1. Introduction

Polymer materials have become increasingly important in the construction industry due to their diverse properties, such as versatility, durability [

1], and lightweight nature. These materials are widely applied in cement additives, reinforcement materials, adhesives, insulation, and protective coatings [

2]. Commonly used polymers include polyurethane (PU), polyisobutylene (PIB), and rubber, each valued for their resilience and adaptability to various environmental conditions [

2]. For example, PU is often used as a sealant in window and door frames to enhance energy efficiency and moisture resistance [

2]. Due to their low density, strong chemical resistance, and insulating characteristics, polymers can improve structural service life as well as performance in harsh environments [

1,

2]. The ongoing development of smart and self-healing polymers continues to expand their role in sustainable and cost-effective construction solutions [

3,

4]. Ongoing breakthroughs in smart and self-healing polymers continue to broaden and diversify their role in sustainable and affordable construction solutions.

The surge in demand for high-performance concrete (HPC) in infrastructure and structural applications has rekindled interest in the challenges associated with early-age shrinkage and cracking. Due to their low water-to-cement (w/c) ratios, HPC mixtures often tend to regularly undergo self-desiccation, which leads to autogenous shrinkage and consequently increases the risk of early cracking. This issue is particularly critical in elements with high surface-to-volume ratios or restrained geometries, such as slabs, bridge decks, and precast members. Traditional external curing methods typically fall short in addressing these challenges, especially in dense or complex structural elements where water ingress is limited. To address these limitations, internal curing has emerged as a promising strategy for mitigating early-age shrinkage. Among various internal curing agents, superabsorbent polymers (SAPs) have gained significant attention due to their ability to absorb large volumes of water during mixing and slowly release it during hydration. This delayed water release helps maintain internal relative humidity and supports continued hydration. This happens especially at later stages when external moisture may not penetrate effectively. Beyond shrinkage control, internal curing using SAPs can also enhance cement hydration, reduce porosity, and improve microstructural development—factors that contribute to overall concrete performance and durability. However, optimizing SAP use requires careful consideration of factors such as particle size, dosage, and interaction with other mix components.

Among polymer-based technologies, superabsorbent polymers (SAPs) have gained considerable traction in cement and concrete research. SAPs are cross-linked hydrophilic materials capable of absorbing and retaining large volumes of water, often several hundred times their own weight [

5,

6]. Their water-retention capacity, combined with their ability for sustained water release, makes them exceptionally effective in facilitating internal curing in concrete mixtures [

7,

8]. Internal curing guarantees sustained moisture availability during early-age hydration, notably when external curing methods are deficient or unrealistic [

9]. This is crucial in low water-to-cement ratio mixtures, where rapid moisture loss can cause early-age cracking, shrinkage, and incomplete hydration [

10]. In addition to improving shrinkage behavior, SAPs may also influence the formation of hydration products and the development of the pore structure, which in turn affects mechanical performance [

11,

12]. Consequently, SAPs are increasingly regarded not only as shrinkage-reducing agents but also as multifunctional modifiers that can enhance the overall performance and sustainability of advanced concrete systems [

6,

13].

Several studies published since 2015 have validated the role of SAPs as effective internal curing agents for minimizing autogenous and drying shrinkage in cement-based materials [

2,

3,

4]. SAPs function by temporarily storing part of the mixing water and then gradually releasing it as hydration proceeds, especially after capillary pores empty out due to self-desiccation [

6,

14]. This process helps mitigate internal stress buildup and suppresses early-age microcrack formation, especially in high-performance or low w/c mixtures where traditional curing may be inadequate [

10,

15].

The effectiveness of SAPs correlates with their physical properties, particularly particle size and absorption capacity. Hasholt et al. [

8] categorized SAPs according to their swelling kinetics, water retention capacity, and distribution within the cement matrix. Their findings revealed that smaller SAP particles tend to swell faster and distribute more uniformly, promoting early hydration, but offering a shorter duration of internal curing. Conversely, while larger SAP particles can retain water longer and extend curing effects, they leave behind large voids that compromise the integrity of the hardened matrix [

11,

12].

Research by Zhu et al. [

16] and Dudziak et al. [

17] further demonstrated that SAP-modified concrete exhibited fewer shrinkage cracks, which translated into improved long-term durability in real-world applications such as slabs, pavements, and tunnel linings. However, the mechanical response of SAP-modified mixtures has shown mixed outcomes. Several authors have reported that improper SAP selection, particularly excessive dosage, or the use of coarse particles—can reduce compressive strength and elastic modulus due to macrovoid formation [

13,

16]. In contrast, studies using optimized SAP sizes and dosages have found improved strength-to-shrinkage performance ratios, especially in ternary or blended cement systems [

13,

18].

Recently, research has shifted towards exploring hybrid or multi-scale internal curing systems, where SAPs are used in combination with shrinkage-reducing admixtures (SRAs), supplementary cementitious materials (SCMs), or lightweight aggregates [

4,

5,

8,

13]. These approaches aim to create synergy by combining the water-buffering effect of SAPs with other physical or chemical shrinkage control mechanisms. Lee et al. [

13] noted that pairing SAPs with fly ash or silica fume enhanced hydration kinetics will improve pore structure refinement. However, the interaction between SAP particle size and other admixtures remains an area requiring further investigation.

Though substantial work has been conducted on SAPs, most studies almost exclusively address shrinkage mitigation independently. Few have systematically evaluated the trade-offs between shrinkage control and mechanical performance under consistent effective w/c ratios. Moreover, the effects of SAP particle size on hydration product formation, especially during early-age curing, have not been comprehensively linked to microstructural or chemical analysis techniques such as XRF. This research seeks to address these gaps by providing a comparative evaluation of concrete formulations modified with SAPs of varying particle sizes while maintaining consistent mix design parameters.

This study focuses on examining the effect of SAP particle size on key concrete properties, including compressive strength, shrinkage behavior, and hydration-related changes in chemical composition. Since autogenous shrinkage primarily occurs within the first 7 days of curing, the hydration response was analyzed at this age using X-ray fluorescence (XRF) to record early-age chemical changes. This approach facilitates the assessment of the effect of SAP sizes on cement hydration by examining variations in elemental composition, especially those associated with hydration products. Concrete mixtures with different SAP particle size ranges, including a blended configuration, were compared to determine an optimal integration strategy that minimizes shrinkage without significantly compromising mechanical performance. The conclusions drawn from this research are intended to bolster ongoing developments in polymer-modified concrete and provide practical guidance for the application of SAPs in structural and infrastructure projects where shrinkage control is critical.

3. Results

3.1. Compressive Strength

The compressive strength test results for all five mixtures are shown in

Figure 1. At 7 days (see

Figure 1a), the control mix (C35) achieved a strength of 31.2 MPa. In comparison, CS300 and CS600 recorded strengths of 28.9 MPa and 27.5 MPa, respectively, while the coarser SAP mixes, CS1180 and CS600+1180, reached 25.8 MPa and 27.1 MPa. The trend sustained itself into later stages. By 28 days (see

Figure 1b), the control attained 43.0 MPa, while the SAP-containing mixtures ranged from 36.2 MPa (CS1180) to 39.8 MPa (CS300). At 42 days (see

Figure 1c), all mixtures showed further strength development, but the SAP-modified concretes consistently exhibited lower compressive strength than the control.

The reduction in strength observed earlier (at 7 days) in the process is due in part to the formation of macrovoids following the release of water from SAP particles. These voids act as discontinuities within the cement matrix, disrupting the transmission of mechanical stress. Coarser SAP particles like mix CS1180 tend to leave behind larger and more unevenly distributed voids, thereby magnifying the decline in strength.

In contrast, finer SAP particles, such as those used in CS300, offer two distinct advantages. First, they absorb and release water more quickly, which supports cement hydration during the early stages when internal curing is most beneficial. Second, their smaller size leads to more uniform dispersion and less disruptive void formation within the matrix. This results in a better strength retention profile relative to coarser SAPs. The superior performance of CS300, especially at 28 (see

Figure 1b) and 42 days (See

Figure 1c), highlights the potential of fine SAPs for balancing hydration support and microstructural integrity.

These findings are consistent with previous studies by Lee et al. [

13], who reported improved strength retention when SAP sizes were maintained below 300 µm. They also align with general observations in the literature that while internal curing enhances long-term hydration, it may reduce early-age strength depending on SAP characteristics such as particle size, absorption rate, and swelling behavior.

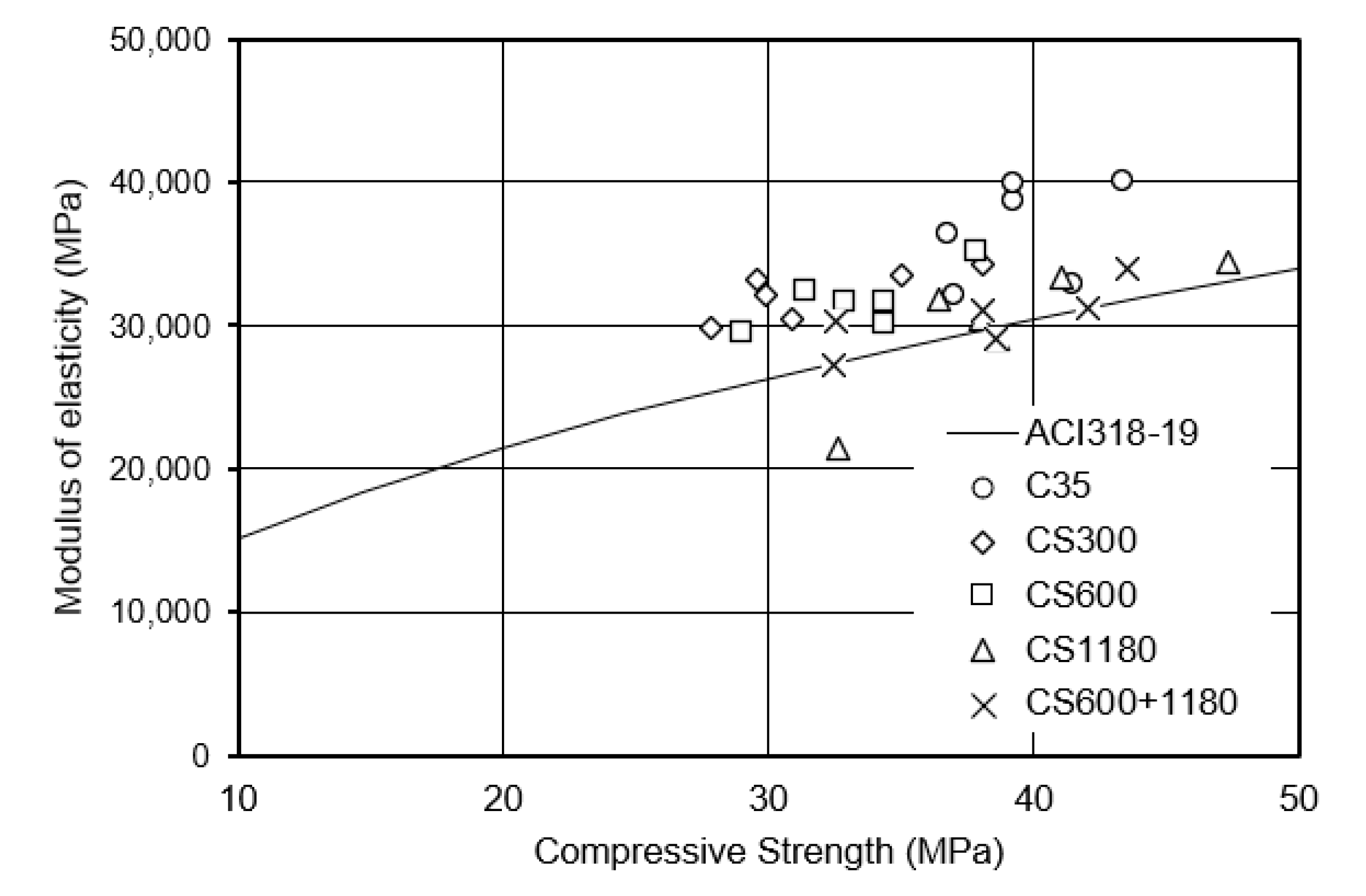

3.2. Elastic Modulus of Concrete

The static modulus of elasticity values at 7 and 28 days are presented in

Figure 2. The control concrete (C35) exhibited the highest stiffness, with a 28-day modulus of 28.2 GPa. In contrast, SAP-modified mixtures showed a gradual reduction in stiffness with increasing SAP particle size. CS300 (150–300 µm) and CS600 recorded the values 26.5 GPa and 25.2 GPa, respectively. The coarsest mix, CS1180 (600–1800 µm), had the lowest modulus at 23.4 GPa, while the blended mix (CS600+1180) yielded 25.0 GPa.

For comparison, the elastic modulus of the control concrete estimated using the ACI 318-19 equation was approximately 31.0 GPa based on its 28-day compressive strength. All measured values, including the control, were lower than the ACI prediction, with greater deviation observed in SAP-modified concretes. This can be attributed to increased internal porosity from SAP-induced voids, which the empirical ACI formula does not account for.

The reduction in stiffness is primarily due to pores formed as SAPs swell and release water, then shrink during hydration. Larger SAPs create larger, more localized voids, disrupting matrix continuity and reducing resistance to deformation. Conversely, finer SAPs (CS300) result in smaller, more evenly distributed pores, which less severely affect stiffness while still promoting internal curing.

These trends align with the findings of Huang et al. [

6], who associated lower modulus values with increased porosity and microcracking near SAP particles. The blended mix showed a moderate reduction in stiffness, suggesting that combining SAP sizes can help balance internal curing efficiency and mechanical performance.

3.3. Shrinkage Behaviors

Concrete shrinkage was assessed based on total shrinkage, autogenous shrinkage, and drying shrinkage. Total shrinkage is defined as the overall dimensional change that stems from internal self-desiccation and moisture loss to the environment. To expand comprehension of the underlying mechanisms behind shrinkage reduction in SAP-modified concrete, autogenous and drying shrinkage were monitored independently under sealed and unsealed conditions, respectively.

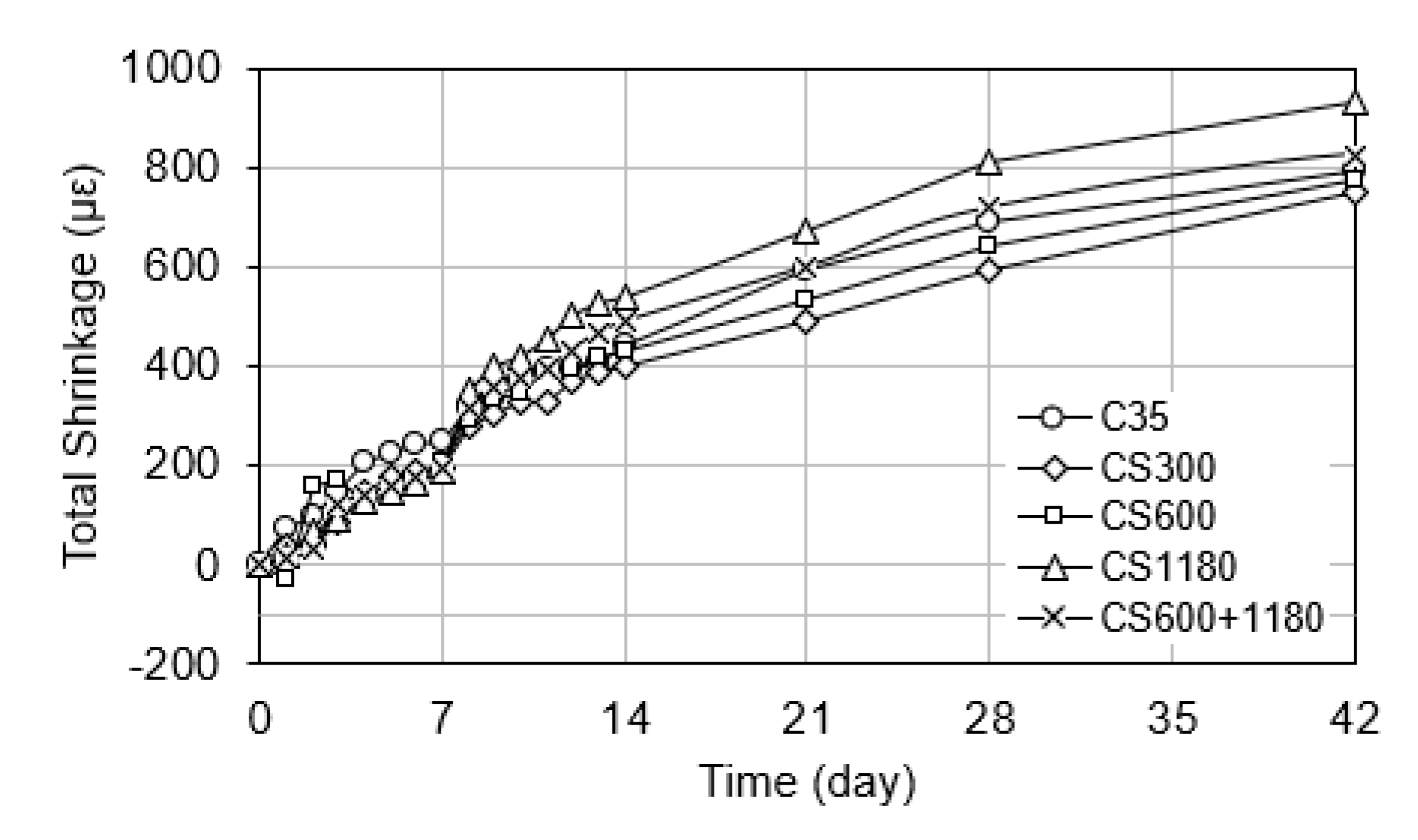

3.3.1. Total Shrinkage

Total shrinkage represents the combined effect of autogenous and drying shrinkage over the entire 42-day period. As shown in

Figure 3, the control mix (C35) exhibited the highest total shrinkage, reflecting the lack of internal curing and full exposure to both self-desiccation and moisture loss. In contrast, all SAP-modified mixtures demonstrated notable reductions in total shrinkage, consistent with findings reported in previous studies [

2,

6,

18,

25].

Among the SAP mixtures, CS300, which contained the finest SAP particles (150–300 µm), showed the lowest total shrinkage, followed closely by the blended CS600 mix. CS600+1180 and CS1180 exhibited higher total shrinkage values, which were higher than the control. These results are in agreement with the work of Dudziak et al. [

17], who demonstrated that SAPs effectively mitigate shrinkage by providing continuous moisture release during early and intermediate curing stages. Similarly, De Meyst et al. [

25] confirmed that SAPs reduce total shrinkage and crack risk in high-performance concrete elements exposed to drying environments.

The trend observed in this study reinforces the established understanding that the internal curing efficiency of SAPs depends heavily on particle size and absorption kinetics. Coarser SAPs retain water longer, releasing it gradually as hydration and drying progress, thus maintaining internal humidity for an extended period [

4,

5]. This prolonged release supports both early-age and long-term hydration, reducing cumulative shrinkage. On the other hand, finer SAPs tend to release absorbed water quickly, offering hydration benefits primarily during early stages, with diminishing effects thereafter [

10,

14].

The blended mixture (CS600+1180) demonstrated a balanced shrinkage profile, combining early internal curing from smaller SAPs with prolonged moisture retention from larger ones. This result is supported by Mignon et al. [

2], who highlighted that SAP blends with complementary absorption profiles can provide extended curing effects while minimizing porosity and strength loss. Overall, the total shrinkage performance of the SAP-modified concretes confirms that SAP selection based on particle size distribution can be a strategic approach for controlling volumetric deformation in drying-sensitive structural applications.

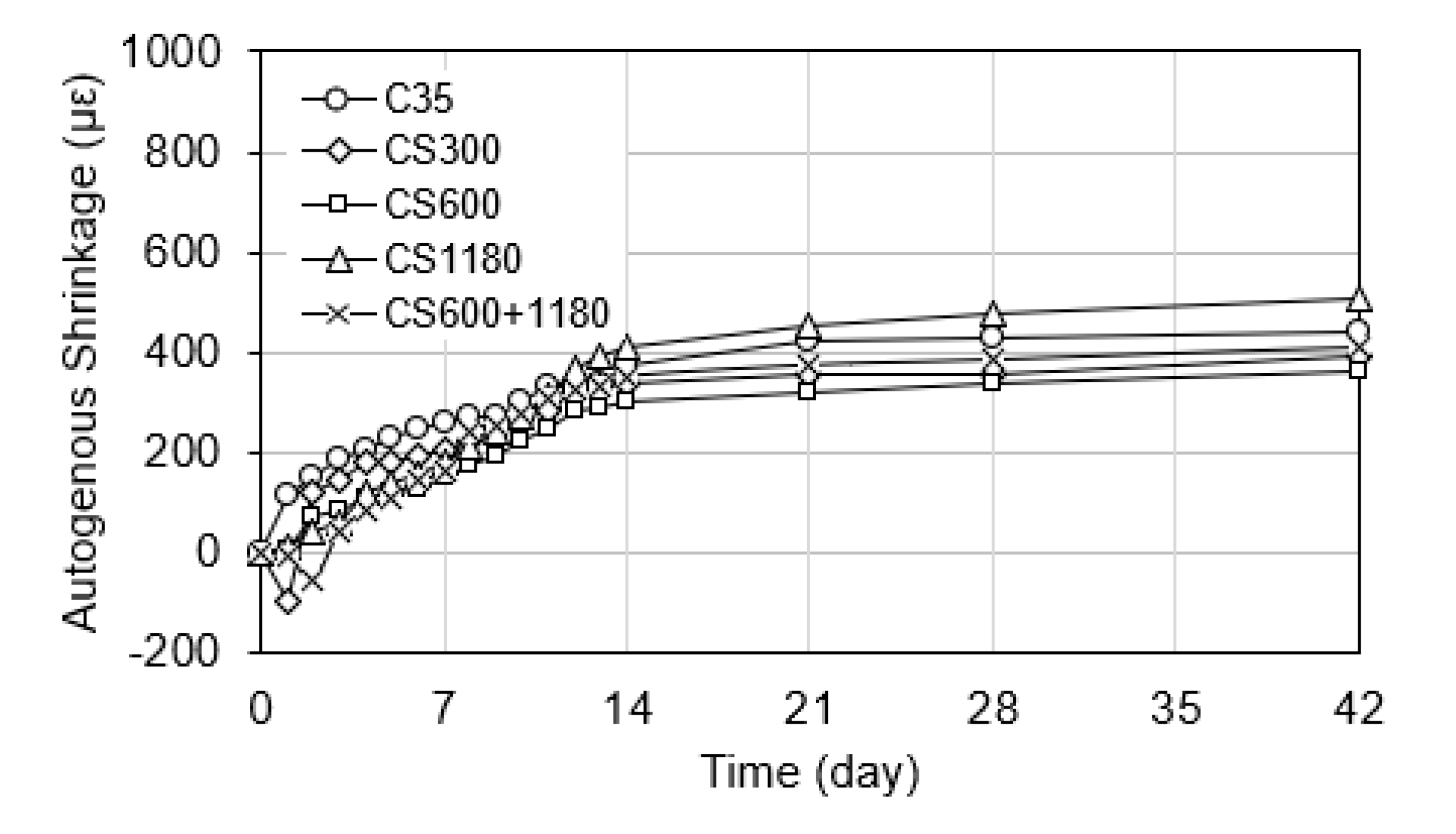

3.3.2. Autogenous Shrinkage

Autogenous shrinkage principally derives from self-desiccation during cement hydration. It is more pronounced in low water-to-cement ratios, where internal water is inadequate for complete saturation/hydration. In sealed conditions, the consumption of capillary water leads to internal drying, resulting in volume contraction. This mechanism is particularly pronounced during the first 7 days, making early-age monitoring essential.

As shown in

Figure 4, the control mixture (C35) and CS1180 experienced the highest level of autogenous shrinkage, with rapid deformation observed within the first few days. In contrast, all SAP-modified mixtures exhibited significant reductions in autogenous shrinkage. Among them, the CS600, CS300, and CS600+1180 mixtures showed the most effective mitigation, indicating the benefit of prolonged internal curing from SAPs.

These observations are consistent with the internal curing mechanism described by Jensen and Hansen [

5], where SAPs serve as localized water reservoirs that gradually release moisture as hydration proceeds. The size and structure of SAPs directly affect the rate of water release and, therefore, the shrinkage control period. Larger SAPs deliver a slower and more prolonged water supply, maintaining internal humidity and decreasing early-age stress development [

10,

26].

The reduced autogenous shrinkage in SAP-containing mixes also aligns with findings from Li and Chen [

26]; these researchers showed/established that under low w/c concrete conditions, SAPs increase internal relative humidity and suppress capillary tension. Similarly, Hasholt et al. [

8] and Liu et al. [

12] demonstrated that the internal curing capacity of SAPs leads to better hydration continuity and lower shrinkage strain under sealed conditions. While fine SAPs promote rapid hydration and early strength gain, they may not sustain internal humidity long enough to mitigate autogenous shrinkage over extended curing periods.

In summary, the results confirm that SAP particle size significantly influences the autogenous shrinkage behavior of concrete. Coarser particles enhance internal curing duration, effectively mitigating early-age volume change, while finer SAPs are more suitable for short-term hydration support. These findings support the use of particle-size-engineered SAPs for tailored shrinkage control in high-performance concrete.

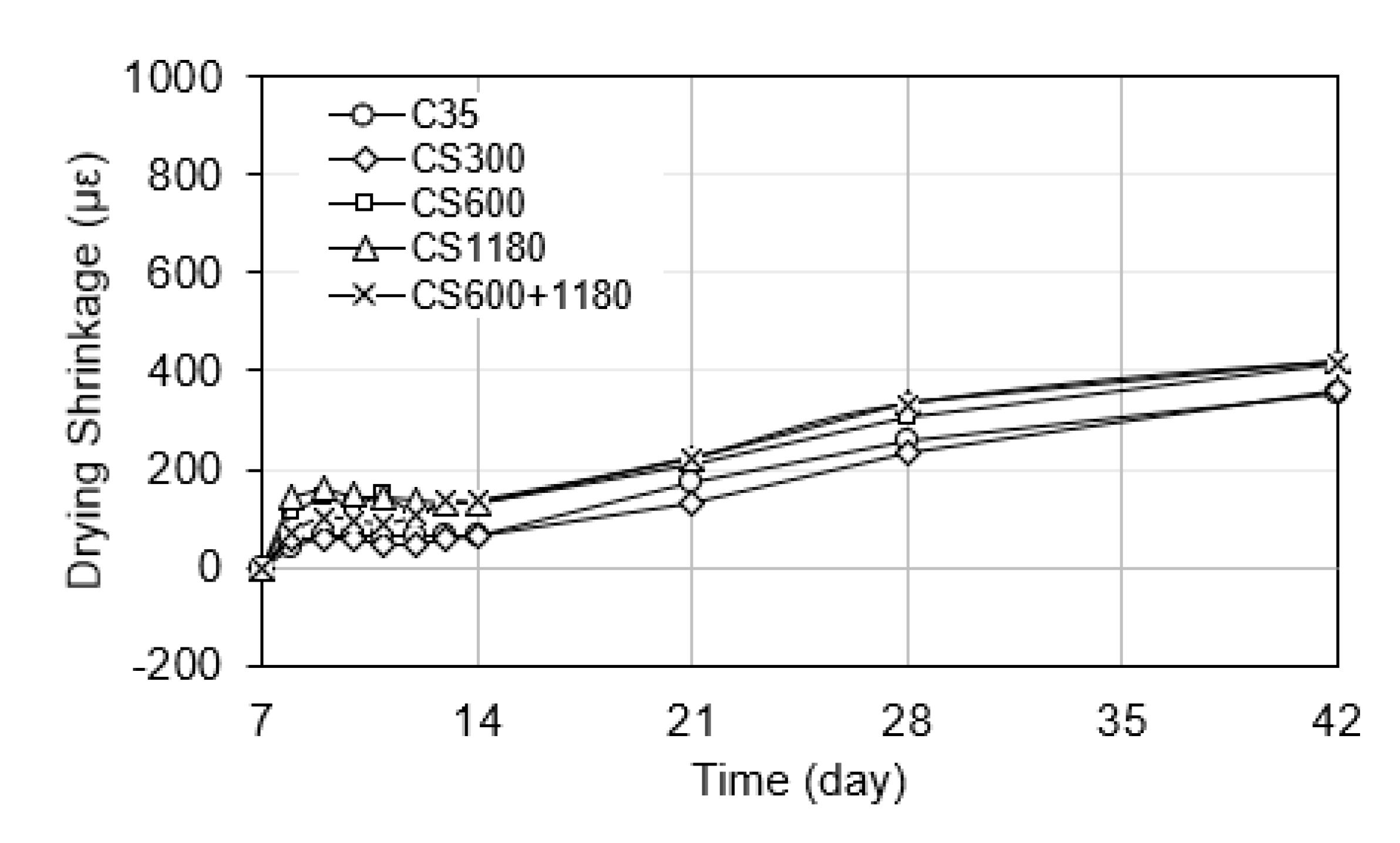

3.3.3. Drying Shrinkage

Drying shrinkage occurs when hardened concrete loses moisture to the surrounding environment, typically after the end of the initial curing phase. It is caused by water evaporation from capillary pores, leading to capillary tension and volumetric contraction. In this study, drying shrinkage was monitored starting at day 7, after the sealed specimens were exposed to ambient laboratory conditions.

As illustrated in

Figure 5, the CS600+1180 exhibited the highest drying shrinkage over the 42-day monitoring period. The CS300 mixtures showed the most substantial reductions in drying shrinkage. This is attributed to the more even dispersion rate of the finer SAP particles, which extended the internal curing effect beyond the initial hydration phase and into the drying period. Their sustained water retention delayed the development of internal moisture gradients, thereby reducing capillary stress and shrinkage.

In contrast, the CS600, CS1180, and CS600+1180 mix demonstrated the least reduction in drying shrinkage among the SAP-containing mixes. While these larger particles improved early-age hydration and reduced autogenous shrinkage, their rapid water release was largely completed during the sealed phase, offering limited benefit once the specimens were exposed to the drying environment. This behavior aligns with observations by Li et al. [

27] and Kong et al. [

10], who noted that the water retention duration of SAPs plays a more critical role in drying shrinkage control than absorption capacity alone.

Drying shrinkage mitigation is closely tied to the timing of internal water availability relative to moisture loss to the environment. SAPs that retain water beyond 7 days contribute more effectively to shrinkage control under drying conditions. This reinforces the importance of selecting SAPs not only based on absorption rate and size, but also on their water release profile and compatibility with anticipated curing and exposure conditions.

Overall, the results confirm that SAP particle size influences drying shrinkage behavior by regulating the duration and effectiveness of internal curing. The superior performance of the blended mix (CS600+1180) suggests that combining SAPs with different size ranges can provide both early-age hydration support and extended moisture retention, making it a promising approach for minimizing drying-induced deformation in concrete.

3.4. X-Ray Fluorescence (XRF) Results

X-ray fluorescence (XRF) analysis was conducted on paste samples extracted from each mixture at 7 days to evaluate the influence of SAP particle size on early-age hydration. The goal was to assess whether internal curing by SAPs altered the chemical composition of hydration products, as seen in

Table 6. Special emphasis was placed on calcium oxide (CaO) and silicon dioxide (SiO

2), key indicators for assessing cement hydration progress/stages/kinetics.

As shown in

Table 6, the CS300 and CS600 mixtures exhibited slightly higher levels of CaO and SiO

2 compared to the control and the mixes containing coarser SAPs. This suggests that finer SAP particles contributed to more complete early hydration, likely due to their faster water release kinetics. An important characteristic of fine SAPs is their capacity to rapidly furnish additional moisture to mixtures during the early stages of hydration. This phenomenon and phase promote the formation of calcium silicate hydrate (C–S–H), the primary adhesive agent in concrete. These results align with observations from Zhao et al. [

14] and Chen et al. [

9], who reported enhanced cement hydration and increased C–S–H development in SAP-modified systems with optimized water availability.

In contrast, the mixtures with coarser SAPs (CS1180 and CS600+1180) showed slightly lower CaO and SiO2 contents at 7 days. This may be attributed to the delayed water release from larger SAPs, which prolongs internal curing and supports hydration at later ages rather than early stages. While beneficial for long-term shrinkage control, this slower hydration progression is reflected in the reduced early-age reaction rates captured by XRF.

These chemical findings support the mechanical and shrinkage results discussed earlier. Mixtures with finer SAPs, such as CS300, demonstrated higher early compressive strength, which correlates with greater hydration product formation at 7 days. Meanwhile, mixtures with coarser SAPs exhibited more gradual strength development and improved shrinkage control, suggesting extended hydration beyond the XRF analysis-captured timeframe.

Although the magnitude of chemical variation observed by XRF was relatively small, the trends reinforce the conclusion that SAP particle size influences the rate and extent of cement hydration. These results are consistent with findings from Huang et al. [

6] and Li and Chen [

26], who noted that SAP-modified systems exhibit altered hydration dynamics depending on SAP size and dispersion characteristics. This study’s combined mechanical, shrinkage, and chemical data highlights the link between internal curing behavior and early-age cement chemistry. The findings emphasize the importance of matching SAP properties with performance objectives in concrete design.