Development of Filaments for 3D Printing from Poly(Lactic Acid) Polymeric Nanocomposites and Carbon Nanotubes

Abstract

1. Introduction

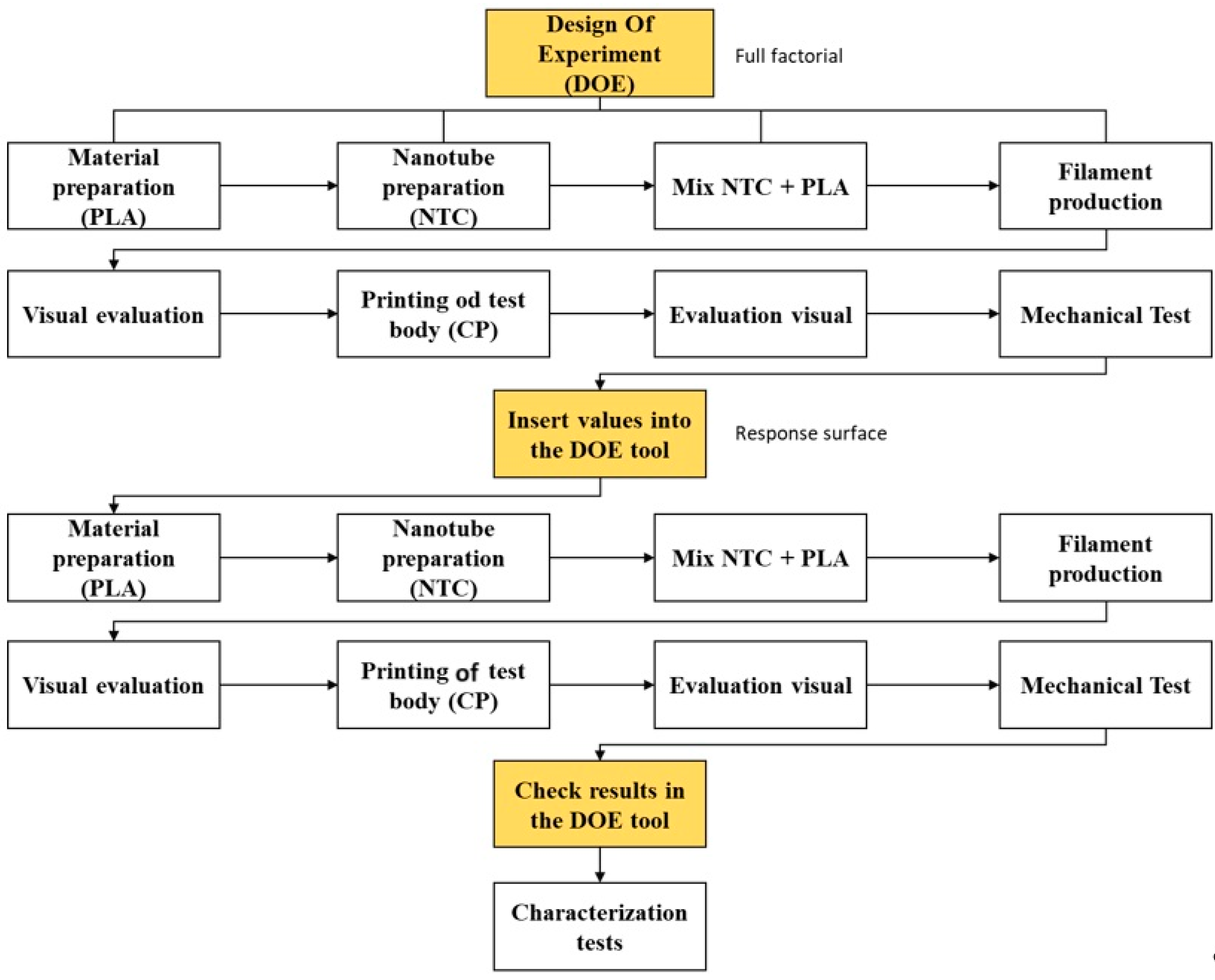

2. Methodology

2.1. DOE (Design of Experiments)

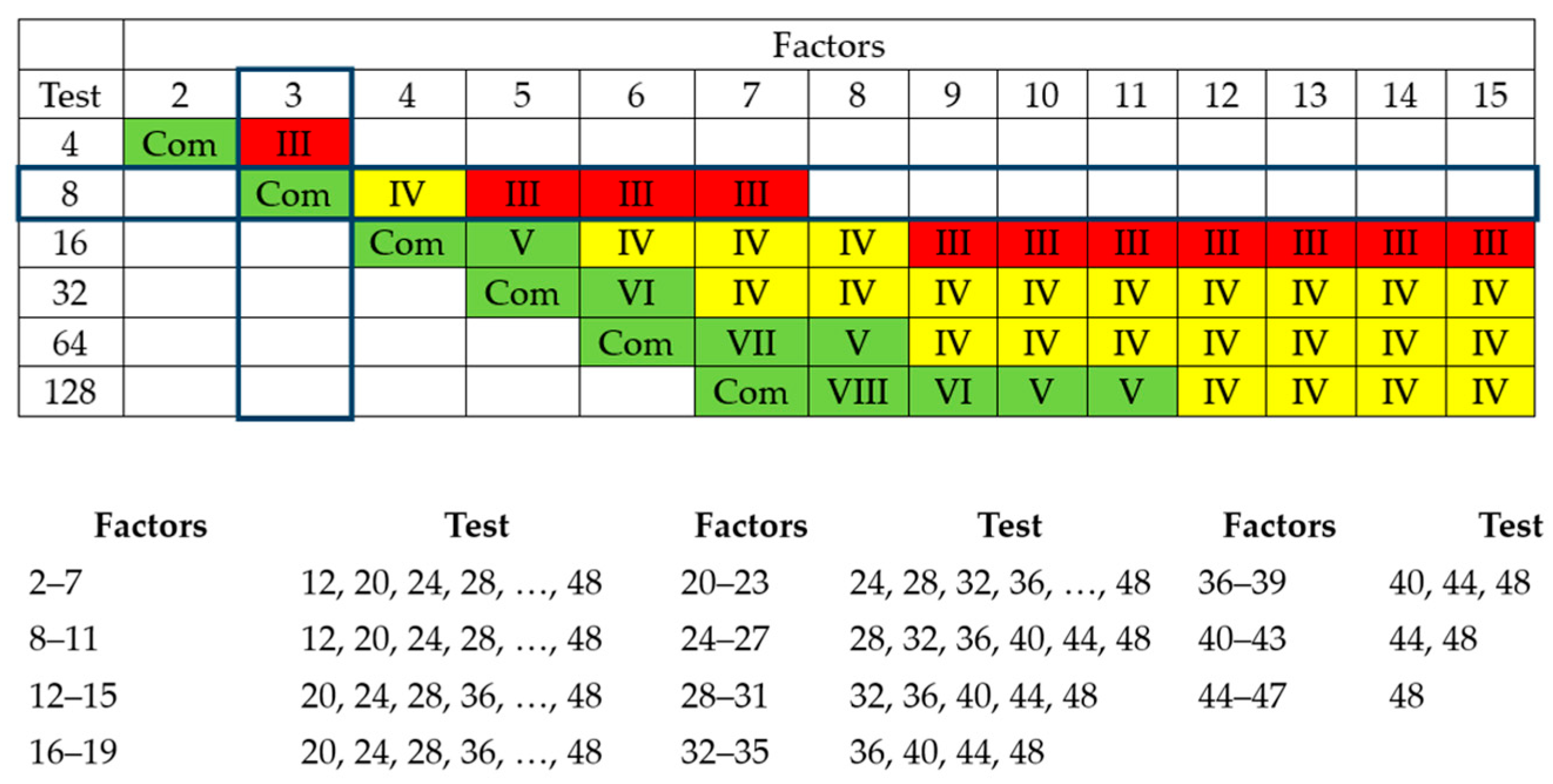

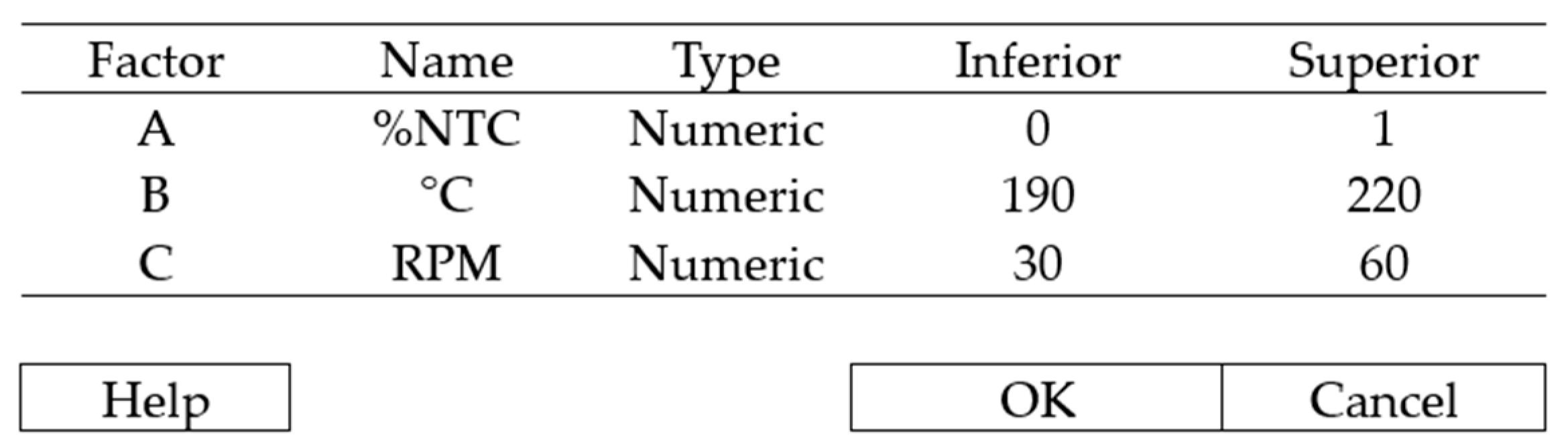

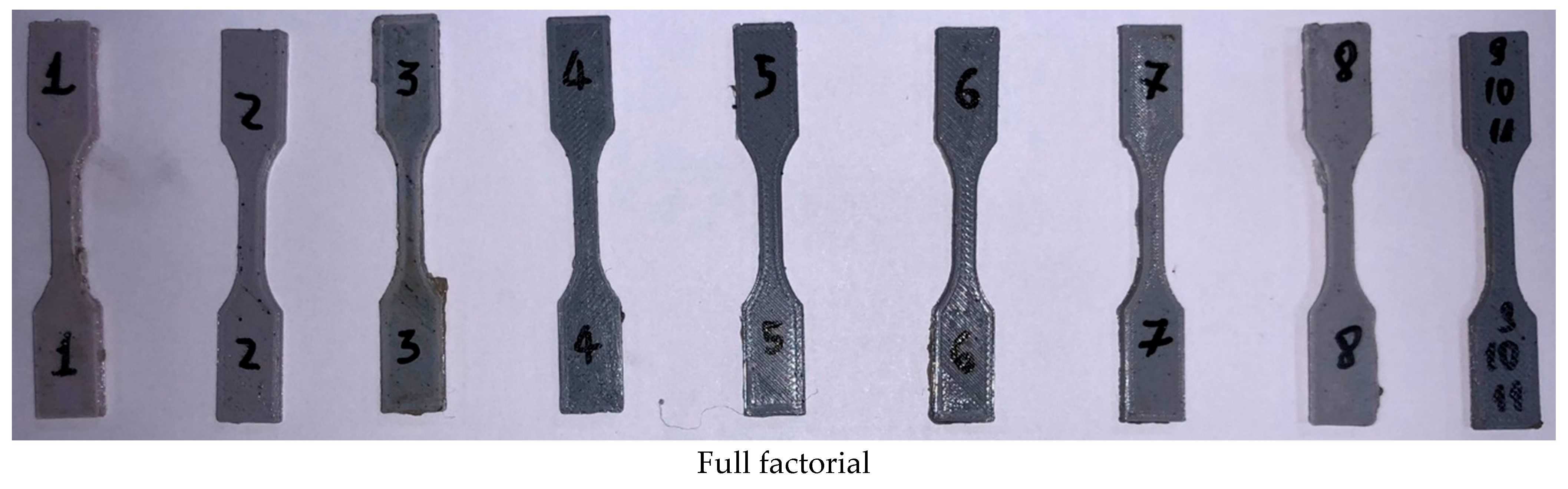

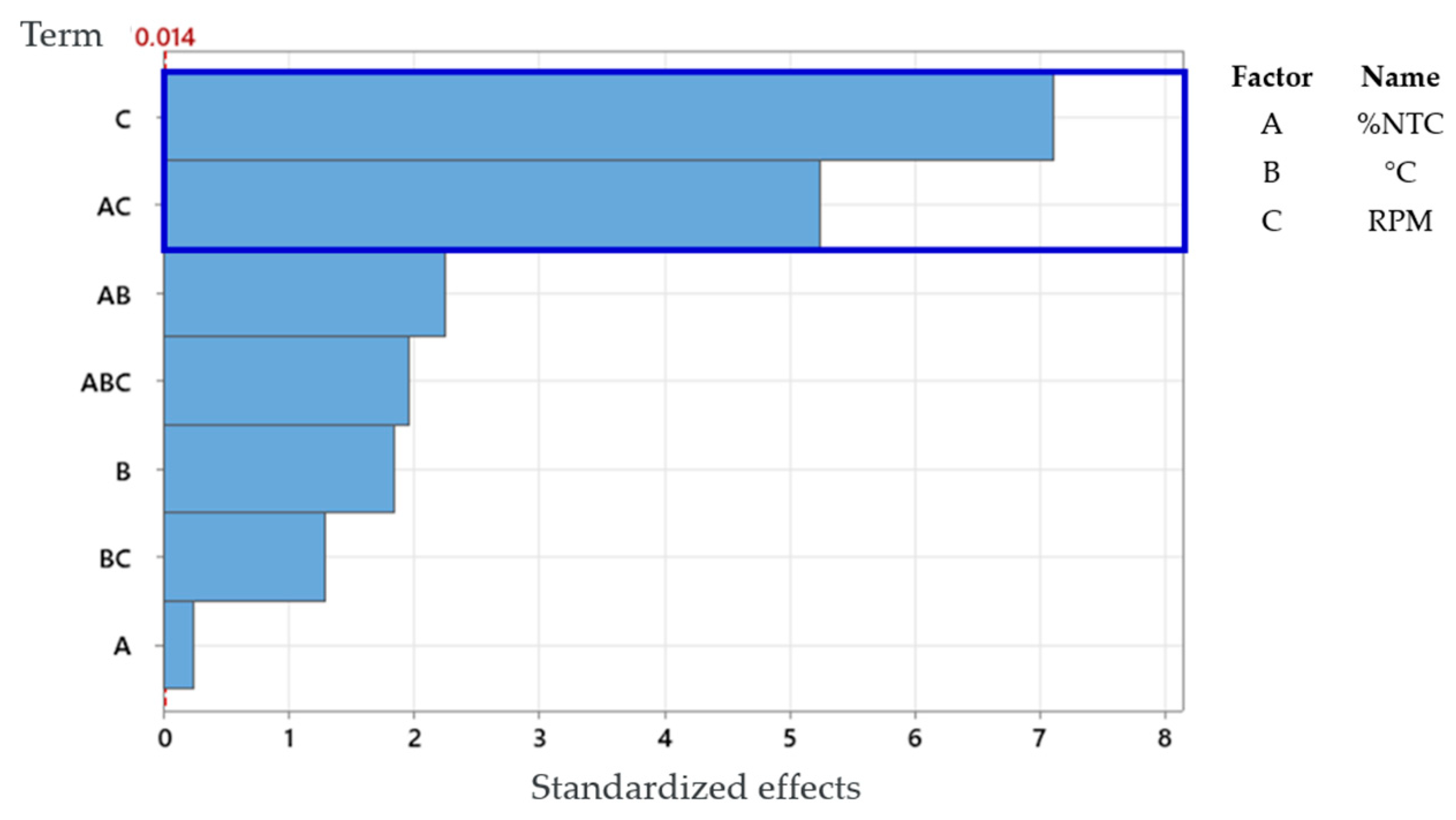

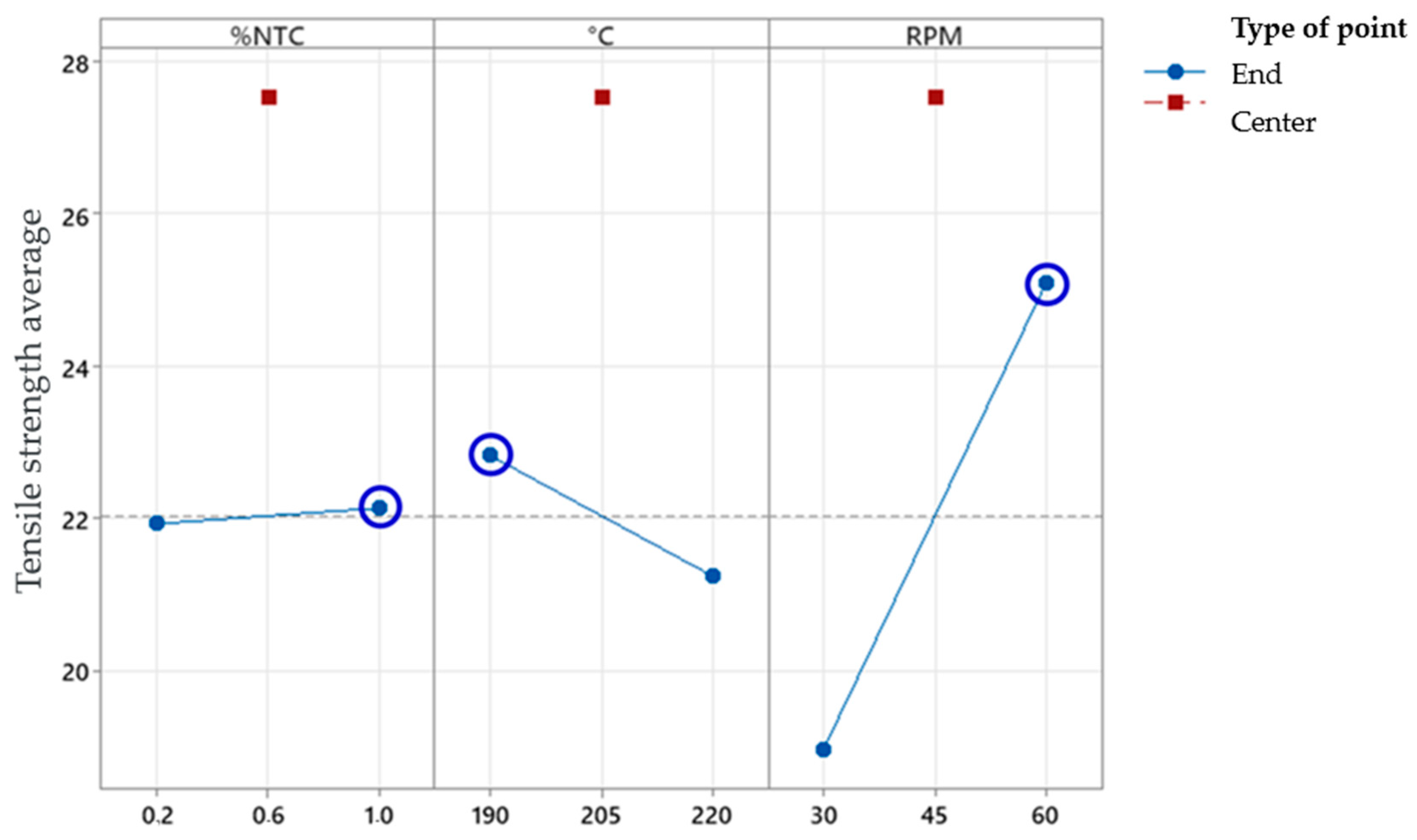

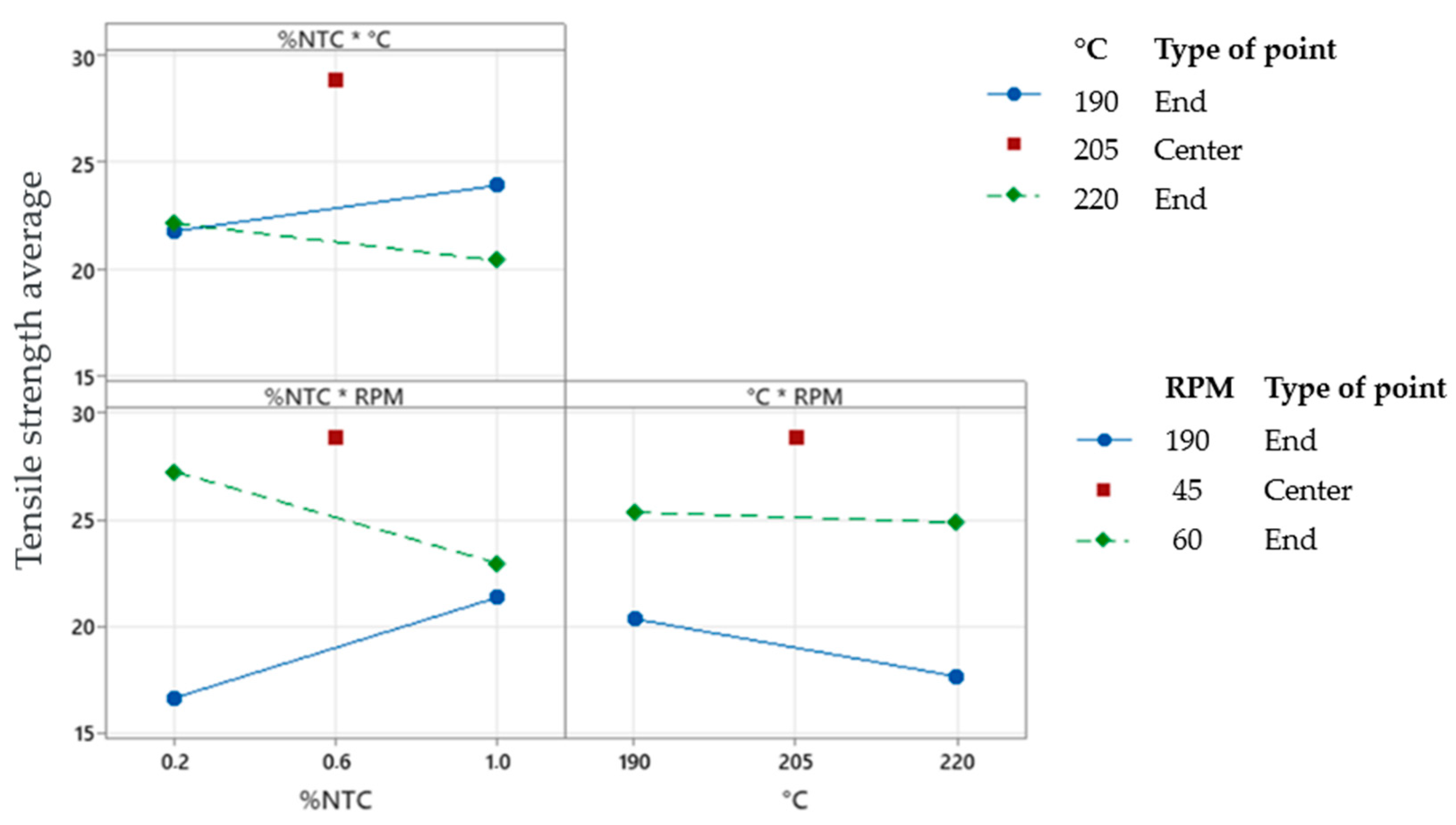

2.1.1. Full Factorial 23

- CNT content (%CNT): 0.2~1%.

- Filament Extrusion Temperature (ΔT): 190~220 °C (same temperature in all 3 zones).

- Extruder Screw RPM (RPM): 30~60 rpm.

- Green: good results.

- Yellow: reasonable results.

- Red: undesirable results.

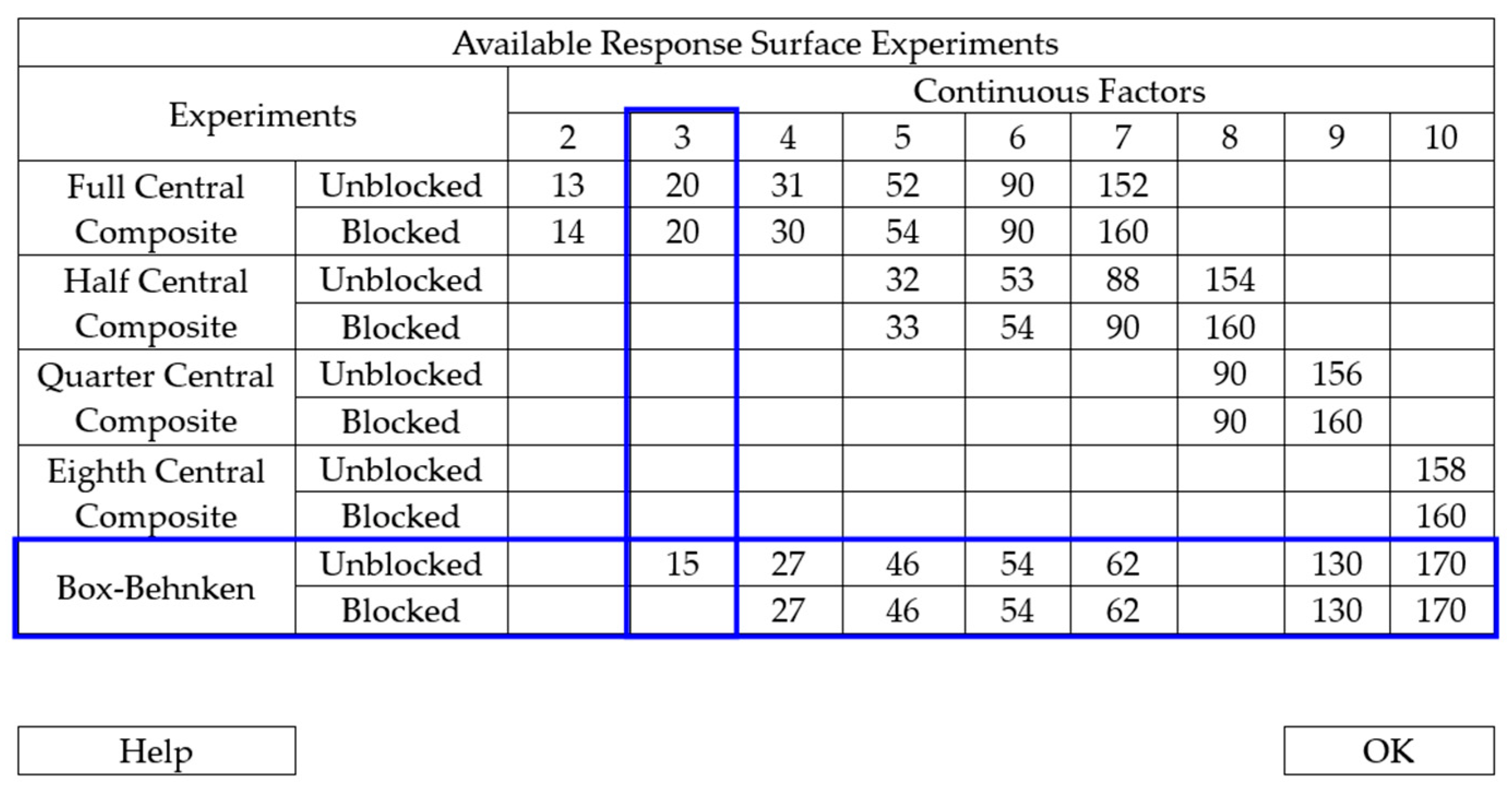

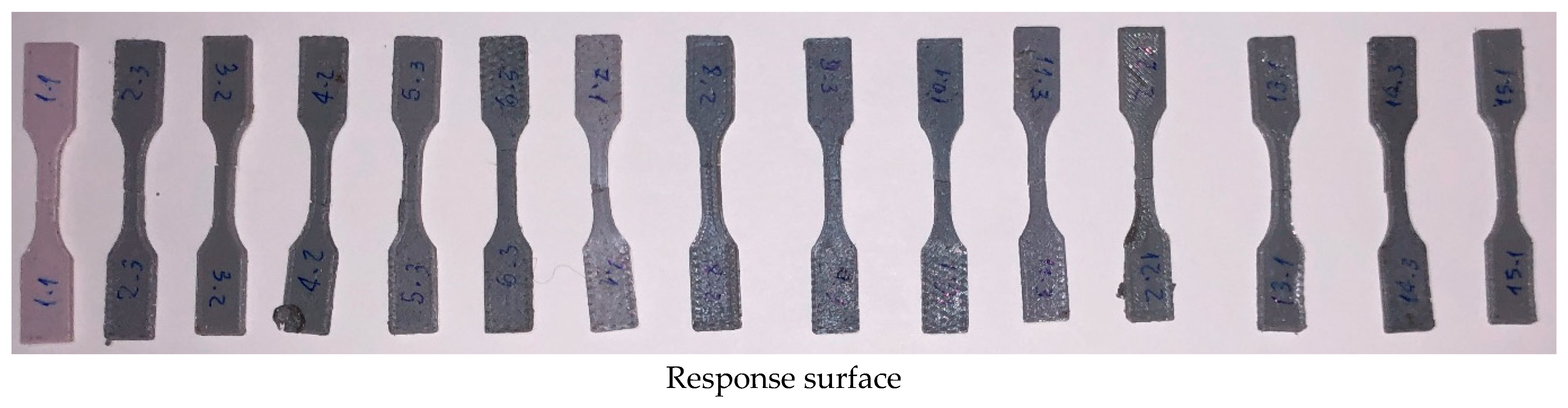

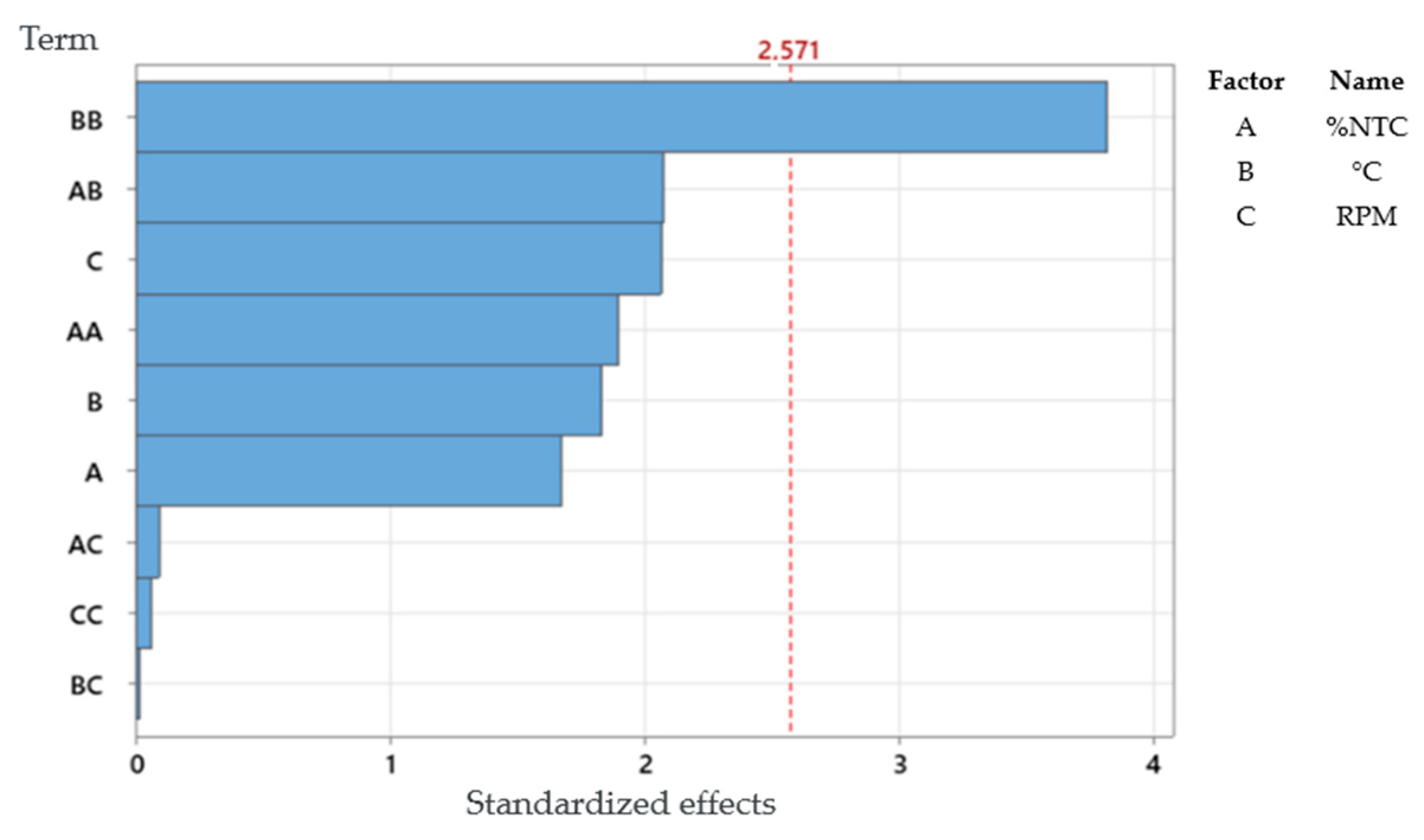

2.1.2. Response Surface (Box–Behnken)

- CNT content (%CNT): 0.2~1%.

- Filament extrusion temperature (ΔT): 190~220 °C.

- Extruder screw RPM (RPM): 30~60 rpm.

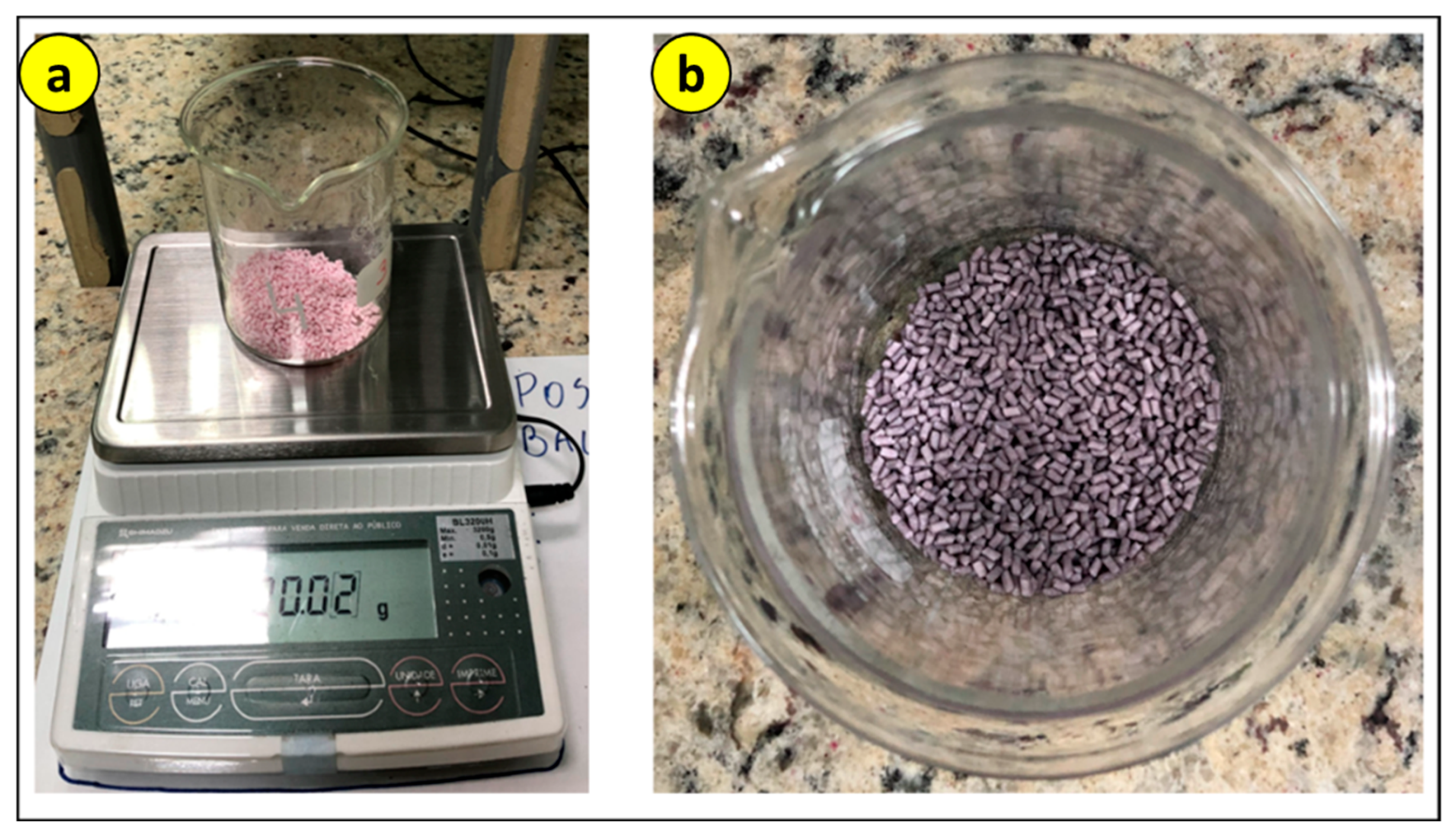

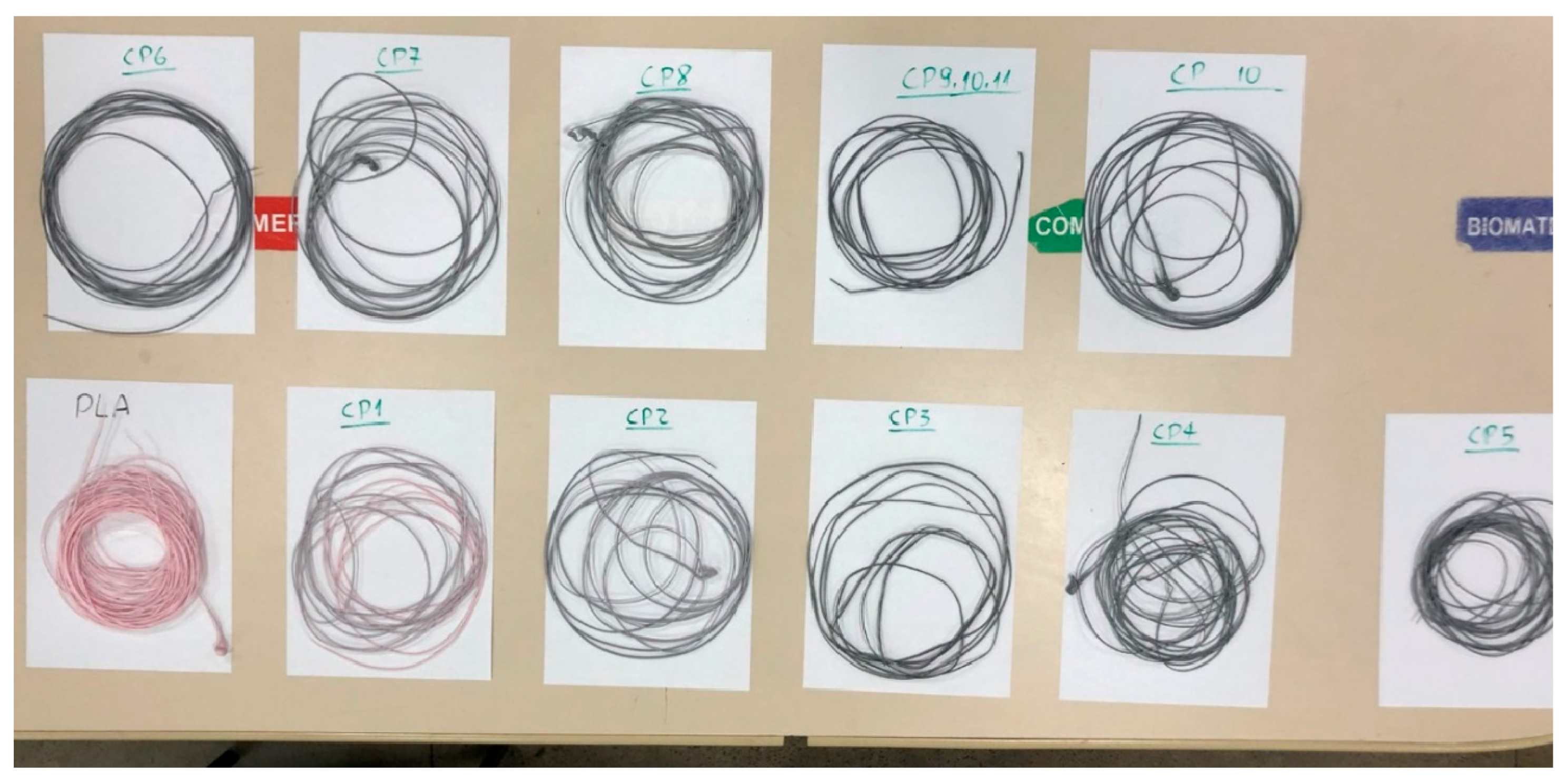

2.2. Manufacturing of Filaments

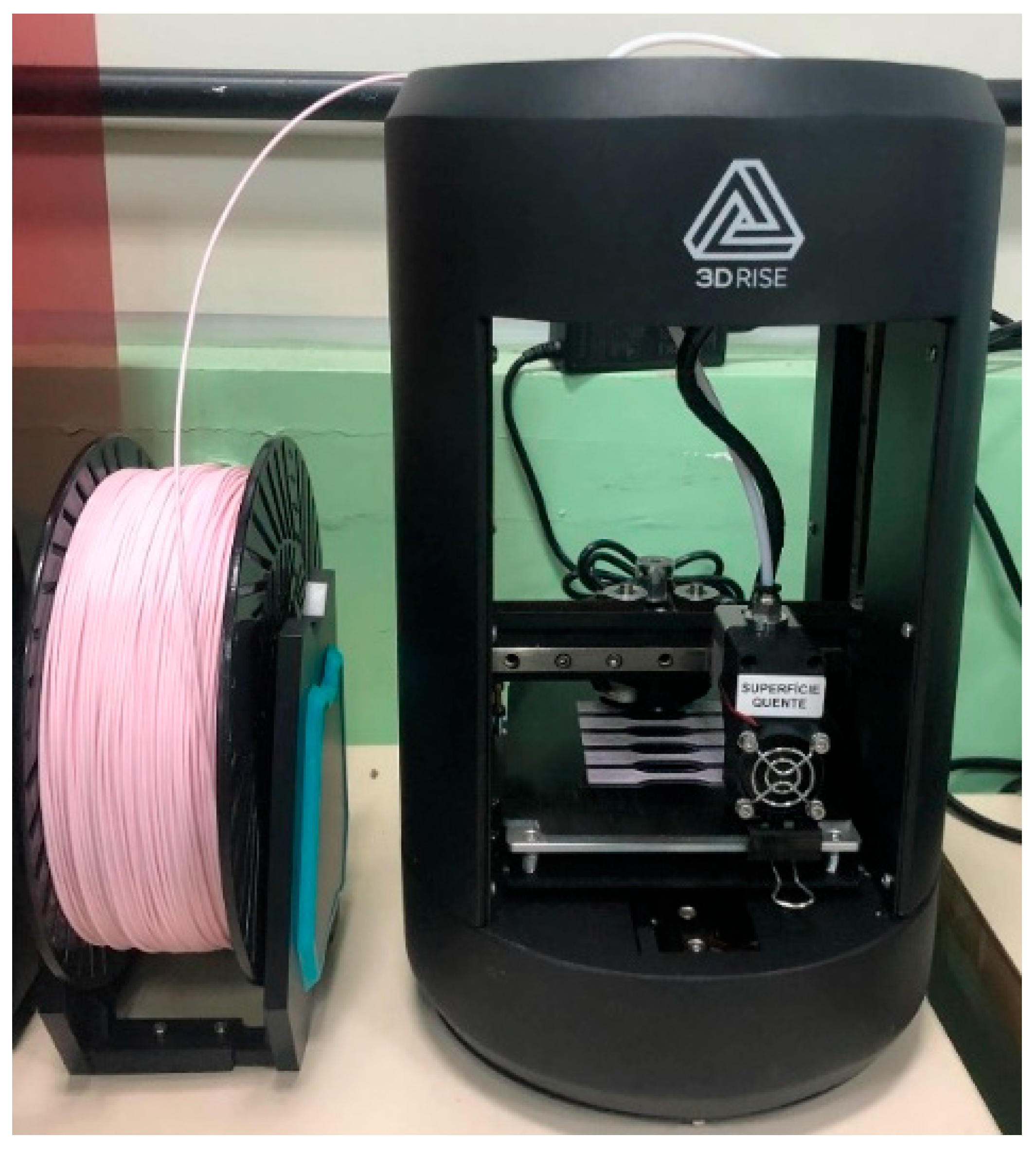

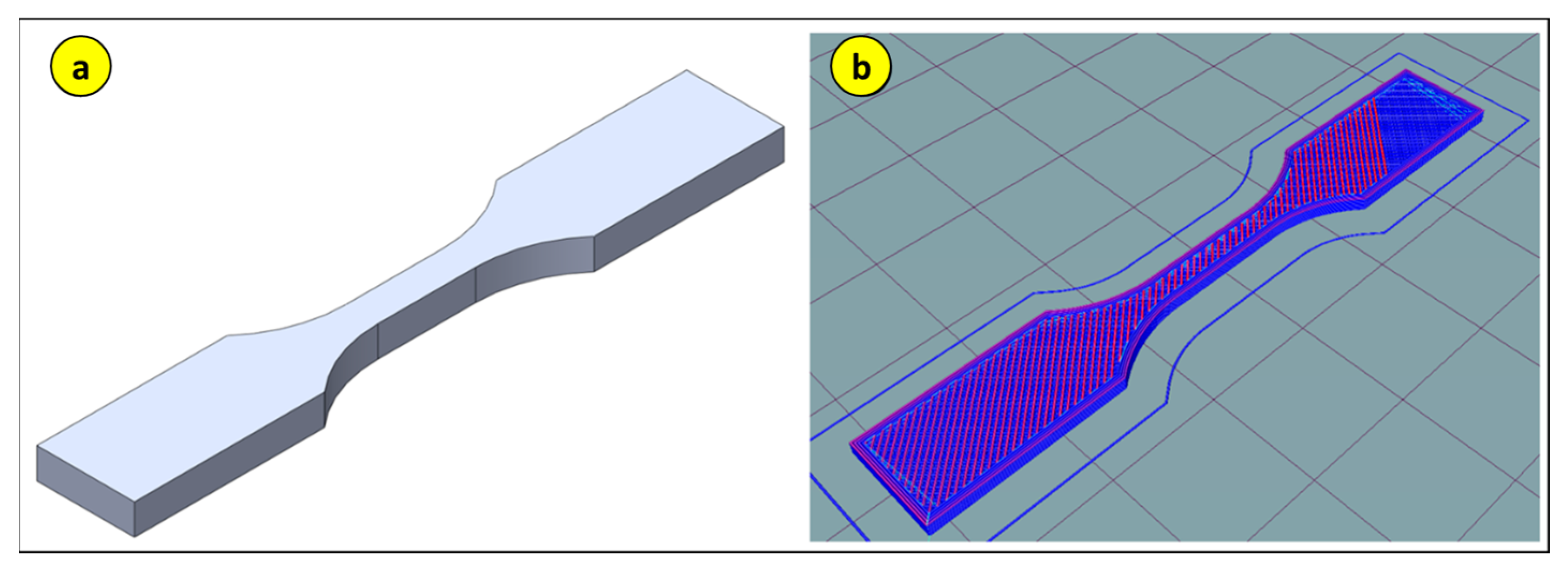

2.3. Manufacturing of Test Specimens

- Printing Technology: Fused Deposition Modeling (FDM).

- Layer Resolution: 100 Microns.

- Print Volume: 100 × 140 × 120 mm.

- Precision: X and Y Axes: 11 Microns (0.0011 mm); Z Axis: 2.5 Microns (0.00025 mm).

- Filament Diameter: 1.75 mm.

- Compatible Filaments: PLA.

- Print Quality: 0.2 mm.

- Print Speed: 50 mm/s.

- Outer Perimeter Speed: 45 mm/s.

- Infill Speed: 80 mm/s.

- Infill Density: 80 mm/s.

- Flow Rate: 110%.

- Extruder Nozzle Temperature: 210 °C.

- Infill: 40%.

- Print Orientation: 45°/−45°.

- Adjusting the extruder nozzle temperature;

- Extruder nozzle clogging;

- Print speed;

- Ambient temperature.

2.4. Thermogravimetric Analysis (TGA) Methdology

2.5. Scanning Electron Microscopy (SEM) Methdology

2.6. Transmission Electron Microscopy (TEM) Methdology

2.7. Fourier Transform Infrared (FTIR) Radiation

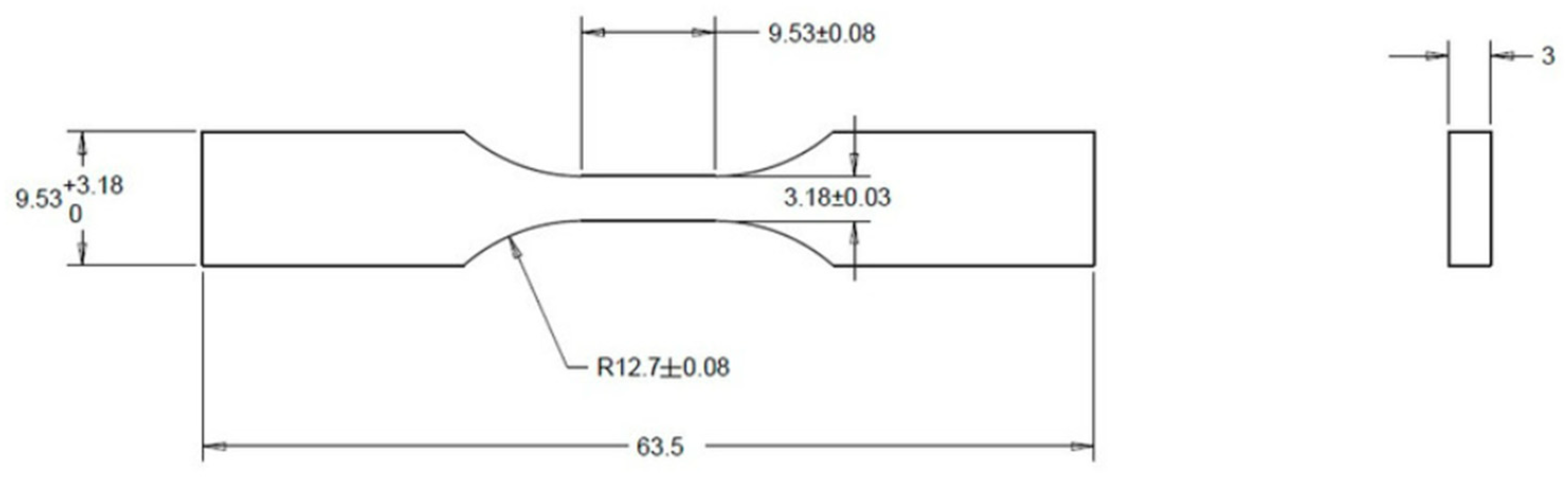

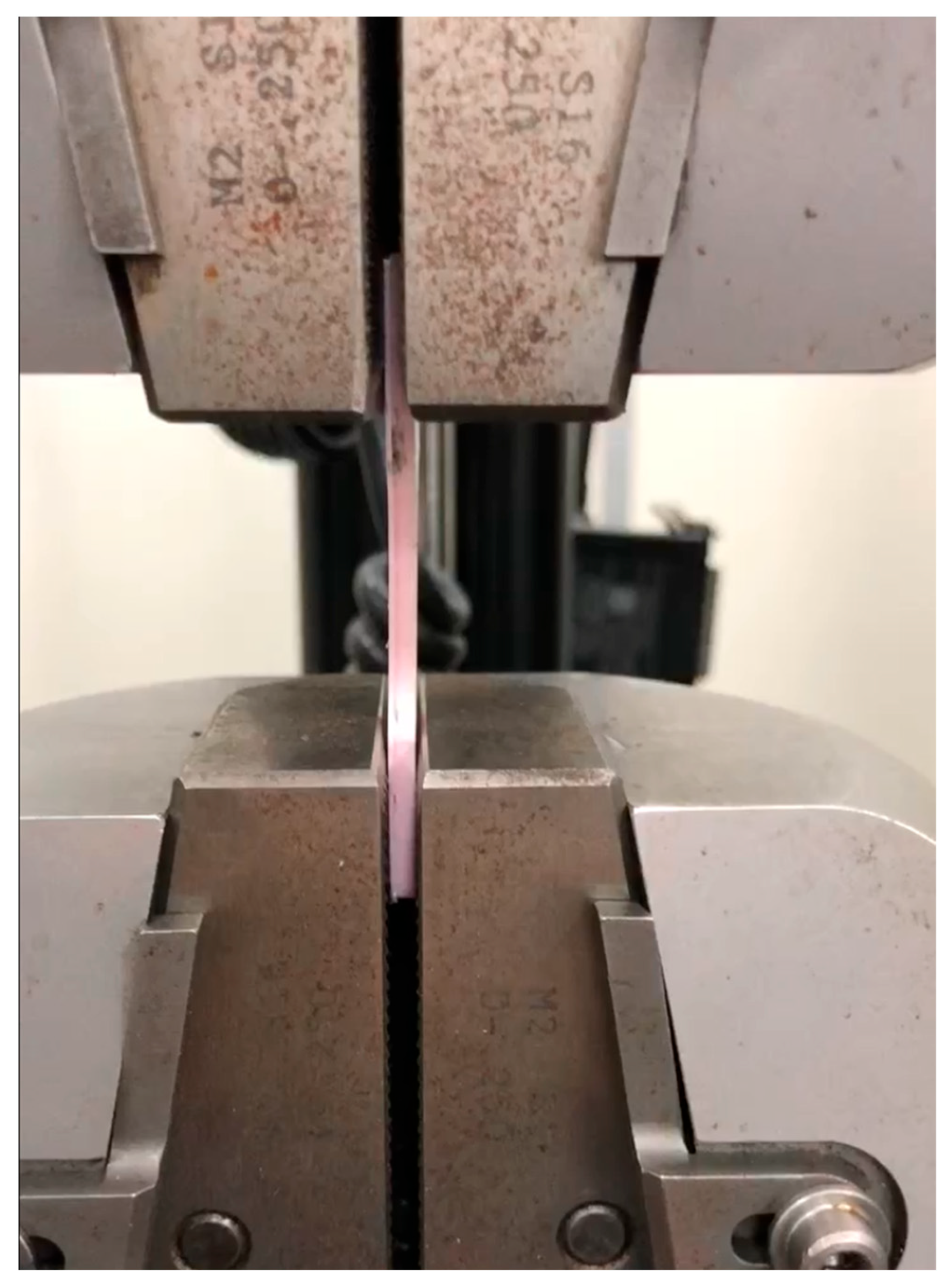

2.8. Tensile Mechanical Testing

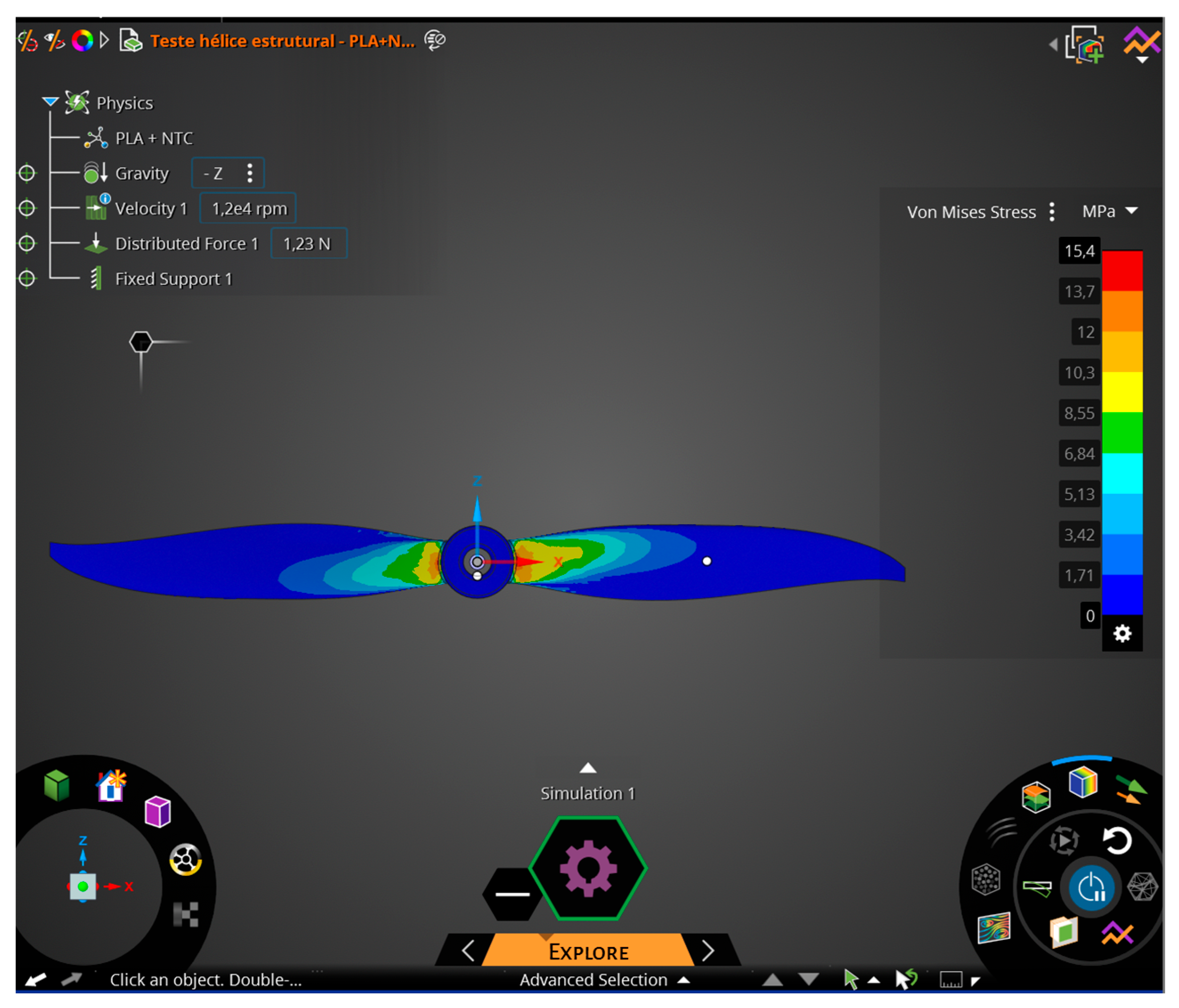

2.9. Computer Simulation

- Gravity: 9.81 m/s2.

- Propeller rotation: 12,000 rpm.

- Pressure on the blade surface from the bottom: 5.9 MPa.

- Load on the propeller: 19.6 N.

3. Discussion

3.1. Full Factorial

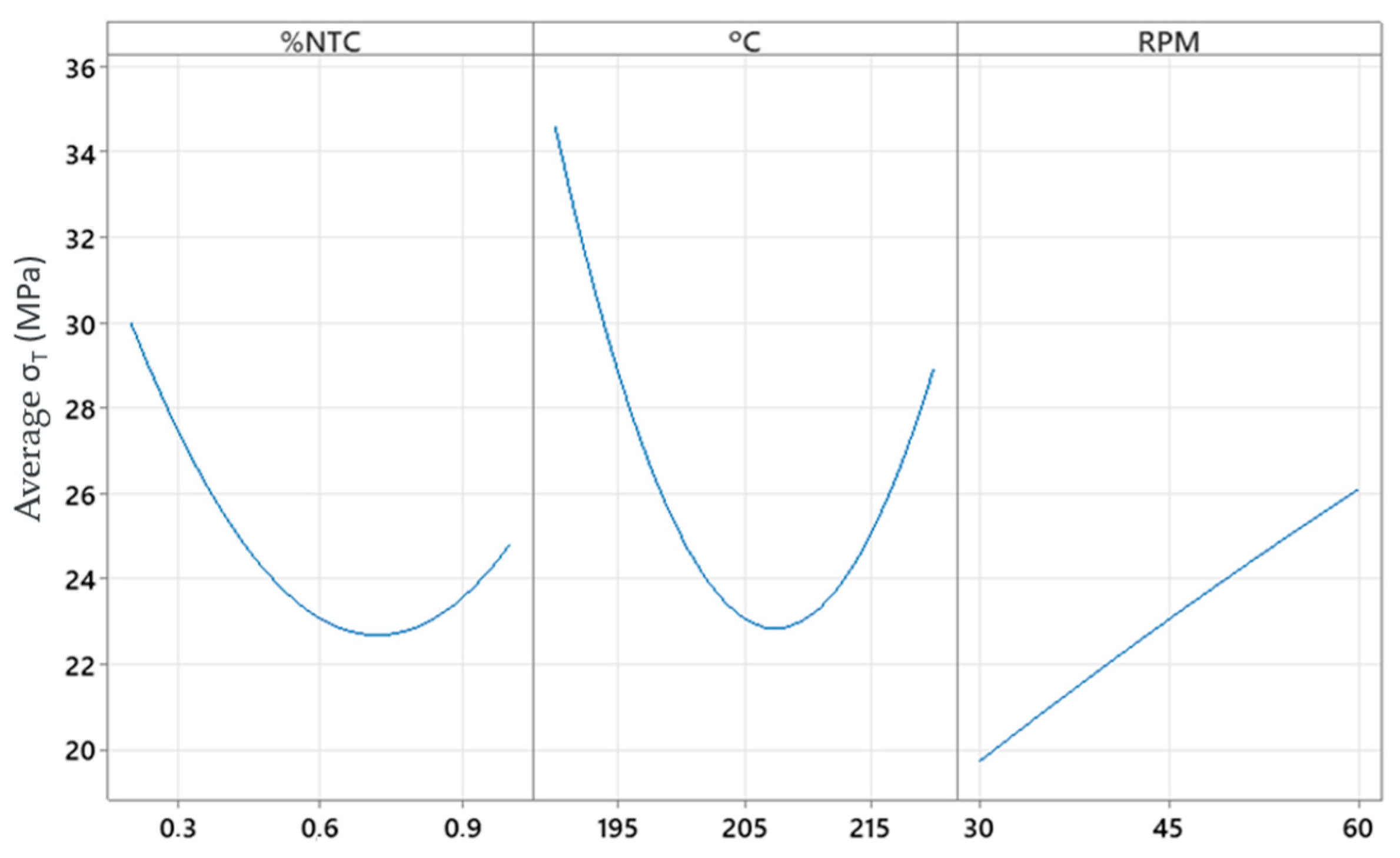

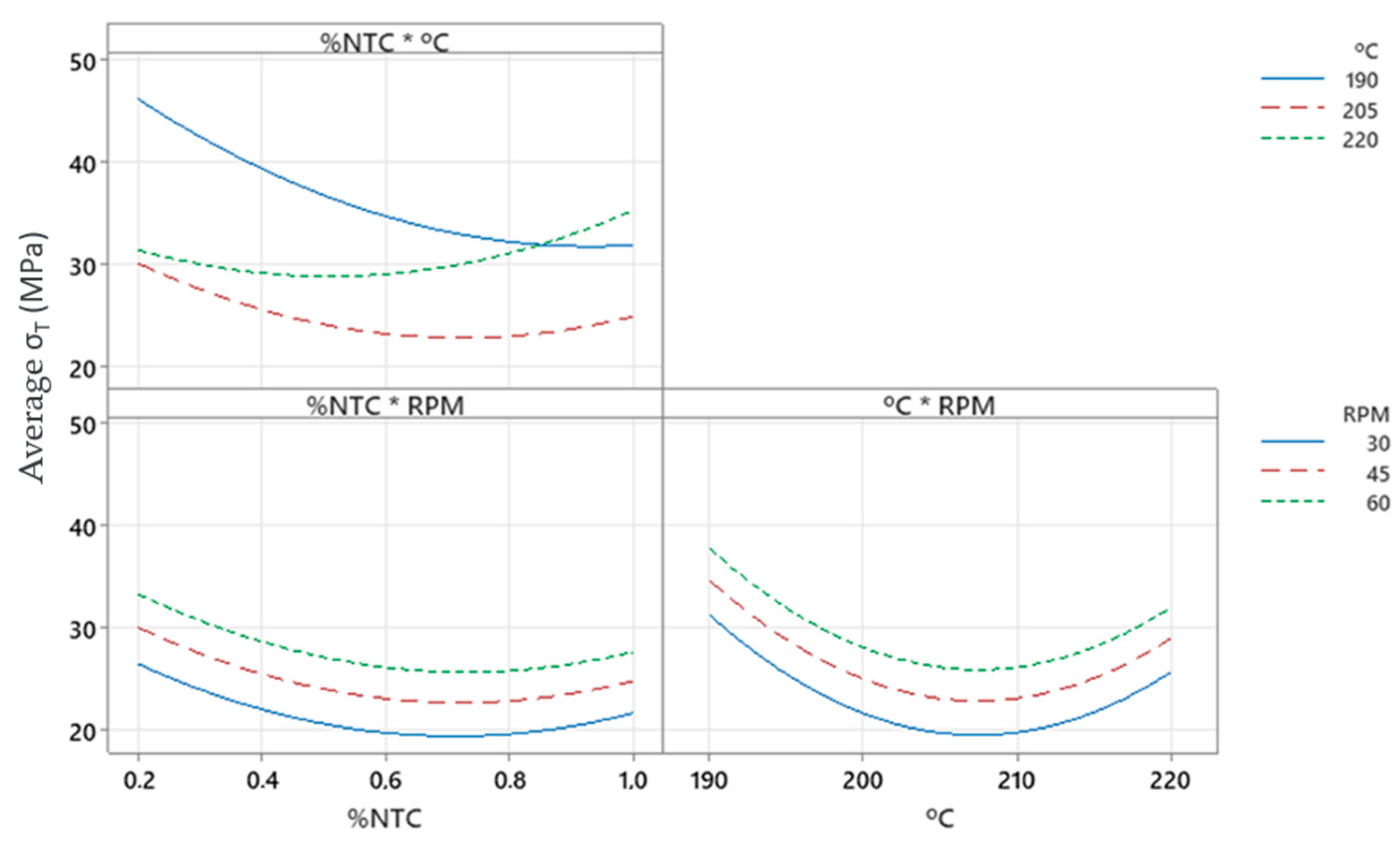

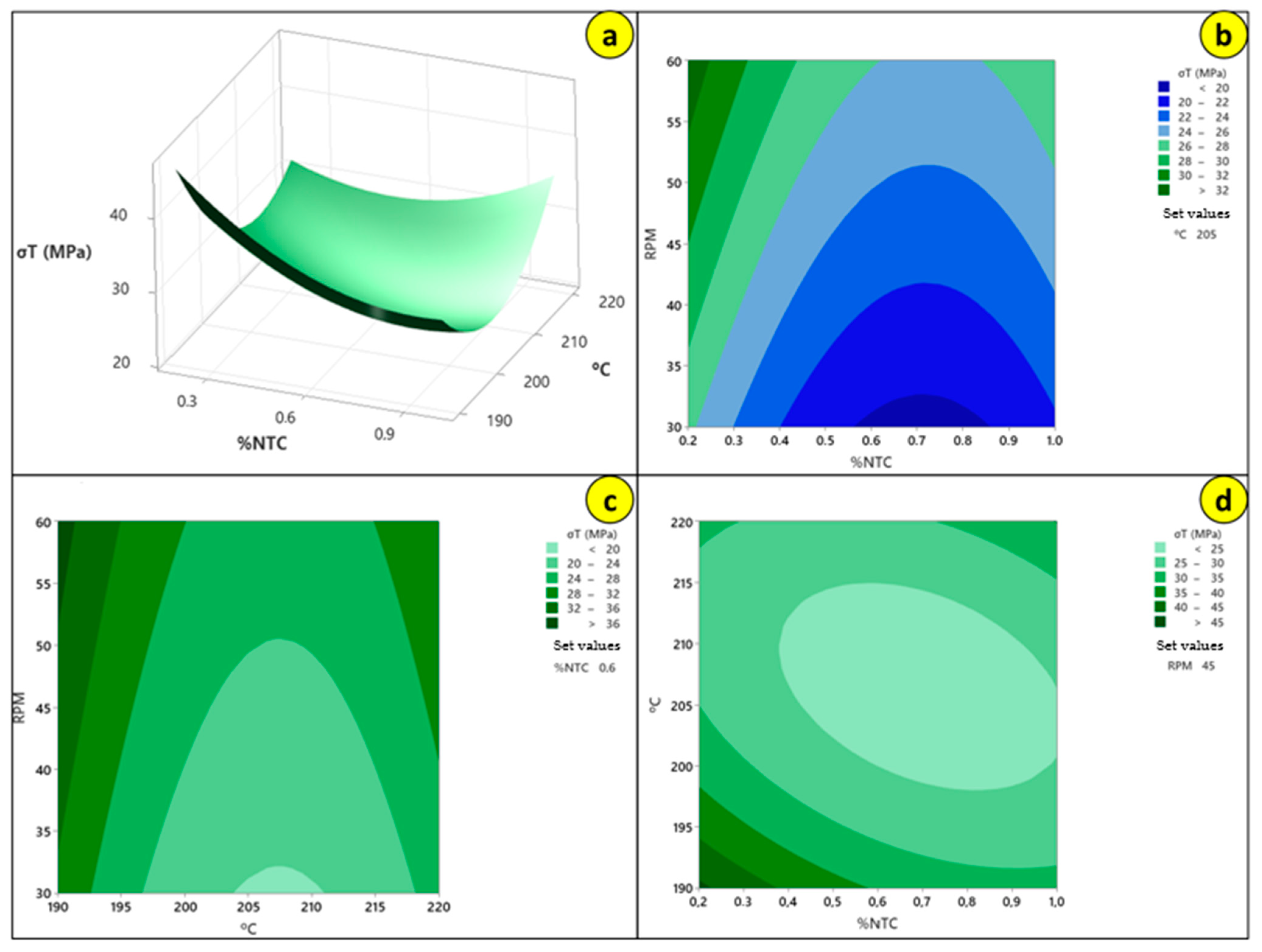

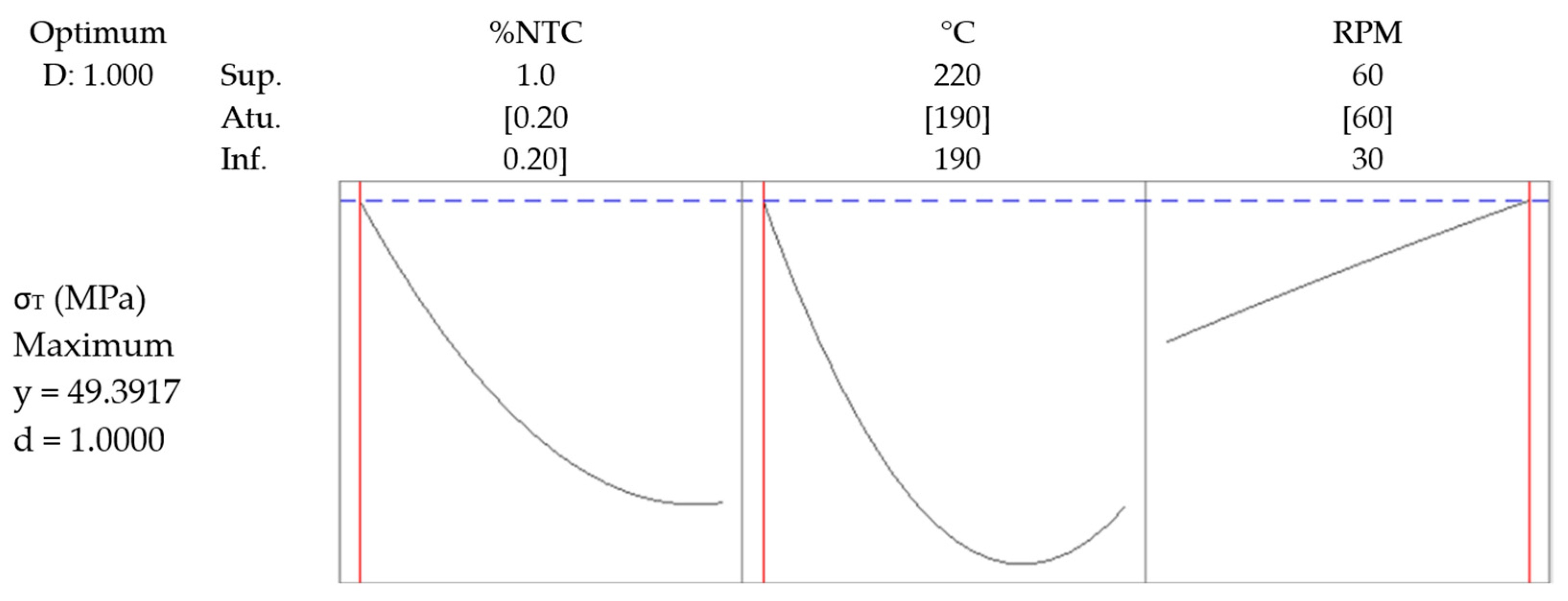

3.2. Response Surface

- CNT content (A);

- Temperature (B);

- RPM (C).

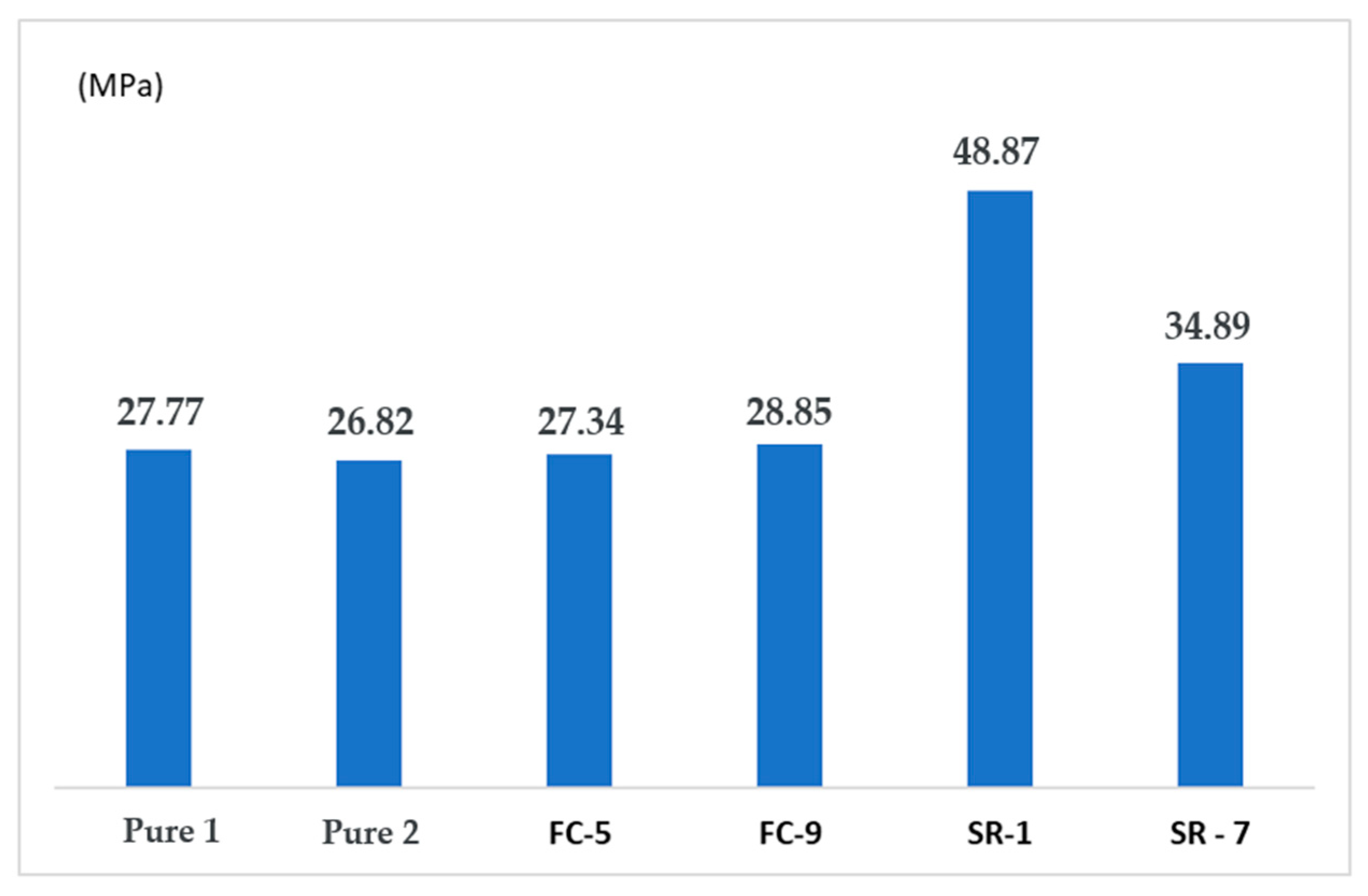

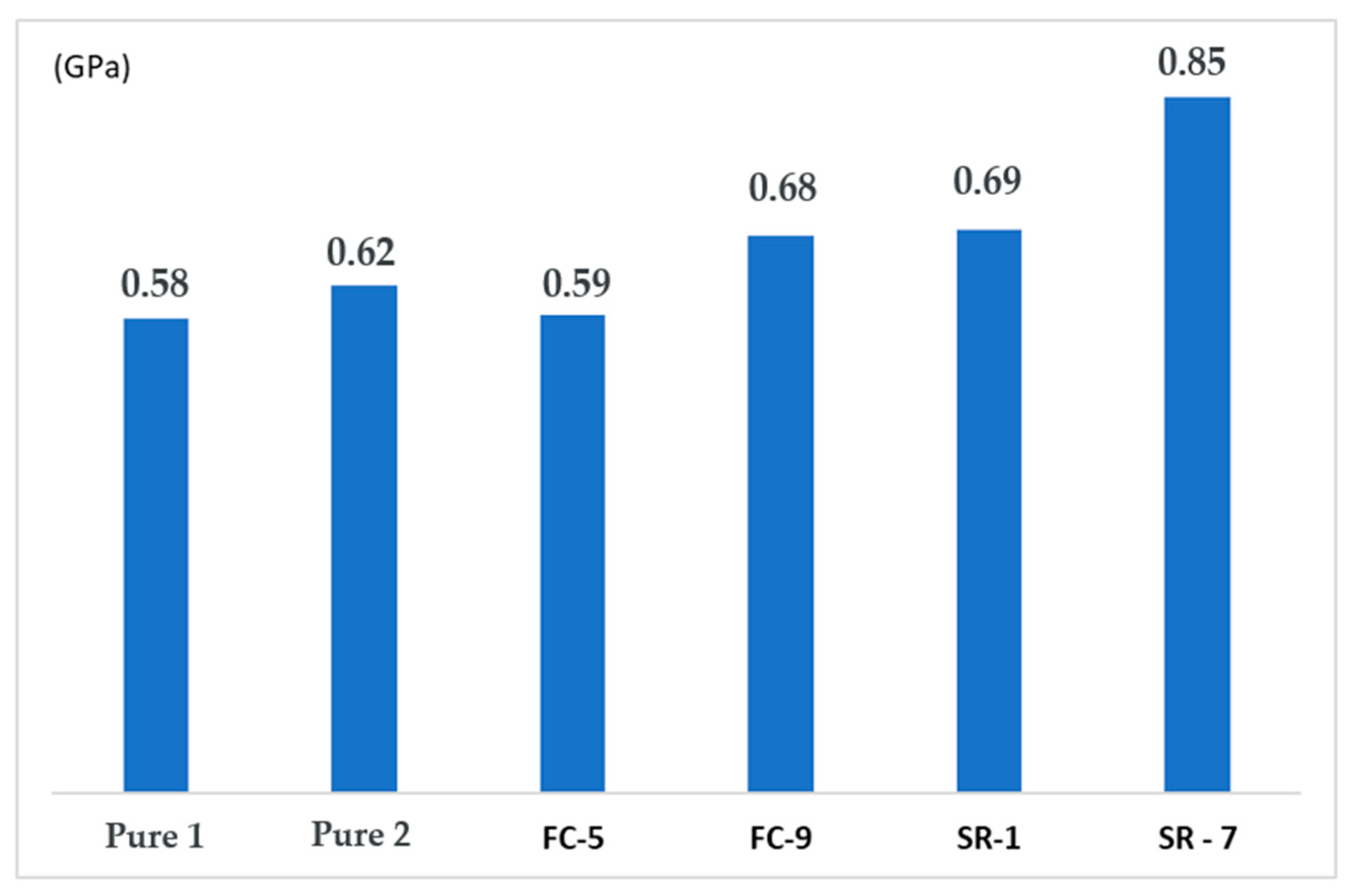

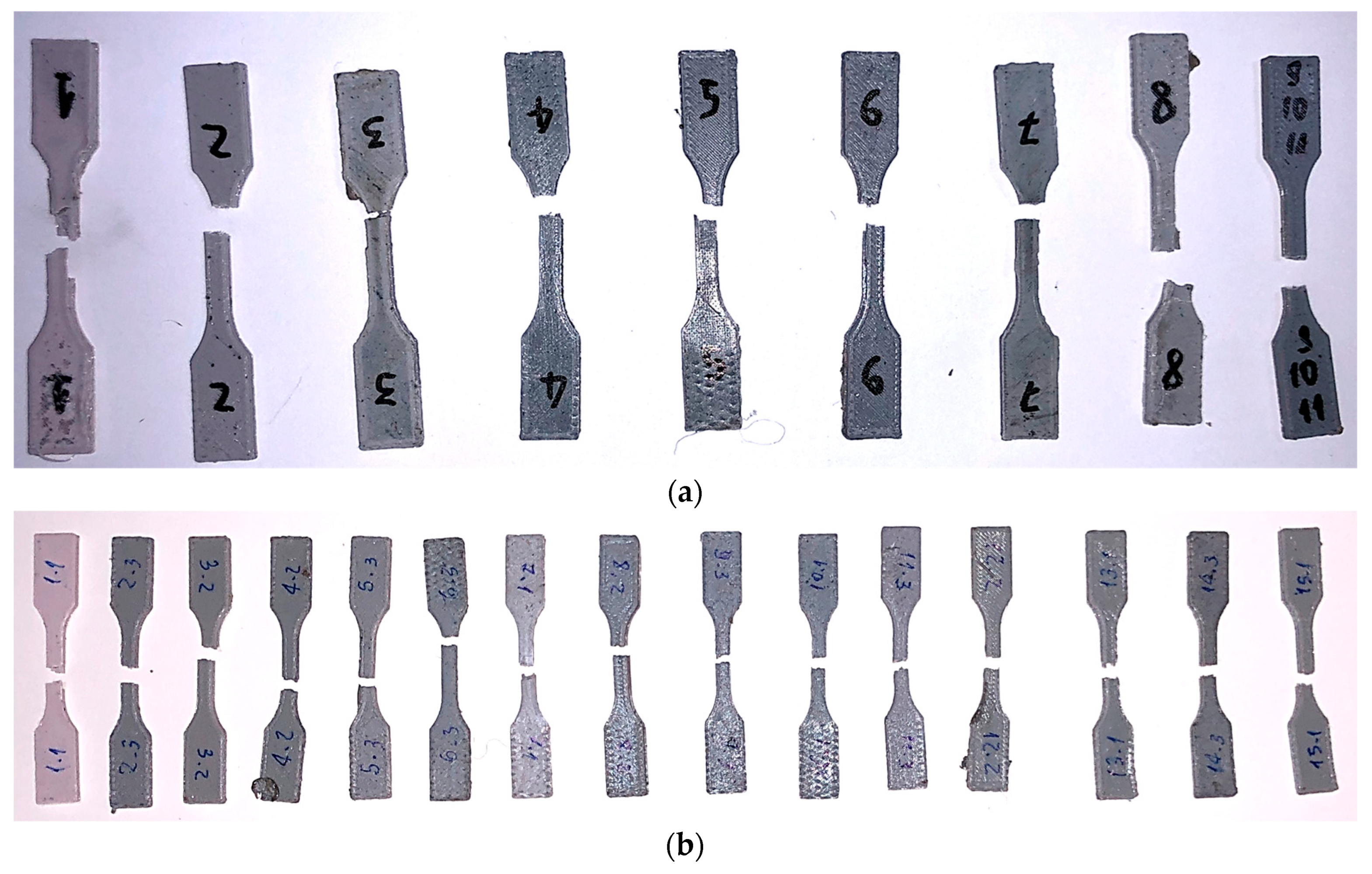

3.3. Mechanical Test Comparison

- SR-1 (Run 11): Corresponds to the sample that exhibited the highest tensile strength (48.9 MPa), manufactured with 0.2% CNT, at a temperature of 190 °C and 45 RPM **.

- SR-7 (Run 15): Showed a strength of 34.9 MPa, manufactured with 0.2% CNT, at 205 °C and 60 RPM **.

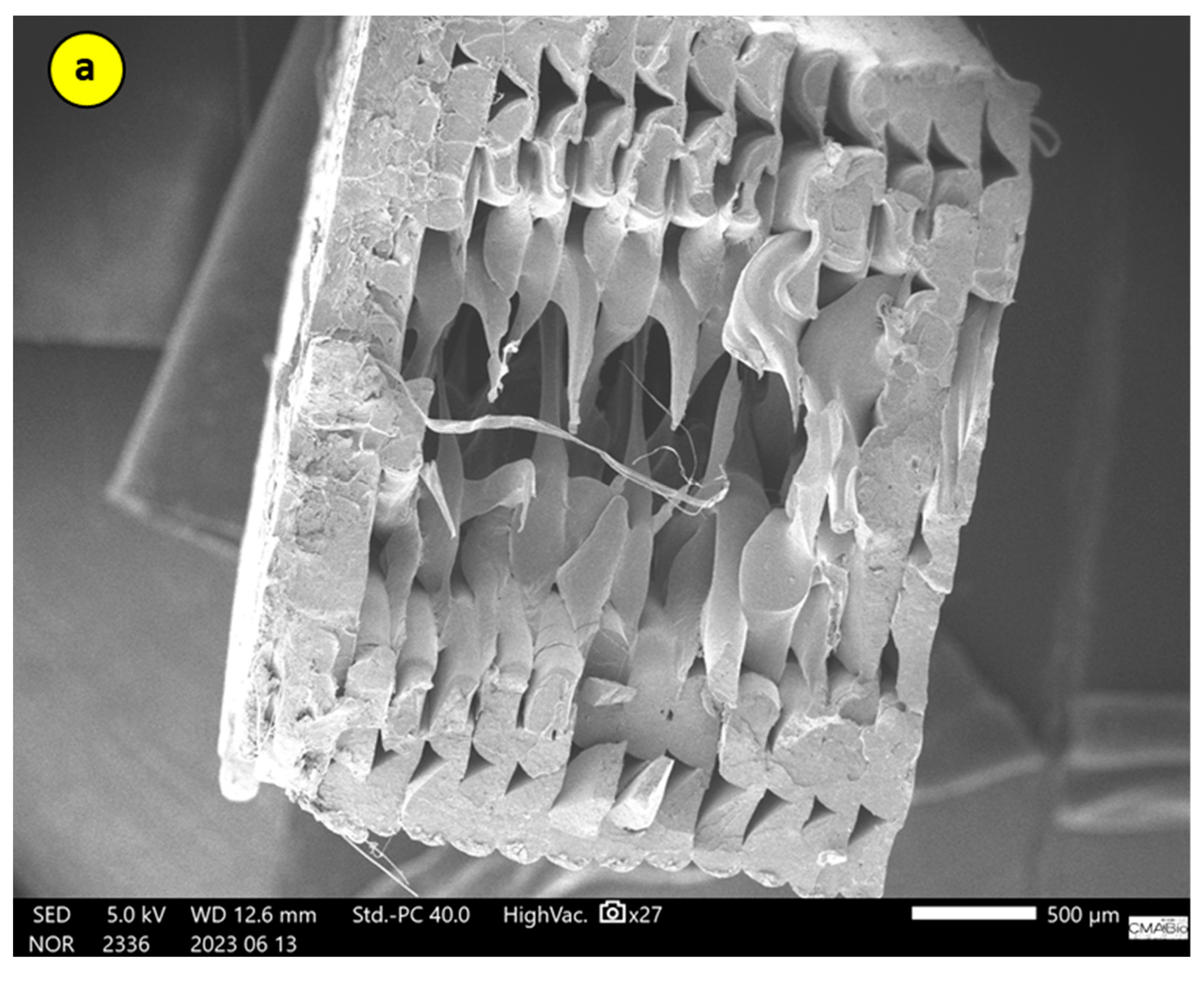

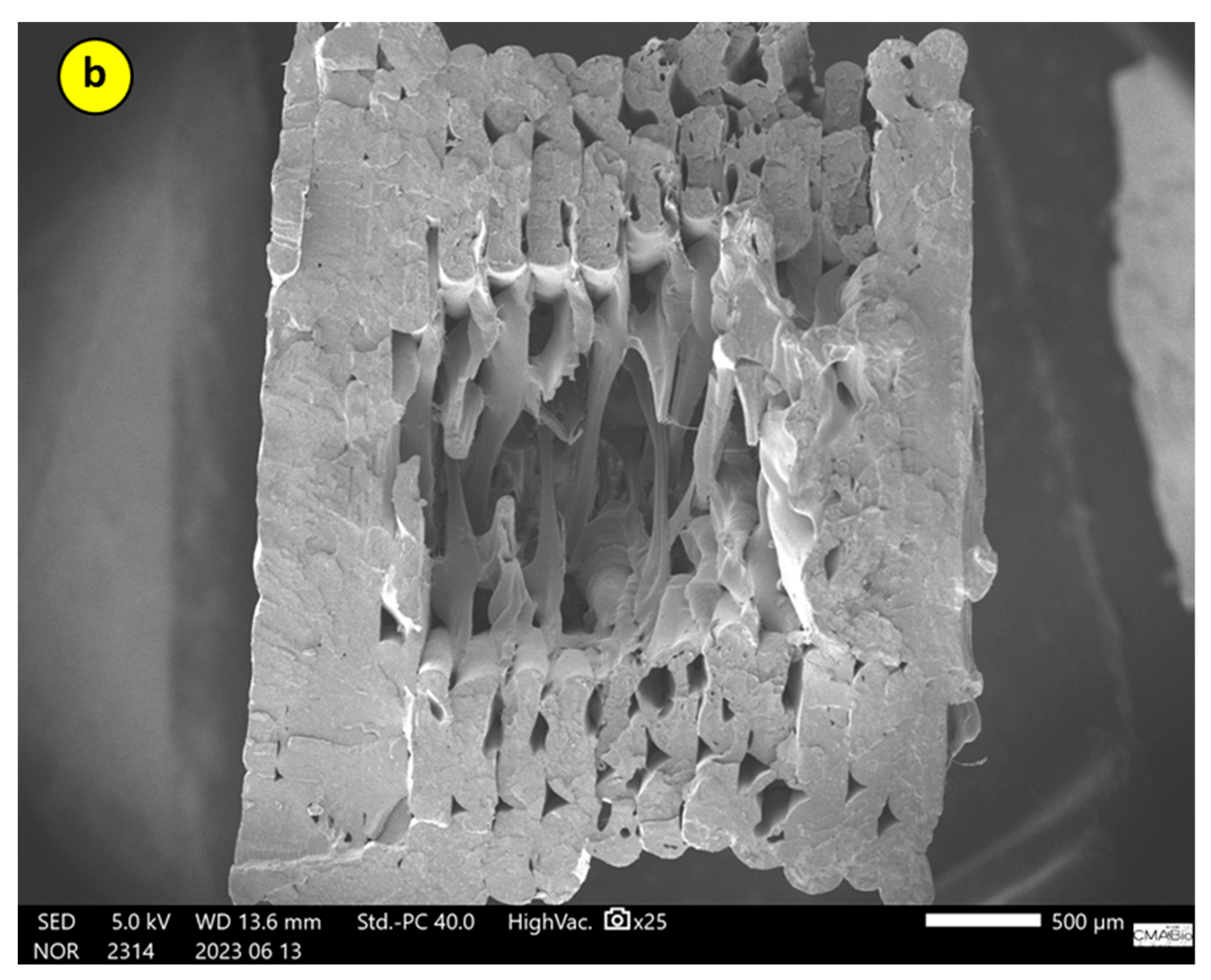

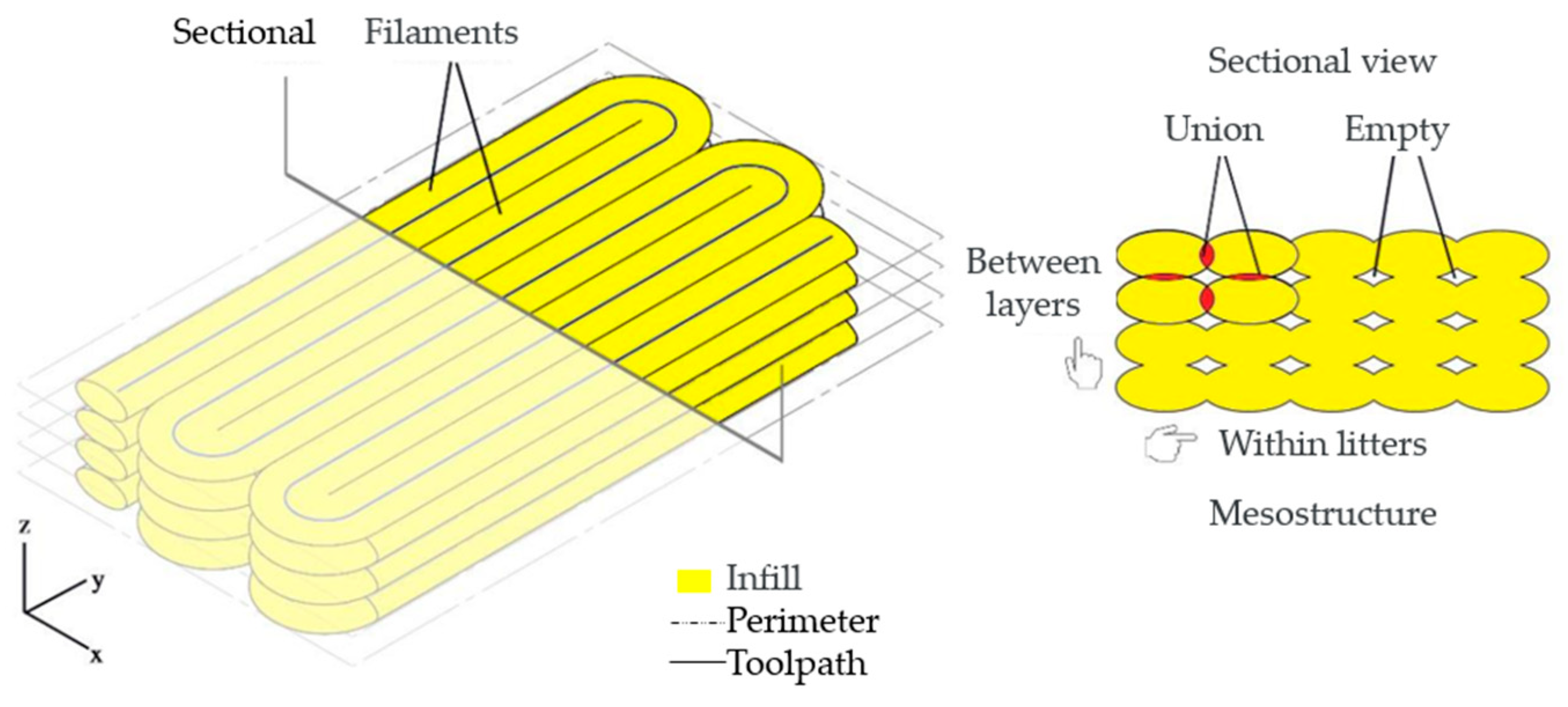

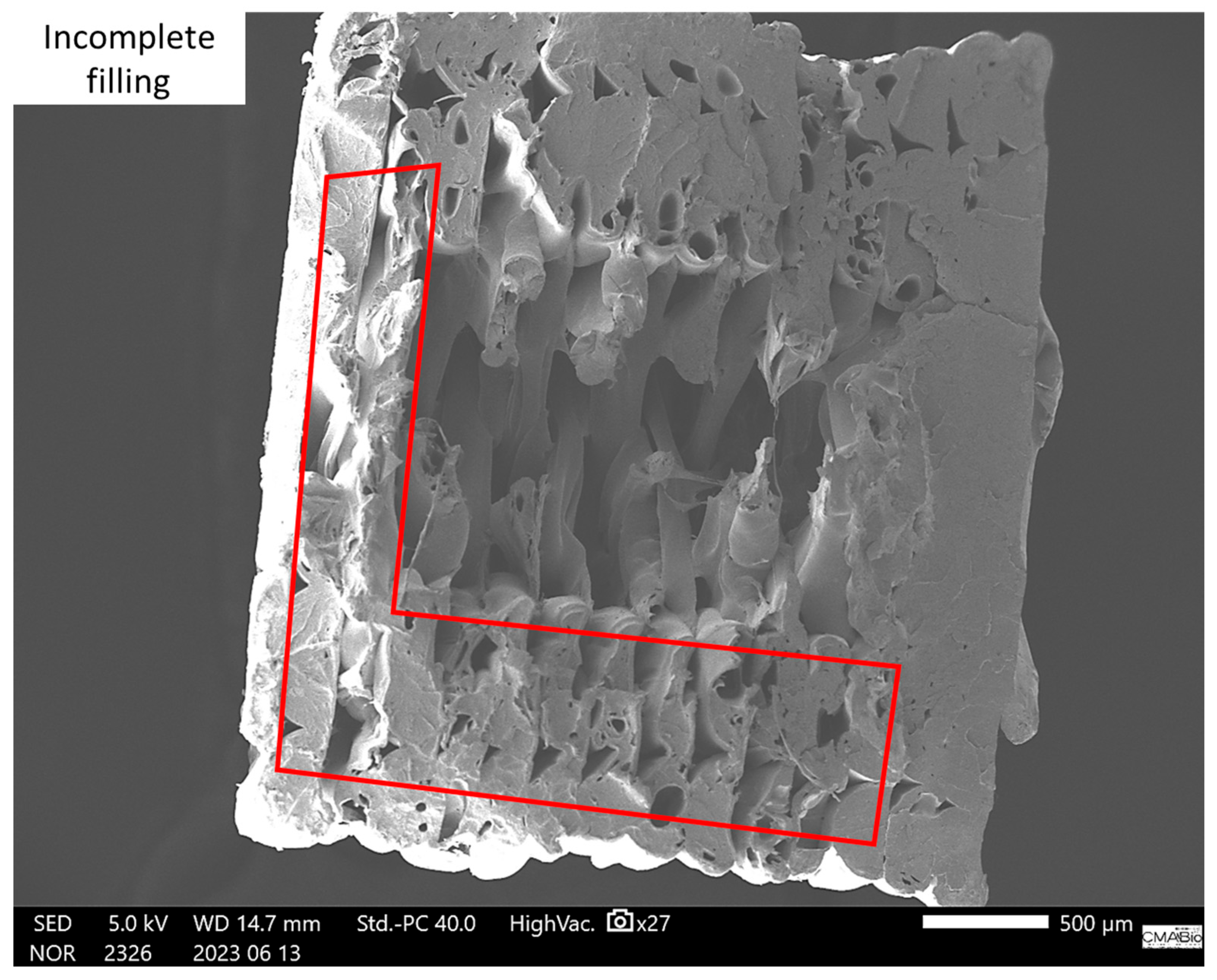

3.4. Fracture Study by Scanning Electron Microscopy (SEM)

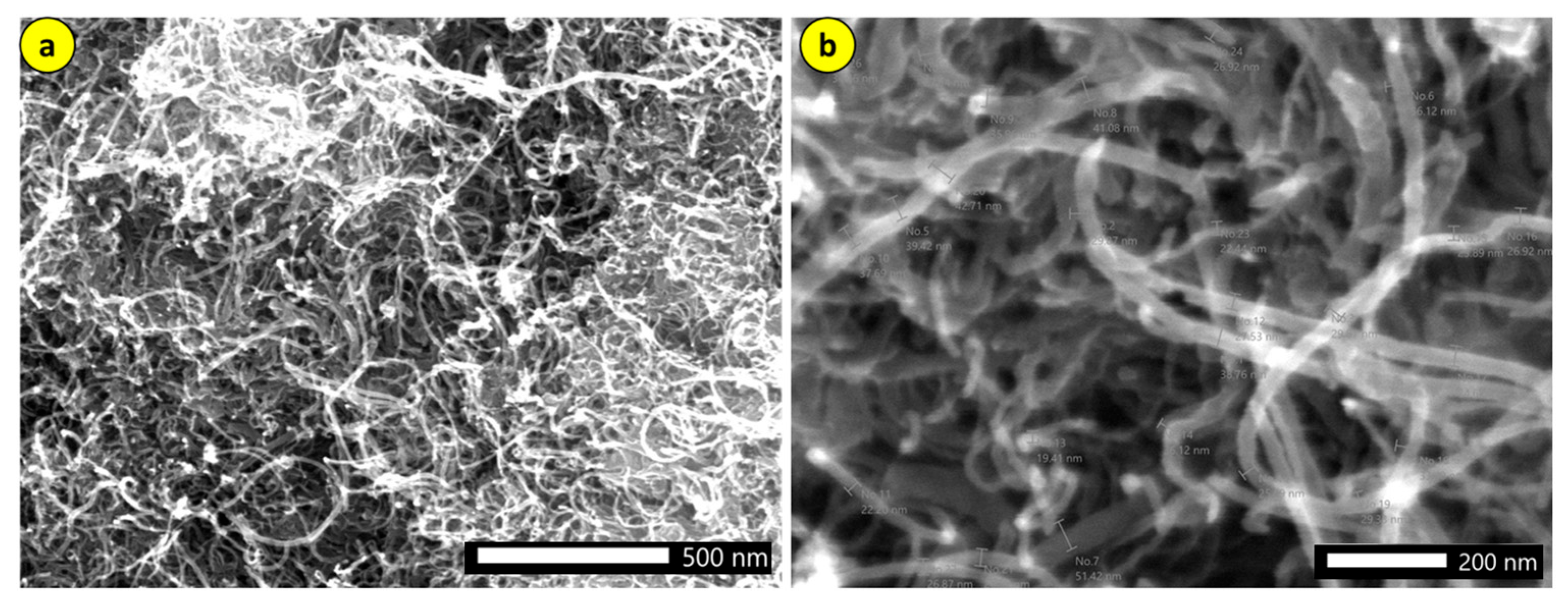

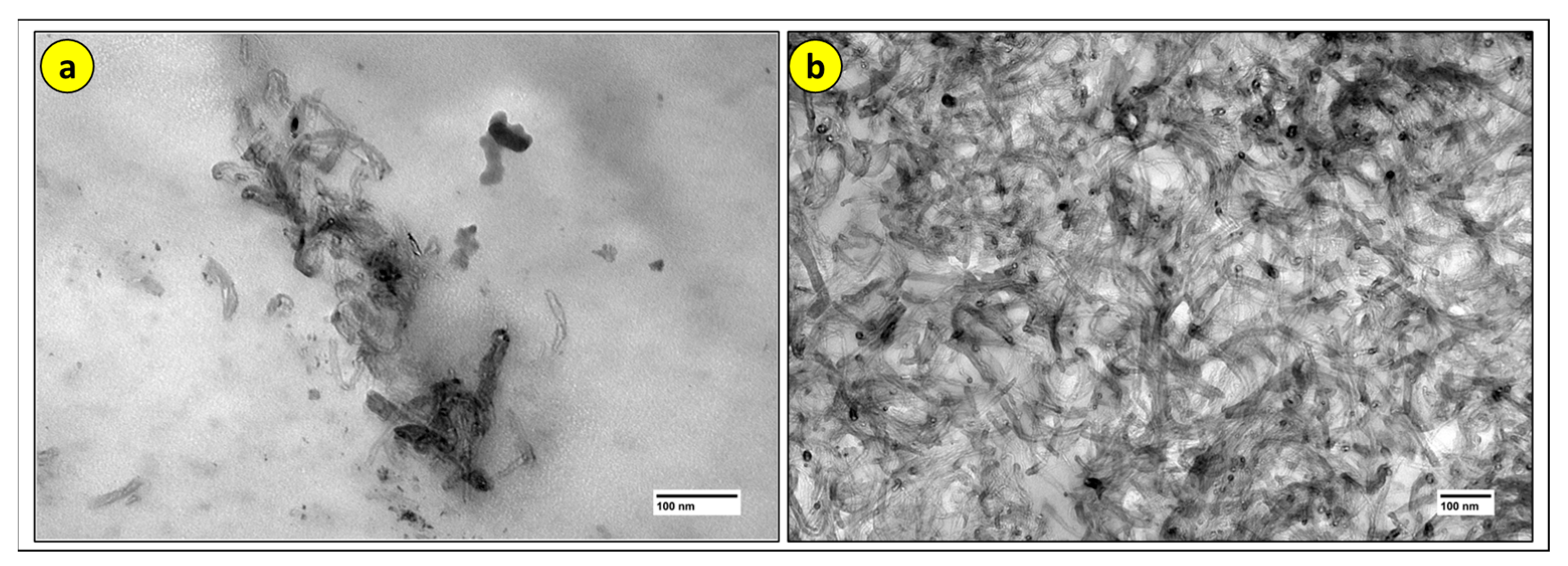

3.5. Transmission Electron Microscopy (TEM)

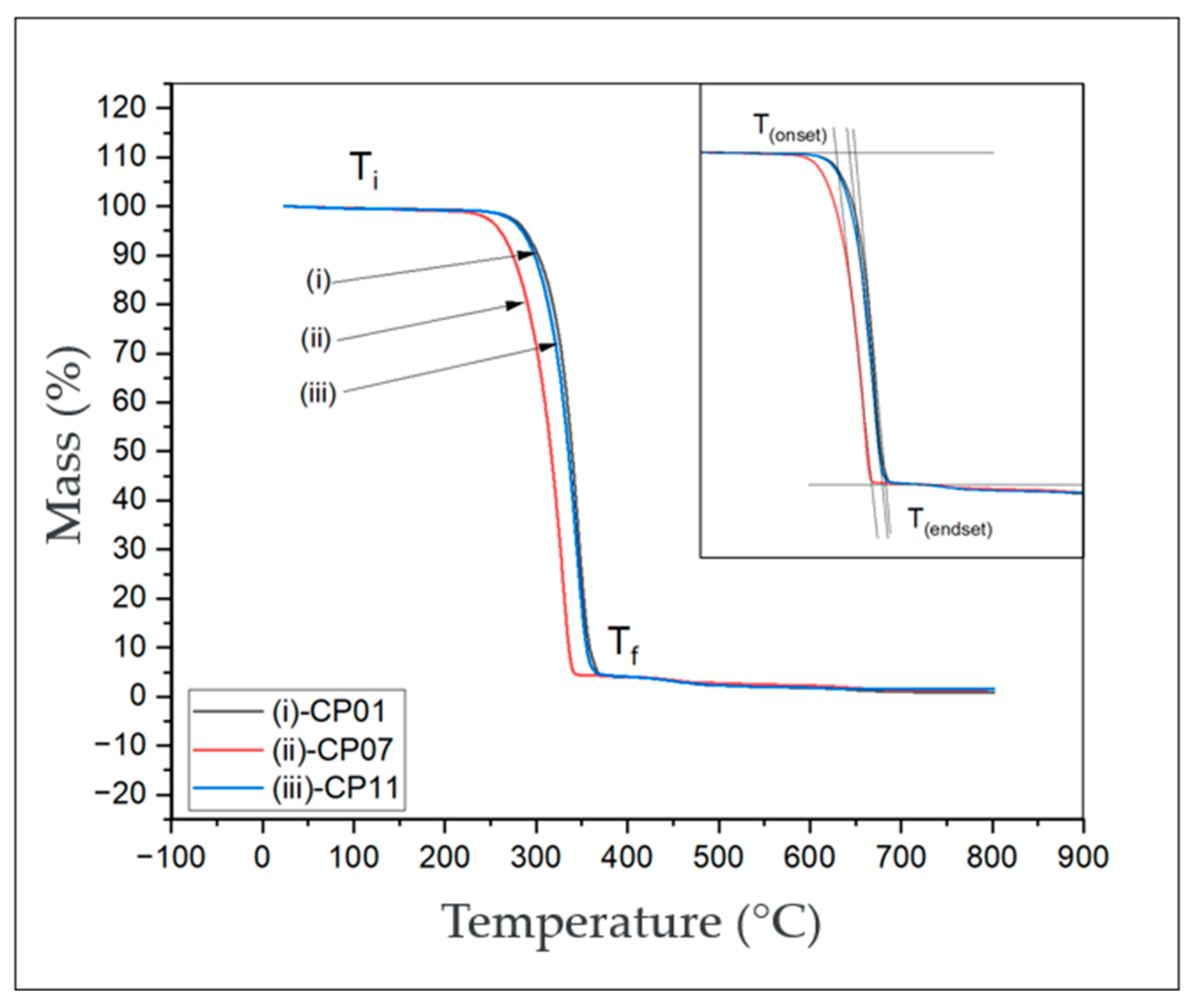

3.6. Thermogravimetric Analysis (TGA)

- Ti—The initial temperature is the lowest temperature at which the onset of mass change can be detected for a given set of experimental conditions.

- Tf—The final temperature is the lowest temperature indicating that the process responsible for the mass change has been completed.

- Tonset—It is identified by the crossing of the lines and is referred to as the extrapolated onset or mathematical onset.

- Tendset—It is identified by the crossing of the lines and is referred to as the extrapolated end or mathematical end.

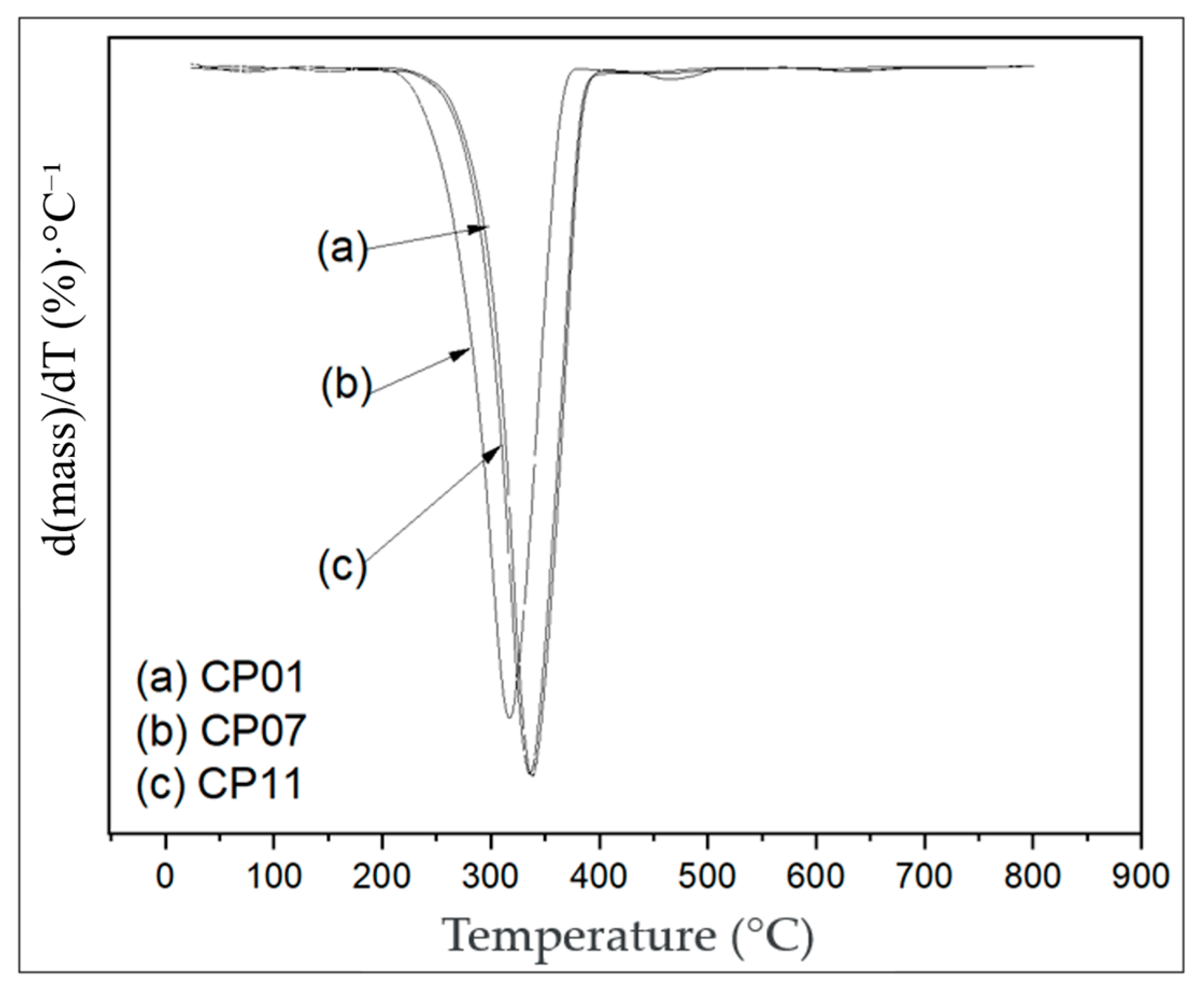

3.7. Derivative Thermogravimetric Analysis (DTG)

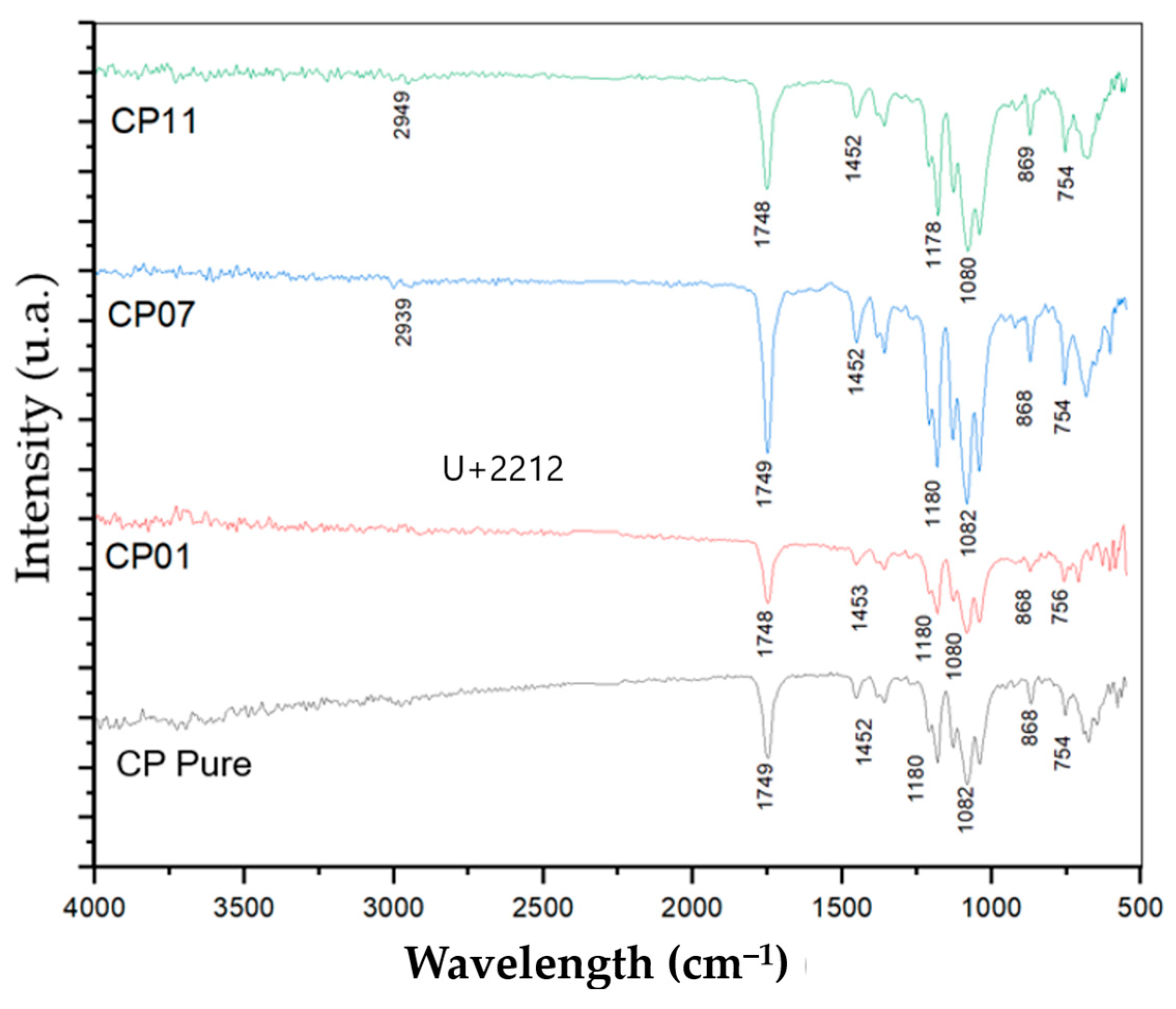

3.8. Infrared Radiation by Fourier Transform (IRTF)

3.9. Finite Element Method (FEM) Simulation

- Good dispersion of nanoparticles in the PLA matrix;

- Adequate printing temperature;

- Printing orientation at 45°/−45°, as used in this research;

- Printing fill pattern.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mustafa, M.A.S.; Mohammed, K.S.; Abbood, H.H.; Majdi, H.S. Optimizations of Different Materials for Drone Blades Using Computational Fluid Dynamics. Eng. Technol. Appl. Sci. Res. 2025, 4, 25836–25843. [Google Scholar] [CrossRef]

- Malim, A.; Mourousias, N.; Marinus, B.G.; De Troyer, T. Structural Desing of a Large-Scale 3D-Printed High-Altitude Propeller: Methodology and Experimental Validation. Aerospace 2023, 10, 256. [Google Scholar] [CrossRef]

- dos Santos, A.L.; de Souza, F.C.R.; Martins da Costa, J.C.; Gonçalves, D.A.; Passos, R.R.; Pocrifka, L.A. Development and Characterization of 3D-Printed PLA/Exfoliated Graphite Composites for Enhanced Electrochemical Performance in Energy Storage Applications. Polymers 2024, 16, 3131. [Google Scholar] [CrossRef] [PubMed]

- Silva Dias, W.; Demosthenes, L.C.d.C.; Costa, J.C.M.d.; Pocrifka, L.A.; Reis do Nascimento, N.; Coelho Pinheiro, S.; Garcia del Pino, G.; Valin Rivera, J.L.; Valin Fernández, M.; Costa de Macêdo Neto, J. 3D Printing of Virucidal Polymer Nanocomposites (PLA/Copper Nanoparticles). Polymers 2025, 17, 283. [Google Scholar] [CrossRef]

- Faria, L.V.; Nascimento, S.F.L.; Villafuerte, L.M.; Semaan, F.S.; Pacheco, W.F.; Dornellas, R.M. 3D Printed Graphite-based Electrode Coupled with Batch Injection Analysis: An Affordable High-throughput Strategy for Atorvastatin Determination. Talanta 2023, 265, 124873. [Google Scholar] [CrossRef]

- Ray, S.S.; Bousmina, M. Biodegradable Polymers and Their Layered Silicate Nanocomposites: In Greening the 21st Century Materials World. Prog. Mater. Sci. 2005, 50, 962–1079. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Fernández, M.V.; Rivera, J.L.V.; Rodríguez, F.P.; Losada, H.F.; Abreu, M.E.F.; Diaz, F.R.V.; Soto, A.R.; Alvarez, A.A.; Quinteros, R.; Ketterer, G.; et al. Mechanical Characterization of a Polymer/Natural Fibers/Bentonite Composite Material with Implementation of a Continuous Damage Model. Appl. Sci. 2023, 13, 2677. [Google Scholar] [CrossRef]

- Assis, E.G.; dos Santos, J.C.; da Silva, R.J.; de Oliveira, L.A.; Del Pino, G.G.; Scarpa, F.; Panzera, T.H. Water Aging Effects on the Flexural Properties of Fully Biobased Coir Fiber Composites. Polym. Eng. Sci. 2023, 63, 3719–3730. [Google Scholar] [CrossRef]

- Neto, J.C.M.; Freitas, B.M.; Miranda, A.G.; Rodrigues, R.A.; Del Pino, G.G.; Kieling, A.C.; Santos, M.D.; Junior Duvoisin, S.; Sanches, A.E.; Torné, G.I.; et al. The Stability and Properties of Polystyrene/Kaolinite Nanocomposites During Synthesis via Emulsion Polymerization. Polymers 2023, 15, 2094. [Google Scholar] [CrossRef] [PubMed]

- Neto, J.C.M.; Nascimento, N.R.; Bello, R.H.; Verçosa, L.A.; Neto, J.E.; Costa, J.C.M.; Diaz, F.R.V. Kaolinite Review: Intercalation and Production of Polymer Nanocomposites. Eng. Sci. 2022, 17, 28–44. [Google Scholar] [CrossRef]

- Colorado, H.A.; Gutierrez-Velasquez, E.I.; Gil, L.D.; de Camargo, I.L. Exploring the Advantages and Applications of Nanocomposites Produced via Vat Photopolymerization in Additive Manufacturing: A Review. Adv. Compos. Hybrid Mater. 2024, 7, 1. [Google Scholar] [CrossRef]

- Boff, M.O.; Monteiro, A.C.L.; Fracassi, M.A.T.; Fuhr, M.I. Avaliação dos Métodos de Obtenção e Propriedades de Nanocompósitos de Polímeros com Nanotubos de Carbono-Uma Revisão. Rev. Lib. 2022, 23, 61–76. [Google Scholar]

- Silva, E.C.; Pinto, A.C.; Gomes, C.G.; Passos, R.R.; da Frotta, C.A.; Pocrifka, L.A. Applied to Energy Storage: A Statistical and Electrochemical Study of the Effect of High-Energy Milling on the Efficiency of the Material. J. Braz. Chem. Soc. 2025, 36, e-20250092. [Google Scholar] [CrossRef]

- Zarbin, A.J.G.; Oliveira, M.M. Nanoestruturas de Carbono (Nanotubos, Grafeno): Quo Vadis? Química Nova 2013, 36, 1533–1539. [Google Scholar] [CrossRef][Green Version]

- Gonçalves, C.; Gonçalves, I.C.; Magalhães, F.D.; Pinto, A.M. Poly(Lactic Acid) Composites Containing Carbon-Based Nanomaterials: A Review. Polymers 2017, 9, 269. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yang, M.; Yuan, Q.; Zhang, W. Effects of Carbon Nanotube on the Thermal, Mechanical, and Electrical Properties of PLA/CNT Printed Parts in the FDM Process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Santana, L.; Alves, J.L.; Netto, A.C.S.; Merlini, C. Estudo Comparativo entre PETG e PLA para Impressão 3D Através de Caracterização Térmica, Química e Mecânica. Matéria 2018, 23, e12267. [Google Scholar] [CrossRef]

- Podsiadły, B.; Matuszewski, P.; Skalski, A.; Słoma, M. Carbon Nanotube-Based Composite Filaments for 3D Printing of Structural and Conductive Elements. Appl. Sci. 2021, 11, 1272. [Google Scholar] [CrossRef]

- Crandall, B.S.; Naughton, M.; Park, S.; Yu, J.; Zhang, C.; Mahtabian, S.; Wang, K.; Liang, X.; Fu, K.; Jiao, F. Transforming CO2 into Advanced 3D Printed Carbon Nanotube Nanocomposites. Nat. Commun. 2024, 15, 54957. [Google Scholar] [CrossRef]

- ASTM D638–14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Ren, P.G.; Wang, J.; Fan, Q.; Yang, S.; Wu, Z.Q.; Yan, D.X.; Chen, Y.H. Synergetic Toughening Effect of Carbon Nanotubes and β-Nucleating Agents on the Polypropylene Random Copolymer/Styrene-Ethylene-Butylene- Styrene Block Copolymer Blends. Polymers 2018, 11, 29. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A Review of Conductive Carbon Materials for 3D Printing. Materials 2021, 14, 3911. [Google Scholar] [CrossRef]

- Bortoli, L.S.; Farias, R.; Mezalira, D.Z.; Schabbach, L.M.; Fredel, M.C. Functionalized Carbon Nanotubes for 3D-Printed PLA-Nanocomposites: Effects on Thermal and Mechanical Properties. Mater. Today Commun. 2022, 31, 103402. [Google Scholar] [CrossRef]

- Iyer, N.P.; Arunkumar, N. Dynamic analysis of hybrid basalt and carbon fiber reinforced Bismaleimide composites suited for high temperature structural applications. Mater. Res. Express 2021, 8, 125302. [Google Scholar] [CrossRef]

- Spinelli, G.; Kotsilkova, R.; Ivanov, E.; Petrova-Doycheva, I.; Menseidov, D.; Georgiev, V.; Di Maio, R.; Silvestre, C. Effects of Filament Extrusion, 3D Printing and Hot-Pressing on Electrical and Tensile Properties of Poly(Lactic Acid) Composites Filled with Carbon Nanotubes and Graphene. Nanomaterials 2020, 10, 35. [Google Scholar] [CrossRef]

- Xu, Z.; Dou, T.; Wang, Y.; Zuo, H.; Chen, X.; Zhang, M.; Zou, L. Three-Dimensional-Printed Carbon Nanotube/Polylactic Acid Composite for Electromagnetic Interference Shielding. Polymers 2023, 15, 3080. [Google Scholar] [CrossRef] [PubMed]

- Albooyeh, A.R. The Effect of Addition of Multiwall Carbon Nanotubes on the Vibration Properties of Short Glass Fiber Reinforced Polypropylene and Polypropylene Foam Composites. Polym. Test. 2019, 74, 86–98. [Google Scholar] [CrossRef]

- Doronin, F.; Savel’ev, M.; Rytikov, G.; Evdokimov, A.; Nazarov, V. A New Approach to Carbon Nanotube Filament for Additive Manufacturing: Volumetric Nanostructuring via High-Speed Mechanical Mixing. Polymers 2024, 16, 1423. [Google Scholar] [CrossRef]

- Plamadiala, I.; Croitoru, C.; Pop, M.A.; Roata, I.C. Enhancing Polylactic Acid (PLA) Performance: A Review of Additives in Fused Deposition Modelling (FDM) Filaments. Polymers 2025, 17, 191. [Google Scholar] [CrossRef] [PubMed]

- Paz-González, J.A.; Gochi-Ponce, Y.; Velasco-Santos, C.; Alcudia-Zacarias, E.; Zizumbo-López, A.; Trujillo-Navarrete, B.; Morales-Contreras, O.A.; Villarreal-Gómez, L.J. Enhancing PLA/Carbon Fiber-Reinforced Biomedical Composites (PLA/CFRCs) with Multi-Walled Carbon Nanotube (MWCNT) Fillers: A Comparative Study on Reinforcing Techniques. J. Compos. Sci. 2025, 9, 167. [Google Scholar] [CrossRef]

- Nascimento, N.R.; Pinheiro, I.F.; Alves, G.F.; Mei, L.H.I.; Macedo Neto, J.C.; Morales, A.R. Role of Cellulose Nanocrystals in Epoxy-Based Nanocomposites: Mechanical Properties, Morphology and Thermal Behavior. Polímeros 2021, 31, e2021034. [Google Scholar] [CrossRef]

| Factor 1: %CNT | Level 1: 0.2% Level 2: 1.0% |

| Factor 2: Temperature | Level 1: 190 °C Level 2: 220 °C |

| Factor 3: RPM | Level 1: 30 rpm Level 2: 60 rpm |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 |

|---|---|---|---|---|---|---|

| Standard Order | Run Order | Center Point | Blocks | %CNT | °C | RPM |

| 3 | 1 | 1 | 1 | 0.2 | 220 | 30 |

| 1 | 2 | 1 | 1 | 0.2 | 190 | 30 |

| 11 | 3 | 0 | 1 | 0.6 | 205 | 45 |

| 10 | 4 | 0 | 1 | 0.6 | 205 | 45 |

| 4 | 5 | 1 | 1 | 1.0 | 220 | 30 |

| 9 | 6 | 0 | 1 | 0.6 | 205 | 45 |

| 7 | 7 | 1 | 1 | 0.2 | 220 | 60 |

| 6 | 8 | 1 | 1 | 1.0 | 190 | 60 |

| 2 | 9 | 1 | 1 | 1.0 | 190 | 30 |

| 5 | 10 | 1 | 1 | 0.2 | 190 | 60 |

| 8 | 11 | 1 | 1 | 1.0 | 220 | 60 |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 |

|---|---|---|---|---|---|---|

| Standard Order | Run Order | Center Point | Blocks | %CNT | °C | RPM |

| 14 | 1 | 0 | 1 | 0.6 | 205 | 45 |

| 11 | 2 | 2 | 1 | 0.6 | 190 | 60 |

| 15 | 3 | 0 | 1 | 0.6 | 205 | 45 |

| 3 | 4 | 2 | 1 | 0.2 | 220 | 45 |

| 8 | 5 | 2 | 1 | 1.0 | 205 | 60 |

| 12 | 6 | 2 | 1 | 0.6 | 220 | 60 |

| 9 | 7 | 2 | 1 | 0.6 | 190 | 30 |

| 2 | 8 | 2 | 1 | 1.0 | 190 | 45 |

| 5 | 9 | 2 | 1 | 0.2 | 205 | 30 |

| 13 | 10 | 0 | 1 | 0.6 | 205 | 45 |

| 1 | 11 | 2 | 1 | 0.2 | 190 | 45 |

| 10 | 12 | 2 | 1 | 0.6 | 220 | 30 |

| 4 | 13 | 2 | 1 | 1.0 | 220 | 45 |

| 6 | 14 | 2 | 1 | 1.0 | 205 | 30 |

| 7 | 15 | 2 | 1 | 0.2 | 205 | 60 |

| Property | Value |

|---|---|

| Density | |

| Young’s modulus | 1.9 GPa |

| Poisson’s ratio | 0.3 |

| Shear modulus | 0.729 GPa |

| Bulk modulus | 1.58 GPa |

| Tensile yield strength | 0 |

| Tensile ultimate strength | 46 GPa |

| Material | PLA + CNT |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

|---|---|---|---|---|---|---|---|

| Standard Order | Run Order | Center Point | Blocks | %CNT | °C | RPM | Tension |

| 3 | 1 | 1 | 1 | 0.2 | 220 | 30 | 17.07 |

| 1 | 2 | 1 | 1 | 0.2 | 190 | 40 | 16.14 |

| 11 | 3 | 0 | 1 | 0.6 | 205 | 45 | 26.45 |

| 10 | 4 | 0 | 1 | 0.6 | 205 | 45 | 28.85 |

| 4 | 5 | 1 | 1 | 1.0 | 220 | 30 | 18.16 |

| 9 | 6 | 0 | 1 | 0.6 | 205 | 45 | 27.30 |

| 7 | 7 | 1 | 1 | 0.2 | 220 | 60 | 27.13 |

| 6 | 8 | 1 | 1 | 1.0 | 190 | 60 | 23.29 |

| 2 | 9 | 1 | 1 | 1.0 | 190 | 30 | 24.49 |

| 5 | 10 | 1 | 1 | 0.2 | 190 | 60 | 27.34 |

| 8 | 11 | 1 | 1 | 1.0 | 220 | 60 | 22.57 |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 |

|---|---|---|---|---|---|---|---|---|

| Standard Order | Run Order | TypePt | Blocks | %CNT | °C | RPM | σT (MPa) | S (Standard Deviation) |

| 14 | 1 | 0 | 1 | 0.6 | 205 | 45 | 20.96 | 4.1 |

| 11 | 2 | 2 | 1 | 0.6 | 190 | 60 | 33.29 | 5.21 |

| 15 | 3 | 0 | 1 | 0.6 | 205 | 45 | 23.32 | 4.04 |

| 3 | 4 | 2 | 1 | 0.2 | 220 | 45 | 30.47 | 1.48 |

| 8 | 5 | 2 | 1 | 1.0 | 205 | 60 | 31.23 | 3.61 |

| 12 | 6 | 2 | 1 | 0.6 | 220 | 60 | 31.16 | 1.76 |

| 9 | 7 | 2 | 1 | 0.6 | 190 | 30 | 32.01 | 2.9 |

| 2 | 8 | 2 | 1 | 1.0 | 190 | 45 | 32.63 | 3.42 |

| 5 | 9 | 2 | 1 | 0.2 | 205 | 30 | 22.87 | 1.68 |

| 13 | 10 | 0 | 1 | 0.6 | 205 | 45 | 24.92 | 4.8 |

| 1 | 11 | 2 | 1 | 0.2 | 190 | 45 | 48.87 | 4.59 |

| 10 | 12 | 2 | 1 | 0.6 | 220 | 30 | 30.05 | 4.04 |

| 4 | 13 | 2 | 1 | 1.0 | 220 | 45 | 32.43 | 3.52 |

| 6 | 14 | 2 | 1 | 1.0 | 205 | 30 | 20.04 | 4.79 |

| 7 | 15 | 2 | 1 | 0.2 | 205 | 60 | 34.89 | 1.42 |

| Material | Ti °C | T(onset) °C | T(endset) °C | Tf °C |

|---|---|---|---|---|

| CP-01 | 247.48 | 316.74 | 363.09 | 369.95 |

| CP-07 | 226.65 | 286.50 | 341.67 | 346.49 |

| CP-11 | 238.45 | 307.67 | 358.21 | 389.18 |

| Material | T(onset) °C | % Degraded Mass | T(endset) °C | %Residue | Tf °C | %Residue |

|---|---|---|---|---|---|---|

| CP-01 | 316.7 | 81.3 | 363.1 | 7.05 | 670 | 0.80 |

| CP-07 | 286.5 | 83.1 | 341.7 | 4.82 | 690 | 1.50 |

| CP-11 | 307.7 | 84.3 | 358.2 | 7.24 | 638 | 1.54 |

| Specimen | Tpeak °C |

|---|---|

| CP01 | 338.6 |

| CP07 | 316.7 |

| CP11 | 336.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira, S.I.; Costa, J.C.M.d.; Nascimento, N.R.d.; Pino, G.G.d.; Valin Rivera, J.L.; Valin Fernández, M.; Neto, J.C.d.M. Development of Filaments for 3D Printing from Poly(Lactic Acid) Polymeric Nanocomposites and Carbon Nanotubes. Polymers 2025, 17, 2426. https://doi.org/10.3390/polym17172426

de Oliveira SI, Costa JCMd, Nascimento NRd, Pino GGd, Valin Rivera JL, Valin Fernández M, Neto JCdM. Development of Filaments for 3D Printing from Poly(Lactic Acid) Polymeric Nanocomposites and Carbon Nanotubes. Polymers. 2025; 17(17):2426. https://doi.org/10.3390/polym17172426

Chicago/Turabian Stylede Oliveira, Sanches Ismael, João Carlos Martins da Costa, Nayra Reis do Nascimento, Gilberto Garcia del Pino, José Luis Valin Rivera, Meylí Valin Fernández, and José Costa de Macedo Neto. 2025. "Development of Filaments for 3D Printing from Poly(Lactic Acid) Polymeric Nanocomposites and Carbon Nanotubes" Polymers 17, no. 17: 2426. https://doi.org/10.3390/polym17172426

APA Stylede Oliveira, S. I., Costa, J. C. M. d., Nascimento, N. R. d., Pino, G. G. d., Valin Rivera, J. L., Valin Fernández, M., & Neto, J. C. d. M. (2025). Development of Filaments for 3D Printing from Poly(Lactic Acid) Polymeric Nanocomposites and Carbon Nanotubes. Polymers, 17(17), 2426. https://doi.org/10.3390/polym17172426