Polyarylene Ether Nitrile/Modified Hollow Silica Composite Films for Ultralow Dielectric Properties and Enhanced Thermal Resistance

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of PEN

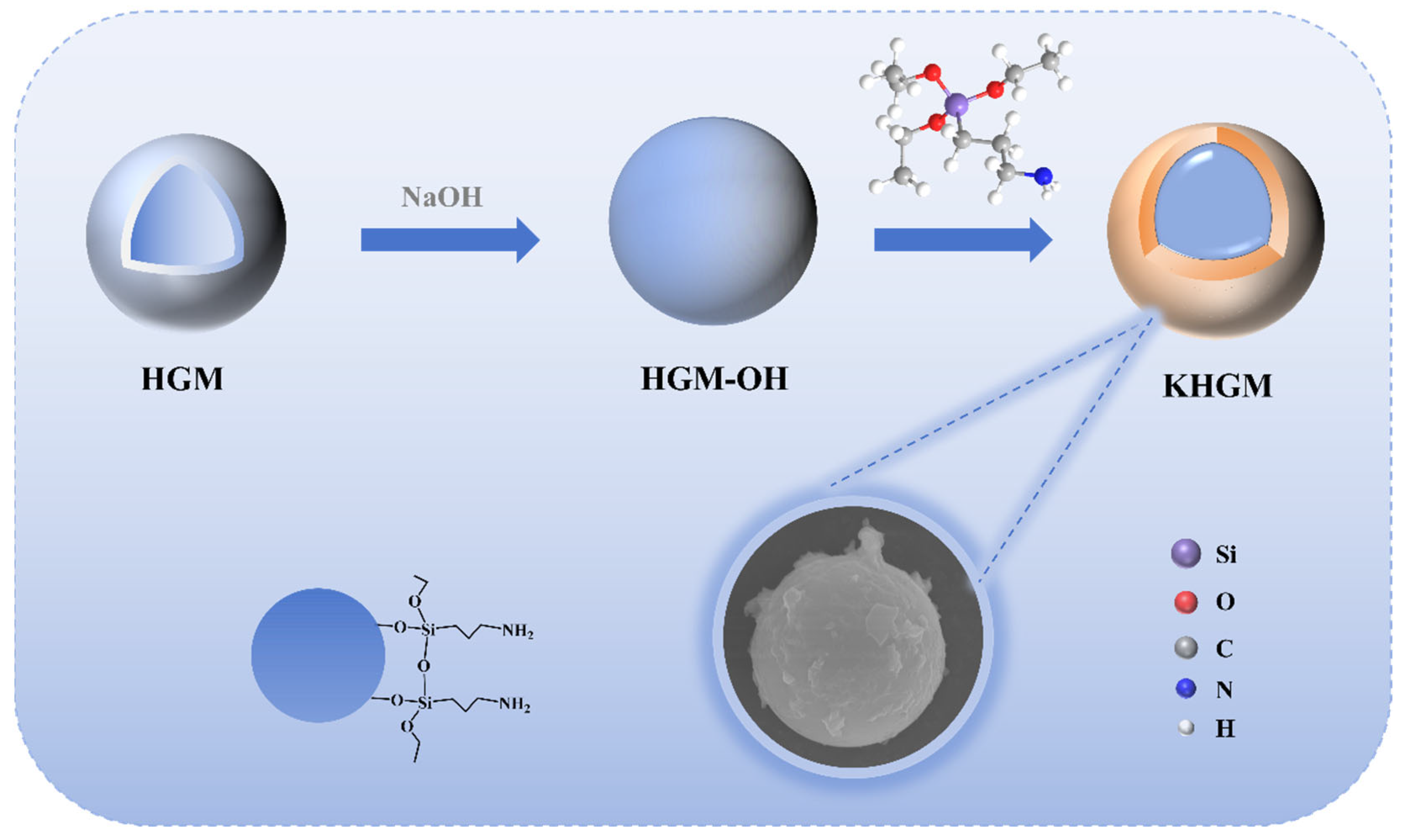

2.3. Synthesis of KHGM

2.4. Preparation of PEN/KHGM Films

2.5. Characterization

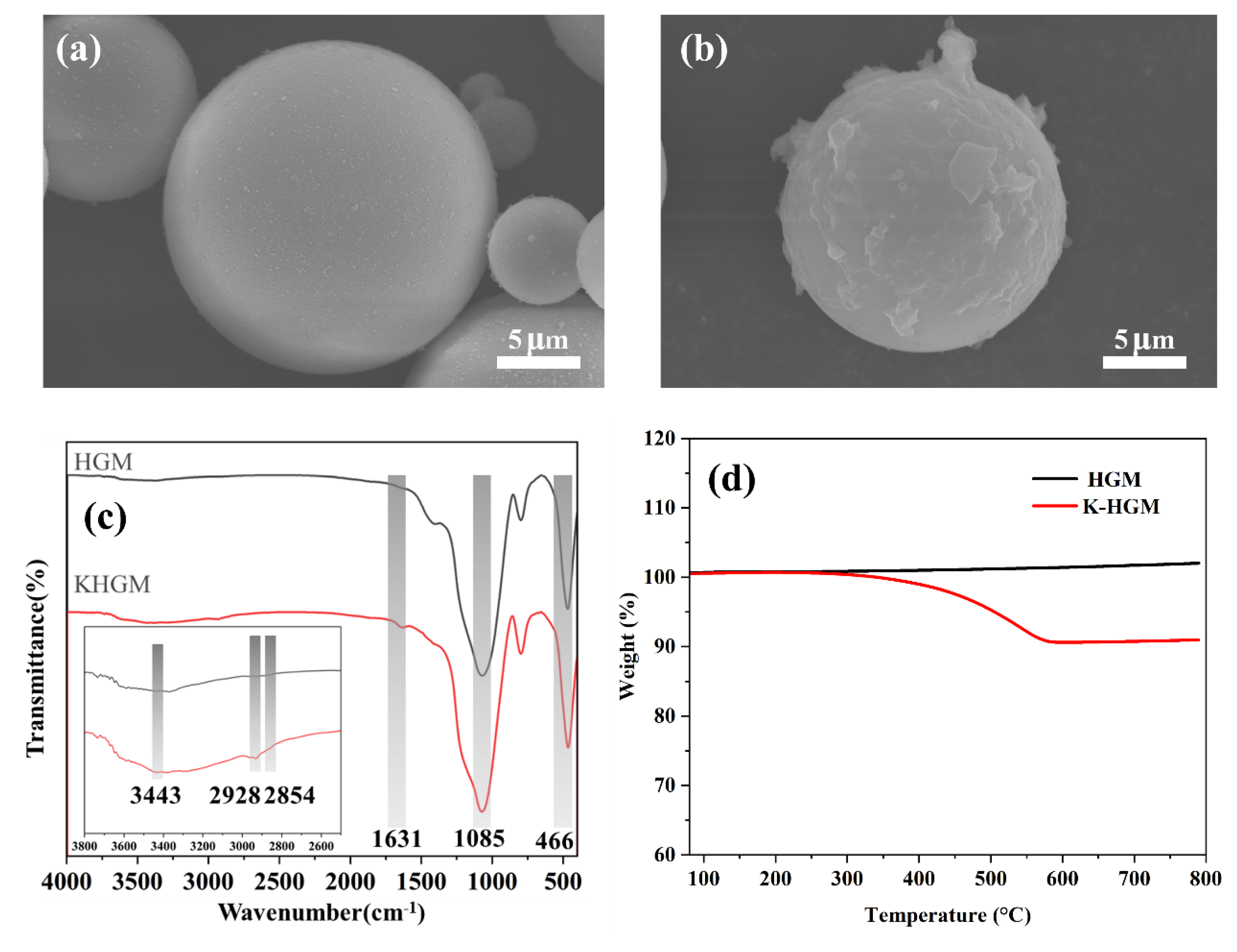

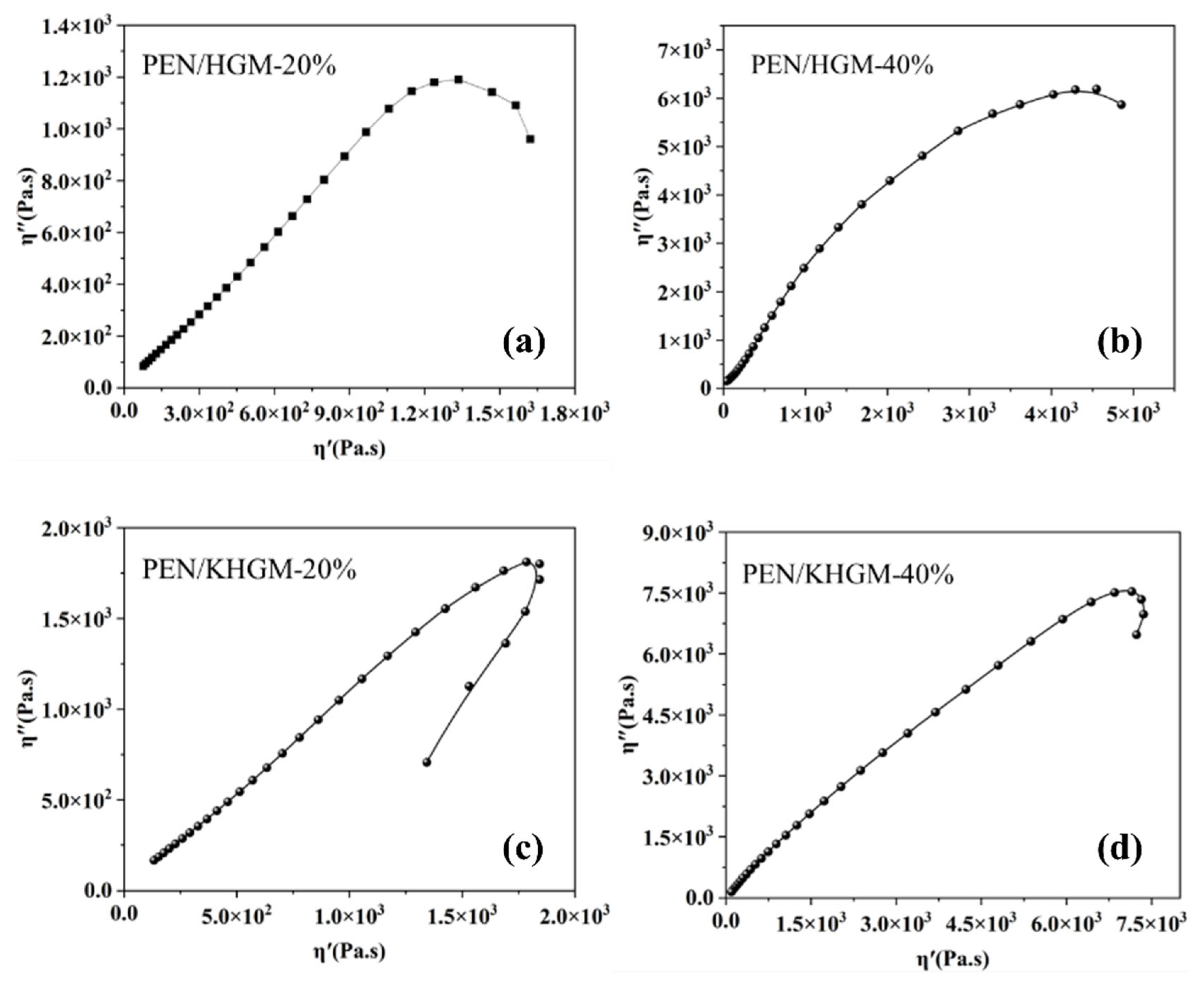

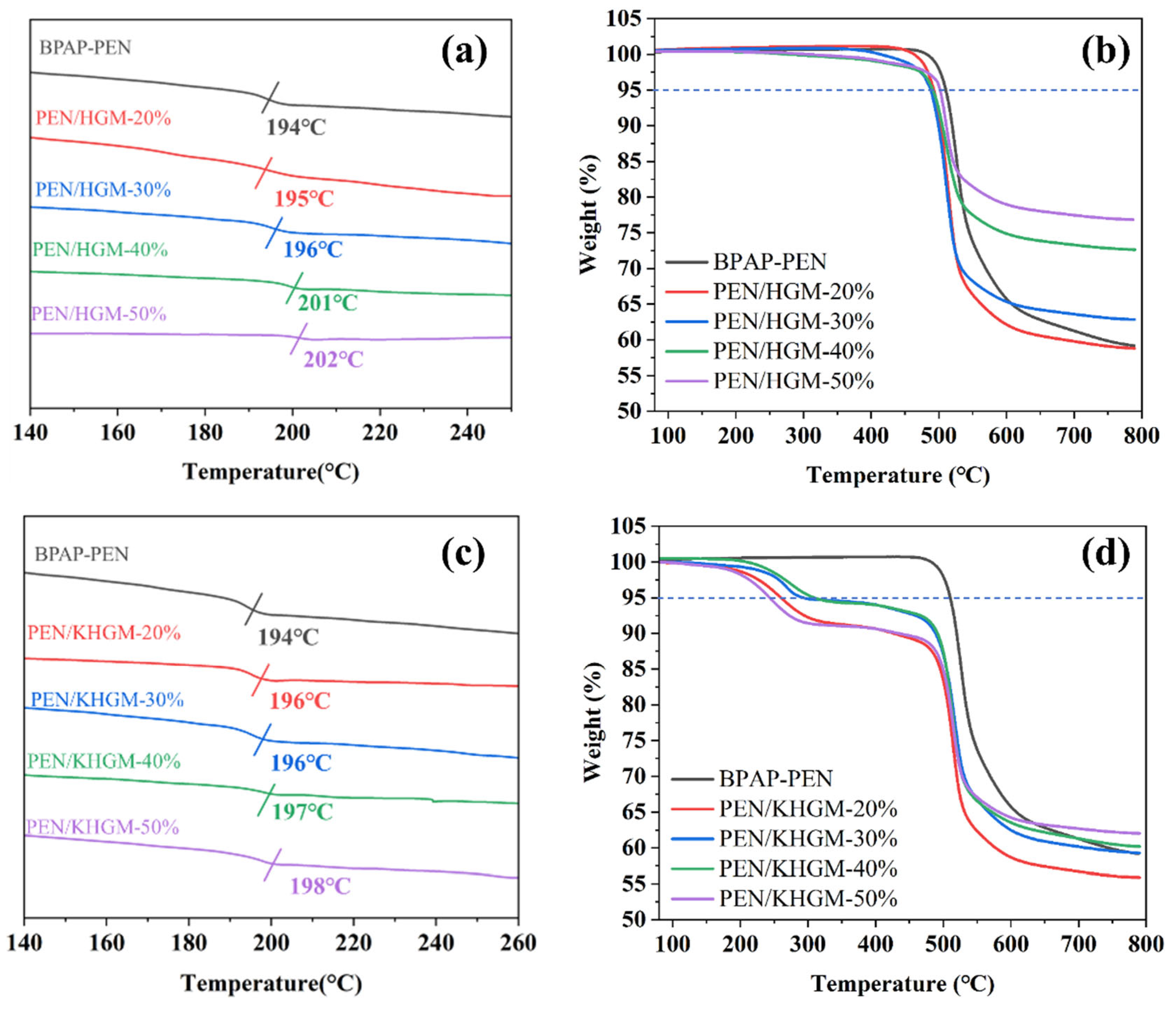

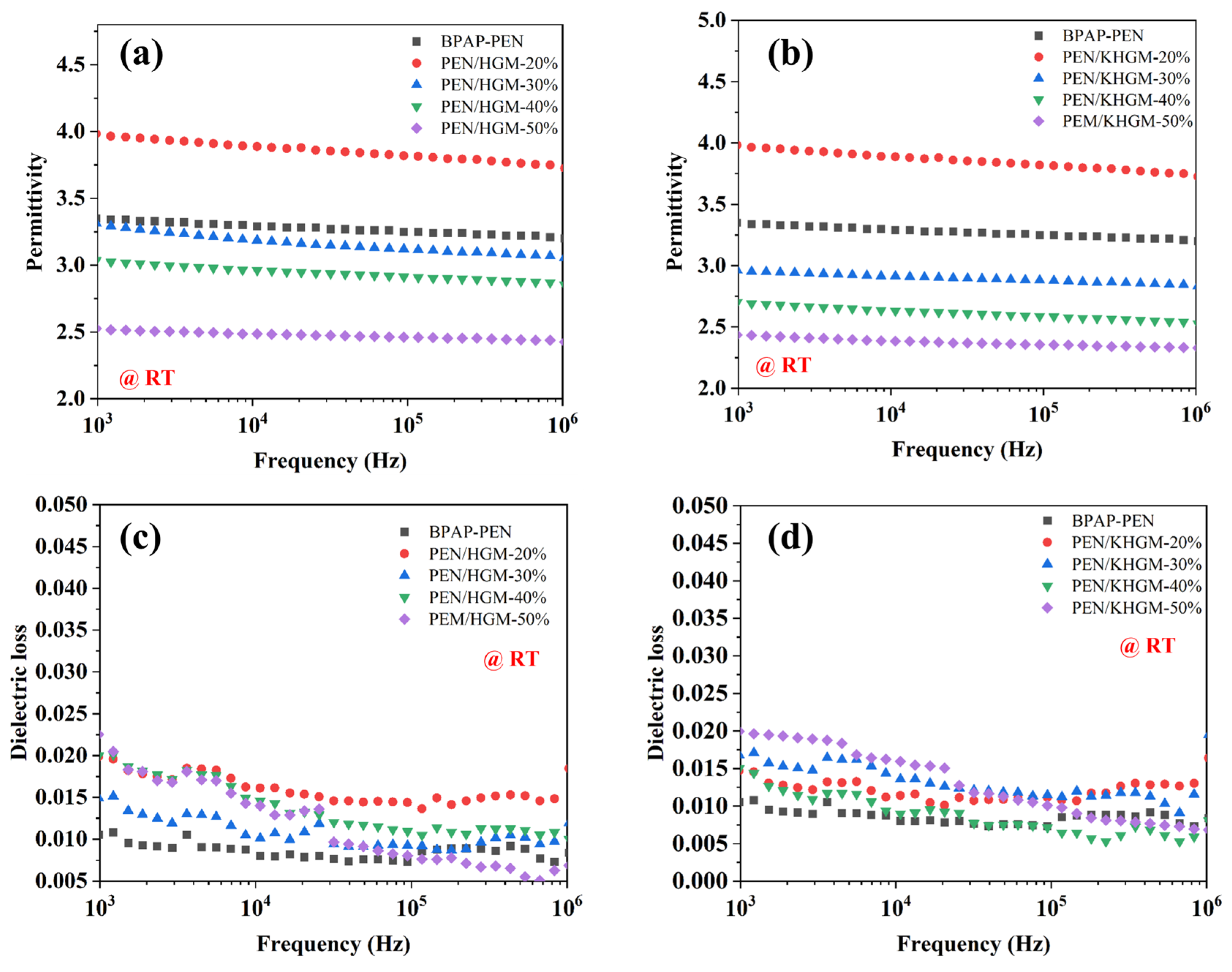

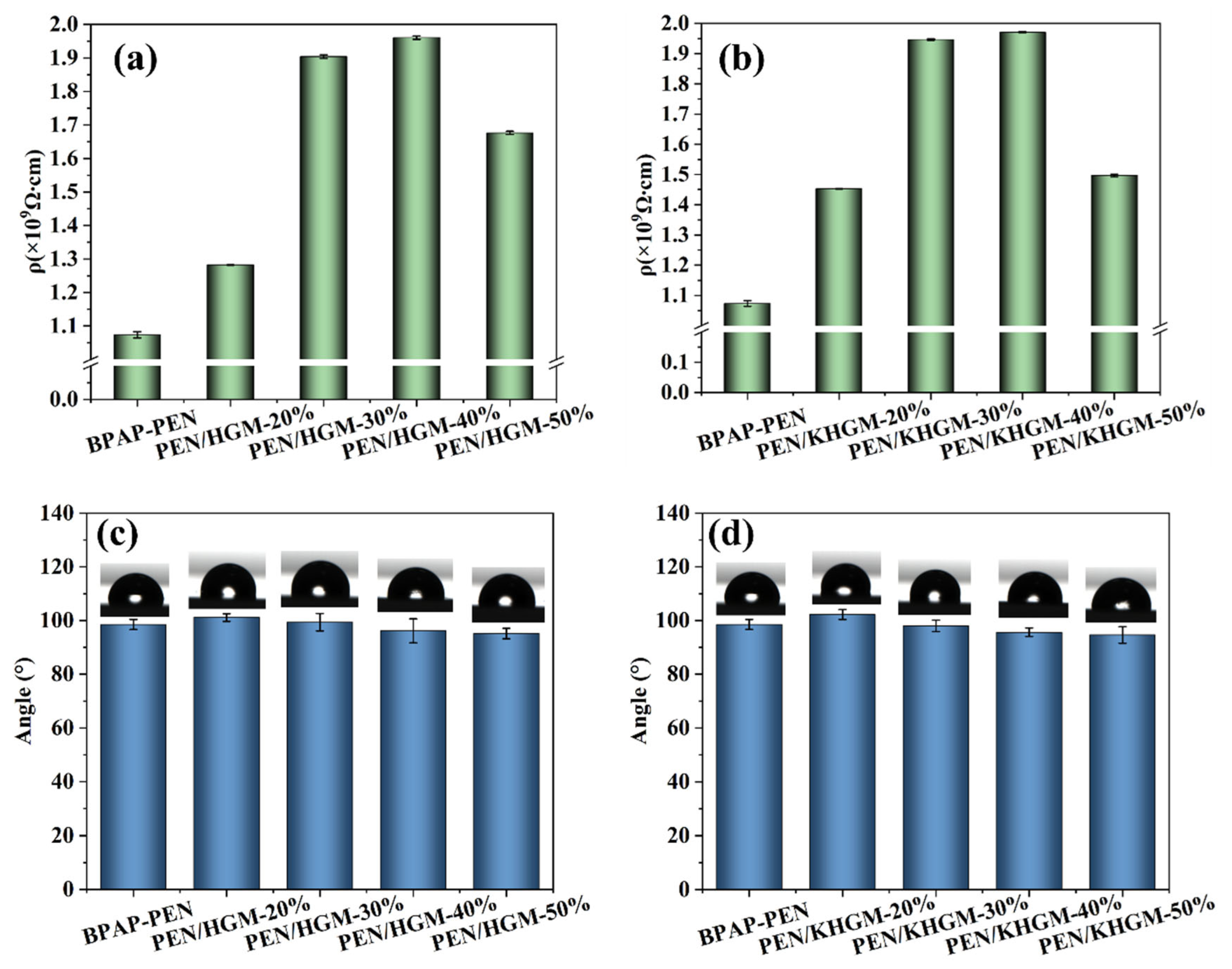

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, W.; Wei, Z.; Lu, C.; Tong, Y.; Huang, J.; Cao, X.; Shi, D.; Li, R.K.Y.; Wu, W. Construction of all-organic low dielectric polyimide hybrids via synergistic effect between covalent organic framework and cross-linking structure. Nano Mater. Sci. 2023, 5, 429–438. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, S.; Li, C.; Xiao, Y.; Zheng, L.; Liu, J.; Zhang, B. Ultra-low dielectric constant fluorinated graphene/polybenzoxazole composite films with excellent thermal stabilities and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106387. [Google Scholar] [CrossRef]

- Li, H.; Lan, X.; Bao, F.; Li, S.; Zhu, H.; Zhu, Z.; Li, Y.; Wang, M.; Zhu, C.; Xu, J. Preparation of triphenylamine polyimides with low dielectric constants with different side group sizes based on β-relaxation theory. Eur. Polym. J. 2024, 211, 112969. [Google Scholar] [CrossRef]

- Evans, A.M.; Giri, A.; Sangwan, V.K.; Xun, S.; Bartnof, M.; Torres-Castanedo, C.G.; Balch, H.B.; Rahn, M.S.; Bradshaw, N.P.; Vitaku, E.; et al. Thermally conductive ultra-low-k dielectric layers based on two-dimensional covalent organic frameworks. Nat. Mater. 2021, 20, 1142–1148. [Google Scholar] [CrossRef]

- Zhao, W.; Tong, Y.; Lu, C.; Huang, Q.; Cao, X.; Li, R.K.Y.; Wu, W. Bioinspired construction of size adjustable hollow polydopamine microspheres for ultra-low dielectric polyimide composites. Appl. Surf. Sci. 2024, 643, 158714. [Google Scholar] [CrossRef]

- Li, Y.; Sun, G.; Zhou, Y.; Liu, G.; Wang, J.; Han, S. Progress in low dielectric polyimide film—A review. Prog. Org. Coat. 2022, 172, 107103. [Google Scholar] [CrossRef]

- Xiao, P.; He, X.; Zheng, F.; Lu, Q. Super-heat resistant, transparent and low dielectric polyimides based on spirocyclic bisbenzoxazole diamines with Tg > 450 °C. Polym. Chem. 2022, 13, 3660–3669. [Google Scholar] [CrossRef]

- Maier, G. Low dielectric constant polymers for microelectronics. Prog. Polym. Sci. 2001, 26, 3–65. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, Z.; Li, W.; Ren, Q.; Zhang, H.; Pang, J.; Jiang, Z. Biaxially Stretched High-Strength Isotropic Poly(ether ether ketone) Films for Low Dielectric Constant Materials. ACS Appl. Polym. Mater. 2024, 6, 5404–5412. [Google Scholar] [CrossRef]

- Han, S.; Li, Y.; Hao, F.; Zhou, H.; Qi, S.; Tian, G.; Wu, D. Ultra-low dielectric constant polyimides: Combined efforts of fluorination and micro-branched crosslink structure. Eur. Polym. J. 2021, 143, 110206. [Google Scholar] [CrossRef]

- Li, M.; Sun, J.; Fang, Q. Low dielectric constant polymers derived from bio-based anethole and isoeugenol. Eur. Polym. J. 2024, 202, 112639. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Wang, Z.Y.; Qiao, W. Synthesis and characterizations of polystyrene materials with low dielectric constant and low dielectric loss at high frequency. J. Appl. Polym. Sci. 2023, 140, e54012. [Google Scholar] [CrossRef]

- Kamitani, T.; Nakamura, M.; Watase, S.; Suzuki, T.; Imoto, H.; Naka, K. Synthesis of Low-Dielectric Polyureas by Incorporating Phenyl-Substituted Cage Silsesquioxanes in the Main Chain. ACS Appl. Polym. Mater. 2023, 5, 5169–5176. [Google Scholar] [CrossRef]

- Ohara, Y.; Akutsu, D.; Morita, H.; Saito, T. Facile Hydrophobic Polymer Coating of Metal–Organic Frameworks for Insulating Materials with Low Dielectric Constant. ACS Appl. Mater. Interfaces 2025, 17, 21857–21865. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Zhang, X.; Guo, S. Interface design and dielectric response behavior of SiO2/PB composites with low dielectric constant and ultra-low dielectric loss. Surf. Interfaces 2021, 22, 100807. [Google Scholar] [CrossRef]

- Chen, R.; Hu, J.; Li, G.; Zhang, J.; Lian, X.; Wang, B. Comprehensive Performance of High-Temperature-Resistant and Low-Dielectric-Coefficient Phthalonitrile Resin. ACS Appl. Polym. Mater. 2024, 6, 2856–2867. [Google Scholar] [CrossRef]

- Xie, M.; Li, G.; Fan, W.; Li, M.; Sun, Q.; Guo, J.; Xia, S.; Fu, W. Low dielectric silsesquioxane-modified benzocyclobutene composites. Polymer 2023, 282, 126188. [Google Scholar] [CrossRef]

- Sawada, R. Colorless, Low Dielectric, and Optically Active Semialicyclic Polyimides Incorporating a Biobased Isosorbide Moiety in the Main Chain. Macromolecules 2022, 55, 6787–6800. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Hu, X.; He, R.; Liu, H. A novel low-dielectric nanocomposite with hydrophobicity property: Fluorinated MOFs modified bismaleimide-triazine resin. Mater. Today Commun. 2021, 29, 102802. [Google Scholar] [CrossRef]

- Islam, M.D.Z.; Fu, Y.; Deb, H.; Hasan, M.D.K.; Dong, Y.; Shi, S. Polymer-based low dielectric constant and loss materials for high-speed communication network: Dielectric constants and challenges. Eur. Polym. J. 2023, 200, 112543. [Google Scholar] [CrossRef]

- Kandanarachchi, P.; Meyer, G.A.; Musolino, S.F.; Wulff, J.E.; Rhodes, L.F. Crosslinking Vinyl-Addition Polynorbornenes via Difunctional Diazirines to Generate Low Dielectric-Constant and Low Dielectric-Loss Thermosets. Macromol. Rapid Commun. 2024, 45, 2400200. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Feng, X.; Liu, S.; Lin, G.; Bai, Z.; Wang, L.; Zhu, K.; Li, X.; Liu, X. Graphene reinforced nanoarchitectonics of 3D interconnected magnetic-dielectric frameworks for high-efficient and anti-corrosive microwave absorbers. J. Mater. Sci. Technol. 2024, 168, 194–207. [Google Scholar] [CrossRef]

- Liu, C.; Liu, S.; Wang, L.; Bai, Z.; Lin, G.; Feng, X.; Jia, K.; Liu, X. Reactive polymeric ligand mediated one-pot synthesis of hybrid magnetite nanospheres for enhanced electromagnetic absorption. Polymer 2022, 240, 124497. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; Bai, Z.; Zhang, W.; Tong, L.; Liu, X. Design and properties of polyarylene ether nitrile copolymers with improved elongation at break. J. Appl. Polym. Sci. 2021, 138, 50522. [Google Scholar] [CrossRef]

- You, J.; Liu, C.; Li, S.; Jiang, N.; Feng, X.; Liu, X.; Liu, X. Aromatic phase change microspheres constructed nanocomposite films for fluorine-free self-cleaning. absorption-dominated EMI shielding, and high-temperature thermal camouflage. Compos. Part B Eng. 2024, 283, 111650. [Google Scholar] [CrossRef]

- Ran, Q.; Zhao, D.; Ji, Y.; Fan, Z.; Lin, G.; Liu, X.; Jia, K. Recyclable adsorption removal and fluorescent monitoring of hexavalent chromium by electrospun nanofibers membrane derived from Tb3+ coordinating polyarylene ether amidoxime. Talanta 2024, 266, 125058. [Google Scholar] [CrossRef]

- Hou, J.; Ye, J.; Liu, X.; Liu, S.; Tong, L.; Liu, X. Synthesis and preparation of benzoxazines containing aryl ether nitriles with self-toughening functionality: Modulation of curing reactivity and toughness through chain segment length. Mater. Today Commun. 2025, 45, 112207. [Google Scholar] [CrossRef]

- Cao, T.; Wang, L.; Lin, G.; An, Y.; Liu, X.; Huang, Y. Cross-linked porous polyarylene ether nitrile films with ultralow dielectric constant and superior mechanical properties. Polymer 2022, 259, 125361. [Google Scholar] [CrossRef]

- Tong, L.; Lei, X.; Yang, G.; Liu, X. Self-Toughening and Self-Enhancement Poly(arylene ether nitrile) with Low Dielectric Constant by Solid Crosslinking Reaction. Polymers 2019, 11, 1403. [Google Scholar] [CrossRef]

- Tong, L.; Jia, K.; Liu, X. Novel phthalonitrile-terminated polyarylene ether nitrile with high glass transition temperature and enhanced thermal stability. Mater. Lett. 2014, 128, 267–270. [Google Scholar] [CrossRef]

- Peng, J.; Cao, T.; You, Y.; Liu, X.; Huang, Y. Fabrication of low dielectric constant fluorinated poly(arylene ether nitrile) composites by cross-linking with metal-organic frameworks. Polymer 2023, 283, 126229. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, T.; Wu, H.; Peng, A.; Tong, L.; Liu, X.; Huang, Y. Low dielectric constant and ultra-low dielectric loss poly(arylene ether nitrile)/octaphenyl-POSS composite films with dual cross-linked networks. Compos. Commun. 2025, 54, 102268. [Google Scholar] [CrossRef]

- Yu, Z.; Du, X.; Zhu, P.; Zhao, T.; Sun, R.; Chen, J.; Wang, N.; Li, W. Surface modified hollow glass microspheres-epoxy composites with enhanced thermal insulation and reduced dielectric constant. Mater. Today Commun. 2022, 32, 104046. [Google Scholar] [CrossRef]

- Li, M.; Zhu, Z.; Jiao, R.; Chen, Y.; Cao, X.; Sun, H.; Li, J.; Li, A. Preparation of DOPO-KH550 modified hollow glass microspheres/PVA composite aerogel for thermal insulation and flame retardancy. J. Colloid Interface Sci. 2024, 654, 719–730. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Liu, C.; Liu, C.; Tu, L.; You, Y.; Wei, R.; Liu, X. Polyarylene Ether Nitrile and Barium Titanate Nanocomposite Plasticized by Carboxylated Zinc Phthalocyanine Buffer. Polymers 2019, 11, 418. [Google Scholar] [CrossRef]

- Lei, X.; Tong, L.; Pan, H.; Yang, G.; Liu, X. Preparation of polyarylene ether nitriles/fullerene composites with low dielectric constant by cosolvent evaporation. J. Mater. Sci. Mater. Electron. 2019, 30, 18297–18305. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Wu, J.; Chen, Y.; Zhang, T.; Tong, L.; Liu, X. Polyarylene Ether Nitrile/Modified Hollow Silica Composite Films for Ultralow Dielectric Properties and Enhanced Thermal Resistance. Polymers 2025, 17, 1623. https://doi.org/10.3390/polym17121623

Liu S, Wu J, Chen Y, Zhang T, Tong L, Liu X. Polyarylene Ether Nitrile/Modified Hollow Silica Composite Films for Ultralow Dielectric Properties and Enhanced Thermal Resistance. Polymers. 2025; 17(12):1623. https://doi.org/10.3390/polym17121623

Chicago/Turabian StyleLiu, Shuning, Jinqi Wu, Yani Chen, Ting Zhang, Lifen Tong, and Xiaobo Liu. 2025. "Polyarylene Ether Nitrile/Modified Hollow Silica Composite Films for Ultralow Dielectric Properties and Enhanced Thermal Resistance" Polymers 17, no. 12: 1623. https://doi.org/10.3390/polym17121623

APA StyleLiu, S., Wu, J., Chen, Y., Zhang, T., Tong, L., & Liu, X. (2025). Polyarylene Ether Nitrile/Modified Hollow Silica Composite Films for Ultralow Dielectric Properties and Enhanced Thermal Resistance. Polymers, 17(12), 1623. https://doi.org/10.3390/polym17121623