Effect of Hot-Pressing Temperature on the Properties of Eco-Friendly Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol–Formaldehyde Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

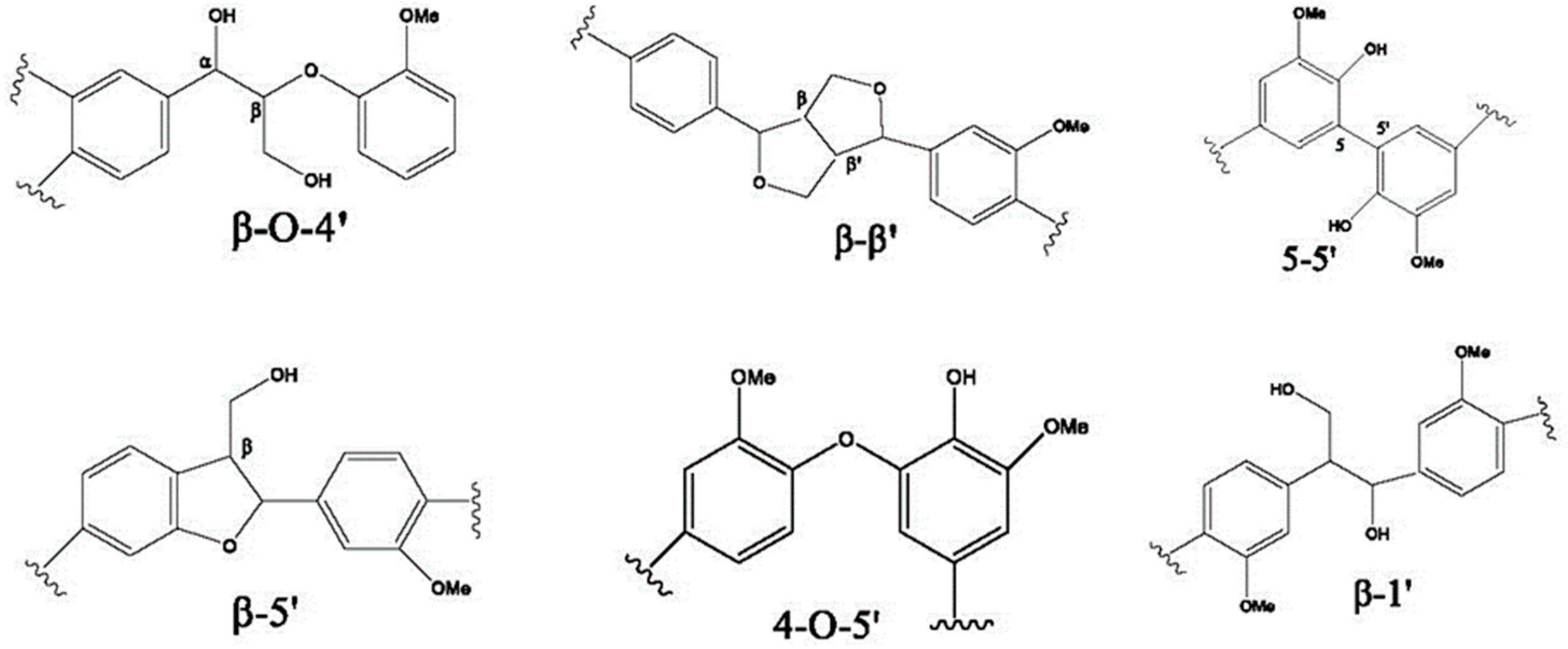

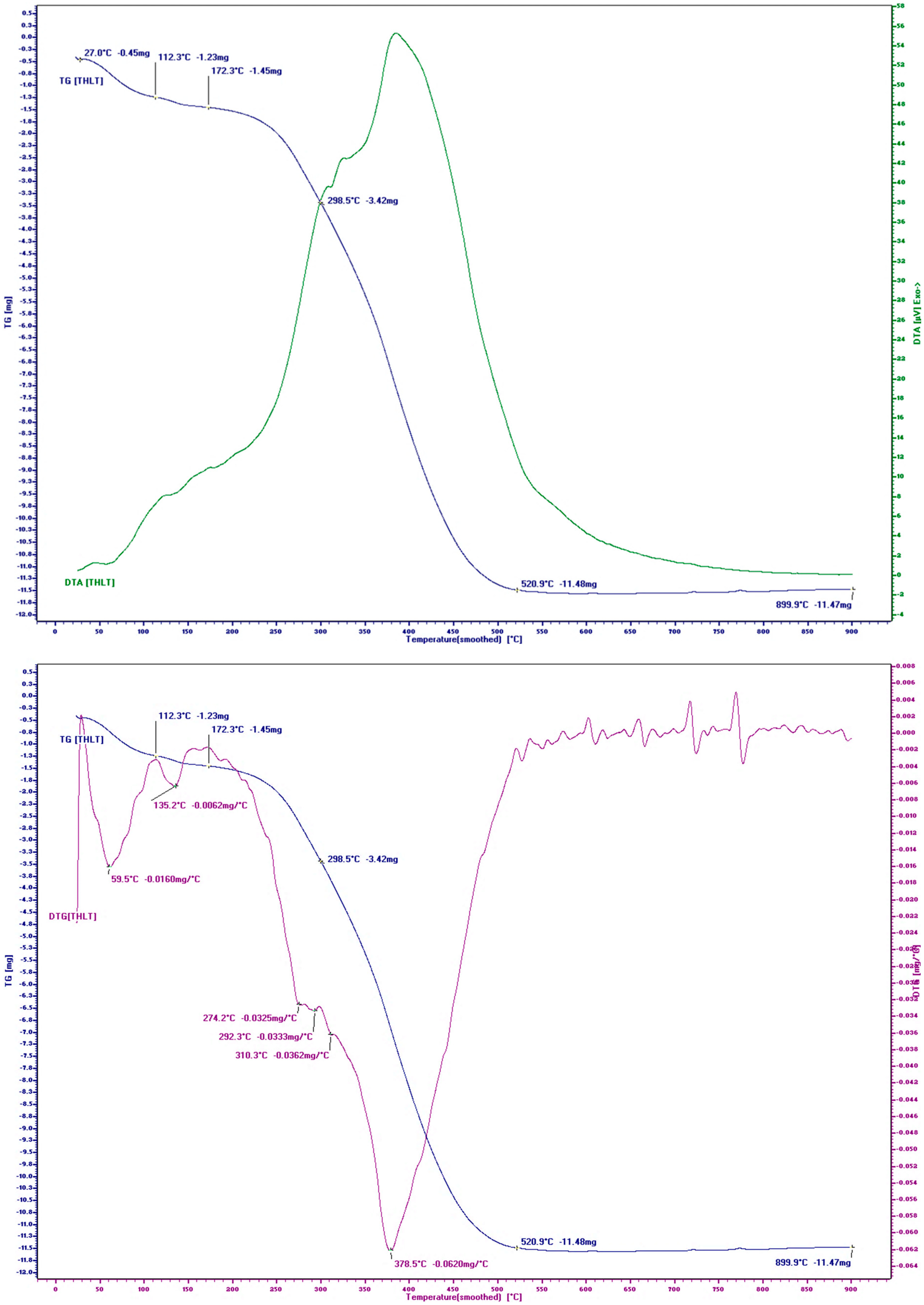

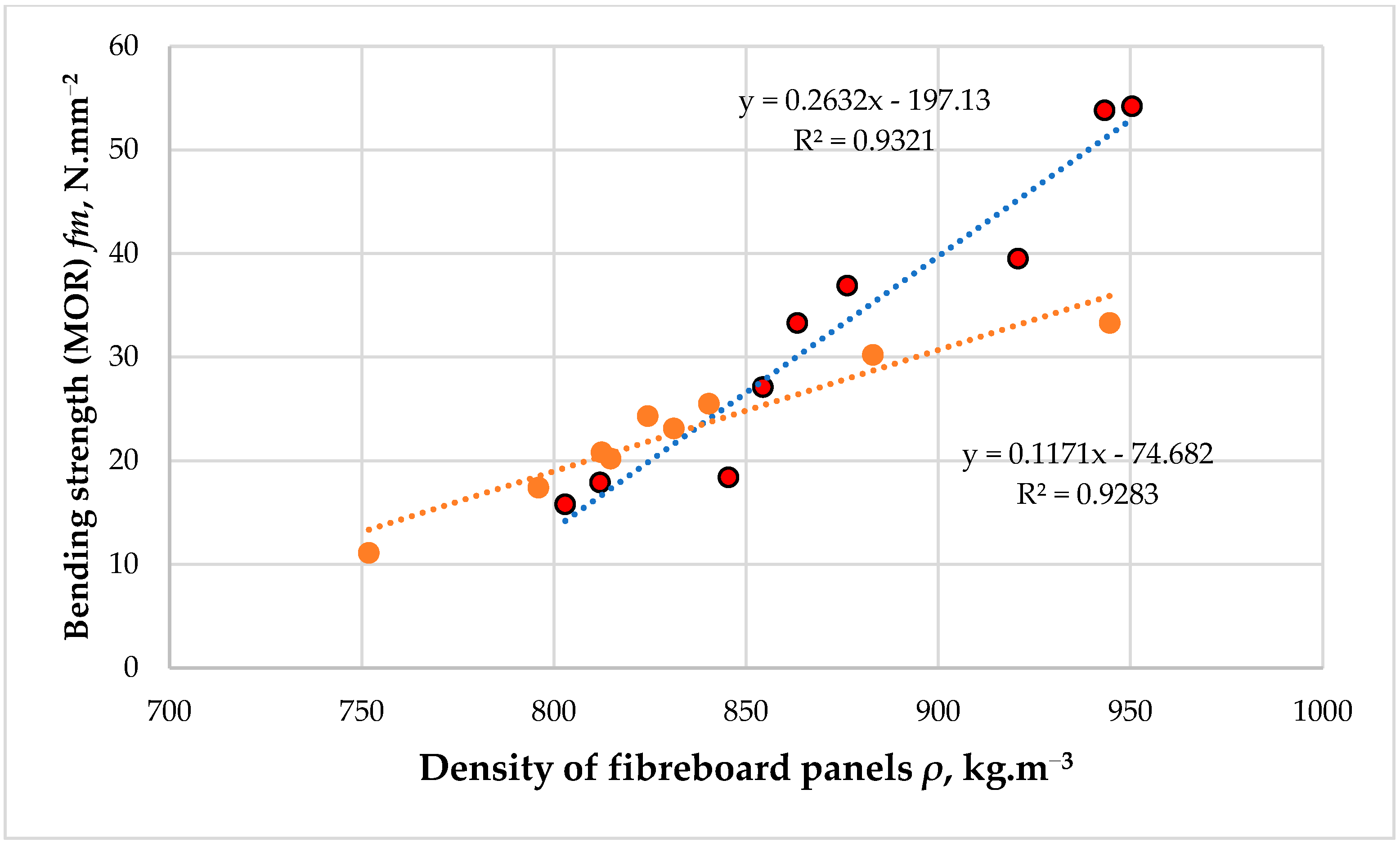

3.1. Preliminary Results

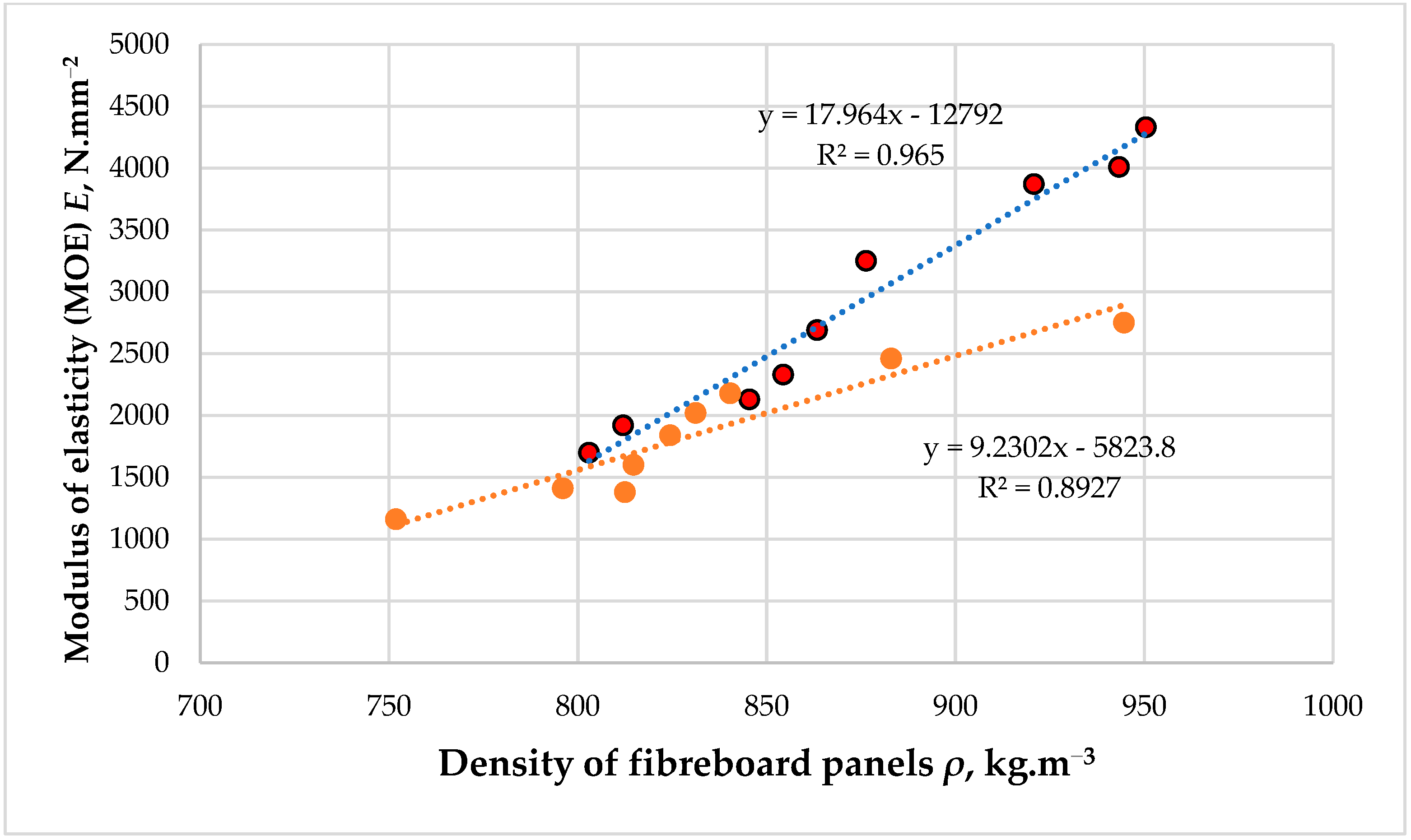

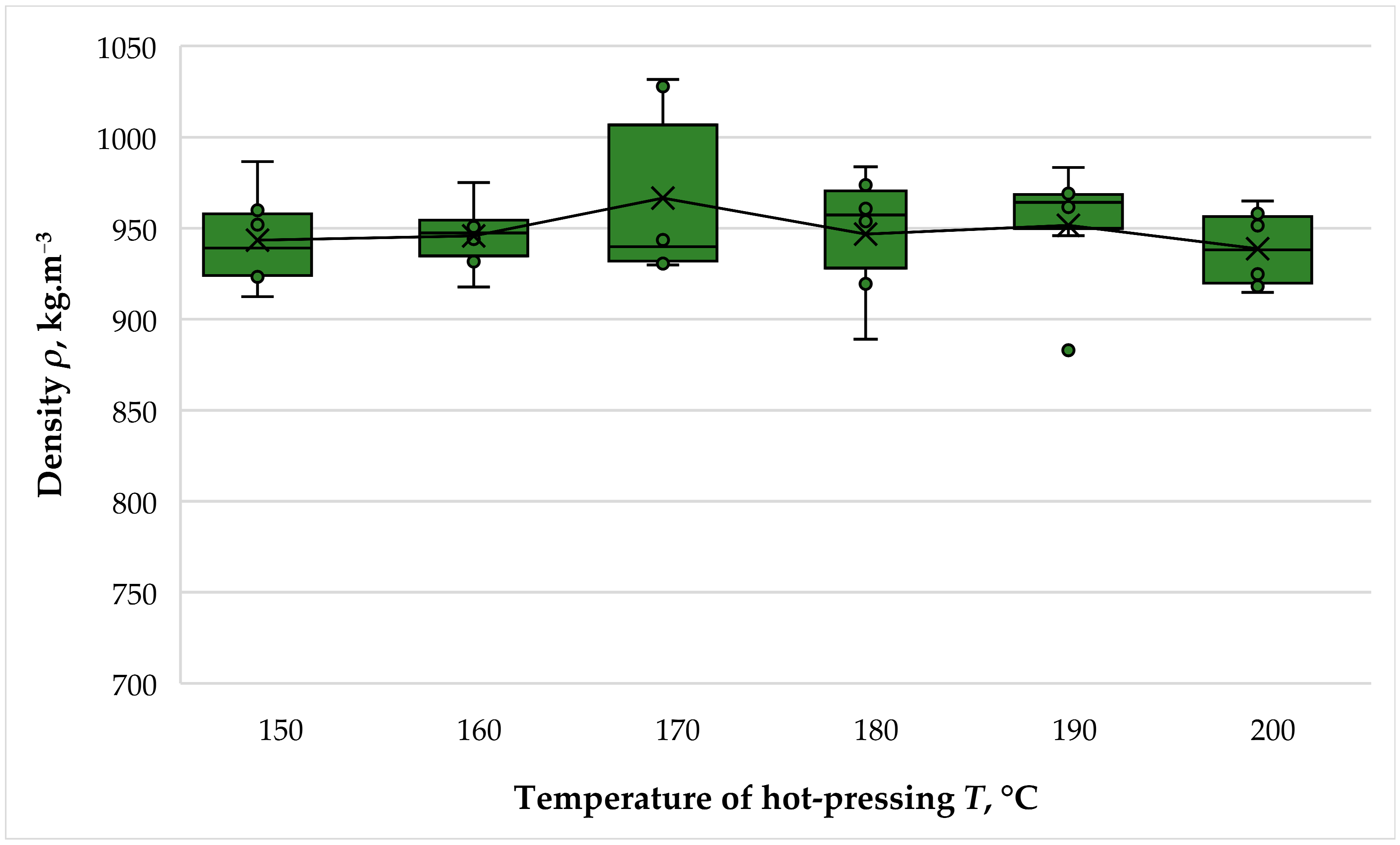

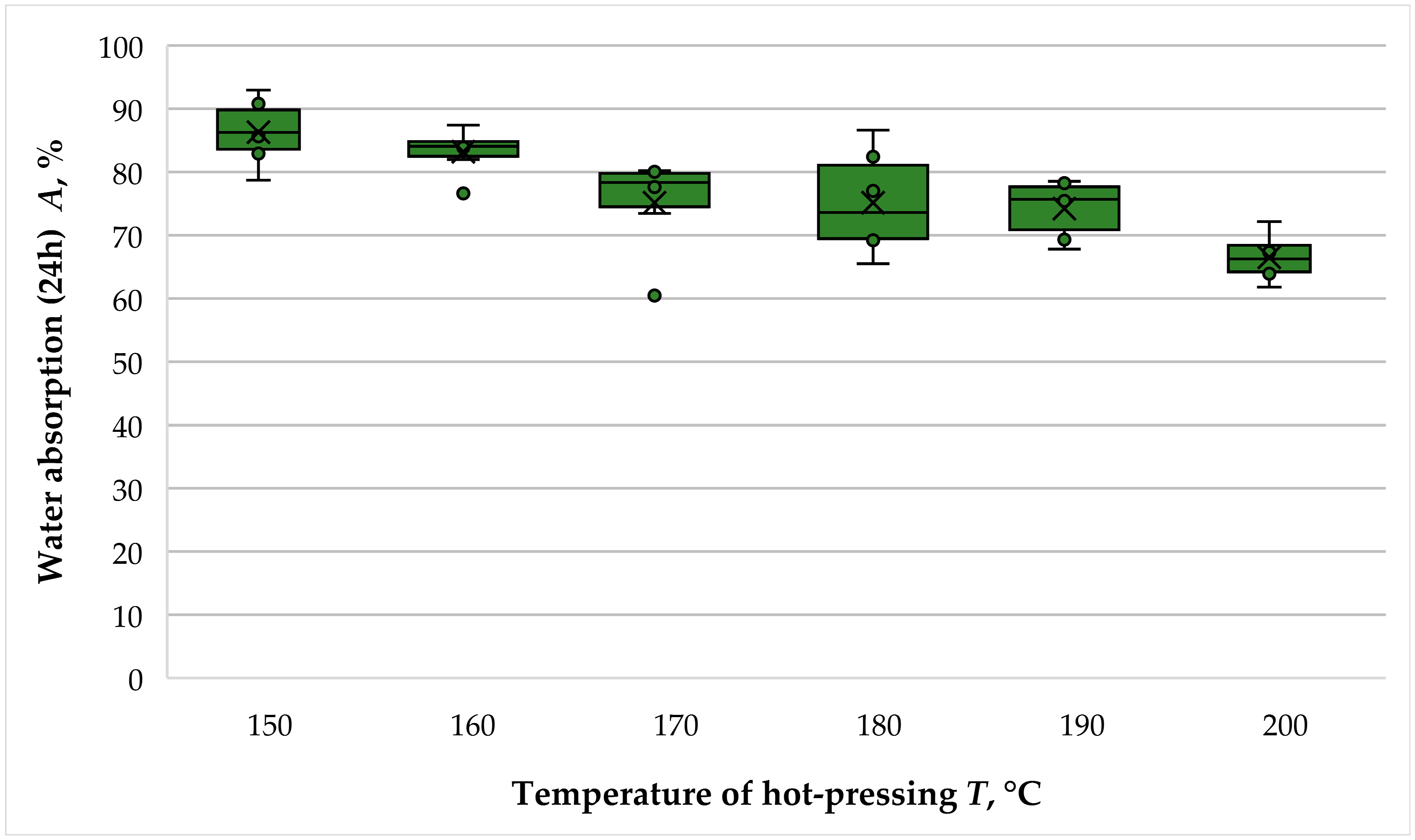

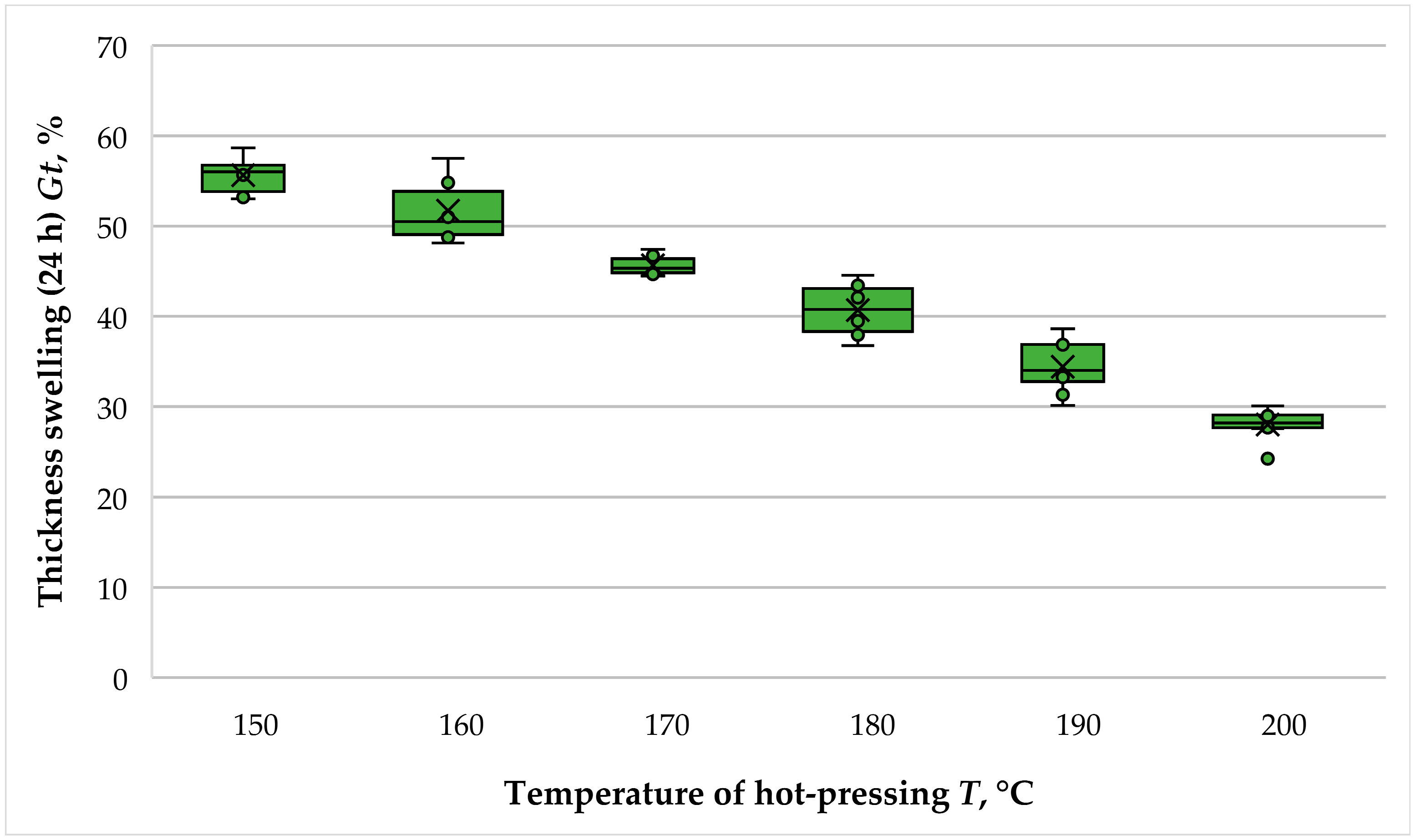

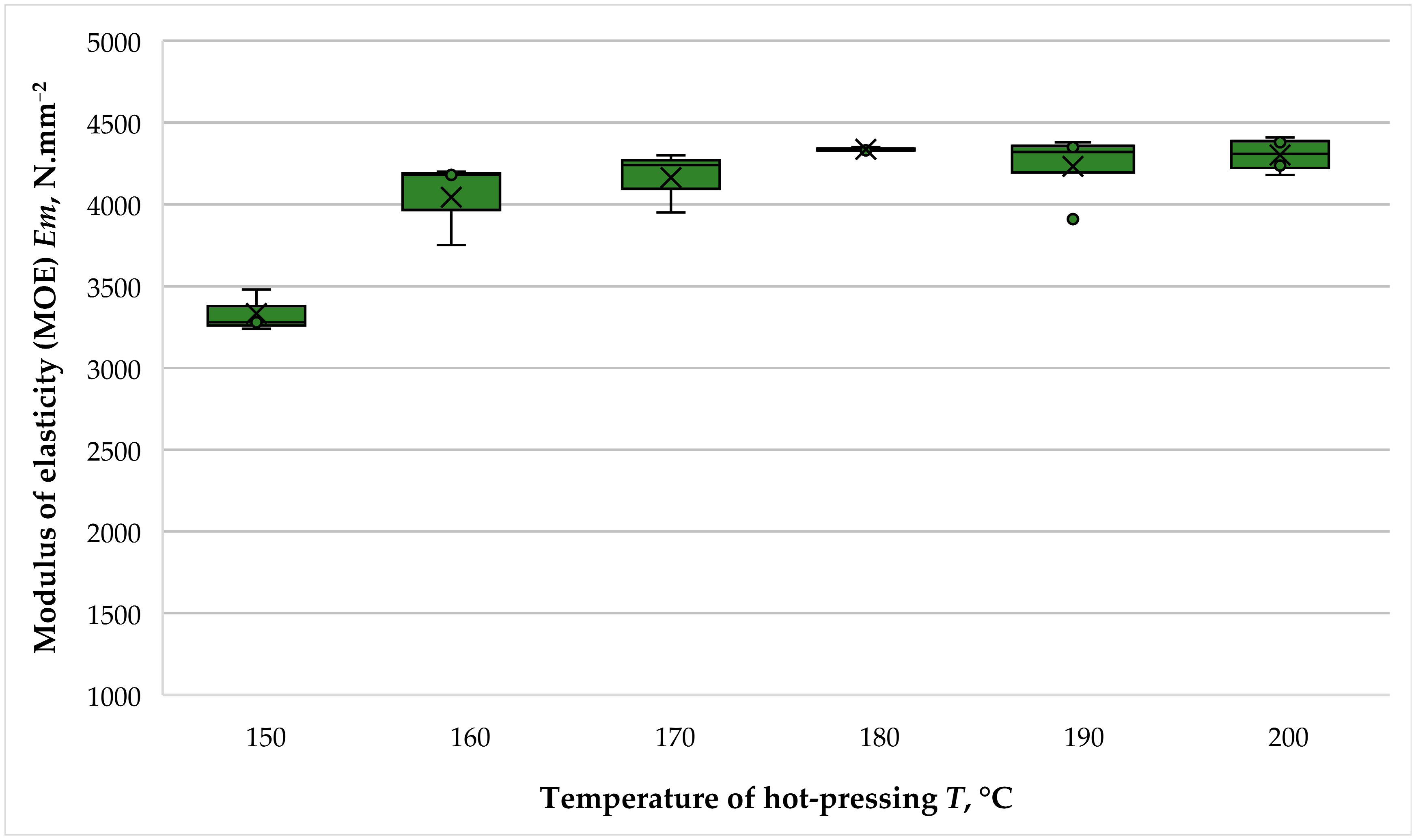

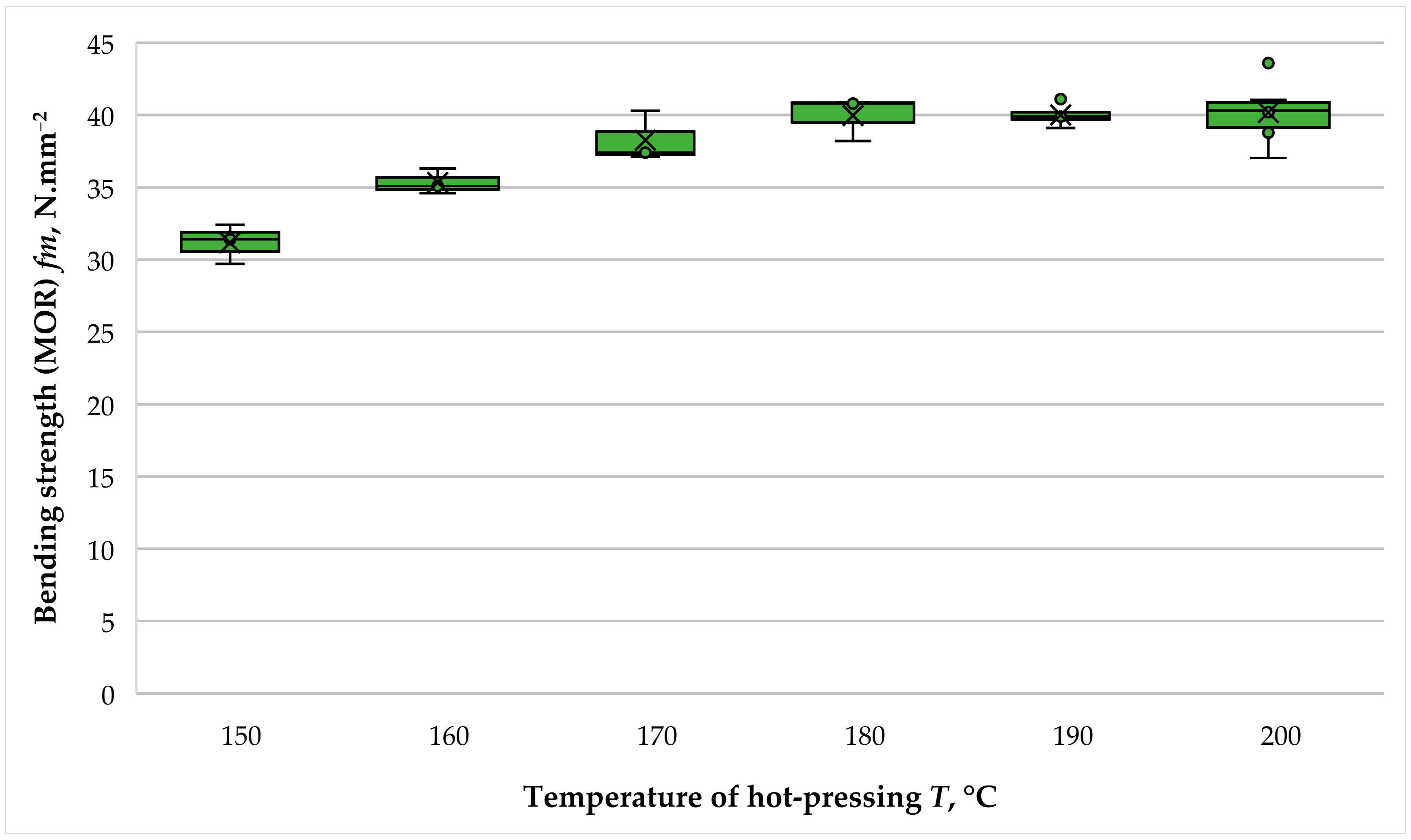

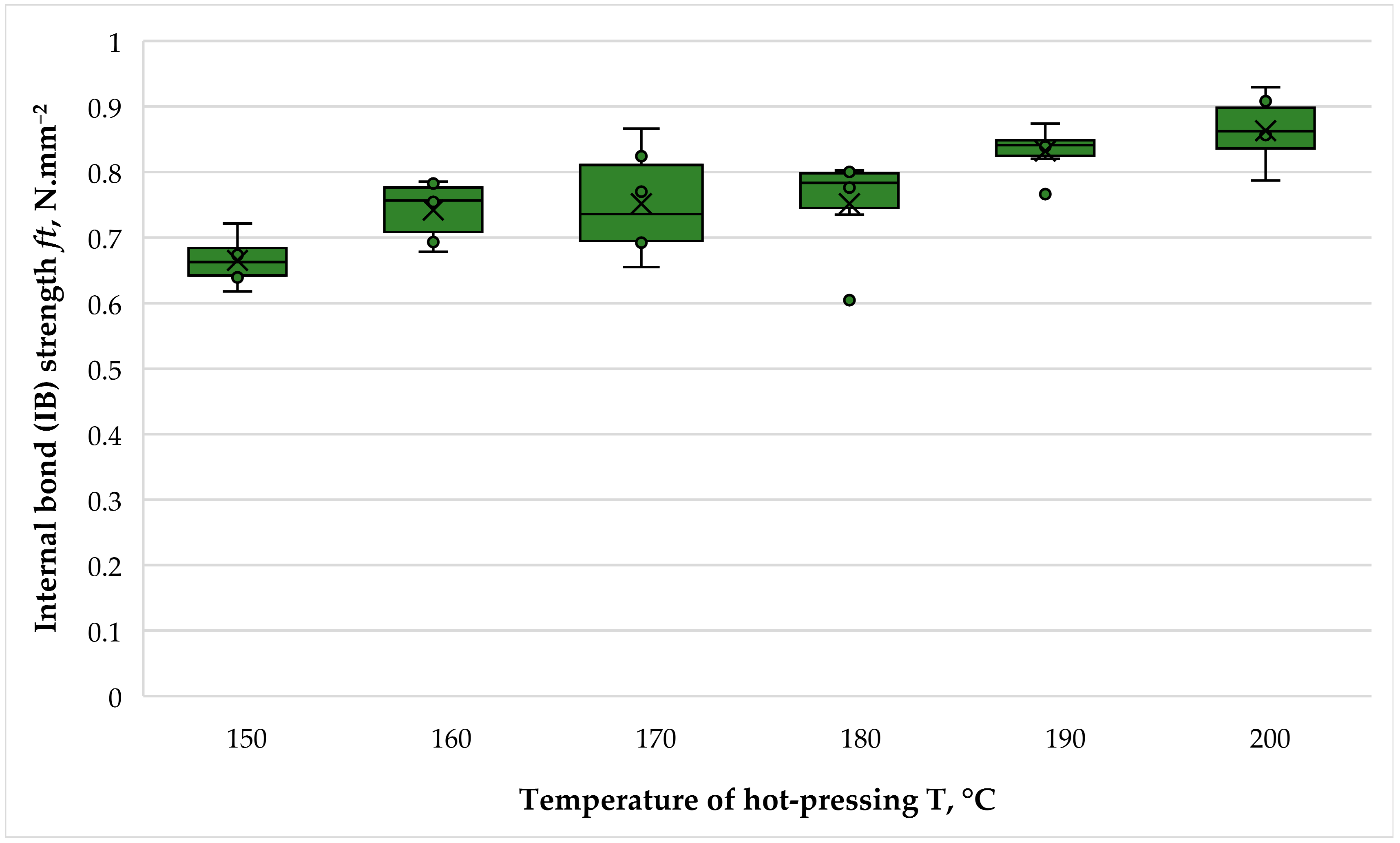

3.2. Effect of Hot-Pressing Temperature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Forest Product Statistics. Available online: http://www.fao.org/forestry/statistics/ (accessed on 4 February 2024).

- Kumar, R.N.; Pizzi, A. Adhesives for Wood and Lignocellulosic Materials; Wiley Publishing House: Hoboken, NJ, USA, 2019; p. 491. [Google Scholar]

- Pizzi, A.; Papadopoulus, A.N.; Policardi, F. Wood Composites and Their Polymer Binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef] [PubMed]

- Popovic, M.; Momčilović, M.D.; Gavrilovic’-Grmuša, I. New standards and regulations on formaldehyde emission from wood-based composite panels. Zast. Mater. 2020, 61, 152–160. [Google Scholar] [CrossRef]

- Zhang, J.; Song, F.; Tao, J.; Zhang, Z.; Shi, S.Q. Research Progress on Formaldehyde Emission of Wood-Based Panel. Int. J. Polym. Sci. 2018, 2018, 9349721. [Google Scholar] [CrossRef]

- Bertaud, F.; Tapin-Lingua, S.; Pizzi, A.; Navarrete, P.; Petit-Conil, M. Development of green adhesives for fibreboard manufacturing, using tannins and lignin from pulp mill residues. Cellul. Chem. Technol. 2012, 46, 449–455. [Google Scholar]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels—A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Dunky, M. Wood Adhesives Based on Natural Resources: A Critical Review Part III. Tannin- and Lignin-Based Adhesives. Rev. Adhes. Adhes. 2020, 8, 379–525. [Google Scholar]

- Lee, T.C.; Puad, N.A.D.; Selimin, M.A.; Manap, N.; Abdullah, H.Z.; Idris, M.I. An overview on development of environmental friendly medium density fibreboard. Mater. Today 2020, 29, 52–57. [Google Scholar] [CrossRef]

- Karthäuser, J.; Biziks, V.; Mai, C.; Militz, H. Lignin and Lignin-Derived Compounds for Wood Applications—A Review. Molecules 2021, 26, 2533. [Google Scholar] [CrossRef]

- Balakshin, M.; Capanema, E.A.; Zhu, X.; Sulaeva, I.; Potthast, A.; Rosenau, T.; Rojas, O.J. Spruce milled wood lignin: Linear, branched or cross-linked? Green Chem. 2020, 22, 3985–4001. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R.S. Greener synthesis of lignin nanoparticles and their applications. Green Chem. 2020, 22, 612. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Kim, S.; Ceylan, H. Lignin Recovery and Utilization. In Bioenergy and Biofuel from Biowastes and Biomass; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 247–278. [Google Scholar]

- Yildirim, M.; Candan, Z.; Aksoy, B.; Dundar, T. Performance properties of engineered wood composites reinforced by lignosulfonate. Green Mater. 2023, 11, 60–68. [Google Scholar] [CrossRef]

- Valchev, I.; Yordanov, Y.; Savov, V.; Antov, P. Optimization of the Hot-Pressing Regime in the Production of Eco-Friendly Fibreboards Bonded with Hydrolysis Lignin. Period. Polytech. Chem. Eng. 2022, 66, 125–134. [Google Scholar] [CrossRef]

- Balea Paul, G.; Timar, M.C.; Zeleniuc, O.; Lunguleasa, A.; Coșereanu, C. Mechanical Properties and Formaldehyde Release of Particleboard Made with Lignin-Based Adhesives. Appl. Sci. 2021, 11, 8720. [Google Scholar] [CrossRef]

- Rabinovich, M. Wood Hydrolysis Industry in the Soviet Union and Russia—A Mini Review. Cellulose Chem. Technol. 2010, 44, 173–186. [Google Scholar]

- Solihat, N.N.; Sari, F.P.; Falah, F.; Ismayati, M.; Lubis, M.A.R.; Fatriasari, W.; Santoso, E.B.; Syafii, W. Lignin as an Active Biomaterial: A Review. J. Sylva Lestari 2021, 9, 1–22. [Google Scholar] [CrossRef]

- Cui, S.; Xie, Y.; Wei, X.; Zhang, K.; Chen, X. Exploration of the chemical linkages between lignin and cellulose in poplar wood with 13C and Deuterium dual isotope tracer. Ind. Crops Prod. 2022, 187, 115452. [Google Scholar] [CrossRef]

- El Mansouri, N.E.; Yuan, O.; Huang, F. Study of chemical modification of alkaline lignin by the glyoxalation reaction. BioResources 2011, 6, 4523–4536. [Google Scholar] [CrossRef]

- Ariton, A.M.; Greanga, S.; Trinca, L.M.; Bors, S.I.; Ungureanu, E.; Malutan, T.; Popa, V. Valorization of lignin modified by hydroxymethylation to ensure birch veneer bioprotection. Cellul. Chem. Technol. 2015, 49, 765–774. [Google Scholar]

- Nasir, M.; Asim, M.; Singh, K. Fiberboard Manufacturing from Laccase Activated Lignin Based Bioadhesive. In Eco-Friendly Adhesives for Wood and Natural Fiber Composites. Composites Science and Technology; Springer: Singapore, 2021; pp. 51–83. [Google Scholar]

- Euring, M.; Ostendorf, K.; Rühl, M.; Kües, U. Enzymatic Oxidation of Ca-Lignosulfonate and Kraft Lignin in Different Lignin-Laccase-Mediator-Systems and MDF Production. Front. Bioeng. Biotechnol. 2022, 9, 788622. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Robles, J.; Tarrés, Q.; Delgado-Aguilar, M.; Rodríguez, A.; Espinach, F.X.; Mutjé, P. Approaching a new generation of fiberboards taking advantage of self lignin as green adhesive. Int. J. Biol. Macromol. 2018, 108, 927–935. [Google Scholar] [CrossRef]

- Savov, V.; Valchev, I.; Antov, P.; Yordanov, I.; Popski, Z. Effect of the Adhesive System on the Properties of Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol-Formaldehyde Resin. Polymers 2022, 14, 1768. [Google Scholar] [CrossRef] [PubMed]

- Valchev, I.; Savov, V.; Yordanov, I. Reduction of Phenol Formaldehyde Resin Content in Dry-Processed Fibreboards by Adding Hydrolysis Lignin. In Proceedings of the 2020 Society of Wood Science and Technology International Convention Renewable Resources for Sustainable and Healthy Future, Portorož, Slovenia, 12–15 July 2020; pp. 592–602. [Google Scholar]

- Jiang, X.; Liu, J.; Du, X.; Hu, Z.; Chang, H.; Jameel, H. Phenolation to Improve Lignin Reactivity toward Thermosets Application. ACS Sustain. Chem. Eng. 2018, 6, 5504–5512. [Google Scholar] [CrossRef]

- Sala, C.M.; Kowaluk, G. An impact of surface spray and pressing temperature on the properties of high density fibreboards. Ann. Wars. Univ. Life Sci. SGGW (For. Wood Technol.) 2020, 112, 36–53. [Google Scholar] [CrossRef]

- Gul, W.; Khan, A.; Shakoor, A. Impact of Hot Pressing Temperature on Medium Density Fiberboard (MDF) Performance. Adv. Mater. Sci. Eng. 2017, 2017, 4056360. [Google Scholar] [CrossRef]

- Naydenova, I.; Radoykova, T.; Petrova, T.; Sandov, O.; Valchev, I. Utilization Perspectives of Lignin Biochar from Industrial Biomass Residue. Molecules 2023, 28, 4842. [Google Scholar] [CrossRef] [PubMed]

- Technical Association of the Pulp and Paper Industry. T 203 Alpha-, Beta- and Gamma-Cellulose in Pulp; Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2013. [Google Scholar]

- Technical Association of the Pulp and Paper Industry. T 222 om-11 Acid-Insoluble Lignin in Wood and Pulp; Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2011. [Google Scholar]

- Technical Association of the Pulp and Paper Industry. T 211 om-12 Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525 °C; Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2012. [Google Scholar]

- Hemmilä, V.; Hosseinpourpia, R.; Adamopoulos, S.; Eceiza, А. Characterization of Wood-based Industrial Biorefinery Lignosulfonates and Supercritical Water Hydrolysis Lignin. Waste Biomass Valori. 2020, 11, 5835–5845. [Google Scholar] [CrossRef]

- EN 310:1999; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 317:1998; Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization (CEN): Brussels, Belgium, 1998.

- EN 319:1998; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization (CEN): Brussels, Belgium, 1993.

- EN 323:2001; Wood-Based Panels—Determination of Density. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- Mancera, C.; Mansouri, N.E.; Pelach, M.A.; Francesc, F.; Salvadó, J. Feasibility of incorporating treated lignins in fiberboards made from agricultural waste. Waste Manag. 2012, 32, 1962–1967. [Google Scholar] [CrossRef] [PubMed]

- Westin, M.; Simonson, R.; Östman, B. Kraft lignin wood fiberboards—The effect of kraft lignin addition to wood chips or board pulp prior to fiberboard production. Holz Als Roh Werkst. 2001, 58, 393–400. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Gravitis, J.; Abolins, J.; Veveris, A.; Andzs, M.; Liitia, T.; Tamminen, T. Utilization of lignin powder for manufacturing self-binding HDF. Holzforschung 2017, 71, 555–561. [Google Scholar] [CrossRef]

- Velásquez, J.A.; Ferrando, F.; Salvadó, J. Effects of kraft lignin addition in the production of binderless fiberboard from steam exploded Miscanthus sinensis. Ind. Crop. Prod. 2003, 18, 17–23. [Google Scholar] [CrossRef]

- Wang, J.; Wang, B.; Liu, J.; Ni, L.; Li, J. Effect of Hot-Pressing Temperature on Characteristics of Straw-Based Binderless Fiberboards with Pulping Effluent. Materials 2019, 12, 922. [Google Scholar] [CrossRef]

- Theng, D.; El Mansouri, N.-E.; Arbat, G.; Ngo, B.; Delgado-Aguilar, M.; Pèlach, M.À.; Fullana-i-Palmer, P.; Mutjé, P. Fiberboards Made from Corn Stalk Thermomechanical Pulp and Kraft Lignin as a Green Adhesive. BioResources 2017, 12, 2379–2393. [Google Scholar] [CrossRef]

- Bouajila, A.; Limare, A.; Joly, C.; Dole, P. Lignin plasticization to improve binderless fiberboard mechanical properties. Polym. Eng. Sci. 2005, 45, 809–816. [Google Scholar] [CrossRef]

- EN 622-5:2010; Fibreboards—Specifications—Part 5: Requirements for Dry Process Boards. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Okuda, N.; Hori, K.; Sato, M. Chemical changes of kenaf core binderless boards during hot pressing (I): Influence of the pressing temperature condition. J. Wood. Sci. 2006, 52, 244–248. [Google Scholar] [CrossRef]

- Okuda, N.; Hori, K.; Sato, M. Chemical changes of kenaf core binderless boards during hot pressing (II): Effects on the binderless board properties. J. Wood. Sci. 2006, 52, 249–254. [Google Scholar] [CrossRef]

- Suzuki, S.; Hiroyuki, S.; Park, S.-Y.; Saito, K.; Laemsak, N.; Okuma, M.; Iiyama, K. Preparation of binderless boards from steam exploded pulps of oil palm (Elaeis guneensis Jaxq.) fronds and structural characteristics of lignin and wall polysaccharides in steam exploded pulps to be discussed for self-bindings. Holzforschung 1998, 52, 417–426. [Google Scholar] [CrossRef]

- Quintana, G.; Velasquez, J.; Betancourt, S.; Ganan, P. Binderless fiberboard from steam exploded banana bunch. Ind. Crop. Prod. 2009, 29, 60–66. [Google Scholar] [CrossRef]

- Nasir, M.; Gupta, A.; Beg, M.D.H.; Chua, G.K.; Kumar, A. Physical and Mechanical Properties of Medium-Density Fibreboards Using Soy-Lignin Adhesives. J. Trop. For. Sci. 2014, 26, 41–49. [Google Scholar]

- Hoareau, W.; Oliveira, F.B.; Grelier, S.; Siegmund, B.; Frollini, E.; Castellan, A. Fiberboards Based on Sugarcane Bagasse Lignin and Fibers. Macromol. Mater. Eng. 2006, 291, 829–839. [Google Scholar] [CrossRef]

| Lignin, % | Cellulose, % | Ash, % | C, % | S, % | H, % | N, % |

|---|---|---|---|---|---|---|

| 72.6 | 25.5 | 2.8 | 55.54 | 0.74 | 7.10 | 0.26 |

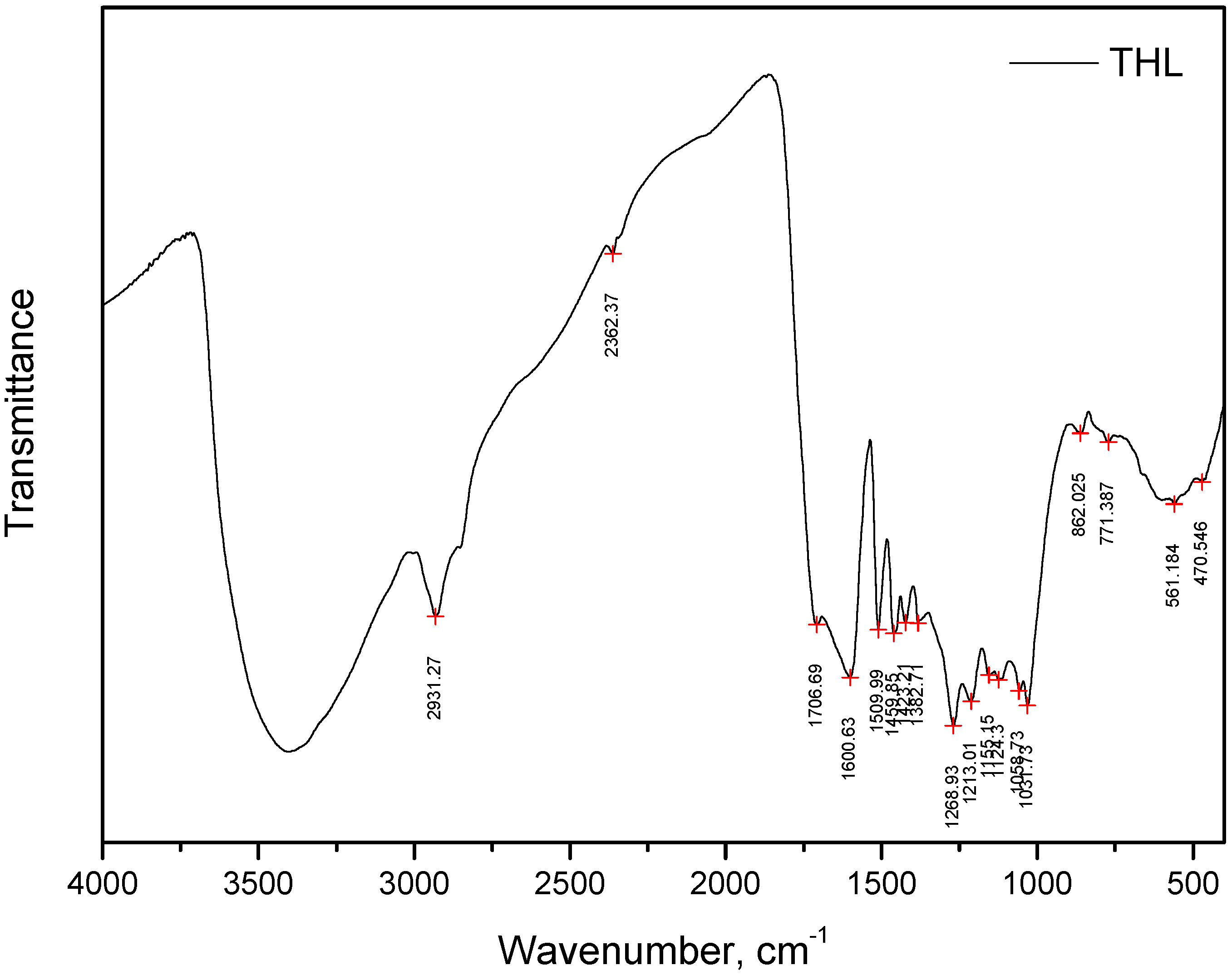

| Band (cm−1) | Assignments [34] | THL |

|---|---|---|

| 3412–3460 | O–H stretching (phenolic and aliphatic OH) | 3391 |

| 2960–2925 | C–H stretching (CH3 and CH2) | 2931 |

| 2850–2840 | C–H stretching (OCH3) | 2839 |

| 1705–1720 | C=O stretching (unconjugated carbonyl) | 1707 |

| ~1600 | C=C stretching (aromatic skeleton) with C=O stretching | 1600 |

| ~1513 | C=C stretching (aromatic skeleton) | 1510 |

| 1460 | C–H deformation (asymmetric in CH3 and CH2) combined with C–H in-plane deformation | 1459 |

| ~1425 | C=C stretching (aromatic skeleton) with C–H in-plane deformation (aromatic skeleton) | 1423 |

| 1365–1370 | H–O in-plane deformation (phenolic OH) and C–H in methyl groups | 1382 |

| 1266–1270 | G-ring breathing with C–O stretching | 1268 |

| 1215–1220 | C–C with C–O and C=O stretching | 1213 |

| 1166 | C=O (conjugated ester groups) | 1155 |

| 1115 | Aromatic C–H in-plane deformation (S-ring) | 1124 |

| 1030–1035 | Aromatic C–H in-plane deformation with C–O deformation (primary alcohol and ether) and C=O stretching (unconjugated) | 1031 |

| 853–858 | C–H out-of-plane bending (C2, C5, and C6 of G-ring) | 862 |

| Panel № | Temperature of Hot-Pressing T, °C |

|---|---|

| 1. | 150 |

| 2. | 160 |

| 3. | 170 |

| 4. | 180 |

| 5. | 190 |

| 6. | 200 |

| Source of Variation | SS | df | MS | F | p-Value | F Crit |

|---|---|---|---|---|---|---|

| Hot-pressing temperature | 2813.112 | 5 | 562.6224 | 0.50898 | 0.767169 | 2.533555 |

| Error | 33,161.73 | 30 | 1105.391 | |||

| Total | 35,974.85 | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valchev, I.; Savov, V.; Yordanov, I.; Petrin, S.; Antov, P. Effect of Hot-Pressing Temperature on the Properties of Eco-Friendly Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol–Formaldehyde Resin. Polymers 2024, 16, 1059. https://doi.org/10.3390/polym16081059

Valchev I, Savov V, Yordanov I, Petrin S, Antov P. Effect of Hot-Pressing Temperature on the Properties of Eco-Friendly Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol–Formaldehyde Resin. Polymers. 2024; 16(8):1059. https://doi.org/10.3390/polym16081059

Chicago/Turabian StyleValchev, Ivo, Viktor Savov, Ivaylo Yordanov, Stoyko Petrin, and Petar Antov. 2024. "Effect of Hot-Pressing Temperature on the Properties of Eco-Friendly Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol–Formaldehyde Resin" Polymers 16, no. 8: 1059. https://doi.org/10.3390/polym16081059

APA StyleValchev, I., Savov, V., Yordanov, I., Petrin, S., & Antov, P. (2024). Effect of Hot-Pressing Temperature on the Properties of Eco-Friendly Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol–Formaldehyde Resin. Polymers, 16(8), 1059. https://doi.org/10.3390/polym16081059