The Effects of Microcrystalline Cellulose Addition on the Properties of Wood–PLA Filaments for 3D Printing

Abstract

1. Introduction

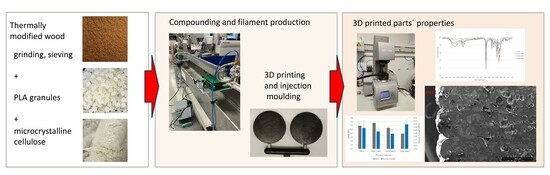

2. Materials and Methods

2.1. Materials and Preparation

2.1.1. Wood Particles Preparation

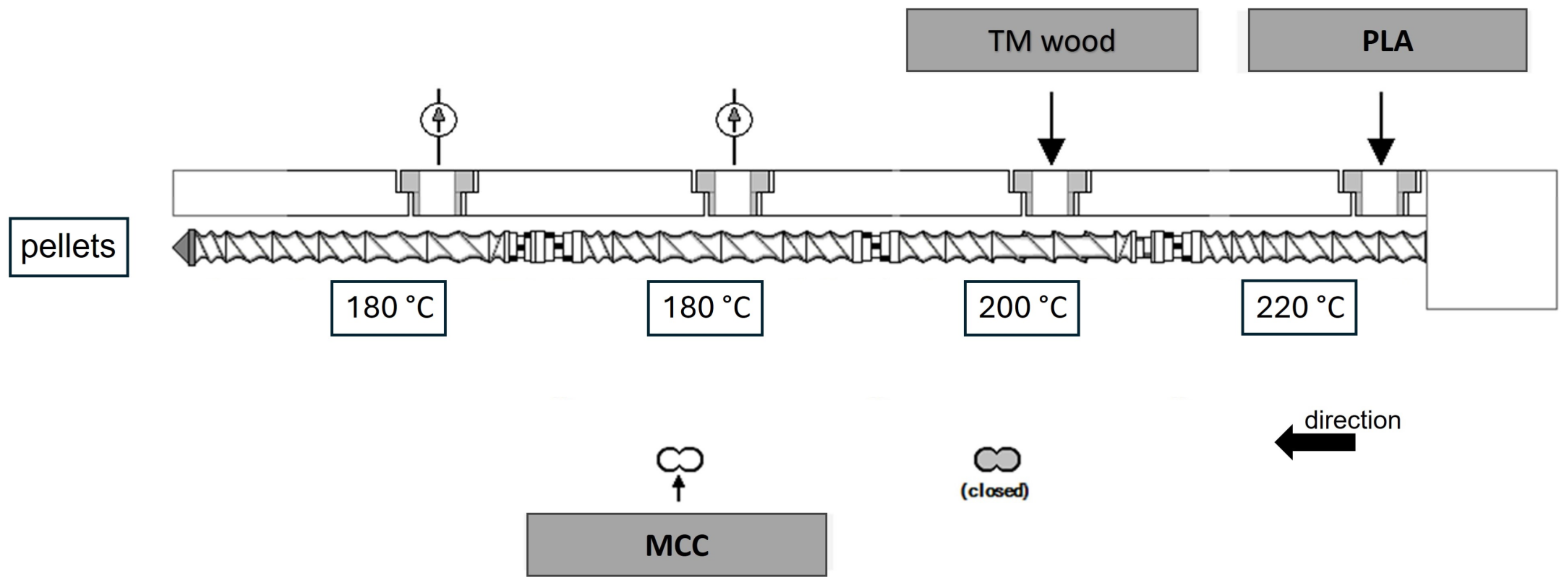

2.1.2. Compounding

2.1.3. Filament Extrusion

2.1.4. Fused Filament Fabrication of 3D-Printed Parts

2.1.5. Injection Molding

2.2. Characterization Techniques

2.2.1. Differential Scanning Calorimetry (DSC)

2.2.2. FT-IR Characterization

2.2.3. Rheology Measurements

2.2.4. Flexural Strength and MOE

- Ls is the distance between supports [mm];

- b and t are the width and thickness of the specimen, respectively [mm];

- (F2 − F1) is the increment of the load on the straight line of the load–deflection curve [N];

- (U2 − U1) is the increment of deflection corresponding to (F2 − F1) [mm].

2.2.5. Tensile Strength

2.2.6. Scanning Electron Microscopy (SEM)

2.2.7. Statistics

3. Results and Discussion

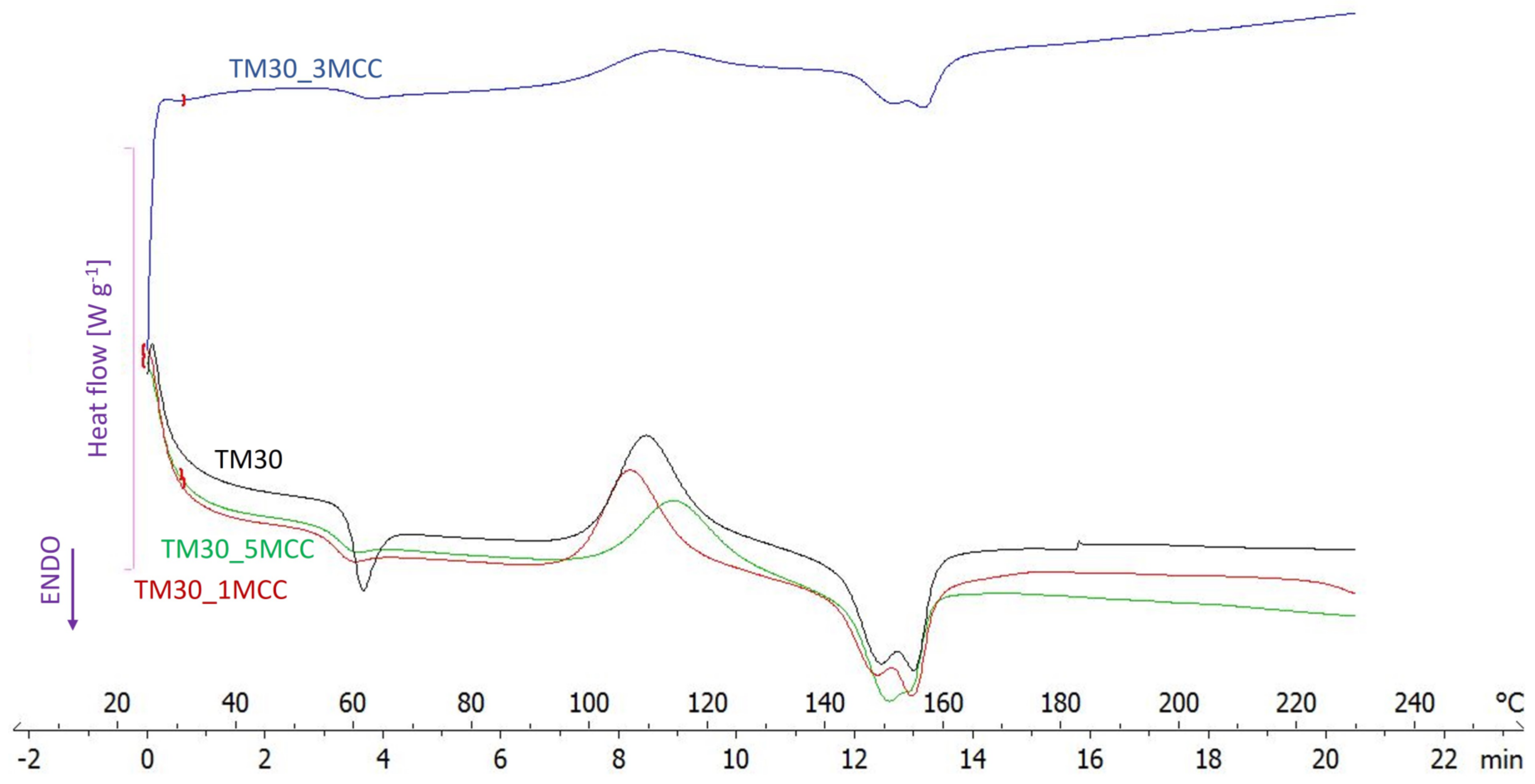

3.1. DSC Analysis

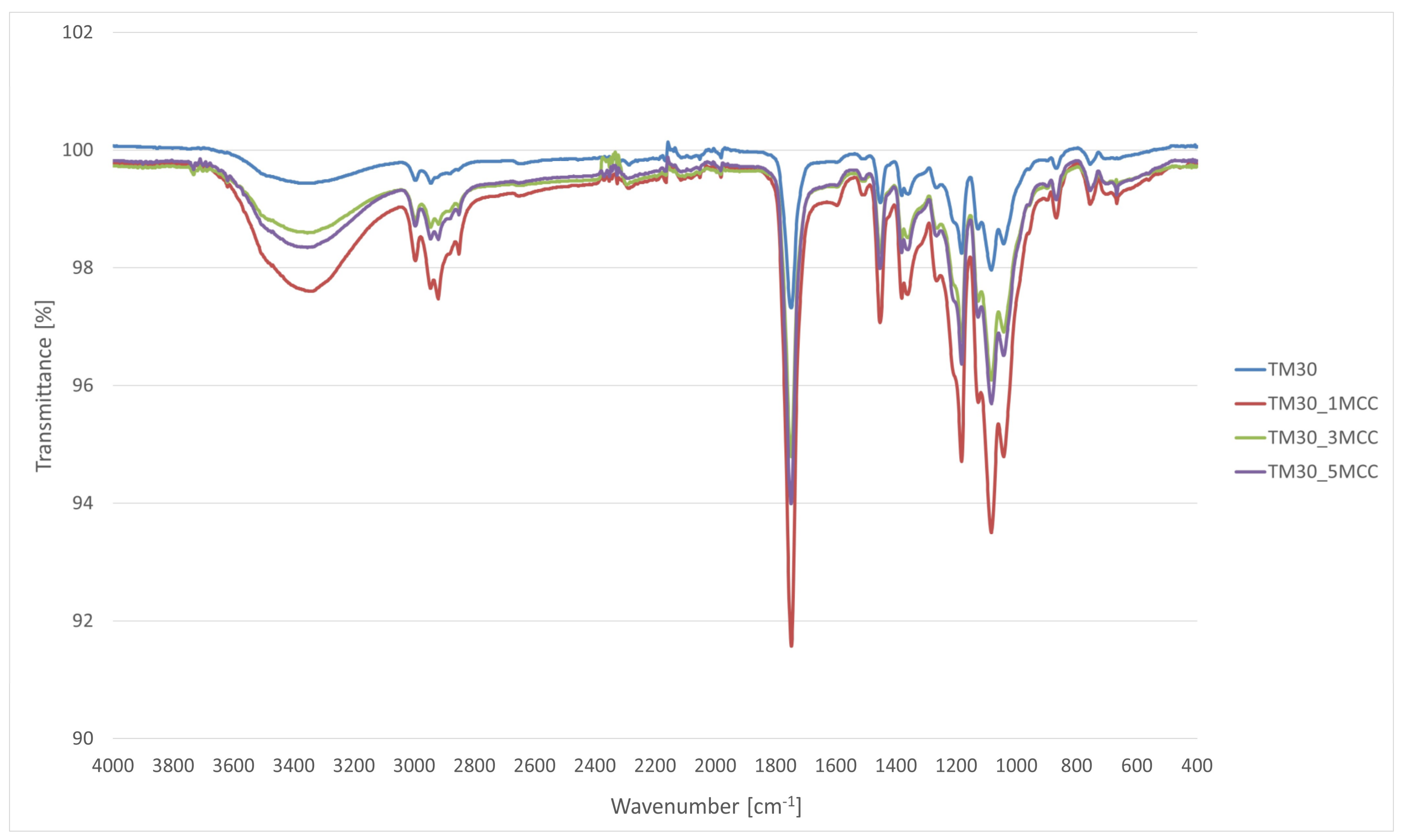

3.2. FT-IR Characterization

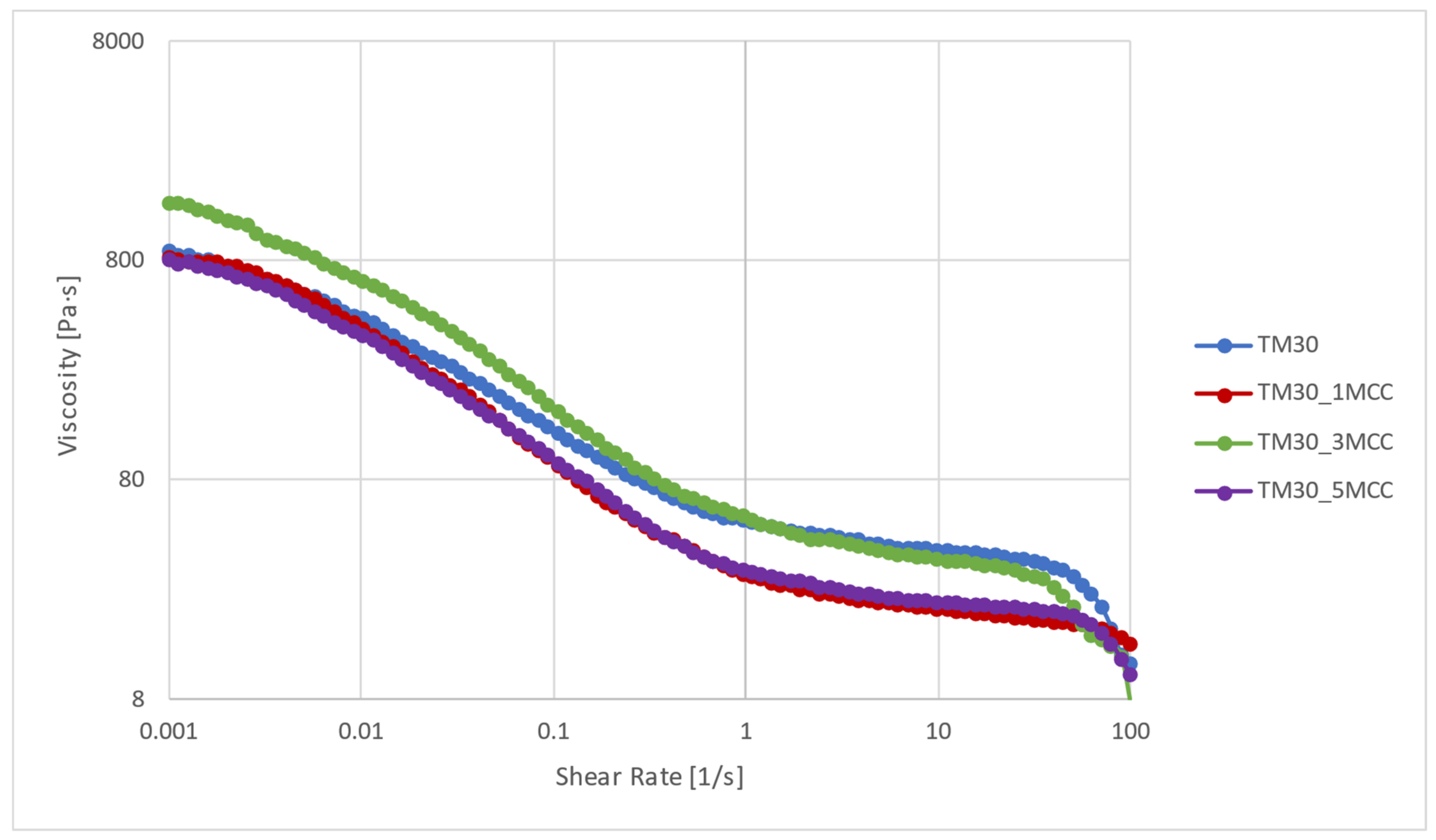

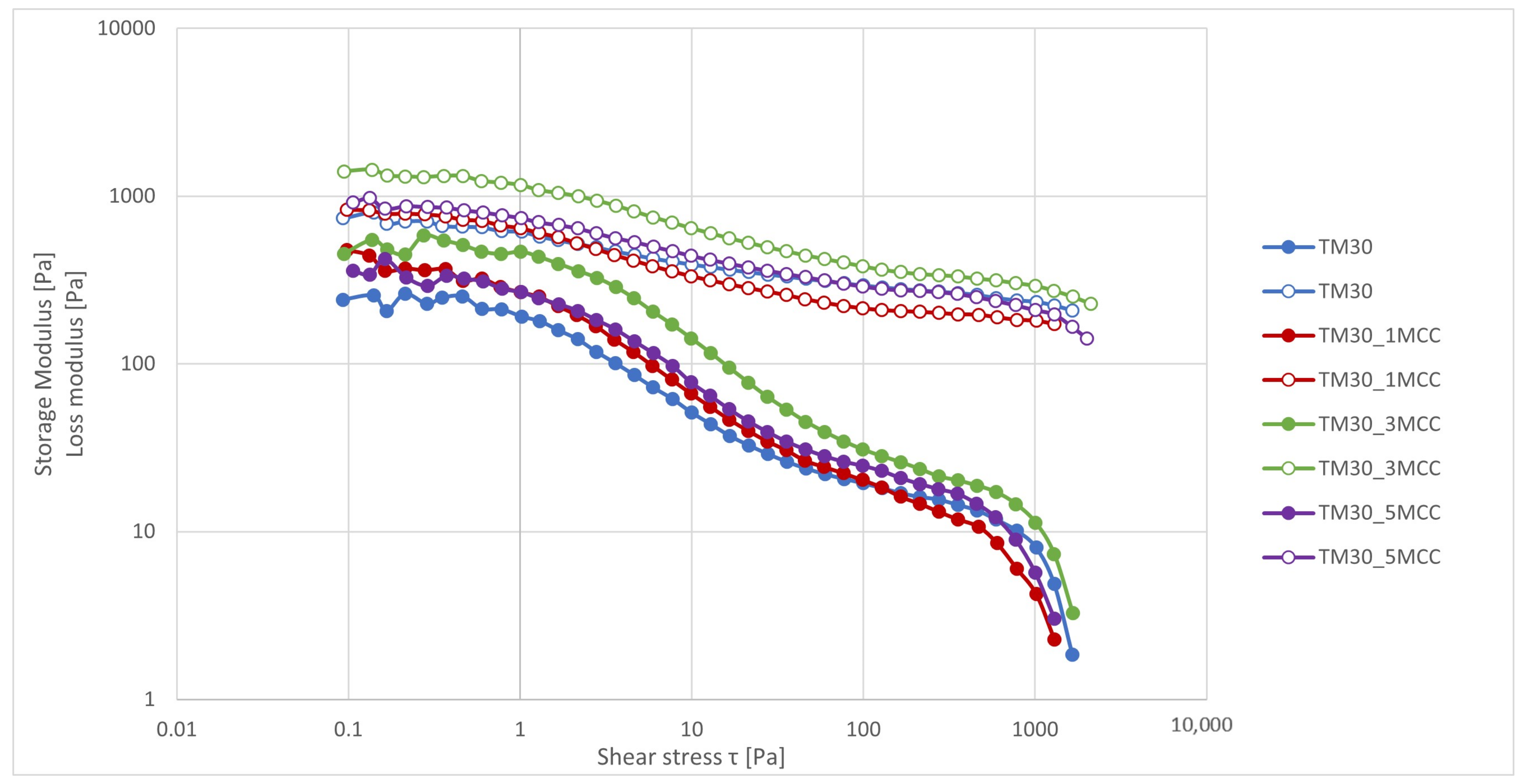

3.3. Rheological Characterization

3.4. Flexural Strength and MOE Results

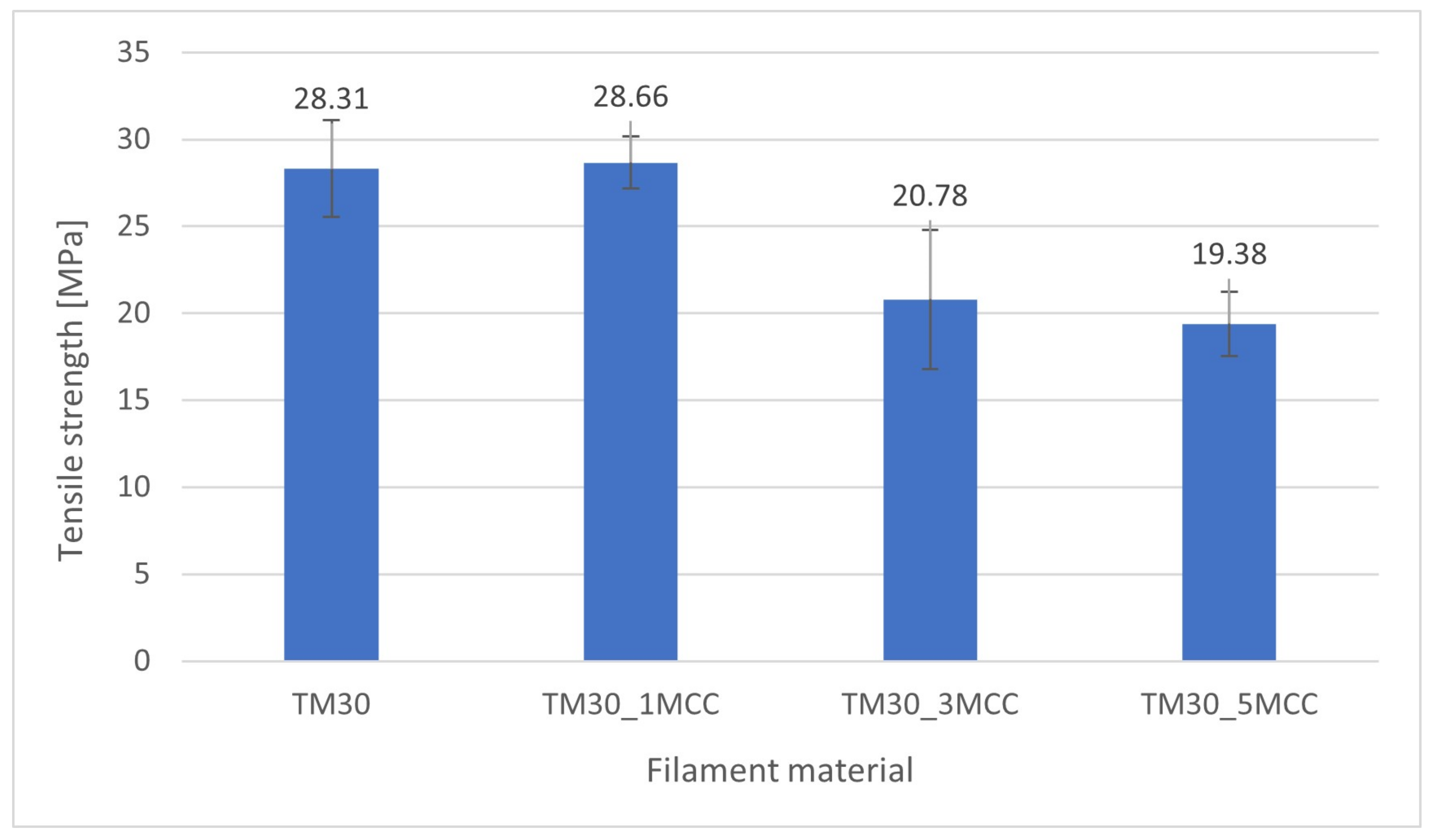

3.5. Tensile Strength Results

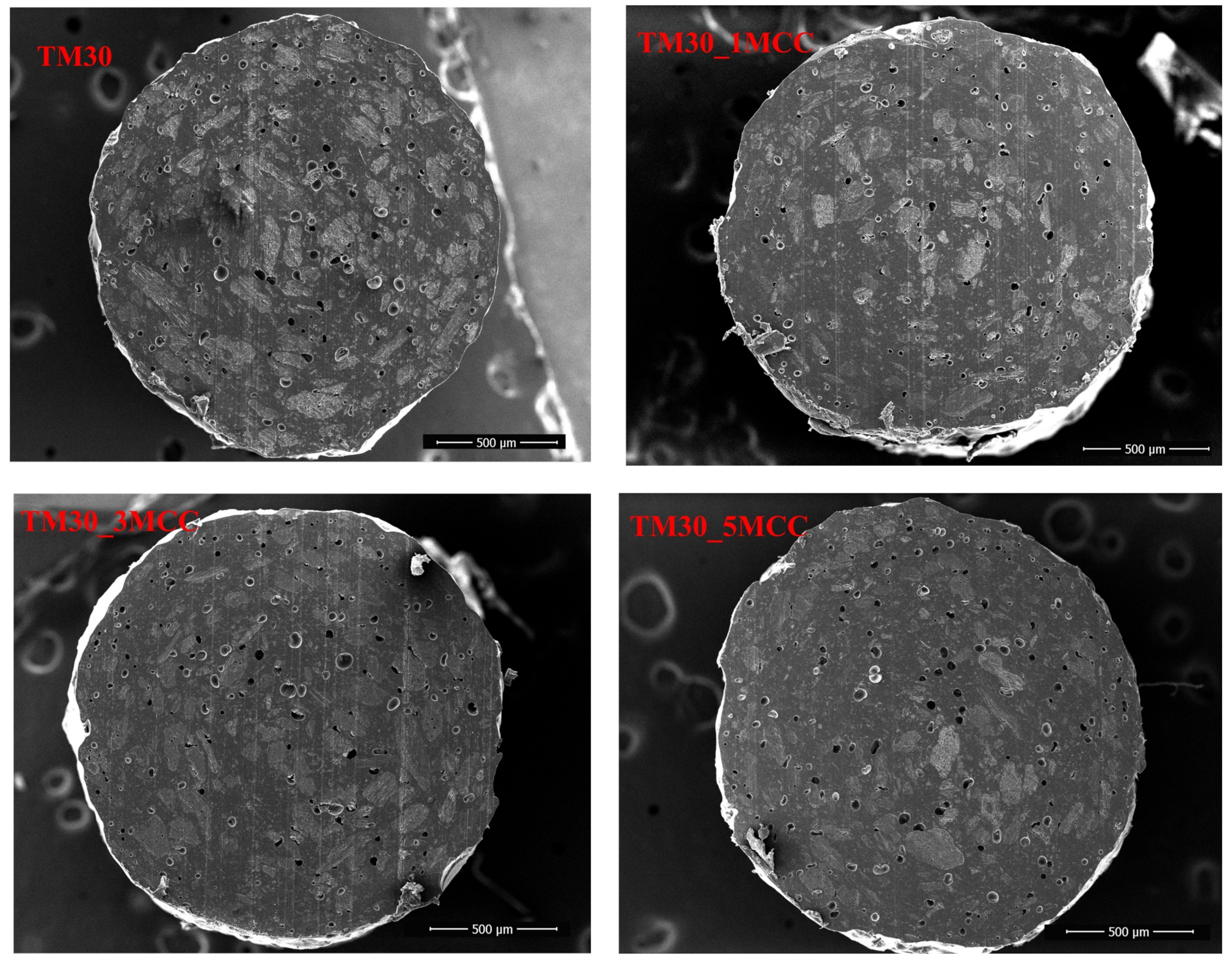

3.6. Scanning Electron Microscopy (SEM) Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- van Wijk, A.; van Wijk, I. 3D Printing with Biomaterials: Towards a Sustainable and Circular Economy; IOS Press: Amsterdam, The Netherlands, 2015; ISBN 9781614994862. [Google Scholar]

- Sin, L.T.; Rahmat, A.R.; Wan, W.A.A.R. Polylactic Acid: PLA Biopolymer Technology and Applications; William Andrew: Oxford, UK, 2012; ISBN 9781437744606. [Google Scholar]

- Ahmad, N.D.; Kusmono; Wildan, M.W.; Herianto. Preparation and Properties of Cellulose Nanocrystals-Reinforced Poly (Lactic Acid) Composite Filaments for 3D Printing Applications. Results Eng. 2023, 17, 100842. [Google Scholar] [CrossRef]

- Perić, M.; Putz, R.; Paulik, C. 3D-Printed Pla Filaments Reinforced with Nanofibrillated Cellulose. J. Renew. Mater. 2020, 8, 759–772. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Functional Biopolymers; Springer International Publishing: Cham, Switzerland, 2018; p. 382. [Google Scholar] [CrossRef]

- Ding, W.D.; Pervaiz, M.; Sain, M. Cellulose-Enabled Polylactic Acid (PLA) Nanocomposites: Recent Developments and Emerging Trends; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Dufresne, A. Processing of Polymer Nanocomposites Reinforced with Polysaccharide Nanocrystals. Molecules 2010, 15, 4111–4128. [Google Scholar] [CrossRef]

- Gauss, C.; Pickering, K.L.; Tshuma, J.; McDonald-Wharry, J. Production and Assessment of Poly(Lactic Acid) Matrix Composites Reinforced with Regenerated Cellulose Fibres for Fused Deposition Modelling. Polymers 2022, 14, 3991. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.P.S.; Bhat, A.H.; Ireana Yusra, A.F. Green Composites from Sustainable Cellulose Nanofibrils: A Review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Rojas, O.J.; Lucia, L.A.; Sain, M. Cellulosic Nanocomposites: A Review. Bioresources 2008, 3, 929–980. [Google Scholar] [CrossRef]

- Ahmad, F.; Choi, H.S.; Park, M.K. A Review: Natural Fiber Composites Selection in View of Mechanical, Light Weight, and Economic Properties. Macromol. Mater. Eng. 2015, 300, 10–24. [Google Scholar] [CrossRef]

- Zugenmaier, P. Crystalline Cellulose and Derivatives, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2008; p. 285. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Meng, X.; Lu, Y.; Kunc, V.; Love, L.J.; Peter, W.H.; Ozcan, S. High Modulus Biocomposites via Additive Manufacturing: Cellulose Nanofibril Networks as “Microsponges”. Compos. B Eng. 2019, 173, 106817. [Google Scholar] [CrossRef]

- Xu, W.; Wang, X.; Sandler, N.; Willför, S.; Xu, C. Three-Dimensional Printing of Wood-Derived Biopolymers: A Review Focused on Biomedical Applications. ACS Sustain. Chem. Eng. 2018, 6, 5663–5680. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. Mechanical Properties of Biodegradable Composites from Poly Lactic Acid (PLA) and Microcrystalline Cellulose (MCC). J. Appl. Polym. Sci. 2005, 97, 2014–2025. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Hui Chuin, C.T.; Sabar, S.; Fazita, M.R.N.; Taiwo, O.F.A.; Hassan, T.M.; Haafiz, M.K.M. Microcrystalline Cellulose: Isolation, Characterization and Bio-Composites Application—A Review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef]

- Sinquefield, S.; Ciesielski, P.N.; Li, K.; Gardner, D.J.; Ozcan, S. Nanocellulose Dewatering and Drying: Current State and Future Perspectives. ACS Sustain. Chem. Eng. 2020, 8, 9601–9615. [Google Scholar] [CrossRef]

- Abdulkhani, A.; Hosseinzadeh, J.; Ashori, A.; Dadashi, S.; Takzare, Z. Preparation and Characterization of Modified Cellulose Nanofibers Reinforced Polylactic Acid Nanocomposite. Polym. Test. 2014, 35, 73–79. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable Composites Based on Lignocellulosic Fibers—An Overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are Natural Fiber Composites Environmentally Superior to Glass Fiber Reinforced Composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Ambone, T.; Torris, A.; Shanmuganathan, K. Enhancing the Mechanical Properties of 3D Printed Polylactic Acid Using Nanocellulose. Polym. Eng. Sci. 2020, 60, 1842–1855. [Google Scholar] [CrossRef]

- Giubilini, A.; Siqueira, G.; Clemens, F.J.; Sciancalepore, C.; Messori, M.; Nyström, G.; Bondioli, F. 3D-Printing Nanocellulose-Poly(3-Hydroxybutyrate- Co-3-Hydroxyhexanoate) Biodegradable Composites by Fused Deposition Modeling. ACS Sustain. Chem. Eng. 2020, 8, 10292–10302. [Google Scholar] [CrossRef]

- Mohan Bhasney, S.; Kumar, A.; Katiyar, V. Microcrystalline Cellulose, Polylactic Acid and Polypropylene Biocomposites and Its Morphological, Mechanical, Thermal and Rheological Properties. Compos. B Eng. 2020, 184, 107717. [Google Scholar] [CrossRef]

- Incarnato, L.; Nobile, M.R.; Scarfato, P. Development of PLA/Microcellulose Biocomposite Filaments for 3D Printing. Macromol. Symp. 2022, 405, 2–5. [Google Scholar] [CrossRef]

- Mohamad Haafiz, M.K.; Hassan, A.; Abdul Khalil, H.P.S.; Khan, I.; Inuwa, I.M.; Saiful Islam, M.; Sohrab Hossain, M.; Syakir, M.I.; Nurul Fazita, M.R. Bionanocomposite Based on Cellulose Nanowhisker from Oil Palm Biomass-Filled Poly(Lactic Acid). Polym. Test. 2015, 48, 133–139. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Huang, J.; Lin, N.; Ahmad, I.; Mariano, M.; Dufresne, A.; Thomas, S.; Gałęski, A. Recent Developments in Nanocellulose-Based Biodegradable Polymers, Thermoplastic Polymers, and Porous Nanocomposites. Prog. Polym. Sci. 2018, 87, 197–227. [Google Scholar] [CrossRef]

- Ioelovich, M.J. Microcellulose Vs Nanocellulose—A Review. World J. Adv. Eng. Technol. Sci. 2022, 5, 001–015. [Google Scholar] [CrossRef]

- Martin, O.; Avérous, L. Poly(Lactic Acid): Plasticization and Properties of Biodegradable Multiphase Systems. Polymer 2001, 42, 6209–6219. [Google Scholar] [CrossRef]

- Krapež Tomec, D.; Schöflinger, M.; Leßlhumer, J.; Žigon, J.; Humar, M.; Kariž, M. Effect of Thermal Modification of Wood on the Rheology, Mechanical Properties and Dimensional Stability of Wood Composite Filaments and 3D-Printed Parts. Wood Mater. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- ASTM D882; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: Conshohocken, PA, USA, 1991.

- ASTM D792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: Conshohocken, PA, USA, 1958.

- ASTM D1238; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM International: Conshohocken, PA, USA, 1954.

- Pohleven, F.; Rep, G. Wood Modification-a Promising Method for Wood Preservation. Drv. Ind. 2001, 52, 71–76. [Google Scholar]

- Krapež Tomec, D.; Schwarzkopf, M.; Repič, R.; Žigon, J.; Gospodarič, B.; Kariž, M. Effect of Thermal Modification of Wood Particles for Wood-PLA Composites on Properties of Filaments, 3D-Printed Parts and Injection Moulded Parts. Eur. J. Wood Wood Prod. 2023. [Google Scholar] [CrossRef]

- Marathe, Y.N.; Arun Torris, A.T.; Ramesh, C.; Badiger, M.V. Borassus Powder-Reinforced Poly(Lactic Acid) Composites with Improved Crystallization and Mechanical Properties. J. Appl. Polym. Sci. 2019, 136, 47440. [Google Scholar] [CrossRef]

- EN 310:1996; Wood-Based Panels-Determination of Modulus of Elasticity in Bending and of Bending Strength. Institute of Turkish Standards: Ankara, Turkey, 1996.

- EN ISO 527-2:1996; Plastics—Determination of tensile properties—Part 2: Test conditions for moulding and extrusion plastics. European Committee for Standardization (CEN): Brussels, Belgium; International Organization for Standardization (ISO): Geneva, Switzerland, 1996.

- Liu, Z.; Lei, Q.; Xing, S. Mechanical Characteristics of Wood, Ceramic, Metal and Carbon Fiber-Based PLA Composites Fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3743–3753. [Google Scholar] [CrossRef]

- Halász, K.; Csóka, L. Plasticized Biodegradable Poly(Lactic Acid) Based Composites Containing Cellulose in Micro- and Nanosize. J. Eng. 2013, 2013, 329379. [Google Scholar] [CrossRef]

- Molinari, G.; Gigante, V.; Fiori, S.; Aliotta, L.; Lazzeri, A. Dispersion of Micro Fibrillated Cellulose (MFC) in Poly(Lactic Acid) (PLA) from Lab-Scale to Semi-Industrial Processing Using Biobased Plasticizers as Dispersing Aids. Chemistry 2021, 3, 896–915. [Google Scholar] [CrossRef]

- Popa, E.E.; Rapa, M.; Popa, O.; Mustatea, G.; Popa, V.I.; Mitelut, A.C.; Popa, M.E. Polylactic Acid/Cellulose Fibres Based Composites for Food Packaging Applications. Mater. Plast. 2017, 54, 673–677. [Google Scholar] [CrossRef]

- Kalita, R.D.; Nath, Y.; Ochubiojo, M.E.; Buragohain, A.K. Extraction and Characterization of Microcrystalline Cellulose from Fodder Grass; Setaria glauca (L.) P. Beauv, and Its Potential as a Drug Delivery Vehicle for Isoniazid, a First Line Antituberculosis Drug. Colloids Surf. B Biointerfaces 2013, 108, 85–89. [Google Scholar] [CrossRef]

- Murphy, C.A.; Collins, M.N. Microcrystalline Cellulose Reinforced Polylactic Acid Biocomposite Filaments for 3D Printing. Polym. Compos. 2018, 39, 1311–1320. [Google Scholar] [CrossRef]

- Das, A.; Gilmer, E.L.; Biria, S.; Bortner, M.J. Importance of Polymer Rheology on Material Extrusion Additive Manufacturing: Correlating Process Physics to Print Properties. ACS Appl. Polym. Mater. 2021, 3, 1218–1249. [Google Scholar] [CrossRef]

- Gilmer, E.L.; Mansfield, C.; Gardner, J.M.; Siochi, E.J.; Baird, D.G.; Bortner, M.J. Characterization and Analysis of Polyetherimide: Realizing Practical Challenges of Modeling the Extrusion-Based Additive Manufacturing Process. In Polymer-Based Additive Manufacturing: Recent Developments; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2019; Volume 1315, pp. 5–69. ISBN 9780841234260. [Google Scholar]

- Zhang, Y.C.; Wu, H.Y.; Qiu, Y.P. Morphology and Properties of Hybrid Composites Based on Polypropylene/Polylactic Acid Blend and Bamboo Fiber. Bioresour. Technol. 2010, 101, 7944–7950. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F. A Review of Wood Polymer Composites Rheology and Its Implications for Processing. Polymers 2020, 12, 2304. [Google Scholar] [CrossRef]

- Kuzman, M.K.; Ayrilmis, N.; Sernek, M.; Kariz, M. Effect of Selected Printing Settings on Viscoelastic Behaviour of 3D Printed Polymers with and without Wood. Mater. Res. Express 2019, 6, 105362. [Google Scholar] [CrossRef]

- Shah, D.U. Developing Plant Fibre Composites for Structural Applications by Optimising Composite Parameters: A Critical Review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Fortunati, E.; Armentano, I.; Zhou, Q.; Puglia, D.; Terenzi, A.; Berglund, L.A.; Kenny, J.M. Microstructure and Nonisothermal Cold Crystallization of PLA Composites Based on Silver Nanoparticles and Nanocrystalline Cellulose. Polym. Degrad. Stab. 2012, 97, 2027–2036. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. The Effect of Morphology and Chemical Characteristics of Cellulose Reinforcements on the Crystallinity of Polylactic Acid. J. Appl. Polym. Sci. 2006, 101, 300–310. [Google Scholar] [CrossRef]

- Petersson, L.; Oksman, K. Biopolymer Based Nanocomposites: Comparing Layered Silicates and Microcrystalline Cellulose as Nanoreinforcement. Compos. Sci. Technol. 2006, 66, 2187–2196. [Google Scholar] [CrossRef]

- Boran, S.; Kiziltas, A.; Kiziltas, E.E.; Gardner, D.J. Characterization of Ultrafine Cellulose-Filled High-Density Polyethylene Composites Prepared Using Different Compounding Methods. Bioresources 2016, 11, 8178–8199. [Google Scholar] [CrossRef]

- Yang, H.S.; Gardner, D.J.; Nader, J.W. Characteristic Impact Resistance Model Analysis of Cellulose Nanofibril-Filled Polypropylene Composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2028–2035. [Google Scholar] [CrossRef]

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A Review on Voids of 3D Printed Parts by Fused Filament Fabrication. J. Mater. Res. Technol. 2021, 15, 4860–4879. [Google Scholar] [CrossRef]

| Formulation Code | Material Compositions (wt%) | ||

|---|---|---|---|

| PLA | TM Beech | MCC | |

| TM30 | 70 | 30 | - |

| TM30_1MCC | 69 | 30 | 1 |

| TM30_3MCC | 67 | 30 | 3 |

| TM30_5MCC | 65 | 30 | 5 |

| Filament | Tg [°C] | Tm [°C] | ΔHm [J/g] | Xc [%] |

|---|---|---|---|---|

| TM30 | 61.81 | 155.52 | 8.34 | 12.73 |

| TM30_1MCC | 60.15 | 154.21 | 11.47 | 17.76 |

| TM30_3MCC | 63.36 | 156.78 | 3.37 | 5.37 |

| TM30_5MCC | 60.67 | 150.57 | 7.62 | 12.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krapež Tomec, D.; Schöflinger, M.; Leßlhumer, J.; Gradišar Centa, U.; Žigon, J.; Kariž, M. The Effects of Microcrystalline Cellulose Addition on the Properties of Wood–PLA Filaments for 3D Printing. Polymers 2024, 16, 836. https://doi.org/10.3390/polym16060836

Krapež Tomec D, Schöflinger M, Leßlhumer J, Gradišar Centa U, Žigon J, Kariž M. The Effects of Microcrystalline Cellulose Addition on the Properties of Wood–PLA Filaments for 3D Printing. Polymers. 2024; 16(6):836. https://doi.org/10.3390/polym16060836

Chicago/Turabian StyleKrapež Tomec, Daša, Manfred Schöflinger, Jürgen Leßlhumer, Urška Gradišar Centa, Jure Žigon, and Mirko Kariž. 2024. "The Effects of Microcrystalline Cellulose Addition on the Properties of Wood–PLA Filaments for 3D Printing" Polymers 16, no. 6: 836. https://doi.org/10.3390/polym16060836

APA StyleKrapež Tomec, D., Schöflinger, M., Leßlhumer, J., Gradišar Centa, U., Žigon, J., & Kariž, M. (2024). The Effects of Microcrystalline Cellulose Addition on the Properties of Wood–PLA Filaments for 3D Printing. Polymers, 16(6), 836. https://doi.org/10.3390/polym16060836