In Situ Following Oriented Crystallization of Pre-Stretched Poly(ethylene 2,5-Furandicarboxylate) Under Post Heating

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

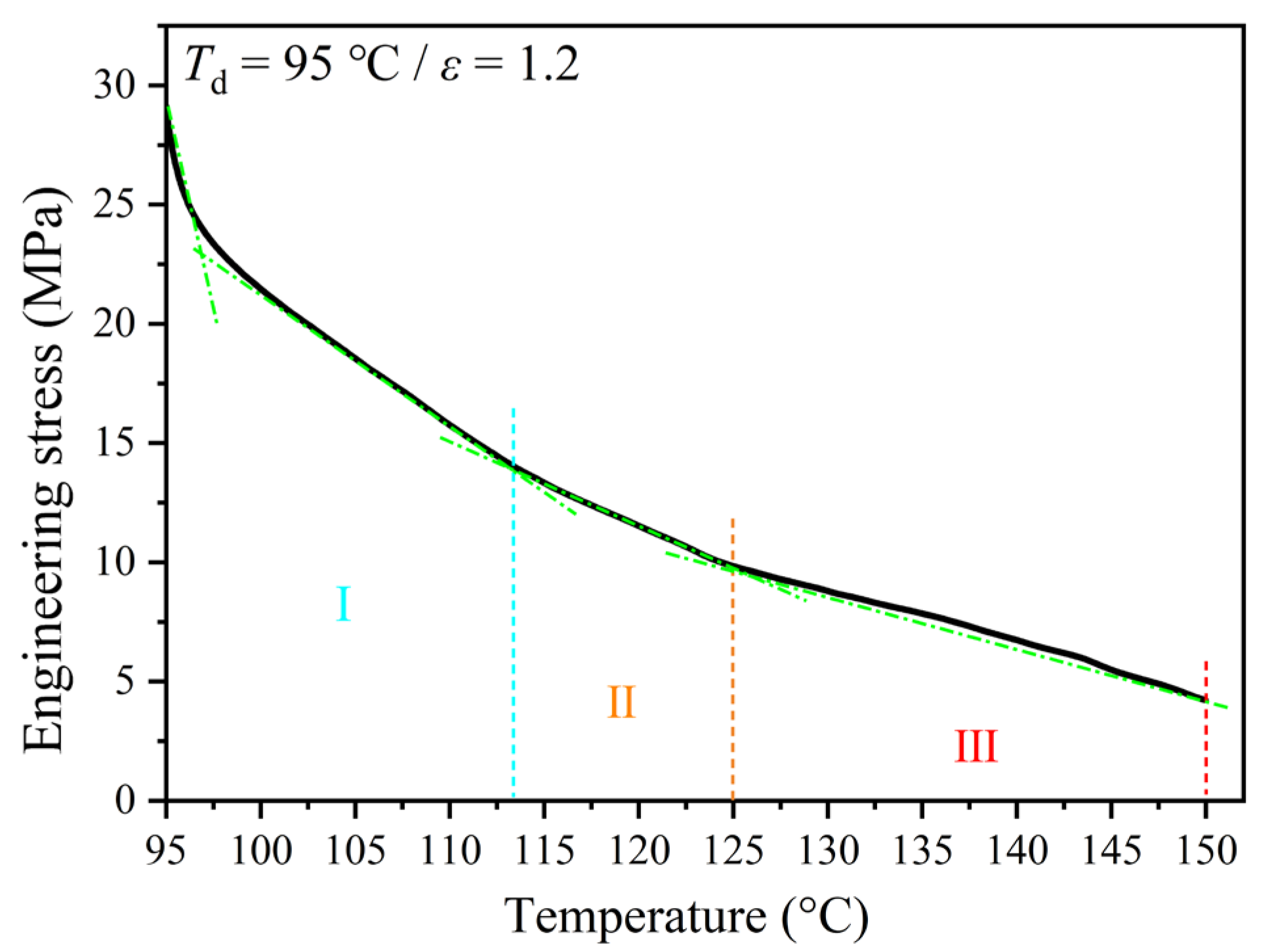

3.1. Simultaneously Mechanical Response

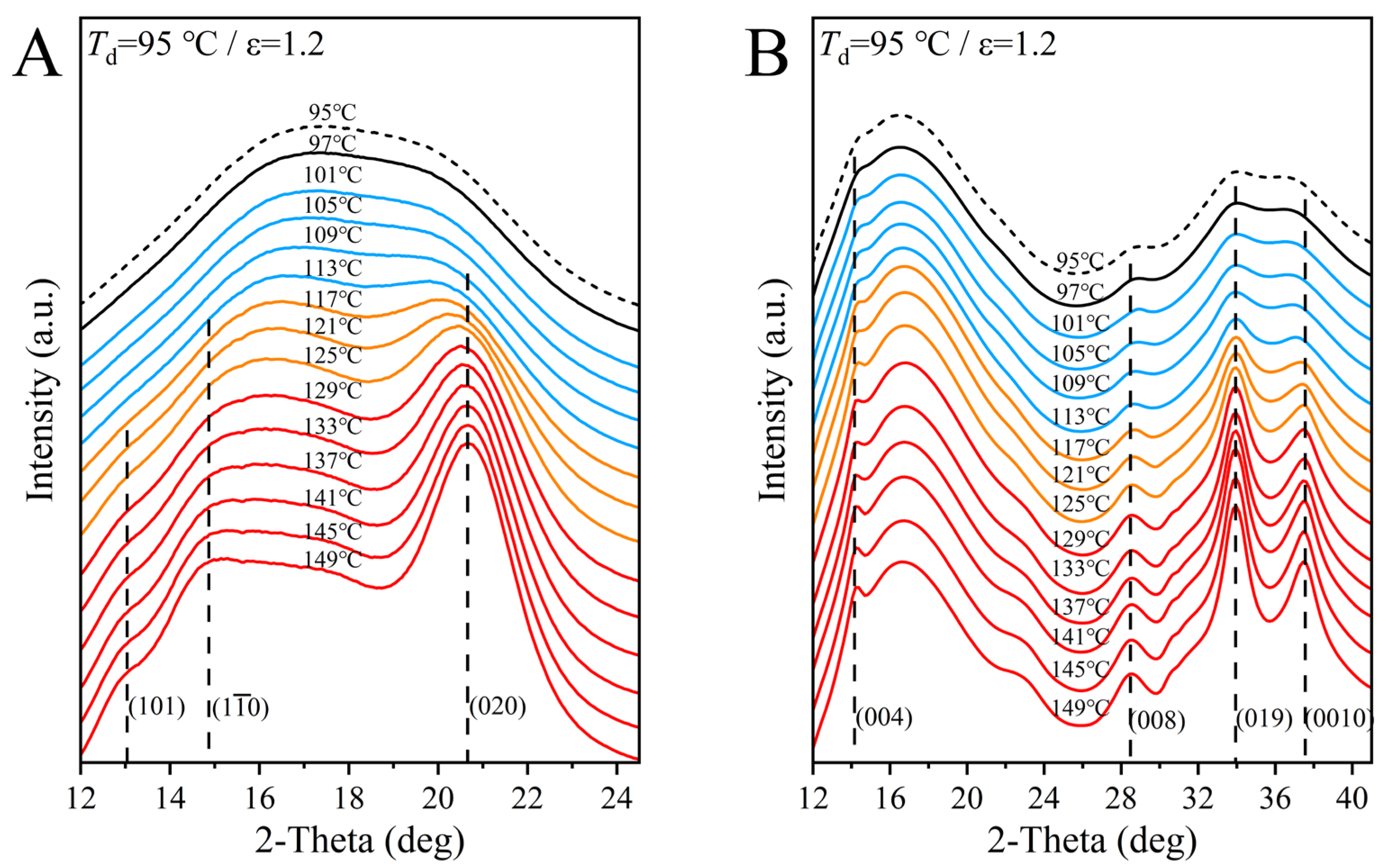

3.2. On-Line WAXD/SAXS Observations

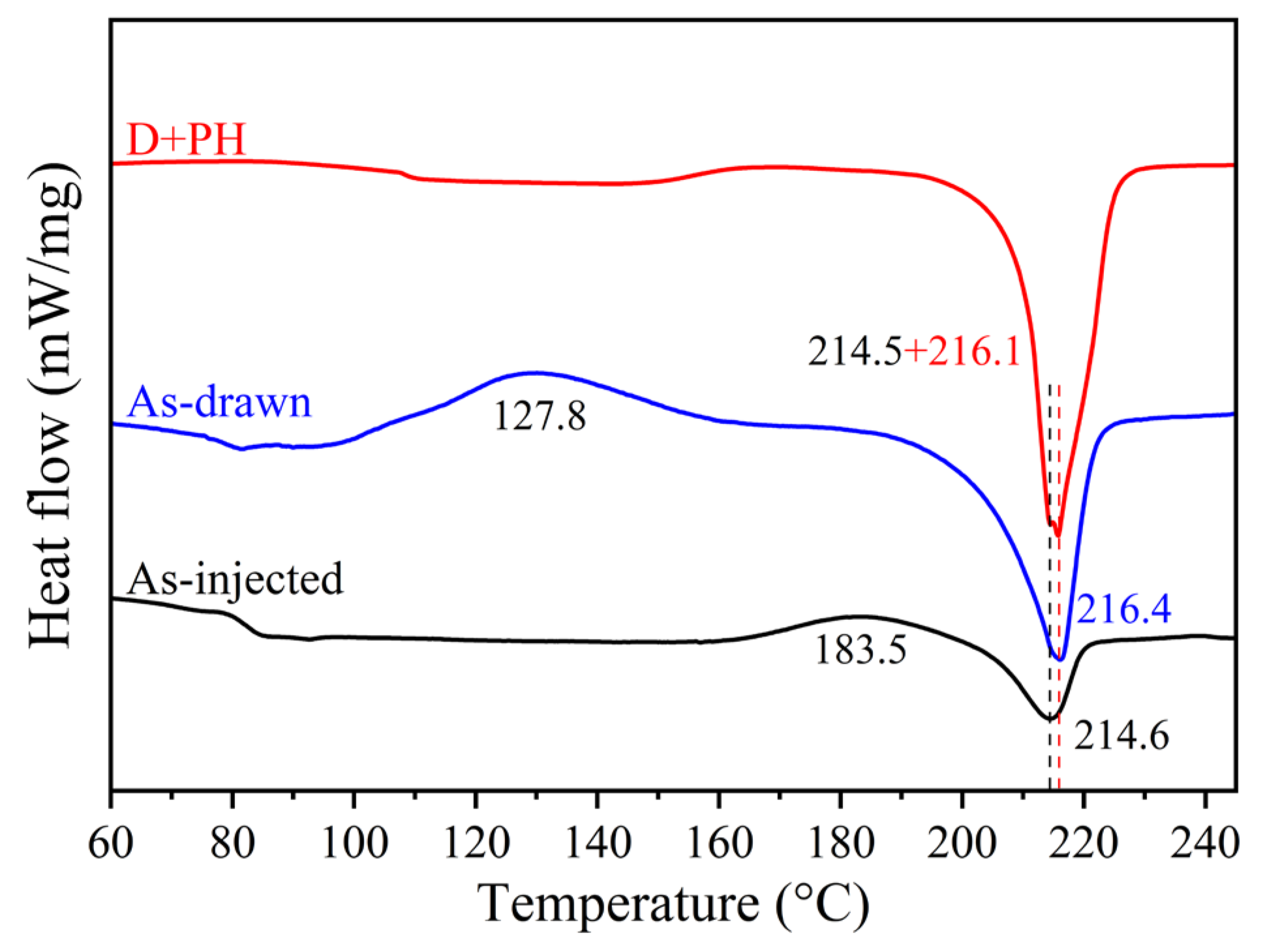

3.3. DSC Melting Measurement

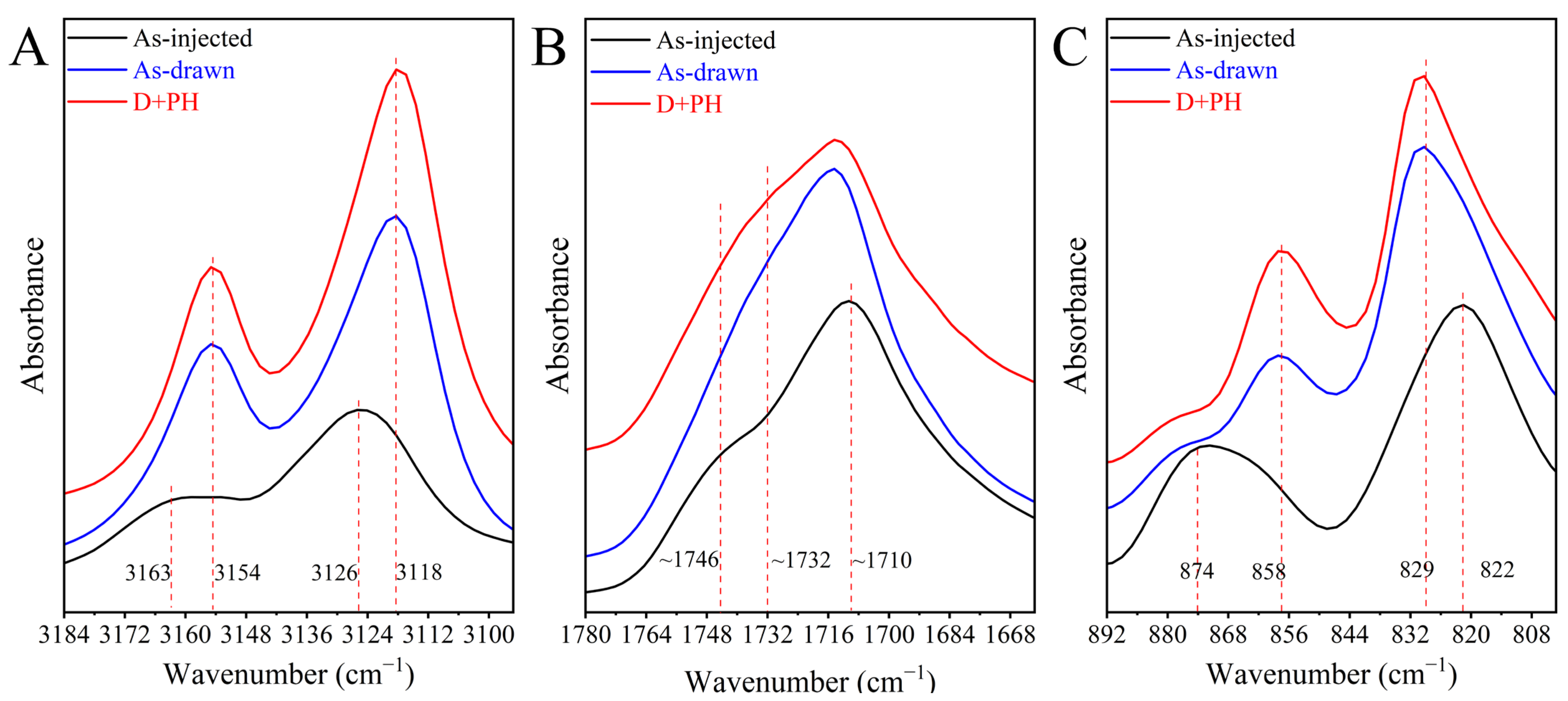

3.4. Ex Situ ATR-FTIR Analysis

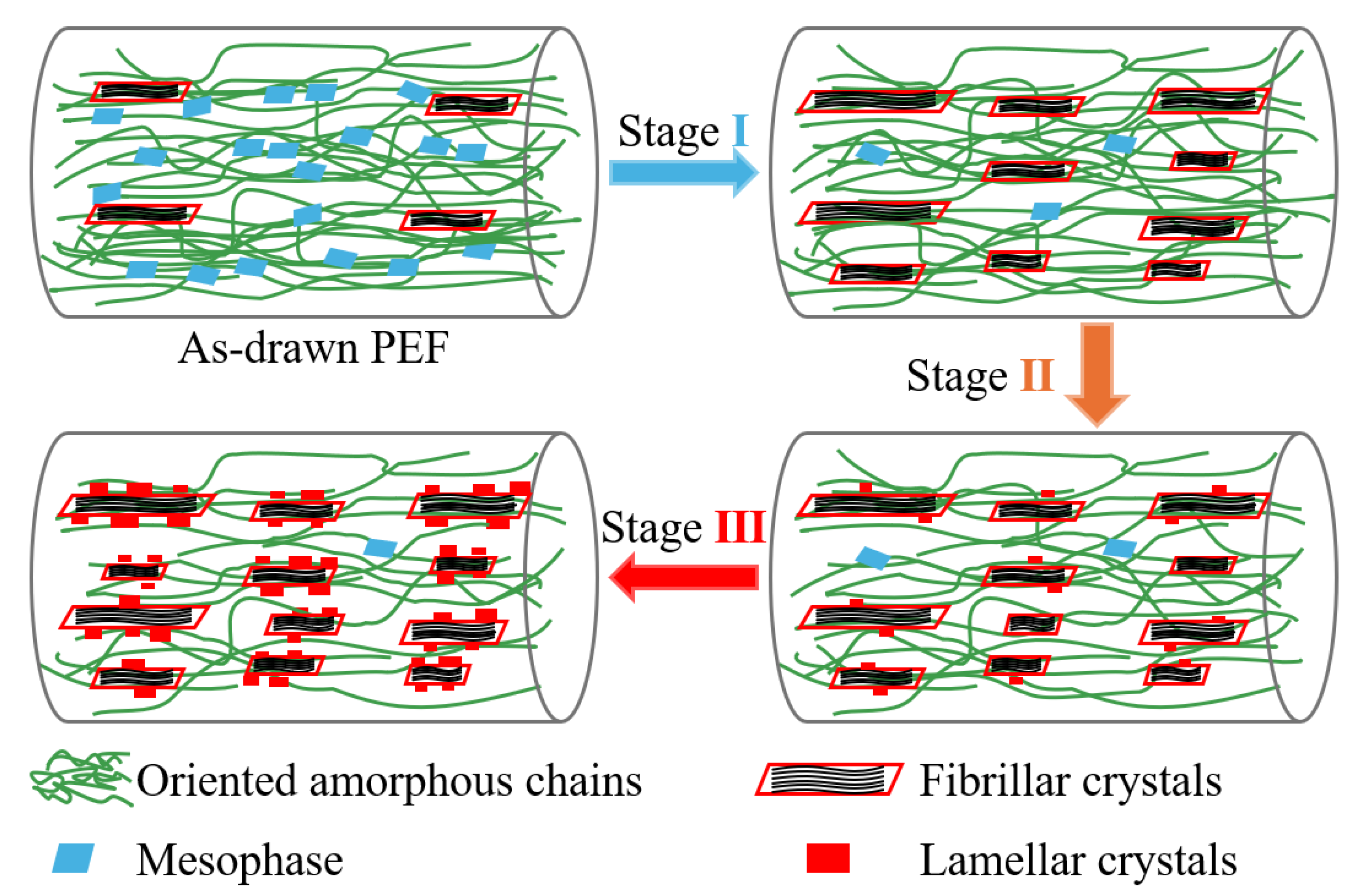

3.5. Structure Evolution Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sahu, P.; Thorbole, A.; Gupta, R.K. Polyesters Using Bioderived Furandicarboxylic Acid: Recent Advancement and Challenges toward Green PET. ACS Sustain. Chem. Eng. 2024, 12, 6811–6826. [Google Scholar] [CrossRef]

- Miah, M.R.; Dong, Y.; Wang, J.; Zhu, J. Recent Progress on Sustainable 2,5-Furandicarboxylate-Based Polyesters: Properties and Applications. ACS Sustain. Chem. Eng. 2024, 12, 2927–2961. [Google Scholar] [CrossRef]

- Fei, X.; Wang, J.; Zhu, J.; Wang, X.; Liu, X. Biobased Poly(ethylene 2,5-furancoate): No Longer an Alternative, but an Irreplaceable Polyester in the Polymer Industry. ACS Sustain. Chem. Eng. 2020, 8, 8471–8485. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Sousa, A.F.; Patrício, R.; Terzopoulou, Z.; Bikiaris, D.N.; Stern, T.; Wenger, J.; Loos, K.; Lotti, N.; Siracusa, V.; Szymczyk, A.; et al. Recommendations for replacing PET on packaging, fiber, and film materials with biobased counterparts. Green Chem. 2021, 23, 8795–8820. [Google Scholar] [CrossRef]

- Tzourtzouklis, I.; Kardasis, P.; Papageorgiou, G.Z.; Floudas, G. Phase Diagram, Glassy Dynamics and Crystallization Kinetics of the Biobased Polyester Poly(ethylene 2,5-furanoate) (PEF). Macromolecules 2024, 57, 11395–11406. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Nikolaidis, G.N.; Ioannidis, R.O.; Rinis, K.; Papageorgiou, D.G.; Klonos, P.A.; Achilias, D.S.; Kapnisti, M.; Terzopoulou, Z.; Bikiaris, D.N. A Step Forward in Thermoplastic Polyesters: Understanding the Crystallization and Melting of Biobased Poly(ethylene 2,5-furandicarboxylate) (PEF). ACS Sustain. Chem. Eng. 2022, 10, 7050–7064. [Google Scholar] [CrossRef]

- van Berkel, J.G.; Guigo, N.; Kolstad, J.J.; Sipos, L.; Wang, B.; Dam, M.A.; Sbirrazzuoli, N. Isothermal Crystallization Kinetics of Poly (Ethylene 2,5-Furandicarboxylate). Macromol. Mater. Eng. 2015, 300, 466–474. [Google Scholar] [CrossRef]

- Codou, A.; Guigo, N.; van Berkel, J.; de Jong, E.; Sbirrazzuoli, N. Non-isothermal Crystallization Kinetics of Biobased Poly(ethylene 2,5-furandicarboxylate) Synthesized via the Direct Esterification Process. Macromol. Chem. Phys. 2014, 215, 2065–2074. [Google Scholar] [CrossRef]

- Wu, J.; Xie, H.; Wu, L.; Li, B.-G.; Dubois, P. DBU-catalyzed biobased poly(ethylene 2,5-furandicarboxylate) polyester with rapid melt crystallization: Synthesis, crystallization kinetics and melting behavior. RSC Adv. 2016, 6, 101578–101586. [Google Scholar] [CrossRef]

- Xie, H.; Wu, L.; Li, B.-G.; Dubois, P. Poly(ethylene 2,5-furandicarboxylate-mb-poly(tetramethylene glycol)) multiblock copolymers: From high tough thermoplastics to elastomers. Polymer 2018, 155, 89–98. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, R.; Sousa, A.; Long, Y.; Ying, W.B.; Wang, J.; Zhu, J. Bio-based poly(butylene 2,5-furandicarboxylate)-b-poly(ethylene glycol) copolymers with adjustable degradation rate and mechanical properties: Synthesis and characterization. Eur. Polym. J. 2018, 106, 42–52. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Liu, S.; Wang, G. Biobased copolyesters: Synthesis, structure, thermal and mechanical properties of poly(ethylene 2,5-furandicarboxylate-co-ethylene 1,4-cyclohexanedicarboxylate). Polym. Degrad. Stab. 2018, 154, 96–102. [Google Scholar] [CrossRef]

- Wei, J.; Long, L.; Ye, B.; Li, Y.; Wang, Z. Unexpected enhancements of biobased poly(butylene 2,5-furandicarboxylate) by blending with biodegradable poly(ε-caprolactone). Mater. Lett. 2022, 313, 131753. [Google Scholar] [CrossRef]

- Liu, Y.; Qiu, Z. Enhanced melt crystallization of biobased Poly(ethylene 2,5-furandicarboxylate) by low loading of octavinyl-polyhedral oligomeric silsesquioxanes. Compos. Commun. 2020, 19, 20–24. [Google Scholar] [CrossRef]

- Klonos, P.A.; Papadopoulos, L.; Tzetzis, D.; Kyritsis, A.; Papageorgiou, G.Z.; Bikiaris, D.N. Thermal, nanoindentation and dielectric study of nanocomposites based on poly(propylene furanoate) and various inclusions. Mater. Today Commun. 2019, 20, 100585. [Google Scholar] [CrossRef]

- Martino, L.; Guigo, N.; van Berkel, J.G.; Sbirrazzuoli, N. Influence of organically modified montmorillonite and sepiolite clays on the physical properties of bio-based poly(ethylene 2,5-furandicarboxylate). Compos. Part B Eng. 2017, 110, 96–105. [Google Scholar] [CrossRef]

- Codou, A.; Guigo, N.; van Berkel, J.G.; de Jong, E.; Sbirrazzuoli, N. Preparation and crystallization behavior of poly(ethylene 2,5-furandicarboxylate)/cellulose composites by twin screw extrusion. Carbohydr. Polym. 2017, 174, 1026–1033. [Google Scholar] [CrossRef]

- Martino, L.; Niknam, V.; Guigo, N.; Gabriël van Berkel, J.; Sbirrazzuoli, N. Morphology and thermal properties of novel clay-based poly(ethylene 2,5-furandicarboxylate) (PEF) nanocomposites. RSC Adv. 2016, 6, 59800–59807. [Google Scholar] [CrossRef]

- Lotti, N.; Munari, A.; Gigli, M.; Gazzano, M.; Tsanaktsis, V.; Bikiaris, D.N.; Papageorgiou, G.Z. Thermal and structural response of in situ prepared biobased poly(ethylene 2,5-furan dicarboxylate) nanocomposites. Polymer 2016, 103, 288–298. [Google Scholar] [CrossRef]

- Kourtidou, D.; Grigora, M.-E.; Papadopoulos, L.; Tzetzis, D.; Bikiaris, D.N.; Chrissafis, K. Crystallization kinetics and nanomechanical behavior of biobased poly(ethylene 2,5-furandicarboxylate) reinforced with carbon nanotubes. Polym. Compos. 2023, 44, 632–649. [Google Scholar] [CrossRef]

- Long, L.; Ye, B.; Wei, J.; Wu, B.; Li, Y.; Wang, Z. Structure and enhanced mechanical properties of biobased poly(ethylene 2,5-furandicarboxylate) by incorporating with low loadings of talc platelets. Polymer 2021, 237, 124351. [Google Scholar] [CrossRef]

- Shao, Q.; Long, L.; Zhao, J.; Li, Y.; Wang, Z. Directional Epitaxy Intensifying Intermolecular =C–H···O=C Hydrogen Bonding to Expedite Bulk Crystallization of Biobased Poly(butylene 2,5-furandicarboxylate). Macromolecules 2024, 57, 3282–3294. [Google Scholar] [CrossRef]

- Shao, Q.; Long, L.; Zhao, J.; Li, Y.; Wang, Z. Accelerated nonisothermal crystallization and improved material properties of biobased poly(butylene 2,5-furandicarboxylate)/talc composites. Thermochim. Acta 2023, 730, 179618. [Google Scholar] [CrossRef]

- Albouy, P.-A.; Sotta, P. Draw Ratio at the Onset of Strain-Induced Crystallization in Cross-Linked Natural Rubber. Macromolecules 2020, 53, 992–1000. [Google Scholar] [CrossRef]

- Toki, S. 5—The effect of strain-induced crystallization (SIC) on the physical properties of natural rubber (NR). In Chemistry, Manufacture and Applications of Natural Rubber; Kohjiya, S., Ikeda, Y., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 135–167. [Google Scholar] [CrossRef]

- Larrañaga, A.; Lizundia, E. Chapter 15—Strain-Induced Crystallization. In Crystallization in Multiphase Polymer Systems; Thomas, S., Arif, P.M., Gowd, E.B., Kalarikkal, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 471–508. [Google Scholar] [CrossRef]

- Ma, J.; Yu, L.; Chen, S.; Chen, W.; Wang, Y.; Guang, S.; Zhang, X.; Lu, W.; Wang, Y.; Bao, J. Structure–Property Evolution of Poly(ethylene terephthalate) Fibers in Industrialized Process under Complex Coupling of Stress and Temperature Field. Macromolecules 2019, 52, 565–574. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, J.; Pan, P. Structural Evolutions of Initially Amorphous Polymers during Near-Tg Stretching: A Minireview of Recent Progresses. Macromol. Chem. Phys. 2022, 223, 2100427. [Google Scholar] [CrossRef]

- Billimoria, K.; Heeley, E.L.; Parsons, N.; Figiel, Ł. An investigation into the crystalline morphology transitions in poly-L-lactic acid (PLLA) under uniaxial deformation in the quasi-solid-state regime. Eur. Polym. J. 2018, 101, 127–139. [Google Scholar] [CrossRef]

- Stoclet, G.; Seguela, R.; Lefebvre, J.M.; Rochas, C. New Insights on the Strain-Induced Mesophase of Poly(d,l-lactide): In Situ WAXS and DSC Study of the Thermo-Mechanical Stability. Macromolecules 2010, 43, 7228–7237. [Google Scholar] [CrossRef]

- Billon, N. Development of order during strain induced crystallization of polymers, case of PET. Polymer 2022, 262, 125476. [Google Scholar] [CrossRef]

- Ran, S.; Wang, Z.; Burger, C.; Chu, B.; Hsiao, B.S. Mesophase as the Precursor for Strain-Induced Crystallization in Amorphous Poly(ethylene terephthalate) Film. Macromolecules 2002, 35, 10102–10107. [Google Scholar] [CrossRef]

- Keum, J.K.; Kim, J.; Lee, S.M.; Song, H.H.; Son, Y.-K.; Choi, J.-I.; Im, S.S. Crystallization and Transient Mesophase Structure in Cold-Drawn PET Fibers. Macromolecules 2003, 36, 9873–9878. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, K.; Pei, L.; Shi, J.; Chen, W. Effect of drawing and heat-setting process on aggregate structure of Poly(ethylene terephthalate) industrial fiber in large-scale spinning production. J. Polym. Sci. 2024, 62, 3929–3946. [Google Scholar] [CrossRef]

- Lee, K.G.; Schultz, J.M. The development of structure and mechanical properties in poly(ethylene terephthalate) fibres during heat treatment under stress. Polymer 1993, 34, 4455–4470. [Google Scholar] [CrossRef]

- Liu, Y.; Yin, L.; Zhao, H.; Song, G.; Tang, F.; Wang, L.; Shao, H.; Zhang, Y. Lamellar and fibrillar structure evolution of poly(ethylene terephthalate) fiber in thermal annealing. Polymer 2016, 105, 157–166. [Google Scholar] [CrossRef]

- Li, Y.; Shen, H.; Wang, S.; Zhang, H.; Hu, J.; Xin, R.; Yan, S. Structure evolution of amorphous poly(d-lactic acid) on highly oriented poly(l-lactic acid) film during annealing. Polymer 2023, 280, 126037. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Li, M.; Cao, W.; Liu, C.; Shen, C. Spectroscopic analysis of post drawing relaxation in poly(lactic acid) with oriented mesophase. Polym. Test. 2015, 43, 103–107. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Wang, K.; Shao, C.; Li, Q.; Shen, C. Unusual structural evolution of poly(lactic acid) upon annealing in the presence of an initially oriented mesophase. Soft Matter 2014, 10, 1512–1518. [Google Scholar] [CrossRef]

- Stoclet, G.; Lefebvre, J.M.; Yeniad, B.; Gobius du Sart, G.; de Vos, S. On the strain-induced structural evolution of Poly(ethylene-2,5-furanoate) upon uniaxial stretching: An in-situ SAXS-WAXS study. Polymer 2018, 134, 227–241. [Google Scholar] [CrossRef]

- Mao, Y.; Bucknall, D.G.; Kriegel, R.M. Synchrotron X-ray scattering study on amorphous poly(ethylene furanoate) under uniaxial deformation. Polymer 2018, 139, 60–67. [Google Scholar] [CrossRef]

- Forestier, E.; Combeaud, C.; Guigo, N.; Monge, G.; Haudin, J.-M.; Sbirrazzuoli, N.; Billon, N. Strain-induced crystallization of poly(ethylene 2,5-furandicarboxylate). Mechanical and crystallographic analysis. Polymer 2020, 187, 122126. [Google Scholar] [CrossRef]

- Forestier, E.; Combeaud, C.; Guigo, N.; Sbirrazzuoli, N.; Billon, N. Understanding of strain-induced crystallization developments scenarios for polyesters: Comparison of poly(ethylene furanoate), PEF, and poly(ethylene terephthalate), PET. Polymer 2020, 203, 122755. [Google Scholar] [CrossRef]

- Forestier, E.; Guigo, N.; Combeaud, C.; Billon, N.; Sbirrazzuoli, N. Conformational Change Analysis of Poly(ethylene 2,5-furandicarboxylate) and Poly(ethylene terephthalate) under Uniaxial Stretching. Macromolecules 2020, 53, 8693–8703. [Google Scholar] [CrossRef]

- Forestier, E.; Combeaud, C.; Guigo, N.; Sbirrazzuoli, N.; Monge, G.; Haudin, J.-M. Poly(ethylene 2,5-furandicarboxylate) pole figures to determine the microstructural scheme upon uniaxial stretching: Link between orientation and crystallisation. Polymer 2024, 312, 127613. [Google Scholar] [CrossRef]

- Forestier, E.; Combeaud, C.; Guigo, N.; Sbirrazzuoli, N. A proposal for enhanced microstructural development of Poly(ethylene 2,5-furandicarboxylate), PEF, upon stretching: On strain-induced crystallization and amorphous phase stability improvement. Polymer 2022, 246, 124775. [Google Scholar] [CrossRef]

- Forestier, E.; Combeaud, C.; Guigo, N.; Corvec, G.; Pradille, C.; Sbirrazzuoli, N.; Billon, N. Comparative Analysis of the Mechanical Behaviour of PEF and PET Uniaxial Stretching Based on the Time/Temperature Superposition Principle. Polymers 2021, 13, 3295. [Google Scholar] [CrossRef]

- Menager, C.; Guigo, N.; Martino, L.; Sbirrazzuoli, N.; Visser, H.; Boyer, S.A.E.; Billon, N.; Monge, G.; Combeaud, C. Strain induced crystallization in biobased Poly(ethylene 2,5-furandicarboxylate) (PEF); conditions for appearance and microstructure analysis. Polymer 2018, 158, 364–371. [Google Scholar] [CrossRef]

- Perret, E.; Hufenus, R. Insights into strain-induced solid mesophases in melt-spun polymer fibers. Polymer 2021, 229, 124010. [Google Scholar] [CrossRef]

- Li, Y.; Duan, T.; Yao, G.; Tang, Y.; Miao, W.; Wang, Z. Structural evolution of stretch deformed HDPE/RGO nanocomposites: An in-situ synchrotron SAXS and WAXD study. Compos. Sci. Technol. 2019, 183, 107798. [Google Scholar] [CrossRef]

- Mao, Y.; Kriegel, R.M.; Bucknall, D.G. The crystal structure of poly(ethylene furanoate). Polymer 2016, 102, 308–314. [Google Scholar] [CrossRef]

- Hong, K.; Strobl, G. Network Stretching during Tensile Drawing of Polyethylene: A Study Using X-ray Scattering and Microscopy. Macromolecules 2006, 39, 268–273. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Tsanaktsis, V.; Bikiaris, D.N. Synthesis of poly(ethylene furandicarboxylate) polyester using monomers derived from renewable resources: Thermal behavior comparison with PET and PEN. Phys. Chem. Chem. Phys. 2014, 16, 7946–7958. [Google Scholar] [CrossRef] [PubMed]

- Araujo, C.F.; Nolasco, M.M.; Ribeiro-Claro, P.J.A.; Rudić, S.; Silvestre, A.J.D.; Vaz, P.D.; Sousa, A.F. Inside PEF: Chain Conformation and Dynamics in Crystalline and Amorphous Domains. Macromolecules 2018, 51, 3515–3526. [Google Scholar] [CrossRef]

- Ye, B.; Shao, Q.; Long, L.; Wu, B.; Liu, Z.; Li, Y.; Wang, Z. Intermolecular =C–H···O=C Hydrogen Bonding and Conformational Preference in Crystalline Poly(butylene 2,5-furandicarboxylate). Macromolecules 2023, 56, 3595–3606. [Google Scholar] [CrossRef]

- Burgess, S.K.; Leisen, J.E.; Kraftschik, B.E.; Mubarak, C.R.; Kriegel, R.M.; Koros, W.J. Chain Mobility, Thermal, and Mechanical Properties of Poly(ethylene furanoate) Compared to Poly(ethylene terephthalate). Macromolecules 2014, 47, 1383–1391. [Google Scholar] [CrossRef]

- Murthy, N.S.; Minor, H.; Bednarczyk, C.; Krimm, S. Structure of the amorphous phase in oriented polymers. Macromolecules 1993, 26, 1712–1721. [Google Scholar] [CrossRef]

| Samples | Tcco (°C) | Tccp (°C) | ΔHcc (J/g) | Xcc (%) * | Tm (°C) | ΔHm (J/g) | Xm (%) * | ΔX (%) |

|---|---|---|---|---|---|---|---|---|

| As-injected | 163.8 | 183.5 | −8.5 | 6.2 | 214.6 | 9.4 | 6.9 | 0.7 |

| As-drawn | 105.9 | 127.8 | −30.6 | 22.3 | 216.4 | 44.2 | 32.3 | 9.9 |

| D + PH | - | - | - | - | 214.5/216.1 | 52.9 | 38.6 | 38.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Yang, M.; Wu, B.; Li, H.; Li, Y. In Situ Following Oriented Crystallization of Pre-Stretched Poly(ethylene 2,5-Furandicarboxylate) Under Post Heating. Polymers 2025, 17, 1508. https://doi.org/10.3390/polym17111508

Zhao J, Yang M, Wu B, Li H, Li Y. In Situ Following Oriented Crystallization of Pre-Stretched Poly(ethylene 2,5-Furandicarboxylate) Under Post Heating. Polymers. 2025; 17(11):1508. https://doi.org/10.3390/polym17111508

Chicago/Turabian StyleZhao, Jianguo, Mengcheng Yang, Binhang Wu, Hang Li, and Yiguo Li. 2025. "In Situ Following Oriented Crystallization of Pre-Stretched Poly(ethylene 2,5-Furandicarboxylate) Under Post Heating" Polymers 17, no. 11: 1508. https://doi.org/10.3390/polym17111508

APA StyleZhao, J., Yang, M., Wu, B., Li, H., & Li, Y. (2025). In Situ Following Oriented Crystallization of Pre-Stretched Poly(ethylene 2,5-Furandicarboxylate) Under Post Heating. Polymers, 17(11), 1508. https://doi.org/10.3390/polym17111508