Study on Impact of Monomers Towards High Molecular Weight Bio-Based Poly(ethylene Furanoate) via Solid State Polymerization Technique

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of PEF Using Dimethyl 2,5-Furandicarboxylate (DMFD)

2.3. Synthesis of PEF Using 2,5-Furandicarboxylic Acid (FDCA)

2.4. Solid State Polymerization

2.5. Characterization

2.5.1. Intrinsic Viscosity

2.5.2. End-Group Analysis

2.5.3. Differential Scanning Calorimetry (DSC)

2.5.4. Wide Angle X-Ray Diffraction Patterns (WAXRD)

3. Modeling of the Solid-State Polymerization of PEF Polyesters Kinetics

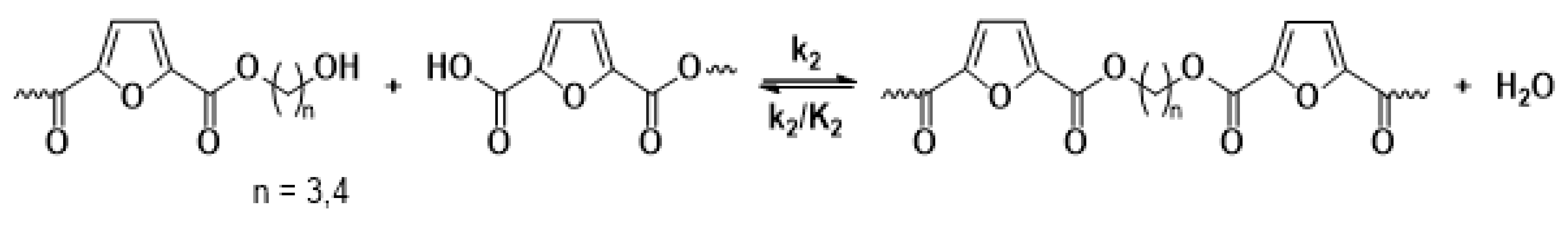

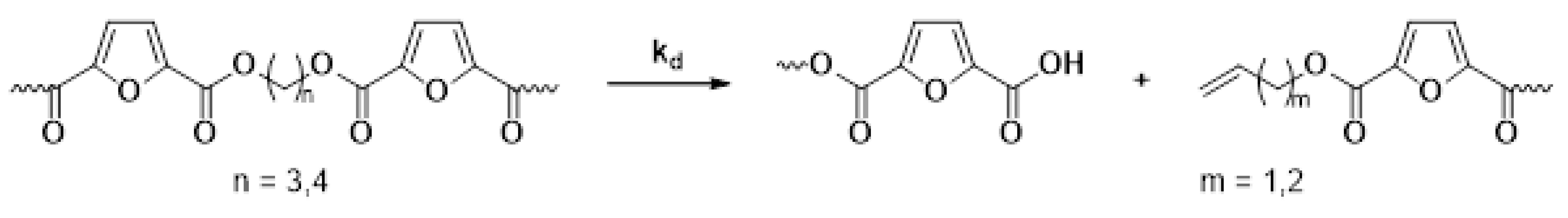

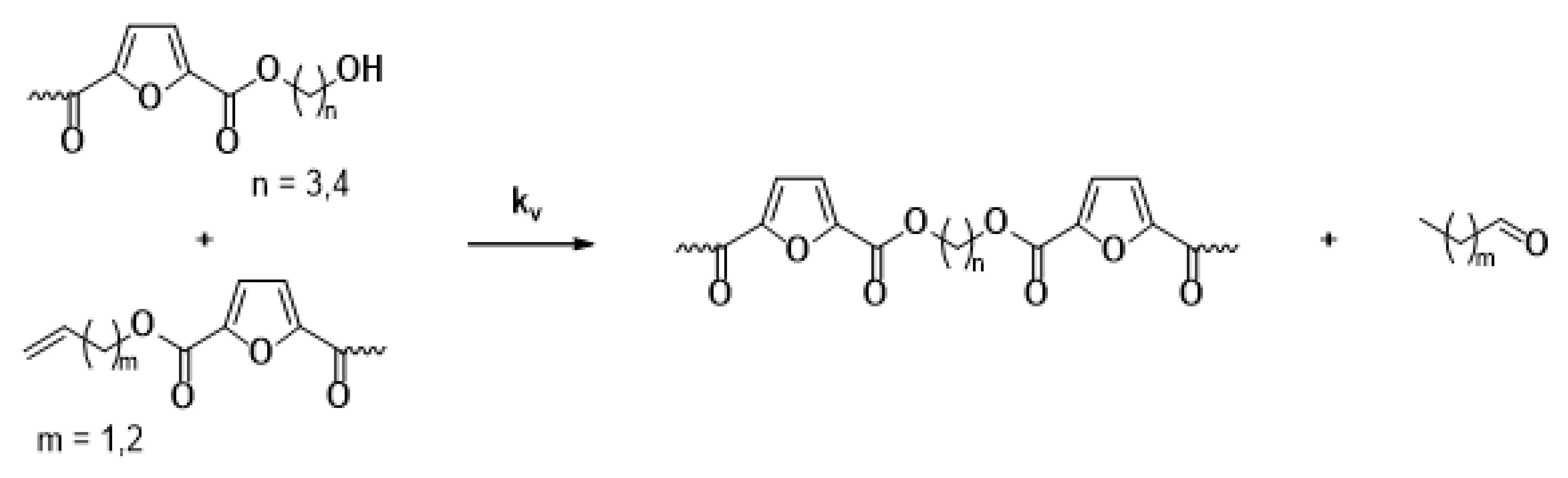

3.1. Reaction Mechanism

3.2. Simplified Mathematical Model

- The kinetic rate constants are found to be unaffected by the polymer chain lengths, focusing solely on the reactivity of the end groups.

- The glycols and water are efficiently removed from the reaction mixture through the application of a high vacuum (below 3–4 Pa), leading to the omission of the reverse reactions presented in Equations (5) and (6).

- Owing to the polycondensation process operating at comparatively low temperatures (185–195 °C), neither thermal degradation nor acetaldehyde formation are considered side reactions (Equations (7) and (8) are eliminated).

- Any diffusional limitations resulting from the desorption of volatile species are disregarded.

4. Results and Discussion

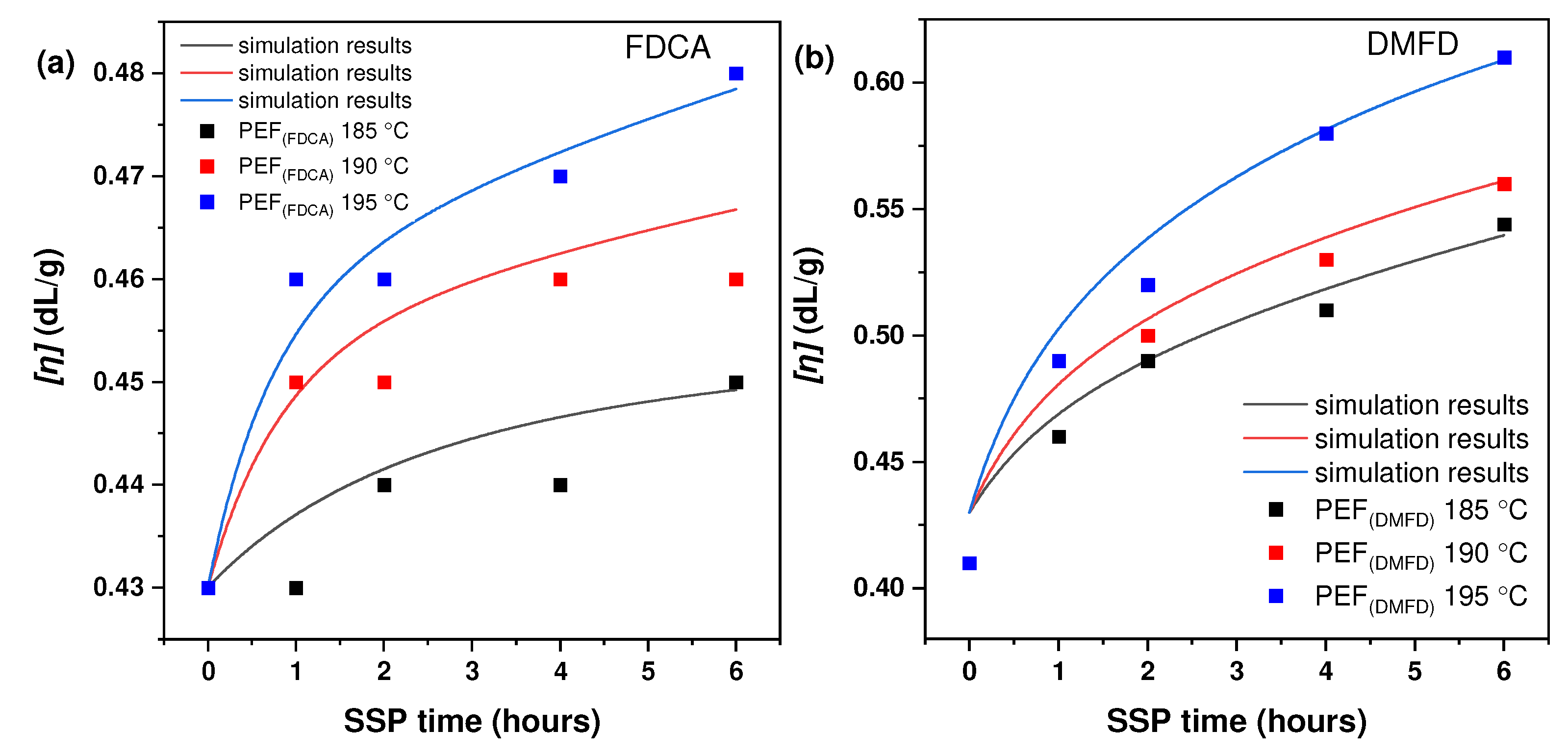

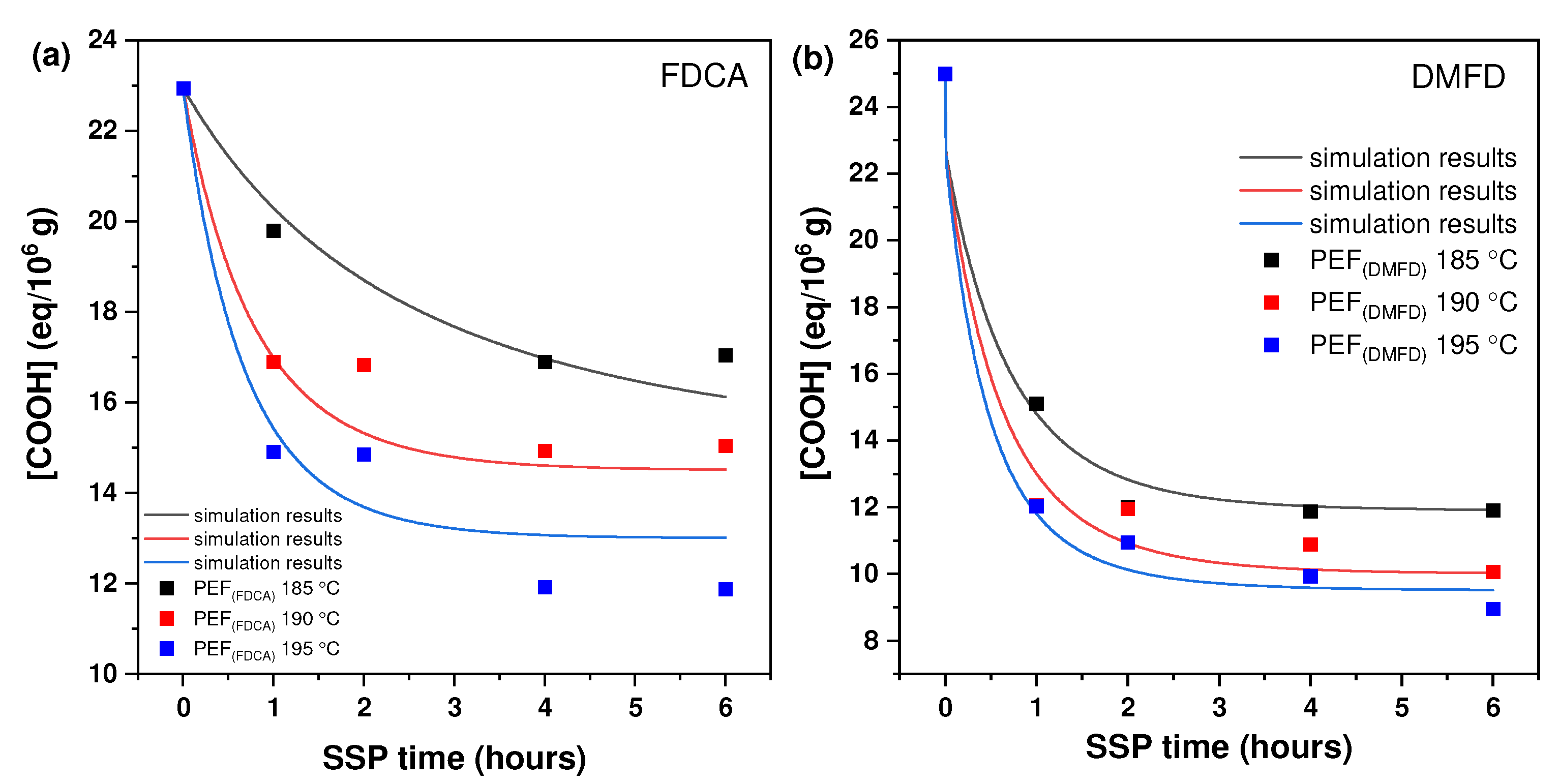

4.1. Synthesis and Kinetic Study of PEF Polyesters After SSP

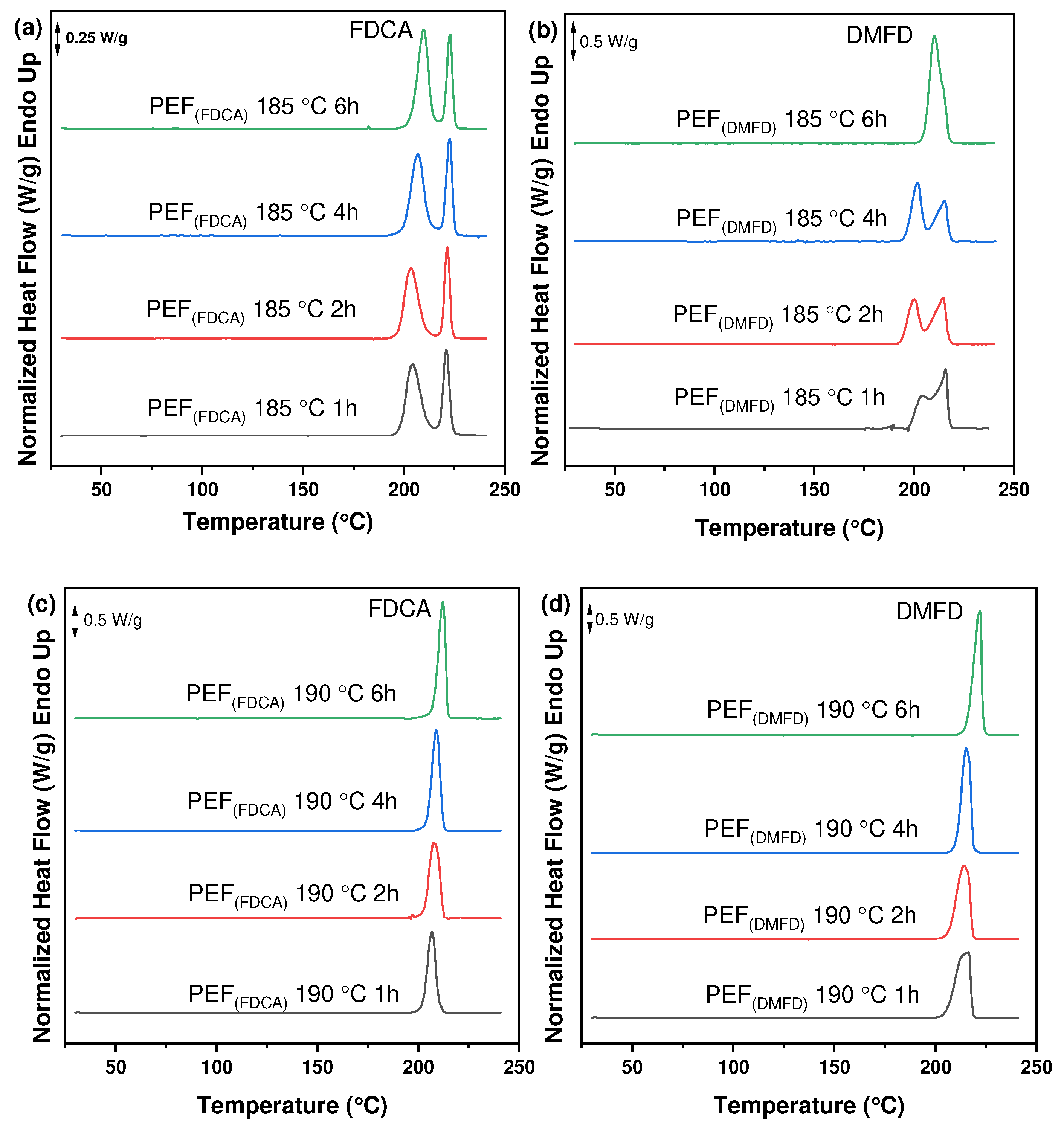

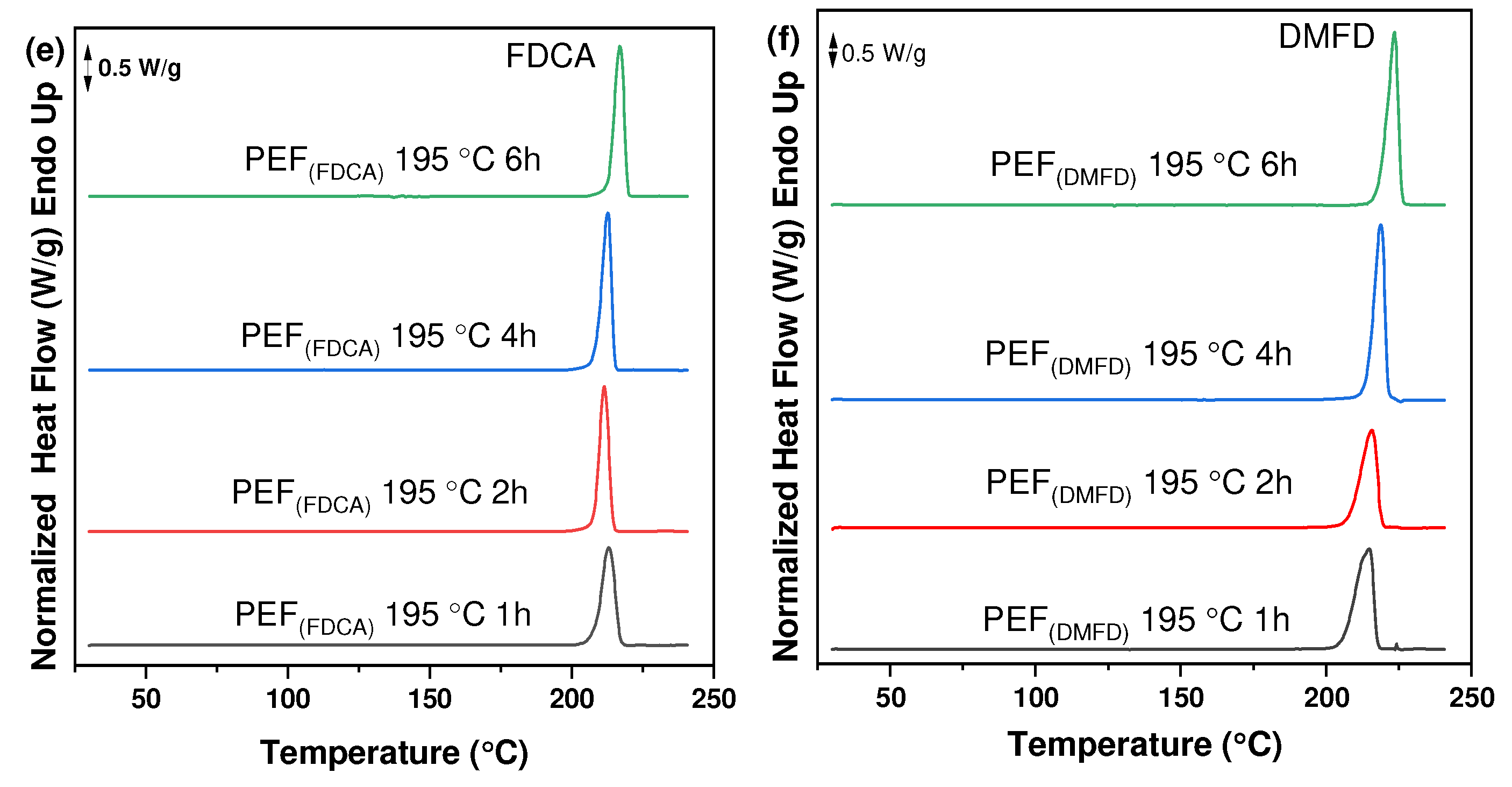

4.2. Thermal Analysis of Polyesters After SSP

4.2.1. DSC Analysis

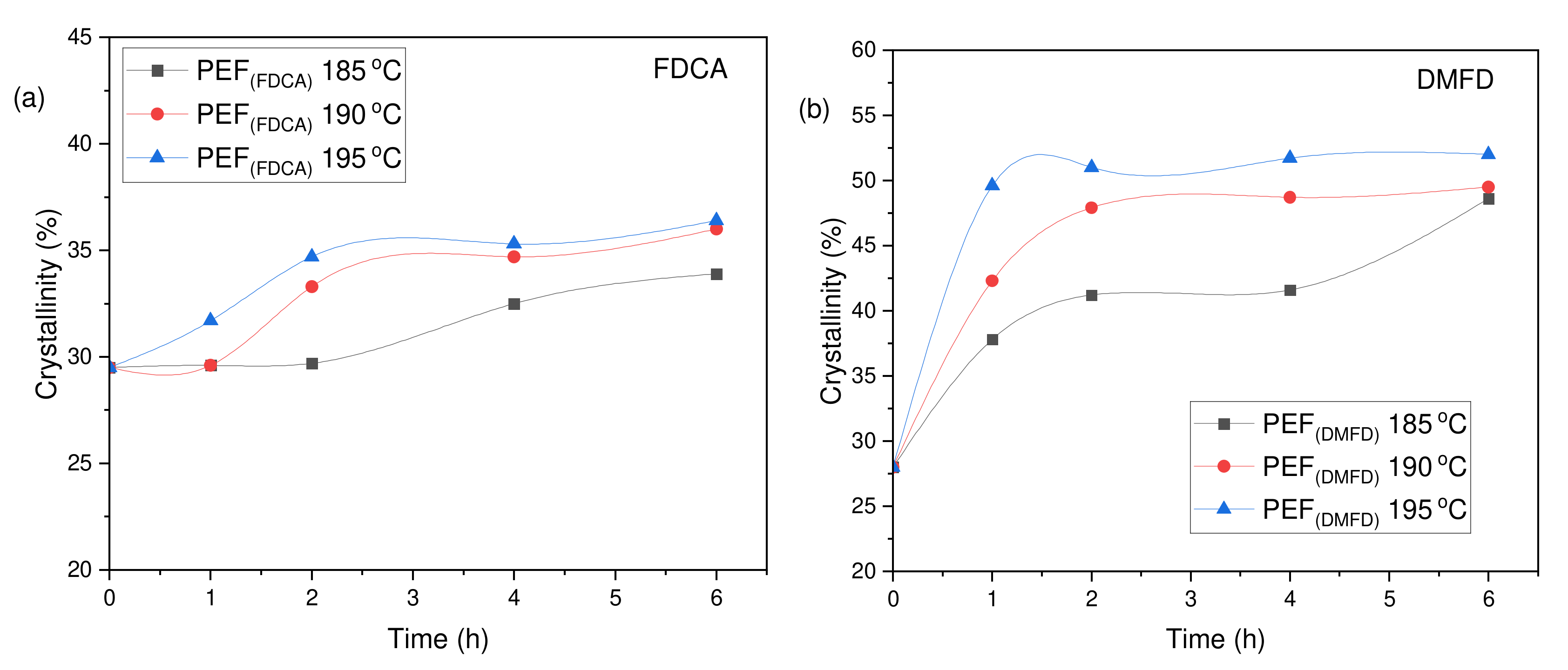

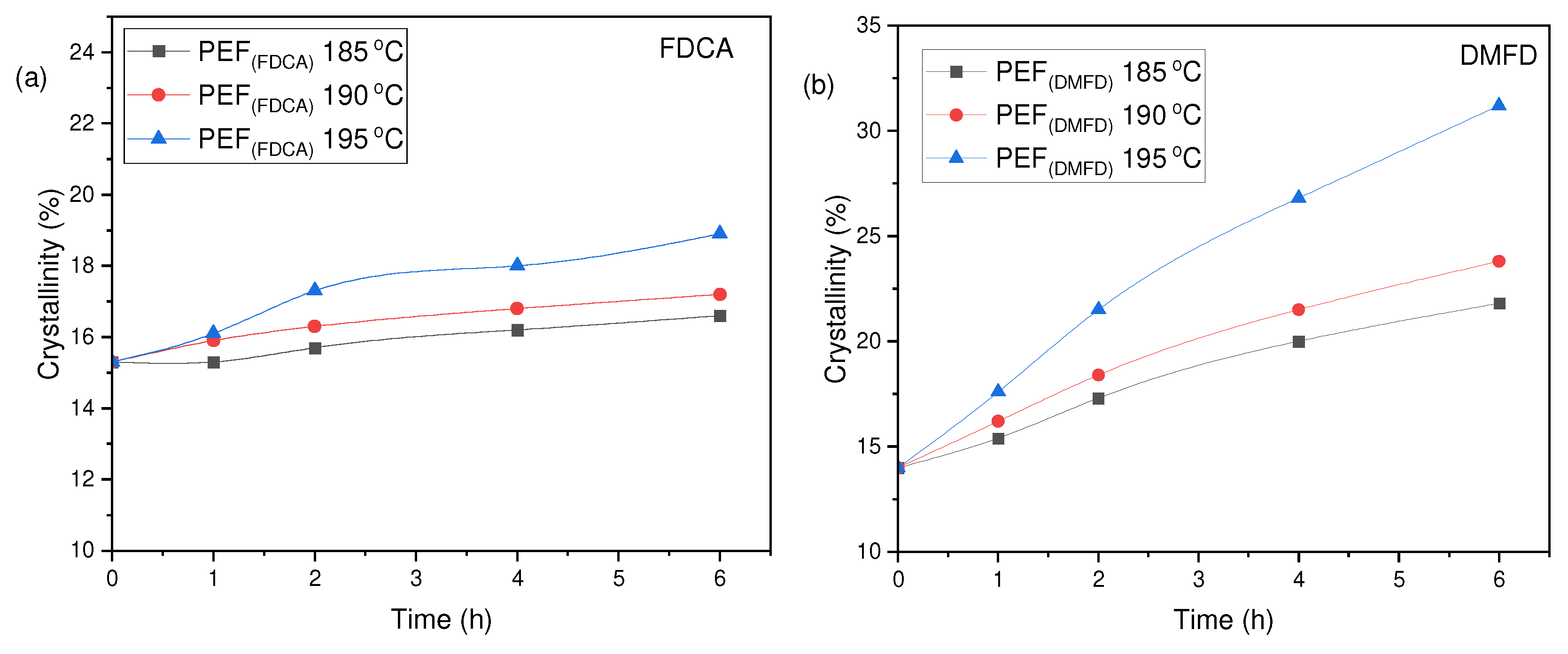

4.2.2. XRD Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PEF | Poly(ethylene 2,5-furan dicarboxylate) |

| DMFD | Dimethyl-2,5 furandicarboxylate |

| FDCA | 2,5-furan dicarboxylic acid |

| XRD | X-ray diffraction |

| PET | Poly(ethylene terephthalate) |

| GHG | Greenhouse gas |

| LCA | Life cycle assessment |

| EG | Ethylene glycol |

| SSP | Solid-state polymerization |

| PPF | Poly(propylene furanoate |

| PBF | Poly(butylene furanoate |

| DSC | Differential scanning calorimetry |

| WAXD | Wide Angle X-ray Diffraction Patterns |

| DGO | Diguaiacyl oxalate |

References

- Prieto, A. To Be, or Not to Be Biodegradable… That Is the Question for the Bio-Based Plastics. Microb. Biotechnol. 2016, 9, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Salgado, P.R.; Di Giorgio, L.; Musso, Y.S.; Mauri, A.N. Recent Developments in Smart Food Packaging Focused on Biobased and Biodegradable Polymers. Front. Sustain. Food Syst. 2021, 5, 630393. [Google Scholar] [CrossRef]

- Eerhart, A.J.J.E.; Faaij, A.P.C.; Patel, M.K. Replacing Fossil Based PET with Biobased PEF; Process Analysis, Energy and GHG Balance. Energy Environ. Sci. 2012, 5, 6407. [Google Scholar] [CrossRef]

- Kim, T.; Bamford, J.; Gracida-Alvarez, U.R.; Benavides, P.T. Life Cycle Greenhouse Gas Emissions and Water and Fossil-Fuel Consumptions for Polyethylene Furanoate and Its Coproducts from Wheat Straw. ACS Sustain. Chem. Eng. 2022, 10, 2830–2843. [Google Scholar] [CrossRef]

- De Jong, E.; Dam, M.A.; Sipos, L.; Gruter, G.-J.M. Furandicarboxylic Acid (FDCA), A Versatile Building Block for a Very Interesting Class of Polyesters; ACS Publications: Washington, DC, USA, 2012; pp. 1–13. [Google Scholar]

- De Jong, E.; Visser, H.A.; Dias, A.S.; Harvey, C.; Gruter, G.-J.M. The Road to Bring FDCA and PEF to the Market. Polymers 2022, 14, 943. [Google Scholar] [CrossRef]

- Gomes, F.W.; Lima, R.C.; Piombini, C.R.; Sinfitele, J.F.; De Souza, F.G.; Coutinho, P.L.A.; Pinto, J.C. Comparative Analyses of Poly(Ethylene 2,5-Furandicarboxylate)−PEF−and Poly(Ethylene Terephthalate) − PET − Resins and Production Processes. Macromol. Symp. 2018, 381, 1800129. [Google Scholar] [CrossRef]

- Louw, J.; Farzad, S.; Görgens, J.F. Polyethylene Furanoate: Technoeconomic Analysis of Biobased Production. Biofuels Bioprod. Biorefining 2023, 17, 135–152. [Google Scholar] [CrossRef]

- Sanders, J.H.; Cunniffe, J.; Carrejo, E.; Burke, C.; Reynolds, A.M.; Dey, S.C.; Islam, M.N.; Wagner, O.; Argyropoulos, D. Biobased Polyethylene Furanoate: Production Processes, Sustainability, and Techno-Economics. Adv. Sustain. Syst. 2024, 8, 2400074. [Google Scholar] [CrossRef]

- Eid, N.; Ameduri, B.; Boutevin, B. Synthesis and Properties of Furan Derivatives for Epoxy Resins. ACS Sustain. Chem. Eng. 2021, 9, 8018–8031. [Google Scholar] [CrossRef]

- Van Berkel, J.G.; Guigo, N.; Visser, H.A.; Sbirrazzuoli, N. Chain Structure and Molecular Weight Dependent Mechanics of Poly(Ethylene 2,5-Furandicarboxylate) Compared to Poly(Ethylene Terephthalate). Macromolecules 2018, 51, 8539–8549. [Google Scholar] [CrossRef]

- Jensen, M.H.; Riisager, A. Advances in the Synthesis and Application of 2,5-Furandicarboxylic Acid. In Biomass, Biofuels, Biochemicals; Elsevier: Amsterdam, The Netherlands, 2020; pp. 135–170. [Google Scholar]

- Pluta, M.; Bojda, J.; Svyntkivska, M.; Makowski, T.; De Boer, E.L.; Piorkowska, E. Crystallization-Controlled Structure and Thermal Properties of Biobased Poly(Ethylene2,5-Furandicarboxylate). Polymers 2024, 16, 3052. [Google Scholar] [CrossRef] [PubMed]

- Van der Maas, K.; Weinland, D.H.; Van Putten, R.J.; Wang, B.; Gruter, G.J.M. Catalyst Free PET and PEF Polyesters Using a New Traceless Oxalate Chain Extender. Green. Chemistry 2024, 26, 11182–11195. [Google Scholar] [CrossRef] [PubMed]

- Yao, B.; Ni, C.; Chen, M.; Song, H. Self-Assembly and Solid-State Photo Polymerization of Acrylamide Crystal Film. Colloid. Polym. Sci. 2009, 287, 73–79. [Google Scholar] [CrossRef]

- Bernabé Vírseda, I.; Beltrán, F.R.; De la Orden, M.U.; Martínez Urreaga, J. Effects of Solid-State Polymerization on the Structure and Properties of Degraded Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate). Polym. Degrad. Stab. 2024, 220, 110630. [Google Scholar] [CrossRef]

- Knoop, R.J.I.; Vogelzang, W.; Van Haveren, J.; Van Es, D.S. High Molecular Weight Poly(Ethylene-2,5-Furanoate); Critical Aspects in Synthesis and Mechanical Property Determination. J. Polym. Sci. A Polym. Chem. 2013, 51, 4191–4199. [Google Scholar] [CrossRef]

- Hong, S.; Min, K.D.; Nam, B.U.; Park, O.O. High Molecular Weight Bio Furan-Based Co-Polyesters for Food Packaging Applications: Synthesis, Characterization and Solid-State Polymerization. Green. Chemistry 2016, 18, 5142–5150. [Google Scholar] [CrossRef]

- Gabirondo, E.; Melendez-Rodriguez, B.; Arnal, C.; Lagaron, J.M.; Martínez De Ilarduya, A.; Sardon, H.; Torres-Giner, S. Organocatalyzed Closed-Loop Chemical Recycling of Thermo-Compressed Food Packaging Films of Poly(Ethylene Furanoate). Polym. Chem. 2021. [Google Scholar] [CrossRef]

- Kasmi, N.; Papageorgiou, G.; Achilias, D.; Bikiaris, D. Solid-State Polymerization of Poly(Ethylene Furanoate) Biobased Polyester, II: An Efficient and Facile Method to Synthesize High Molecular Weight Polyester Appropriate for Food Packaging Applications. Polymers 2018, 10, 471. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Xanthopoulou, E.; Nikolaidis, G.N.; Zamboulis, A.; Achilias, D.S.; Papageorgiou, G.Z.; Bikiaris, D.N. Towards High Molecular Weight Furan-Based Polyesters: Solid State Polymerization Study of Bio-Based Poly(Propylene Furanoate) and Poly(Butylene Furanoate). Materials 2020, 13, 4880. [Google Scholar] [CrossRef]

- Stanley, J.; Terzopoulou, Z.; Klonos, P.A.; Zamboulis, A.; Xanthopoulou, E.; Koltsakidis, S.; Tzetzis, D.; Zemljič, L.F.; Lambropoulou, D.A.; Kyritsis, A.; et al. Effect of Monomer Type on the Synthesis and Properties of Poly(Ethylene Furanoate). Polymers 2023, 15, 2707. [Google Scholar] [CrossRef]

- Pohl, H.A. Determination of Carboxyl End Groups in Polyester, Polyethylene Terephthalate. Anal. Chem. 1954, 26, 1614–1616. [Google Scholar] [CrossRef]

- Vouyiouka, S.N.; Karakatsani, E.K.; Papaspyrides, C.D. Solid State Polymerization. Prog. Polym. Sci. 2005, 30, 10–37. [Google Scholar] [CrossRef]

- Ravindranath, K.; Mashelkar, R.A. Modeling of Poly(Ethylene Terephthalate) Reactors. I. A Semibatch Ester Interchange Reactor. J. Appl. Polym. Sci. 1981, 26, 3179–3204. [Google Scholar] [CrossRef]

- Mallon, F.K.; Ray, W.H. Modeling of Solid-State Polycondensation. II. Reactor Design Issues. J. Appl. Polym. Sci. 1998, 69, 1775–1788. [Google Scholar] [CrossRef]

- Ma, Y.; Agarwal, U.S.; Sikkema, D.J.; Lemstra, P.J. Solid-State Polymerization of PET: Influence of Nitrogen Sweep and High Vacuum. Polymer (Guildf) 2003, 44, 4085–4096. [Google Scholar] [CrossRef]

- Ma, Y.; Agarwal, U.S. Solvent Assisted Post-Polymerization of PET. Polymer 2005, 46, 5447–5455. [Google Scholar] [CrossRef]

- Achilias, D.S.; Chondroyiannis, A.; Nerantzaki, M.; Adam, K.V.; Terzopoulou, Z.; Papageorgiou, G.Z.; Bikiaris, D.N. Solid State Polymerization of Poly(Ethylene Furanoate) and Its Nanocomposites with SiO2 and TiO2. Macromol. Mater. Eng. 2017, 302, 1700012. [Google Scholar] [CrossRef]

- Kasmi, N.; Majdoub, M.; Papageorgiou, G.; Achilias, D.; Bikiaris, D. Solid-State Polymerization of Poly(Ethylene Furanoate) Biobased Polyester, I: Effect of Catalyst Type on Molecular Weight Increase. Polymers 2017, 9, 607. [Google Scholar] [CrossRef]

- Qu, X.; Zhou, G.; Wang, R.; Zhang, H.; Wang, Z.; Jiang, M.; Tang, J. Insights into High Molecular Weight Poly(Ethylene 2,5-Furandicarboxylate) with Satisfactory Appearance: Roles of in-Situ Catalysis of Metal Zinc. J. Ind. Eng. Chem. 2021, 99, 422–430. [Google Scholar] [CrossRef]

- Zhang, T.; Howell, B.A.; Smith, P.B. Thermal Degradation of Glycerol/Adipic Acid Hyperbranched Poly(Ester)s Containing Either Hydroxyl or Carboxyl End-Groups. J. Therm. Anal. Calorim. 2015, 122, 1221–1229. [Google Scholar] [CrossRef]

- Stoclet, G.; Gobius du Sart, G.; Yeniad, B.; De Vos, S.; Lefebvre, J.M. Isothermal Crystallization and Structural Characterization of Poly(Ethylene-2,5-Furanoate). Polymer 2015, 72, 165–176. [Google Scholar] [CrossRef]

- Fei, X.; Wang, J.; Zhu, J.; Wang, X.; Liu, X. Biobased Poly(Ethylene 2,5-Furanoate): No Longer an Alternative, but an Irreplaceable Polyester in the Polymer Industry. ACS Sustain. Chem. Eng. 2020, 8, 8471–8485. [Google Scholar] [CrossRef]

| Temperature (°C) | SSP Time (h) | PEF (FDCA) | PEF (DMFD) | ||

|---|---|---|---|---|---|

| [ղ] | [ղ] | ||||

| as received | 0 | 0.43 | 8969 (49) | 0.41 | 6822 (37) |

| 185 | 1 | 0.43 | 8969 (49) | 0.46 | 9950 (54) |

| 2 | 0.44 | 9292 (50) | 0.49 | 10,967 (59) | |

| 4 | 0.44 | 9292 (50) | 0.51 | 11,664 (63) | |

| 6 | 0.45 | 9619 (52) | 0.54 | 12,737 (69) | |

| 190 | 1 | 0.45 | 9619 (52) | 0.49 | 10,967 (59) |

| 2 | 0.45 | 9619 (52) | 0.50 | 11,313 (63) | |

| 4 | 0.46 | 9950 (54) | 0.53 | 12,376 (67) | |

| 6 | 0.46 | 9950 (54) | 0.56 | 13,471 (73) | |

| 195 | 1 | 0.46 | 9950 (54) | 0.49 | 10,967 (59) |

| 2 | 0.46 | 9950 (54) | 0.52 | 12,018 (65) | |

| 4 | 0.47 | 10,285 (56) | 0.58 | 14,219 (77) | |

| 6 | 0.48 | 10,624 (57) | 0.61 | 15,367 (83) | |

| Sample | k1 (kg/meq/h) | k2 (kg/meq/h) | [OH]i (meq/kg) | [COOH]i (meq/kg) |

|---|---|---|---|---|

| FDCA | ||||

| 185 °C | 0.000305 | 0.022 | 80 | 15 |

| 190 °C | 0.00035 | 0.022 | 90 | 14.5 |

| 195 °C | 0.0004 | 0.022 | 85 | 13 |

| DFMD | ||||

| 185 °C | 0.0005 | 0.012 | 180 | 12 |

| 190 °C | 0.00085 | 0.015 | 140 | 10 |

| 195 °C | 0.00145 | 0.0185 | 130 | 9.5 |

| SSP Temperature (°C) | SSP Time (h) | PEF (FDCA) (Xca (%)) | PEF (DMFD) (Xca (%)) |

|---|---|---|---|

| As received | 0 | 29.5 | 28 |

| 185 | 1 | 29.6 | 37.8 |

| 2 | 29.7 | 41.2 | |

| 4 | 32.5 | 41.6 | |

| 6 | 33.9 | 48.6 | |

| 190 | 1 | 29.6 | 42.3 |

| 2 | 33.3 | 47.9 | |

| 4 | 34.7 | 48.7 | |

| 6 | 36 | 49.5 | |

| 195 | 1 | 31.7 | 49.6 |

| 2 | 34.7 | 51 | |

| 4 | 35.3 | 51.7 | |

| 6 | 36.4 | 52 |

| SSP Temperature (°C) | SSP Time (h) | PEF (FDCA) (Xcb (%)) | PEF (DMFD) (Xcb (%)) |

|---|---|---|---|

| As received | 0 | 15.3 | 14 |

| 185 | 1 | 15.3 | 15.4 |

| 2 | 15.7 | 17.3 | |

| 4 | 16.2 | 20 | |

| 6 | 16.6 | 21.8 | |

| 190 | 1 | 15.9 | 16.2 |

| 2 | 16.3 | 17.4 | |

| 4 | 16.8 | 21.5 | |

| 6 | 17.2 | 23.8 | |

| 195 | 1 | 16.1 | 17.6 |

| 2 | 17.3 | 21.5 | |

| 4 | 18 | 26.8 | |

| 6 | 18.9 | 31.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stanley, J.; Xanthopoulou, E.; Kostoglou, M.; Fras Zemljič, L.; Lambropoulou, D.A.; Bikiaris, D.N. Study on Impact of Monomers Towards High Molecular Weight Bio-Based Poly(ethylene Furanoate) via Solid State Polymerization Technique. Polymers 2024, 16, 3305. https://doi.org/10.3390/polym16233305

Stanley J, Xanthopoulou E, Kostoglou M, Fras Zemljič L, Lambropoulou DA, Bikiaris DN. Study on Impact of Monomers Towards High Molecular Weight Bio-Based Poly(ethylene Furanoate) via Solid State Polymerization Technique. Polymers. 2024; 16(23):3305. https://doi.org/10.3390/polym16233305

Chicago/Turabian StyleStanley, Johan, Eleftheria Xanthopoulou, Margaritis Kostoglou, Lidija Fras Zemljič, Dimitra A. Lambropoulou, and Dimitrios N. Bikiaris. 2024. "Study on Impact of Monomers Towards High Molecular Weight Bio-Based Poly(ethylene Furanoate) via Solid State Polymerization Technique" Polymers 16, no. 23: 3305. https://doi.org/10.3390/polym16233305

APA StyleStanley, J., Xanthopoulou, E., Kostoglou, M., Fras Zemljič, L., Lambropoulou, D. A., & Bikiaris, D. N. (2024). Study on Impact of Monomers Towards High Molecular Weight Bio-Based Poly(ethylene Furanoate) via Solid State Polymerization Technique. Polymers, 16(23), 3305. https://doi.org/10.3390/polym16233305