Synergistic Optimization of Polymer–Surfactant Binary Flooding for EOR: Core-Scale Experimental Analysis of Formulation, Slug Design, and Salinity Effect

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Core Flooding Procedures

3. Results and Discussion

3.1. Impact of Surfactant Concentration on EOR Ability of Combination Flooding

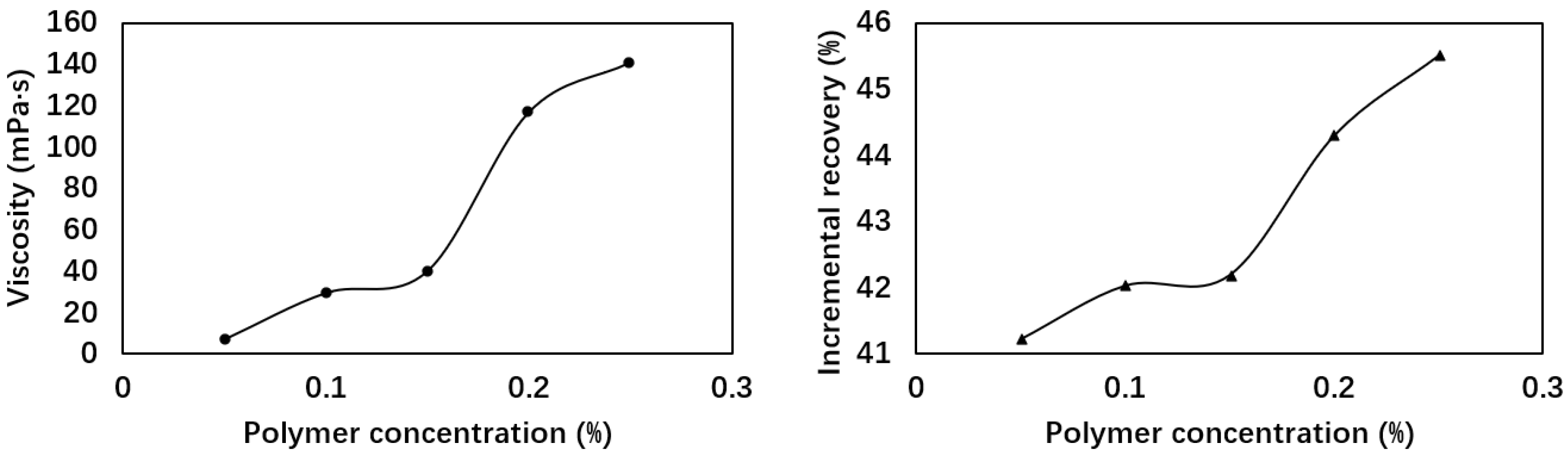

3.2. Influence of Polymer Concentration on EOR Efficiency of Combination Flooding

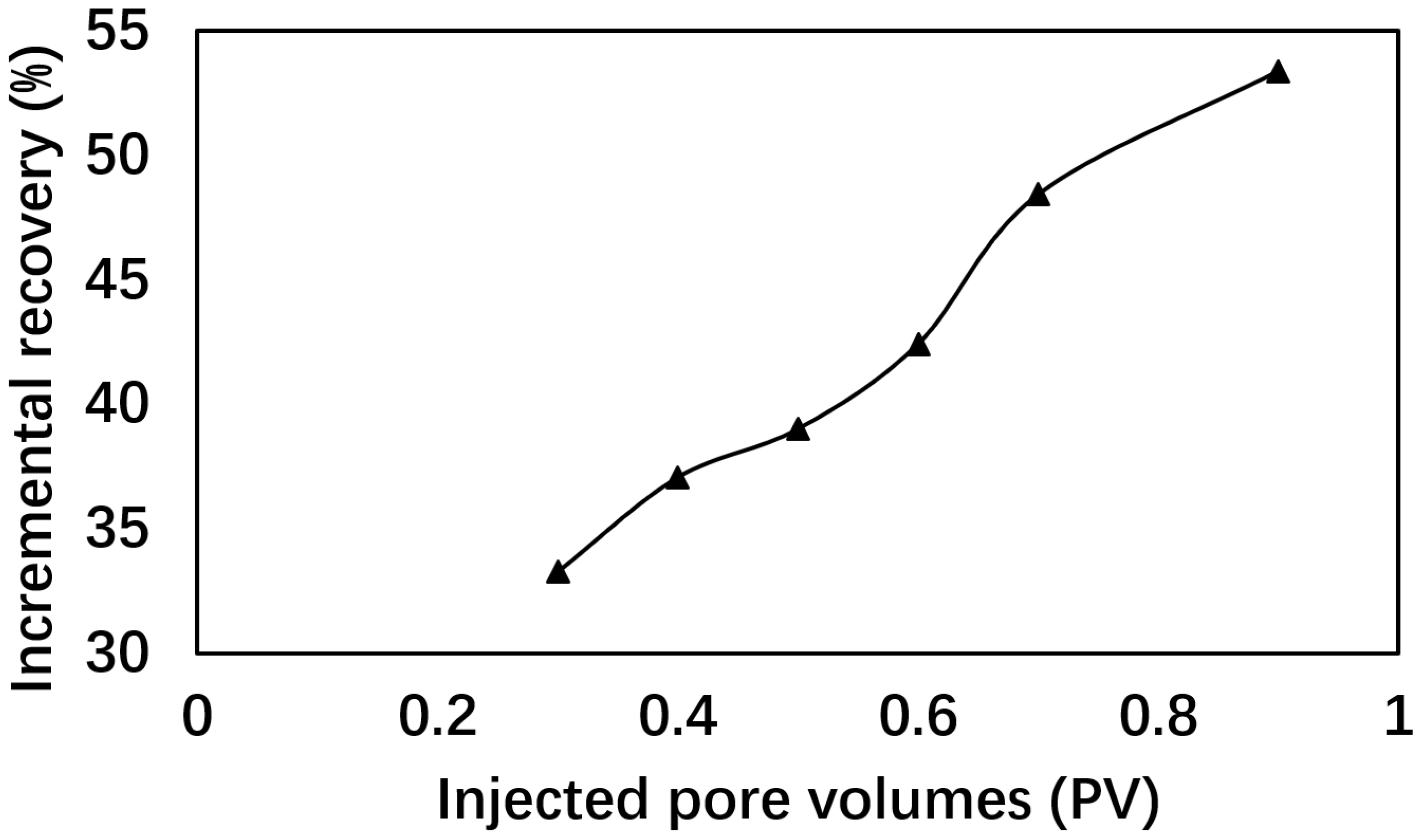

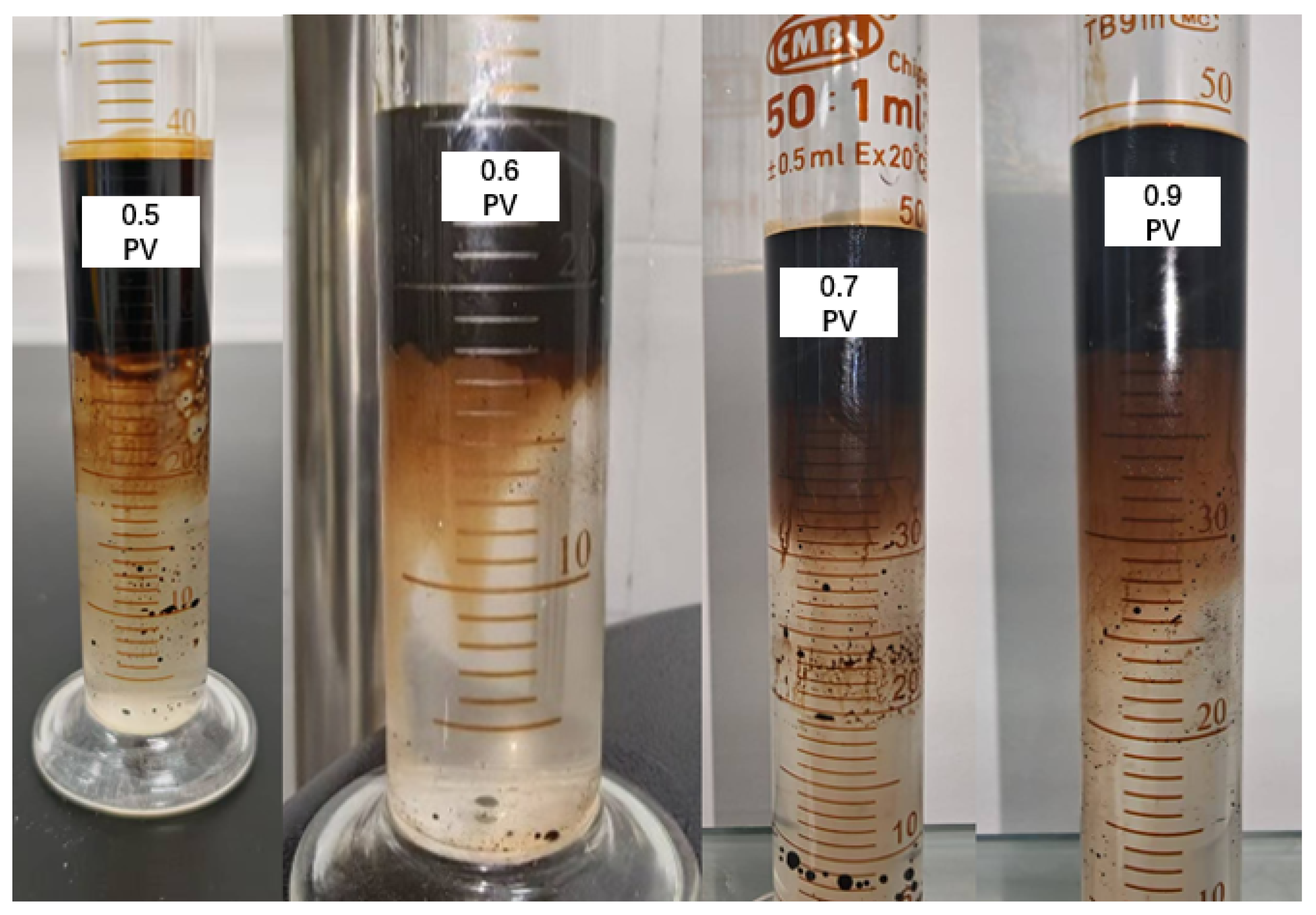

3.3. Influence of Injection Volume on Incremental Recovery

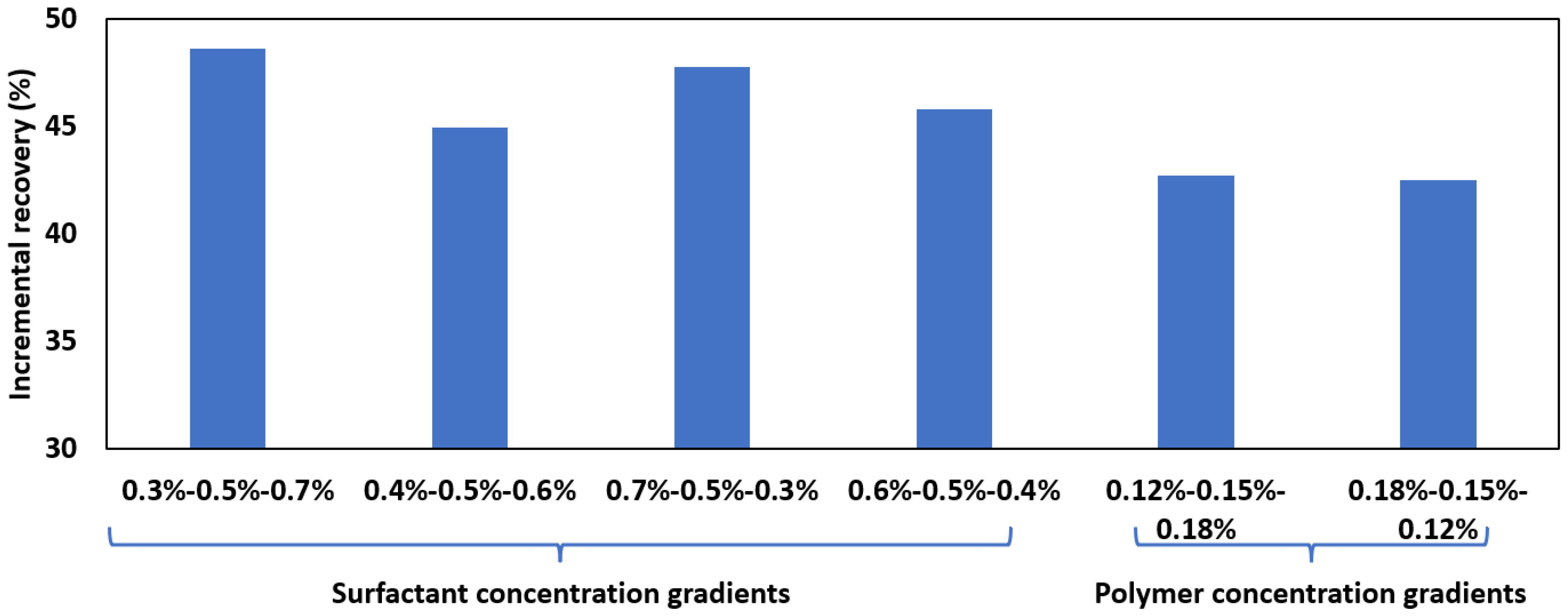

3.4. Comparison Between Different Slug Designs

3.5. Impact of Salinity on the EOR Performance

4. Conclusions

- The optimal formulation (0.5% surfactant + 0.15% polymer) achieves synergistic benefits: elevated viscosity (40.2 mPa·s) enhances mobility control, while reduced IFT (0.007 mN/m) improves microscopic displacement.

- The 0.5 PV injection volume represents a practical compromise between incremental recovery and operational constraints such as injectivity.

- Sequential slug design with surfactant gradients outperforms fixed-concentration injection, highlighting the importance of tailored slug sequences.

- High salinity reduces viscosity and does not lead to emulsification at the effluent, whereas low salinity increases the viscosity without contributing to higher recovery, possibly due to the insignificant level of heterogeneity of the cores.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| IFT | Interfacial tension |

| PV | Pore volume |

| EOR | Enhanced oil recovery |

| TDS | Total dissolved solids |

References

- Hongyan, W.; Xulong, C.; Jichao, Z.; Aimei, Z. Development and Application of Dilute Surfactant-Polymer Flooding System for Shengli Oilfield. J. Pet. Sci. Eng. 2009, 65, 45–50. [Google Scholar] [CrossRef]

- Hoff, E.; Nyström, B.; Lindman, B. Polymer-Surfactant Interactions in Dilute Mixtures of Nonionic Cellulose Derivatives and Anionic Surfactants. Langmuir 2001, 17, 28–34. [Google Scholar] [CrossRef]

- Tan, F.; Liu, W.; Ma, C.; Chen, H.; Li, X.; Zhang, C. Classification methods of conglomerate reservoirs based on the adsorption and retention law of surfactant-polymer binary systems. J. Pet. Sci. Eng. 2022, 208, 109195. [Google Scholar] [CrossRef]

- Zhao, G.; Li, J.; Gu, C.; Li, L.; Sun, Y.; Dai, C. Dispersed Particle Gel-Strengthened Polymer/Surfactant as a Novel Combination Flooding System for Enhanced Oil Recovery. Energy Fuels 2018, 32, 11317–11327. [Google Scholar] [CrossRef]

- Wang, D.; Song, Y.; Wang, P.; Li, G.; Niu, W.; Shi, Y.; Zhao, L. Study on Oil Recovery Mechanism of Polymer-Surfactant Flooding Using X-Ray Microtomography and Integral Geometry. Molecules 2022, 27, 8621. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.E.; Sultan, A.; Al-Sofi, A.; Al-Hashim, H. Optimization of Surfactant-Polymer Flooding for Enhanced Oil Recovery. J. Pet. Explor. Prod. Technol. 2023, 13, 2109–2123. [Google Scholar] [CrossRef]

- Soleimani, M.; Abdalisousan, A.; Manshad, A.K.; Sajadiyan, V.A. Advanced Polymer-based Surfactant for Improved Heat and Salinity Stability in Enhanced Oil Recovery Processes. J. Surfactants Deterg. (JSD) 2024, 27, 421–432. [Google Scholar] [CrossRef]

- Ar-Raihan, M.H.; Salsabila, R.; Adharis, A.; Ratri, P.J.; Mayangsari, T.R. Analysis of Surfactant and Polymer Behavior on Water/Oil Systems as Additives in Enhanced Oil Recovery (EOR) Technology Through Molecular Dynamics Simulation: A Preliminary Study. J. Earth Energy Eng. 2023, 12, 27–39. [Google Scholar] [CrossRef]

- Austad, T.; Fjelde, I.; Veggeland, K.; Taugbøl, K. Physicochemical Principles of Low-Tension Polymer Flooding. J. Pet. Sci. Eng. 1994, 10, 255–269. [Google Scholar] [CrossRef]

- Ge, S.; Shi, L.; Ye, Z.; Liu, G.; Ba, Y.; Wang, X.; Yang, Y.; Chen, M.; Yuan, N.; Li, P. Synthesis and Mechanistic Investigation of an Amphiphilic Polymer in Enhancing Extra-Heavy Oil Recovery via Viscosity Reduction. Langmuir 2024, 40, 18049–18062. [Google Scholar] [CrossRef]

- Azad, M.S. Does Polymer’s Viscoelasticity Influence Heavy Oil Sweep Efficiency and Injectivity at 1ft/Day? SPE Reserv. Eval. Eng. 2018, 23, 446–462. [Google Scholar] [CrossRef]

- Agzamov, A.; Zakirov, A.; Igamberdieva, L.; Agzamova, S. Rheological Properties of Polymer Solutions and Ways to Improve the Efficiency of Development of High-Viscosity Oil Fields in Uzbekistan. In Proceedings of the E3S Web of Conferences, Samarkand, Uzbekistan, 13–14 May 2024. [Google Scholar]

- Eseimokumoh, I.B. Improving Oil Recovery Efficiency in Niger Delta Reservoirs Using Corn Starch as a Local Polymer. Int. J. Curr. Sci. Res. Rev. 2021, 4, 1525–1536. [Google Scholar] [CrossRef]

- Hublik, G.; Kharrat, R.; Dastjerdi, A.M.; Ott, H. Investigating the Potential of a Transparent Xanthan Polymer for Enhanced Oil Recovery: A Comprehensive Study on Properties and Application Efficacy. Energies 2024, 17, 1266. [Google Scholar] [CrossRef]

- He, H.; Ning, W.; Pei, H.; Chen, R.; Tian, Y.; Liu, Y.; Zuo, Q. Insights Into Enhanced Oil Recovery by Viscosity Reduction Combination Flooding System for Conventional Heavy Oil Reservoir. Processes 2025, 13, 618. [Google Scholar] [CrossRef]

- Belhaj, A.; Elraies, K.; Mahmood, S.M.; Zulkifli, N.; Akbari, S.; Hussien, O. The Effect of Surfactant Concentration, Salinity, Temperature, and pH on Surfactant Adsorption for Chemical Enhanced Oil Recovery: A Review. J. Pet. Explor. Prod. Technol. 2020, 10, 125–137. [Google Scholar] [CrossRef]

- Kumari, R.; Kakati, A.; Nagarajan, R.; Sangwai, J. Synergistic Effect of Mixed Anionic and Cationic Surfactant Systems on the Interfacial Tension of Crude Oil-Water and Enhanced Oil Recovery. J. Dispers. Sci. Technol. 2018, 40, 969–981. [Google Scholar] [CrossRef]

- Haghighi, O.; Zargar, G.; Manshad, A.K.; Ali, M.; Takassi, M.; Ali, J.A.; Keshavarz, A. Effect of Environment-Friendly Non-Ionic Surfactant on Interfacial Tension Reduction and Wettability Alteration; Implications for Enhanced Oil Recovery. Energies 2020, 13, 3988. [Google Scholar] [CrossRef]

- Nadir, N.; Shahruddin, S.; Othman, J. Surfactant Evaluation for Enhanced Oil Recovery: Phase Behavior and Interfacial Tension. Open Chem. 2022, 20, 1110–1120. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Lun, Z.; Zhang, Y.; Yang, P.; Tang, X.; Zhang, Q. Factors, Mechanisms, and Kinetics of Spontaneous Emulsification for Heavy Oil-in-Water Emulsions. Molecules 2024, 29, 2998. [Google Scholar] [CrossRef]

- Zhang, B.; Guan, B.; Liu, W.; Peng, B.; Cong, S. Dissipative Particle Dynamics Simulation and Microscopic Experimental Study of Emulsification Performance of Surfactant/Polymer Flooding. Processes 2023, 11, 1411. [Google Scholar] [CrossRef]

- Michels, A.M.; Djojosoeparto, R.S.; Haas, H.; Mattern, R.B. Enhanced Waterflooding with Dilute Surfactant-Polymer for North Sea Reservoirs. SPE Reserv. Eng. 1996, 11, 189–195. [Google Scholar] [CrossRef]

- Druetta, P.; Picchioni, F. Surfactant–Polymer Flooding: Influence of the Injection Scheme. Energy Fuels 2018, 32, 12231–12246. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, J.C.; Zhang, X.; Guo, X.; Chen, L.; Zhang, A.; Cao, K.; Li, J. Experimental Study on the Evaluation of Surfactant/Polymer Flooding for Enhancing Oil Recovery in Kumkol Oil Field. J. Pet. Explor. Prod. Technol. 2022, 13, 853–864. [Google Scholar] [CrossRef]

- Dadlani, H.V.; Chauhan, P.; Tiwlekar, S.N.; Behera, A.; Moatoshi, C.; Swain, D.K. Design, Implementation, and Performance of Surfactant Polymer Flood Pilot in Mehsana Asset. In Proceedings of the SPE Conference at Oman Petroleum & Energy Show, Muscat, Oman, 12–14 May 2025. [Google Scholar]

- Oliveira, G.F.; Sousa, G.L.; Syahyuda, Z.; Carvalho, M.A. Surfactant-Polymer Slug Optimization, Injection Rate & Pattern Size Determination Using the CMG Simulator in the Mj Well. J. Geosci. Eng. Environ. Technol. 2024, 9, 343–350. [Google Scholar] [CrossRef]

- Gao, S.; He, Y.; Zhu, Y.; Han, P.; Peng, S.; Liu, X. Associated Polymer ASP Flooding Scheme Optimization Design and Field Test after Polymer Flooding in Daqing Oilfield. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 31 August–4 September 2020. number SPE-200443-MS. [Google Scholar]

- Khamees, T.K.; Flori, R.E.; Alsubaih, A.A.; Alhuraishawy, A.K. Modeling the Effects of Salinity, Polymer Rheology, Temperature, and Reservoir Wettability on the Performance of in-Depth Gel Treatment Coupled With Surfactant and Polymer Flooding. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13 November 2018. Day 2. [Google Scholar]

- Ghosh, P.; Mohanty, K. Study of Surfactant–Polymer Flooding in High-Temperature and High-Salinity Carbonate Rocks. Energy Fuels 2019, 33, 4130–4145. [Google Scholar] [CrossRef]

- Abbott, S. Surfactant Science: Principles and Practice; DEStech Publications, Inc.: Lancaster, PA, USA, 2018; pp. 1–255. [Google Scholar]

- Magzymov, D.; Qiao, C.; Johns, R.T. Impact of Surfactant Mixtures on Microemulsion Phase Behavior. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar]

- Lv, J.; Liao, G.; Liu, W.; Wang, X.; Jing, Y.; Liu, H.; Jiang, R. Effect of Reservoir Heterogeneity on Polymer–Surfactant Binary Chemical Flooding Efficiency in Conglomerate Reservoirs. Polymers 2024, 16, 3405. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Gai, C.; Song, B.; Jiang, J.; Wang, Z. The Influence of Permeability and Heterogeneity on Chemical Flooding Efficiency and Remaining Oil Distribution—Based on NMR Displacement Imaging. Sci. Rep. 2023, 13, 14316. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.-H.; Kang, C.-Y.; Liu, T.-F.; Li, H.; Yu, H.-M.; Liu, Z.-Z.; Fan, H.-M. Synergistic stabilization of emulsions by microspheres and surfactants for enhanced oil recovery. Pet. Sci. 2025, 22, 2535–2545. [Google Scholar] [CrossRef]

- Joshi, D.; Maurya, N.K.; Kumar, N.; Mandal, A. Experimental investigation of silica nanoparticle assisted surfactant and polymer systems for enhanced oil recovery. J. Pet. Sci. Eng. 2022, 216, 110791. [Google Scholar] [CrossRef]

| Formulation | Viscosity (mPa·s) | IFT (10−3 mN/m) | Incremental Recovery (%) |

|---|---|---|---|

| 0.3% S + 0.2% P | 107.68 ± 0.45 | 9.13 ± 0.27 | 35.28 |

| 0.5% S + 0.2% P | 117.17 ± 0.23 | 7.11 ± 0.02 | 42.19 |

| 0.6% S + 0.2% P | 123.86 ± 0.14 | 6.57 ± 0.11 | 43.48 |

| 0.7% S + 0.2% P | 132.10 ± 0.21 | 5.14 ± 0.04 | 44.32 |

| 0.9% S + 0.2% P | 147.22 ± 0.20 | 1.89 ± 0.04 | 45.63 |

| Formulation | Viscosity (mPa·s) | IFT (10−3 mN/m) | Incremental Recovery (%) | Peak Pressure (MPa) |

|---|---|---|---|---|

| 0.5% S + 0.05% P | 7.34 ± 0.08 | 7.17 ± 0.03 | 41.22 | 0.75 |

| 0.5% S + 0.1% P | 27.92 ± 0.04 | 7.27 ± 0.04 | 42.03 | 0.88 |

| 0.5% S + 0.15% P | 40.18 ± 0.03 | 7.12 ± 0.14 | 42.19 | 1.35 |

| 0.5% S + 0.2% P | 117.17 ± 0.23 | 7.11 ± 0.02 | 44.30 | 1.91 |

| 0.5% S + 0.25% P | 141.42 ± 0.41 | 8.13 ± 0.33 | 45.51 | 1.93 |

| PV | Viscosity (mPa·s) | IFT (10−3 mN/m) | Incremental Recovery (%) | Peak Pressure (MPa) |

|---|---|---|---|---|

| 0.3 | 40.18 ± 0.03 | 7.12 ± 0.14 | 34.27 | 1.21 |

| 0.4 | 40.18 ± 0.03 | 7.12 ± 0.14 | 39.07 | 1.27 |

| 0.5 | 40.18 ± 0.03 | 7.12 ± 0.14 | 42.19 | 1.35 |

| 0.6 | 40.18 ± 0.03 | 7.12 ± 0.14 | 45.42 | 2.16 |

| 0.7 | 40.18 ± 0.03 | 7.12 ± 0.14 | 48.43 | 2.34 |

| 0.9 | 40.18 ± 0.03 | 7.12 ± 0.14 | 53.38 | 3.11 |

| Formulation | Incremental Recovery (%) |

|---|---|

| 0.7% S + 0.15% P (0.15 PV) | |

| 0.5% S + 0.15% P (0.15 PV) | 47.78 |

| 0.3% S + 0.15% P (0.15 PV) | |

| 0.3% S + 0.15% P (0.15 PV) | |

| 0.5% S + 0.15% P (0.2 PV) | 48.64 |

| 0.7% S + 0.15% P (0.15 PV) | |

| 0.6% S + 0.15% P (0.15 PV) | |

| 0.5% S + 0.15% P (0.2 PV) | 45.81 |

| 0.4% S + 0.15% P (0.15 PV) | |

| 0.4% S + 0.15% P (0.15 PV) | |

| 0.5% S + 0.15% P (0.2 PV) | 44.93 |

| 0.6% S + 0.15% P (0.15 PV) |

| Formulation | Incremental Recovery (%) |

|---|---|

| 0.5% S + 0.18% P (0.15 PV) | |

| 0.5% S + 0.15% P (0.2 PV) | 42.48 |

| 0.5% S + 0.12% P (0.15 PV) | |

| 0.5% S + 0.12% P (0.15 PV) | |

| 0.5% S + 0.15% P (0.2 PV) | 42.74 |

| 0.5% S + 0.18% P (0.15 PV) |

| Formulation | Viscosity (mPa·s) | Incremental Recovery (%) |

|---|---|---|

| Original salinity | 40.18 ± 0.03 | 45.30 |

| 2.7 × salinity | 30.45 ± 0.27 | 40.46 |

| 5.3 × salinity | 27.61 ± 0.14 | 41.52 |

| 0.5 × salinity | 53.22 ± 0.44 | 44.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, W.; Maimaiti, P.; Shao, H.; Que, T.; Liu, J.; Bai, S. Synergistic Optimization of Polymer–Surfactant Binary Flooding for EOR: Core-Scale Experimental Analysis of Formulation, Slug Design, and Salinity Effect. Polymers 2025, 17, 2166. https://doi.org/10.3390/polym17162166

Tang W, Maimaiti P, Shao H, Que T, Liu J, Bai S. Synergistic Optimization of Polymer–Surfactant Binary Flooding for EOR: Core-Scale Experimental Analysis of Formulation, Slug Design, and Salinity Effect. Polymers. 2025; 17(16):2166. https://doi.org/10.3390/polym17162166

Chicago/Turabian StyleTang, Wenjie, Patiguli Maimaiti, Hongzhi Shao, Tingli Que, Jiahui Liu, and Shixun Bai. 2025. "Synergistic Optimization of Polymer–Surfactant Binary Flooding for EOR: Core-Scale Experimental Analysis of Formulation, Slug Design, and Salinity Effect" Polymers 17, no. 16: 2166. https://doi.org/10.3390/polym17162166

APA StyleTang, W., Maimaiti, P., Shao, H., Que, T., Liu, J., & Bai, S. (2025). Synergistic Optimization of Polymer–Surfactant Binary Flooding for EOR: Core-Scale Experimental Analysis of Formulation, Slug Design, and Salinity Effect. Polymers, 17(16), 2166. https://doi.org/10.3390/polym17162166