Recent Advances in the Analysis of Functional and Structural Polymer Composites for Wind Turbines

Abstract

1. Introduction

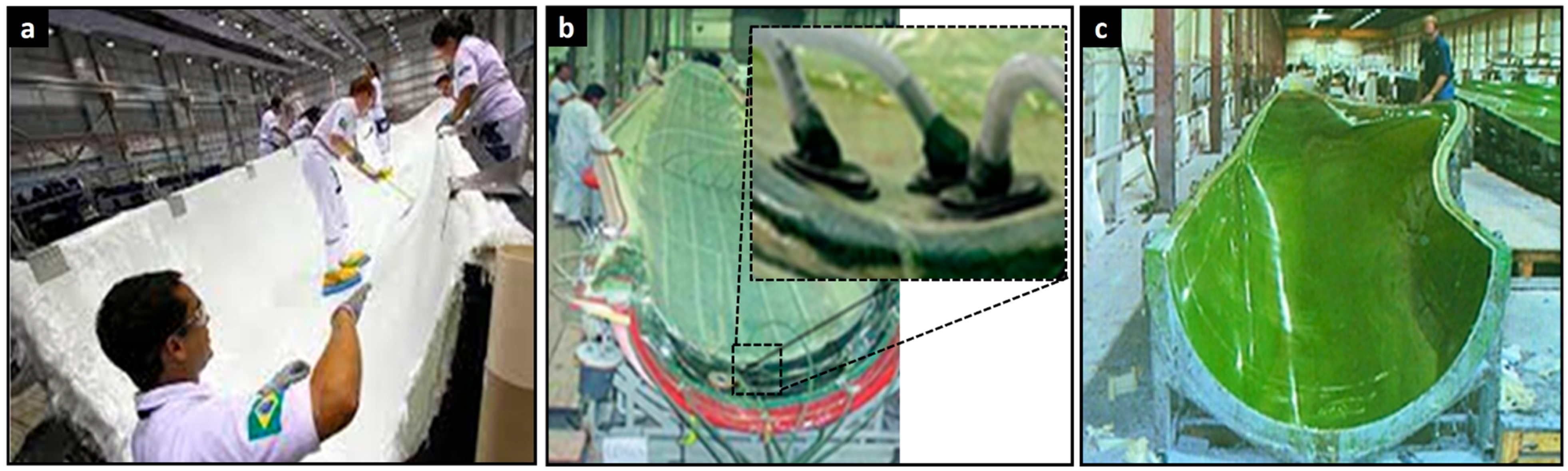

2. Polymer Composite Systems for Wind Turbine Blades

2.1. Conventional Polymer Composites and Their Limitations

2.2. Next-Generation High-Performance Composite Materials

2.3. Smart and Adaptive Polymer Composite Materials

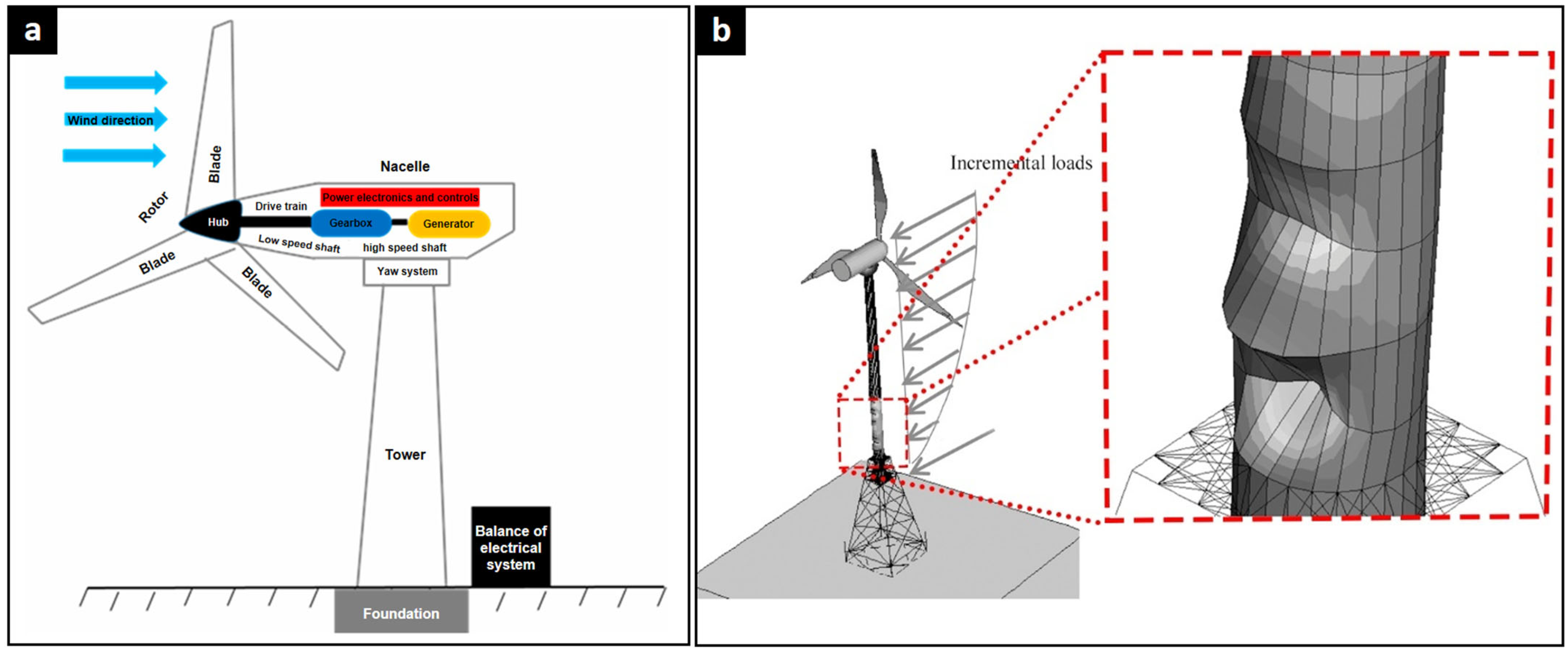

3. Structural and Functional Analysis of Wind Turbines

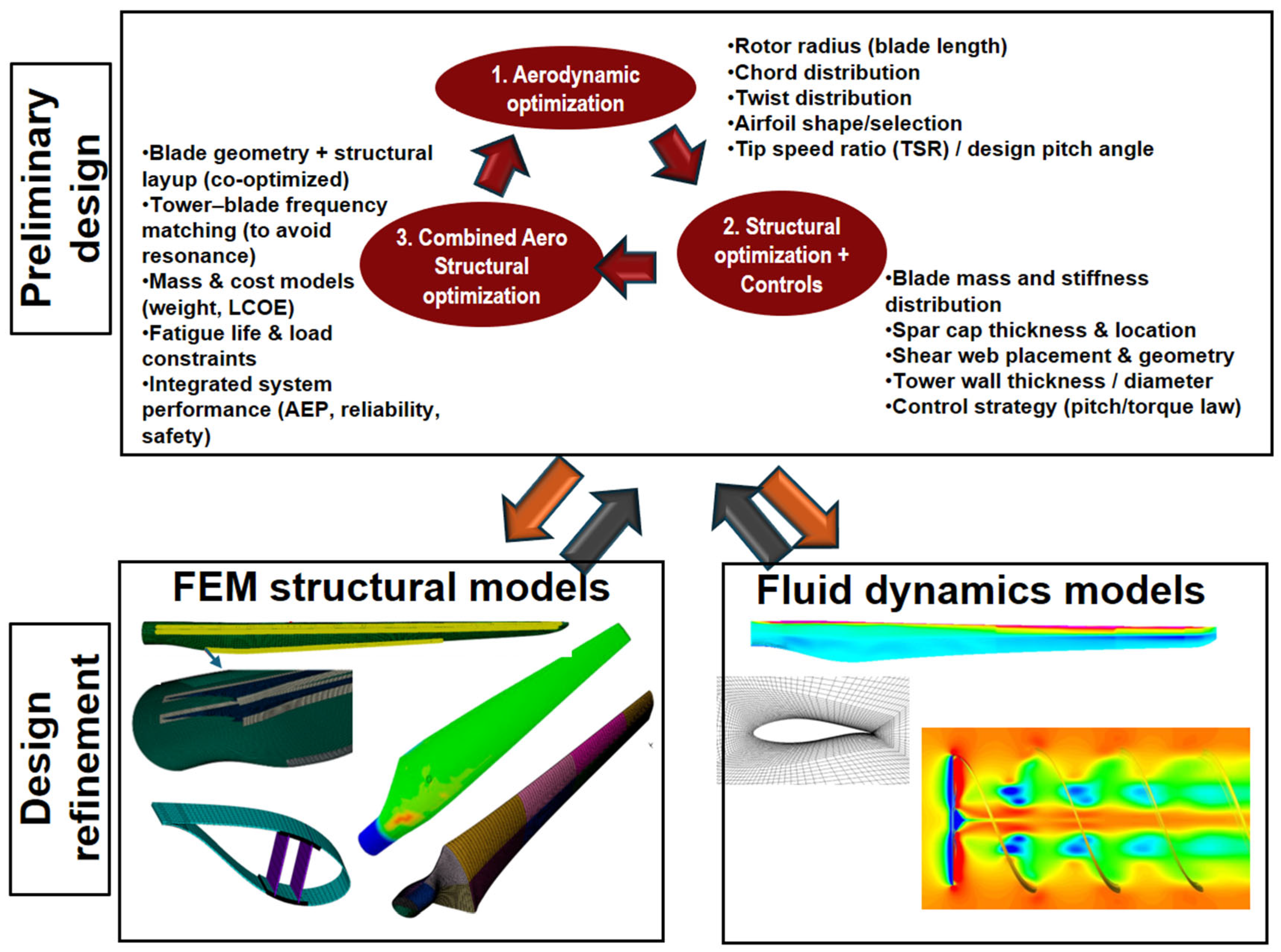

3.1. Optimization of Polymer Composite Blade Design

3.2. Aerodynamic and Structural Analysis of Composite Blades

3.3. Coupled Fluid–Structure Interaction Models for Composite Blade Analysis

4. Monitoring and Fault Detection

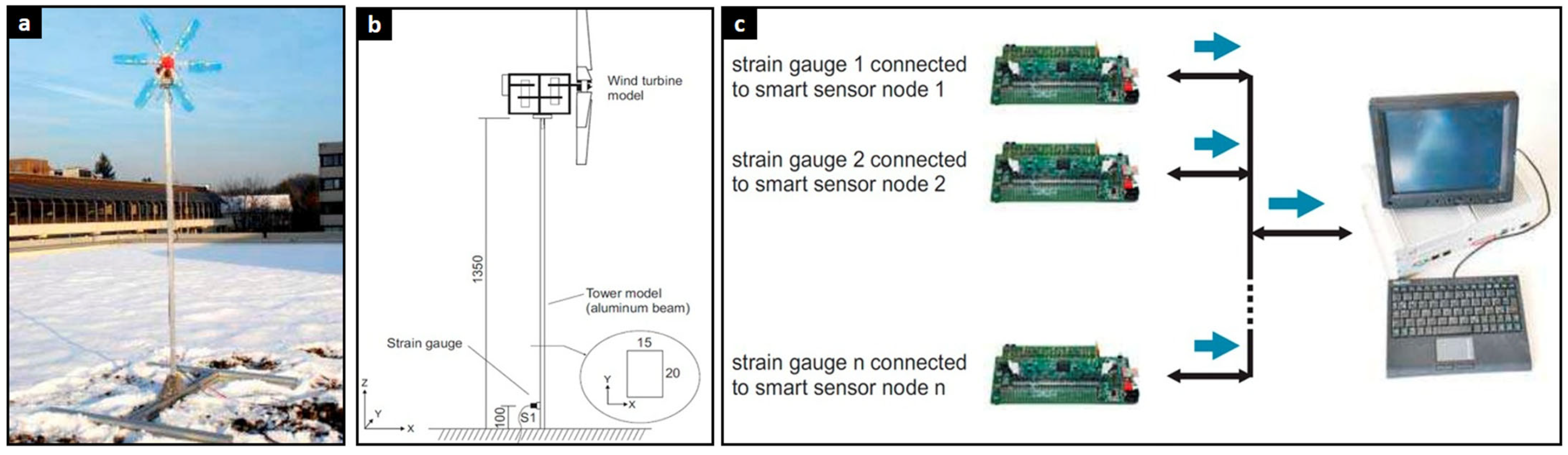

4.1. Structural Health Monitoring (SHM) of Composites Blades

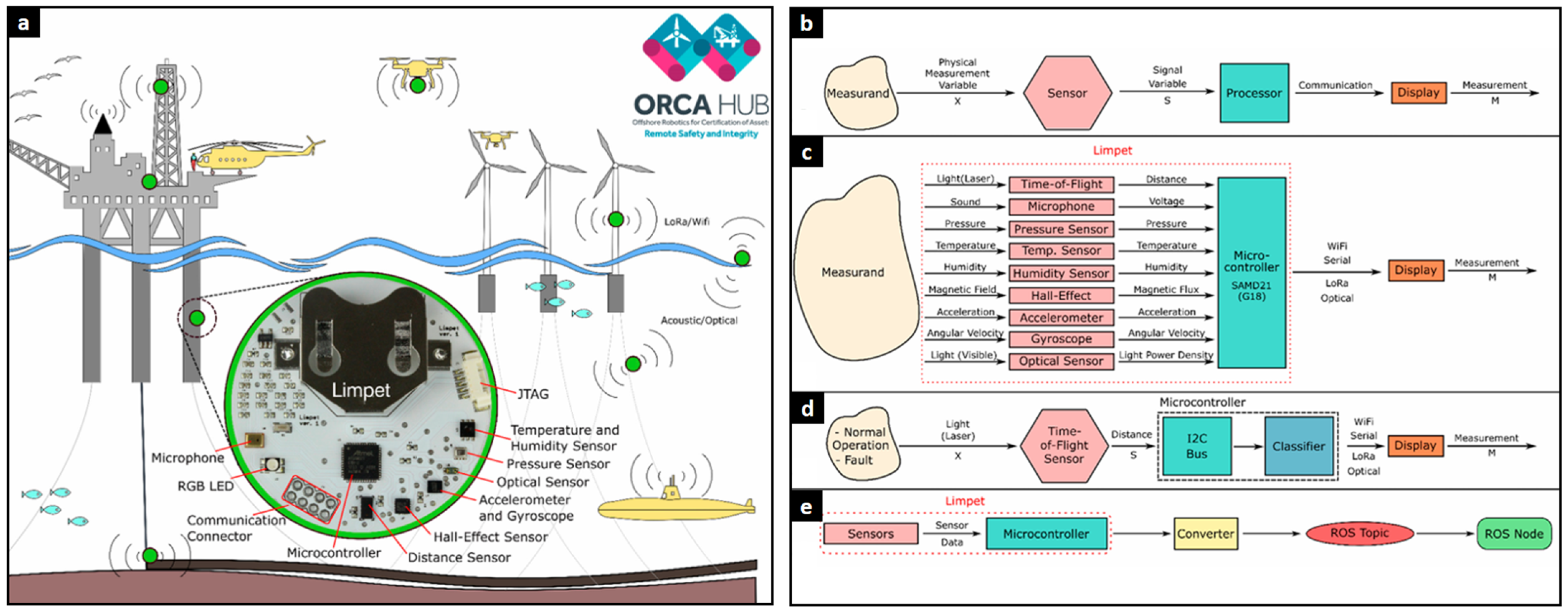

4.2. AI and IoT Applications for Composite Health Monitoring

4.3. Structural Optimization of Supporting Structures

5. Case Studies in the Analysis of Polymer Composite Blades

6. Offshore Wind Turbines

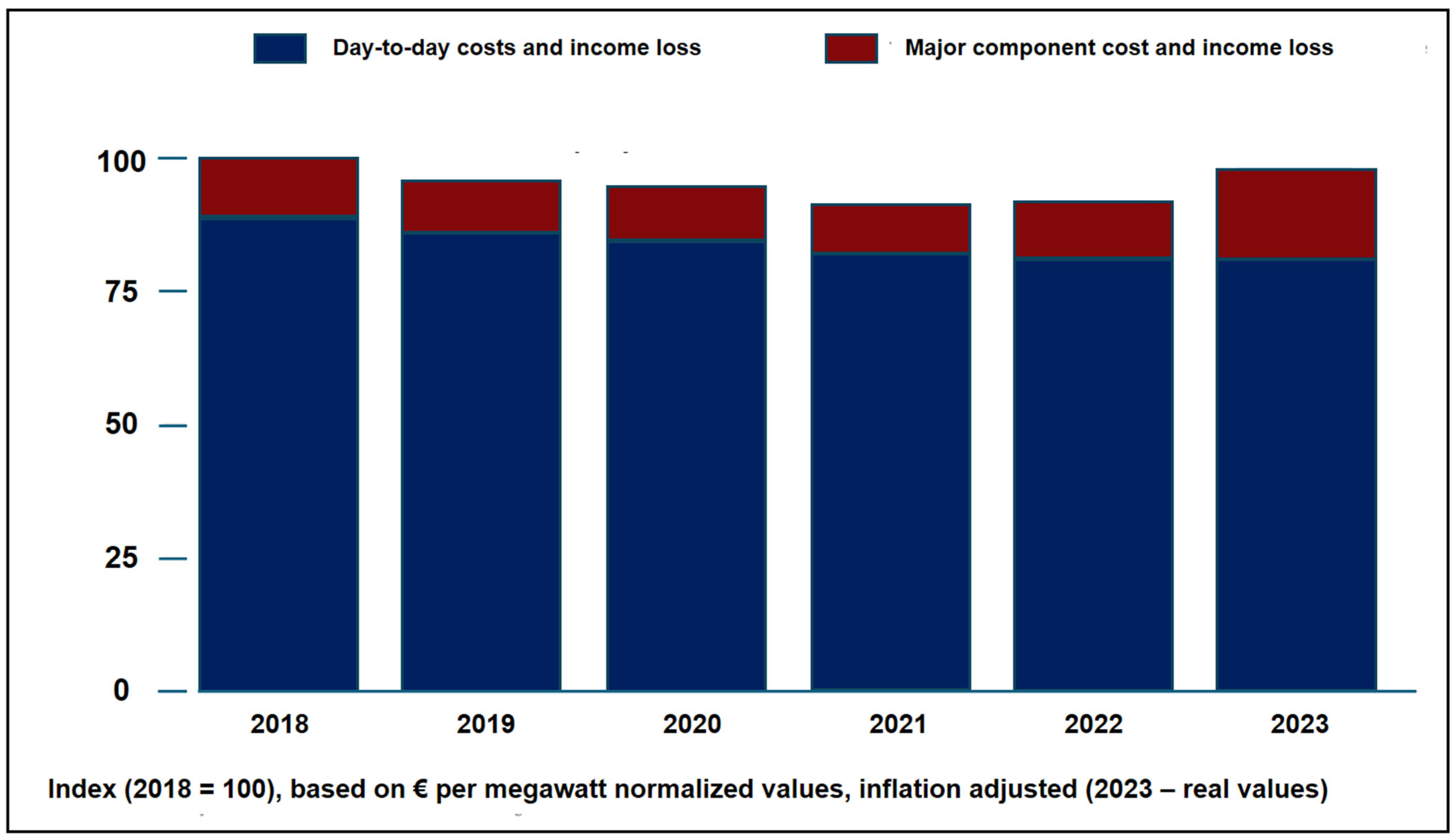

6.1. Operational and Economic Challenges

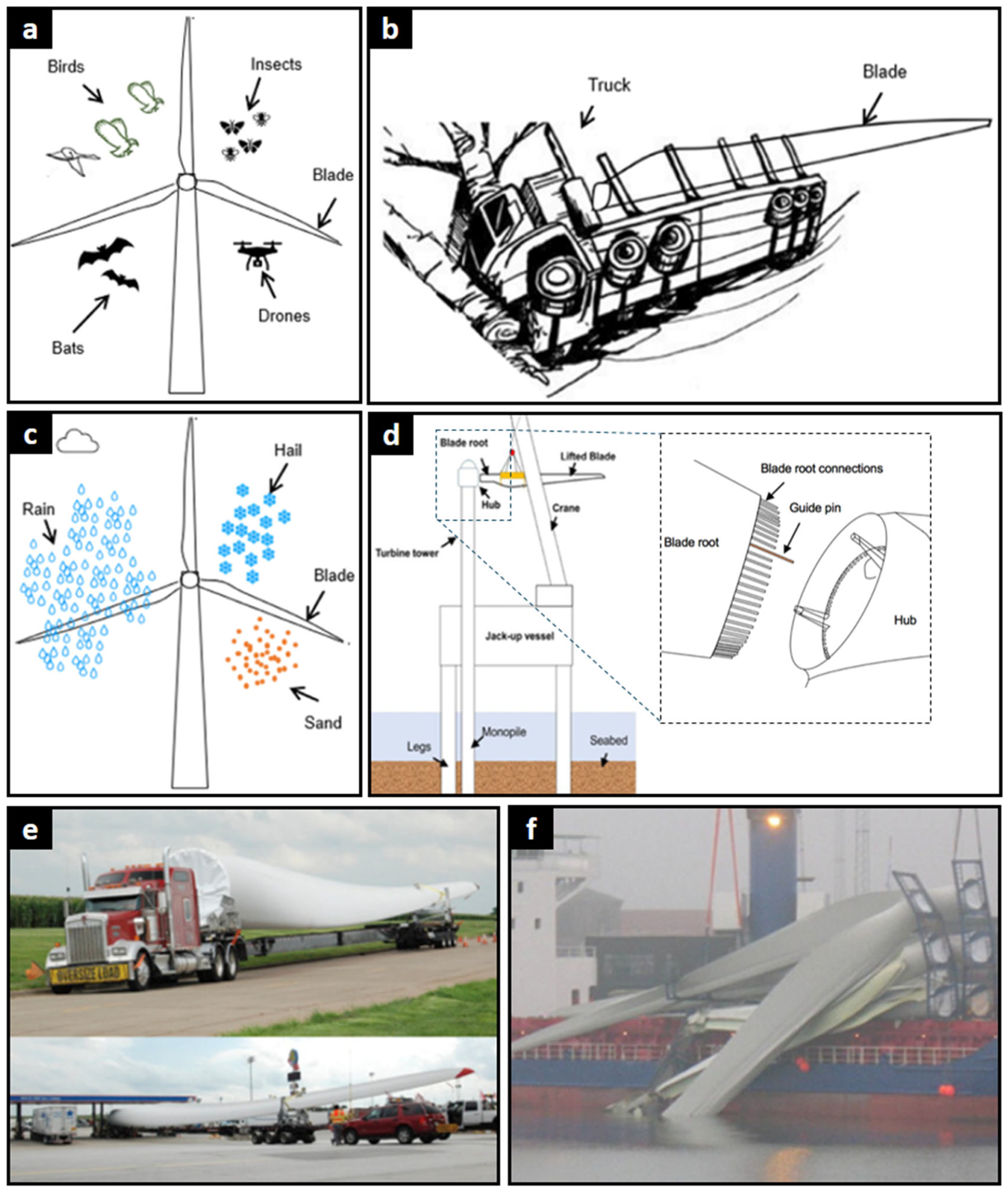

6.2. Environmental Loads and Installation Challenges

6.3. Innovations in Supporting Platforms for Offshore Turbines

6.4. Advanced Simulation Tools for Offshore Systems

7. Resilience of Wind Turbine Polymer Composites to Extreme Weather Events

8. Research Frontiers in Polymer Composite Wind Turbine Technology

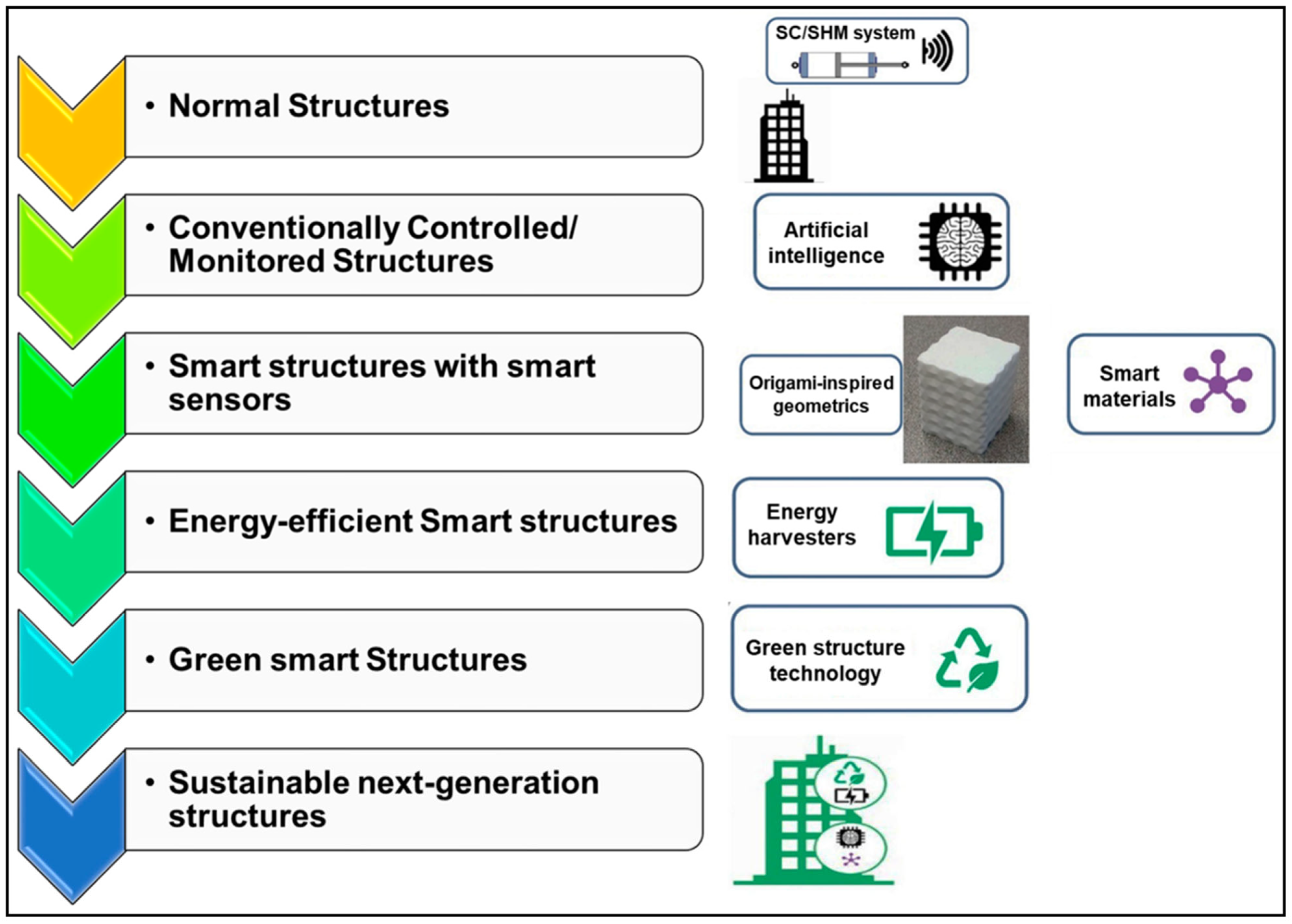

8.1. Hybrid Modeling and Intelligent Control Systems for Composite Structures

8.2. Advanced Polymer Composites and the Search for Sustainability

8.3. The Circular Economy Imperative

9. Conclusions

- The optimization of wind turbines is no longer a sequential process. Integrated MDO frameworks that combine aerodynamics, structural mechanics, and control systems are now standard, enabling the design of lighter, more efficient, and more reliable systems.

- The integration of AI, IoT, and advanced sensors is transforming turbine operation. From SHM systems that detect damage in real-time to hybrid digital twins that predict failures, data-driven approaches are becoming essential for improving performance and reducing operational costs.

- The push into deeper, more remote waters is the primary catalyst for radical innovations in floating platforms, mooring systems, and advanced FSI simulation tools. These developments are essential for unlocking the vast potential of offshore wind. Resilience is a new design pillar. As turbines face more extreme weather events, designing for resilience has become as important as designing for efficiency. This requires a shift toward system-level thinking, probabilistic risk assessment, and the integration of real-time weather forecasting with adaptive turbine controls.

- Sustainability is an urgent, unsolved challenge. While advanced materials continue to improve performance, the wind industry faces a critical challenge in managing blades at their end-of-life. The development of scalable recycling technologies and circular economy business models is no longer optional but essential for the long-term viability of the industry.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABC | Artificial Bee Colony |

| ACO | Ant Colony Optimization |

| AEP | Annual Energy Production |

| AI | Artificial Intelligence |

| ALC | Active Load Control |

| AMI-PSO | Adaptive Mutation Identity Particle Swarm Optimization |

| ANN | Artificial Neural Networks |

| ANOVA | Analysis of Variance |

| BEM | Blade Element Momentum |

| BiMADS | Bi-objective Mesh Adaptive Direct Search |

| CAWT | Cross-Axis Wind Turbine |

| CCD | Control Co-Design |

| CFD | Computational Fluid Dynamics |

| CFRPs | Carbon Fiber Reinforced Polymers |

| CoE | Cost of Energy |

| CoV | Coefficient of Variation |

| DFSM | Dynamic System Derivative Function Surrogate Model |

| DMTO | Discrete Material and Thickness Optimization |

| DOF | Degrees of Freedom |

| DTU | Technical University of Denmark |

| FEA | Finite Element Analysis |

| FEM | Finite Element Method |

| FOWT | Floating Offshore Wind Turbine |

| FSI | Fluid–Structure Interaction |

| FVCOM | Finite Volume Community Ocean Model |

| GA | Genetic Algorithm |

| GFRPs | Glass Fiber Reinforced Polymers |

| HAHT | Horizontal Axis Hydrokinetic Turbine |

| HAWT | Horizontal Axis Wind Turbine |

| HBC-COMEA | Hybrid Bidirectional Cooperative Constrained Multi-objective Evolutionary Algorithm |

| HSFD | Hinge-Spring-Friction Device |

| IEC | International Electrotechnical Commission |

| IoT | Internet of Things |

| LEP | Leading-Edge Protection |

| LES | Large Eddy Simulation |

| LSTM | Long Short-Term Memory |

| MDO | Multidisciplinary Design Optimization |

| NSGA-III | Non-dominated Sorting Genetic Algorithm III |

| O&M | Operations and Maintenance |

| ODFC | Omnidirectional Flow Concentrator |

| OWC | Oscillating Water Columns |

| OWT | Offshore Wind Turbine |

| PSO | Particle Swarm Optimization |

| QBlade | Open-source BEM-based wind turbine simulation tool |

| RANS | Reynolds-Averaged Navier–Stokes |

| RBFNN | Radial Basis Function Neural Network |

| ROS | Robot Operating System |

| RSM | Response Surface Methodology |

| SCADA | Supervisory Control and Data Acquisition |

| SDGs | Sustainable Development Goals |

| SHM | Structural Health Monitoring |

| SiC | Silicon Carbide |

| SMAs | Shape Memory Alloys |

| SST | Shear Stress Transport |

| STA | Super-Twisting Algorithm |

| SWAN | Simulating Waves Nearshore Model |

| TMDs | Tuned Mass Dampers |

| TSR | Tip Speed Ratio |

| UHPC | Ultra-High-Performance Concrete |

| VARTM | Vacuum-Assisted Resin Transfer Molding |

| VAWT | Vertical-Axis Wind Turbine |

| WOA | Whale Optimization Algorithm |

| WRF | Weather Research and Forecasting Model |

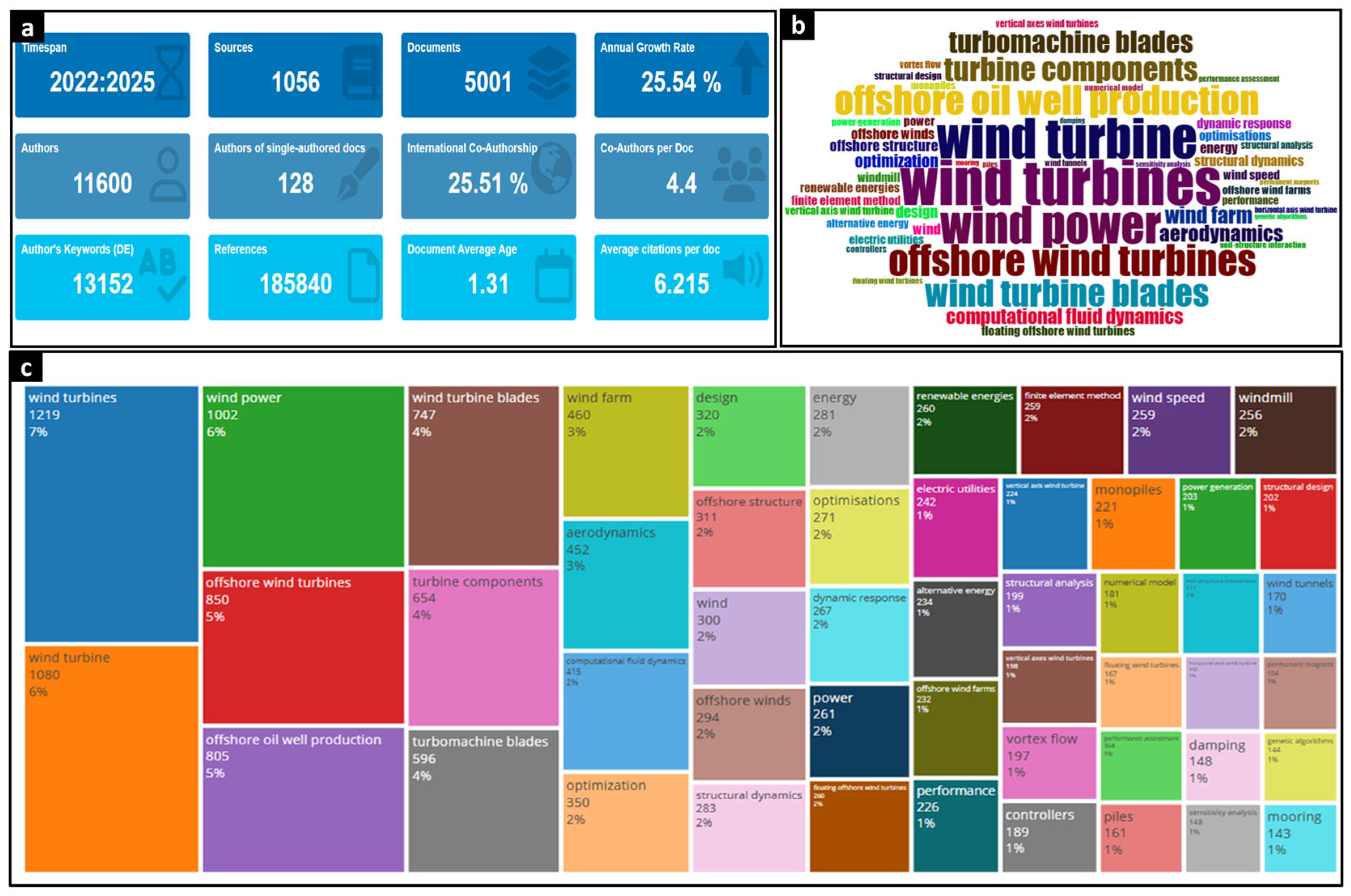

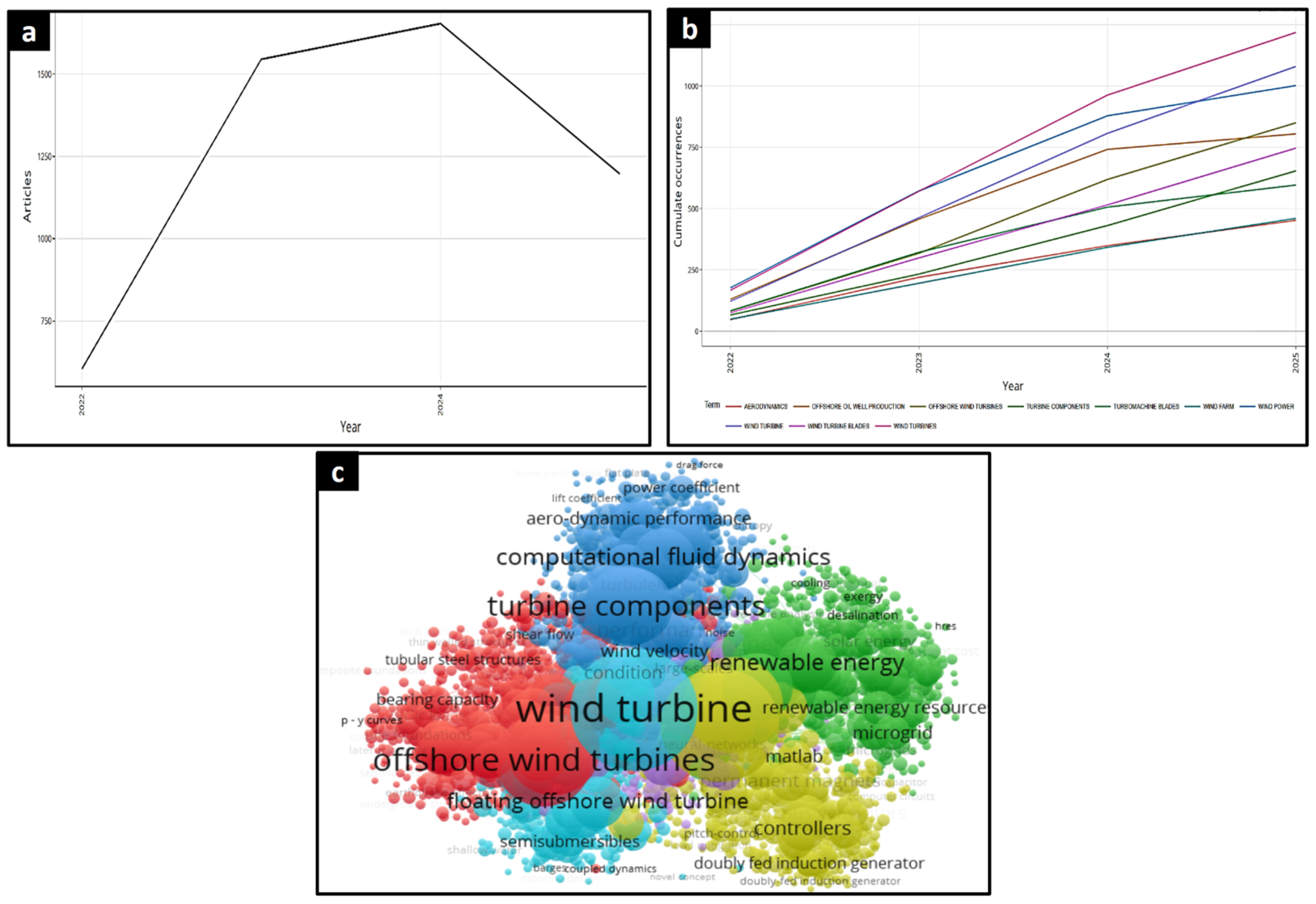

Appendix A. Bibliometric Analysis Methodology

Appendix A.1. Data Collection and Filtering

| Database | Search Strings | Results | Export Format |

|---|---|---|---|

| OpenAlex | “Challenges in design of wind turbines” | 1 | CSV via Publish or Perish |

| Scopus | “Design” AND “Wind turbines” | 5 | CSV |

| Dimensions AI | “Wind turbines” AND “Structural analysis” | 501 | CSV |

| Total | 6501 | ||

| Duplicate records (removed) | 5445 | ||

| Final records | 1056 | ||

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Published between 1 January 2022 and 30 June 2025 | Articles published outside the specified date range |

| Full research articles only | Reviews, letters, notes, book chapters, conference papers, and errata |

| Must include search keywords in title or abstract | Articles without an abstract |

Appendix A.2. Analysis and Visualization

References

- Zhang, D.; Xu, Z.; Li, C.; Yang, R.; Shahidehpour, M.; Wu, Q.; Yan, M. Economic and sustainability promises of wind energy considering the impacts of climate change and vulnerabilities to extreme conditions. Electr. J. 2019, 32, 7–12. [Google Scholar] [CrossRef]

- Bachmann, L.; Lex, R.; Regli, F.; Vögeli, S.; Mühlhofer, E.; McCaughey, J.W.; Hanger-Kopp, S.; Bresch, D.N.; Kropf, C.M. Climate-resilient strategy planning using the SWOT methodology: A case study of the Japanese wind energy sector. Clim. Risk Manag. 2024, 46, 100665. [Google Scholar] [CrossRef]

- Canul-Reyes, D.A.; Rodríguez-Hernández, O.; Jarquin-Laguna, A. Potential zones for offshore wind power development in the Gulf of Mexico using reanalyses data and capacity factor seasonal analysis. Energy Sustain. Dev. 2022, 68, 211–219. [Google Scholar] [CrossRef]

- Osorio, L.; Moreno, M.; Rivera, M.; Tuninetti, V.; Chavarria, G.R.; Duchêne, L.; Wheeler, P. A metaheuristic-based method for photovoltaic temperature computation under tropical conditions. Sol. Energy 2024, 271, 112414. [Google Scholar] [CrossRef]

- Rajamohan, S.; Vinod, A.; Pragada Venkata Sesha Aditya, M.; Gopalakrishnan Vadivudaiyanayaki, H.; Nhanh Nguyen, V.; Arıcı, M.; Nižetić, S.; Thai Le, T.; Hidayat, R.; Tuyen Nguyen, D. Approaches in performance and structural analysis of wind turbines—A review. Sustain. Energy Technol. Assess. 2022, 53, 102570. [Google Scholar] [CrossRef]

- UN Take Action for the Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 20 August 2025).

- Olabi, A.G.; Obaideen, K.; Abdelkareem, M.A.; AlMallahi, M.N.; Shehata, N.; Alami, A.H.; Mdallal, A.; Hassan, A.A.M.; Sayed, E.T. Wind Energy Contribution to the Sustainable Development Goals: Case Study on London Array. Sustainability 2023, 15, 4641. [Google Scholar] [CrossRef]

- He, F.; Zheng, X.; Luo, W.; Zhong, J.; Huang, Y.; Ye, A.; Qiu, R.; Ma, H. Collaborative Optimization of Aerodynamics and Wind Turbine Blades. Appl. Sci. 2025, 15, 834. [Google Scholar] [CrossRef]

- Batay, S.; Baidullayeva, A.; Zhao, Y.; Wei, D.; Baigarina, A.; Sarsenov, E.; Shabdan, Y. Aerostructural Design Optimization of Wind Turbine Blades. Processes 2023, 12, 22. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, W.; Dong, W.; Gao, Z.; Ren, Z. Structural Reliability Analysis of Wind Turbines: A Review. Energies 2017, 10, 2099. [Google Scholar] [CrossRef]

- Lim, S.; Ahn, S.; Park, H. Aerodynamic Design and Performance Analysis of a Large-Scale Composite Blade for Wind Turbines. Appl. Sci. 2025, 15, 928. [Google Scholar] [CrossRef]

- Radi, J.; Sierra-García, J.E.; Santos, M.; Armenta-Déu, C.; Djebli, A. Metaheuristic Optimization of Wind Turbine Airfoils with Maximum-Thickness and Angle-of-Attack Constraints. Energies 2024, 17, 6440. [Google Scholar] [CrossRef]

- Vázquez, M.; López, V.; Campos, R.; Cadenas, E.; Marin, P. Structural and Modal Analysis of a Small Wind Turbine Blade Considering Composite Material and the IEC 61400-2 Standard. Energies 2025, 18, 566. [Google Scholar] [CrossRef]

- Jaszczur, M.; Borowski, M.; Halibart, J.; Zwolińska-Glądys, K.; Marczak, P. Optimization of the Small Wind Turbine Design—Performance Analysis. Computation 2024, 12, 215. [Google Scholar] [CrossRef]

- Benim, A.C.; Diederich, M.; Pfeiffelmann, B. Aerodynamic Optimization of Airfoil Profiles for Small Horizontal Axis Wind Turbines. Computation 2018, 6, 34. [Google Scholar] [CrossRef]

- Lin, J.; Xu, Y.-L.; Xia, Y.; Li, C. Structural Analysis of Large-Scale Vertical-Axis Wind Turbines, Part I: Wind Load Simulation. Energies 2019, 12, 2573. [Google Scholar] [CrossRef]

- Zouboulis, P.; Koumoulos, E.P.; Karatza, A. Wind Turbine Blade-Tip Optimization: A Systemic Computational Approach. Processes 2023, 11, 1170. [Google Scholar] [CrossRef]

- Barnes, R.H.; Morozov, E. V Structural optimisation of composite wind turbine blade structures with variations of internal geometry configuration. Compos. Struct. 2016, 152, 158–167. [Google Scholar] [CrossRef]

- Zhang, Q.; Hou, M.; Zhao, Y.; Wang, H.; Hu, B.; Liu, J.; Lu, Q. Self-triggered H-infinity pitch control for wind turbines considering stochastic wind speed. Renew. Energy 2026, 256, 123769. [Google Scholar] [CrossRef]

- Sanda, M.G.; Emam, M.; Hassan, H. Combined vertical axis wind turbine and solar photovoltaic energy generation on dual land use with shading impact: Technical-economic-environmental assessment. Renew. Energy 2026, 256, 123934. [Google Scholar] [CrossRef]

- Xiao, P.; Tian, L.; Zhao, N.; Song, Y.; Wang, Z.; Lu, X. An integrated model for predicting wind turbine wake velocity and turbulence intensity under different atmospheric stability regimes. Renew. Energy 2026, 256, 123904. [Google Scholar] [CrossRef]

- Kale, F.M.; Yilmaz, N.; Bademlioglu, A.H.; Sokmen, K.F.; Shi, W. Design and optimization of the hydrokinetic turbine blades using statistical approaches. Renew. Energy 2026, 256, 123909. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, J.; Sun, K.; Lin, X.; Xu, B.; Yan, Z. Effect of duct designs and external separated vortex on the performance of bidirectional ducted tidal turbines. Renew. Energy 2026, 256, 123910. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, J.; Zhou, X.; Qi, H.; Cheng, Y.; Shan, W. Customized design of wind turbine towers based on a multi-layer optimization model and integrated simulation. Structures 2025, 79, 109527. [Google Scholar] [CrossRef]

- Tan, J.-K.; Zheng, W.-L.; Wang, Y.-H.; Su, M.-N.; Zhao, L.; Zhang, Y.-H.; Feng, Y.; Chen, D.-X. Finite element modelling and design of concrete wind turbine towers subjected to combined compression and bending. Structures 2025, 77, 108811. [Google Scholar] [CrossRef]

- Mishra, I.; Chetan, M.; Sakib, M.S.; Griffith, D.T.; Gupta, A.; Rotea, M.A. Active load control applied to upscaled wind turbines: Design and cost impacts. Renew. Energy 2025, 251, 123411. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, W.-L.; Liu, J. Aerodynamic design and analysis for offshore wind turbine blade model. Energy 2025, 330, 136659. [Google Scholar] [CrossRef]

- Tehrani, K.; Beikbabaei, M.; Mehrizi-Sani, A.; Jamshidi, M. A smart multiphysics approach for wind turbines design in industry 5.0. J. Ind. Inf. Integr. 2024, 42, 100704. [Google Scholar] [CrossRef]

- Wang, X.-H.; Foo, J.S.-Y.; Fazlizan, A.; Chong, W.-T.; Wong, K.-H. Effects of endplate designs on the performance of Savonius vertical axis wind turbine. Energy 2024, 310, 133205. [Google Scholar] [CrossRef]

- Kaya, A.F.; Morselli, N.; Puglia, M.; Allesina, G.; Pedrazzi, S. Design optimization of two-blade Savonius wind turbines for hydrogen generation. Renew. Energy 2024, 231, 121028. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, C.; Shen, X.; Zhou, X.; Hua, X. Conceptual design of a prestressed precast UHPC-steel hybrid tower to support a 15 MW offshore wind turbine. Eng. Struct. 2024, 321, 118939. [Google Scholar] [CrossRef]

- Su, H.; Ma, J.; Wang, J.; Gao, Z.; Li, Q.; Pan, W.; Yang, L. Cooperative optimization algorithm for wind turbine airfoil design and numerical validation of blade aerodynamic and flutter performance. Energy Convers. Manag. 2025, 333, 119818. [Google Scholar] [CrossRef]

- Rusli, C.C.; Kong, K.K.; Khoo, S.Y.; Long, S.X.; Chong, W.T. Performance enhancement of cross-axis-wind-turbine: Design and CFD analysis of an omni-directional flow concentrator. Alexandria Eng. J. 2025, 127, 500–521. [Google Scholar] [CrossRef]

- Zhang, X.; Tao, J.; Noshadravan, A. Probabilistic digital twin for reliability-based maintenance optimization of offshore wind turbines. Renew. Energy 2026, 256, 123777. [Google Scholar] [CrossRef]

- Liang, Z.; Liu, H. Novel yaw-based wake modelling and controlling to enhance the power output of floating offshore wind farms. Renew. Energy 2026, 256, 123838. [Google Scholar] [CrossRef]

- Alves Ribeiro, J.; Alves Ribeiro, B.; Pimenta, F.; Tavares, S.M.O.; Zhang, J.; Ahmed, F. Offshore wind turbine tower design and optimization: A review and AI-driven future directions. Appl. Energy 2025, 397, 126294. [Google Scholar] [CrossRef]

- Lei, B.; Fei, S. Adaptive fuzzy coordinated control design for wind turbine using gray wolf optimization algorithm. Appl. Soft Comput. 2024, 167, 112319. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Y.; Liu, Y.; Wang, X.; Bai, W.; Cao, T. Improved control strategy and designed control parameters of pitch system for wind turbine considering blade load reduction. Renew. Energy 2024, 232, 121050. [Google Scholar] [CrossRef]

- Qin, S.; Wang, Z.; Li, S.; Chen, R.; Jia, L.; Peng, X. Design of sub-synchronous oscillation proportional resonance damping controller for doubly-fed wind turbines based on impedance analysis. Int. J. Electr. Power Energy Syst. 2024, 162, 110333. [Google Scholar] [CrossRef]

- Lee, Y.H.; Bayat, S.; Allison, J.T. Wind turbine control co-design using dynamic system derivative function surrogate model (DFSM) based on OpenFAST linearization. Appl. Energy 2025, 396, 126203. [Google Scholar] [CrossRef]

- Didier, F.; Basbas, H.; Larioumlil, D.; Laghrouche, S.; Depernet, D. Neural network-based super-twisting control for floating wind turbines: Design and real-time validation. Ocean Eng. 2025, 338, 121973. [Google Scholar] [CrossRef]

- Li, W.; Ke, S.; Qian, K.; Ren, H. Instability mechanism and criterion of wind-wave co-generation structural system under typhoon-wave-current coupled action. Renew. Energy 2026, 256, 123888. [Google Scholar] [CrossRef]

- Fan, S.; Liu, Z. Experimental investigation of pitch and surge motion effects on wake characteristics of a floating offshore wind turbine. Energy 2025, 331, 136970. [Google Scholar] [CrossRef]

- Sorge, E.; Riascos, C.; Caterino, N.; Demartino, C.; Georgakis, C.T. Optimal design of a hinge-spring-friction device for enhancing wind induced structural response of onshore wind turbines. Eng. Struct. 2024, 314, 118305. [Google Scholar] [CrossRef]

- Yahya, W.; Saied, K.M.; Nassar, A.; Qader, M.R.; Al-Nehari, M.; Zarabia, J.; Jian, Z. Optimization of a hybrid renewable energy system consisting of a of PV/wind turbine/battery/fuel cell integration and component design. Int. J. Hydrogen Energy 2024, 94, 1406–1418. [Google Scholar] [CrossRef]

- Gong, Y.; Dong, S.; Wang, Z. A novel method to estimate the typhoon-affected multi-dimensional environmental design parameters for floating offshore wind turbines. Sustain. Energy Technol. Assess. 2024, 69, 103889. [Google Scholar] [CrossRef]

- Xie, W.; Chen, H.; Yijing, L.; Liang, H.; He, Y.; Zhang, Z.; Guo, T.; Liu, J. Vibration monitoring, load simulation, and vibration reduction design for existing wind turbines. Structures 2025, 79, 109614. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Salameh, T.; Abdelkareem, M.A.; Baroutaji, A. A Review on Failure Modes of Wind Turbine Components. Energies 2021, 14, 5241. [Google Scholar] [CrossRef]

- Petrini, F.; Li, H.; Bontempi, F. Basis of design and numerical modeling of offshore wind turbines. Struct. Eng. Mech. 2010, 36, 599–624. [Google Scholar] [CrossRef]

- Shi, S.; Zhai, E.; Xu, C.; Iqbal, K.; Sun, Y.; Wang, S. Influence of Pile-Soil Interaction on Dynamic Properties and Response of Offshore Wind Turbine with Monopile Foundation in Sand Site. Appl. Ocean Res. 2022, 126, 103279. [Google Scholar] [CrossRef]

- Jiang, T.; Lv, P.; Li, D. A new shape reconstruction method for monitoring the large deformations of offshore wind turbine towers. Ocean Eng. 2024, 312, 119253. [Google Scholar] [CrossRef]

- Grujicic, M.; Arakere, G.; Subramanian, E.; Sellappan, V.; Vallejo, A.; Ozen, M. Structural-Response Analysis, Fatigue-Life Prediction, and Material Selection for 1 MW Horizontal-Axis Wind-Turbine Blades. J. Mater. Eng. Perform. 2010, 19, 790–801. [Google Scholar] [CrossRef]

- Grujicic, M.; Arakere, G.; Pandurangan, B.; Sellappan, V.; Vallejo, A.; Ozen, M. Multidisciplinary Design Optimization for Glass-Fiber Epoxy-Matrix Composite 5 MW Horizontal-Axis Wind-Turbine Blades. J. Mater. Eng. Perform. 2010, 19, 1116–1127. [Google Scholar] [CrossRef]

- Gukendran, R.; Sambathkumar, M.; Sabari, C.; Ranjith Raj, C.R.; Ranjeeth Kumar, V. Structural analysis of composite wind turbine blade using ANSYS. Mater. Today Proc. 2022, 50, 1011–1016. [Google Scholar] [CrossRef]

- Gantenbein, S.; Mascolo, C.; Houriet, C.; Zboray, R.; Neels, A.; Masania, K.; Studart, A.R. Spin-Printing of Liquid Crystal Polymer into Recyclable and Strong All-Fiber Materials. Adv. Funct. Mater. 2021, 31, 2104574. [Google Scholar] [CrossRef]

- Capuzzi, M.; Pirrera, A.; Weaver, P.M. Structural design of a novel aeroelastically tailored wind turbine blade. Thin-Walled Struct. 2015, 95, 7–15. [Google Scholar] [CrossRef]

- Jones, M.P.; Murali, G.G.; Laurin, F.; Robinson, P.; Bismarck, A. Functional flexibility: The potential of morphing composites. Compos. Sci. Technol. 2022, 230, 109792. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhao, Y.; Qi, H.; Zhou, X. Intelligent optimal design of steel-concrete hybrid wind turbine tower based on evolutionary algorithm. J. Constr. Steel Res. 2024, 218, 108729. [Google Scholar] [CrossRef]

- Fortini, A.; Suman, A.; Aldi, N.; Merlin, M.; Pinelli, M. A Shape Memory Alloy-Based Morphing Axial Fan Blade—Part I: Blade Structure Design and Functional Characterization. J. Eng. Gas Turbines Power 2016, 138, 022601. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Marin-Tellez, P.; López-Garza, V.; Soriano-Peña, J.F.; Marin-Tellez, G.J.; Santibañez-Maldonado, A. Structural evaluation of natural fiber composite materials for low-capacity wind turbine blades. MRS Adv. 2025, 10, 316–321. [Google Scholar] [CrossRef]

- Al-Maharma, A.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, T.; Wang, X.; Zheng, Y.; Zheng, J.; Song, G.; Liu, S. Recent Progress on Moisture Absorption Aging of Plant Fiber Reinforced Polymer Composites. Polymers 2023, 15, 4121. [Google Scholar] [CrossRef] [PubMed]

- Fotouh, A.; Wolodko, J.; Lipsett, M. Isotherm moisture absorption kinetics in natural-fiber-reinforced polymer under immersion conditions. J. Compos. Mater. 2015, 49, 1301–1314. [Google Scholar] [CrossRef]

- Das, P.P.; Acharya, A.; Chaudhary, V. Influence of moisture uptake on the mechanical properties of natural fiber-reinforced polymer composites. In Composite Materials; Taylor & Francis: London, UK, 2021; ISBN 9781003080633. [Google Scholar]

- Pavlovic, A.; Valzania, L.; Minak, G. Effects of Moisture Absorption on the Mechanical and Fatigue Properties of Natural Fiber Composites: A Review. Polymers 2025, 17, 1996. [Google Scholar] [CrossRef] [PubMed]

- Batu, T.; Lemu, H.; Sirhabizuh, B. Study of the Performance of Natural Fiber Reinforced Composites for Wind Turbine Blade Applications. Adv. Sci. Technol. Res. J. 2020, 14, 67–75. [Google Scholar] [CrossRef]

- Wang, J.; Wang, C.; Ji, Y.; Qie, R.; Wang, D.; Liu, G. Mechanical Properties and Microscopic Study of Recycled Fibre Concrete Based on Wind Turbine Blades. Materials 2024, 17, 3565. [Google Scholar] [CrossRef]

- Miliket, T.A.; Ageze, M.B.; Tigabu, M.T.; Zeleke, M.A. Experimental characterizations of hybrid natural fiber-reinforced composite for wind turbine blades. Heliyon 2022, 8, e09092. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.; Beauson, J.; McGugan, M.; Sørensen, B. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef]

- Ursache, Ș.; Cerbu, C.; Hadăr, A. Characteristics of Carbon and Kevlar Fibres, Their Composites and Structural Applications in Civil Engineering—A Review. Polymers 2023, 16, 127. [Google Scholar] [CrossRef]

- Verma, A.S.; Vedvik, N.P.; Haselbach, P.U.; Gao, Z.; Jiang, Z. Comparison of numerical modelling techniques for impact investigation on a wind turbine blade. Compos. Struct. 2019, 209, 856–878. [Google Scholar] [CrossRef]

- Verma, A.S.; Yan, J.; Hu, W.; Jiang, Z.; Shi, W.; Teuwen, J.J.E. A review of impact loads on composite wind turbine blades: Impact threats and classification. Renew. Sustain. Energy Rev. 2023, 178, 113261. [Google Scholar] [CrossRef]

- Rahman, M.; Hussein, M.R.; Shaikat, A.S.; Tasnim, R. Composite Materials for Wind Turbine Structure. In Composite Materials: Applications in Engineering, Biomedicine and Food Science; Springer International Publishing: Cham, Switzerland, 2020; pp. 201–212. ISBN 978-303045489-0/978-303045488-3. [Google Scholar]

- Reddy, S.S.P.; Suresh, R.; Hanamantraygouda., M.B.; Shivakumar, B.P. Use of composite materials and hybrid composites in wind turbine blades. Mater. Today Proc. 2021, 46, 2827–2830. [Google Scholar] [CrossRef]

- Griffith, D.T.; Cao, D.; Lu, H.; Qian, D. Composite materials in wind energy: Design, manufacturing, operation, and end-of-life. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1293, 012002. [Google Scholar] [CrossRef]

- Shinde, P.; Sharma, P.; Sharma, A.K.; Soni, A.; Shukla, A. Composite Material for Design and Manufacturing of the Wind Turbine Blades—A Review. In Advances in Materials Engineering; Bhingole, P., Joshi, K., Yadav, S.D., Sharma, A., Eds.; Lecture Notes in Mechanical Engineering; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2025; pp. 293–307. ISSN 21954356. ISBN 978-981977113-4. [Google Scholar]

- Ennis, B.L.; Das, S.; Norris, R.E. Economic competitiveness of pultruded fiber composites for wind turbine applications. Compos. Part B Eng. 2023, 265, 110960. [Google Scholar] [CrossRef]

- Kalkanis, K.; Psomopoulos, C.S.; Kaminaris, S.; Ioannidis, G.; Pachos, P. Wind turbine blade composite materials—End of life treatment methods. Energy Procedia 2019, 157, 1136–1143. [Google Scholar] [CrossRef]

- Dorigato, A. Recycling of thermosetting composites for wind blade application. Adv. Ind. Eng. Polym. Res. 2021, 4, 116–132. [Google Scholar] [CrossRef]

- Cheng, X.; Du, B.; He, J.; Long, W.; Su, G.; Liu, J.; Fan, Z.; Chen, L. A review of thermoplastic composites on wind turbine blades. Compos. Part B Eng. 2025, 299, 112411. [Google Scholar] [CrossRef]

- Yan, S.; Abdin, Y. Fatigue behavior of Elium®-based thermoplastic composites fabricated by liquid composite molding : A review. Compos. Part B Eng. 2025, 295, 112159. [Google Scholar] [CrossRef]

- Murray, R.E.; Beach, R.; Barnes, D.; Snowberg, D.; Berry, D.; Rooney, S.; Jenks, M.; Gage, B.; Boro, T.; Wallen, S.; et al. Structural validation of a thermoplastic composite wind turbine blade with comparison to a thermoset composite blade. Renew. Energy 2021, 164, 1100–1107. [Google Scholar] [CrossRef]

- Cousins, D.S.; Arwood, Z.; Young, S.; Hinkle, B.; Snowberg, D.; Penumadu, D.; Stebner, A.P. Infusible Thermoplastic Composites for Wind Turbine Blade Manufacturing: Fatigue Life of Thermoplastic Laminates under Ambient and Low-Temperature Conditions. Adv. Eng. Mater. 2023, 25, 2201941. [Google Scholar] [CrossRef]

- Murray, R.E.; Jenne, S.; Snowberg, D.; Berry, D.; Cousins, D. Techno-economic analysis of a megawatt-scale thermoplastic resin wind turbine blade. Renew. Energy 2019, 131, 111–119. [Google Scholar] [CrossRef]

- Qin, Y.; Summerscales, J.; Graham-Jones, J.; Meng, M.; Pemberton, R. Monomer selection for in situ polymerization infusion manufacture of natural-fiber reinforced thermoplastic-matrix marine composites. Polymers 2020, 12, 2928. [Google Scholar] [CrossRef] [PubMed]

- Mishnaevsky, L. Sustainable End-of-Life Management of Wind Turbine Blades: Overview of Current and Coming Solutions. Materials 2021, 14, 1124. [Google Scholar] [CrossRef]

- Panduranga, R.; Alamoudi, Y.; Ferrah, A. Nanoengineered Composite Materials for Wind Turbine Blades. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–7. [Google Scholar]

- Essassi, K.; Ayachi, A.; Feki, N.; Bouguecha, A.; Chaari, F.; Haddar, M. Mechanical Characterization of Glass Fibers–Reinforced Composites for Wind Turbine Blades Applications. In Design and Modeling of Mechanical Systems-V. CMSM 2021; Walha, L., Jarraya, A., Djemal, F., Chouchane, M., Aifaoui, N., Chaari, F., Abdennadher, M., Benamara, A., Haddar, M., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2023; pp. 901–908. ISBN 21954356/978-303114614-5. [Google Scholar]

- Rubiella, C.; Hessabi, C.A.; Fallah, A.S. State of the art in fatigue modelling of composite wind turbine blades. Int. J. Fatigue 2018, 117, 230–245. [Google Scholar] [CrossRef]

- Aydın, Y.; Cakiroglu, C.; Bekdaş, G.; Geem, Z.W. Fatigue Predictive Modeling of Composite Materials for Wind Turbine Blades Using Explainable Gradient Boosting Models. Coatings 2025, 15, 325. [Google Scholar] [CrossRef]

- Raj, E.F.I.; Appadurai, M.; Ram, V.; Gnaniah, A.M.; Salkuti, S.R. Natural-Fibre-Reinforced Composite-Based Micro-Size Wind Turbines: Numerical Analysis and Feasibility Study. J. Compos. Sci. 2023, 7, 197. [Google Scholar] [CrossRef]

- Celik, E.; Sacmaozu, G.; Irez, A.B. Development of Carbon-Glass Fiber Reinforced Hybrid Composites: Applications in Offshore Wind Turbine Blades. In Conference Proceedings of the Society for Experimental Mechanics Series; Chalivendra, V., Beese, A.M., Berke, R.B., Eds.; Springer: Istanbul, Turkey, 2022; pp. 17–22. ISSN 21915644. ISBN 978-303086740-9. [Google Scholar]

- Hermansen, S.M.; Lund, E. Multi-material and thickness optimization of a wind turbine blade root section. Struct. Multidiscip. Optim. 2024, 67, 107. [Google Scholar] [CrossRef]

- Tuninetti, V.; Mariqueo, M. Performance of Combined Woven Roving and Mat Glass-Fiber Reinforced Polymer Composites Under Absorption Tower Lifting Loads. Polymers 2024, 16, 2937. [Google Scholar] [CrossRef]

- Tuninetti, V.; Martínez, D.; Narayan, S.; Menacer, B.; Oñate, A. Design Optimization of a Marine Propeller Shaft for Enhanced Fatigue Life: An Integrated Computational Approach. J. Mar. Sci. Eng. 2024, 12, 2227. [Google Scholar] [CrossRef]

- Li, W.; Zhao, W.; Li, J.; Zhu, Q.; Du, Y. Investigation on vibration behavior of onshore wind turbine tower based on long-term monitoring data. J. Renew. Sustain. Energy 2025, 17, 023303. [Google Scholar] [CrossRef]

- Zuo, H.; Bi, K.; Hao, H.; Li, C. Numerical study of using shape memory alloy-based tuned mass dampers to control seismic responses of wind turbine tower. Eng. Struct. 2022, 250, 113452. [Google Scholar] [CrossRef]

- Haghdoust, P.; Lo Conte, A.; Cinquemani, S.; Lecis, N. Investigation of shape memory alloy embedded wind turbine blades for the passive control of vibrations. Smart Mater. Struct. 2018, 27, 105012. [Google Scholar] [CrossRef]

- Nicoletti, R.; Liebich, R. Analysis of long wind turbine blades with shape memory alloy wires in super-elastic phase. J. Intell. Mater. Syst. Struct. 2018, 29, 3108–3123. [Google Scholar] [CrossRef]

- Riley, D.-K.; Chen, Y.; Lu, C.; Mohagheghian, I.; Hassanin, H.; Sareh, P. Morphing structural materials used in wind turbine blades. Renew. Sustain. Energy Rev. 2025, 216, 115618. [Google Scholar] [CrossRef]

- Bellah, M.; Srivastava, V.; Nosonovsky, M.; Church, B.; Rohatgi, P. Shape Memory Alloy Reinforced Self-Healing Aluminum Composites for Energy Conservation. In Minerals, Metals and Materials Series; Al-Majali, Y., Wisner, B., Mastorakos, I.N., Hunyadi Murph, S.E., Paramsothy, M., Eds.; Springer Science and Business Media Deutschland GmbH: Milwaukee, WI, USA, 2025; pp. 191–202. ISBN 23671181/978-303181056-5. [Google Scholar]

- Valdivia, I.; Canales, C.; Tuninetti, V.; Flores, P.; Medina, C. Numerical Prediction of Failure in Unidirectional Fiber Reinforced Composite. Int. J. Appl. Mech. 2021, 13, 2150073. [Google Scholar] [CrossRef]

- Tuninetti, V.; Sepúlveda, H. Computational Mechanics for Turbofan Engine Blade Containment Testing: Fan Case Design and Blade Impact Dynamics by Finite Element Simulations. Aerospace 2024, 11, 333. [Google Scholar] [CrossRef]

- Beecher, C.; Sepúlveda, H.; Oñate, A.; Habraken, A.M.; Duchêne, L.; Pincheira, G.; Tuninetti, V. Sensitivity Analysis of the Johnson-Cook Model for Ti-6Al-4V in Aeroengine Applications. Aerospace 2024, 12, 3. [Google Scholar] [CrossRef]

- Tuninetti, V.; Ales, B.; Chandía, T.M. Numerical and Experimental Analysis of Thermal Stratification in Locally Heated Residential Spaces. Buildings 2025, 15, 2417. [Google Scholar] [CrossRef]

- Venegas, I.; Oñate, A.; Pierart, F.G.; Valenzuela, M.; Narayan, S.; Tuninetti, V. Efficient Mako Shark-Inspired Aerodynamic Design for Concept Car Bodies in Underground Road Tunnel Conditions. Biomimetics 2024, 9, 448. [Google Scholar] [CrossRef]

- Sesalim, D.; Naser, J. Airfoil Control of Small Wind Turbines. Energies 2024, 17, 1217. [Google Scholar] [CrossRef]

- Carcangiu, C.E.; Sørensen, J.N.; Cambuli, F.; Mandas, N. CFD–RANS analysis of the rotational effects on the boundary layer of wind turbine blades. J. Phys. Conf. Ser. 2007, 75, 012031. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Hsu, M.-C.; Kiendl, J.; Wüchner, R.; Bletzinger, K.-U. 3D simulation of wind turbine rotors at full scale. Part II: Fluid–structure interaction modeling with composite blades. Int. J. Numer. Methods Fluids 2011, 65, 236–253. [Google Scholar] [CrossRef]

- Hansen, M.O.L.; Sørensen, J.N.; Voutsinas, S.; Sørensen, N.; Madsen, H.A. State of the art in wind turbine aerodynamics and aeroelasticity. Prog. Aerosp. Sci. 2006, 42, 285–330. [Google Scholar] [CrossRef]

- Vaz, J.R.P.; Pinho, J.T.; Mesquita, A.L.A. An extension of BEM method applied to horizontal-axis wind turbine design. Renew. Energy 2011, 36, 1734–1740. [Google Scholar] [CrossRef]

- Li, X.; Chi, Y.; Tang, H.; Wei, L. Study on Modelling Standardization of Double-fed Wind Turbine and Its Application. MATEC Web Conf. 2016, 70, 09009. [Google Scholar] [CrossRef]

- Smarsly, K.; Hartmann, D.; Law, K.H. A computational framework for life-cycle management of wind turbines incorporating structural health monitoring. Struct. Health Monit. 2013, 12, 359–376. [Google Scholar] [CrossRef]

- Friedmann, A.; Mayer, D.; Koch, M.; Siebel, T. Monitoring and Damage Detection in Structural Parts of Wind Turbines. In Fundamental and Advanced Topics in Wind Power; Carriveau, R., Ed.; IntechOpen: Rijeka, Croatia, 2011. [Google Scholar][Green Version]

- Liu, Z.; Li, Y.; Zhang, N.; Liang, Z.; Li, F. Reliability Analysis of CFRP-Packaged FBG Sensors Using FMEA and FTA Techniques. Appl. Sci. 2021, 11, 10859. [Google Scholar] [CrossRef]

- Sayed, M.E.; Nemitz, M.P.; Aracri, S.; McConnell, A.C.; McKenzie, R.M.; Stokes, A.A. The Limpet: A ROS-Enabled Multi-Sensing Platform for the ORCA Hub. Sensors 2018, 18, 3487. [Google Scholar] [CrossRef]

- Taware, G.B.; Mankar, S.H.; Ghagare, V.B.; Bharambe, G.P.; Kale, S.A. Vibration Analysis of a Small Wind Turbine Blade. Int. J. Eng. Technol. 2016, 8, 2121–2126. [Google Scholar] [CrossRef]

- Shaler, K.; Kecskemety, K.M.; McNamara, J.J. Benchmarking of a Free Vortex Wake Model for Prediction of Wake Interactions. Renew. Energy 2019, 136, 607–620. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Korobenko, A.; Deng, X.; Yan, J. Fluid–Structure Interaction Modeling for Fatigue-Damage Prediction in Full-Scale Wind-Turbine Blades. J. Appl. Mech. 2016, 83, 061010. [Google Scholar] [CrossRef]

- Bottasso, C.L.; Campagnolo, F.; Croce, A. Multi-disciplinary constrained optimization of wind turbines. Multibody Syst. Dyn. 2012, 27, 21–53. [Google Scholar] [CrossRef]

- Echavarría, E.; van Bussel, G.J.W.; Tomiyama, T. Finding functional redundancies in offshore wind turbine design. Wind Energy 2012, 15, 609–626. [Google Scholar] [CrossRef]

- Krishnan, A.; Al-Obaidi, A.S.M.; Hao, L.C. A comprehensive review of innovative wind turbine airfoil and blade designs: Toward enhanced efficiency and sustainability. Sustain. Energy Technol. Assess. 2023, 60, 103511. [Google Scholar] [CrossRef]

- Yan, Y.; Avital, E.; Williams, J.; Cui, J. Aerodynamic performance improvements of a vertical axis wind turbine by leading-edge protuberance. J. Wind Eng. Ind. Aerodyn. 2021, 211, 104535. [Google Scholar] [CrossRef]

- Lee, S.-L.; Shin, S. Wind Turbine Blade Optimal Design Considering Multi-Parameters and Response Surface Method. Energies 2020, 13, 1639. [Google Scholar] [CrossRef]

- El Mouhsine, S.; Oukassou, K.; Ichenial, M.M.; Kharbouch, B.; Hajraoui, A. Aerodynamics and structural analysis of wind turbine blade. Procedia Manuf. 2018, 22, 747–756. [Google Scholar] [CrossRef]

- Ghorbanpoor Lafmejani, A.; Karimian, S.M.H.; Ghareghani, M.S.M. Aerodynamic performance improvement of 3-PB VAWT using blades with optimized tilted angles. Clean. Eng. Technol. 2024, 22, 100801. [Google Scholar] [CrossRef]

- Lee, S.-L.; Shin, S.J. Structural design optimization of a wind turbine blade using the genetic algorithm. Eng. Optim. 2022, 54, 2053–2070. [Google Scholar] [CrossRef]

- Özkan, R.; Genç, M.S. Aerodynamic design and optimization of a small-scale wind turbine blade using a novel artificial bee colony algorithm based on blade element momentum (ABC-BEM) theory. Energy Convers. Manag. 2023, 283, 116937. [Google Scholar] [CrossRef]

- Faisal, A.E.; Lim, C.W.; Al-Quraishi, B.A.J.; Alkawsi, G.; Tan, C.H.; Milano, J.; Phing, C.C.; Al-Farhany, K.; Tiong, S.K. Investigating the techniques used for improving the aerodynamic performance of Archimedes spiral wind turbines: A comprehensive review and future work avenues. Results Eng. 2025, 25, 103992. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, Z.; Li, W.; Zhang, J.; Cheng, L.; Hu, G. Fluid-structure interaction analysis of wind turbine aerodynamic loads and aeroelastic responses considering blade and tower flexibility. Eng. Struct. 2024, 301, 117289. [Google Scholar] [CrossRef]

- Roul, R.; Kumar, A. Fluid-Structure Interaction of Wind Turbine Blade Using Four Different Materials: Numerical Investigation. Symmetry 2020, 12, 1467. [Google Scholar] [CrossRef]

- Raihan, G.A.; Chakravarty, U.K. Fluid-Structure Interaction Model of a Wind Turbine Blade. In Advanced Materials: Design 2023, Processing, Characterization and Applications; Advances in Aerospace Technology, Proceedings of the ASME 2023 International Mechanical Engineering Congress and Exposition, New Orleans, LA, USA, 29 October–2 November 2023; American Society of Mechanical Engineers: New York, NY, USA, 2023; Volume 4. [Google Scholar]

- Shakya, P.; Thomas, M.; Seibi, A.C.; Shekaramiz, M.; Masoum, M.S. Fluid-structure interaction and life prediction of small-scale damaged horizontal axis wind turbine blades. Results Eng. 2024, 23, 102388. [Google Scholar] [CrossRef]

- Huque, Z.; Zemmouri, F.; Lu, H.; Kommalapati, R.R. Fluid–Structure Interaction Simulations of Wind Turbine Blades with Pointed Tips. Energies 2024, 17, 1090. [Google Scholar] [CrossRef]

- Samet, A.; Yangui, M.; Ben Souf, M.A.; Haddar, M. Fluid-Structure Interaction: Application to Segmented Wind Turbine Blades. In Applied Condition Monitoring; Springer Science and Business Media Deutschland GmbH, Laboratoire de Mécanique, Modélisation et Productique (LA2MP), École Nationale d’Ingénieurs de Sfax: Sfax, Tunisia, 2023; Volume 22, pp. 109–115. ISBN 23636998. [Google Scholar]

- Yassen, Y.E.S.; Abdelhameed, A.S.; Elshorbagy, K.A. An examination of hub wind turbine utilizing fluid-structure interaction strategy. Alexandria Eng. J. 2023, 64, 1–11. [Google Scholar] [CrossRef]

- Leng, J.; Gao, Z.; Wu, M.C.H.; Guo, T.; Li, Y. A fluid–structure interaction model for large wind turbines based on flexible multibody dynamics and actuator line method. J. Fluids Struct. 2023, 118, 103857. [Google Scholar] [CrossRef]

- Zheng, S.; Chua, L.P.; Zhao, Y. Simulations of Fluid-Structure Interaction of a Wind Turbine. In Fluid-Structure-Sound Interactions and Control; Zhou, Y., Lucey, A., Liu, Y., Huang, L., Eds.; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg Germany; Singapore, 2016; pp. 407–413. ISSN 21954356. ISBN 978-366248866-9. [Google Scholar]

- Hsu, M.-C.; Bazilevs, Y. Fluid–structure interaction modeling of wind turbines: Simulating the full machine. Comput. Mech. 2012, 50, 821–833. [Google Scholar] [CrossRef]

- Korobenko, A.; Deng, X.; Yan, J.; Bazilevs, Y. Recent Advances in Fluid–Structure Interaction Simulations of Wind Turbines. In Modeling and Simulation in Science, Engineering and Technology; Springer: Basel, Switzerland, 2016; pp. 489–500. ISSN 21643679. [Google Scholar]

- Jin, X.; Gan, Y.; Ju, W.; Yang, X.; Han, H. Research on wind turbine safety analysis: Failure analysis, reliability analysis, and risk assessment. Environ. Prog. Sustain. Energy 2016, 35, 1848–1861. [Google Scholar] [CrossRef]

- Verma, A.S.; Jiang, Z.; Ren, Z.; Gao, Z.; Vedvik, N.P. Response-Based Assessment of Operational Limits for Mating Blades on Monopile-Type Offshore Wind Turbines. Energies 2019, 12, 1867. [Google Scholar] [CrossRef]

- Manwell, J.F.; McGowan, J.G.; Rogers, A.L. Wind Energy Explained; Wiley: Hoboken, NJ, USA, 2009; ISBN 9780470015001. [Google Scholar]

- Chen, P.; Chen, J.; Hu, Z. Review of Experimental-Numerical Methodologies and Challenges for Floating Offshore Wind Turbines. J. Mar. Sci. Appl. 2020, 19, 339–361. [Google Scholar] [CrossRef]

- Altabey, W.A.; Noori, M. Artificial-Intelligence-Based Methods for Structural Health Monitoring. Appl. Sci. 2022, 12, 12726. [Google Scholar] [CrossRef]

- Koragappa, P.; Verdin, P.G. Design and optimisation of a 20 MW offshore wind turbine blade. Ocean Eng. 2024, 305, 117975. [Google Scholar] [CrossRef]

- Zivansky, J.; Andersen, A.; Schlosser, A.; Batlle, F.; Schülde, M.; Beckmann, N. Offshore Wind Operations and Maintenance: A Turning Point; Mckinsey&Company: New York, NY, USA, 2025. [Google Scholar]

- Barthelmie, R.J.; Dantuono, K.E.; Renner, E.J.; Letson, F.L.; Pryor, S.C. Extreme wind and waves in U.S. east coast offshore wind energy lease areas. Energies 2021, 14, 1053. [Google Scholar] [CrossRef]

- Jiang, J.; Jeong, H.K.; Dou, H. Study on the Structural Strength Assessment of Mega Offshore Wind Turbine Tower. Energies 2025, 18, 69. [Google Scholar] [CrossRef]

- Bailey, H.; Brookes, K.L.; Thompson, P.M. Assessing environmental impacts of offshore wind farms: Lessons learned and recommendations for the future. Aquat. Biosyst. 2014, 10, 8. [Google Scholar] [CrossRef]

- Gallardo, Y.; Tampier, G.; Palma, V.; Cifuentes, C.; Ahumada, J.M.; Troncoso, C.; Mendoza, M.Y. An Early-Stage Structural Design of a Semi-Submersible Platform for Floating Offshore Wind Turbines in Chilean Waters. J. Mar. Sci. Eng. 2024, 12, 1951. [Google Scholar] [CrossRef]

- Cayuela-Padilla, S.; M’zoughi, F.; Garrido, I.; Garrido, A.J. Design and stability analysis of a new six-floater oscillating water column-based floating offshore wind turbine platform. Sci. Rep. 2024, 14, 16191. [Google Scholar] [CrossRef]

- Wang, H.; Ran, Q.; Ma, G.; Wen, J.; Zhang, J.; Zhou, S. Optimization design of floating offshore wind turbine mooring system based on DNN and NSGA-III. Ocean Eng. 2025, 316, 121973. [Google Scholar] [CrossRef]

- Ojo, A.; Collu, M.; Coraddu, A. Multidisciplinary design analysis and optimization of floating offshore wind turbine substructures: A review. Ocean Eng. 2022, 266, 112727. [Google Scholar] [CrossRef]

- Fadaei, S.; Afagh, F.F.; Langlois, R.G. A Survey of Numerical Simulation Tools for Offshore Wind Turbine Systems. Wind 2024, 4, 1–24. [Google Scholar] [CrossRef]

- Bangga, G. Comparison of Blade Element Method and CFD Simulations of a 10 MW Wind Turbine. Fluids 2018, 3, 73. [Google Scholar] [CrossRef]

- Ehrich, S.; Schwarz, C.M.; Rahimi, H.; Stoevesandt, B.; Peinke, J. Comparison of the Blade Element Momentum Theory with Computational Fluid Dynamics for Wind Turbine Simulations in Turbulent Inflow. Appl. Sci. 2018, 8, 2513. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, X.; Lin, S.; Wang, Y.; Guo, X. CFD Simulation of Co-Planar Multi-Rotor Wind Turbine Aerodynamic Performance Based on ALM Method. Energies 2022, 15, 6422. [Google Scholar] [CrossRef]

- Wu, J.; Sun, Z.; Zhu, W.; Fu, S.; Xu, C.; Shen, W. A New Modified Blade Element Momentum Method for Calculating the Aerodynamic Performance of a Wind Turbine in Yaw. Energies 2025, 18, 1063. [Google Scholar] [CrossRef]

- López-Queija, J.; Sotomayor, E.; Jugo, J.; Aristondo, A.; Robles, E. A novel python-based floating offshore wind turbine simulation framework. Renew. Energy 2024, 222, 119973. [Google Scholar] [CrossRef]

- NREL Wind Data and Tools. Available online: https://www.nrel.gov/wind/data-tools (accessed on 20 August 2025).

- Kim, Y.J.; Charlou, M.; Bouscasse, B.; Leroy, V.; Aliyar, S.; Bonnefoy, F.; Kim, K.-H.; Choi, Y.-M. High fidelity simulations of a floating offshore wind turbine in irregular waves by coupling OpenFOAM and OpenFAST. Renew. Energy 2025, 243, 122486. [Google Scholar] [CrossRef]

- Abdelaziz, S.; Sparrow, S.N.; Hua, W.; Wallom, D. Extreme Wind Gust Impact on UK Offshore Wind Turbines: Long-Term Return Level Estimation. In Proceedings of the IEEE Power and Energy Society General Meeting, Orlando, FL, USA, 16–20 July 2023. [Google Scholar]

- Chen, Y.; Wu, D.; Yu, Y.; Gao, W. Do cyclone impacts really matter for the long-term performance of an offshore wind turbine? Renew. Energy 2021, 178, 184–201. [Google Scholar] [CrossRef]

- Leng, J.; Li, G.; Duan, L. The impact of extreme wind conditions and yaw misalignment on the aeroelastic responses of a parked offshore wind turbine. Ocean Eng. 2024, 313, 119403. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Y.; Wu, S.; Yu, M.; Xie, J.; Xue, X. Super typhoon impact on the dynamic behavior of floating offshore wind turbine drivetrains: A comprehensive study. Ocean Eng. 2024, 312, 119084. [Google Scholar] [CrossRef]

- Zhou, D.; Pan, X.; Guo, J.; Sun, X.; Wang, C.; Zheng, J. Resilience quantification of offshore wind farm cluster under the joint influence of typhoon and its secondary disasters. Appl. Energy 2025, 383, 125323. [Google Scholar] [CrossRef]

- Liu, M.; Qin, J.; Lu, D.-G.; Zhang, W.-H.; Zhu, J.-S.; Faber, M.H. Towards resilience of offshore wind farms: A framework and application to asset integrity management. Appl. Energy 2022, 322, 119429. [Google Scholar] [CrossRef]

- Rong, J.; Zhou, M.; Li, G. Resilience-Oriented Restoration Strategy by Offshore Wind Power Considering Risk. CSEE J. Power Energy Syst. 2023, 9, 2052–2065. [Google Scholar] [CrossRef]

- Pani, S.R.; Samal, R.K. Evaluation of reliability and resilience in wind integrated power systems using 80 meter mast measurements. Electr. Power Syst. Res. 2025, 241, 111263. [Google Scholar] [CrossRef]

- Forsberg, S.; Göteman, M.; Thomas, K.; Bergkvist, M. Resilience to extreme storm conditions: A comparative study of two power systems with varying dependencies on offshore wind. Results Eng. 2024, 23, 102408. [Google Scholar] [CrossRef]

- Köpke, C.; Mielniczek, J.; Stolz, A. Testing Resilience Aspects of Operation Options for Offshore Wind Farms beyond the End-of-Life. Energies 2023, 16, 4771. [Google Scholar] [CrossRef]

- Pujana, A.; Esteras, M.; Perea, E.; Maqueda, E.; Calvez, P. Hybrid-Model-Based Digital Twin of the Drivetrain of a Wind Turbine and Its Application for Failure Synthetic Data Generation. Energies 2023, 16, 861. [Google Scholar] [CrossRef]

- Syawitri, T.P.; Yao, Y.F.; Chandra, B.; Yao, J. Comparison study of URANS and hybrid RANS-LES models on predicting vertical axis wind turbine performance at low, medium and high tip speed ratio ranges. Renew. Energy 2021, 168, 247–269. [Google Scholar] [CrossRef]

- Yan, J.; Nuertayi, A.; Yan, Y.; Liu, S.; Liu, Y. Hybrid physical and data driven modeling for dynamic operation characteristic simulation of wind turbine. Renew. Energy 2023, 215, 118958. [Google Scholar] [CrossRef]

- Pei, S.; Li, Y. Wind turbine power curve modeling with a hybrid machine learning technique. Appl. Sci. 2019, 9, 4930. [Google Scholar] [CrossRef]

- Flórez, S.L.; Hernández González, G.; Prieto, J.; de la Prieta, F. Hybrid Physics-LSTM Framework for Wind Power Prediction and Control in Virtual Microgrid Simulations. IEEE Access 2025, 13, 122175–122186. [Google Scholar] [CrossRef]

- Li, Y.; Tang, S.; Li, Y.; Zhu, R.; Yu, H. Tropical cyclone wind hazard assessment for Donghaitang wind farm (Zhejiang Province, China): Case study. Front. Earth Sci. 2022, 10, 1109026. [Google Scholar] [CrossRef]

- Wu, Z.; Li, Y. Hybrid Model Predictive Control of Floating Offshore Wind Turbines With Artificial Muscle Actuated Mooring Lines. J. Dyn. Syst. Meas. Control Trans. ASME 2022, 144, 051003. [Google Scholar] [CrossRef]

- De Simone, M.; Ungureanu, D.-V.; Campagna, D. Circular Economy of Wind Turbines Waste in Constructions and Cities. In 4th International Conference "Coordinating Engineering for Sustainability and Resilience" & Midterm Conference of CircularB “Implementation of Circular Economy in the Built Environment”, Timisoara, Romania, 29–31 May 2024; Ungureanu, V., Bragança, L., Baniotopoulos, C., Abdalla, K.M., Eds.; Lecture Notes in Civil Engineering, LNCE; Springer Nature Switzerland AG: Cham, Switzerland, 2024; Volume 489, pp. 592–602. [Google Scholar]

- Salas, A.; Berrio, M.E.; Martel, S.; Díaz-Gómez, A.; Palacio, D.A.; Tuninetti, V.; Medina, C.; Meléndrez, M.F. Towards recycling of waste carbon fiber: Strength, morphology and structural features of recovered carbon fibers. Waste Manag. 2023, 165, 59–69. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Li, Y.; Wang, Y.; Li, G.; Liu, X. Wind turbine blade recycling: A review of the recovery and high-value utilization of decommissioned wind turbine blades. Resour. Conserv. Recycl. 2024, 210, 107813. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Ni, A. Recycling and reuse of composite materials for wind turbine blades: An overview. J. Reinf. Plast. Compos. 2019, 38, 567–577. [Google Scholar] [CrossRef]

- Diez-Cañamero, B.; Mendoza, J.M.F. Circular economy performance and carbon footprint of wind turbine blade waste management alternatives. Waste Manag. 2023, 164, 94–105. [Google Scholar] [CrossRef]

- Ramaswamy, N.; Joshi, B.; Song, G.; Mo, Y.L. Repurposing decommissioned wind turbine blades: A circular economy approach to sustainable resource management and infrastructure innovation. Renew. Sustain. Energy Rev. 2025, 215, 115629. [Google Scholar] [CrossRef]

- Tyurkay, A.; Kirkelund, G.M.; Lima, A.T.M. State-of-the-art circular economy practices for end-of-life wind turbine blades for use in the construction industry. Sustain. Prod. Consum. 2024, 47, 17–36. [Google Scholar] [CrossRef]

| Material | Tensile Strength (MPa) | Young’s Modulus (GPa) | Density (g/cm3) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| E-Glass Fiber | 2000–3800 | 72–85 | 2.54–2.70 | Low cost, good insulation, corrosion resistance | Lower stiffness, higher density than carbon fiber |

| S-Glass Fiber | 4590–4832 | 88–91 | 2.46–2.49 | ~40–50% higher strength and ~10–20% higher stiffness than E-glass | Higher cost than E-glass |

| Carbon Fiber (Standard Modulus) | 3500–5000 | 230–240 | 1.8 | Excellent stiffness-to-weight ratio, superior fatigue life | High cost, lower damage tolerance than glass fiber |

| Aramid Fiber (e.g., Kevlar® 49) | ~3000 | 110–130 | 1.44 | Excellent impact resistance, high tensile strength-to-weight ratio | Poor compressive strength, difficult to machine, high cost |

| Basalt Fiber | 3000–4840 | 85–95 | 2.65–3.00 | Superior to E-glass in strength and stiffness, good thermal/chemical resistance | Higher cost than E-glass, less mature supply chain |

| Natural Fibers (Flax, Hemp) | 500–1500 | 50–70 | 1.5 | Low cost, low density, biodegradable, good damping | Low mechanical properties, high moisture absorption, property variability |

| Parameter | Finite Element Method (FEM) | Computational Fluid Dynamics (CFD) |

|---|---|---|

| Primary Domain | Solid Mechanics | Fluid Dynamics |

| Governing Equations | Equations of solid mechanics and elasticity | Navier–Stokes equations |

| Key Outputs | Stress, strain, deformation, natural frequencies, buckling loads | Pressure, velocity, lift and drag forces, wake characteristics, turbulence |

| Computational Cost | High, dependent on mesh density and non-linearity | Very high, especially for turbulent, unsteady flows (e.g., DES, LES) |

| Primary Use in Blade Design | Structural integrity analysis; vibration and modal analysis; fatigue life prediction; material failure simulation | Airfoil and blade aerodynamic performance; predicting aerodynamic loads; wake and turbine interaction analysis; stall and flow separation studies |

| Area | Study Focus | Ref. | Methodology | Key Findings |

|---|---|---|---|---|

| Aerodynamic and Structural Design | Blade aerodynamic design | [27] | Wind tunnel test | <2% error between calculated and experimental thrust |

| Aerodynamic profile optimization | [32] | HBC-COMEA algorithm | 5.07% torque increase, 24% vibration reduction | |

| Rotor upscaling and load control | [26] | Sizing calculations and ALC | Fatigue load reduction and lower capital costs | |

| Blade shape optimization | [28] | Genetic Algorithm (GA) | 10% increase in power output | |

| Endplate design comparison | [29] | CFD + experiments | Circular endplate performed best | |

| CAWT performance improvement | [33] | Optimized Deflector Cone (ODFC) | Power coefficient doubled | |

| Savonius turbine optimization | [30] | Taguchi + ANOVA | Inner blade angle most critical | |

| Control Strategies and Smart Systems | Yaw control in wind farms | [35] | Dual yaw strategy | Output increased by 11.3% |

| AI in turbine design | [36] | Review of digital twin, loads, standards | AI enables scalable, sustainable design | |

| Coordinated control (pitch/speed) | [37] | Multi-objective adaptive fuzzy control | Robust, dynamic system performance | |

| Blade damping via pitch control | [38] | Dynamic model | Effective power, speed and load control | |

| FOWT real-time control | [41] | RBFNN + Super-Twisting Algorithm | Improved stability in offshore conditions | |

| CCD of turbine systems | [40] | DFSM surrogate model | Tower stress limits critical to design | |

| Fatigue, Vibration, and Structural Analysis | Structural fatigue mitigation | [44] | HSFD system | Reduced fatigue damage |

| Vibration reduction strategies | [47] | Spectral analysis and simulation | Vibration reduction via blade-structure coupling | |

| Compression-bending capacity | [25] | Finite Element Model | Prediction error minimal (CoV = 0.0454) | |

| UHPC–steel hybrid tower design | [31] | Dynamic FE + cost analysis | Economically efficient hybrid design | |

| Impedance control and damping | [39] | Eigenvalue analysis | Stability drops as wind speed decreases | |

| Typhoon-induced loading | [46] | Dynamic simulation | Wind loads dominate extreme structural responses | |

| Environmental Effects and Simulation | Atmospheric stability effect | [21] | 3D Stability-COUTI + LES | High coherence in field vs. simulation data |

| Wake flow in FOWTs | [43] | 6-DOF dynamic model | Turbulence intensity increases with pitch amplitude | |

| Typhoon wind–wave forces | [42] | WRF-SWAN-FVCOM model | Pitch instability at 11.6° pitch angle | |

| Post-rated wind speed performance | [148] | CFD vs. BEM | CFD (RANS) more accurate than QBlade | |

| Optimization and Efficiency Analysis | Offshore WT lifecycle analysis | [34] | Probabilistic failure prediction | Supports lifecycle decision-making |

| WT generator system optimization | [24] | AMI-PSO algorithm | 2.43% cost/kWh reduction, 5× cycle time cut | |

| HAWT hydrokinetic turbine blades | [22] | Taguchi + ANOVA | 6% improvement in power coefficient | |

| Economic efficiency of tidal HAWT | [35] | Actuator disc model | Rotor shows high- and low-frequency fluctuations | |

| Hybrid renewable system design | [45] | PSO, WOA, ACO, GA | Alkhums, Libya: lowest COE achieved |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lagos, F.; Menacer, B.; Salas, A.; Narayan, S.; Medina, C.; Valle, R.; Garrido, C.; Pincheira, G.; Oñate, A.; Hunter-Alarcón, R.; et al. Recent Advances in the Analysis of Functional and Structural Polymer Composites for Wind Turbines. Polymers 2025, 17, 2339. https://doi.org/10.3390/polym17172339

Lagos F, Menacer B, Salas A, Narayan S, Medina C, Valle R, Garrido C, Pincheira G, Oñate A, Hunter-Alarcón R, et al. Recent Advances in the Analysis of Functional and Structural Polymer Composites for Wind Turbines. Polymers. 2025; 17(17):2339. https://doi.org/10.3390/polym17172339

Chicago/Turabian StyleLagos, Francisco, Brahim Menacer, Alexis Salas, Sunny Narayan, Carlos Medina, Rodrigo Valle, César Garrido, Gonzalo Pincheira, Angelo Oñate, Renato Hunter-Alarcón, and et al. 2025. "Recent Advances in the Analysis of Functional and Structural Polymer Composites for Wind Turbines" Polymers 17, no. 17: 2339. https://doi.org/10.3390/polym17172339

APA StyleLagos, F., Menacer, B., Salas, A., Narayan, S., Medina, C., Valle, R., Garrido, C., Pincheira, G., Oñate, A., Hunter-Alarcón, R., & Tuninetti, V. (2025). Recent Advances in the Analysis of Functional and Structural Polymer Composites for Wind Turbines. Polymers, 17(17), 2339. https://doi.org/10.3390/polym17172339