Transparent and Efficient Wood-Based Triboelectric Nanogenerators for Energy Harvesting and Self-Powered Sensing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

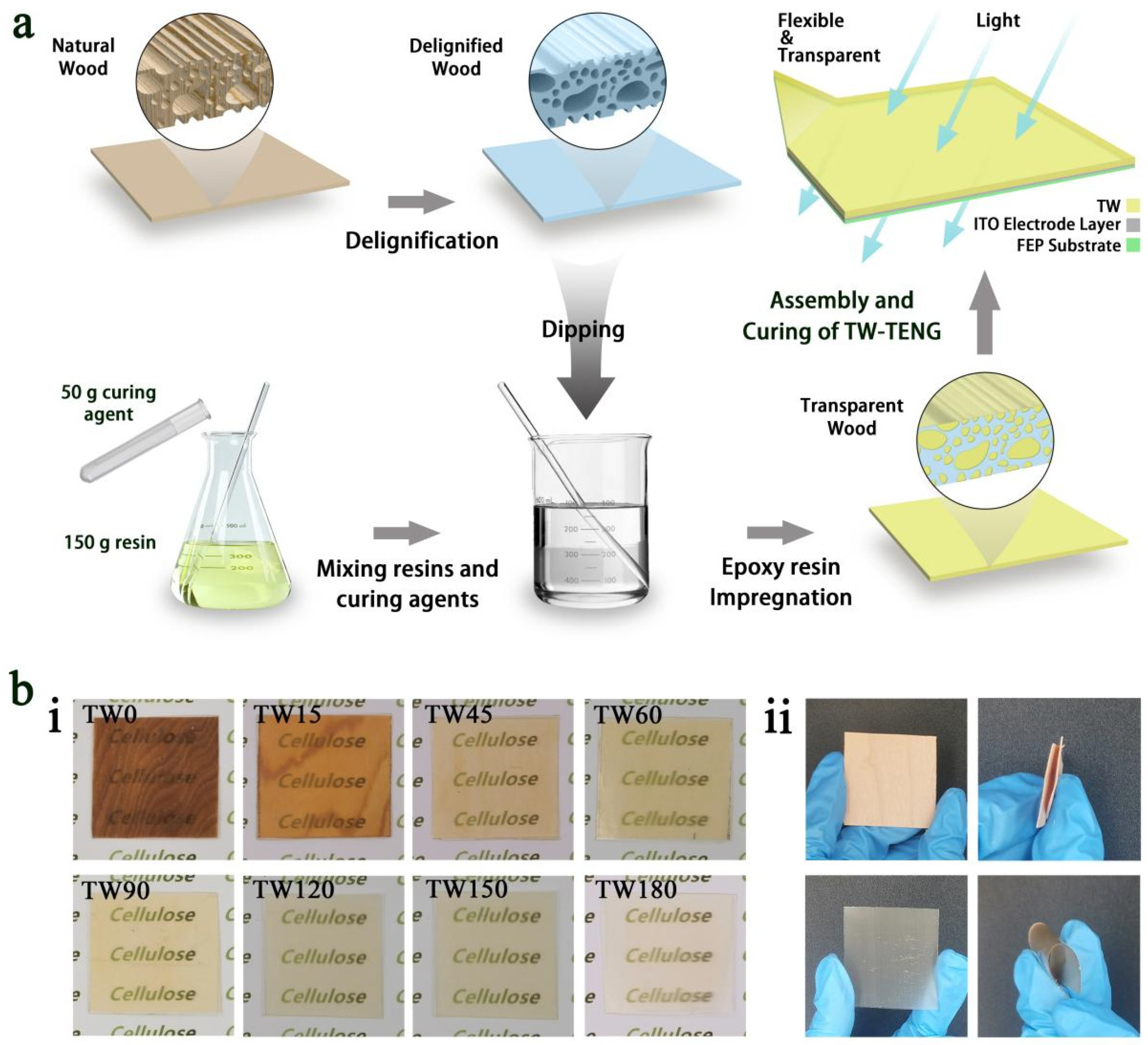

2.2. Fabrication of TW-TENG

2.3. Scanning Electron Microscopy

2.4. Fourier-Transform Infrared Analysis

2.5. Chemical Composition Content Analysis

2.6. Optical Properties

2.7. Mechanical Properties

2.8. Electrical Output Performance

3. Results and Discussion

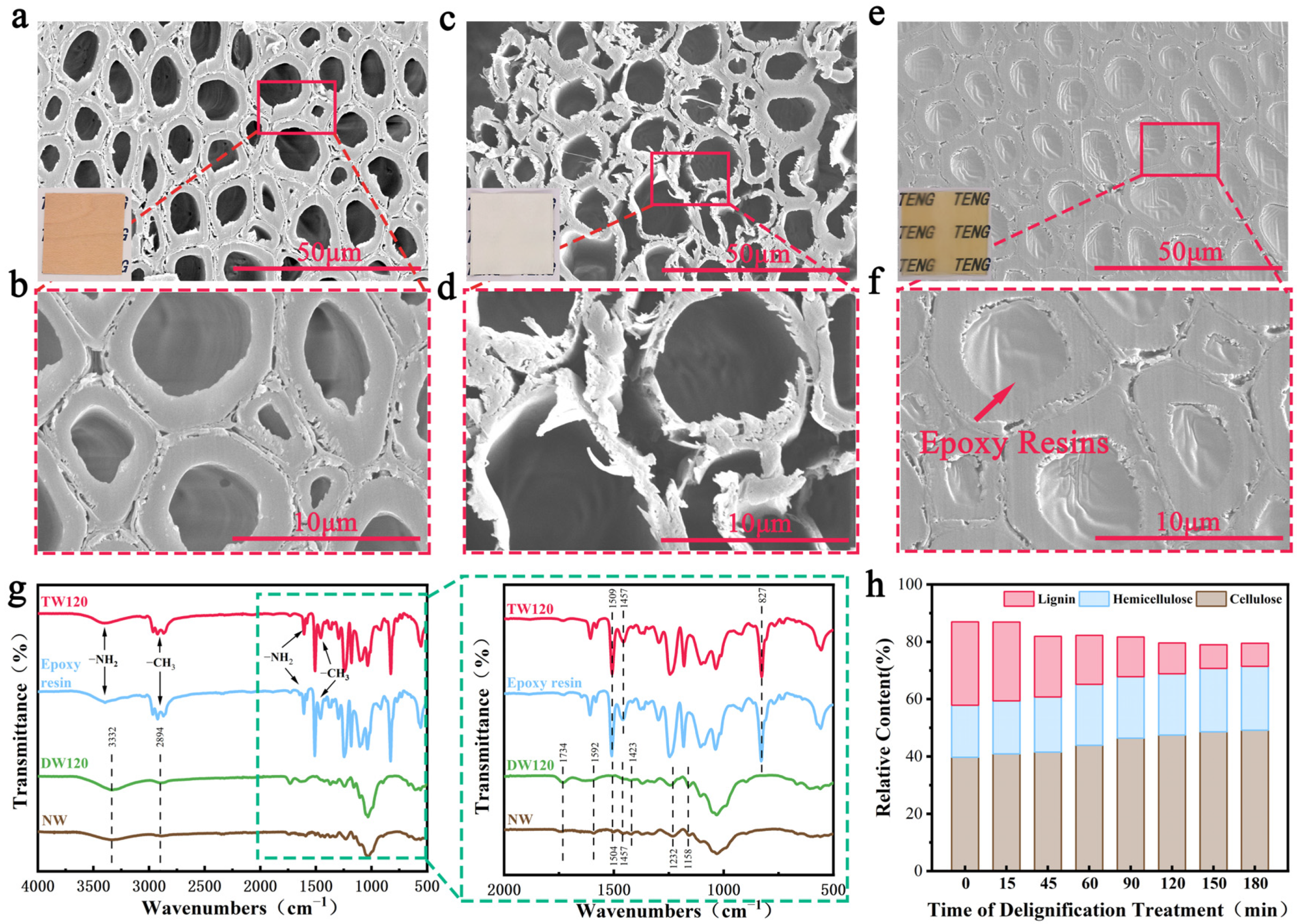

3.1. Scanning Electron Microscopy

3.2. Fourier-Transform Infrared Analysis

3.3. Chemical Composition Content Analysis

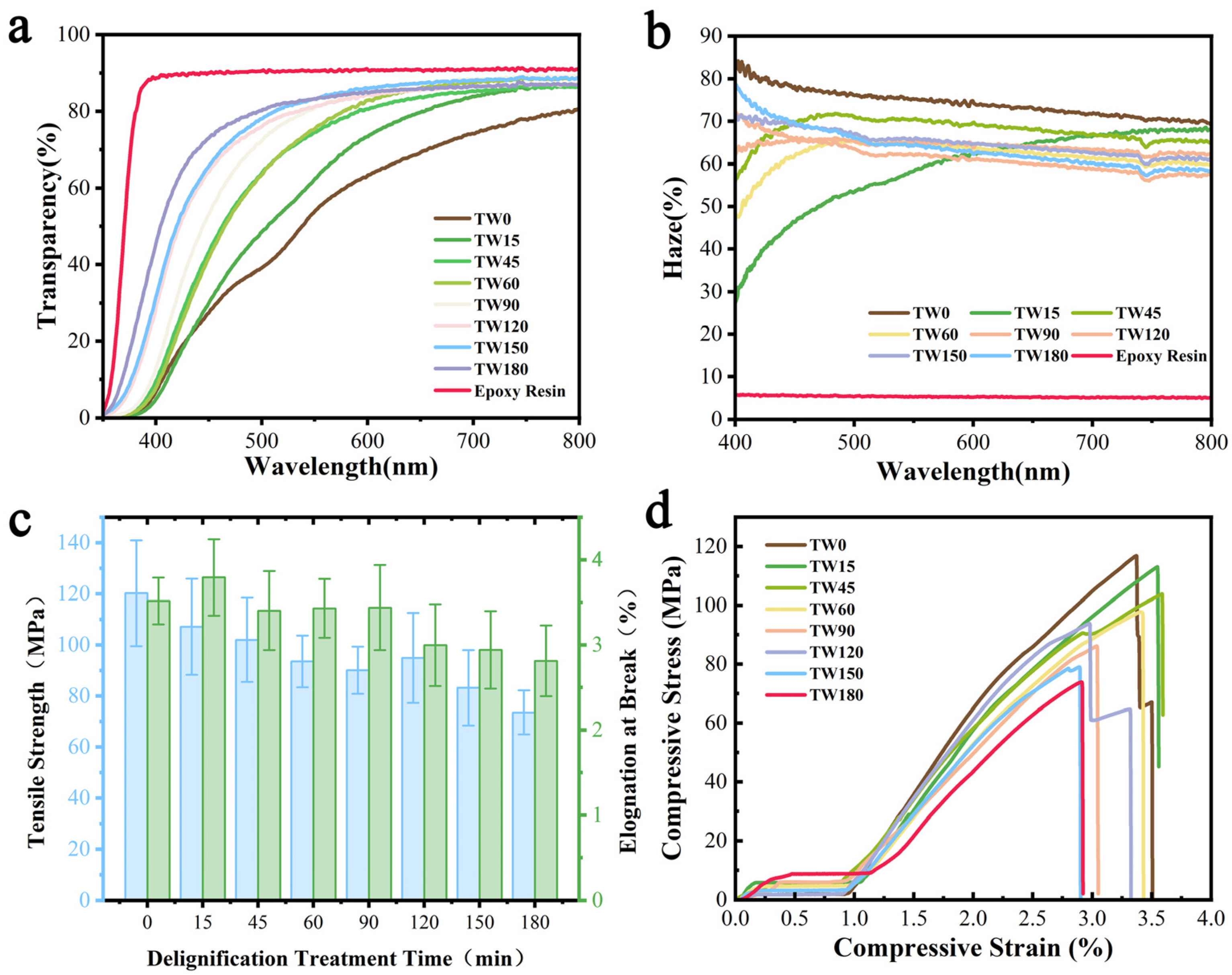

3.4. Optical Properties

3.5. Mechanical Properties

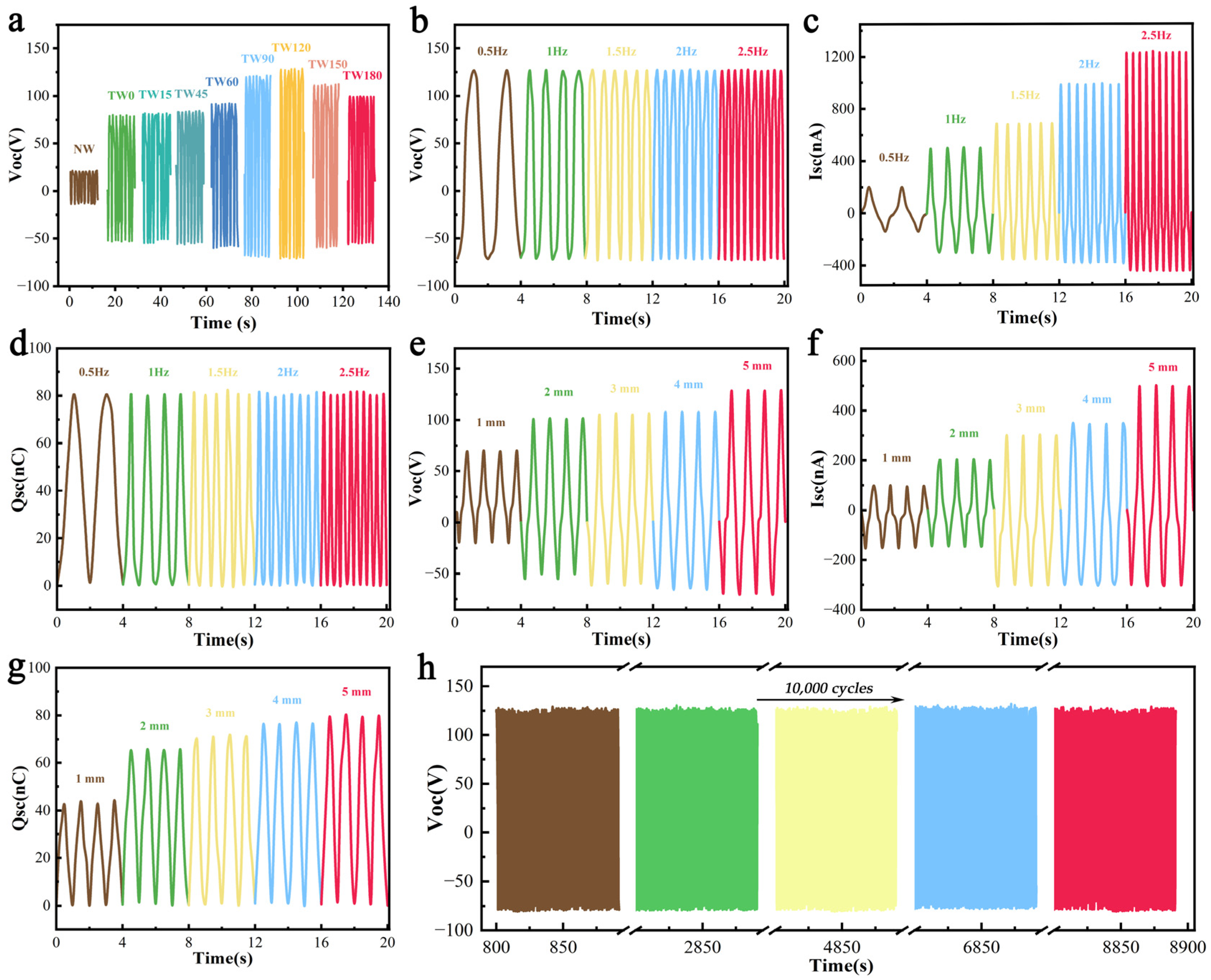

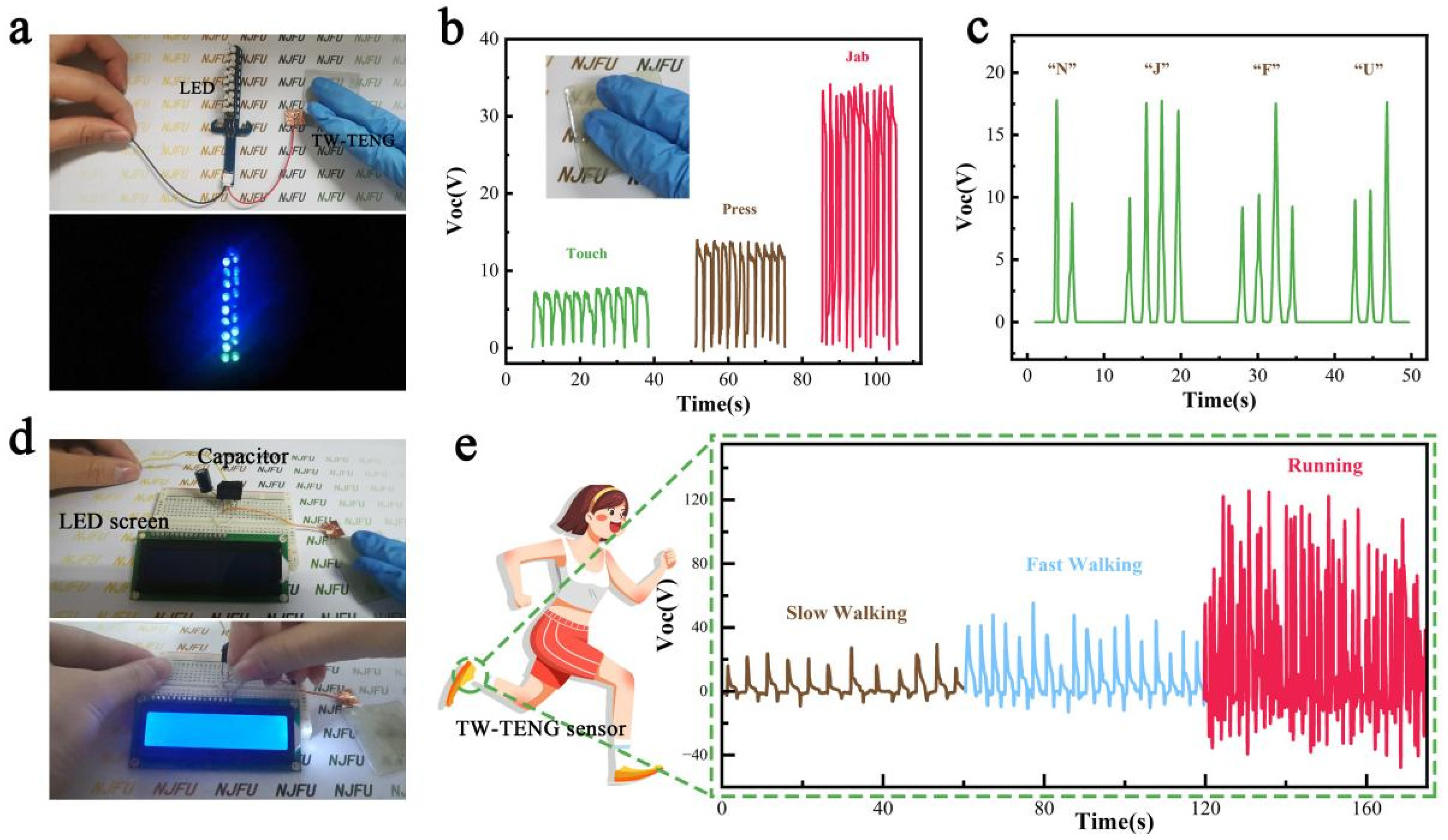

3.6. Electrical Output Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Abbasi, T.; Abbasi, S.A. Decarbonization of fossil fuels as a strategy to control global warming. Renew. Sustain. Energy Rev. 2011, 15, 1828–1834. [Google Scholar] [CrossRef]

- Gargallo, P.; Lample, L.; Miguel, J.; Salvador, M. Dynamic comparison of portfolio risk: Clean vs. dirty energy. Financ. Res. Lett. 2022, 47, 102957. [Google Scholar] [CrossRef]

- Yuan, J.S.; Tiller, K.H.; Al-Ahmad, H.; Stewart, N.R.; Stewart, C.N., Jr. Plants to power: Bioenergy to fuel the future. Trends Plant Sci. 2008, 13, 421–429. [Google Scholar] [CrossRef] [PubMed]

- Iyke, B.N. Climate change, energy security risk, and clean energy investment. Energy Econ. 2024, 129, 107225. [Google Scholar] [CrossRef]

- Lei, B.; Feng, Y. Sustainable thermoplastic bio-based materials from sisal fibers. J. Clean. Prod. 2020, 265, 121631. [Google Scholar] [CrossRef]

- Wu, X.; Kong, Z.; Yao, X.; Gan, J.; Zhan, X.; Wu, Y. Transparent wood with self-cleaning properties for next-generation smart photovoltaic panels. Appl. Surf. Sci. 2023, 613, 155927. [Google Scholar] [CrossRef]

- Mao, Y.; Hu, L.; Ren, Z.J. Engineered wood for a sustainable future. Matter 2022, 5, 1326–1329. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure-property-function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Chen, C.; Berglund, L.; Burgert, I.; Hu, L. Wood Nanomaterials and Nanotechnologies. Adv. Mater. 2021, 33, 2006207. [Google Scholar] [CrossRef]

- Hu, X.; Yu, R.; Wang, F.; Liu, Z.; Yang, H.; Chen, C.; Li, Y.; Noor, N.; Fei, B. Fabrication, Functionalities and Applications of Transparent Wood: A Review. Adv. Funct. Mater. 2023, 33, 2303278. [Google Scholar] [CrossRef]

- Zhou, T.; Zhou, J.; Feng, Q.; Yang, Q.; Jin, Y.; Li, D.; Xu, Z.; Chen, C. Mechanically strong, hydrostable, and biodegradable all-biobased transparent wood films with UV-blocking performance. Int. J. Biol. Macromol. 2024, 255, 128188. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Liu, S.; Li, Y.; Chen, X.; Ho, T.C.; Chao, L.C.; Tso, C.Y. Perovskite-Coated Thermochromic Transparent Wood: A Novel Material for Smart Windows in Energy-Efficient and Sustainable Buildings. ACS Appl. Mater. Interfaces 2023, 15, 49665–49677. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Sanchez-Rodriguez, D.; Kamo, T. A comprehensive study on the oxidative pyrolysis of epoxy resin from fiber/epoxy composites: Product characteristics and kinetics. J. Hazard. Mater. 2021, 412, 125329. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-F.; Xiao, Y.-F.; Luo, X.; Liu, B.-W.; Guo, D.-M.; Chen, L.; Wang, Y.-Z. Flame-Retardant multifunctional epoxy resin with high performances. Chem. Eng. J. 2022, 427, 132031. [Google Scholar] [CrossRef]

- Capricho, J.C.; Fox, B.; Hameed, N. Multifunctionality in Epoxy Resins. Polym. Rev. 2019, 60, 1–41. [Google Scholar] [CrossRef]

- Wu, H.; Wang, Z.; Zhu, B.; Wang, H.; Lu, C.; Kang, M.; Kang, S.; Ding, W.; Yang, L.; Liao, R.; et al. All-in-One Sensing System for Online Vibration Monitoring via IR Wireless Communication as Driven by High-Power TENG. Adv. Energy Mater. 2023, 13, 2300051. [Google Scholar] [CrossRef]

- Shan, C.; Liu, W.; Wang, Z.; Pu, X.; He, W.; Tang, Q.; Fu, S.; Li, G.; Long, L.; Guo, H.; et al. An inverting TENG to realize the AC mode based on the coupling of triboelectrification and air-breakdown. Energy Environ. Sci. 2021, 14, 5395–5405. [Google Scholar] [CrossRef]

- Xi, Y.; Guo, H.; Zi, Y.; Li, X.; Wang, J.; Deng, J.; Li, S.; Hu, C.; Cao, X.; Wang, Z.L. Multifunctional TENG for Blue Energy Scavenging and Self-Powered Wind-Speed Sensor. Adv. Energy Mater. 2017, 7, 1602397. [Google Scholar] [CrossRef]

- Shi, X.; Luo, J.; Luo, J.; Li, X.; Han, K.; Li, D.; Cao, X.; Wang, Z.L. Flexible Wood-Based Triboelectric Self-Powered Smart Home System. ACS Nano 2022, 16, 3341–3350. [Google Scholar] [CrossRef]

- Shan, C.; He, W.; Wu, H.; Fu, S.; Tang, Q.; Wang, Z.; Du, Y.; Wang, J.; Guo, H.; Hu, C. A High-Performance Bidirectional Direct Current TENG by Triboelectrification of Two Dielectrics and Local Corona Discharge. Adv. Energy Mater. 2022, 12, 2200963. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerator (TENG)—Sparking an Energy and Sensor Revolution. Adv. Energy Mater. 2020, 10, 2000137. [Google Scholar] [CrossRef]

- Wang, C.; Guo, H.; Wang, P.; Li, J.; Sun, Y.; Zhang, D. An Advanced Strategy to Enhance TENG Output: Reducing Triboelectric Charge Decay. Adv. Mater. 2023, 35, 2209895. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Wang, T.; Wei, Y.; Sun, X.; Zhang, S.; Wang, X.; Luo, L. Low-cost, environmentally friendly and high-performance cellulose-based triboelectric nanogenerator for self-powered human motion monitoring. Cellulose 2022, 29, 8733–8747. [Google Scholar] [CrossRef]

- Guan, H.; Meng, J.; Cheng, Z.; Wang, X. Processing Natural Wood into a High-Performance Flexible Pressure Sensor. ACS Appl. Mater. Interfaces 2020, 12, 46357–46365. [Google Scholar] [CrossRef]

- Sun, J.; Tu, K.; Büchele, S.; Koch, S.M.; Ding, Y.; Ramakrishna, S.N.; Stucki, S.; Guo, H.; Wu, C.; Keplinger, T.; et al. Functionalized wood with tunable tribopolarity for efficient triboelectric nanogenerators. Matter 2021, 4, 3049–3066. [Google Scholar] [CrossRef]

- Hao, S.; Jiao, J.; Chen, Y.; Wang, Z.L.; Cao, X. Natural wood-based triboelectric nanogenerator as self-powered sensing for smart homes and floors. Nano Energy 2020, 75, 104957. [Google Scholar] [CrossRef]

- Sun, J.; Schütz, U.; Tu, K.; Koch, S.M.; Roman, G.; Stucki, S.; Chen, F.; Ding, Y.; Yan, W.; Wu, C.; et al. Scalable and sustainable wood for efficient mechanical energy conversion in buildings via triboelectric effects. Nano Energy 2022, 102, 107670. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.; Xu, L.; Wang, A.C.; Han, K.; Jiang, T.; Lai, Q.; Bai, Y.; Tang, W.; Fan, F.R.; et al. Flexible and durable wood-based triboelectric nanogenerators for self-powered sensing in athletic big data analytics. Nat. Commun. 2019, 10, 5147. [Google Scholar] [CrossRef]

- Liao, J.; Wang, Y.; Shi, S.; Liu, C.; Sun, Q.; Shen, X. Flexible wood-based triboelectric nanogenerator for versatile self-powered sensing. Sustain. Mater. Technol. 2023, 38, e00771. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Qu, Y.; Zhang, J. Selective removal of lignin with sodium chlorite to improve the quality and antioxidant activity of xylo-oligosaccharides from lignocellulosic biomass. Bioresour. Technol. 2021, 337, 125506. [Google Scholar] [CrossRef]

- Xia, R.; Zhang, W.; Yang, Y.; Zhao, J.; Liu, Y.; Guo, H. Transparent wood with phase change heat storage as novel green energy storage composites for building energy conservation. J. Clean. Prod. 2021, 296, 126598. [Google Scholar] [CrossRef]

- Gan, J.; Wu, Y.; Yang, F.; Wu, X.; Wang, Y.; Wang, J. UV-Filtering Cellulose Nanocrystal/Carbon Quantum Dot Composite Films for Light Conversion in Glass Windows. ACS Appl. Nano Mater. 2021, 4, 12552–12560. [Google Scholar] [CrossRef]

- Zhu, M.; Jia, C.; Wang, Y.; Fang, Z.; Dai, J.; Xu, L.; Huang, D.; Wu, J.; Li, Y.; Song, J.; et al. Isotropic Paper Directly from Anisotropic Wood: Top-Down Green Transparent Substrate Toward Biodegradable Electronics. ACS Appl. Mater. Interfaces 2018, 10, 28566–28571. [Google Scholar] [CrossRef] [PubMed]

- Mi, X.; Liang, N.; Xu, H.; Wu, J.; Jiang, Y.; Nie, B.; Zhang, D. Toughness and its mechanisms in epoxy resins. Prog. Mater. Sci. 2022, 130, 100977. [Google Scholar] [CrossRef]

- Bi, Z.; Li, T.; Su, H.; Ni, Y.; Yan, L. Transparent Wood Film Incorporating Carbon Dots as Encapsulating Material for White Light-Emitting Diodes. ACS Sustain. Chem. Eng. 2018, 6, 9314–9323. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Wu, Y.; Zhao, W. A Multilayer Transparent Bamboo with Good Optical Properties and UV Shielding Prepared by Different Lamination Methods. ACS Sustain. Chem. Eng. 2022, 10, 6106–6116. [Google Scholar] [CrossRef]

- Vidil, T.; Tournilhac, F.; Musso, S.; Robisson, A.; Leibler, L. Control of reactions and network structures of epoxy thermosets. Prog. Polym. Sci. 2016, 62, 126–179. [Google Scholar] [CrossRef]

- Zhang, K.; Zhu, L.; Li, H.; Zheng, M.; Zhang, J.; Zheng, Y.; Zheng, R. From Corn Husks to Scalable, Strong, Transparent Bio-Plastic Using Direct Delignification-Splicing Strategy. Adv. Sustain. Syst. 2022, 6, 2100495. [Google Scholar] [CrossRef]

- Chen, Q.; Li, W.; Yan, F.; Maniar, D.; van Dijken, J.; Rudolf, P.; Pei, Y.; Loos, K. Lightweight Triboelectric Nanogenerators Based on Hollow Stellate Cellulose Films Derived from Juncus effusus L. Aerenchyma. Adv. Funct. Mater. 2023, 33, 2304801. [Google Scholar] [CrossRef]

- Babu, A.; Aazem, I.; Walden, R.; Bairagi, S.; Mulvihill, D.M.; Pillai, S.C. Electrospun nanofiber based TENGs for wearable electronics and self-powered sensing. Chem. Eng. J. 2023, 452, 139060. [Google Scholar] [CrossRef]

- Prasad, G.; Yoon, J.U.; Woo, I.; Bae, J.W. Fabrication of amino and fluorine functionalized graphene-based polymer composites to enhance the electromechanical conversion efficiency of TENGs for energy-harvesting applications. Chem. Eng. J. 2023, 470, 144280. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.; Zhu, J.Y.; Ragauskas, A.J.; Hu, L. In Situ Wood Delignification toward Sustainable Applications. Acc. Mater. Res. 2021, 2, 606–620. [Google Scholar] [CrossRef]

- Feng, L.; Liu, G.; Guo, H.; Tang, Q.; Pu, X.; Chen, J.; Wang, X.; Xi, Y.; Hu, C. Hybridized nanogenerator based on honeycomb-like three electrodes for efficient ocean wave energy harvesting. Nano Energy 2018, 47, 217–223. [Google Scholar] [CrossRef]

- Yuan, M.; Yao, W.; Ding, Z.; Li, J.; Dai, B.; Zhang, X.; Xie, Y. Integrated acoustic metamaterial triboelectric nanogenerator for joint low-frequency acoustic insulation and energy harvesting. Nano Energy 2024, 122, 109328. [Google Scholar] [CrossRef]

- Zhao, D.; Yu, X.; Wang, J.; Gao, Q.; Wang, Z.; Cheng, T.; Wang, Z.L. A standard for normalizing the outputs of triboelectric nanogenerators in various modes. Energy Environ. Sci. 2022, 15, 3901–3911. [Google Scholar] [CrossRef]

- Edith Navarro-Segura, M.; Sánchez-Domínguez, M.; Arizmendi-Morquecho, A.; Alvarez-Quintana, J. Triboelectric nanogenerator based on electrodeposited Ag octahedral nano-assemblies. J. Energy Chem. 2023, 83, 478–495. [Google Scholar] [CrossRef]

- Xu, S.; Zhao, H.; Li, Q.; Zhang, R.; Gao, S.; Wang, F.; Li, G.; Chen, B.; Yu, H.; Liu, S.; et al. Multi-dimensional, transparent and foldable cellulose-based triboelectric nanogenerator for touching password recognition. Nano Energy 2022, 98, 107307. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, T.; Cao, K.; Jing, Y.; Wang, H.; Wu, Y. Transparent and Efficient Wood-Based Triboelectric Nanogenerators for Energy Harvesting and Self-Powered Sensing. Polymers 2024, 16, 1208. https://doi.org/10.3390/polym16091208

Cheng T, Cao K, Jing Y, Wang H, Wu Y. Transparent and Efficient Wood-Based Triboelectric Nanogenerators for Energy Harvesting and Self-Powered Sensing. Polymers. 2024; 16(9):1208. https://doi.org/10.3390/polym16091208

Chicago/Turabian StyleCheng, Ting, Kunli Cao, Yidan Jing, Hongyan Wang, and Yan Wu. 2024. "Transparent and Efficient Wood-Based Triboelectric Nanogenerators for Energy Harvesting and Self-Powered Sensing" Polymers 16, no. 9: 1208. https://doi.org/10.3390/polym16091208

APA StyleCheng, T., Cao, K., Jing, Y., Wang, H., & Wu, Y. (2024). Transparent and Efficient Wood-Based Triboelectric Nanogenerators for Energy Harvesting and Self-Powered Sensing. Polymers, 16(9), 1208. https://doi.org/10.3390/polym16091208