Study on the Electrical Insulation Properties of Modified PTFE at High Temperatures

Abstract

1. Introduction

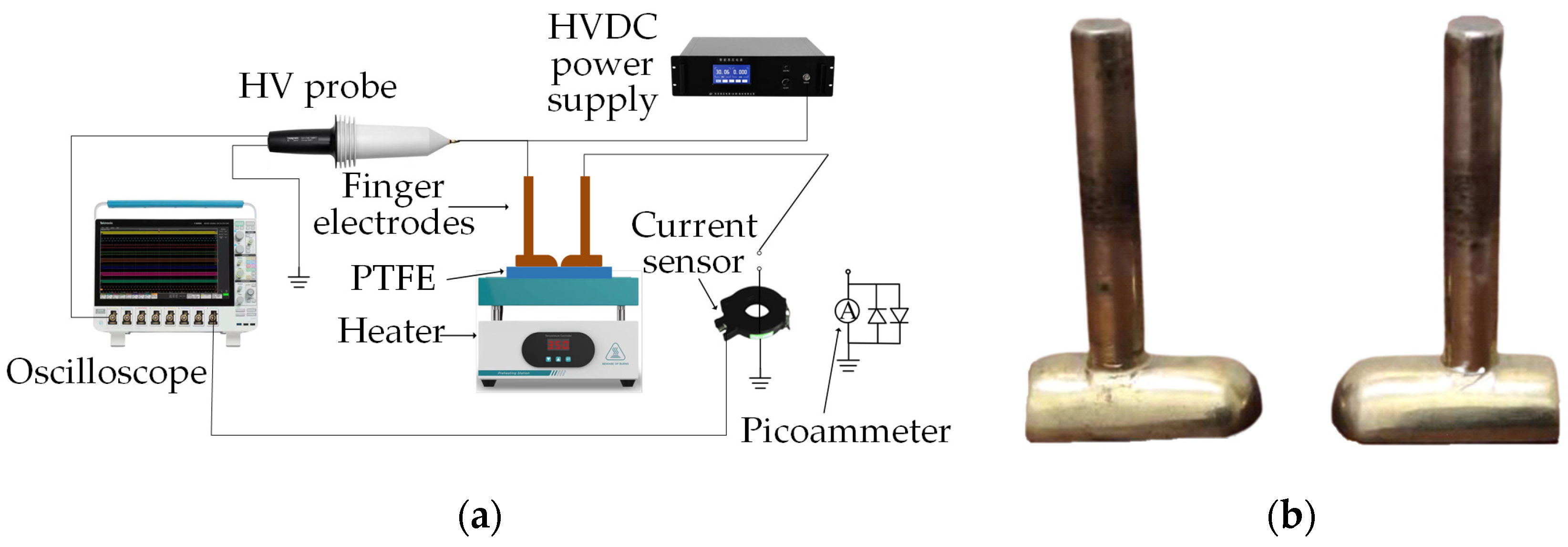

2. Materials and Methods

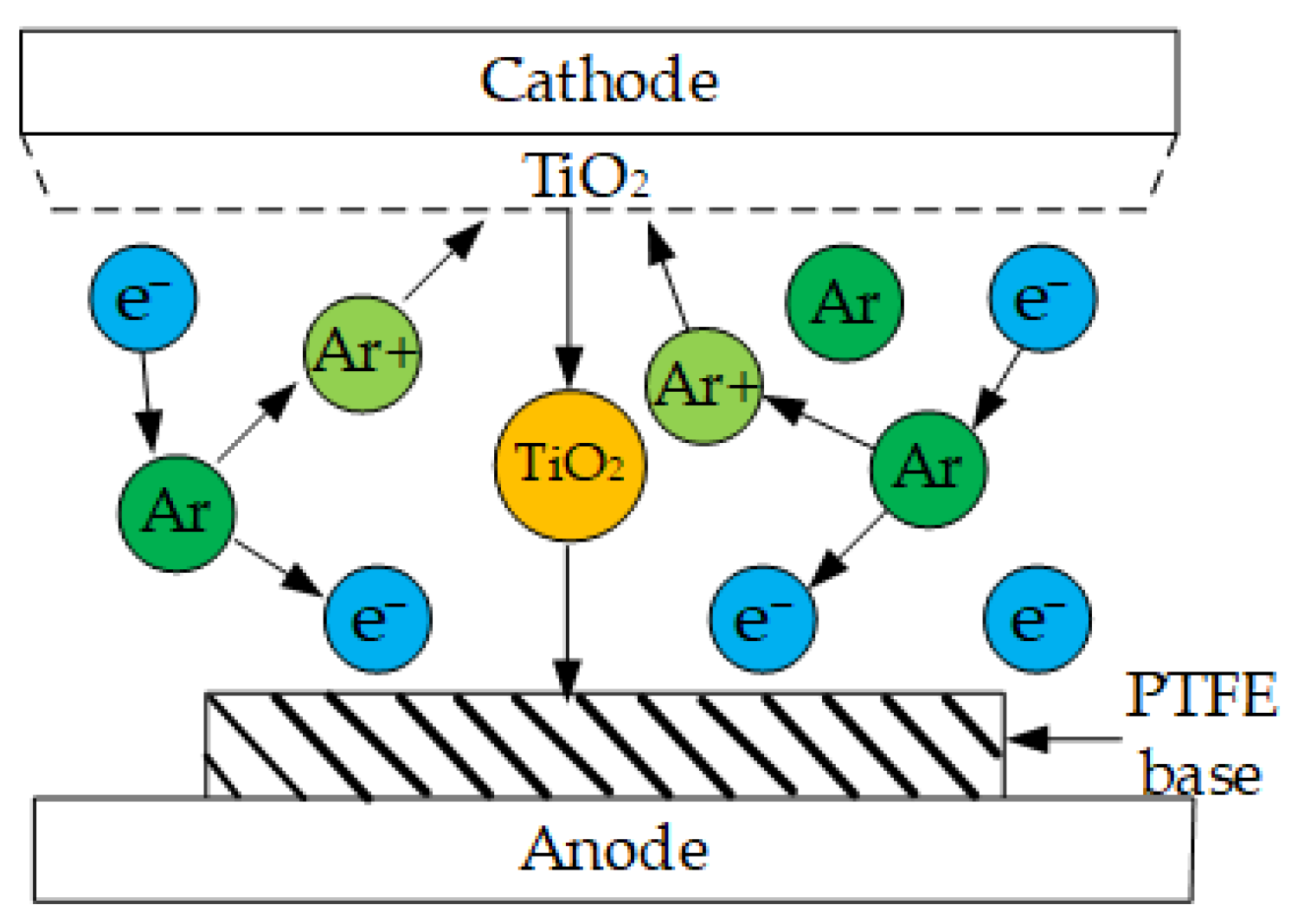

2.1. Materials Preparation

2.2. Experimental Method

3. Results

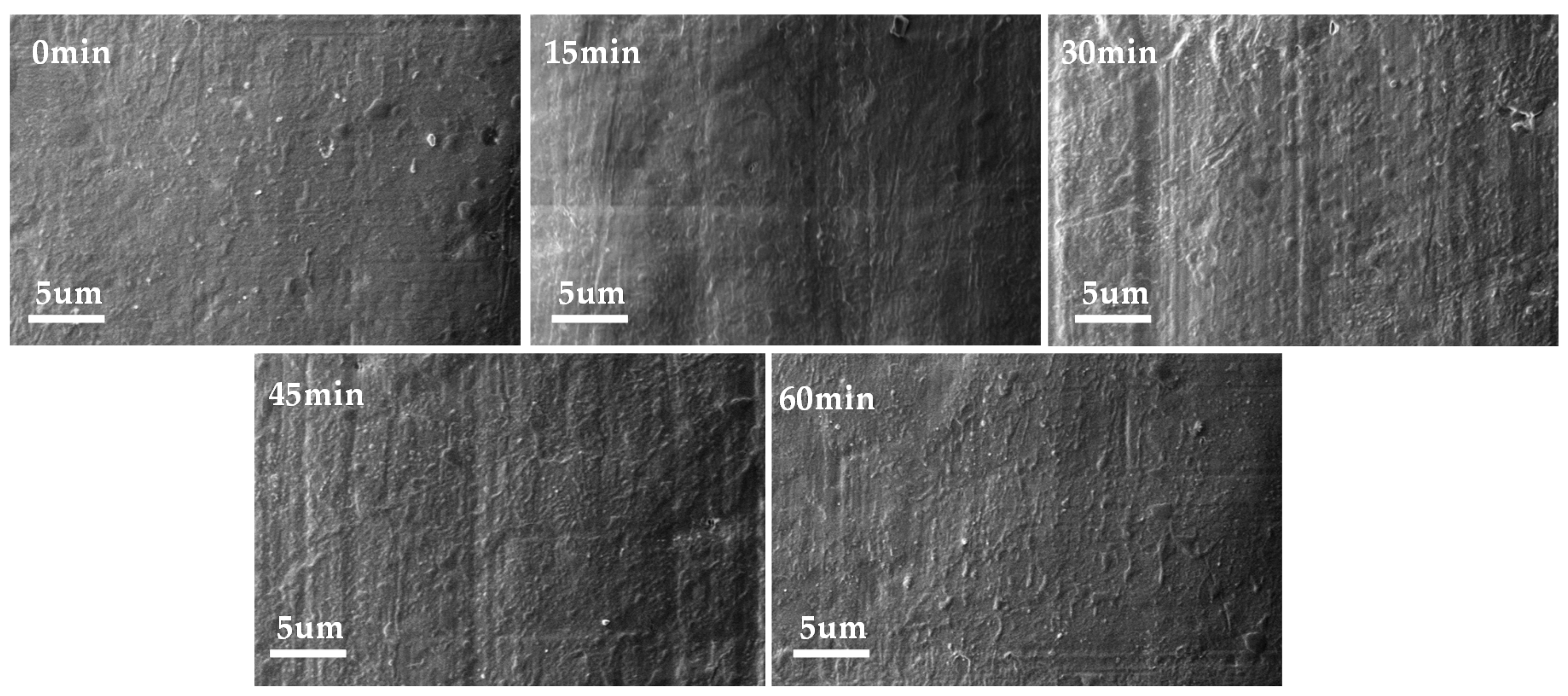

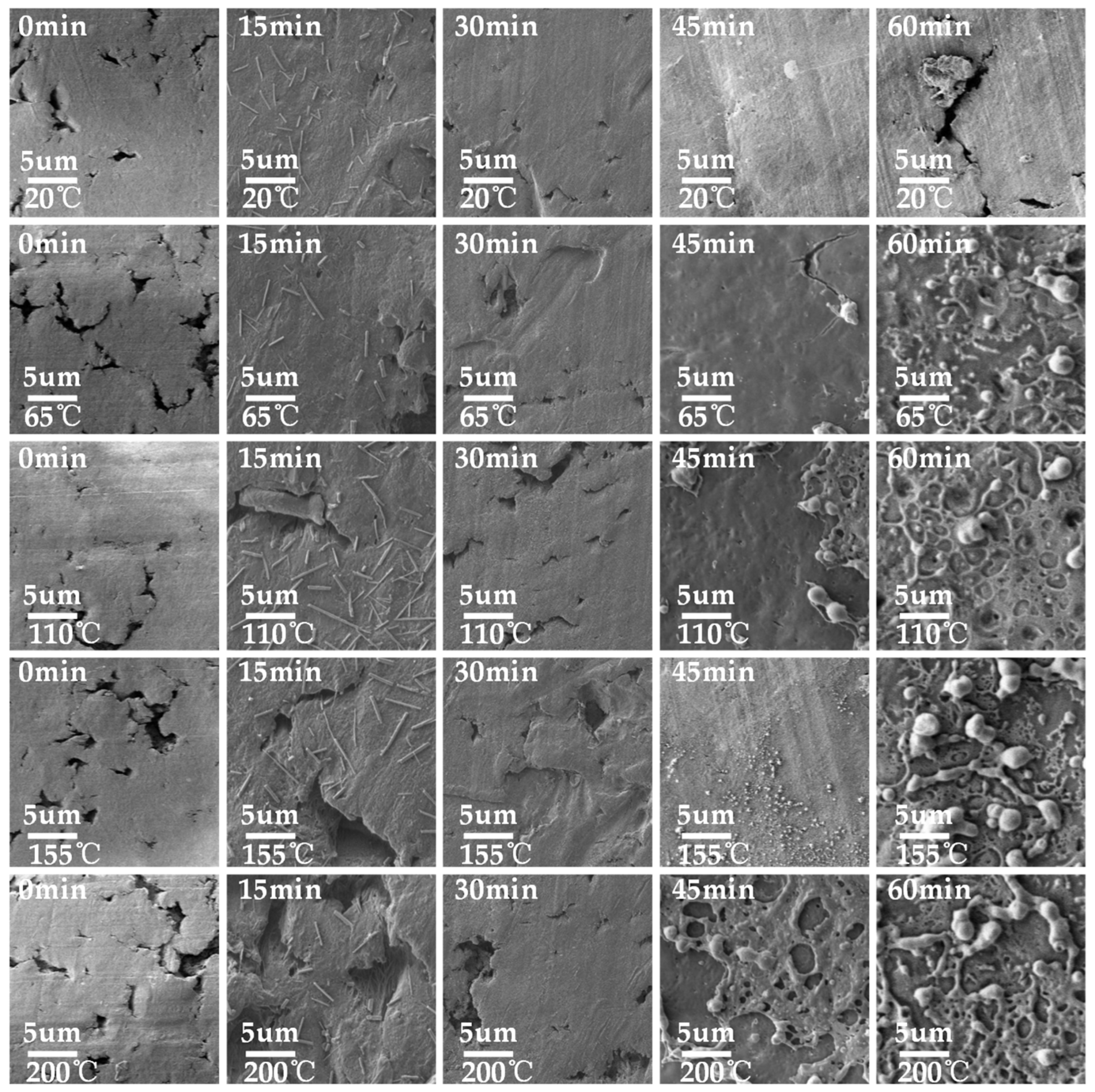

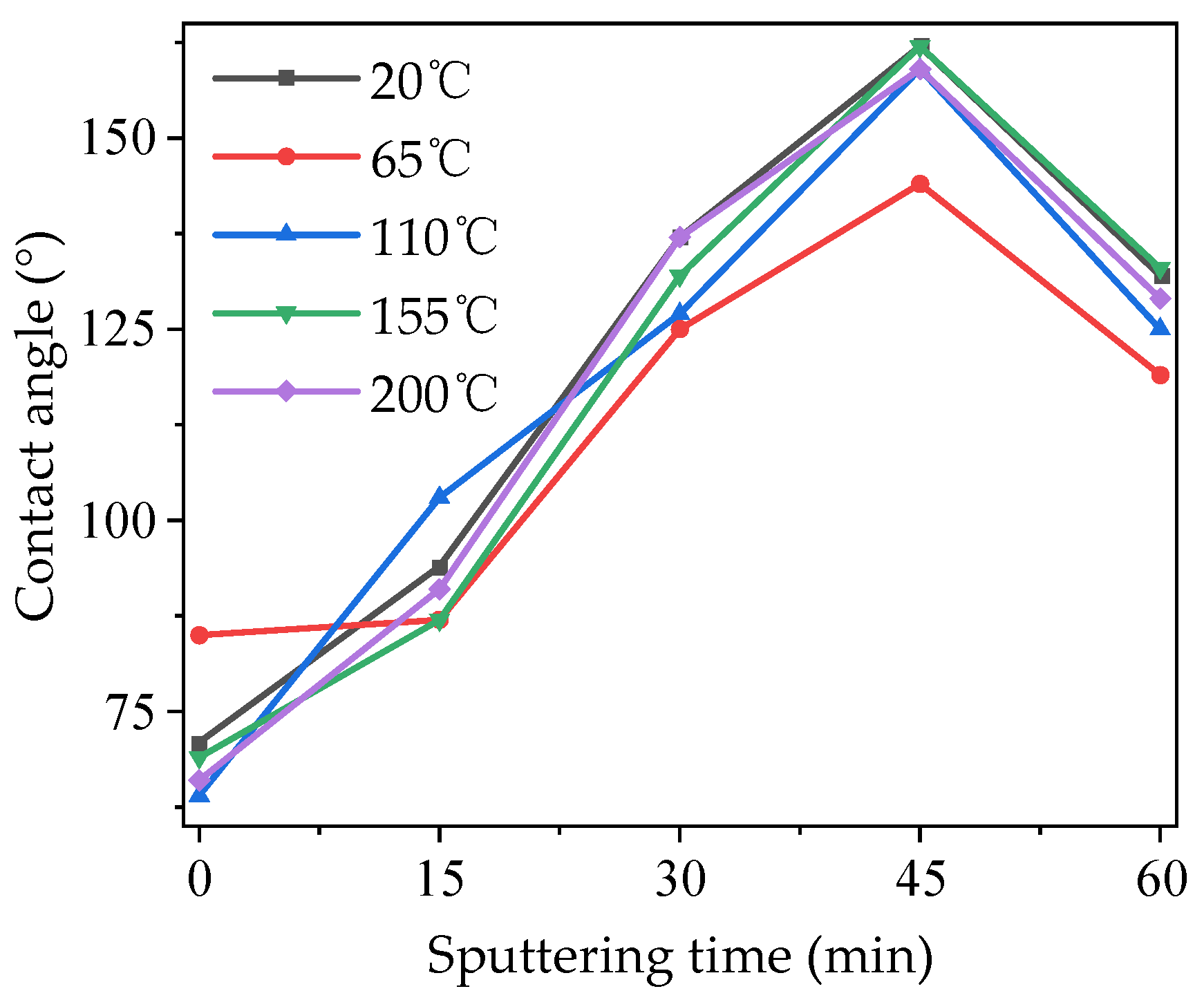

3.1. Sputtering Modification Characteristics

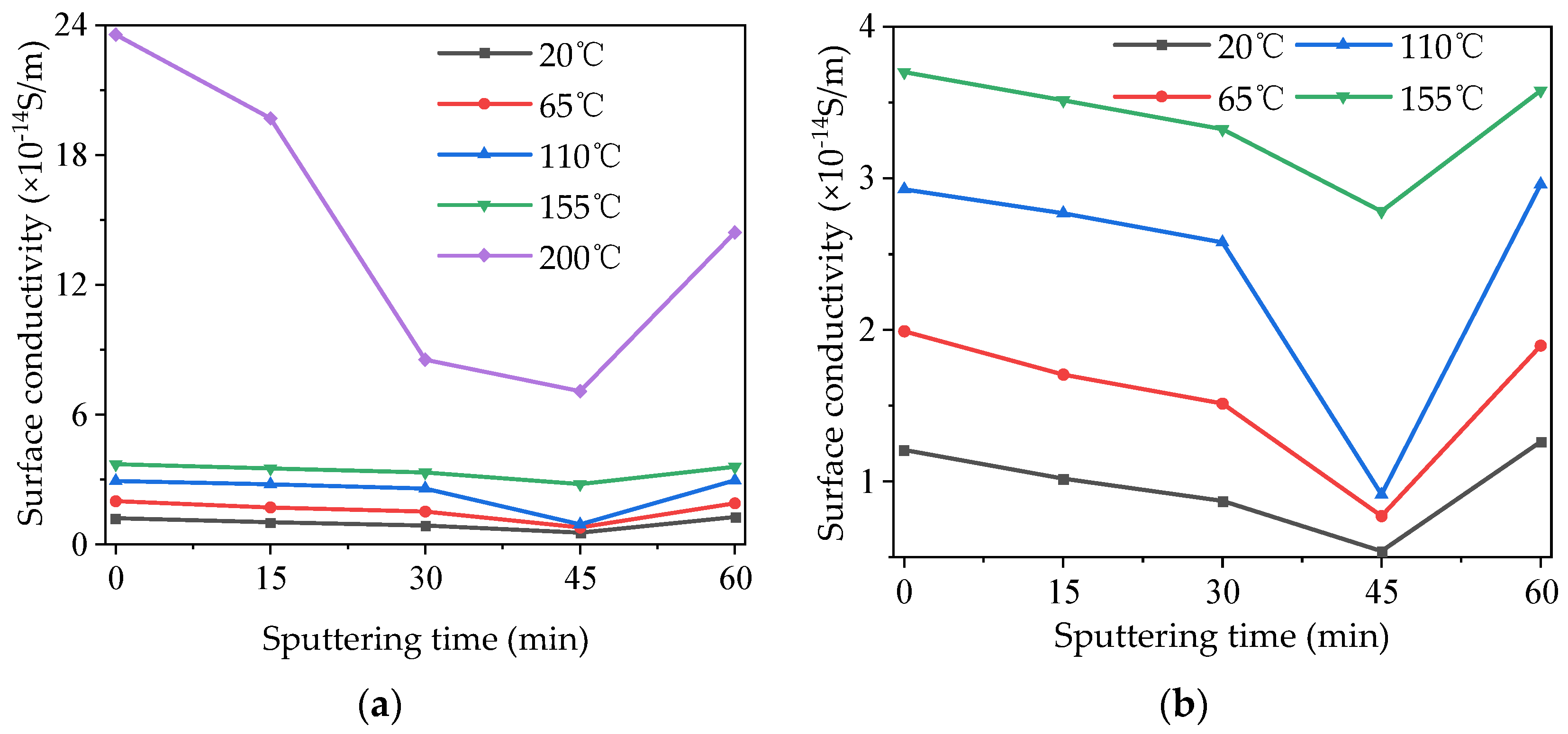

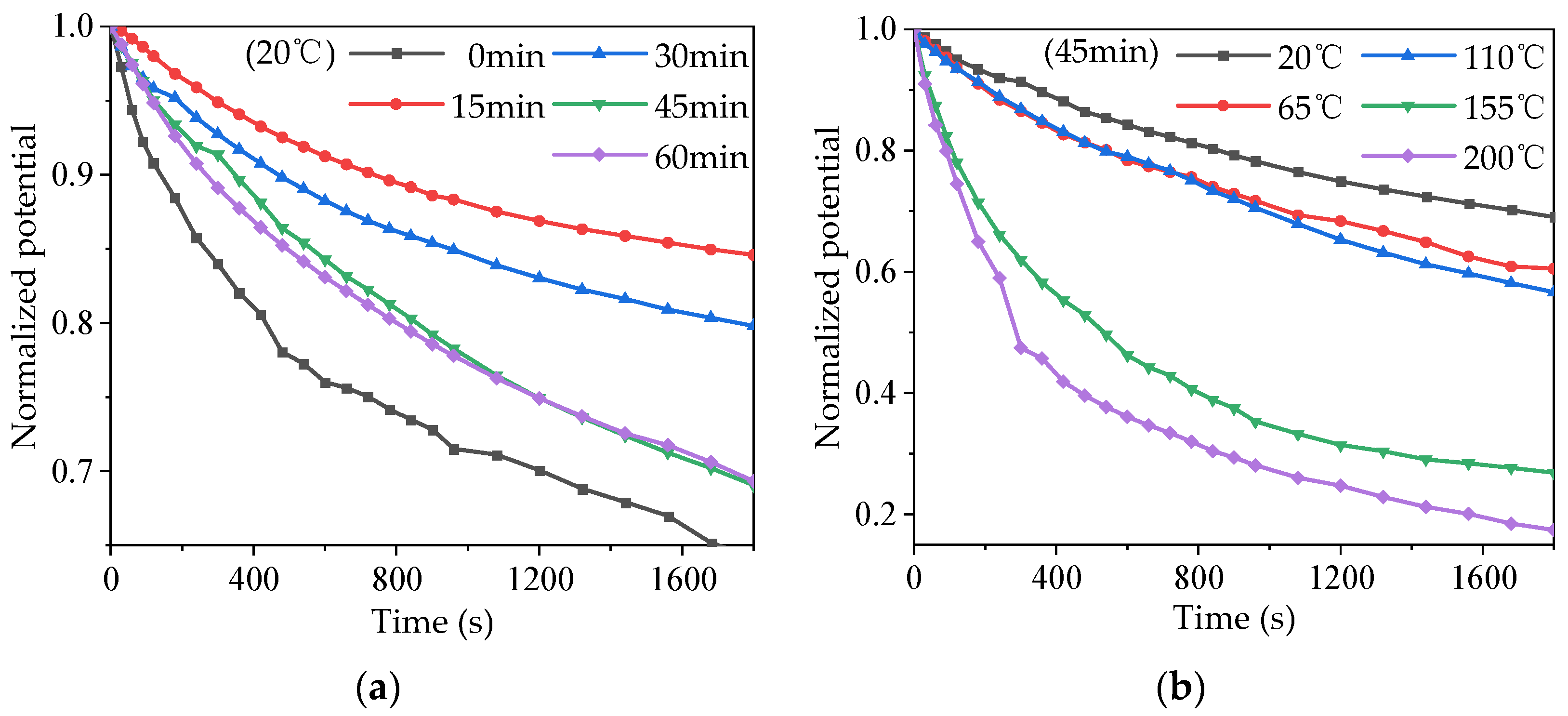

3.2. Surface Conductivity Characteristics

3.3. Initial Characteristics of Surface Discharge

3.4. Development Characteristics of Surface Discharge

3.5. Surface Flashover Characteristics

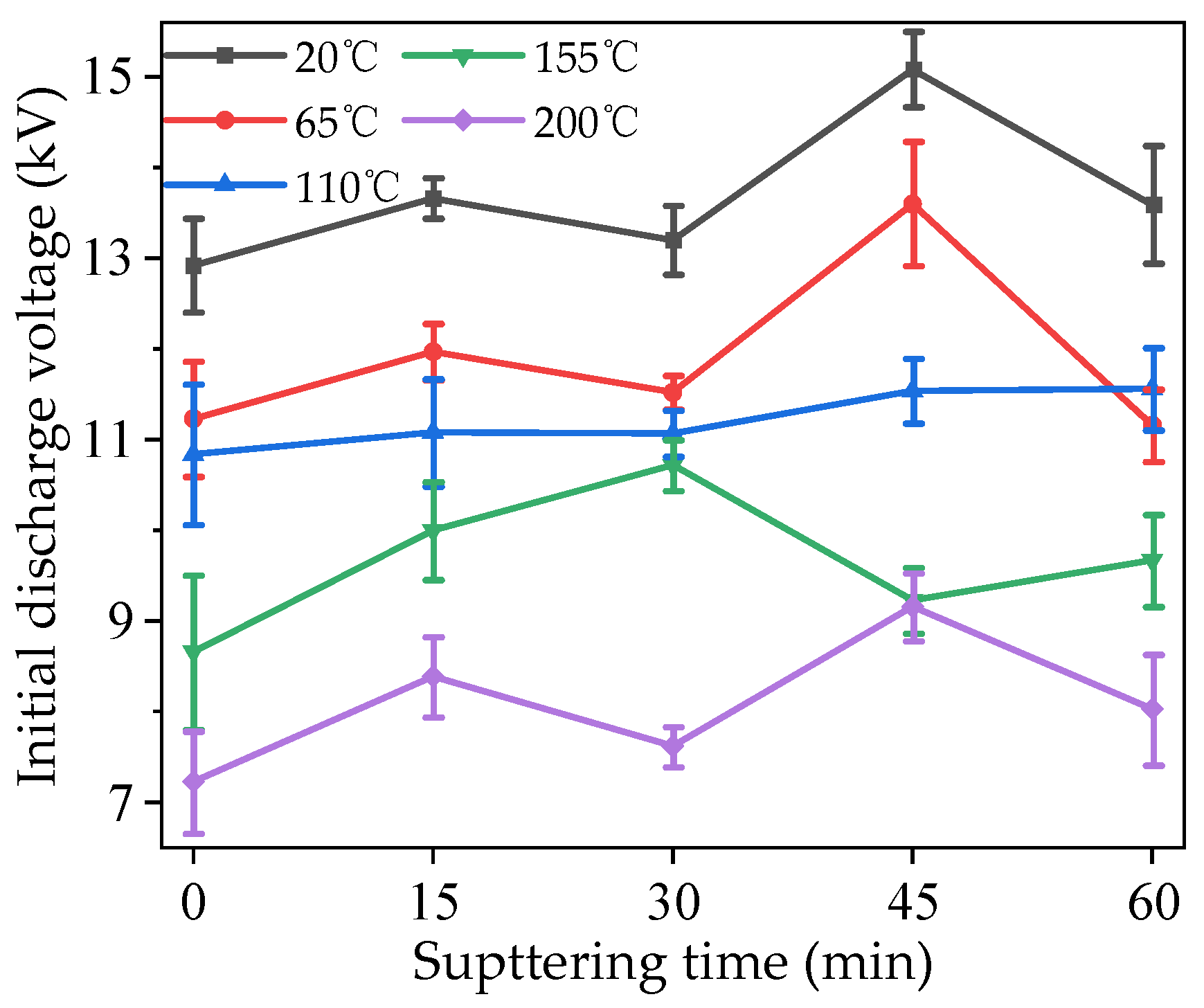

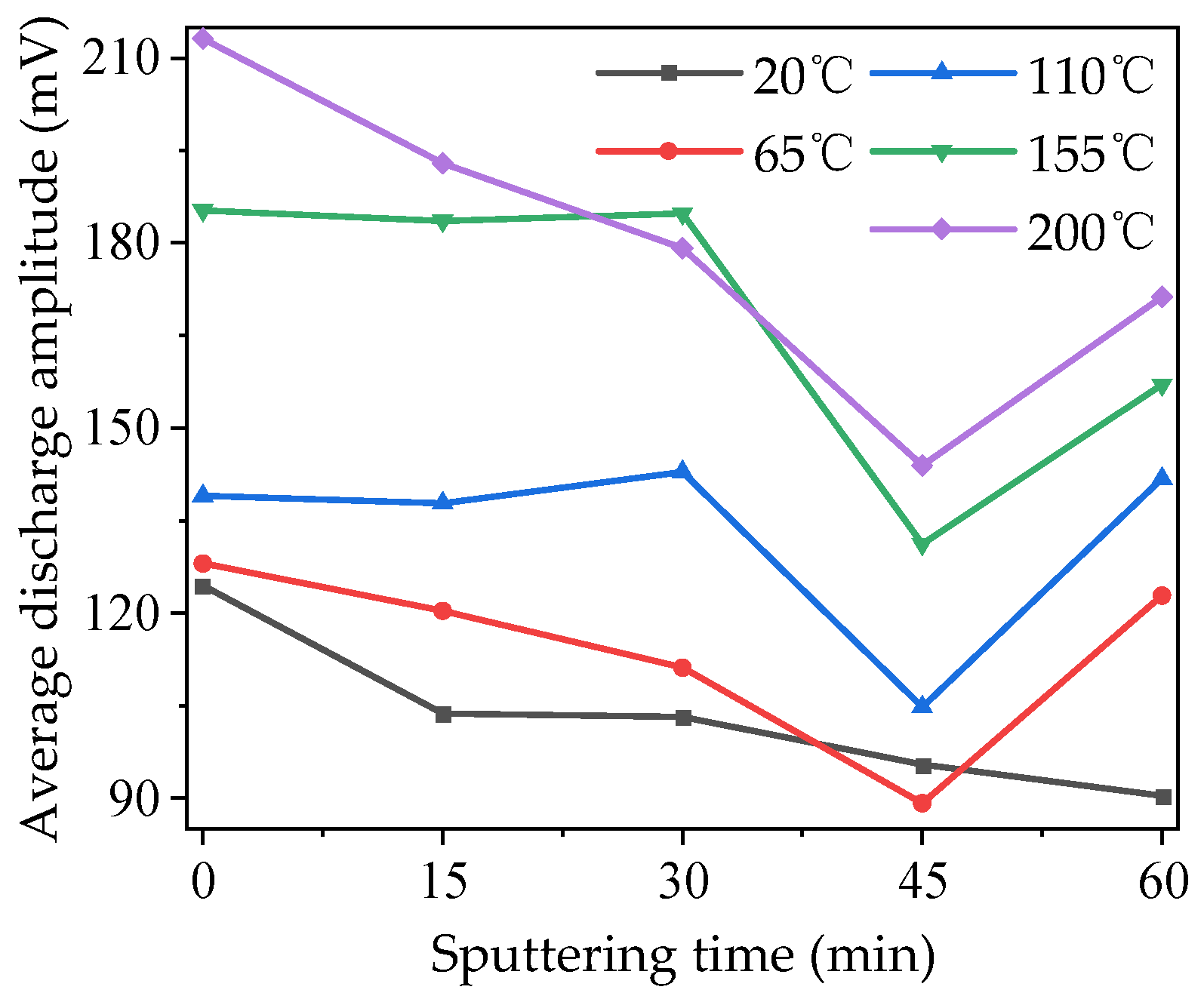

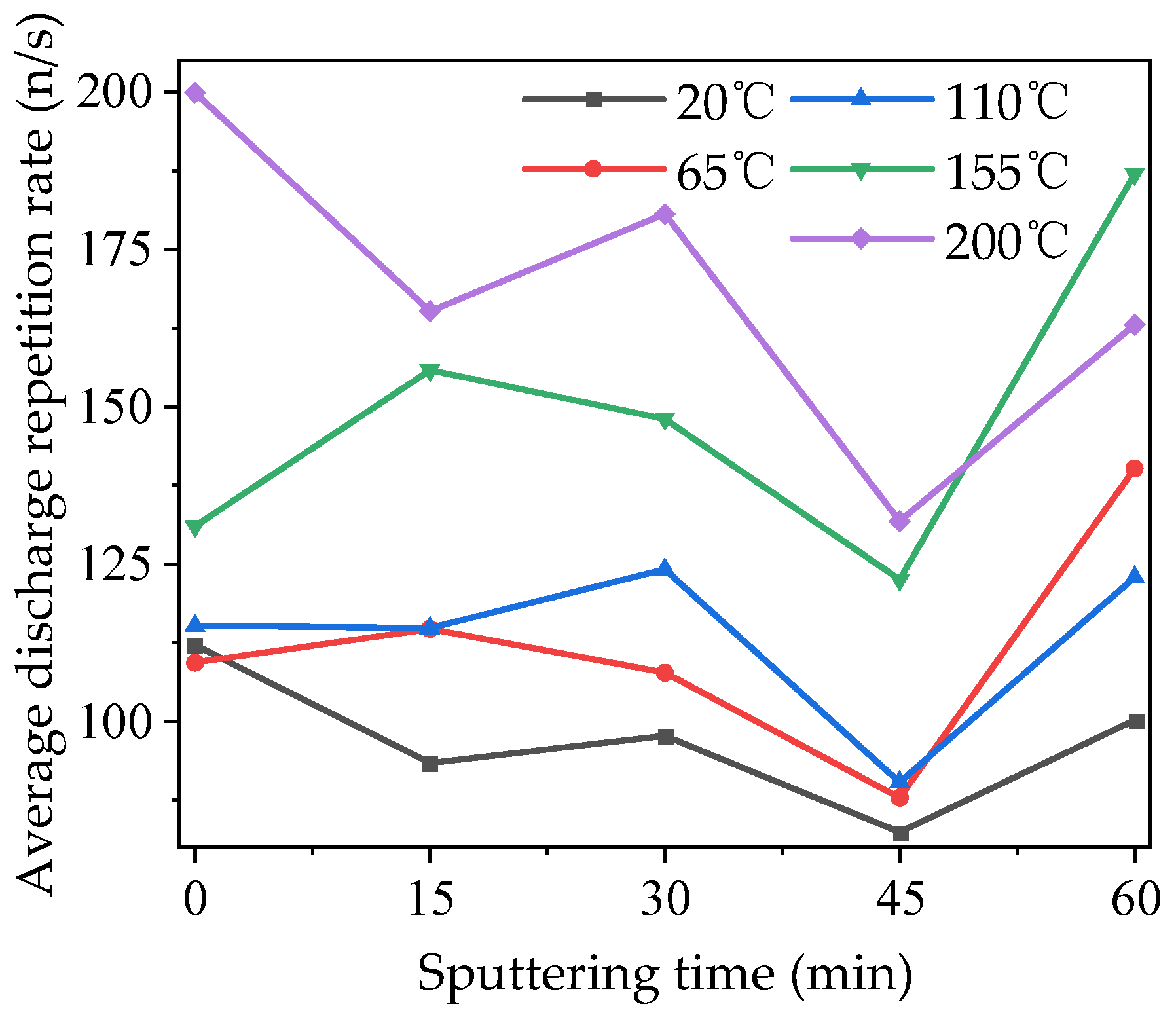

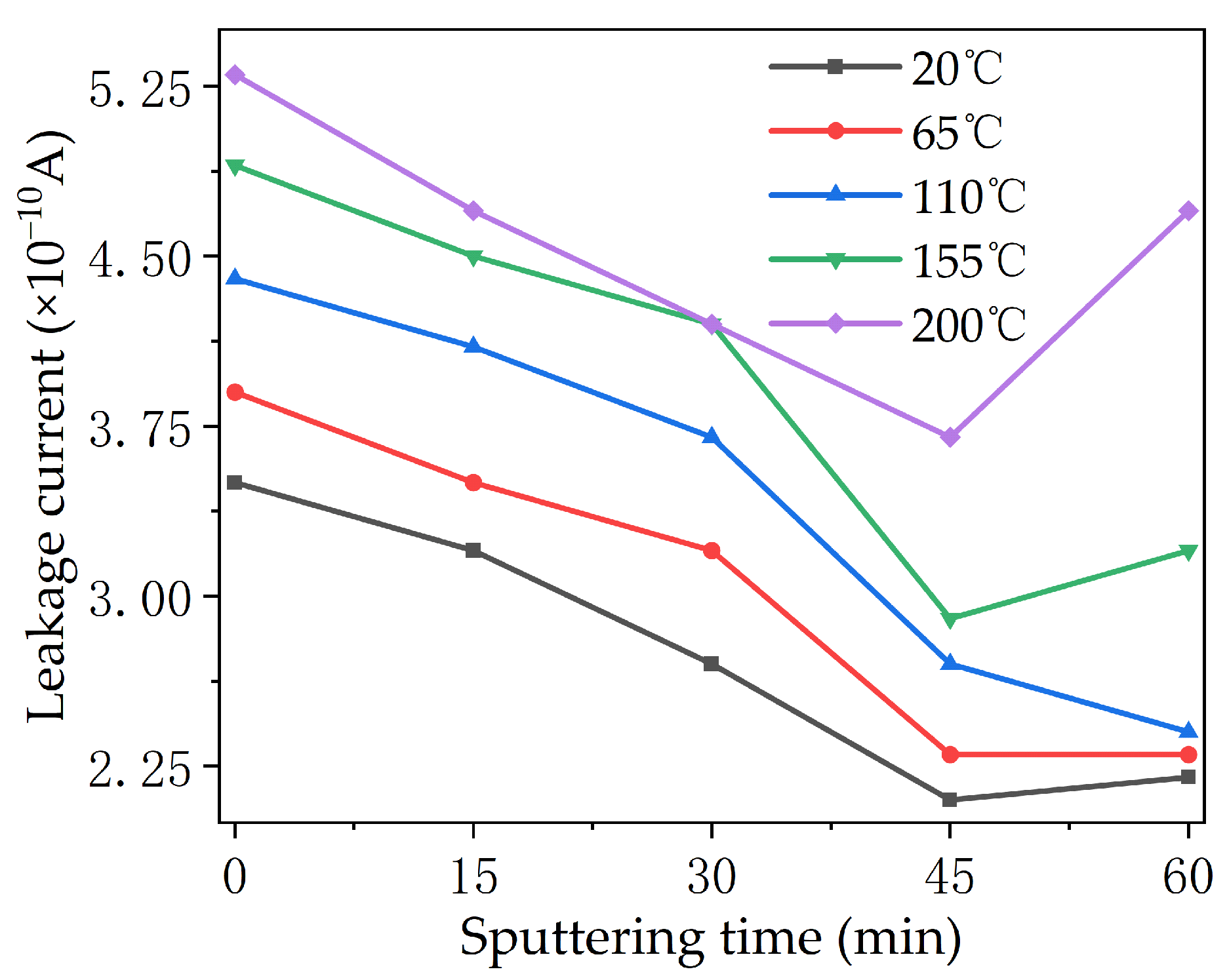

3.6. Electric Aging Characteristic

4. Discussion

4.1. Potential Decay Characteristic

4.2. Trap Distribution Characteristic

5. Conclusions

- The insulation performance of the PTFE was affected by temperature. Higher temperatures were shown to significantly advance a partial discharge, while TiO2 modification by magnetron sputtering regulated the water contact angle, electrical conductivity, insulation, and anti-electrothermal-aging properties of the sample, which improved the adaptability of the PTFE to the aviation environment;

- In the electric aging test, the degree of damage of the surface of the sample at 45 min was the lowest. This is because, after modification by sputtering, the discharge voltage increased, the leakage current decreased, the strength of impact of high-energy particles and the heat accumulation damage on the surface were weakened, and the anti-electric-aging ability reached it optimum at that time;

- By decreasing the trap energy level on the surface of the insulating material and increasing the density of the shallower trap, sputtering modification sped up the electric charge transport and dissipation on the insulating material, inhibited the surface charge accumulation, and then improved the surface insulation performance and anti-aging ability of the insulating material.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jun, J.; Zhi, L.; Bendong, Z.; Wenyuan, L.; Chaohai, Z. Partial discharge characteristics of aeronautical cables at low pressure. Trans. China Electrotech. Soc. 2022, 37, 5578–5586. [Google Scholar]

- Barzkar, A.; Ghassemi, M. Electric power systems in more and all electric aircraft: A review. IEEE Access 2020, 8, 169314–169332. [Google Scholar] [CrossRef]

- Sarlioglu, B.; Morris, C.T. More electric aircraft: Review, challenges, and opportunities for commercial transport aircraft. IEEE Trans. Transp. Electrif. 2015, 1, 54–64. [Google Scholar] [CrossRef]

- Altamimi, M.M.S.; Saeed, U.; Al-Turaif, H. BaSO4/TiO2 microparticle embedded in polyvinylidene fluoride-co-hexafluoropropylene/polytetrafluoroethylene polymer film for daytime radiative cooling. Polymers 2023, 15, 3876. [Google Scholar] [CrossRef] [PubMed]

- Shengzhao, P.; Yigeng, H.; Liang, G.; Rui, M. A novel wide stability control strategy of constant power load power converter based on the analysis of Lyapunov indirect method. Trans. China Electrotech. Soc. 2017, 32, 146–154. [Google Scholar]

- Qingchao, S.; Jiawei, C.; Kuncheng, C.; Jie, C. A highly reliable power allocation technology for the fuel cell-battery-supercapacitor hybrid power supply system of a more electric aircraft. Trans. China Electrotech. Soc. 2022, 37, 445–458. [Google Scholar]

- Bendong, Z.; Jun, J.; Zhi, L.; Shimin, L.; Chaohai, Z. Partial discharge characteristics of future more electric aircraft under low air pressure. Acta Aeronaut. Astronaut. Sin. 2022, 43, 275–285. [Google Scholar]

- Shumei, C.; Zhi, K.; Bochao, D. Speed closed-loop control of permanent magnet synchronous motor for all-electric aircraft applications based on active disturbance rejection controller. Trans. China Electrotech. Soc. 2017, 32, 107–115. [Google Scholar]

- Jun, J.; Zhi, L.; Bendong, Z.; Zhibang, S.; Wenyuan, L.; Chaohai, Z. A review on insulation performance and detection for aeronautical cable. Proc. CSEE 2023, 43, 4005–4022. [Google Scholar]

- Chouhan, P.; Mourtos, N.J. Design of a four-seat, general aviation electric aircraft. Athens J. Technol. Eng. 2021, 8, 139–168. [Google Scholar] [CrossRef]

- Seresinhe, R.; Lawson, C.; Sabatini, R. Environmental impact assessment, on the operation of conventional and more electric large commercial aircraft. SAE Int. J. Aerosp. 2013, 6, 56–64. [Google Scholar] [CrossRef]

- Le Roy, S.; Teyssèdre, G.; Aubert, E. Current measurements in high performance polymers used in aeronautic cables. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 2195–2202. [Google Scholar]

- Jun, J.; Zhi, L.; Wenyuan, L.; Prem, R.; Xingdong, W.; Xu, Z.; Chaohai, Z. A review on insulation challenges towards electrification of aircraft. High Volt. 2023, 8, 209–230. [Google Scholar]

- Moein, B.; Mona, G. Insulation materials and systems for more- and all-electric aircraft: A review identifying challenges and future research needs. IEEE Trans. Transp. Electrif. 2021, 7, 1930–1953. [Google Scholar]

- Jun, J.; Bendong, Z.; Kai, W.; Wenyuan, L.; Chaohai, Z. Partial discharge rule of more-electric-aircraft with pulse voltage waveform. Acta Aeronaut. Astronaut. Sin. 2020, 41, 206–215. [Google Scholar]

- Kamenskikh, A.A.; Nosov, Y.O.; Bogdanova, A.P. The study influence analysis of the mathematical model choice for describing polymer behavior. Polymers 2023, 15, 3630. [Google Scholar] [CrossRef]

- Hegazy, M.A.; Ezzat, H.A.; Yahia, I.S.; Zahran, H.Y.; Elhaes, H.; Gomaa, I.; Ibrahim, M.A. Effect of CuO and graphene on PTFE microfibers: Experimental and modeling approaches. Polymers 2022, 14, 1069. [Google Scholar] [CrossRef]

- Asrafali, S.P.; Periyasamy, T.; Kim, S.C. Rapid transformation in wetting properties of PTFE membrane using plasma treatment. Polymers 2023, 15, 3874. [Google Scholar] [CrossRef]

- Guo, B.-H.; Sun, G.-Y.; Zhang, S.; Xue, J.-Y.; Zhou, R.-D.; Song, B.-P.; Mu, H.-B.; Zhang, G.-J. Mechanism of vacuum flashover on surface roughness. J. Phys. Appl. Phys. 2019, 52, 215301. [Google Scholar] [CrossRef]

- Yanqing, L.; Jian, H.; Cong, L.; Ruijin, L.; Lijun, Y. Fabrication of the micro/nano-structure Al2O3/PTFE composite functional film on the surface of insulation pressboard and its effect on space charge injection. Trans. China Electrotech. Soc. 2020, 35, 3960–3971. [Google Scholar]

- Dongxin, H.; Wei, W.; Jiefeng, G.; Shengke, C. Infrared spectral characteristics of PPS and PTFE in the electrical-thermal aging process in oil. Trans. China Electrotech. Soc. 2013, 28, 26–33. [Google Scholar]

- Duan, L.; Liu, W.; Ke, C.; Chen, C.; Li, L. Significantly improved surface flashover characteristics of insulators in vacuum by direct fluorination. Colloids Surf. Physicochem. Eng. Asp. 2014, 456, 1–9. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, H.; Zhang, S.; Xie, Q.; Ren, C.; Shao, T. Plasma surface treatment to improve surface charge accumulation and dissipation of epoxy resin exposed to DC and nanosecond-pulse voltages. J. Phys. Appl. Phys. 2017, 50, 405203. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, Y.; Kong, F.; Wang, R.; Ren, C.; Shao, T. Surface charge decay of epoxy resin treated by AP-DBD deposition and direct fluorination. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 768–775. [Google Scholar] [CrossRef]

- Wei, S.; Zhen, L.; Shengtao, L. Improvement and mechanism of surface flashover performances of epoxy nanocomposites treated by electron beam irradiation. Proc. CSEE 2020, 40, 7144–7152. [Google Scholar]

- Mingming, Z.; Weixin, Y.; Fei, K.; Cheng, Z.; Xian, C.; Tao, S. Improvement of surface insulating properties of ceramics by deposition of TiO2 functional layer by atmospheric pressure plasma with binary gas distribution. Trans. China Electrotech. Soc. 2022, 37, 3404–3412. [Google Scholar]

- Liao, R.; Lv, C.; Yang, L.; Zhang, Y.; Wu, W.; Tang, C. The insulation properties of oil-impregnated insulation paper reinforced with nano-TiO2. J. Nanomater. 2013, 2013, 373959. [Google Scholar] [CrossRef]

- GB/T31838.2-2019; Solid Insulating Materials—Dielectric and Resistive Properties—Part 2: Resistive Properties (DC Methods)—Volume Resistance and Volume Resistivity. Standardization Administration of the People’s Republic of China: Beijing, China, 2019.

- Gao, Y.; Li, N.; Li, J.; Du, B.; Liu, Z. Charge transport behavior in gamma-ray irradiated poly (ethylene terephthalate) estimated by surface potential decay. High Volt. 2021, 6, 435–447. [Google Scholar] [CrossRef]

- Haibin, Z.; Guochang, L.; Jingbing, W.; Yanhui, W. Influence of GPO-3 barrier on AC breakdown voltage of rod-plane gaps and surface residual charge characteristics. Trans. China Electrotech. Soc. 2020, 35, 1799–1806. [Google Scholar]

- Yang, M.; Yuan, Y.; Ruijin, L. Study on improving the space charge behavior in insulating paper by depositing nanostructured alumina on its surface via magnetron sputtering. Thin Solid Film. 2020, 709, 138219. [Google Scholar]

- Boxue, D.; Jinpeng, J.; Jin, L. Effects of ZnO magnetron sputtering on surface charge and flashover voltage of oil-impregnated paper. High Volt. 2019, 4, 308–315. [Google Scholar]

- Montanari, C.; Fabiani, D.; Palmieri, F. Modification of electrical properties and performance of EVA and PP insulation through nanostructure by organophilic silicates. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 754–762. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, L.; Zheng, X.; Zhu, W.; Wang, B.; Chen, Y.; Xing, Y. Study on the Electrical Insulation Properties of Modified PTFE at High Temperatures. Polymers 2024, 16, 316. https://doi.org/10.3390/polym16030316

Yuan L, Zheng X, Zhu W, Wang B, Chen Y, Xing Y. Study on the Electrical Insulation Properties of Modified PTFE at High Temperatures. Polymers. 2024; 16(3):316. https://doi.org/10.3390/polym16030316

Chicago/Turabian StyleYuan, Lijian, Xu Zheng, Wenbo Zhu, Bin Wang, Yuanyuan Chen, and Yunqi Xing. 2024. "Study on the Electrical Insulation Properties of Modified PTFE at High Temperatures" Polymers 16, no. 3: 316. https://doi.org/10.3390/polym16030316

APA StyleYuan, L., Zheng, X., Zhu, W., Wang, B., Chen, Y., & Xing, Y. (2024). Study on the Electrical Insulation Properties of Modified PTFE at High Temperatures. Polymers, 16(3), 316. https://doi.org/10.3390/polym16030316