A Study on the Effect and Suppression of Hydrogen Permeation Behavior on the Friction Characteristics of PEEK/PTFE Composites via Molecular Dynamics Simulation

Abstract

1. Introduction

2. Method

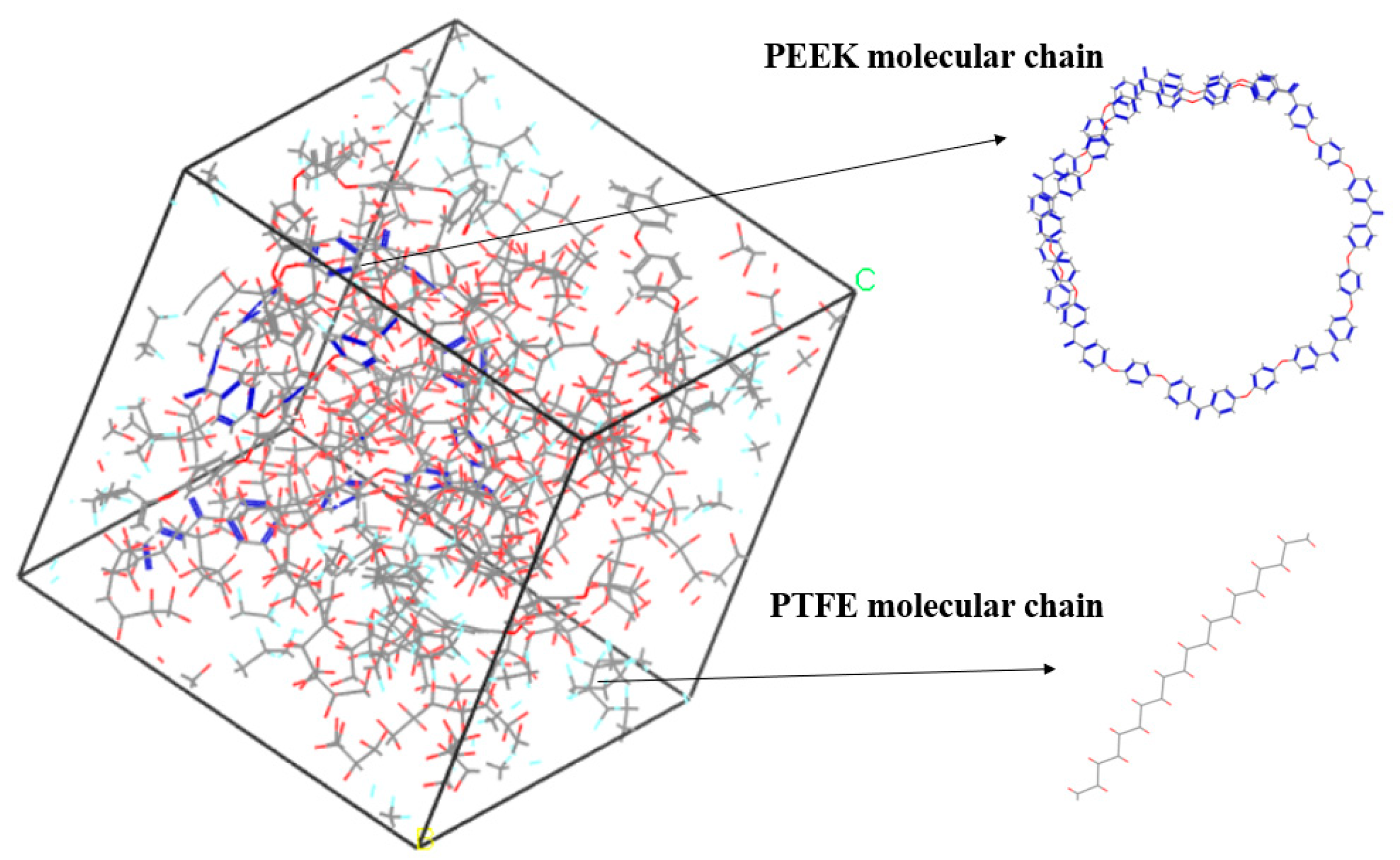

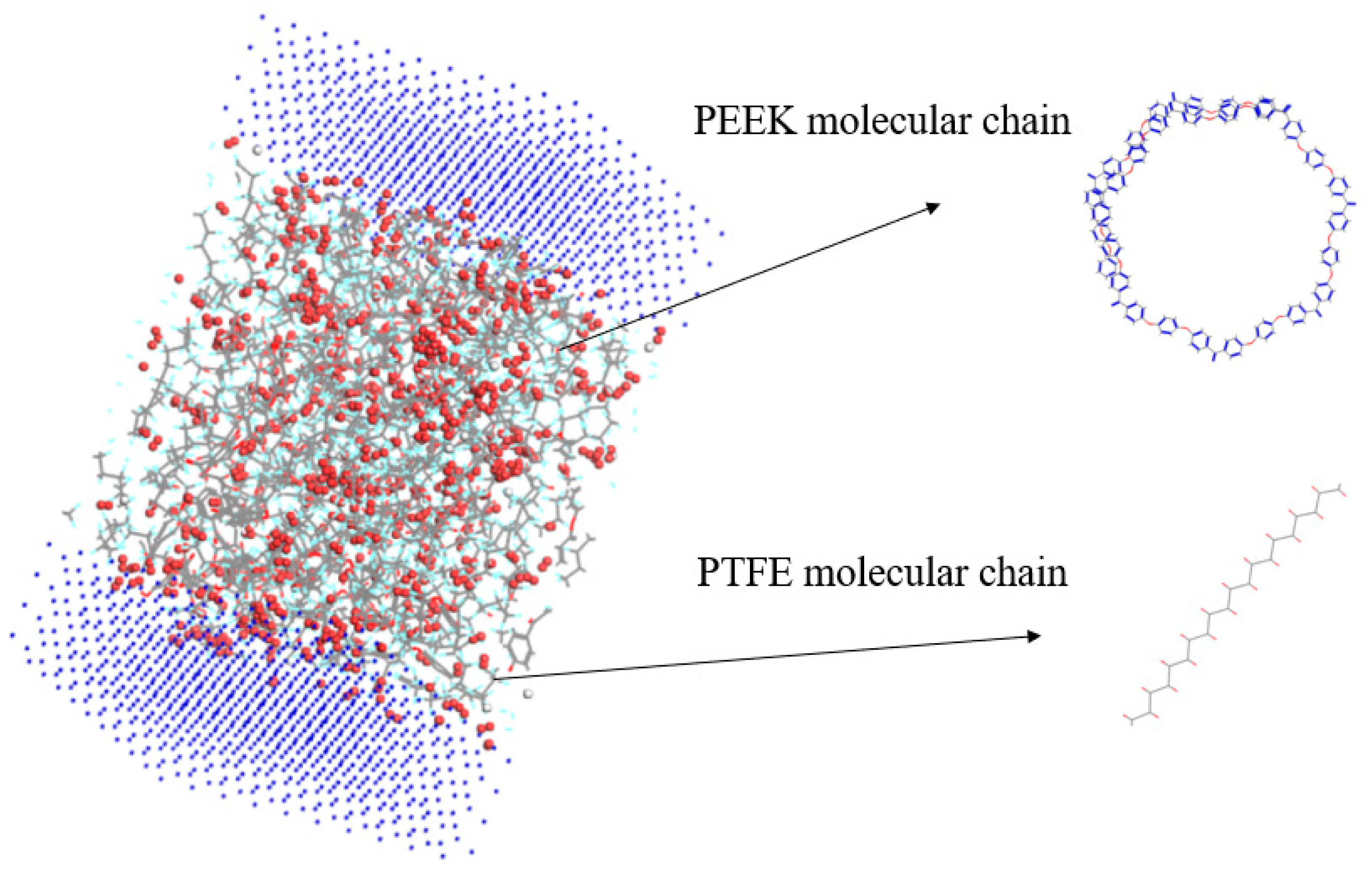

2.1. Molecular Model

2.2. Simulation Process

3. Results and Discussion

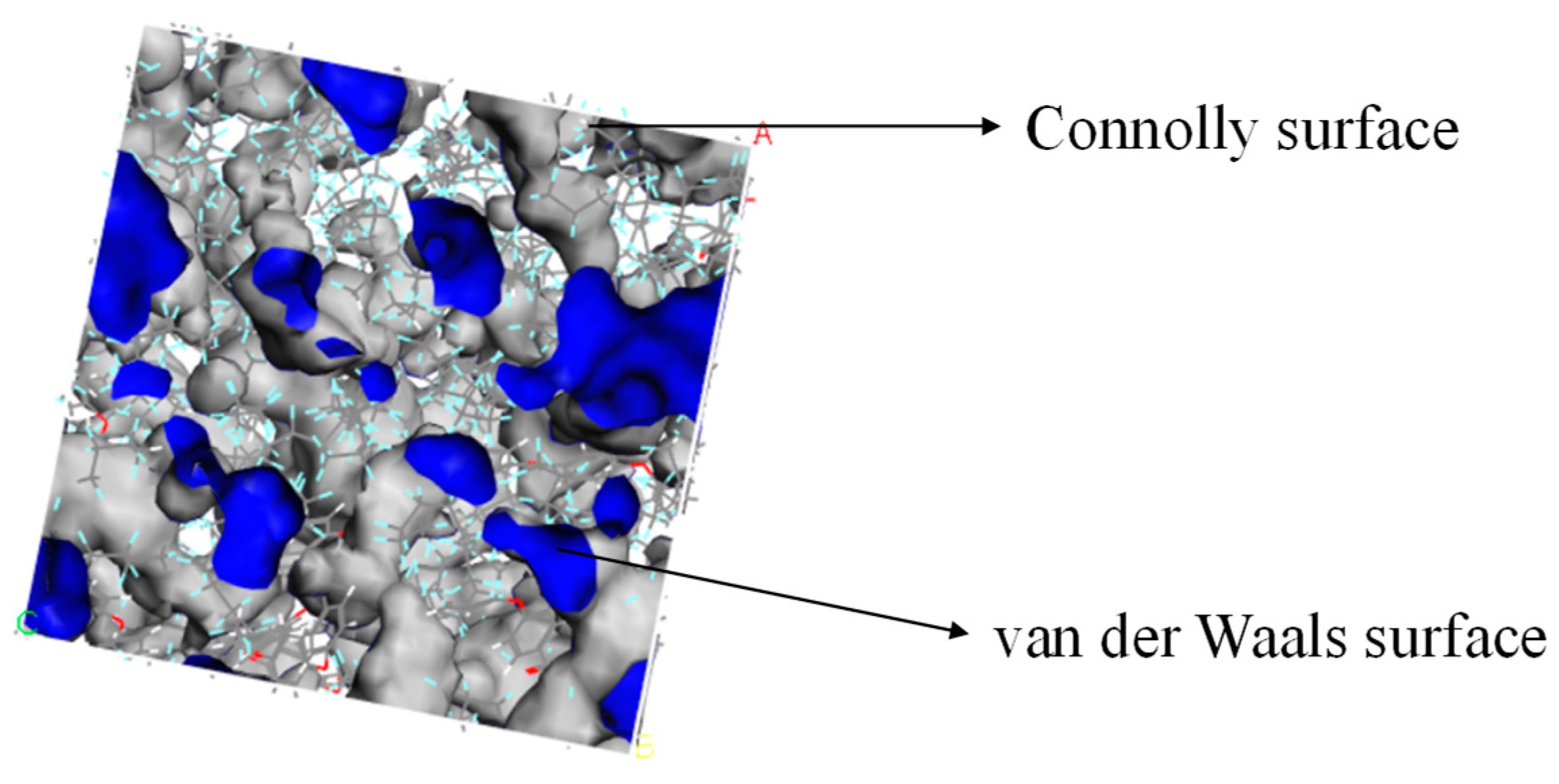

3.1. Free Volume and Atom Distribution of Composites

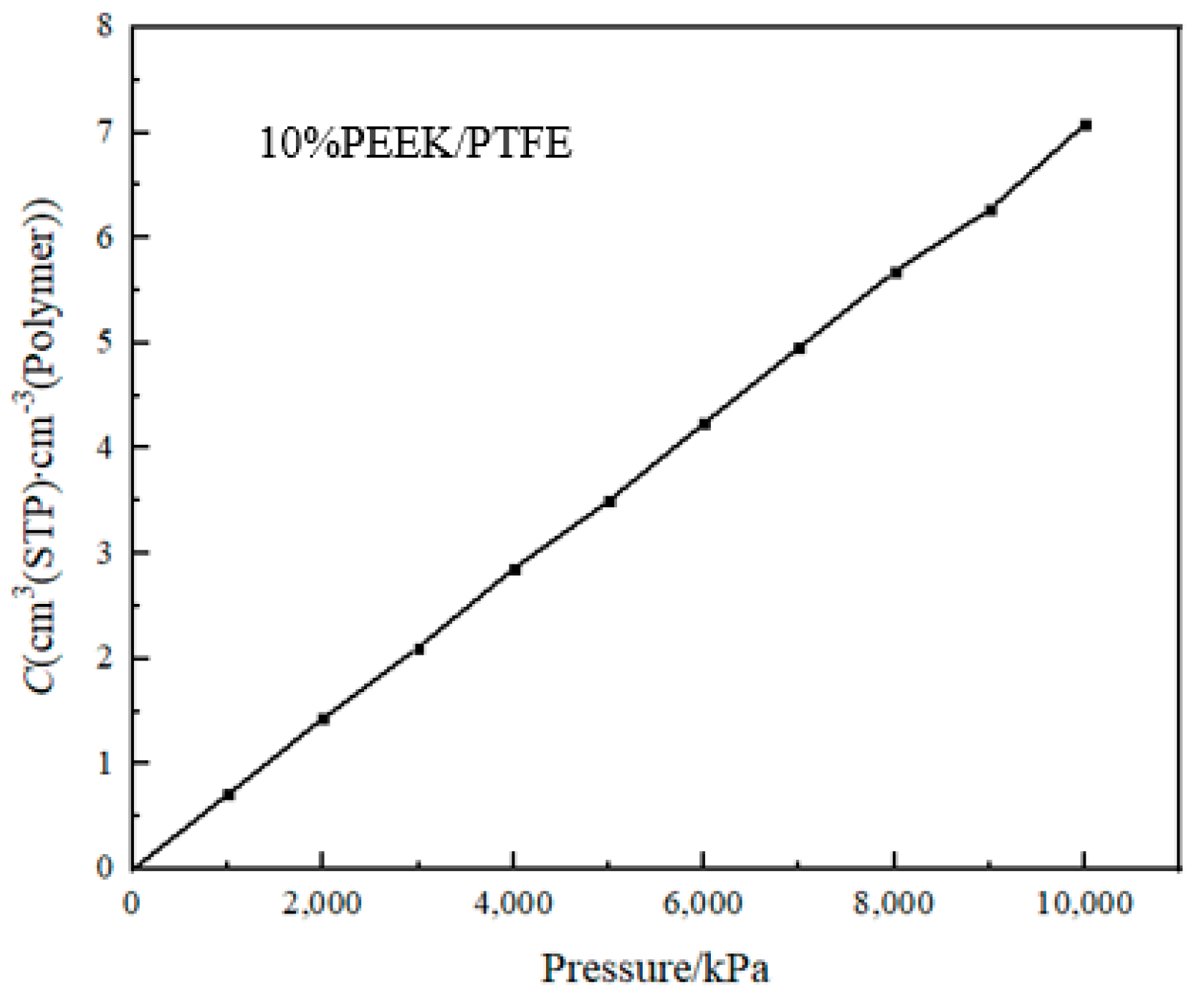

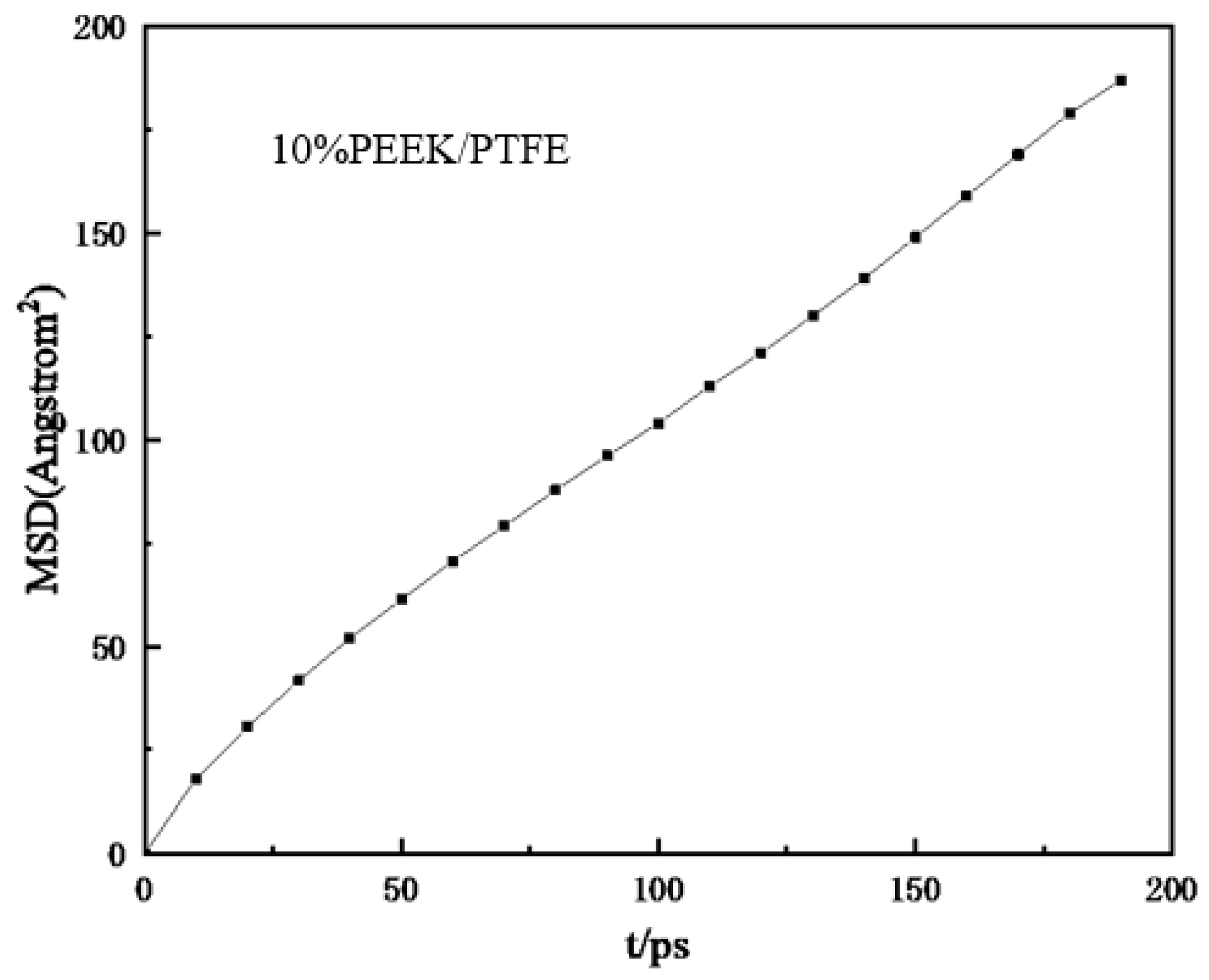

3.2. Solubility Coefficient and Diffusion Coefficient

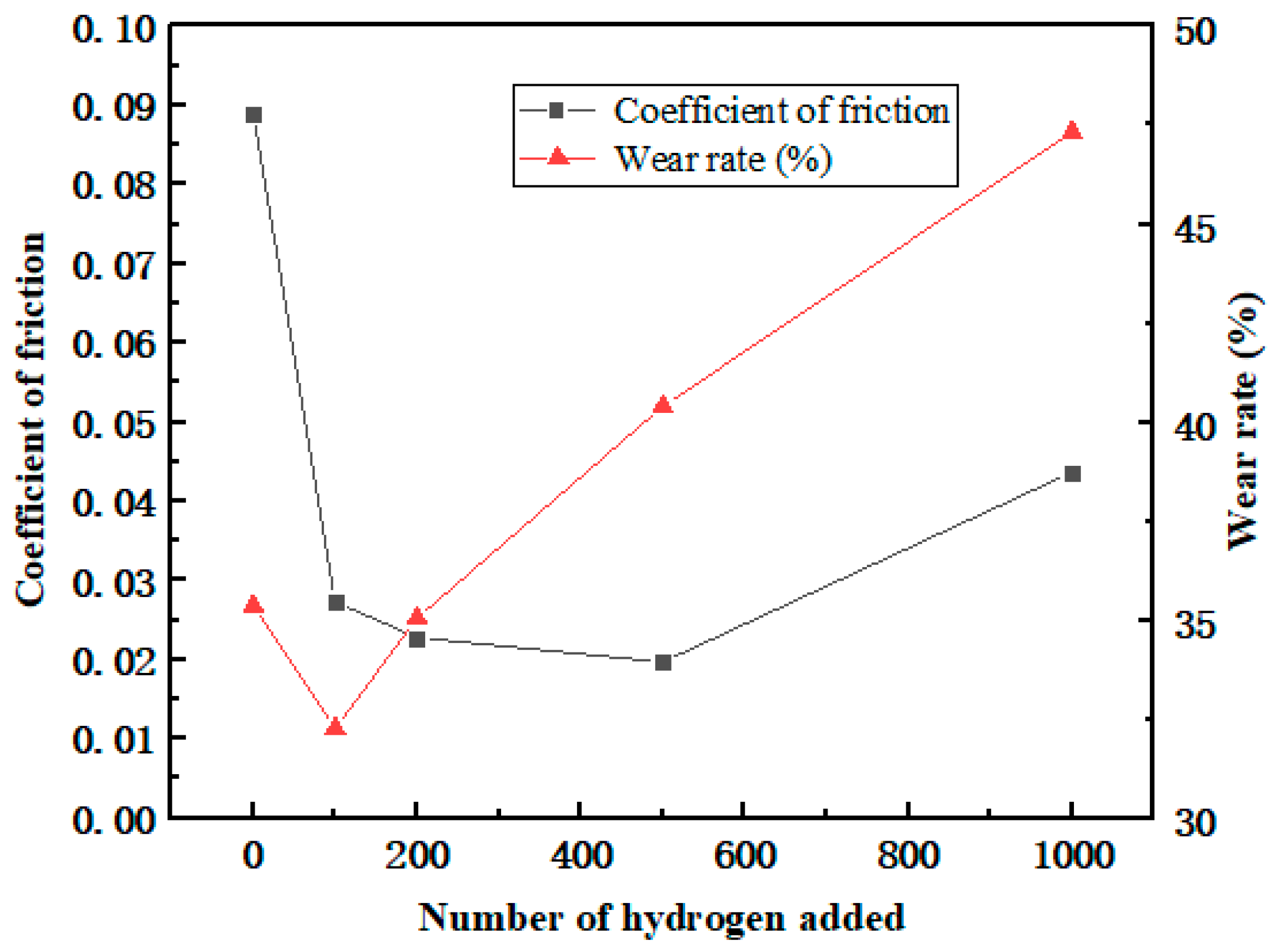

3.3. Effect of Penetration on Friction Performance

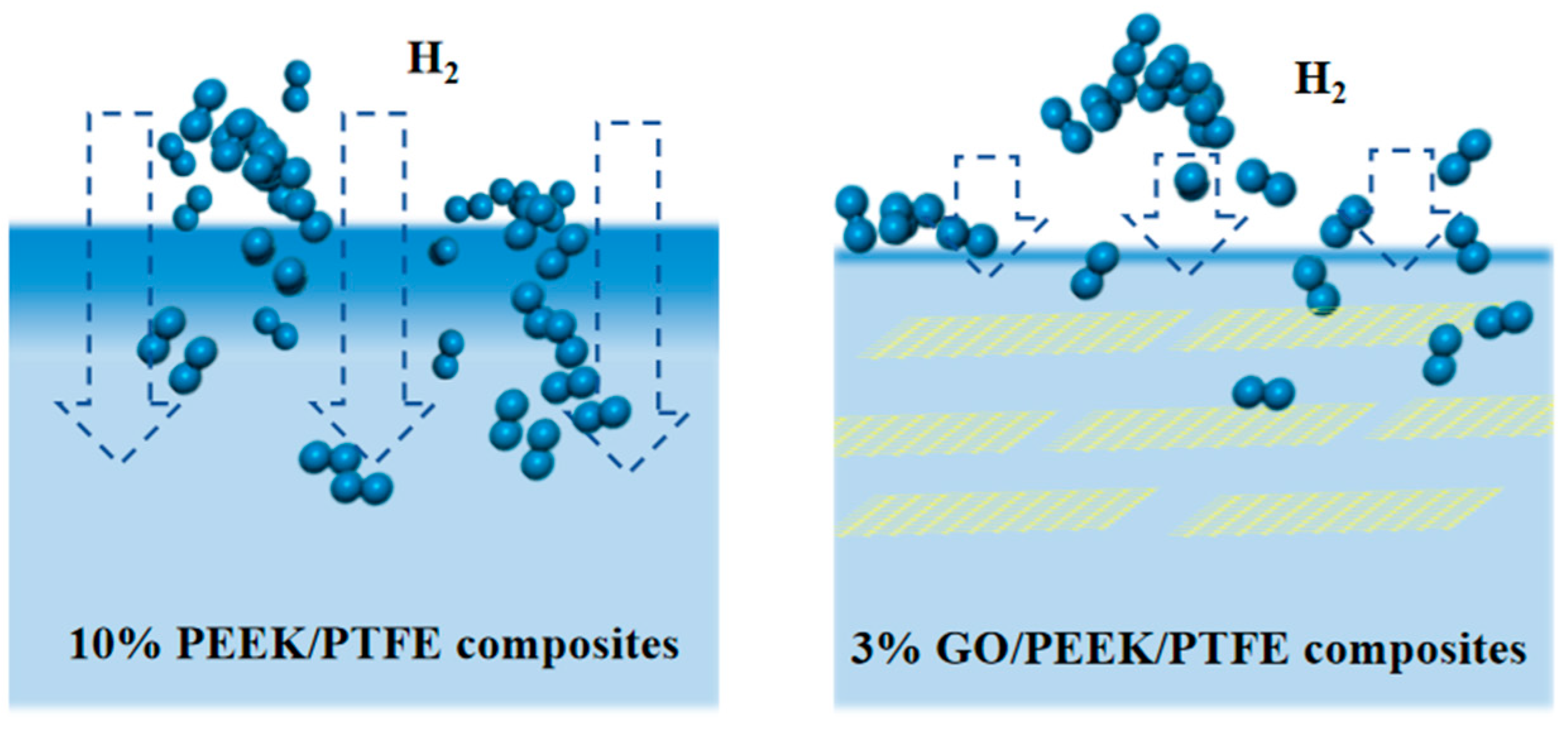

3.4. The Suppression Effect of Filling Graphene on Hydrogen Permeation Behavior and Frictional Performance of PEEK/PTFE Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.-F. Research on the manufacturing process of high-performance PTFE sealing material. Hydraul. Pneum. Seal. 2012, 32, 13–15+20. [Google Scholar]

- Peng, J.; Wei, J.; Du, W.; Zeng, N.; Rao, D. The influence of modified polytetrafluoroethylene on the sealing performance of the plug seal at different temperatures. Metall. Mater. 2021, 41, 5–7. [Google Scholar]

- Tuo, L.; Du, X.; Wang, M.; Du, C.; Zhang, Z. Common faults and analysis of the hydrogen compressor. Biochemistry 2019, 5, 40–44. [Google Scholar]

- Demas, N.G.; Polycarpou, A.A. Tribological performance of PTFE-based coatings for air-conditioning compressors. Surf. Coat. Technol. 2008, 203, 307–316. [Google Scholar] [CrossRef]

- Lei, H.; Zhao, G.; Yin, Y.; Ding, Q.; Shi, Y. Molecular dynamics simulation of the tribological properties of carbon nitride reinforced polytetrafluoroethylene. J. Tribol. 2021, 41, 223–229. [Google Scholar]

- Hu, Y.; Song, J. Progress in gasket sealing technology. Chem. Mach. 2003, 30, 121–124. [Google Scholar]

- Cheng, Z.; Wang, B. Common faults and handling measures in the maintenance of piston compressors. Shanxi Chem. Ind. 2020, 40, 23–40. [Google Scholar]

- Liu, K. Benchmarking the polyatomic reaction dynamics of X+methane. Chin. J. Chem. Phys. 2019, 32, 1–10. [Google Scholar] [CrossRef]

- Zhang, Q.; Tang, H.; Wang, Y.; Zhao, J. Simulation study on the mechanical properties of polyether ether ketone reinforced polytetrafluoroethylene. Lubr. Seal. 2023, 48, 85–89. [Google Scholar]

- Wang, L.; Xu, Y.; Jiang, Z.; Xu, Y.; Xiang, S.; Guo, X.; Wu, X. FTIR, XPS and SEM were used to study the adsorption performance of polycarboxylate dispersant on the surface of pyrazolate granules. Spectrosc. Spectr. Anal. 2018, 38, 3401–3406. [Google Scholar]

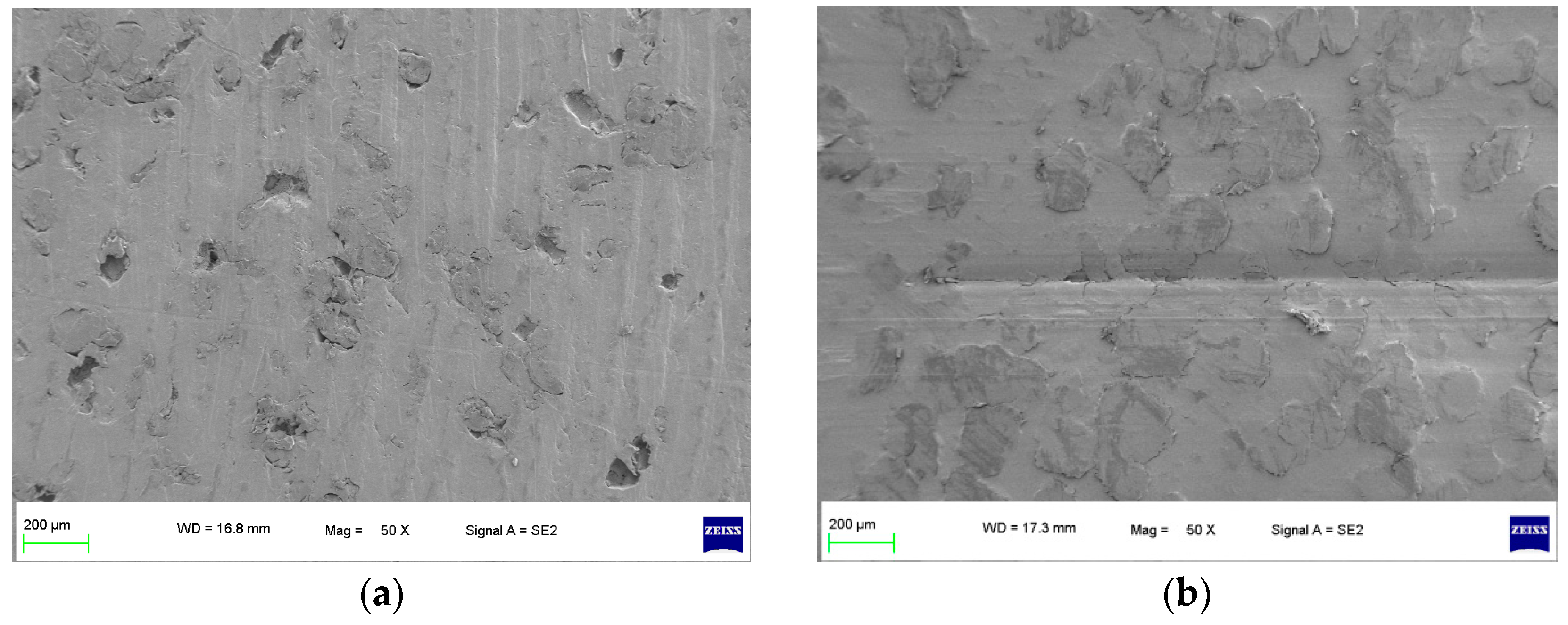

- Zheng, X.; You, J.; Zhu, Y. Application of scanning electron microscopy in the study of PEEK/PTFE composites characterization. J. PEEK/PTFE Compos. 2022, 53, 42–53. [Google Scholar]

- Zhang, Q.; Tang, H.; Wang, Y. Molecular dynamics simulation of carbon nanotube reinforced polyether ether ketone/polytetrafluoroethylene tribological properties. Polym. Mater. Sci. Eng. 2023, 39, 90–102. [Google Scholar]

- Jiao, J.; Pay, Y. Molecular Dynamics Simulation of Mechanical and Frictional Properties of Graphene/Polymer Composites. Ph.D. Thesis, Central North University, Taiyuan, China, 2022. [Google Scholar]

- Yang, B.; Li, Y.; Wang, S.; Nie, R.; Wang, Q. Aminosilane modified graphene oxide for reinforcing nitrile butadiene rubber: Experiments and molecular dynamic simulations. Compos. Sci. Technol. 2023, 235, 109956. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Wang, Q. A molecular dynamics simulation study on enhancement of mechanical and tribological properties of polymer composites by introduction of graphene. Carbon 2017, 111, 538–545. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, J.; Wang, S.; Li, Y. A comparative study on enhancement of mechanical and tribological properties of nitrile rubber composites reinforced by different functionalized graphene sheets: Molecular dynamics simulations. Polym. Compos. 2021, 42, 205–219. [Google Scholar] [CrossRef]

- Zheng, Z. Interface Design and Leakage Performance Analysis of Polyethylene/Carbon Fiber Composites for Pressure Vessels. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Lin, H.; Freeman, B.D. Gas solubility, diffusivity and permeability in poly(ethylene oxide). J. Membr. Sci. 2015, 239, 105–117. [Google Scholar] [CrossRef]

- Wang, G.; Ren, T.; Qi, Q.; Lin, J.; Liu, Q.; Zhang, J. Determining the diffusion coefficient of gas diffusion in coal: Development of numerical solution. Fuel 2017, 196, 47–58. [Google Scholar] [CrossRef]

- Chatterjee, R.; Bisoi, S.; Kumar, A.G.; Padmanabhan, V.; Banerjee, S. Polyimides Containing Phosphaphenanthrene Skeleton: Gas-Transport Properties and Molecular Dynamics Simulations. Acs Omega 2018, 3, 13510–13523. [Google Scholar] [CrossRef]

- Fan, C.; Shuai, M.; Zhou, Y.; Shao, H.; Qi, J.; Dong, F. Numerical simulation study on the permeation behavior of gas molecules in Parylene AF4 and Parylene AF8. Funct. Mater. 2014, 45, 5. [Google Scholar] [CrossRef]

- Zhao, L. Preparation and Hydrogen Barrier Properties of Graphene Oxide/Polyethyleneimine Layer by Layer Self-Assembled Composite Films. Ph.D. Thesis, China University of Petroleum (East China), Dongying, China, 2018. [Google Scholar]

- Junana, G.H. Simulation of CO2/N2 gas Permeability Performance of Hybrid Polyimide Membranes. Membr. Sci. Technol. 2016, 36, 6. [Google Scholar] [CrossRef]

| S | D | P |

|---|---|---|

| /cm3(STP)·cm−3(PEEK/PTFE composites)·Pa | /cm2·s−1 | /cm3(STP)cm·cm−2·s−1·Pa−1 |

| 8.69 × 10−7 | 1.65 × 10−5 | 1.43 × 10−13 |

| Quantity of the Hydrogen | Friction Coefficient | Wear Rate (%) |

|---|---|---|

| 0 | 0.0890 | 35.37 |

| 100 | 0.0273 | 32.26 |

| 200 | 0.0228 | 35.05 |

| 500 | 0.0197 | 40.40 |

| 1000 | 0.0437 | 47.33 |

| Quantity of the Hydrogen | Friction Coefficient | Wear Rate (%) |

|---|---|---|

| 0 | 0.0221 | 35.69 |

| 100 | 0.0216 | 34.91 |

| 200 | 0.0209 | 33.76 |

| 300 | 0.0182 | 32.01 |

| 400 | 0.0190 | 34.46 |

| 500 | 0.0195 | 34.98 |

| 1000 | 0.0245 | 36.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.; Wang, M.; Li, Y.; Wang, Y. A Study on the Effect and Suppression of Hydrogen Permeation Behavior on the Friction Characteristics of PEEK/PTFE Composites via Molecular Dynamics Simulation. Polymers 2024, 16, 1000. https://doi.org/10.3390/polym16071000

Tang H, Wang M, Li Y, Wang Y. A Study on the Effect and Suppression of Hydrogen Permeation Behavior on the Friction Characteristics of PEEK/PTFE Composites via Molecular Dynamics Simulation. Polymers. 2024; 16(7):1000. https://doi.org/10.3390/polym16071000

Chicago/Turabian StyleTang, Henan, Minghui Wang, Yunlong Li, and Yan Wang. 2024. "A Study on the Effect and Suppression of Hydrogen Permeation Behavior on the Friction Characteristics of PEEK/PTFE Composites via Molecular Dynamics Simulation" Polymers 16, no. 7: 1000. https://doi.org/10.3390/polym16071000

APA StyleTang, H., Wang, M., Li, Y., & Wang, Y. (2024). A Study on the Effect and Suppression of Hydrogen Permeation Behavior on the Friction Characteristics of PEEK/PTFE Composites via Molecular Dynamics Simulation. Polymers, 16(7), 1000. https://doi.org/10.3390/polym16071000