Effect of Treatment Methods on Material Properties and Performance of Sawdust-Concrete and Sawdust-Polymer Composites

Abstract

1. Introduction

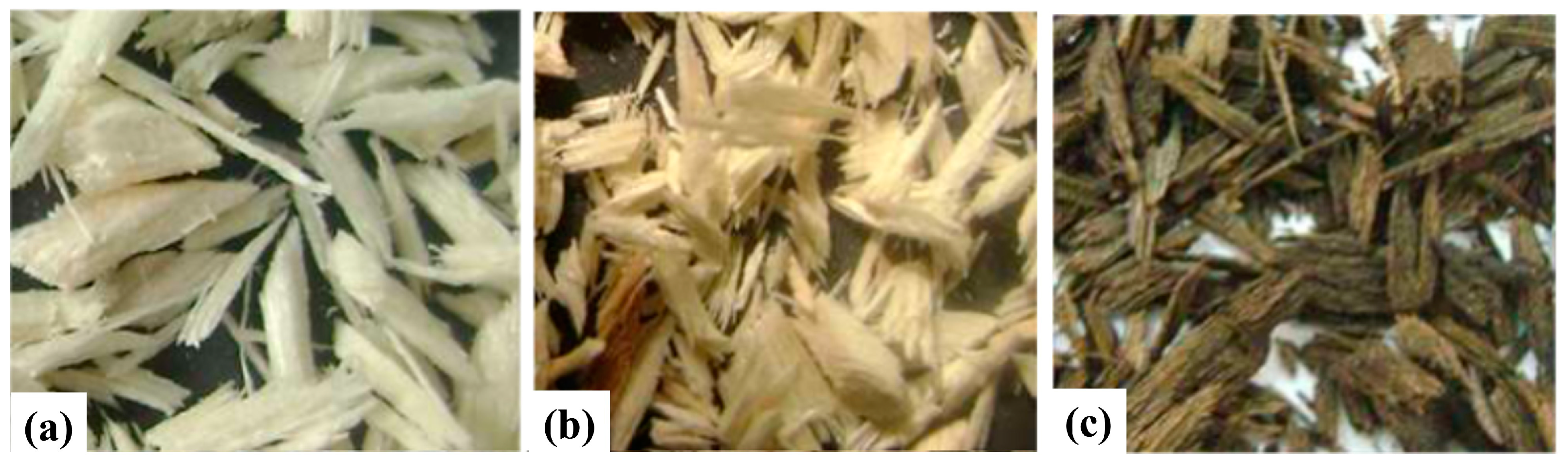

2. Chemical Treatments

2.1. NaOH Treatment

2.2. NaOH and Others

2.2.1. (NaOH + KOH + H2O2) Treatment

2.2.2. (NaOH + C14H10O4 (Benzoyl Peroxide)) Treatment

2.2.3. (NaOH + Dimethyldichlorosilane (DMDCS)+ Polydimethylsiloxane (PDMS)) Treatment

2.3. Ca(OH)2 Treatment

2.4. Na2SiO3 Treatment

2.5. (Ca(OH)2 + Na2SiO3) Treatment

2.6. NaOCl Treatment

2.7. Maleic Anhydride (C4H2O3) Treatment

2.8. (HCl + NH4OH + Polyethylenimine (PEI)) Treatment

2.9. (Ethanol+ NaCl+ H2SO4) Treatment

2.10. (Ethanol +Tolune + H2O2 +Acetic Acid) Treatment

2.11. Potassium Methyl Siliconate (PMS) Treatment

2.12. Detersive Solvent Treatment

2.13. Vinyltriethoxysilane (VTES) and Diethyl Ether Treatment

2.14. (H2O2 + Acetic Acid + KOH + TiO2 + Acrilonitrile) Treatment

- i.

- Wood Pulp Preparation (WP):A total of 200 g of sawdust was soaked in distilled water for 16 h. Following this, the sawdust was placed in a grinder vessel, with water added to fill 2/3 of the vessel, and stirred for 30 min. The mixture then underwent ultrasonication at 80 °C for 1 h in a sonicator bath, which helped remove excess water from the sawdust.

- ii.

- Delignification of Wood Pulp (DWPF):For the delignification process, a bleaching solution of 500 g was prepared by mixing 248.75 g hydrogen peroxide (H2O2), 248.75 g acetic acid, and 2.5 g titanium oxide. This solution was boiled at 130 °C for 3 h in a fume hood. After boiling, the delignified wood pulp was washed with potassium hydroxide (KOH) and distilled water until the pH reached 7.

- iii.

- Alkaline Treatment of DWPF:The delignified wood pulp (DWPF) was treated with a 6 wt.% KOH solution. This solution was made by dissolving 54 g KOH in 846 g of water, yielding 900 mL. Then, 60 g of DWPF was added, and the mixture underwent ultrasonication at 80 °C for further chemical modification.

3. Properties of Sawdust Composite

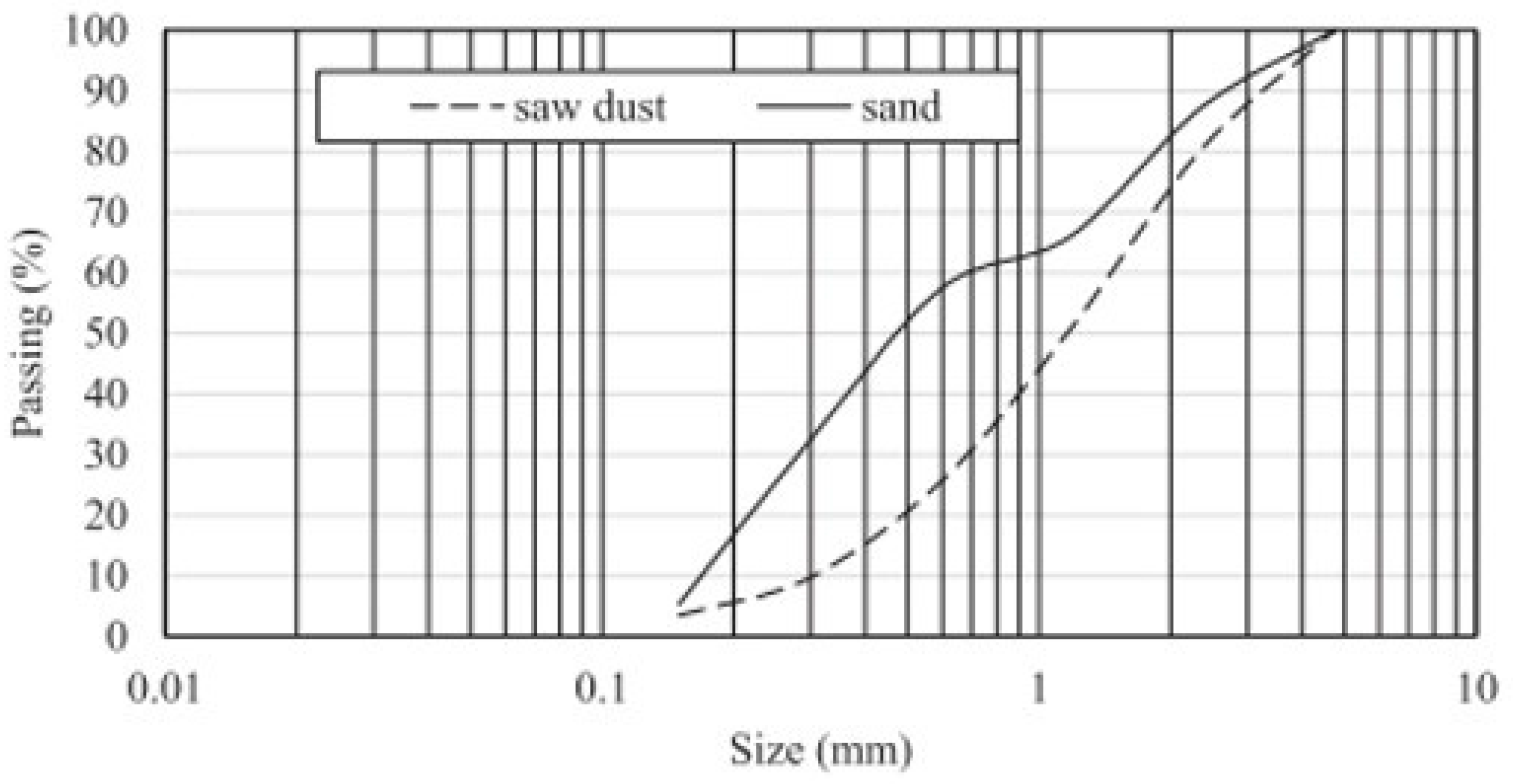

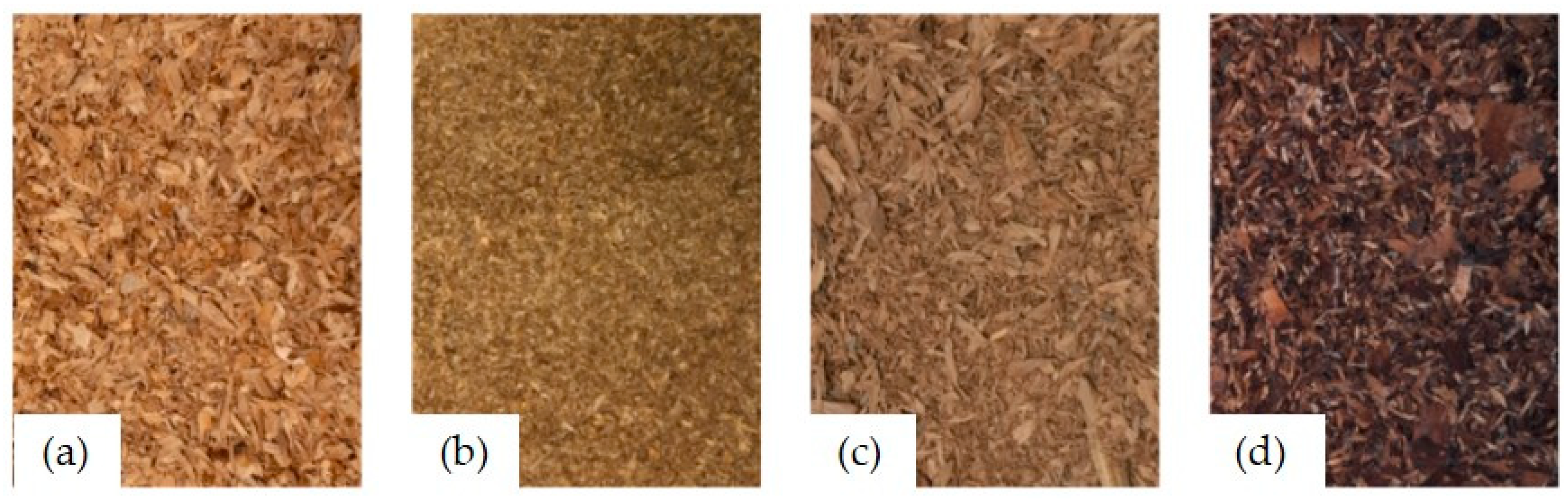

3.1. Sawdust Concrete (SDC)

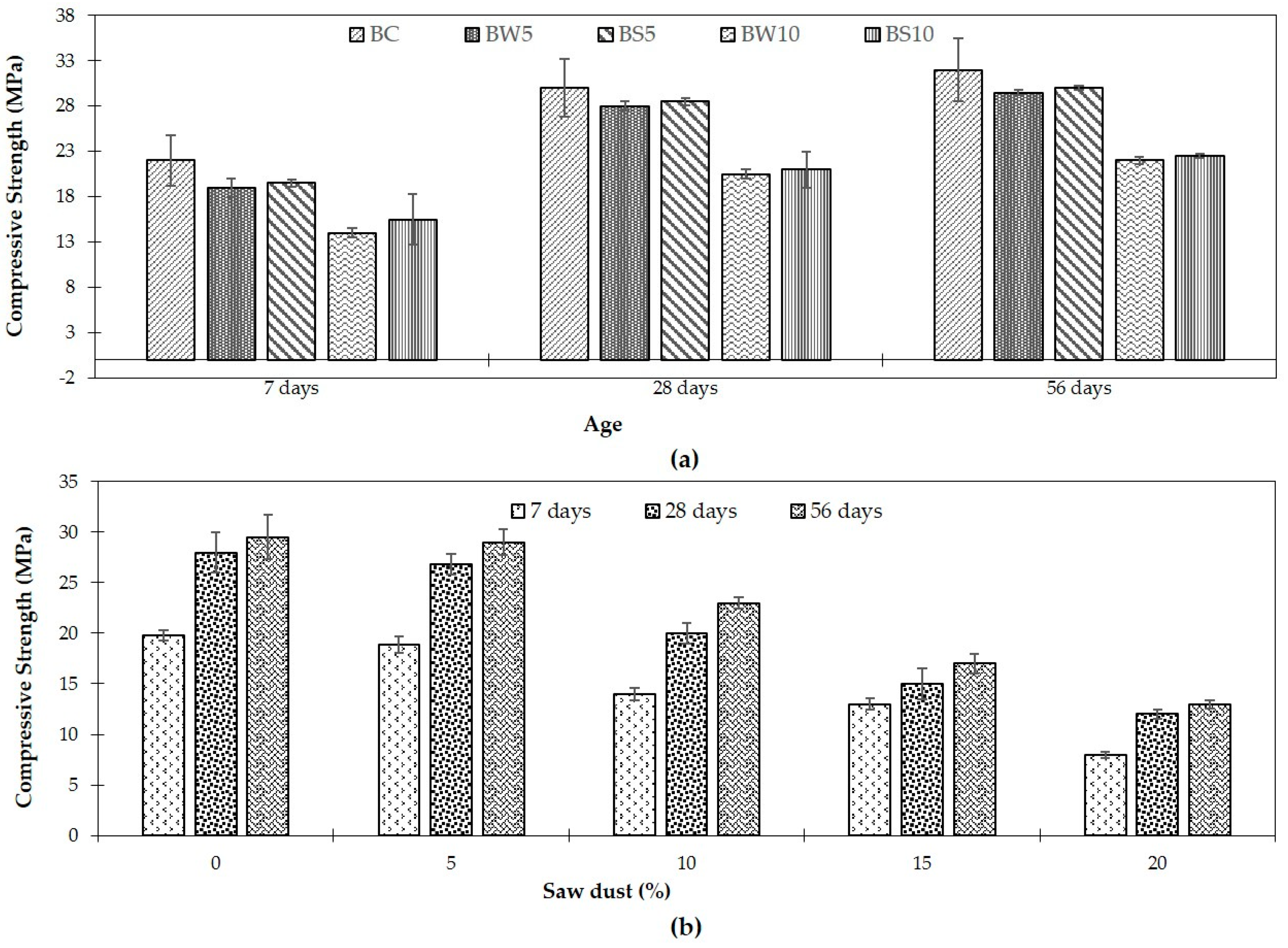

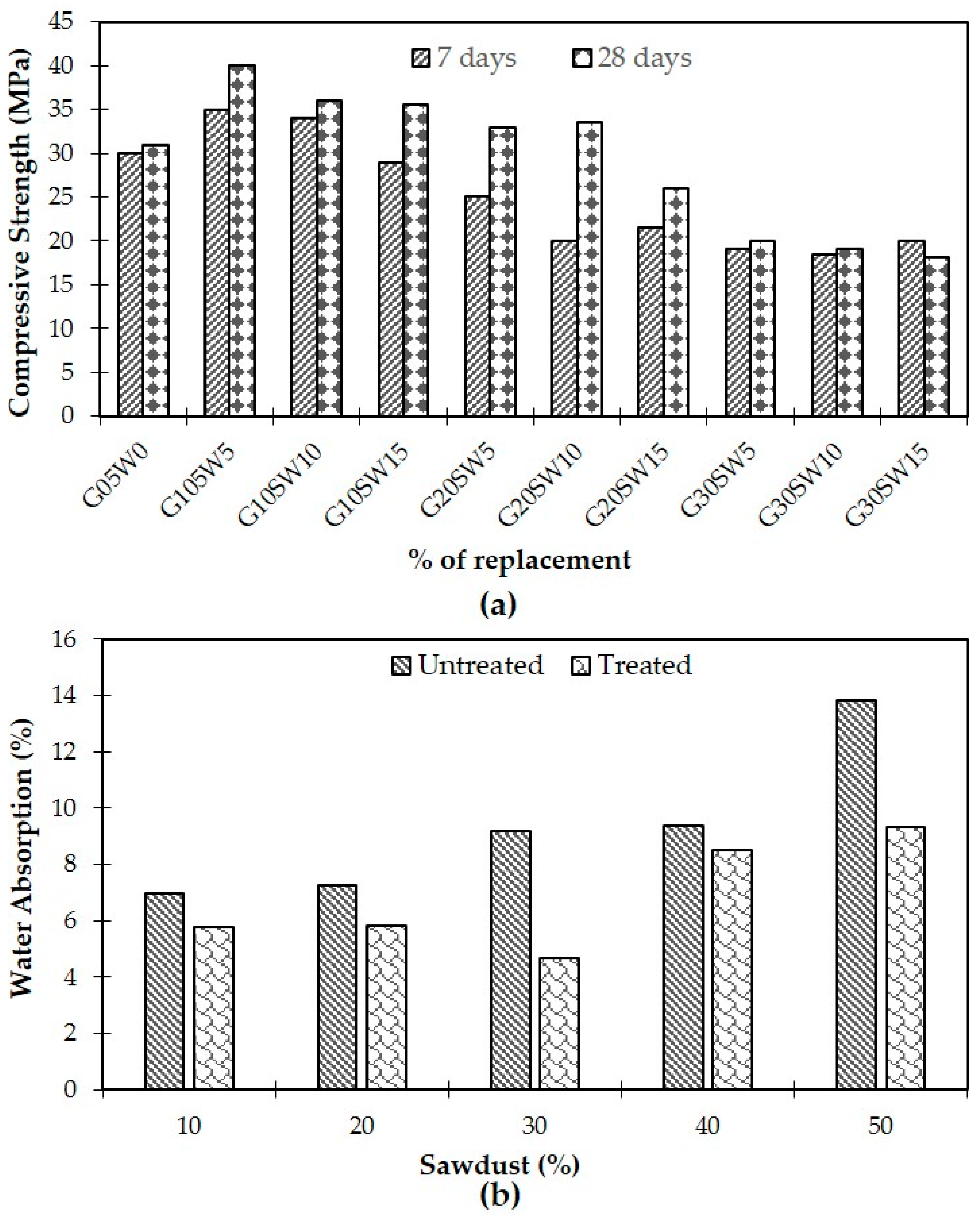

3.1.1. Compressive Strength of Treated SDC

3.1.2. Durability of Treated SDC

3.2. Sawdust-Polymer Composite (SDPC)

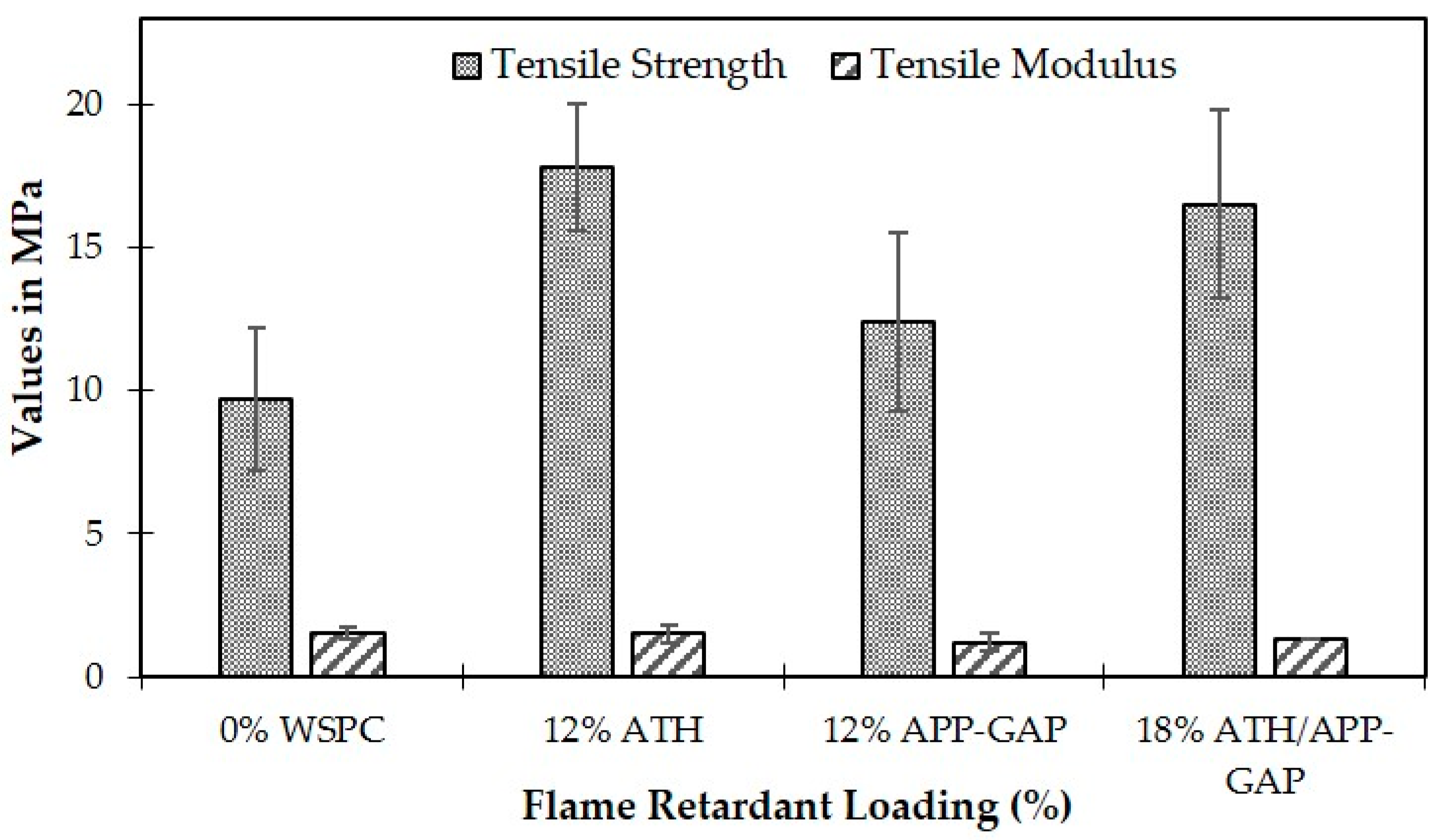

3.2.1. Tensile Properties

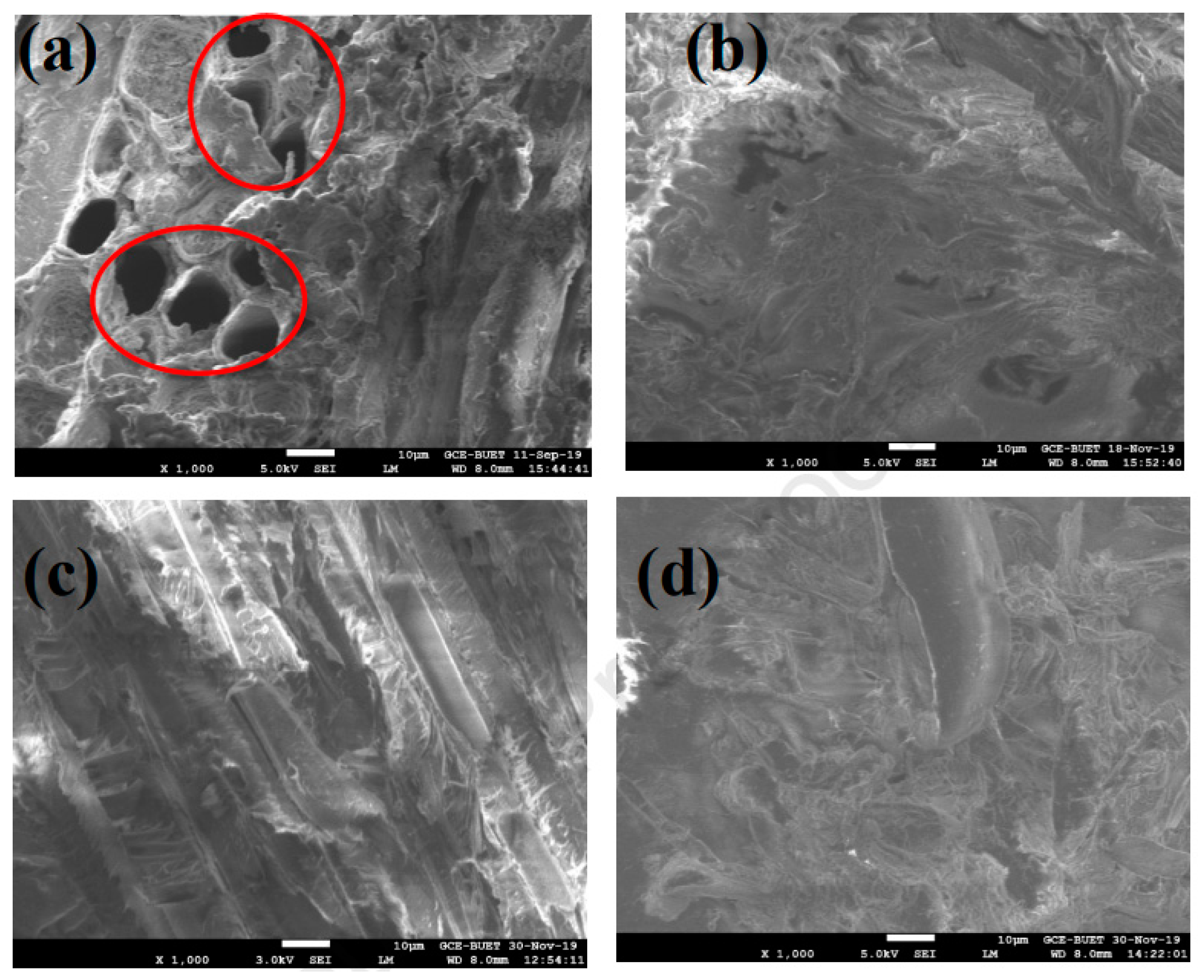

3.2.2. Morphological Observation

4. Conclusions

5. Future Scope

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| SDC | Compression | Durability | References |

| The addition of sawdust with control concrete caused a decrease in compressive strength, where the 5% sawdust, either treated by silicate or water, provided greater results than the 10%, 15%, and 20% treated sawdust. | 1. Concrete cured after 56 days showed better results in each case compared with 7-day and 28-day cured concrete. 2. Water absorption of water-treated sawdust increased sharply with the sawdust addition. | [62] | |

| Distilled water and Ca(OH)2-solution-treated sawdust showed less compressive strength than the control concrete mixture without any sawdust. But treatment with CaCl2 caused a 10% increment compared with control concrete. | Curing time is important because 28-day cured concrete, whatever the control concrete or treated sawdust concrete, showed better results than the 7-day cured samples. | [61] | |

| Compressive strength shows a decreasing trend with the addition of wood particles for both WW1, WW2, and WW3 wood waste, where chemical treatment was identical. | The 28-day cured wood samples showed better compressive strength than the 7-day, such as 21.5%, 14.7%, and 2.5% increments for WW1, WW2, and WW3 samples, respectively. | [63] | |

| Compressive strength decreased gradually with the addition of both sawdust ash and sawdust individually. Again, chemical treatment has a negative influence on strength. | Compressive strength significantly increased after 28 days of curing compared with 7 days and 14 days for both sawdust and sawdust ash. | [59] | |

| The 10% GGBS and 5% sawdust mixed concrete showed the highest compressive strength and started to decrease with further addition. | 1. The 28-day cured sawdust concrete provided better compressive strength than the 7-day cured one in all cases. 2. With the addition of sawdust and ground granulated blast furnace slag (GGBS), the water absorption value decreased. | [46] | |

| 1. The addition of sawdust (treated or untreated) has a negative impact on mechanical properties, such as 50% of sawdust addition exhibiting the lowest values, whereas 10% of sawdust addition shows the greatest strength. 2. NaOCl-treated + washed samples showed better compressive strength than the NaOCl-treated samples. | Untreated sawdust showed the highest water absorption capacity, and treated without wash had minimal water absorption. | [64] | |

| Due to having good bonding with cement, T.scleroxylon-derived-sawdust-cement composites showed greater modulus of elasticity than E. cylindricum sawdust. | T. scleroxylon absorbed 8.82% moisture, which is the lowest compared with 9.52% for the E. cylindricum sawdust-cement block. | [67] | |

| Compressive strength showed a decreasing trend with the increasing sawdust volume after a 10% sawdust addition. | - | [56] | |

| PDMS-treated wood samples exhibited better modulus of elasticity than the DMDCS-treated ones. Again, with the increasing concentration of PDMCS, strength increased significantly, but DMDCS-treated samples acted completely reversed. | The water contact angle was improved with both PDMS and DMDCS treatment. The highest 147° and 143° water contact angles were observed after treatment with PDMS and DMDCS solution. Interestingly, the water contact angle showed an increasing trend with increasing treatment time and concentration. | [58] | |

| Compressive strength dramatically decreased with the addition of sawdust for all groups. | Water absorption phenomena were decreased significantly with MC-70 and a varnish mixture, and the effect of 20% Ca(OH)2 +boiled water was less. | ||

| 1. Compressive strength increased up to 3% NaOH solution. After that, it showed a decreasing trend with the NaOH solution 2. Average compressive strength increased rapidly with the increasing boiling temperature up to 160 °C. | - | [50] | |

| Hot water-treated sawdust presented better shear strength and modulus of rigidity than cold water and ethanol-treated sawdust. | Ethanol-treated sawdust had greater moisture sensitivity, whereas hot water showed the lowest swelling value. | [74] |

| SDPC | Tensile Strength | Morphological Observation | References |

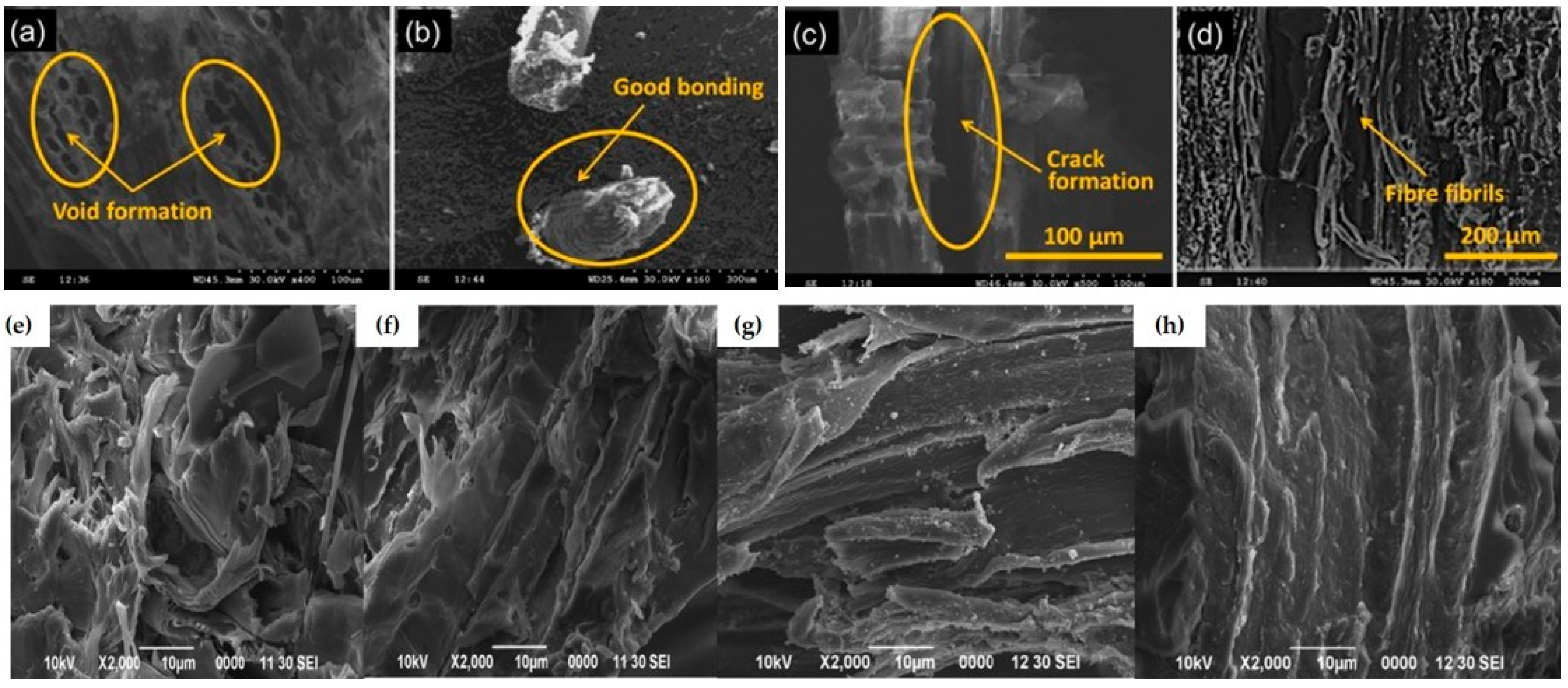

| 1. Tensile strength sharply increased after chemical treatment with a 10% NaOH solution compared with untreated sawdust composites. 2. With the addition of sawdust volume, tensile strength decreased for both treated sawdust and treated sawdust. | Fiber addition caused lower mechanical properties because of low bonding in composites as sawdust clustered at different positions from SEM observation. | [47] | |

| - | Compatibility between matrix and sawdust improved due to chemical treatment from FTIR and SEM observations. | [69] | |

| The 14% tensile strength increased due to the chemical treatment on sawdust compared with untreated samples. | SEM photographs revealed crack initiation and fiber fibrils after 90 min of cryogenic treatment; before that, they showed good bonding between the fibers and the matrix phase. | [70] | |

| The 36.7% tensile strength increased with 4% NaOH treatment in SPDC compared with untreated sawdust. | Alkali-treated-sawdust composites showed better interfacial bonding between sawdust and the resin matrix phase due to having hydroxyl and carbonyl groups. | [48] | |

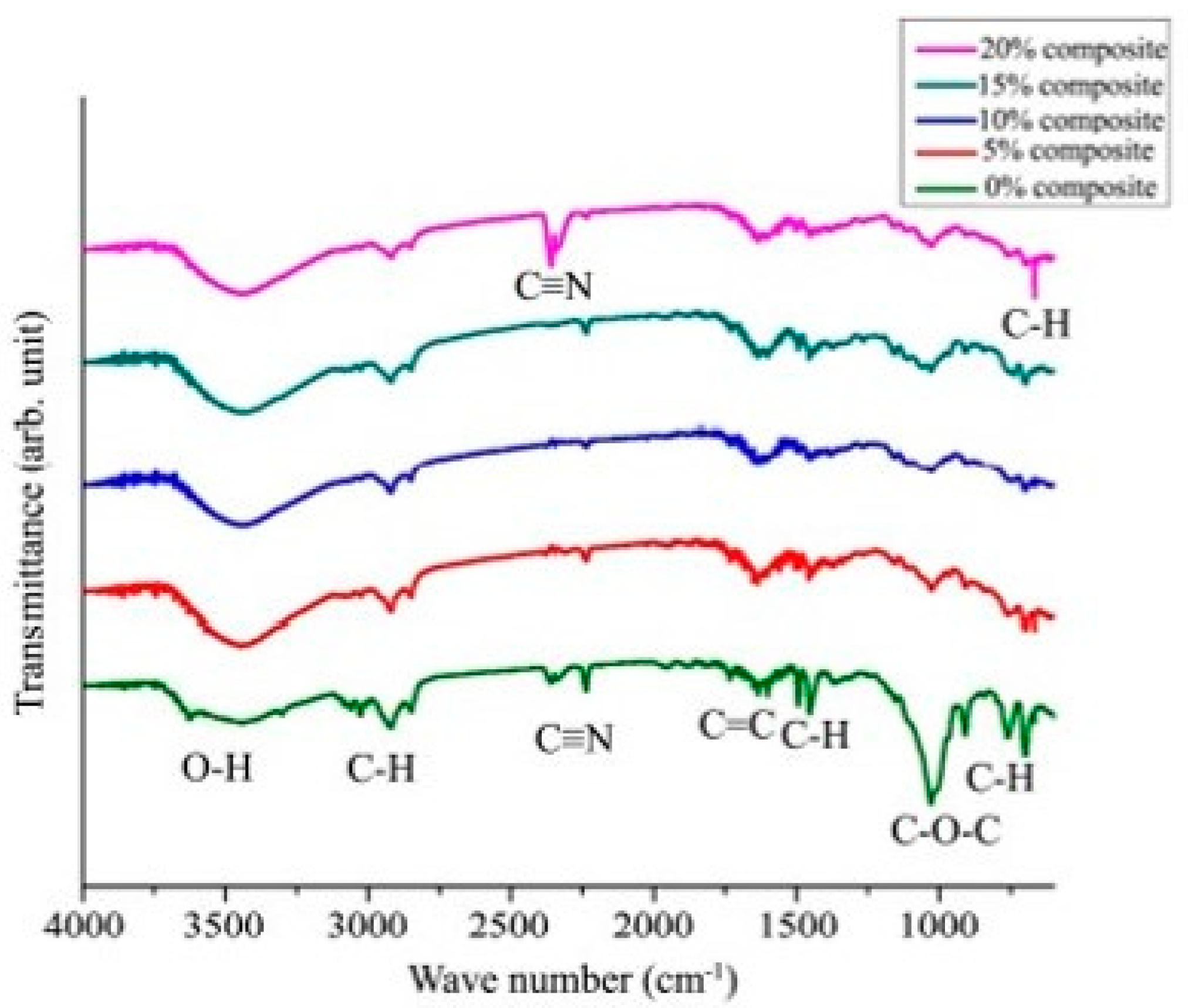

| Tensile strength declined drastically with up to 10% sawdust addition and then rose a little bit at 15% before being followed by another decrement at 20% addition. | In the ABS polymer matrix, sawdust was added, and the C-H rocking was broken, as demonstrated by the FTIR spectrum. | [51] | |

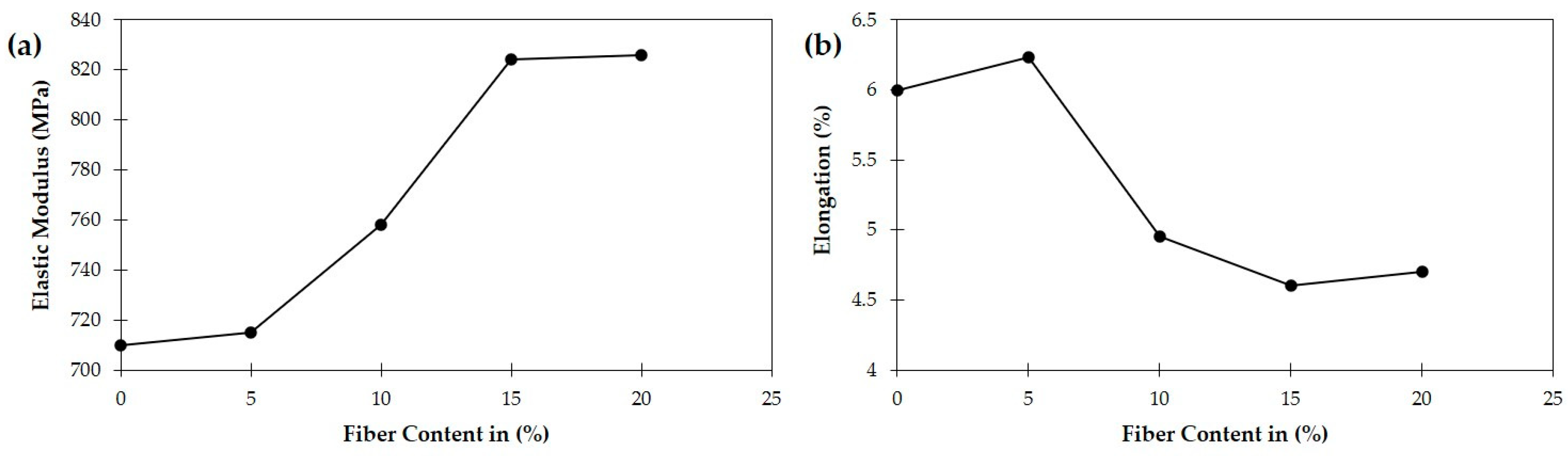

| 1. Tensile strength and elongation at break increased significantly after chemical treatment. 2. Up to 15% addition of treated or untreated sawdust, tensile strength significantly increased, but after, it that decreased drastically. | From FTIR and SEM analysis, treated sawdust illustrated better interfacial adhesion with the HDPE polymer matrix phase. | [57] | |

| 1. Tensile strength illustrated a sharp increasing trend up to 30% treated fillers addition. 2. Young’s modulus showed a 45% increment with the 30:70 ratio for the fibers-epoxy combination when strain increased by approximately 53%. | - | [54] | |

| Tensile strength increased remarkably with the increasing fiber loading up to 50 wt.%, but further addition caused a decrement because the interfacial adhesion between the fibers and the matrix phase reduced significantly. | - | [52] | |

| Ammoxidized sawdust and hydrolyzed sawdust composites provide less mechanical properties as well as interfacial bonding compared with LPEC-treated sawdust. | Mechanical properties, such as tensile strength and bending strength, improved remarkably after LPEC treatment because the interfacial adhesion improved significantly, as seen in the SEM analysis. | [66] | |

| VTES and diethylether solution. treated sawdust provide higher mechanical properties and interfacial adhesion between the matrix phase and the sawdust compared with raw sawdust composites. | From SEM, CaCO3-modified small particle sawdust dispersed properly in the HDPE matrix phase, which ensures the best interfacial adhesion. | [71] | |

| 1. Wood-pulp-unsaturated-polyester-resin composites showed higher mechanical properties such as tensile strength and Young’s modulus with the fiber loading up to 15 wt.% and after that showed a decreasing trend. 2. Cyanoethyl-cellulose-fiber-oriented-unsaturated-polyester composites (CEFUPC) showed the highest mechanical properties and better interfacial adhesion compared with wood pulp composites and cellulose fiber unsaturated polyester resin composites. | 1. SEM images revealed that cyanoethyl cellulose fibers had better interfacial bonding than others because of having a minimal gap between the fibers and the matrix phase. 2. Similarly, FTIR expressed the hydrophobic behavior of CEFUPC as the hydroxyl groups were replaced by cyanoethyl groups. | [72] | |

| 1. After the addition of 12% ATH, tensile strength increased 84% compared with sawdust composites without any flame retardant addition because of better interfacial adhesion between the flame retardant agent and polyester resin, which led to stress transfer. | - | [53] | |

| Though the tensile strength decreased after 15 wt.% fiber loading in both cases; delignified sawdust composites showed better mechanical characteristics than raw sawdust composites in each composition. | 1. FTIR analysis revealed raw sawdust exhibited a 3300 cm−1 peak for high moisture absorption that has been demolished through delignification. 2. From SEM analysis, delignified sawdust showed better interfacial bonding with UP resin. | [68] | |

| 1. Tensile strength showed an increasing trend up to 15 % treated sawdust addition, and after that, it decreased with the fiber addition. But tensile strength showed a decreasing trend with untreated fiber loading, whatever the percentage is. 2. For both treated and untreated sawdust addition, Young’s modulus showed a steady increase up to 15% fiber loading, and after that value, it showed a sharp increasing trend where treated sawdust composites provide better results than untreated composites. | 1. From SEM observation, interfacial adhesion between fibers and PP becomes weak with the fiber addition referred to as fiber pullout, agglomeration, and the presence of the void. 2. FTIR states a stress transfer phenomenon from matrix to sawdust caused interfacial adhesion, which was accelerated by the diazo group through hydroxyl group absorption. | [55] | |

| Tensile properties increased with up to 40 wt.% sawdust addition, and after that, decreased with fiber loading. | - | [75] |

References

- Dorling, D. World Population Prospects at the UN: Our Numbers Are Not Our Problem? In The Struggle for Social Sustainability; Policy Press: Bristol, UK, 2021; pp. 129–154. [Google Scholar]

- Troger, H. Demographic Developments and Other Social Phenomena. In Resetting Human Resource Management; Springer: Cham, Switzerland, 2022; pp. 3–17. [Google Scholar]

- Susman, P.; O’Keefe, P.; Wisner, B. Global disasters A Radical Interpretation. In Interpretations of Calamity; Hewitt, K., Ed.; Routledge: London, UK, 2019; pp. 263–283. [Google Scholar]

- Maja, M.M.; Ayano, S.F. The Impact of Population Growth on Natural Resources and Farmers’ Capacity to Adapt to Climate Change in Low-Income Countries. Earth Syst. Environ. 2021, 5, 271–283. [Google Scholar] [CrossRef]

- Trend of Urban Growth in Nepal with a Focus in Kathmandu Valley: A Review of Processes and Drivers of Change Netra Prasad Timsina, with Input from Anushiya Shrestha, Dilli Prasad Poudel and Rachana Upadhyaya Tomorrow’s Cities Working Paper 001. 2020. Available online: https://hdl.handle.net/1842/37436 (accessed on 19 November 2024).

- Roberts, M.; Sander, F.G.; Tiwari, S. (Eds.) Time to ACT: Realizing Indonesia’s Urban Potential; World Bank Publications: Herndon, VA, USA, 2019. [Google Scholar]

- Forbes, E. Migration, Informal Settlement, and Government Response: The Cases of Four Townships in Yangon, Myanmar. Moussons 2019, 33, 95–117. [Google Scholar] [CrossRef]

- Rodríguez-Pose, A.; Storper, M. Housing, Urban Growth and Inequalities: The Limits to Deregulation and Upzoning in Reducing Economic and Spatial Inequality. Urban Stud. 2020, 57, 223–248. [Google Scholar] [CrossRef]

- Nazir, F.; Edwards, D.J.; Shelbourn, M.; Martek, I.; Thwala, W.D.D.; El-Gohary, H. Comparison of Modular and Traditional UK Housing Construction: A Bibliometric Analysis. J. Eng. Des. Technol. 2021, 19, 164–186. [Google Scholar] [CrossRef]

- Muhit, I.B.; Omairey, E.L.; Pashakolaie, V.G. A Holistic Sustainability Overview of Hemp as Building and Highway Construction Materials. Build. Environ. 2024, 256, 111470. [Google Scholar] [CrossRef]

- Mikulčić, H.; Klemeš, J.J.; Vujanović, M.; Urbaniec, K.; Duić, N. Reducing Greenhouse Gasses Emissions by Fostering the Deployment of Alternative Raw Materials and Energy Sources in the Cleaner Cement Manufacturing Process. J. Clean. Prod. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Smith, J.T. Recycled Concrete Aggregate-A Viable Aggregate Source for Concrete Pavements. Ph.D. Dissertation, University of Waterloo, Waterloo, ON, Canada, 2010. [Google Scholar]

- Batool, F.; Islam, K.; Cakiroglu, C.; Shahriar, A. Effectiveness of Wood Waste Sawdust to Produce Medium- to Low-Strength Concrete Materials. J. Build. Eng. 2021, 44, 103237. [Google Scholar] [CrossRef]

- Shahria Alam, M.; Slater, E.; Muntasir Billah, A.H.M. Green Concrete Made with RCA and FRP Scrap Aggregate: Fresh and Hardened Properties. J. Mater. Civ. Eng. 2013, 25, 1783–1794. [Google Scholar] [CrossRef]

- Ulloa, V.A.; García-Taengua, E.; Pelufo, M.-J.; Domingo, A.; Serna, P. New Views on Effect of Recycled Aggregates on Concrete Compressive Strength. ACI Mater. J. 2013, 110, 687–696. [Google Scholar]

- Van Den Heede, P.; De Belie, N. Environmental Impact and Life Cycle Assessment (LCA) of Traditional and “green” Concretes: Literature Review and Theoretical Calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Parrott, J.; Zandi, M. Overcoming the Nation’s Daunting Housing Supply Shortage; Urban Institutey: Washington, DC, USA, 2021. [Google Scholar]

- Lewis, J.; Hernández, D.; Geronimus, A.T. Energy Efficiency as Energy Justice: Addressing Racial Inequities through Investments in People and Places. Energy Effic. 2020, 13, 419–432. [Google Scholar] [CrossRef] [PubMed]

- Anacker, K.B. Introduction: Housing Affordability and Affordable Housing. Int. J. Hous. Policy 2019, 19, 1–16. [Google Scholar] [CrossRef]

- Reid, C. The Costs of Affordable Housing Production: Insights from California’s 9% Low-Income Housing Tax Credit Program; Terner Center for Housing Innovation, UC Berkeley: Berkeley, CA, USA, 2020. [Google Scholar]

- Ilgın, H.E.; Karjalainen, M.; Koponen, O.-P.; Soikkeli, A. A Study on Contractors’ Perception of Using Wood for Construction. In Engineered Wood Products for Construction; IntechOpen: London, UK, 2022. [Google Scholar]

- Omer, M.A.B.; Noguchi, T. A Conceptual Framework for Understanding the Contribution of Building Materials in the Achievement of Sustainable Development Goals (SDGs). Sustain. Cities Soc. 2020, 52, 101869. [Google Scholar] [CrossRef]

- Caldas, L.R.; Da Gloria, M.Y.R.; Pittau, F.; Andreola, V.M.; Habert, G.; Toledo Filho, R.D. Environmental Impact Assessment of Wood Bio-Concretes: Evaluation of the Influence of Different Supplementary Cementitious Materials. Constr. Build. Mater. 2021, 268, 121146. [Google Scholar] [CrossRef]

- Medina-Martinez, C.J.; Sandoval Herazo, L.C.; Zamora-Castro, S.A.; Vivar-Ocampo, R.; Reyes-Gonzalez, D. Use of Sawdust Fibers for Soil Reinforcement: A Review. Fibers 2023, 11, 58. [Google Scholar] [CrossRef]

- Al-Dhabaan, F.A. Sawdust Biodegradation: Cellulase and Ligninase Production via Submerged Fermentation and Glucose Production by Streptomyces Lazureus. J. Pure Appl. Microbiol. 2022, 16, 2425–2438. [Google Scholar] [CrossRef]

- Owebor, K.; Otuagoma, S.; Eyenubo, O.; Uranta, A.; Ukrakpor, F.; Ezewu, K.; Ebisine, E. Technical Analysis of Sawdust-to-Power: A Paradigm Shift in Waste Management in a Typical Developing Economy. J. Energy Power Technol. 2023, 5, 033. [Google Scholar] [CrossRef]

- Cheng, Z. Renewable Energy and Carbon Emissions—Optimization of the Whole Industrial Chain Based on Super Arundo. SHS Web Conf. 2024, 181, 03001. [Google Scholar] [CrossRef]

- Rećko, K. Production of Alternative Fuels Based on Sewage Sludge. Energies 2024, 17, 48. [Google Scholar] [CrossRef]

- Akhtar, N.; Bokhari, S.A.; Martin, M.A.; Saqib, Z.; Khan, M.I.; Mahmud, A.; Zaman-Ul-haq, M.; Amir, S. Uncovering Barriers for Industrial Symbiosis: Assessing Prospects for Eco-Industrialization through Small and Medium-Sized Enterprises in Developing Regions. Sustainability 2022, 14, 6898. [Google Scholar] [CrossRef]

- Prieto, J.K.J. Wood Coatings: Chemistry and Practice; European Coatings: Hanover, Germany, 2018. [Google Scholar]

- Kim, J.-Y.; Oh, S.; Park, Y.-K. Overview of Biochar Production from Preservative-Treated Wood with Detailed Analysis of Biochar Characteristics, Heavy Metals Behaviors, and Their Ecotoxicity. J. Hazard. Mater. 2020, 384, 121356. [Google Scholar] [CrossRef]

- Garcia, C.A.; Hora, G. State-of-the-Art of Waste Wood Supply Chain in Germany and Selected European Countries. Waste Manag. 2017, 70, 189–197. [Google Scholar] [CrossRef]

- Mlsna, T.E.; Wipf, D.O.; Mlsna, D.A.; Patrick, A.; Chambers, J.E.; Emerson, J.P.; Travis, R. Modified Biochar Adsorbents for Aqueous Contaminant Remediation; Mississippi State University: Starkville, MS, USA, 2021. [Google Scholar]

- Shukla, A.; Zhang, Y.-H.; Dubey, P.; Margrave, J.L.; Shukla, S.S. The Role of Sawdust in the Removal of Unwanted Materials from Water. J. Hazard. Mater. 2002, 95, 137–152. [Google Scholar] [CrossRef]

- Abedi, A.; Cheng, H.; Dalai, A.K. Effects of Natural Additives on the Properties of Sawdust Fuel Pellets. Energy Fuels 2018, 32, 1863–1873. [Google Scholar] [CrossRef]

- Kain, G. Design of Tree Bark Insulation Boards: Analysis of Material, Structure and Property Relationships; Technical University of Munich: München, Germany, 2017. [Google Scholar]

- Steiger, L. Ludwig Steiger Basics Timber Construction, 3rd ed.; Birkhäuser: Basel, Switzerland, 2020. [Google Scholar]

- Owodunni, A.A.; Lamaming, J.; Hashim, R.; Taiwo, O.F.A.; Hussin, M.H.; Mohamad Kassim, M.H.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Adhesive Application on Particleboard from Natural Fibers: A Review. Polym. Compos. 2020, 41, 4448–4460. [Google Scholar] [CrossRef]

- Nomai, J.; Jarapanyacheep, R.; Jarukumjorn, K. Mechanical, Thermal, and Morphological Properties of Sawdust/Poly(Lactic Acid) Composites: Effects of Alkali Treatment and Poly(Butylene Adipate-Co-Terephthalate) Content. Macromol. Symp. 2015, 354, 244–250. [Google Scholar] [CrossRef]

- Idrus, S.; Banks, C.J.; Heaven, S. Assessment of the Potential for Biogas Production from Wheat Straw Leachate in Upflow Anaerobic Sludge Blanket Digesters. Water Sci. Technol. 2012, 66, 2737–2744. [Google Scholar] [CrossRef]

- CRINI, G. Non-Conventional Low-Cost Adsorbents for Dye Removal: A Review. Bioresour. Technol. 2006, 97, 1061–1085. [Google Scholar] [CrossRef]

- Andrews, S.S.; Carroll, C.R. Designing a Soil Quality Assessment Tool for Sustainable Agroecosystem Management. Ecol. Appl. 2001, 11, 1573–1585. [Google Scholar] [CrossRef]

- Maldas, D.; Kokta, B.V.; Raj, R.G.; Daneault, C. Improvement of the Mechanical Properties of Sawdust Wood Fibre—Polystyrene Composites by Chemical Treatment. Polymer 1988, 29, 1255–1265. [Google Scholar] [CrossRef]

- Mouissa, F.; Benyahia, A.; Djehiche, M.; Belmokre, K.; Deghfel, N.; Redjem, A.; Rahmouni, Z.E.A. The Effect of Chemical Treatment on the Mechanical and Thermal Properties of Composite Materials Based on Clay Reinforced with Sawdust. Matériaux Tech. 2021, 109, 101. [Google Scholar] [CrossRef]

- Shanmuga Priya, D.; Sakthieswaran, N.; Ganesh Babu, O. Experimental Study on Mortar as Partial Replacement Using Sawdust Powder and GGBS. Mater. Today Proc. 2021, 37, 1051–1055. [Google Scholar] [CrossRef]

- Hossain, M.F.; Islam, M.K.; Islam, M.A. Effect of Chemical Treatment on the Mechanical and Physical Properties of Wood Saw Dust Particles Reinforced Polymer Matrix Composites. Procedia Eng. 2014, 90, 39–45. [Google Scholar] [CrossRef]

- Haque, M.E.; Khan, M.W.; Kabir Chowdhury, M.N. Synthesis, Characterization, Biocompatibility, Thermal and Mechanical Performances of Sawdust Reinforced Composite. Polym. Test. 2020, 91, 106764. [Google Scholar] [CrossRef]

- Priya, S.; Khan, G.; Uddin, M.; Haque, M.; Islam, M.; Abdullah-Al-Mamun, M.; Gafur, M.; Alam, M. Characterization of Micro-Fibrillated Cellulose Produced from Sawmill Wastage: Crystallinity and Thermal Properties. Am. Chem. Sci. J. 2015, 9, 1–8. [Google Scholar] [CrossRef]

- Aigbomian, E.P.; Fan, M. Development of Wood-Crete from Treated Sawdust. Constr. Build. Mater. 2014, 52, 353–360. [Google Scholar] [CrossRef]

- Neher, B.; Nova, N.T.; Hossain, R.; Gafur, M.A.; Ahmed, F. Fabrication and Characterization on Physico-Mechanical and Structural Properties of Sawdust Reinforced Acrylonitrile Butadiene Styrene (ABS) Composites. Mater. Sci. Appl. 2020, 11, 644–658. [Google Scholar] [CrossRef]

- Oghenerukevwe Prosper, E.; Uguru, H. Effect of Fillers Loading on the Mechanical Properties of Hardwood Sawdust/Oil Bean Shell Reinforced Epoxy Hybrid Composites. Int. J. Sci. Res. Sci. Eng. Technol. 2018, 8, 620–626. [Google Scholar]

- Suoware, T.O.; Edelugo, S.O.; Ezema, I.C. Impact of Hybrid Flame Retardant on the Flammability and Thermomechanical Properties of Wood Sawdust Polymer Composite Panel. Fire Mater. 2019, 43, 335–343. [Google Scholar] [CrossRef]

- Benjamin, U. Tensile Behaviour of Oil Bean Pod Shell and Mahogany Sawdust Reinforced Epoxy Resin Composite. Int. J. Sci. Technol. Soc. 2019, 7, 1. [Google Scholar] [CrossRef]

- Rezaur Rahman, M.; Nazrul Islam, M.; Monimul Huque, M. Influence of Fiber Treatment on the Mechanical and Morphological Properties of Sawdust Reinforced Polypropylene Composites. J. Polym. Environ. 2010, 18, 443–450. [Google Scholar] [CrossRef]

- Kong, I.; Khoo, K.M.; Buddrick, O.; Baharuddin, A.A.; Khalili, P. Synthesis and Characterization of Red Mud and Sawdust Based Geopolymer Composites as Potential Construction Material. Mater. Sci. Forum 2018, 923, 130–134. [Google Scholar] [CrossRef]

- Akter, T.; Nur, H.P.; Sultana, S.; Islam, M.R.; Abedin, M.J.; Islam, Z. Evaluation of Mechanical Properties of Both Benzoyl Peroxide Treated and Untreated Teak Sawdust Reinforced High Density Polyethylene Composites. Cellulose 2018, 25, 1171–1184. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, J.; Wang, S.; Mao, H.; Shi, Y.; Zhou, D. Effect of Hydrophobic Modification on Mechanical Properties of Chinese Fir Wood. BioResearch 2018, 13, 2035–2048. [Google Scholar] [CrossRef]

- Mahmoud, S.Y.M.; Alshiekh, E.T.A.M. Eco-Friendly Concrete Using Local Materials from Sudan. In Proceedings of the International Conference on Civil Infrastructure and Construction (CIC 2020), Doha, Qatar, 2–5 February 2020; Qatar University Press: Doha, Qatar, 2020; pp. 900–908. [Google Scholar]

- Saeed, H.H. Pretreatment of Sawdust for Producing Sawdust Concrete. J. Eng. Appl. Sci. 2013, 31, 541–549. [Google Scholar]

- Hewayde, E.; Kubba, Z. Mechanical Properties of Concrete Incorporating Pre-Treated Wastes Sawdust. Key Eng. Mater. 2021, 895, 147–156. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, M.; Mehta, S.; Belarbi, R. Utilization of Treated Saw Dust in Concrete as Partial Replacement of Natural Sand. J. Clean. Prod. 2020, 261, 121226. [Google Scholar] [CrossRef]

- Dias, S.; Almeida, J.; Santos, B.; Humbert, P.; Tadeu, A.; António, J.; de Brito, J.; Pinhão, P. Lightweight Cement Composites Containing End-of-Life Treated Wood—Leaching, Hydration and Mechanical Tests. Constr. Build. Mater. 2022, 317, 125931. [Google Scholar] [CrossRef]

- Hassen, S.A.; Hameed, S.A. Physical and Mechanical Properties of Sawdust Cement Mortar Treated with Hypochlorite. IOP Conf. Ser. Mater. Sci. Eng. 2020, 745, 012149. [Google Scholar] [CrossRef]

- Fozing Mekeuo, G.A.; Despas, C.; Péguy Nanseu-Njiki, C.; Walcarius, A.; Ngameni, E. Preparation of Functionalized Ayous Sawdust-carbon Nanotubes Composite for the Electrochemical Determination of Carbendazim Pesticide. Electroanalysis 2022, 34, 667–676. [Google Scholar] [CrossRef]

- Shulga, G.; Neiberte, B.; Jaunslavietis, J.; Verovkins, A.; Vitolina, S.; Shakels, V.; Livcha, S. Lignin-Containing Adhesion Enhancer for Wood-Plastic Composites. BioResources 2021, 16, 2804–2823. [Google Scholar] [CrossRef]

- Antwi-Boasiako, C.; Ofosuhene, L.; Boadu, K.B. Suitability of Sawdust from Three Tropical Timbers for Wood-Cement Composites. J. Sustain. For. 2018, 37, 414–428. [Google Scholar] [CrossRef]

- Rahman, M.R.; Ting, J.S.H.; Hamdan, S.; Hasan, M.; Salleh, S.F.; Rahman, M.M. Impact of Delignification on Mechanical, Morphological, and Thermal Properties of Wood Sawdust Reinforced Unsaturated Polyester Composites. J. Vinyl Addit. Technol. 2018, 24, 185–191. [Google Scholar] [CrossRef]

- Piao, C.; Cai, Z.; Stark, N.M.; Monlezun, C.J. Dimensional Stability of Wood-Plastic Composites Reinforced with Potassium Methyl Siliconate Modified Fiber and Sawdust Made from Beetle-Killed Trees. Eur. J. Wood Wood Prod. 2014, 72, 165–176. [Google Scholar] [CrossRef]

- Ganesan, V.; Shanmugam, V.; Kaliyamoorthy, B.; Sanjeevi, S.; Shanmugam, S.K.; Alagumalai, V.; Krishnamoorthy, Y.; Försth, M.; Sas, G.; Javad Razavi, S.M.; et al. Optimisation of Mechanical Properties in Saw-Dust/Woven-Jute Fibre/Polyester Structural Composites under Liquid Nitrogen Environment Using Response Surface Methodology. Polymers 2021, 13, 2471. [Google Scholar] [CrossRef]

- Kusuktham, B. Mechanical Properties and Morphologies of High Density Polyethylene Reinforced with Calcium Carbonate and Sawdust Compatibilized with Vinyltriethoxysilane. Silicon 2019, 11, 1997–2013. [Google Scholar] [CrossRef]

- Rahman, M.R.; Hamdan, S.; Ngaini, Z.B.; Jayamani, E.; Kakar, A.; Bin Bakri, M.K.; Yusof, F.A.B.M. Cellulose Fiber-Reinforced Thermosetting Composites: Impact of Cyanoethyl Modification on Mechanical, Thermal and Morphological Properties. Polym. Bull. 2019, 76, 4295–4311. [Google Scholar] [CrossRef]

- Kisan, M.; Sangathan, S. Specification for Coarse and Fine Aggregates from Natural Sources for Concrete; Bureau of Indian standard: New Delhi, India, 1970; Volume 383. [Google Scholar]

- Boadu, K.B.; Antwi-Boasiako, C.; Ofosuhene, L. Solvent Extraction of Inhibitory Substances from Three Hardwoods of Different Densities and Their Compatibility with Cement in Composite Production. J. Indian Acad. Wood Sci. 2018, 15, 140–148. [Google Scholar] [CrossRef]

- Ferede, E. Evaluation of Mechanical and Water Absorption Properties of Alkaline-Treated Sawdust-Reinforced Polypropylene Composite. J. Eng. 2020, 2020, 3706176. [Google Scholar] [CrossRef]

- Rahman, A.; Hasib, M.A.; Islam, M.A.; Alam, I.; Chanda, S. Fabrication and Performance Investigation of Natural-Glass Fiber Hybrid Laminated Composites at Different Stacking Orientations. J. Nat. Fibers 2023, 20, 2143981. [Google Scholar] [CrossRef]

| Sample No. | Chemical Property | Results |

|---|---|---|

| 1 | 7.09 | |

| 2 | 40.67 | |

| 3 | 13.69 | |

| 4 | 34.58 | |

| 5 | 0.44 | |

| 6 | 0.56 | |

| 7 | 0.32 | |

| 8 | - | |

| 9 | 0.15 |

| Scenario | Strength (MPa) | ||

|---|---|---|---|

| 7 Days | 14 Days | 28 Days | |

| Untreated Sawdust | 34.5 | 37.03 | 38.96 |

| Unsoaked sawdust with 10% replacement | 8.77 | 9.31 | 9.8 |

| Unsoaked sawdust with 20% replacement | 2.08 | 3.9 | 6.3 |

| Soaked sawdust with 10% replacement | 16 | 15.9 | 18.07 |

| Soaked sawdust with 20% replacement | 11.5 | 13.8 | 17.8 |

| Sawdust treated with calcium hydroxide + 10% MC | 15.13 | 11.3 | 18.1 |

| Sawdust treated with calcium hydroxide + 20% MC | 3.24 | 5.5 | 12.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, A.; Khondoker, M.A.H. Effect of Treatment Methods on Material Properties and Performance of Sawdust-Concrete and Sawdust-Polymer Composites. Polymers 2024, 16, 3289. https://doi.org/10.3390/polym16233289

Rahman A, Khondoker MAH. Effect of Treatment Methods on Material Properties and Performance of Sawdust-Concrete and Sawdust-Polymer Composites. Polymers. 2024; 16(23):3289. https://doi.org/10.3390/polym16233289

Chicago/Turabian StyleRahman, Arafater, and Mohammad Abu Hasan Khondoker. 2024. "Effect of Treatment Methods on Material Properties and Performance of Sawdust-Concrete and Sawdust-Polymer Composites" Polymers 16, no. 23: 3289. https://doi.org/10.3390/polym16233289

APA StyleRahman, A., & Khondoker, M. A. H. (2024). Effect of Treatment Methods on Material Properties and Performance of Sawdust-Concrete and Sawdust-Polymer Composites. Polymers, 16(23), 3289. https://doi.org/10.3390/polym16233289