Reactive Nanofiller Reinforced Hybrid Polyurea: The Role of CNC in Material Preparation and Characterization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

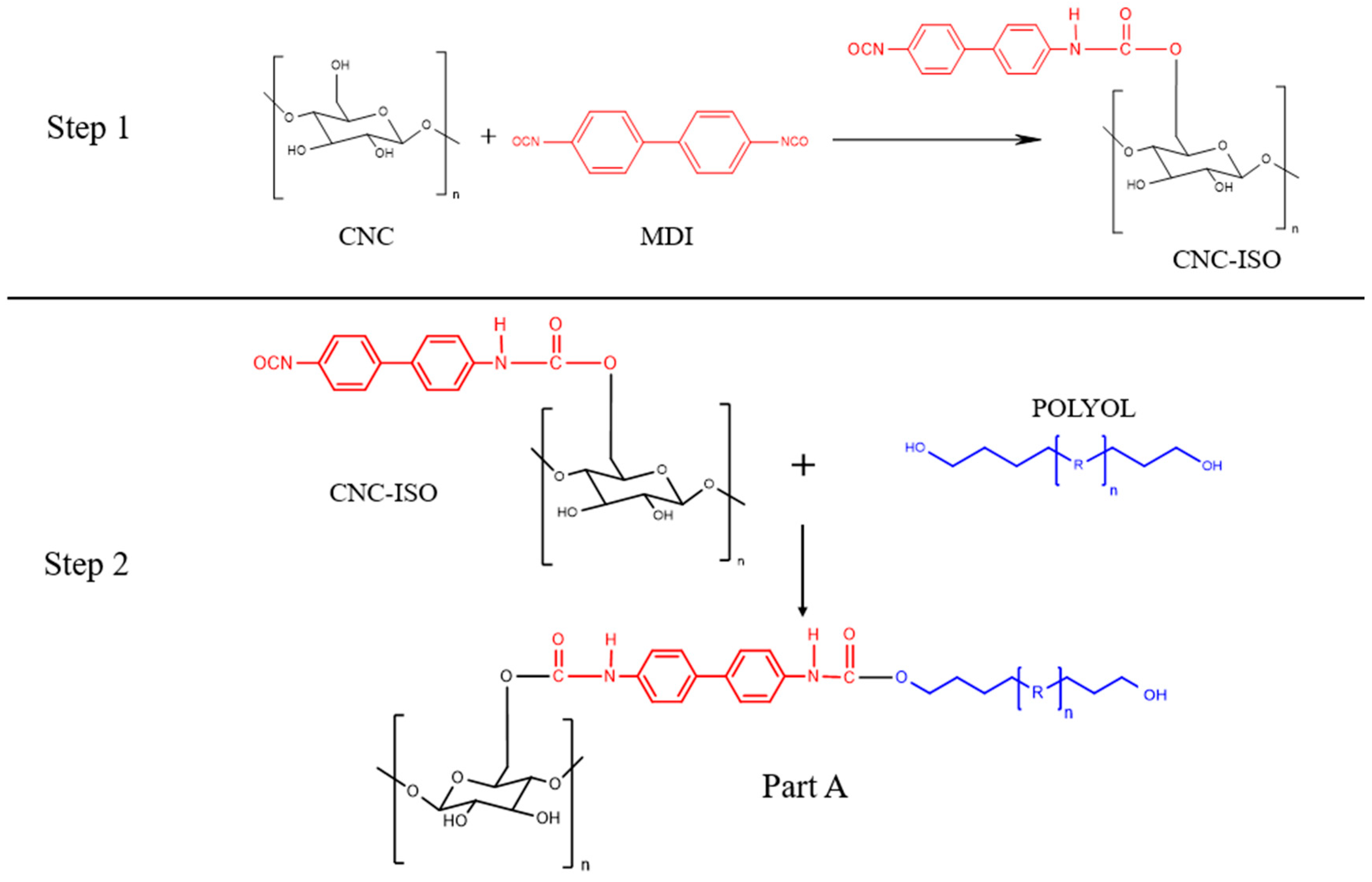

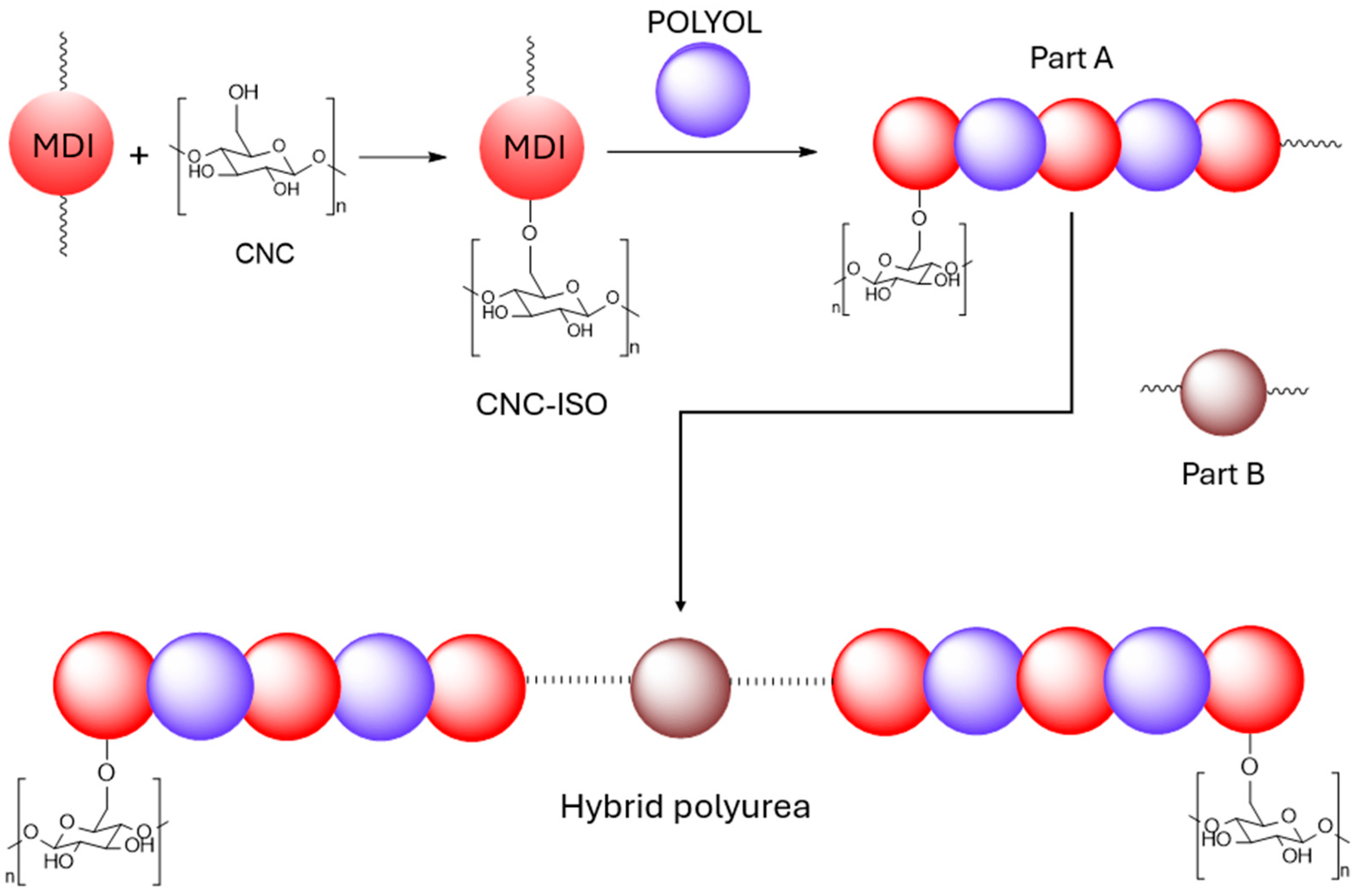

2.2.1. Synthesis of CNC-Grafted Hybrid Polyurea Prepolymer (Part A)

2.2.2. Synthesis of Part B

2.2.3. Preparation of CNC-Reinforced Polyurea Films

2.3. Characterization

3. Results and Discussion

3.1. CNC Characterization

3.1.1. Fourier Transform Infrared Analysis (FT-IR)

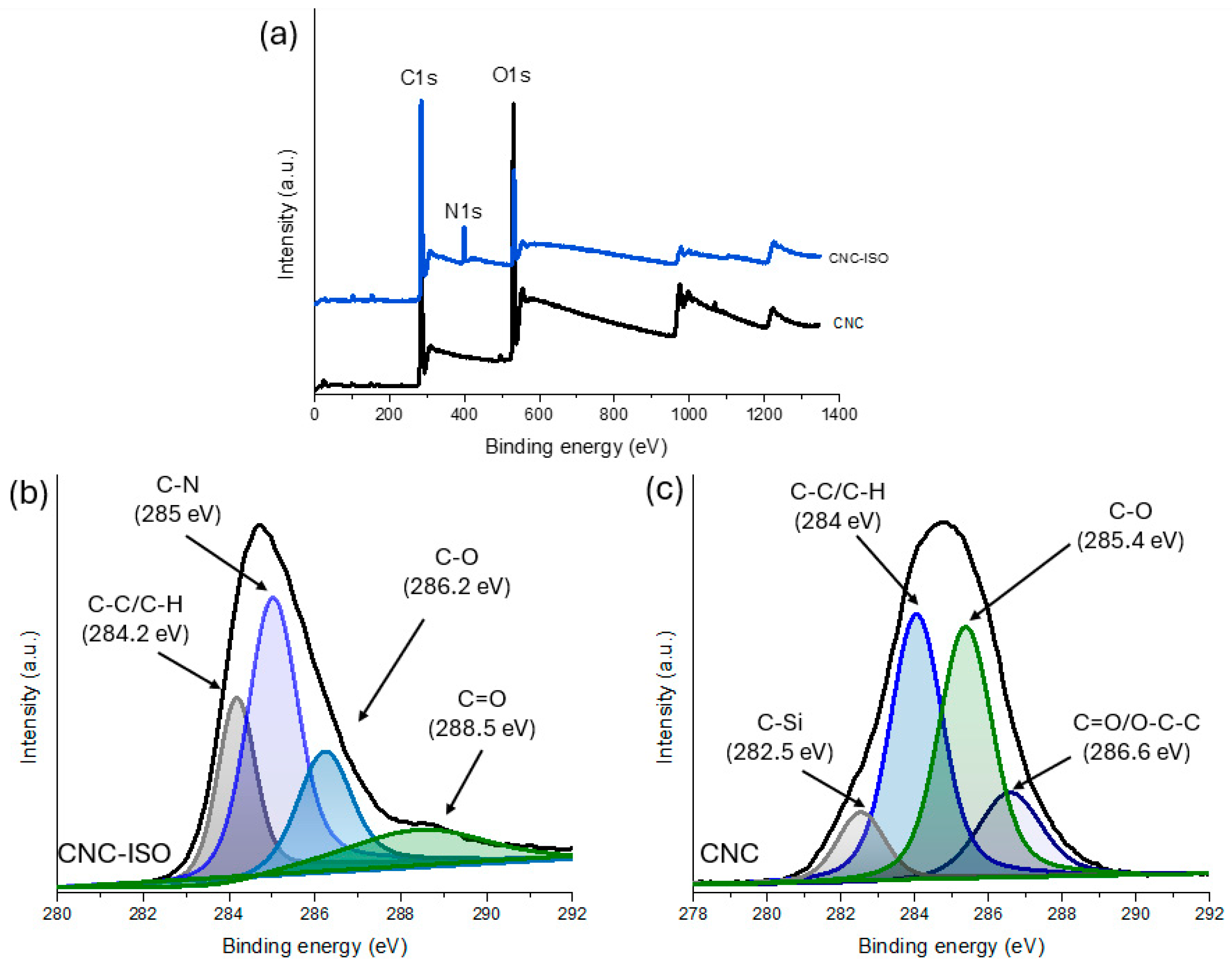

3.1.2. X-Ray Photoelectron Spectroscopy Analysis (XPS)

3.1.3. Differential Scanning Calorimetry Analysis (DSC)

3.1.4. Thermogravimetric Analysis

3.2. CNC-Polyurea Nanocomposites Characterization

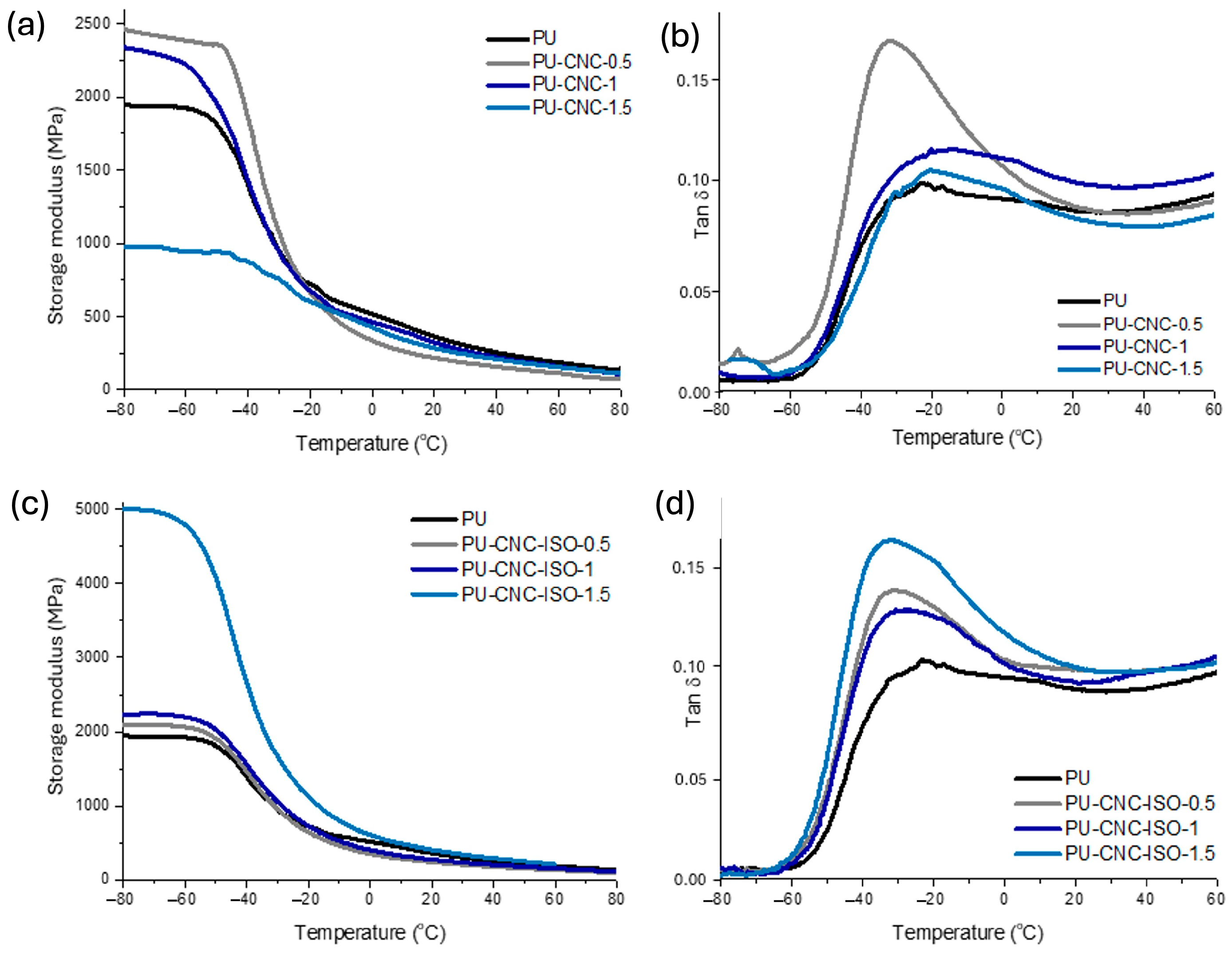

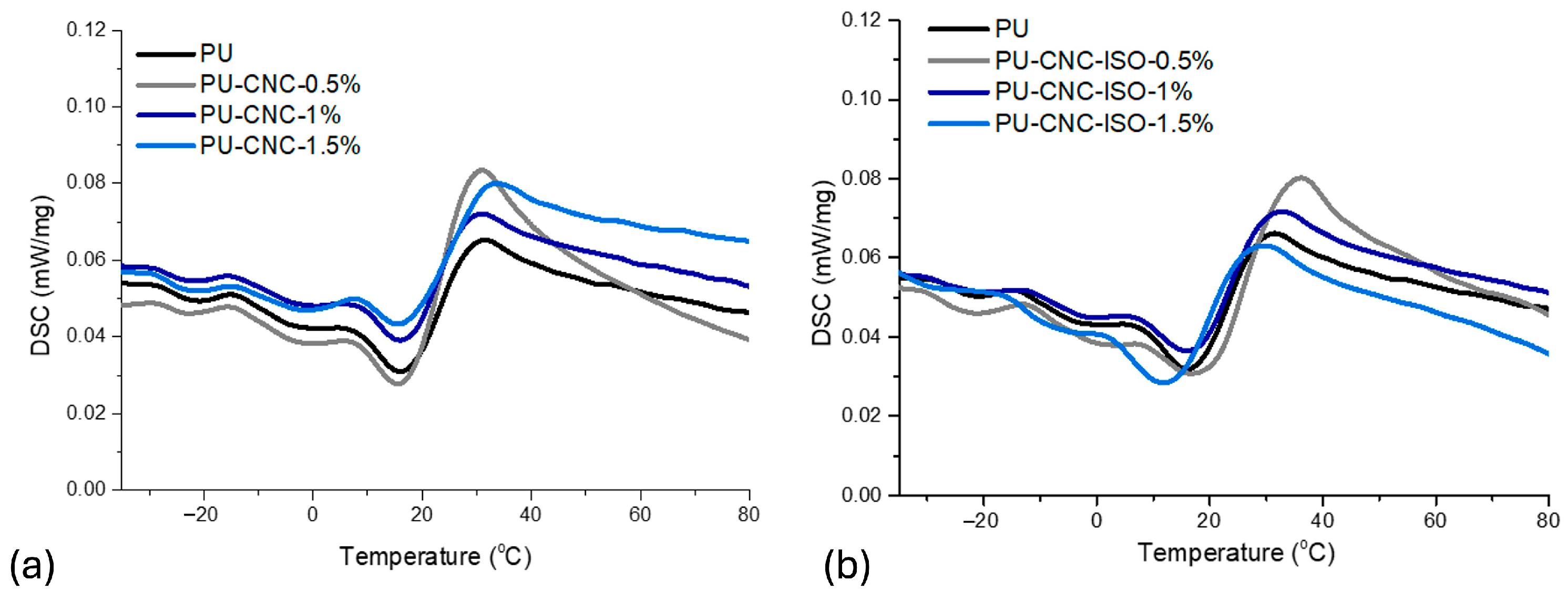

3.2.1. Dynamic Mechanical Analysis (DMA)

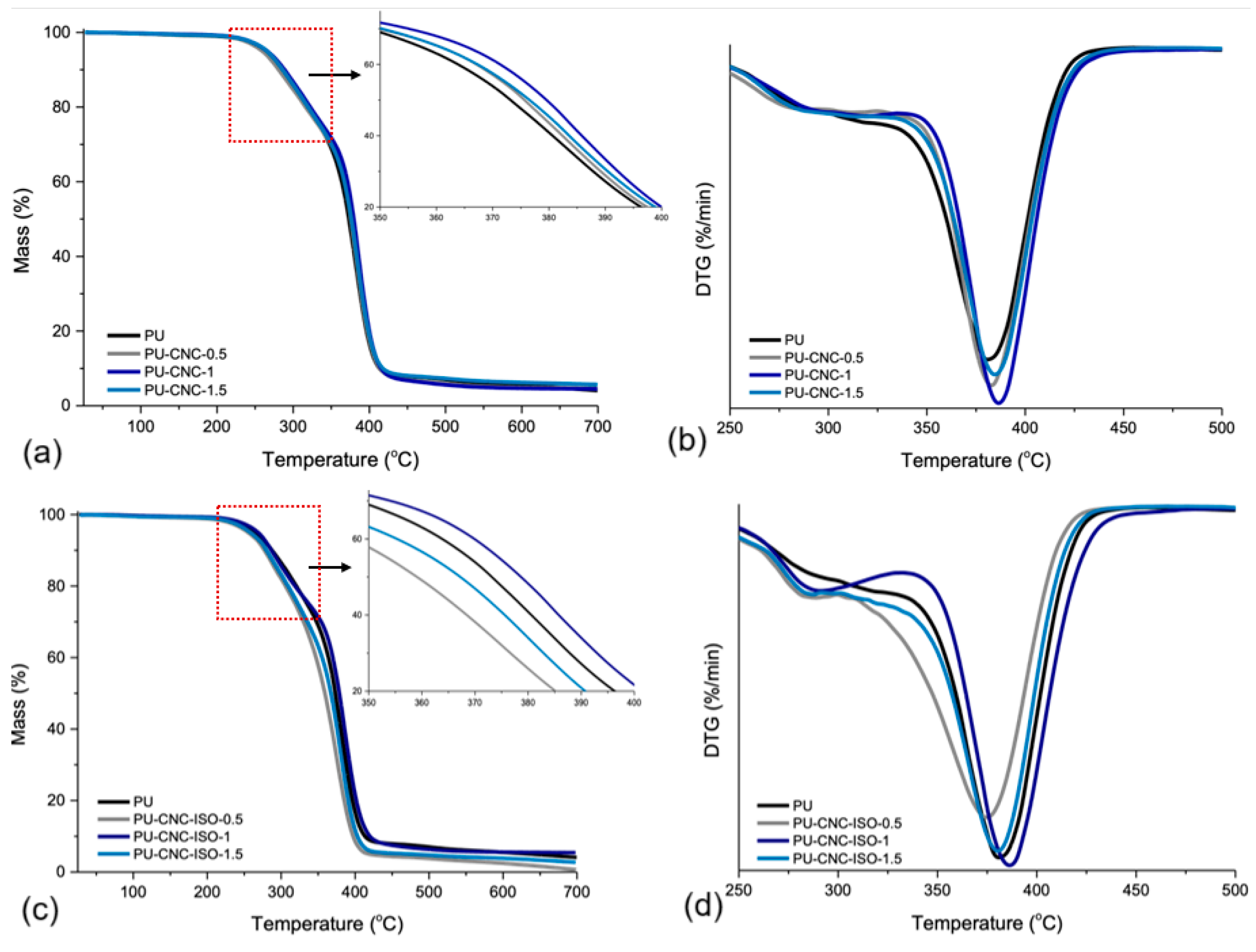

3.2.2. Thermo-Gravimetrical Analysis (TGA)

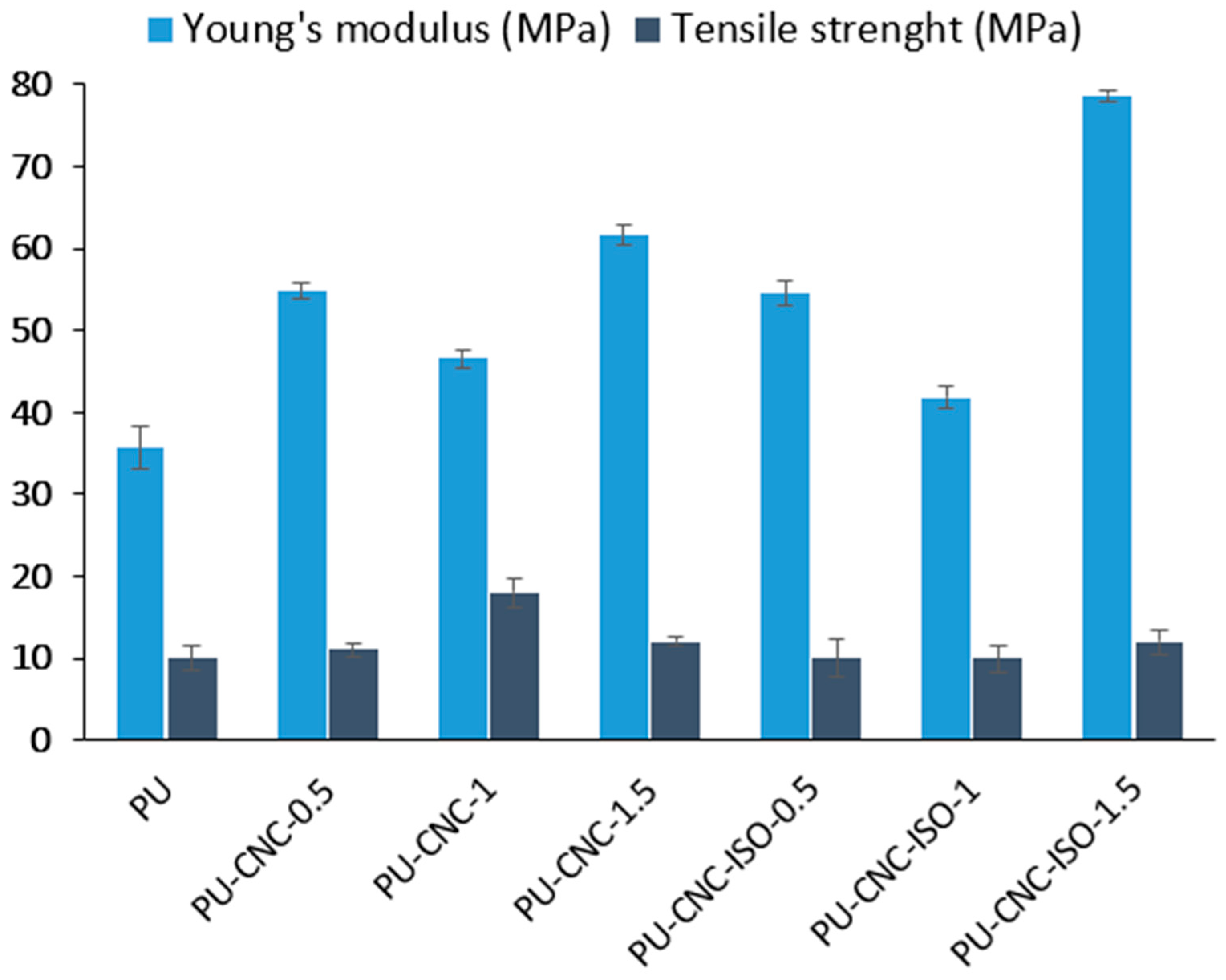

3.3. Mechanical Analysis

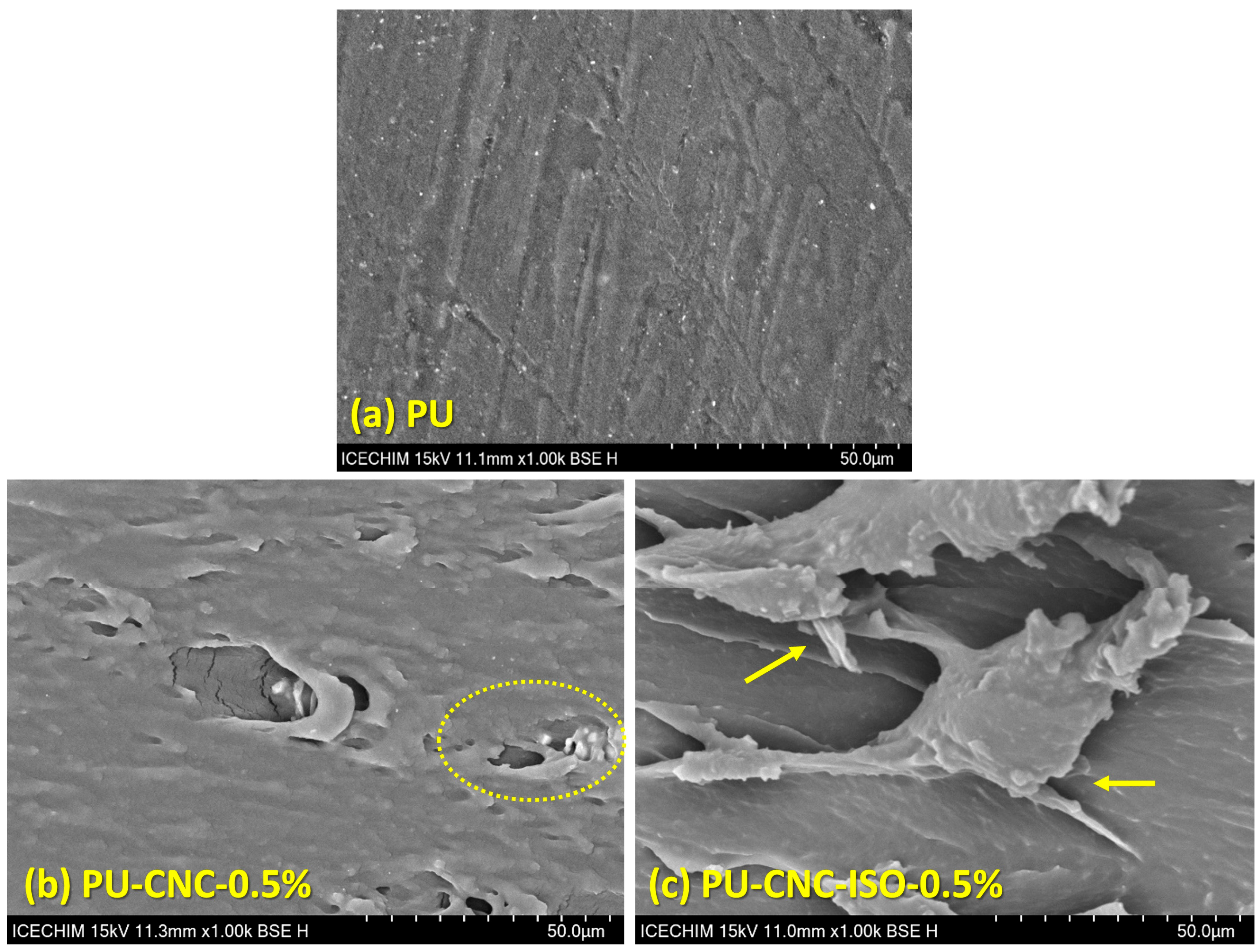

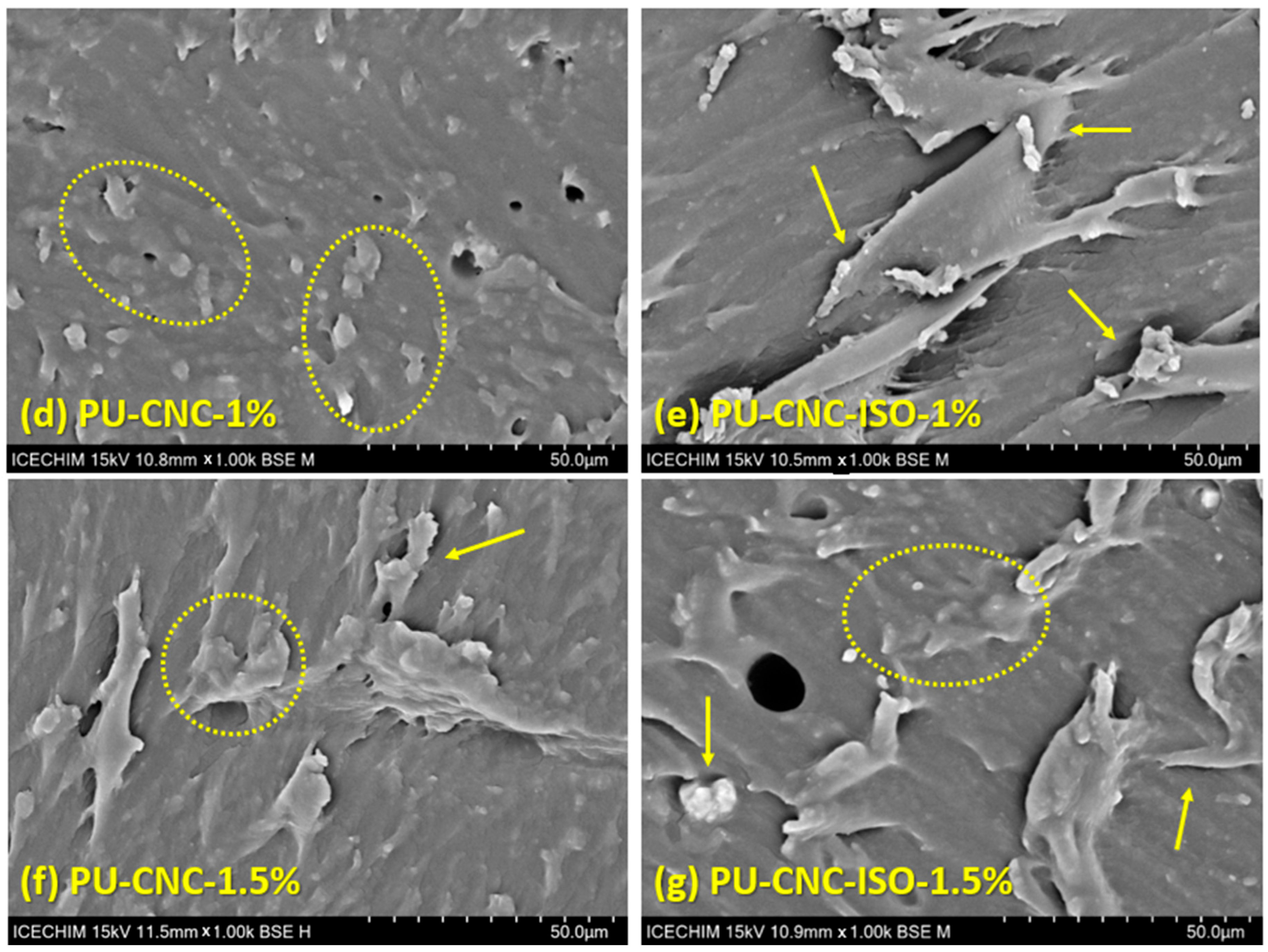

Scanning Electron Microscopy Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, T.; Zhang, C.; Xie, Z.; Xu, J.; Guo, B.-H. A multi-scale investigation on effects of hydrogen bonding on micro-structure and macro-properties in a polyurea. Polymer 2018, 145, 261–271. [Google Scholar] [CrossRef]

- Do, S.; Stepp, S.; Youssef, G. Quasi-static and dynamic characterization of polyurea microspheres reinforced polyurea matrix composite. Mater. Today Commun. 2020, 25, 101464. [Google Scholar] [CrossRef]

- Qiao, J.; Amirkhizi, A.V.; Schaaf, K.; Nemat-Nasser, S.; Wu, G. Dynamic mechanical and ultrasonic properties of polyurea. Mech. Mater. 2011, 43, 598–607. [Google Scholar] [CrossRef]

- Wang, L.; Kong, J.; Chu, D.; Wang, Y.; Wang, T.; Liu, Z. Enhancing ballistic performance: Effect of polyurea coating on backface deformation of UHMWPE laminates. Compos. Struct. 2025, 355, 118846. [Google Scholar] [CrossRef]

- Xie, J.; Pan, H.; Feng, Z.; Zhen, T.; Jiang, C.; Jiang, Y.; Li, X. Experimental study on the blast resistance of polyurea-coated aramid fabrics. Int. J. Impact Eng. 2025, 195, 105120. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wang, Y.; Ji, C.; Zhao, C.; Gao, Y.; Xia, W. Ballistic properties of bioinspired nacre-like ceramic/polyurea staggered composite structures. Int. J. Impact Eng. 2025, 195, 105137. [Google Scholar] [CrossRef]

- Tian, C.; Yang, S.; Feng, J.; Dong, Q. Influence of polyurea on dynamic response behaviors of cylindrical composite shells under internal explosion load. Compos. Struct. 2024, 329, 117800. [Google Scholar] [CrossRef]

- Pangon, A.; Dillon, G.P.; Runt, J. Influence of mixed soft segments on microphase separation of polyurea elastomers. Polymer 2014, 55, 1837–1844. [Google Scholar] [CrossRef]

- Yang, S.J.; Rosenbloom, S.I.; Fors, B.P.; Silberstein, M.N. Elucidating the impact of microstructure on mechanical properties of phase-segregated polyurea: Finite element modeling of molecular dynamics derived microstructures. Mech. Mater. 2024, 188, 104863. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, J.; Li, G.; Situ, G.; Ma, X.; Sha, Y.; Zhao, D.; Gu, Q.; Zhang, M.; Luo, Y.; et al. Mechanically robust self-repairing polyurea elastomers: The roles of hard segment content and ordered/disordered hydrogen-bonding arrays. Eur. Polym. J. 2022, 181, 111657. [Google Scholar] [CrossRef]

- Li, T.; Zheng, T.-Z.; Guo, Z.-X.; Xu, J.; Guo, B.-H. A Well-defined Hierarchical Hydrogen Bonding Strategy to Polyureas with Simultaneously Improved Strength and Toughness. Chin. J. Polym. Sci. 2019, 37, 1257–1266. [Google Scholar] [CrossRef]

- Lv, X.; Yan, H.; Wang, Z.; Dong, J.; Liu, C.; Zhou, Y.; Chen, H. Effects of hydrogen bonding on photo-responsive behavior of healable azobenzene-containing polyurea elastomers. Opt. Mater. 2023, 139, 113755. [Google Scholar] [CrossRef]

- Lu, L.; Niu, W.; Li, J.; Xing, Y.; Yang, Y.; Xu, J.; Zhang, F. Rapid photo-responsive self-healing cross-linked polyurea/polydopamine nanocomposites with multiple dynamic bonds and bio-based rosin. Compos. Sci. Technol. 2024, 254, 110693. [Google Scholar] [CrossRef]

- Palaniandy, K.; Makaremi, M.; Pasbakhsh, P. Chapter 7—Polyurea nanocomposites: Synthesis, functional properties, and applications. In Polyurea; Pasbakhsh, P., Mohotti, D., Palaniandy, K., Banon Auckloo, S.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 107–130. [Google Scholar]

- Mei, S.; Li, K.; Cui, M.; Wu, Y.; Ren, S. Static and dynamic mechanical properties of polyurea nanocomposites reinforced by polydopamine functionalized graphene oxide. J. Mater. Res. Technol. 2024, 29, 2889–2901. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, P.; Yu, Y.; Liu, J.; Su, X.; Kuan, H.-C.; Wang, B.; Zhang, L.; Zhang, Y.; Losic, D.; et al. Polyaspartic polyurea/graphene nanocomposites for multifunctionality: Self-healing, mechanical resilience, electrical and thermal conductivities, and resistance to corrosion and impact. Thin-Walled Struct. 2023, 189, 110853. [Google Scholar] [CrossRef]

- Necolau, M.I.; Damian, C.M.; Fierăscu, R.C.; Chiriac, A.-L.; Vlăsceanu, G.M.; Vasile, E.; Iovu, H. Layered Clay–Graphene Oxide Nanohybrids for the Reinforcement and Fire-Retardant Properties of Polyurea Matrix. Polymers 2022, 14, 66. [Google Scholar] [CrossRef]

- Cai, D.; Song, M. High mechanical performance polyurea/organoclay nanocomposites. Compos. Sci. Technol. 2014, 103, 44–48. [Google Scholar] [CrossRef]

- Dural, S.; Camadanlı, S.Ş.; Kayaman Apohan, N. Improving the mechanical, thermal and surface properties of polyaspartic ester bio-based polyurea coatings by incorporating silica and titania. Mater. Today Commun. 2024, 38, 107654. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, W.; Chu, F.; Zhou, F.; Liang, S.; Ma, C.; Hu, Y. Hydroxyapatite/polyurea nanocomposite: Preparation and multiple performance enhancements. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105681. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, B.; Gao, Z.; Chen, C.; Zhao, S.; Qin, Y. Functionalization of multiwalled carbon nanotubes with uniform polyurea coatings by molecular layer deposition. Carbon 2015, 82, 470–478. [Google Scholar] [CrossRef]

- Yan, J.; Gao, Z.; Song, J.; Liu, Z.; Tan, Q. Corrosion Behavior of Carbon Nanotubes/Polyurea Composite Coatings in Alkaline Environment. Int. J. Electrochem. Sci. 2020, 15, 10253–10261. [Google Scholar] [CrossRef]

- Siddiqui, Z.A.; Wakeel, A.; Nasir, M.A.; Zubair, M.; Ammar, M. Improving anti-corrosion and mechanical properties of mild steel pipelines by using polyurea with nanoparticles. Int. J. Thermofluids 2024, 23, 100729. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Mousavi, S.J.; Mahdavian, M.; Khaleghi, M.; Bordbar, S.; Yola, M.L.; Darabi, R.; Liu, M. Effects of silver nanoparticles added into polyurea coating on sulfate-reducing bacteria activity and electrochemical properties; an environmental nano-biotechnology investigation. Environ. Res. 2021, 198, 111251. [Google Scholar] [CrossRef]

- McNamara, J.T.; Morgan, J.L.; Zimmer, J. A molecular description of cellulose biosynthesis. Annu. Rev. Biochem. 2015, 84, 895–921. [Google Scholar] [CrossRef]

- Genet, M.B.; Zhuang, X.; Tan, X.; Zhang, Q.; Miao, C.; Zhang, Z.; Jembere, A.L. Cellulose nanocrystal-based synthetic biodegradable biopolymeric composites: A comprehensive review on recent progress. Int. J. Biol. Macromol. 2025, 299, 140098. [Google Scholar] [CrossRef]

- Sharma, V.S.; Mishra, S.; Sharma, A.S.; Sharma, N.; Varma, R.S.; Shrivastav, P.S.; Ammathnadu Sudhakar, A. Microcrystalline Cellulose and Cellulose Nanocrystals: Ecofriendly and Sustainable Support Materials in Heterogeneous Nanocatalysis for Green Organic Transformations. Asian J. Org. Chem. 2025, 14, e202400586. [Google Scholar] [CrossRef]

- Girouard, N.; Xu, S.; Schueneman, G.; Shofner, M.; Meredith, J. Site-Selective Modification of Cellulose Nanocrystals with Isophorone Diisocyanate and Formation of Polyurethane-CNC Composites. ACS Appl. Mater. Interfaces 2015, 8, 1458–1467. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.C.; Martin, D.J.; Annamalai, P.K. Hybrid polyether-palm oil polyester polyol based rigid polyurethane foam reinforced with cellulose nanocrystal. Ind. Crops Prod. 2018, 112, 378–388. [Google Scholar] [CrossRef]

- Mackay, M.E.; Tuteja, A.; Duxbury, P.M.; Hawker, C.J.; Van Horn, B.; Guan, Z.; Chen, G.; Krishnan, R.S. General strategies for nanoparticle dispersion. Science 2006, 311, 1740–1743. [Google Scholar] [CrossRef]

- Alvarado, J.; Acosta, G.; Perez, F. Study of the effect of the dispersion of functionalized nanoparticles TiO2 with photocatalytic activity in LDPE. Polym. Degrad. Stab. 2016, 134, 376–382. [Google Scholar] [CrossRef]

- Faure, B.; Salazar-Alvarez, G.; Ahniyaz, A.; Villaluenga, I.; Berriozabal, G.; De Miguel, Y.R.; Bergström, L. Dispersion and surface functionalization of oxide nanoparticles for transparent photocatalytic and UV-protecting coatings and sunscreens. Sci. Technol. Adv. Mater. 2013, 14, 023001. [Google Scholar] [CrossRef]

- Munir, M.M.; Ogi, T.; Okuyama, K. Application 52—Nanoparticle Synthesis, Dispersion, and Functionalization for Industrial Application. In Nanoparticle Technology Handbook, 3rd ed.; Naito, M., Yokoyama, T., Hosokawa, K., Nogi, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 675–681. [Google Scholar]

- Fan, X.; Zhang, L.; Dong, F.; Liu, H.; Xu, X. Room-Temperature Self-Healing Polyurethane–Cellulose Nanocrystal Composites with Strong Strength and Toughness Based on Dynamic Bonds. Carbohydr. Polym. 2023, 308, 120654. [Google Scholar] [CrossRef]

- Yu, T.-Y.; Tseng, Y.-K.; Lin, T.-H.; Wang, T.-C.; Tseng, Y.-H.; Chang, Y.-H.; Wu, M.-C.; Su, W.-F. Effect of Cellulose Compositions and Fabrication Methods on Mechanical Properties of Polyurethane–Cellulose Composites. Carbohydr. Polym. 2022, 291, 119549. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, X.; Yu, H.; Yu, C.; Zhang, F. Dynamic Cross-Linked Polyurea/Polydopamine Nanocomposites for Photoresponsive Self-Healing and Photoactuation. Macromolecules 2022, 55, 2193–2201. [Google Scholar] [CrossRef]

- Garg, H.; Mohanty, J.; Gupta, P.; Das, A.; Tripathi, B.P.; Kumar, B. Polyethylenimine-Based Shape Memory Polyurethane with Low Transition Temperature and Excellent Memory Performance. Macromol. Mater. Eng. 2020, 305, 2000215. [Google Scholar] [CrossRef]

- Popescu, M.-C.; Popescu, C.-M.; Lisa, G.; Sakata, Y. Evaluation of morphological and chemical aspects of different wood species by spectroscopy and thermal methods. J. Mol. Struct. 2011, 988, 65–72. [Google Scholar] [CrossRef]

- Wulandari, W.; Rochliadi, A.; Arcana, I.M. Nanocellulose prepared by acid hydrolysis of isolated cellulose from sugarcane bagasse. IOP Conf. Ser. Mater. Sci. Eng. 2016, 107, 012045. [Google Scholar] [CrossRef]

- Vârban, R.; Crișan, I.; Vârban, D.; Ona, A.; Olar, L.; Stoie, A.; Ștefan, R. Comparative FT-IR Prospecting for Cellulose in Stems of Some Fiber Plants: Flax, Velvet Leaf, Hemp and Jute. Appl. Sci. 2021, 11, 8570. [Google Scholar] [CrossRef]

- Pang, J.; Zhong, J.; Yang, Y.; Yang, K.; Yue, M.; Pu, Z.; Wu, F.; Yu, D.; Zheng, P. Preparation of isocyanate functionalized graphene oxide/thermoplastic polyurethane elastomer nanocomposites and their antistatic properties. Polym. Compos. 2024, 1–14. [Google Scholar] [CrossRef]

- Durand, S.; D’Orlando, A.; Mougnard, L.; Bourmaud, A.; Beaugrand, J. Combining infrared and Raman spectra to assess MDI localization in novel flax-reinforced automotive composites. Compos. Part C Open Access 2023, 12, 100382. [Google Scholar] [CrossRef]

- Selyanchyn, O.; Bayer, T.; Klotz, D.; Selyanchyn, R.; Sasaki, K.; Lyth, S.M. Cellulose Nanocrystals Crosslinked with Sulfosuccinic Acid as Sustainable Proton Exchange Membranes for Electrochemical Energy Applications. Membranes 2022, 12, 658. [Google Scholar] [CrossRef]

- Wang, H.; Fang, S.; Zuo, M.; Li, Z.; Yu, X.; Tang, X.; Sun, Y.; Yang, S.; Zeng, X.; Lin, L. Removal of copper ions by cellulose nanocrystal-based hydrogel and reduced adsorbents for its catalytic properties. Cellulose 2022, 29, 4525–4537. [Google Scholar] [CrossRef]

- Zhang, F.; Dou, J.; Zhang, H. Mixed Membranes Comprising Carboxymethyl Cellulose (as Capping Agent and Gas Barrier Matrix) and Nanoporous ZIF-L Nanosheets for Gas Separation Applications. Polymers 2018, 10, 1340. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, J.; Lin, S.; Xiao, H.; Yang, Q.; Chen, S.; Yan, B.; Gu, Y. Environmentally friendly nanocomposites based on cellulose nanocrystals and polydopamine for rapid removal of organic dyes in aqueous solution. Cellulose 2020, 27, 2085–2097. [Google Scholar] [CrossRef]

- Azubuike, C.P.; Okhamafe, A.O. Physicochemical, spectroscopic and thermal properties of microcrystalline cellulose derived from corn cobs. Int. J. Recycl. Org. Waste Agric. 2012, 1, 9. [Google Scholar] [CrossRef]

- Udoetok, I.; Wilson, L.; Headley, J. Ultra-Sonication Assisted Cross-linking of Cellulose Polymers. Ultrason. Sonochemistry 2017, 42, 567–576. [Google Scholar] [CrossRef]

- Salem, K.S.; Kasera, N.K.; Rahman, M.A.; Jameel, H.; Habibi, Y.; Eichhorn, S.J.; French, A.D.; Pal, L.; Lucia, L.A. Comparison and assessment of methods for cellulose crystallinity determination. Chem. Soc. Rev. 2023, 52, 6417–6446. [Google Scholar] [CrossRef]

- Silvano, S.; Moimare, P.; Gryshchuk, L.; Barak-Kulbak, E.; Recupido, F.; Lama, G.C.; Boggioni, L.; Verdolotti, L. Synthesis of bio-polyol-functionalized nanocrystalline celluloses as reactive/reinforcing components in bio-based polyurethane foams by homogeneous environment modification. Int. J. Biol. Macromol. 2024, 278, 135282. [Google Scholar] [CrossRef]

- Thompson, L.; Nikzad, M.; Sbarski, I.; Yu, A. Esterified cellulose nanocrystals for reinforced epoxy nanocomposites. Prog. Nat. Sci. Mater. Int. 2022, 32, 328–333. [Google Scholar] [CrossRef]

- Pan, S.; Yang, H.; Qiu, Z. Influence of Low Loadings of Cellulose Nanocrystals on the Simultaneously Enhanced Crystallization Rate, Mechanical Property, and Hydrophilicity of Biobased Poly(butylene 2,5-furandicarboxylate). Polymers 2025, 17, 196. [Google Scholar] [CrossRef]

- Rueda, L.; Fernández d’Arlas, B.; Zhou, Q.; Berglund, L.A.; Corcuera, M.A.; Mondragon, I.; Eceiza, A. Isocyanate-Rich Cellulose Nanocrystals and Their Selective Insertion in Elastomeric Polyurethane. Compos. Sci. Technol. 2011, 71, 1953–1960. [Google Scholar] [CrossRef]

- Coccia, F.; Gryshchuk, L.; Moimare, P.; Bossa, F.L.; Santillo, C.; Barak-Kulbak, E.; Verdolotti, L.; Boggioni, L.; Lama, G.C. Chemically Functionalized Cellulose Nanocrystals as Reactive Filler in Bio-Based Polyurethane Foams. Polymers 2021, 13, 2556. [Google Scholar] [CrossRef]

- Bashir, M.A. Use of Dynamic Mechanical Analysis (DMA) for Characterizing Interfacial Interactions in Filled Polymers. Solids 2021, 2, 108–120. [Google Scholar] [CrossRef]

- Anzlovar, A.; Zigon, M. Semi-interpenetrating polymer networks with varying mass ratios of functional urethane and methacrylate prepolymers. Acta Chim. Slov. 2005, 52, 230–237. [Google Scholar]

- Omran, A.A.B.; Mohammed, A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Rahimian Koloor, S.S.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Okonkwo, A.O.; Jagadale, P.; García Herrera, J.E.; Hadjiev, V.G.; Muñoz Saldaña, J.; Tagliaferro, A.; Robles Hernandez, F.C. High-toughness/low-friction ductile epoxy coatings reinforced with carbon nanostructures. Polym. Test. 2015, 47, 113–119. [Google Scholar] [CrossRef]

- Luo, J.; Chang, H.; Bakhtiary Davijani, A.A.; Liu, H.C.; Wang, P.-H.; Moon, R.J.; Kumar, S. Influence of high loading of cellulose nanocrystals in polyacrylonitrile composite films. Cellulose 2017, 24, 1745–1758. [Google Scholar] [CrossRef]

- Guo, Z.; Pereira, T.; Choi, O.; Wang, Y.; Hahn, H.T. Surface functionalized alumina nanoparticle filled polymeric nanocomposites with enhanced mechanical properties. J. Mater. Chem. 2006, 16, 2800–2808. [Google Scholar] [CrossRef]

- Singh, P.; Venugopal, B.; Nandini, D. Effect of Electron Beam Irradiation on Polymers. J. Mod. Mater. 2018, 5, 24–33. [Google Scholar] [CrossRef]

- Huang, Q.; Guo, S.; Li, S.; Gao, Z.; Ma, S.; Han, S. Mechanical Robust and Conductive Polyurea Nanocomposites Using Graphene Platelets. Compos. Mater. 2024, 8, 13–21. [Google Scholar] [CrossRef]

- Anju; Yadav, R.S.; Pötschke, P.; Pionteck, J.; Krause, B.; Kuřitka, I.; Vilcakova, J.; Skoda, D.; Urbánek, P.; Machovsky, M.; et al. High-Performance, Lightweight, and Flexible Thermoplastic Polyurethane Nanocomposites with Zn2+-Substituted CoFe2O4 Nanoparticles and Reduced Graphene Oxide as Shielding Materials against Electromagnetic Pollution. ACS Omega 2021, 6, 28098–28118. [Google Scholar] [CrossRef] [PubMed]

| Nr.crt | Part A | Part B | Polyurea Sample Abbreviation | ||

|---|---|---|---|---|---|

| CNC Type in the Prepolymer Formulation | CNC Amount, wt% | Polyol | Amine | ||

| 1 | Blank prepolymer | 0 | D-2061 | D2000-E300 | PU |

| 2 | CNC | 0.5 | D-2061 | D2000-E300 | PU-CNC-0.5 |

| 3 | CNC | 1 | D-2061 | D2000-E300 | PU-CNC-1 |

| 4 | CNC | 1.5 | D-2061 | D2000-E300 | PU-CNC-1.5 |

| 5 | CNC-ISO | 0.5 | D-2061 | D2000-E300 | PU-CNC-ISO-0.5 |

| 6 | CNC-ISO | 1 | D-2061 | D2000-E300 | PU-CNC-ISO-1 |

| 7 | CNC-ISO | 1.5 | D-2061 | D2000-E300 | PU-CNC-ISO-1.5 |

| C1s (Atomic %) | O1s (Atomic %) | N1s (Atomic %) | |

|---|---|---|---|

| CNC | 61.84 | 38.16 | - |

| CNC-ISO | 76.90 | 13.63 | 6.92 |

| Sample | ΔH1 (J/g) | Tmax1 (°C) | ΔH2 (J/g) | Tmax2 (°C) | Td3% (°C) | Td10% (°C) | Tmax (°C) from DTG | Residual Mass (%) |

|---|---|---|---|---|---|---|---|---|

| CNC | 44.52 | 70.5 | 447.0 | 302.8 | 269.6 | 291.3 | 302.2 | 19.17 |

| CNC-ISO | 30.79 | 72.0 | 181.4 | 294.6 | 243.3 | 276.6 | 306.5 | 25.71 |

| Sample | Tg (°C) from DMA | Tg Soft (°C) from DSC | Tg Hard (°C) from DSC | SD (%) | CD * mol/cm3 |

|---|---|---|---|---|---|

| PU | −24.1 | −23.6 | 13.6 | 23.80 | 5.71 |

| PU-CNC-0.5 | −31.6 | −23.9 | 12.1 | 27.93 | 5.25 |

| PU-CNC-1 | −19.9 | −23.5 | 14.2 | 27.58 | 5.28 |

| PU-CNC-1.5 | −19.5 | −24.1 | 13.5 | 29.84 | 5.05 |

| PU-CNC-ISO-0.5 | −31.1 | −23.8 | 14.9 | 26.09 | 5.44 |

| PU-CNC-ISO-1 | −29.8 | −22.9 | 14.3 | 19.78 | 6.22 |

| PU-CNC-ISO-1.5 | −33.3 | −26.2 | 18.1 | 19.44 | 6.27 |

| Sample | Td3% (°C) | Td10% (°C) | Residual Mass (%) | Tmax (°C) from DTG |

|---|---|---|---|---|

| PU | 248.7 | 287.7 | 4.06 | 381.4 |

| PU-CNC-0.5 | 244.3 | 281.1 | 4.69 | 382.8 |

| PU-CNC-1 | 250.2 | 288.6 | 4.49 | 386.6 |

| PU-CNC-1.5 | 250.0 | 286.3 | 5.68 | 384.5 |

| PU-CNC-ISO-0.5 | 239.2 | 277.2 | 0.65 | 373.6 |

| PU-CNC-ISO-1 | 250.0 | 285.3 | 5.07 | 384.5 |

| PU-CNC-ISO-1.5 | 244.3 | 280.0 | 2.72 | 380.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duman, K.; Necolau, M.I.; Bîru, E.I.; Zaharia, A.; Iovu, H. Reactive Nanofiller Reinforced Hybrid Polyurea: The Role of CNC in Material Preparation and Characterization. Polymers 2025, 17, 1527. https://doi.org/10.3390/polym17111527

Duman K, Necolau MI, Bîru EI, Zaharia A, Iovu H. Reactive Nanofiller Reinforced Hybrid Polyurea: The Role of CNC in Material Preparation and Characterization. Polymers. 2025; 17(11):1527. https://doi.org/10.3390/polym17111527

Chicago/Turabian StyleDuman, Kadir, Madalina Ioana Necolau, Elena Iuliana Bîru, Anamaria Zaharia, and Horia Iovu. 2025. "Reactive Nanofiller Reinforced Hybrid Polyurea: The Role of CNC in Material Preparation and Characterization" Polymers 17, no. 11: 1527. https://doi.org/10.3390/polym17111527

APA StyleDuman, K., Necolau, M. I., Bîru, E. I., Zaharia, A., & Iovu, H. (2025). Reactive Nanofiller Reinforced Hybrid Polyurea: The Role of CNC in Material Preparation and Characterization. Polymers, 17(11), 1527. https://doi.org/10.3390/polym17111527