Efficient Synthesis of Fe3O4/PPy Double-Carbonized Core-Shell-like Composites for Broadband Electromagnetic Wave Absorption

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Materials

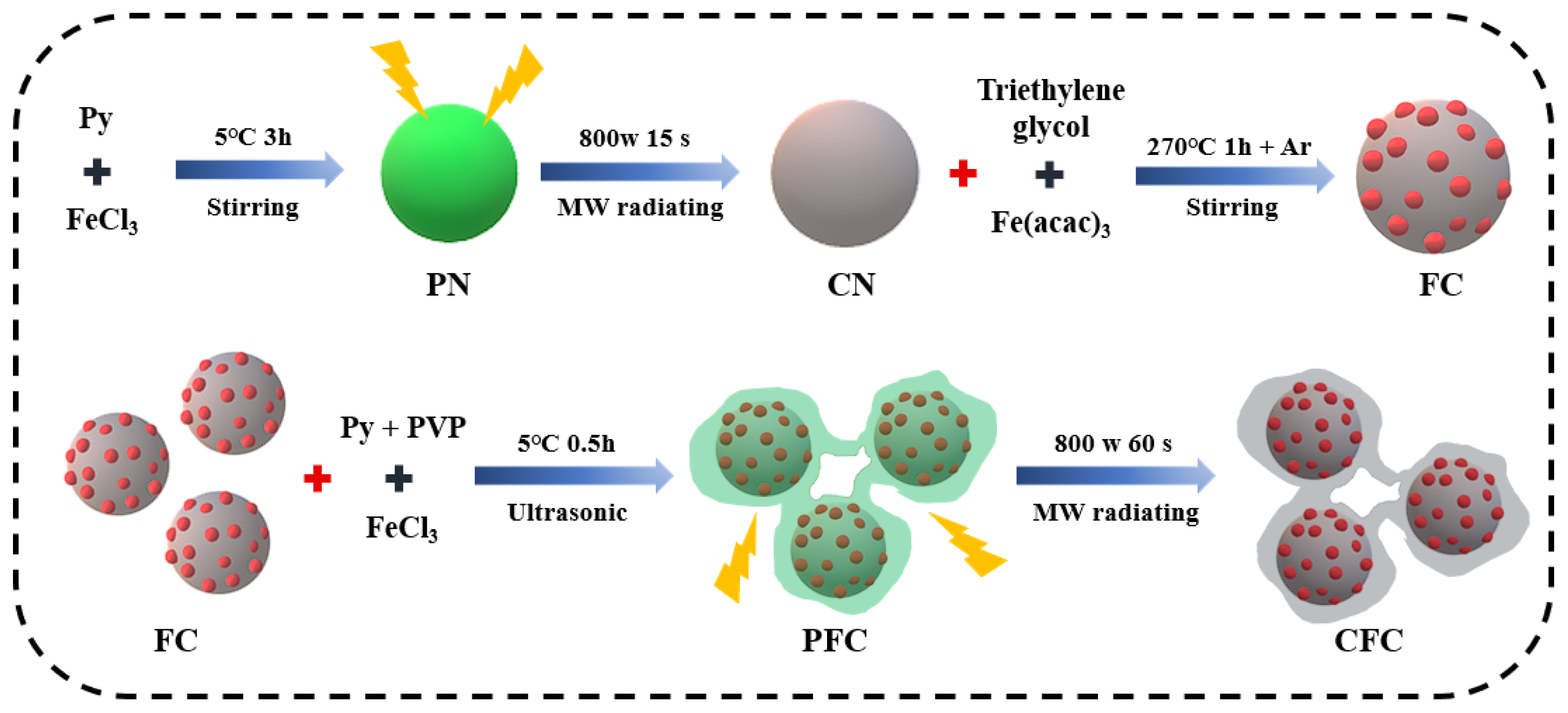

2.2. Preparation of the Carbonized PPy Nanospheres (CNs)

2.3. Preparation of the Functionalized CN (FC)

2.4. Preparation of Double-Carbonized FC (CFC)

2.5. Characterization and Measurements

3. Results and Discussion

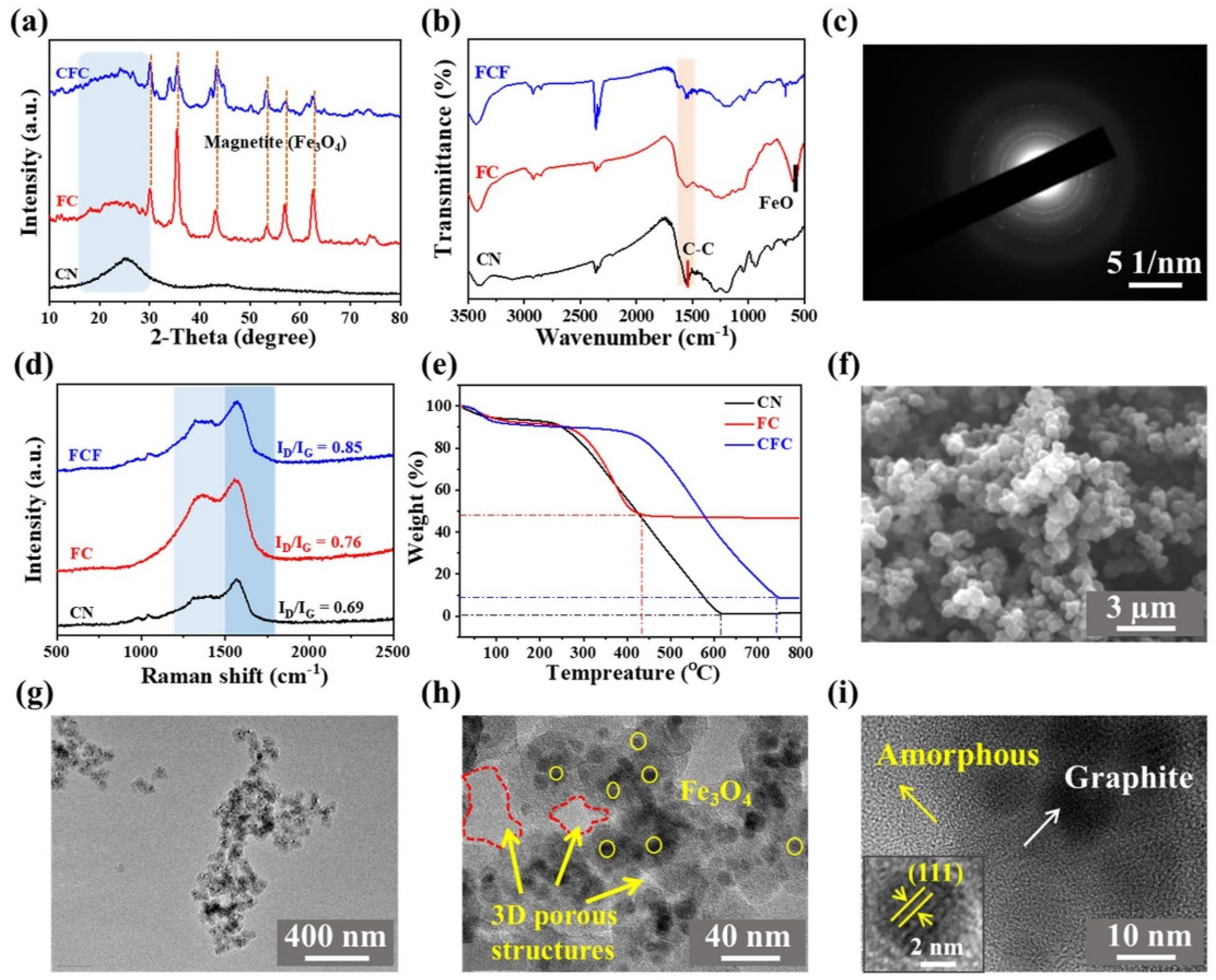

3.1. Morphology and Structure Analysis of Core–Shell-like Composites

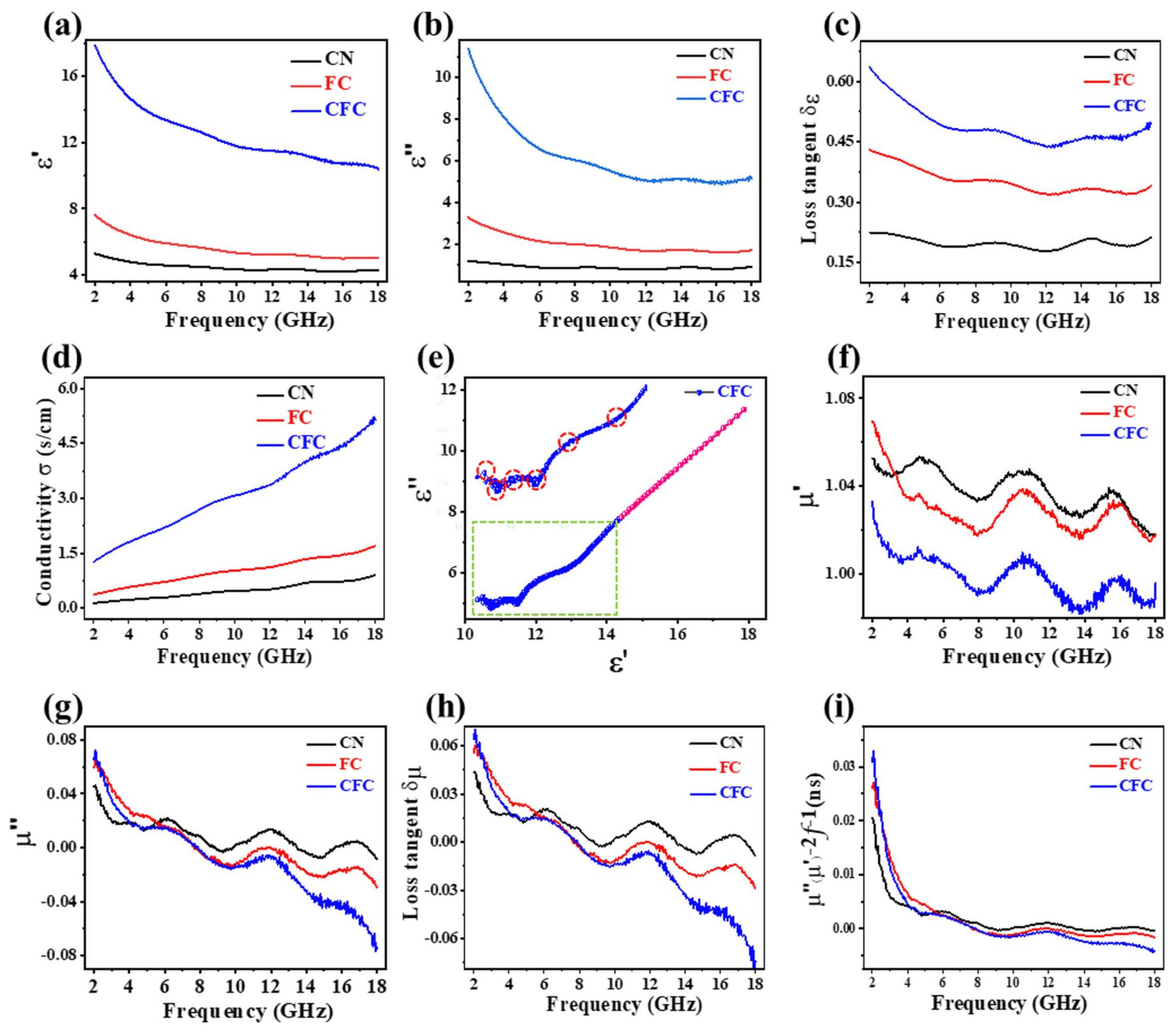

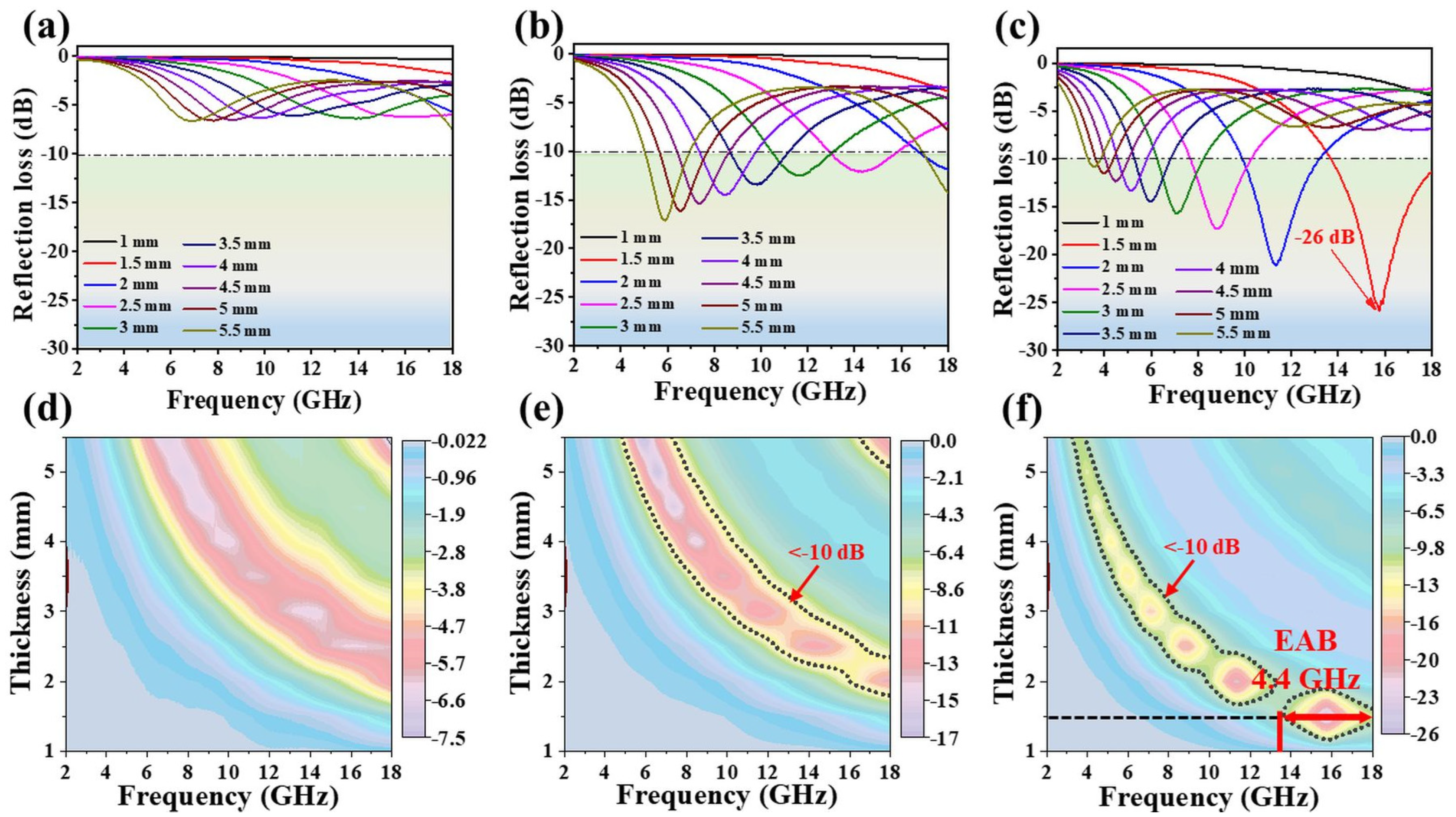

3.2. EMWA Performance of the Core–Shell-like Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, C.; Shan, Z.; Tao, S.; Xie, A.; Yang, H.; Su, J.; Horke, S.; Kitagawa, S.; Zhang, G. Atomic tuning in electrically conducting bimetallic organic frameworks for controllable electromagnetic wave absorption. Adv. Funct. Mater. 2023, 33, 2305082. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, X.; He, X.; Yao, J.; Tan, R.; Chen, P.; Yao, B.; Zhou, J.; Yao, Z. Multifunctional shape memory composites for joule heating, self-healing, and highly efficient microwave absorption. Adv. Funct. Mater. 2023, 33, 2211352. [Google Scholar] [CrossRef]

- Flaifel, M.H.; Ahmad, S.H.; Abdullah, M.H.; Rasid, R.; Shaari, A.H.; El-Saleh, A.A.; Appadu, S. Preparation, thermal, magnetic and microwave absorption properties of thermoplastic natural rubber matrix impregnated with NiZn ferrite nanoparticles. Compos. Sci. Technol. 2014, 96, 103–108. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, L.; Zhang, X.; Tan, S.; Li, H.; Zheng, J.; Ji, G. A novel strategy in electromagnetic wave absorbing and shielding materials design: Multi-responsive field effect. Small Sci. 2022, 2, 2100077. [Google Scholar] [CrossRef]

- Zhao, Z.; Qing, Y.; Kong, L.; Xu, H.; Fan, X.; Yun, J.; Zhang, L.; Wu, H. Advancements in microwave absorption motivated by interdisciplinary research. Adv. Mater. 2024, 36, 2304182. [Google Scholar] [CrossRef] [PubMed]

- Zarepour, A.; Ahmadi, S.; Rabiee, N.; Zarrabi, A.; Iravani, S. Self-healing MXene- and graphene-based composites: Properties and applications. Nano-Micro Lett. 2023, 15, 100. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yi, Y.; Duan, R.; Lu, C.; Zhou, Z. Dual cross-linked and vertically oriented MXene/polyvinyl alcohol aerogel for ultrabroadband electromagnetic interference shielding and thermal camouflage. Polymer 2024, 291, 126604. [Google Scholar] [CrossRef]

- Tao, J.-R.; Yang, D.; Yang, Y.; He, Q.-M.; Fei, B.; Wang, M. Migration mechanism of carbon nanotubes and matching viscosity-dependent morphology in Co-continuous Poly(lactic acid)/Poly(ε-caprolactone) blend: Towards electromagnetic shielding enhancement. Polymer 2022, 252, 124963. [Google Scholar] [CrossRef]

- Abdalla, I.; Shen, J.; Yu, J.; Li, Z.; Ding, B. Co3O4/carbon composite nanofibrous membrane enabled high-efficiency electromagnetic wave absorption. Sci. Rep. 2018, 8, 12402. [Google Scholar] [CrossRef]

- Yu, L.J.; Ahmad, S.; Appadu, S.; Kong, I.; Tarawneh, M.; Flaifel, M. Comparison of magnetic and microwave absorbing properties between multiwalled carbon nanotubes nanocomposite, nickel zinc ferrite nanocomposite and hybrid nanocomposite. World J. Eng. 2014, 11, 317–322. [Google Scholar] [CrossRef]

- Yu, L.J.; Ahmad, S.; Kong, I.; Tarawneh, M. Microwave absorbing properties of nickel-zinc ferrite/multiwalled nanotube thermoplastic natural rubber composites. Adv. Mater. Res. 2012, 501, 24–28. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, C.; Huang, H.; Guo, W.; Yu, J.; Qiu, J. Carbon-enabled microwave chemistry: From interaction mechanisms to nanomaterial manufacturing. Nano Energy 2021, 85, 106027. [Google Scholar] [CrossRef]

- Zheng, W.; Zhang, P.; Chen, J.; Tian, W.B.; Zhang, Y.M.; Sun, Z.M. In situ synthesis of CNTs@Ti3C2 hybrid structures by microwave irradiation for high-performance anodes in lithium ion batteries. J. Mater. Chem. A 2018, 6, 3543–3551. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Singh, R.K.; Kar, K.K. Microwave as a tool for synthesis of carbon-based electrodes for energy storage. ACS Appl. Mater. Interfaces 2022, 14, 20306–20325. [Google Scholar] [CrossRef] [PubMed]

- Głowniak, S.; Szczęśniak, B.; Choma, J.; Jaroniec, M. Advances in microwave synthesis of nanoporous materials. Adv. Mater. 2021, 33, 2103477. [Google Scholar] [CrossRef] [PubMed]

- Poyraz, S.; Zhang, L.; Schroder, A.; Zhang, X. Ultrafast microwave welding/reinforcing approach at the interface of thermoplastic materials. ACS Appl. Mater. Interfaces 2015, 7, 22469–22477. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Poyraz, S.; Smith, J.; Kushvaha, V.; Tippur, H.; Zhang, X. An ultrafast microwave approach towards multi-component and multi-dimensional nanomaterials. RSC Adv. 2014, 4, 9308–9313. [Google Scholar] [CrossRef]

- Zhang, X.; Manohar, S.K. Microwave synthesis of nanocarbons from conducting polymers. Chem. Commun. 2006, 2477–2479. [Google Scholar] [CrossRef]

- Shang, S.; Yang, X.; Tao, X.-M. Easy synthesis of carbon nanotubes with polypyrrole nanotubes as the carbon precursor. Polymer 2009, 50, 2815–2818. [Google Scholar] [CrossRef]

- Kopecká, J.; Mrlík, M.; Olejnik, R.; Kopecký, D.; Prokeš, J.; Bober, P.; Moravkova, Z.; Trchová, M.; Stejskal, J.; Vrnata, M. Polypyrrole nanotubes and their carbonized analogs: Synthesis, characterization, gas sensing properties. Sensors 2016, 16, 1917. [Google Scholar] [CrossRef]

- Zheng, J.; Zhang, M.; Ling, Y.; Xu, J.; Hu, S.; Hayat, T.; Alharbi, N.S.; Yang, F. Fabrication of one dimensional CNTs/Fe3O4@PPy/Pd magnetic composites for the accumulation and electrochemical detection of triclosan. J. Electroanal. Chem. 2018, 818, 97–105. [Google Scholar] [CrossRef]

- Elhassan, A.; Abdalla, I.; Yu, J.; Li, Z.; Ding, B. Microwave-assisted fabrication of sea cucumber-like hollow structured composite for high-performance electromagnetic wave absorption. J. Chem. Eng. 2020, 392, 123646. [Google Scholar] [CrossRef]

- Mordina, B.; Kumar, R.; Tiwari, R.K.; Setua, D.K.; Sharma, A. Fe3O4 nanoparticles embedded hollow mesoporous carbon nanofibers and polydimethylsiloxane-based nanocomposites as efficient microwave absorber. J. Phys. Chem. C 2017, 121, 7810–7820. [Google Scholar] [CrossRef]

- Sun, C.; Guo, Y.; Xu, X.; Du, Q.; Duan, H.; Chen, Y.; Li, H.; Liu, H. In situ preparation of carbon/Fe3C composite nanofibers with excellent electromagnetic wave absorption properties. Compos. Part. A Appl. Sci. Manuf. 2017, 92, 33–41. [Google Scholar] [CrossRef]

- Lu, X.; Wu, Y.; Cai, H.; Qu, X.; Ni, L.; Teng, C.; Zhu, Y.; Jiang, L. Fe3O4 nanopearl decorated carbon nanotubes stemming from carbon onions with self-cleaning and microwave absorption properties. RSC Adv. 2015, 5, 54175–54181. [Google Scholar] [CrossRef]

- Gai, L.; Zhao, Y.; Song, G.; An, Q.; Xiao, Z.; Zhai, S.; Li, Z. Construction of core-shell PPy@MoS2 with nanotube-like heterostructures for electromagnetic wave absorption: Assembly and enhanced mechanism. Compos. Part. A Appl. Sci. Manuf. 2020, 136, 105965. [Google Scholar] [CrossRef]

- Gao, Y.; Lei, Z.; Pan, L.; Wu, Q.; Zhuang, X.; Tan, G.; Ning, M.; Man, Q. Lightweight chitosan-derived carbon/rGO aerogels loaded with hollow Co1-xNixO nanocubes for superior electromagnetic wave absorption and heat insulation. J. Chem. Eng. 2023, 457, 141325. [Google Scholar] [CrossRef]

- Deka, N.; Bera, A.; Roy, D.; De, P. Unraveling the role of counter anions on optical and microwave absorption characteristics of flexible copolymers. Polymer 2023, 282, 126158. [Google Scholar] [CrossRef]

- Yang, X.; Pang, X.; Cao, M.; Liu, X.; Li, X. Efficient microwave absorption induced by hierarchical pores of reed-derived ultralight carbon materials. Ind. Crops Prod. 2021, 171, 113814. [Google Scholar] [CrossRef]

- Luo, H.; Lu, Y.; Qiu, J. An Electromagnetic microwave stealth photothermal soft actuator with lightweight and hydrophobic properties. ACS Appl. Mater. Interfaces 2021, 13, 32046–32057. [Google Scholar] [CrossRef]

- Li, Z.; Han, X.; Ma, Y.; Liu, D.; Wang, Y.; Xu, P.; Li, C.; Du, Y. MOFs-derived hollow Co/C microspheres with enhanced microwave absorption performance. ACS Sustain. Chem. Eng. 2018, 6, 8904–8913. [Google Scholar] [CrossRef]

- Zhu, B.; Cui, Y.; Lv, D.; Liu, P.; Wei, H.; Bu, J. Synthesis and electromagnetic wave absorption properties of peanut shell-like SiC fibers. Mater. Lett. 2020, 263, 127288. [Google Scholar] [CrossRef]

- Peymanfar, R.; Yektaei, M.; Javanshir, S.; Selseleh-Zakerin, E. Regulating the energy band-gap, UV–Vis light absorption, electrical conductivity, microwave absorption, and electromagnetic shielding effectiveness by modulating doping agent. Polymer 2020, 209, 122981. [Google Scholar] [CrossRef]

- Li, Z.; Lin, H.; Ding, S.; Ling, H.; Wang, T.; Miao, Z.; Zhang, M.; Meng, A.; Li, Q. Synthesis and enhanced electromagnetic wave absorption performances of Fe3O4@C decorated walnut shell-derived porous carbon. Carbon 2020, 167, 148–159. [Google Scholar] [CrossRef]

- Chang, Q.; Li, C.; Sui, J.; Waterhouse, G.I.N.; Zhang, Z.-M.; Yu, L.-M. Cage-Like eggshell membrane-derived Co-CoxSy-Ni/N,S-codoped carbon composites for electromagnetic wave absorption. Chem. Eng. J. 2022, 430, 132650. [Google Scholar] [CrossRef]

- Shi, X.L.; Cao, M.S.; Yuan, J.; Fang, X.Y. Dual nonlinear dielectric resonance and nesting microwave absorption peaks of hollow cobalt nanochains composites with negative permeability. Appl. Phys. Lett. 2009, 95, 163108. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, Z.; Lv, X.; Zhang, X.; Zhang, Y.; Zhang, J.; Zhang, L.; Gong, C. Microwave absorption performance of reduced graphene oxide with negative imaginary permeability. J. Phys. D Appl. Phys. 2020, 53, 02LT01. [Google Scholar] [CrossRef]

- Tong, G.; Yuan, J.; Wu, W.; Hu, Q.; Qian, H.; Li, L.; Shen, J. Flower-like Co superstructures: Morphology and phase evolution mechanism and novel microwave electromagnetic characteristics. CrystEngComm 2012, 14, 2071–2079. [Google Scholar] [CrossRef]

- Liu, L.; He, N.; Wu, T.; Hu, P.; Tong, G. Co/C/Fe/C hierarchical flowers with strawberry-like surface as surface plasmon for enhanced permittivity, permeability, and microwave absorption properties. J. Chem. Eng. 2019, 355, 103–108. [Google Scholar] [CrossRef]

- Zeng, Q.; Xu, D.-W.; Chen, P.; Yu, Q.; Xiong, X.-H.; Chu, H.-R.; Wang, Q. 3D graphene-Ni microspheres with excellent microwave absorption and corrosion resistance properties. J. Mater. Sci. Mater. Electron. 2018, 29, 2421–2433. [Google Scholar] [CrossRef]

- Nie, H.; Cui, M.; Russell, T.P. A route to rapid carbon nanotube growth. Chem. Commun. 2013, 49, 5159–5161. [Google Scholar] [CrossRef] [PubMed]

- Raza, A.; Wang, J.; Yang, S.; Si, Y.; Ding, B. Hierarchical porous carbon nanofibers via electrospinning. Carbon Lett. 2014, 15, 1–14. [Google Scholar] [CrossRef]

- Rezvanpanah, E.; Ghaffarian Anbaran, S.R.; Di Maio, E. Carbon nanotubes in microwave foaming of thermoplastics. Carbon 2017, 125, 32–38. [Google Scholar] [CrossRef]

- Zhu, Y.-J.; Chen, F. Microwave-assisted preparation of inorganic nanostructures in liquid phase. Chem. Rev. 2014, 114, 6462–6555. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Pallavkar, S.; Chen, M.; Yerra, N.; Luo, Z.; Colorado, H.A.; Lin, H.; Haldolaarachchige, N.; Khasanov, A.; Ho, T.C.; et al. Magnetic carbon nanostructures: Microwave energy-assisted pyrolysis vs. conventional pyrolysis. Chem. Commun. 2013, 49, 258–260. [Google Scholar] [CrossRef] [PubMed]

- Abdalla, I.; Salim, A.; Zhu, M.; Yu, J.; Li, Z.; Ding, B. Light and flexible composite nanofibrous membranes for high-efficiency electromagnetic absorption in a broad frequency. ACS Appl. Mater. Interfaces 2018, 10, 44561–44569. [Google Scholar] [CrossRef] [PubMed]

- Abdalla, I.; Cai, J.; Lu, W.; Yu, J.; Li, Z.; Ding, B. Recent progress on electromagnetic wave absorption materials enabled by electrospun carbon nanofibers. Carbon 2023, 213, 118300. [Google Scholar] [CrossRef]

- Li, T.; Zhi, D.; Chen, Y.; Li, B.; Zhou, Z.; Meng, F. Multiaxial electrospun generation of hollow graphene aerogel spheres for broadband high-performance microwave absorption. Nano Res. 2020, 13, 477–484. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elhassan, A.; Lv, X.; Abdalla, I.; Yu, J.; Li, Z.; Ding, B. Efficient Synthesis of Fe3O4/PPy Double-Carbonized Core-Shell-like Composites for Broadband Electromagnetic Wave Absorption. Polymers 2024, 16, 1160. https://doi.org/10.3390/polym16081160

Elhassan A, Lv X, Abdalla I, Yu J, Li Z, Ding B. Efficient Synthesis of Fe3O4/PPy Double-Carbonized Core-Shell-like Composites for Broadband Electromagnetic Wave Absorption. Polymers. 2024; 16(8):1160. https://doi.org/10.3390/polym16081160

Chicago/Turabian StyleElhassan, Ahmed, Xiaoshuang Lv, Ibrahim Abdalla, Jianyong Yu, Zhaoling Li, and Bin Ding. 2024. "Efficient Synthesis of Fe3O4/PPy Double-Carbonized Core-Shell-like Composites for Broadband Electromagnetic Wave Absorption" Polymers 16, no. 8: 1160. https://doi.org/10.3390/polym16081160

APA StyleElhassan, A., Lv, X., Abdalla, I., Yu, J., Li, Z., & Ding, B. (2024). Efficient Synthesis of Fe3O4/PPy Double-Carbonized Core-Shell-like Composites for Broadband Electromagnetic Wave Absorption. Polymers, 16(8), 1160. https://doi.org/10.3390/polym16081160