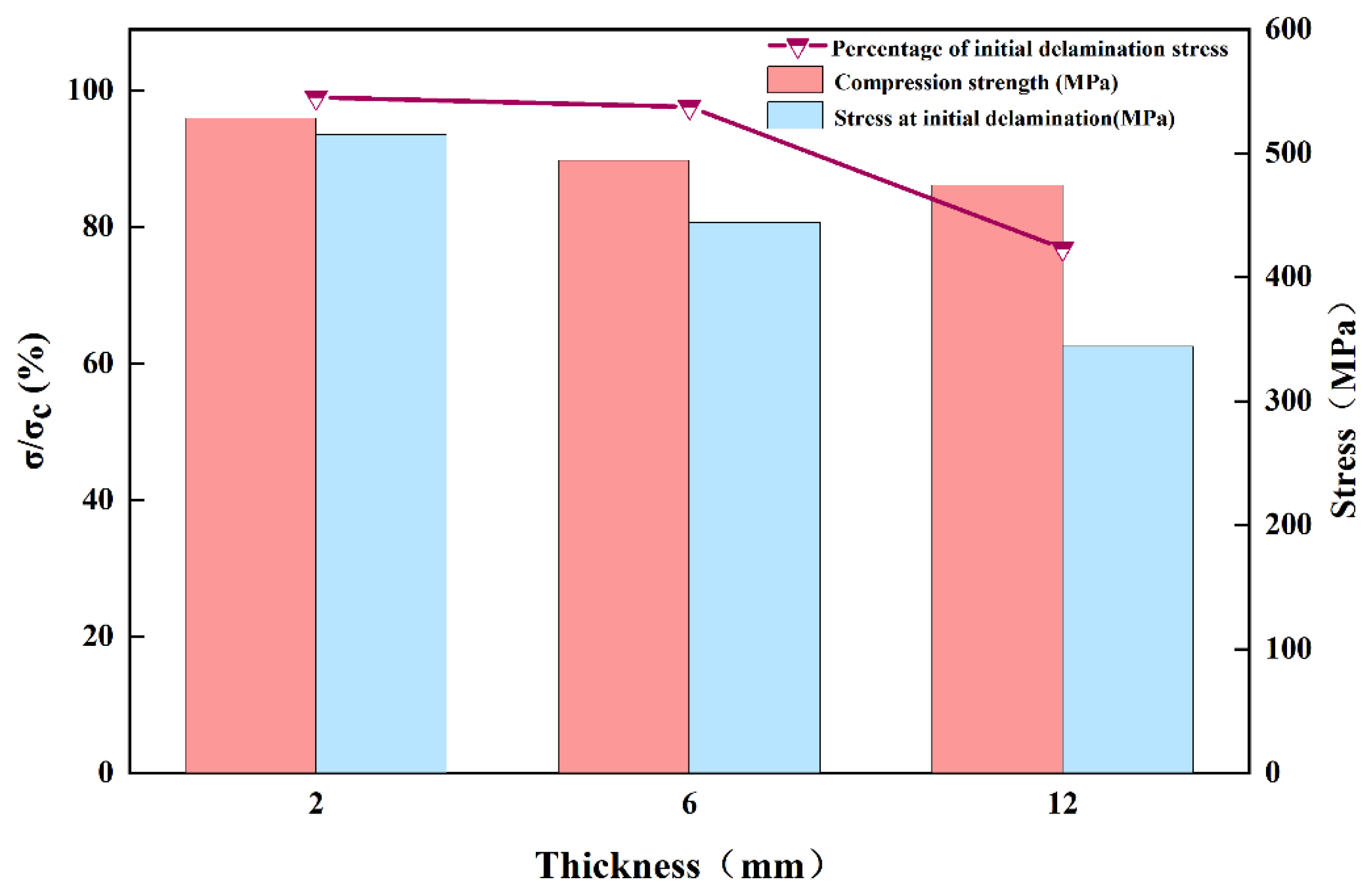

3.1. The Performance of Compression

3.2. The Performance of Interlaminar Shear

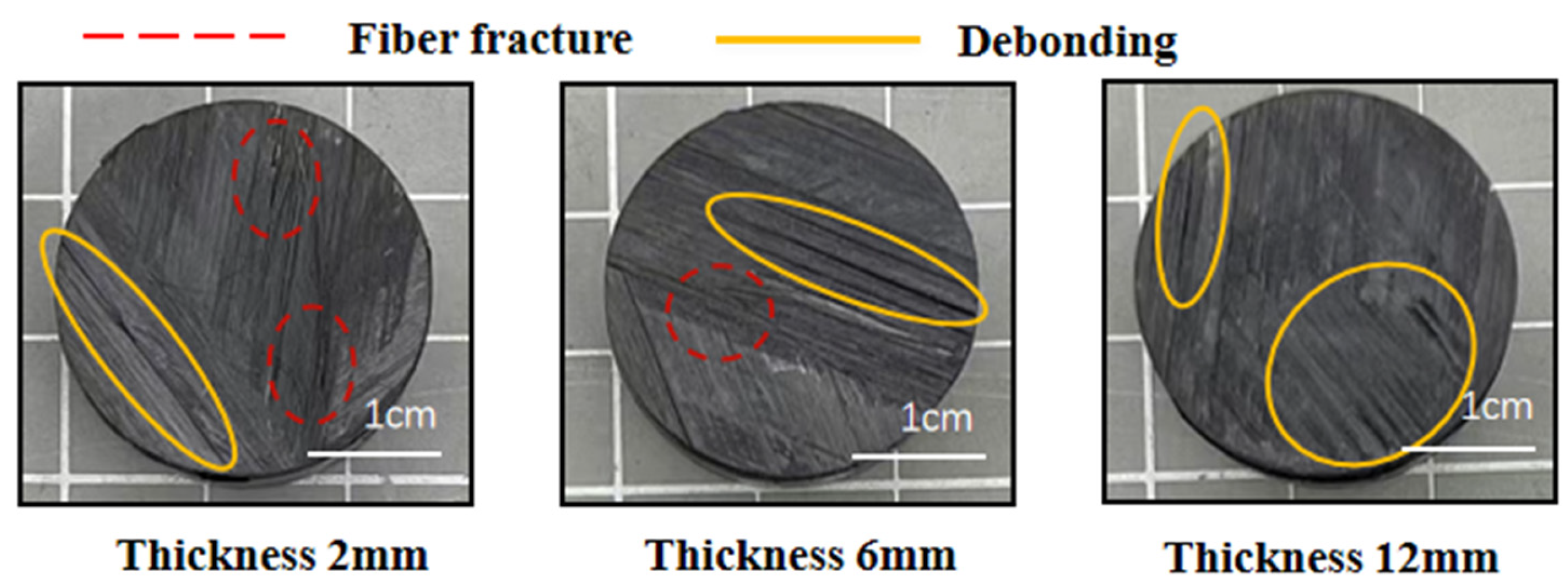

3.3. The Performance of Out-of-Plane Tensile

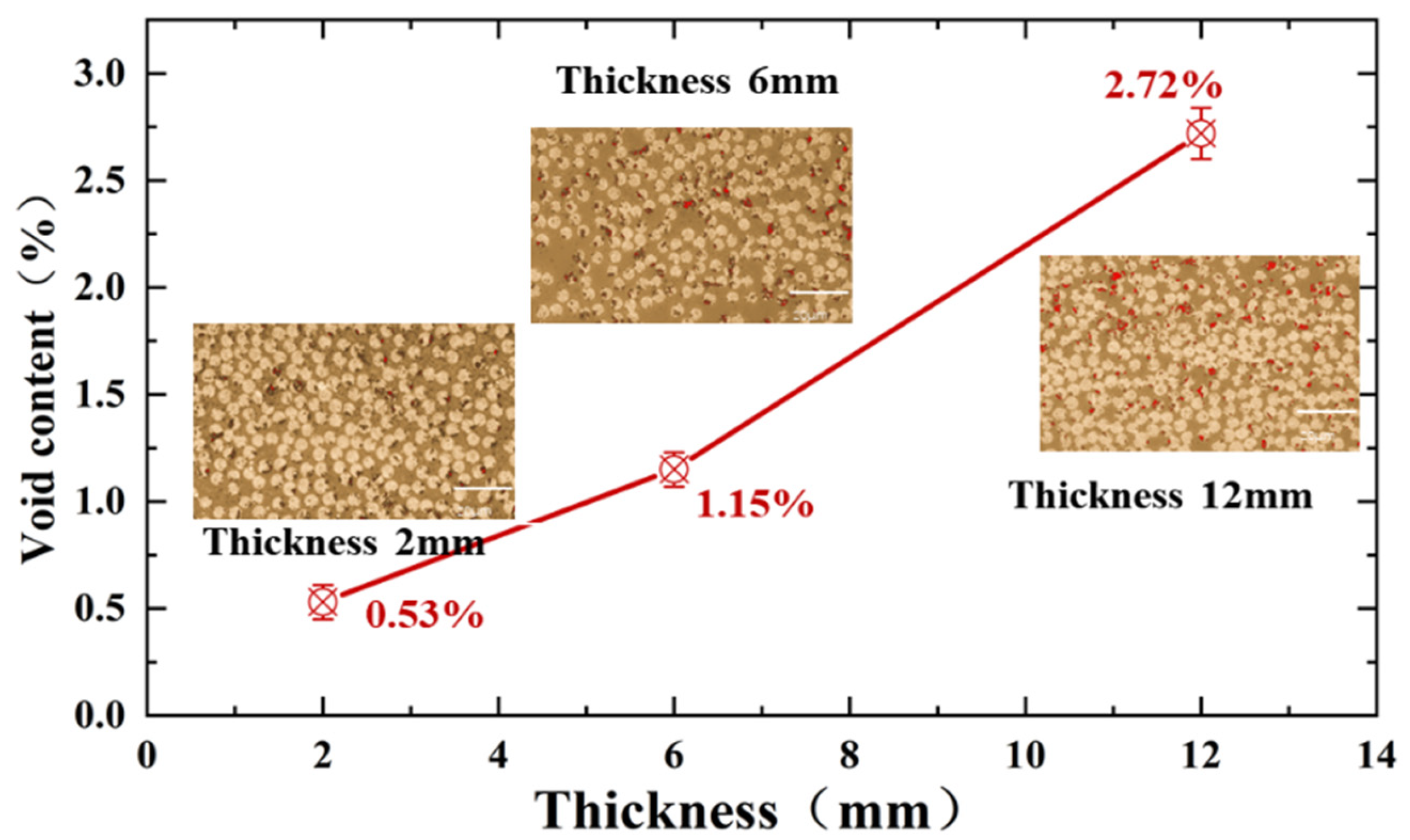

3.4. Influence of Void Content

4. Mechanism of Thickness Effect on Uniaxial Compression Performance

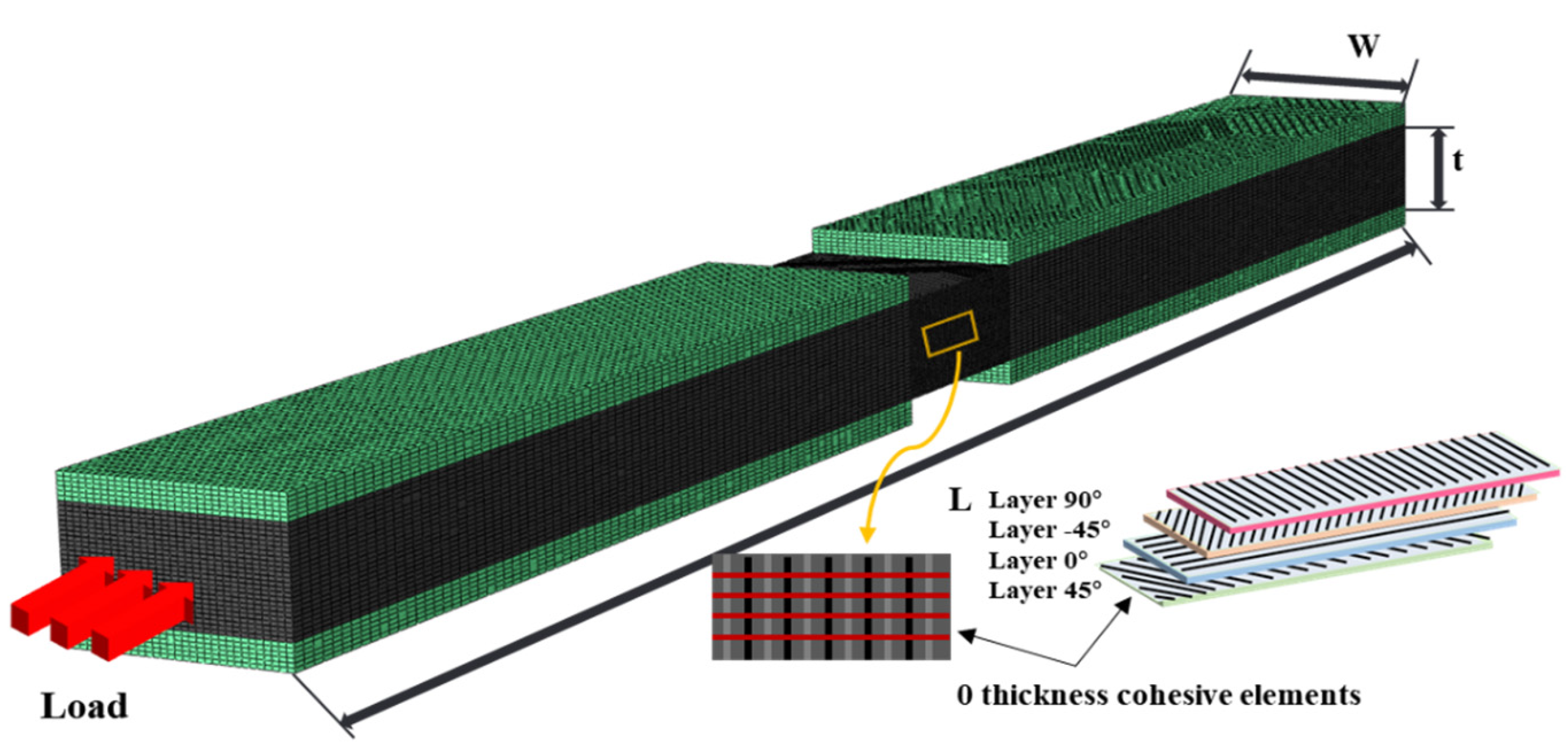

4.1. FEM Model Description

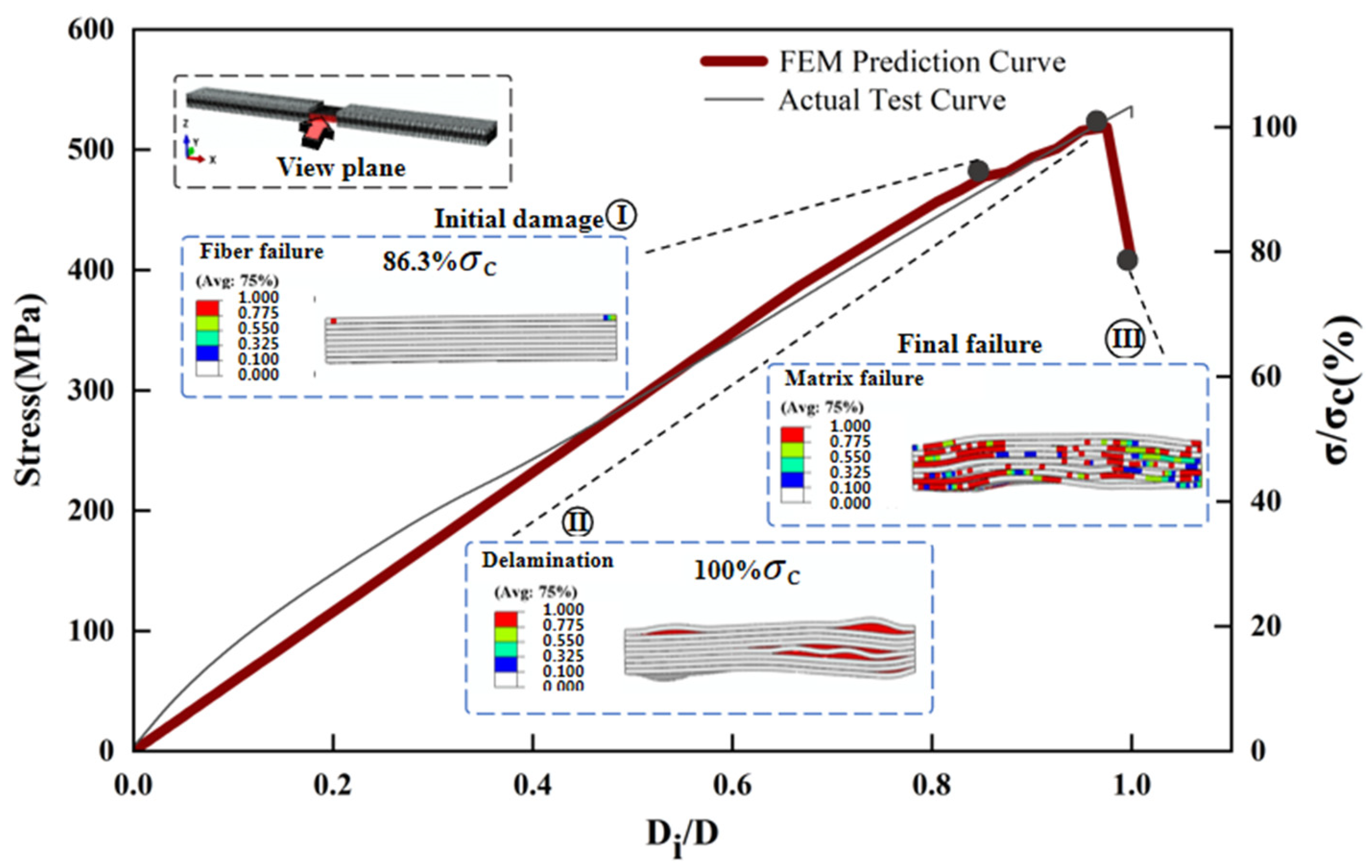

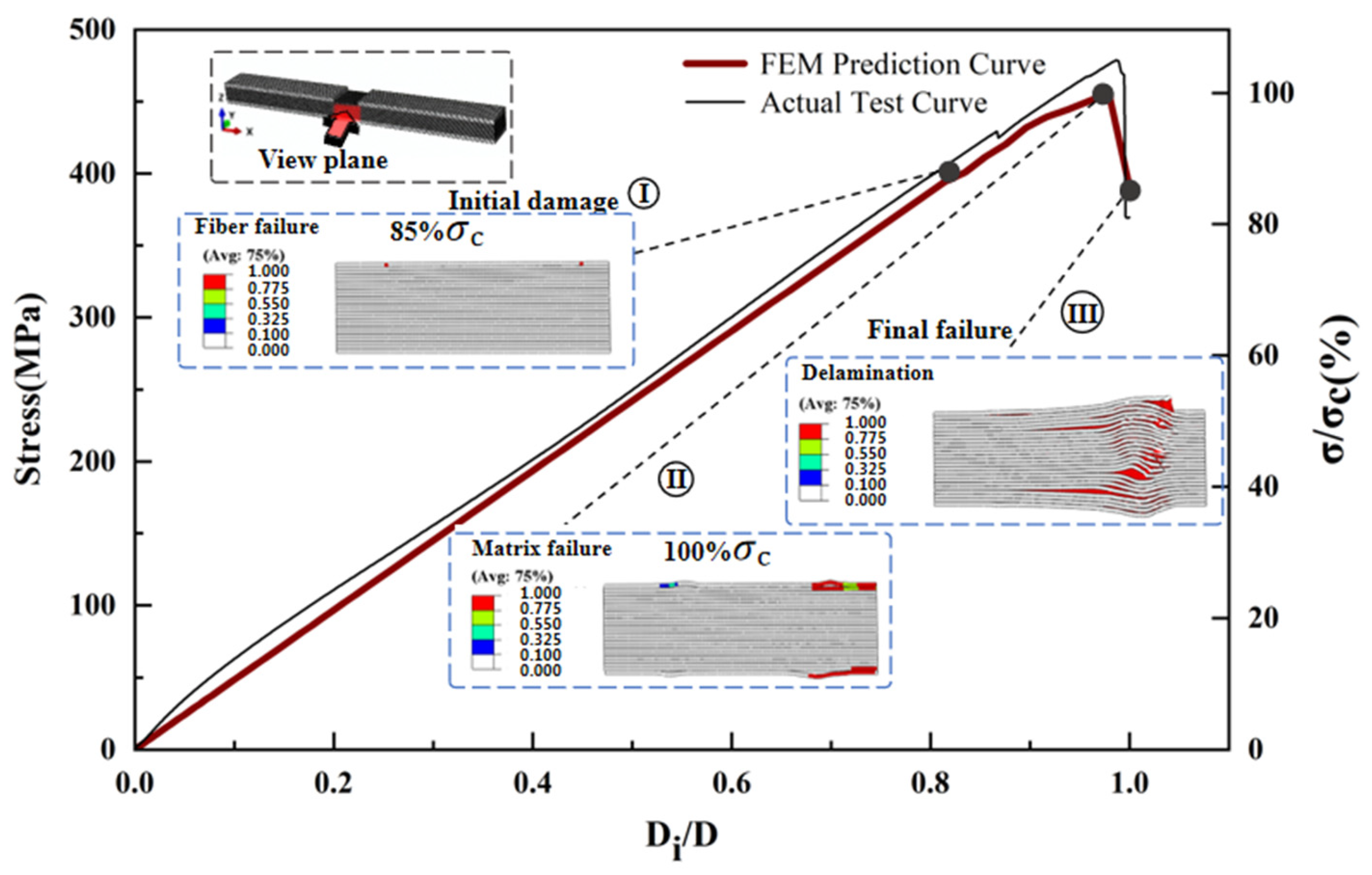

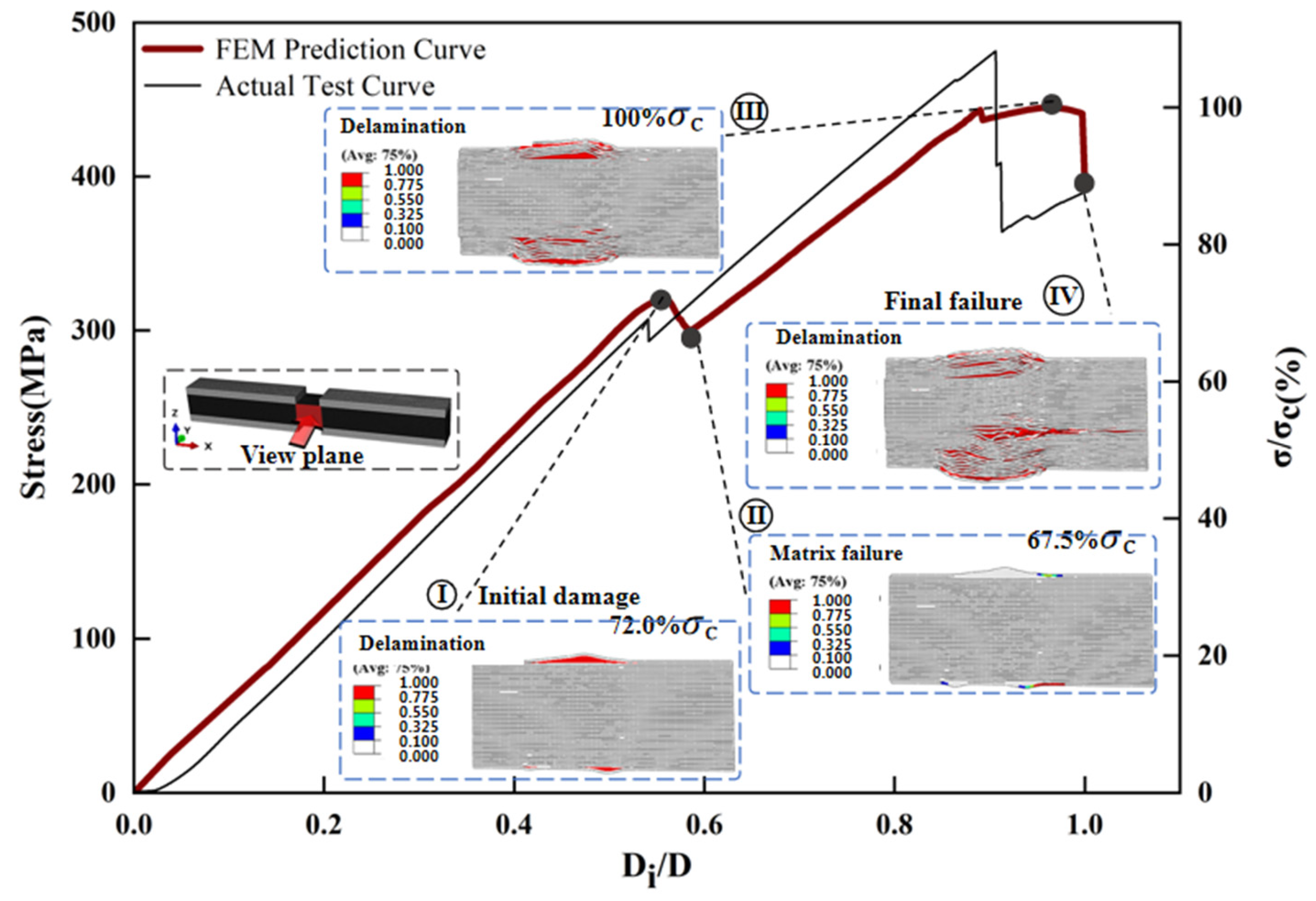

4.2. Failure Mechanism Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFRP | Carbon Fiber Reinforced Composite |

| ILSS | Interlaminar Shear Strength |

References

- Zhou, G.; Sun, Q.; Li, D.; Meng, Z.; Peng, Y.; Chen, Z.; Zeng, D.; Su, X. Meso-scale modeling and damage analysis of carbon/epoxy woven fabric composite under in-plane tension and compression loadings. Int. J. Mech. Sci. 2021, 190, 105980. [Google Scholar] [CrossRef]

- Liao, B.; Zhou, J.; Ai, S.; Lin, Y.; Xi, L.; Cao, Y.; Xiao, D. Comparison of laminate thickness on the low velocity impact behaviors for Z-pinned composite laminates. Int. J. Mech. Sci. 2021, 204, 106567. [Google Scholar] [CrossRef]

- Li, M.; Meng, X.; Zhang, Q. Mixed Interlaminar Fracture Toughness and Durability of Composites under Humid and Hot Conditions. J. Nanomater. 2022, 2022, 2867239. [Google Scholar] [CrossRef]

- Bouhala, L.; Karatrantos, A.; Reinhardt, H.; Schramm, N.; Akin, B.; Rauscher, A.; Mauersberger, A.; Taşkıran, S.T.; Ulaşlı, M.E.; Aktaş, E.; et al. Advancement in the Modeling and Design of Composite Pressure Vessels for Hydrogen Storage: A Comprehensive Review. J. Compos. Sci. 2024, 8, 339. [Google Scholar] [CrossRef]

- Tian, Y.; Li, S.; Li, M.; Zhu, W.; Yan, K.; Ke, Y. CFRP surface ply-centric electrified spatiotemporal self-heating for anti-icing/de-icing. Compos. Sci. Technol. 2024, 257, 110831. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Pérez-Pacheco, E.; Cauich-Cupul, J.I.; Valadez-González, A.; Herrera-Franco, P.J. Effect of moisture absorption on the mechanical behavior of carbon fiber/epoxy matrix composites. J. Mater. Sci. 2013, 48, 1873–1882. [Google Scholar] [CrossRef]

- Tual, N.; Carrere, N.; Davies, P.; Bonnemains, T.; Lolive, E. Characterization of sea water ageing effects on mechanical properties of carbon/epoxy composites for tidal turbine blades. Compos. Part A Appl. Sci. Manuf. 2015, 78, 380–389. [Google Scholar] [CrossRef]

- Petritoli, E.; Leccese, F. Autonomous Underwater Glider: A Comprehensive Review. Drones 2025, 9, 21. [Google Scholar] [CrossRef]

- Alam, K.; Ray, T.; Anavatti, S.G. Design and construction of an autonomous underwater vehicle. Neurocomputing 2014, 142, 16–29. [Google Scholar] [CrossRef]

- Weijermars, R. Comprehensive assessment of deep-water vessel implosion mechanisms: OceanGate’s Titan submersible failure sequence explained. Int. J. Press. Vessel. Pip. 2025, 213, 105340. [Google Scholar] [CrossRef]

- Penhallurick, R.W.; Ichiye, T. Pressure Adaptations in Deep-Sea Moritella Dihydrofolate Reductases: Compressibility versus Stability. Biology 2021, 10, 1211. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yu, C.; Wang, W.; Li, H.; Jiang, X. A Review on Structural Failure of Composite Pressure Hulls in Deep Sea. J. Mar. Sci. Eng. 2022, 10, 1456. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhang, F.; Cheng, L.; Qu, W.; Wang, Q. Experimental and simulation study on compressive failure evolution of multidirectional laminates with different dimensions. Eng. Fail. Anal. 2023, 154, 107633. [Google Scholar] [CrossRef]

- Kumar, Y.; Rezasefat, M.; Li, H.; Dolez, P.I.; Hogan, J.D. Influence of ply thickness in laminated composite under quasi-static in-plane compression loading. Procedia Struct. Integr. 2024, 61, 322–330. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Wang, X.; Sun, J.; Pang, Z.; Zhang, D. Influence of different thickness-to-radius on axial compression damage mechanism of carbon/epoxy 2.5D woven composite cylindrical shells. Compos. Commun. 2025, 55, 102293. [Google Scholar] [CrossRef]

- Xu, M.; Zeng, B.; An, Z.; Xiong, X.; Cheng, X. Experimental and Numerical Investigation on Fatigue Properties of Carbon Fiber Cross-Ply Laminates in Hygrothermal Environments. Polymers 2022, 14, 1857. [Google Scholar] [CrossRef]

- Gao, Y.; Zhu, S.; Ding, H.; Song, X.; Hu, H.; Wang, H.; Ke, Y. Thickness variation effect on compressive properties of ultra-thick CFRP laminates. Int. J. Mech. Sci. 2023, 253, 108390. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, J.; Song, X.; Ding, H.; Wang, H.; Bi, Y.; Ke, Y. Investigation on the compressive mechanical properties of ultra-thick CFRP laminates. Int. J. Mech. Sci. 2023, 241, 107966. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, X.; Wang, B.; Shi, H. An experimental investigation of the compressive failure in quasi-isotropic ultra-thick CFRP laminates. Compos. Struct. 2025, 354, 118818. [Google Scholar] [CrossRef]

- Hao, Z.; Wang, X.; Ke, H.; Wei, G.; Kardomateas, G.; Liu, L. Experimental and numerical investigation on the size effect of interlaminar shear strength for thick composites. Compos. Struct. 2025, 353, 118710. [Google Scholar] [CrossRef]

- ASTM D 6641/D 6641 M-16; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D 3410/D 3410 M-16; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading. ASTM International: West Conshohocken, PA, USA, 2016.

- GB/T 1448; Fiber-Reinforced Plastics Composites-Determination of Compressive Properties. China Standard Press: Beijing, China, 2005.

- Lee, J.; Soutis, C. A study on the compressive strength of thick carbon fibre–epoxy laminates. Compos. Sci. Technol. 2007, 67, 2015–2026. [Google Scholar] [CrossRef]

- ASTM D2344/D2344M; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D7291/D7291M-22; Standard Test Method for Through-Thickness “Flatwise” Tensile Strength and Elastic Modulus of a Fiber-Reinforced Polymer Matrix Composite Material. ASTM International: West Conshohocken, PA, USA, 2022.

- Goto, K.; Arai, M.; Kano, Y.; Hara, E.; Ishikawa, T. Compressive fracture aspect of thick quasi-isotropic carbon fiber reinforced plastic laminates. Compos. Sci. Technol. 2019, 181, 107706. [Google Scholar] [CrossRef]

- Hitchon, J.W.; Phillips, D.C. The effect of specimen size on the strength of cfrp. Composites 1978, 9, 119–124. [Google Scholar] [CrossRef]

- Wisnom, M.R. Size effects in the testing of fibre-composite materials. Compos. Sci. Technol. 1999, 59, 1937–1957. [Google Scholar] [CrossRef]

- Cui, W.; Wisnom, M.R.; Jones, M. Effect of specimen size on interlaminar shear strength of unidirectional carbon fibre-epoxy. Compos. Eng. 1994, 4, 299–307. [Google Scholar] [CrossRef]

- Yamada, K.; Kötter, B.; Nishikawa, M.; Fukudome, S.; Matsuda, N.; Kawabe, K.; Fiedler, B.; Hojo, M. Mechanical properties and failure mode of thin-ply fiber metal laminates under out-of-plane loading. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106267. [Google Scholar]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2018, 53, 1579–1669. [Google Scholar] [CrossRef]

- Gao, X.; Wang, T.; Kim, J. On ductile fracture initiation toughness: Effects of void volume fraction, void shape and void distribution. Int. J. Solids Struct. 2005, 42, 5097–5117. [Google Scholar] [CrossRef]

- Yuan, Z.; Tong, X.; Yang, G.; Yang, Z.; Song, D.; Li, S.; Li, Y. Curing Cycle Optimization for Thick Composite Laminates Using the Multi-Physics Coupling Model. Appl. Compos. Mater. 2020, 27, 839–860. [Google Scholar] [CrossRef]

- Yang, J.B.; Bai, Y.R.; Sun, J.S.; Lv, K.H. Curing kinetics and plugging mechanism of high strength curable resin plugging material. Pet. Sci. 2024, 21, 3446–3463. [Google Scholar] [CrossRef]

- Shujian, L.; Lihua, Z.; Rong, C.; Liran, Z.; Yuanqi, Z. Formation, Influence Mechanism and Experimental Characterization of Composite Porosity. Rare Met. Mater. Eng. 2016, 45, 2282–2286. [Google Scholar] [CrossRef]

- Hernández, S.; Sket, F.; Molina-Aldareguı, J.M.; González, C.; LLorca, J. Effect of curing cycle on void distribution and interlaminar shear strength in polymer-matrix composites. Compos. Sci. Technol. 2011, 71, 1331–1341. [Google Scholar] [CrossRef]

- Hernández, S.; Sket, F.; González, C.; Llorca, J. Optimization of curing cycle in carbon fiber-reinforced laminates: Void distribution and mechanical properties. Compos. Sci. Technol. 2013, 85, 73–82. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, C.; Yang, Y.; Zhang, Y.; Bi, Y. Effect of riveting displacement on the mechanical behavior of CFRP bolted joints with elliptical-head non-lug self-locking rivet nut. Int. J. Adv. Manuf. Technol. 2023, 125, 2161–2182. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Ji, Y.; Hu, H.; Cao, D.; Zheng, K.; Liu, H.; Li, S. Modeling Progressive Damage and Failure of Single-Lap Thin-Ply-Laminated Composite-Bolted Joint Using LaRC Failure Criterion. Materials 2022, 15, 8123. [Google Scholar] [CrossRef]

- Zhang, Y.; Van Paepegem, W.; De Corte, W. An Enhanced Progressive Damage Model for Laminated Fiber-Reinforced Composites Using the 3D Hashin Failure Criterion: A Multi-Level Analysis and Validation. Materials 2024, 17, 5176. [Google Scholar] [CrossRef]

- Hashin, Z. Failure Criteria for Unidirectional Fiber Composites. J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Shao, J.R.; Liu, N.; Zheng, Z.J. Numerical comparison between Hashin and Chang-Chang failure criteria in terms of inter-laminar damage behavior of laminated composite. Mater. Res. Express 2021, 8, 085602. [Google Scholar] [CrossRef]

- Odom, E.M.; Adams, D.F. Failure modes of unidirectional carbon/epoxy composite compression specimens. Composites 1990, 21, 289–296. [Google Scholar] [CrossRef]

- Hoshino, T.; Okamoto, Y.; Yamamoto, A.; Masunaga, H. Heterogeneous dynamics in the curing process of epoxy resins. Sci. Rep. 2021, 11, 9767. [Google Scholar] [CrossRef]

| Laminate Thickness (t/mm) | Total Length (L/mm) | Gauge Length (L0/mm) | Width (w/mm) | Tab Thickness (t1/mm) |

|---|---|---|---|---|

| 2 | 140 | 13 | 13 | 1.5 |

| 6 | 140 | 13 | 13 | 1.5 |

| 12 | 140 | 15 | 15 | 4 |

| Intralaminar Properties | = 120 GPa, = = 8 GPa, = = 4.5 GPa, = 3 GPa = = 0.25, = 0.3, = 1600 (kg/m3); = 1600 MPa, = 1200 MPa, = 55 MPa, = 200 MPa = = 100 MPa, = 90 MPa; |

| Interlaminar Properties | = 35 MPa, = 60 MPa, = 60 MPa, = 0.6 N/mm, = = 2.1 N/mm; |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Z.; Ding, H.; Zhu, S.; Jin, C.; Wang, J.; Li, J.; Wang, H. Effect of Thickness on the Uniaxial Compression Failure Behavior of CFRP Laminates. Polymers 2025, 17, 2518. https://doi.org/10.3390/polym17182518

Qin Z, Ding H, Zhu S, Jin C, Wang J, Li J, Wang H. Effect of Thickness on the Uniaxial Compression Failure Behavior of CFRP Laminates. Polymers. 2025; 17(18):2518. https://doi.org/10.3390/polym17182518

Chicago/Turabian StyleQin, Zixing, Huiming Ding, Shiyang Zhu, Can Jin, Jian Wang, Jiaxin Li, and Han Wang. 2025. "Effect of Thickness on the Uniaxial Compression Failure Behavior of CFRP Laminates" Polymers 17, no. 18: 2518. https://doi.org/10.3390/polym17182518

APA StyleQin, Z., Ding, H., Zhu, S., Jin, C., Wang, J., Li, J., & Wang, H. (2025). Effect of Thickness on the Uniaxial Compression Failure Behavior of CFRP Laminates. Polymers, 17(18), 2518. https://doi.org/10.3390/polym17182518