New Eco-Friendly Thermal Insulation and Sound Absorption Composite Materials Derived from Waste Black Tea Bags and Date Palm Tree Surface Fibers

Abstract

1. Introduction

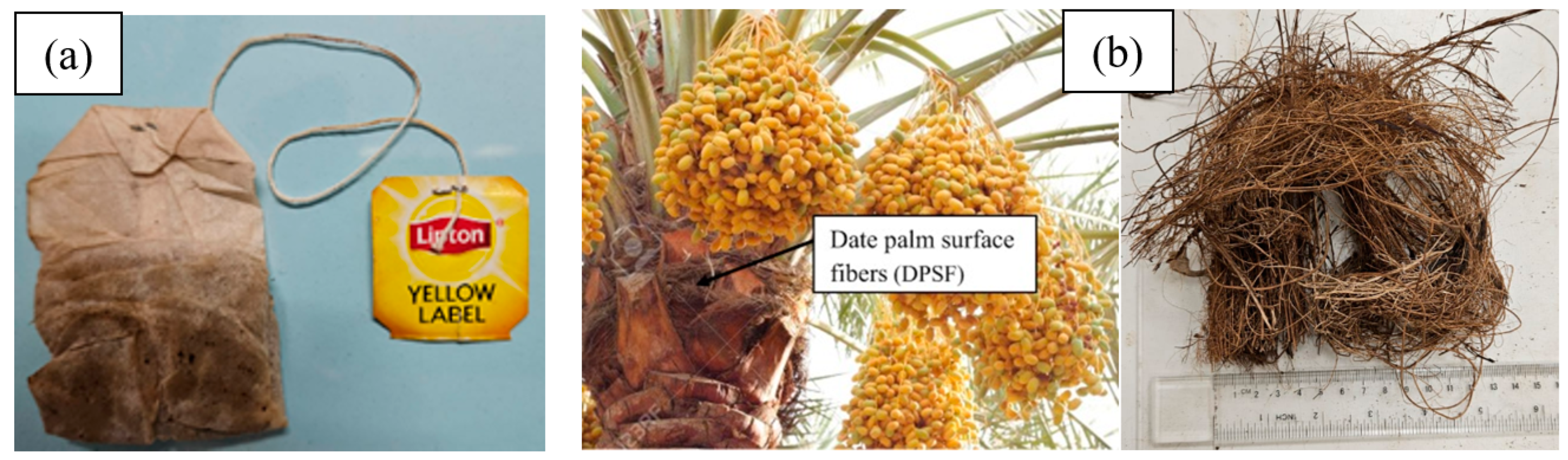

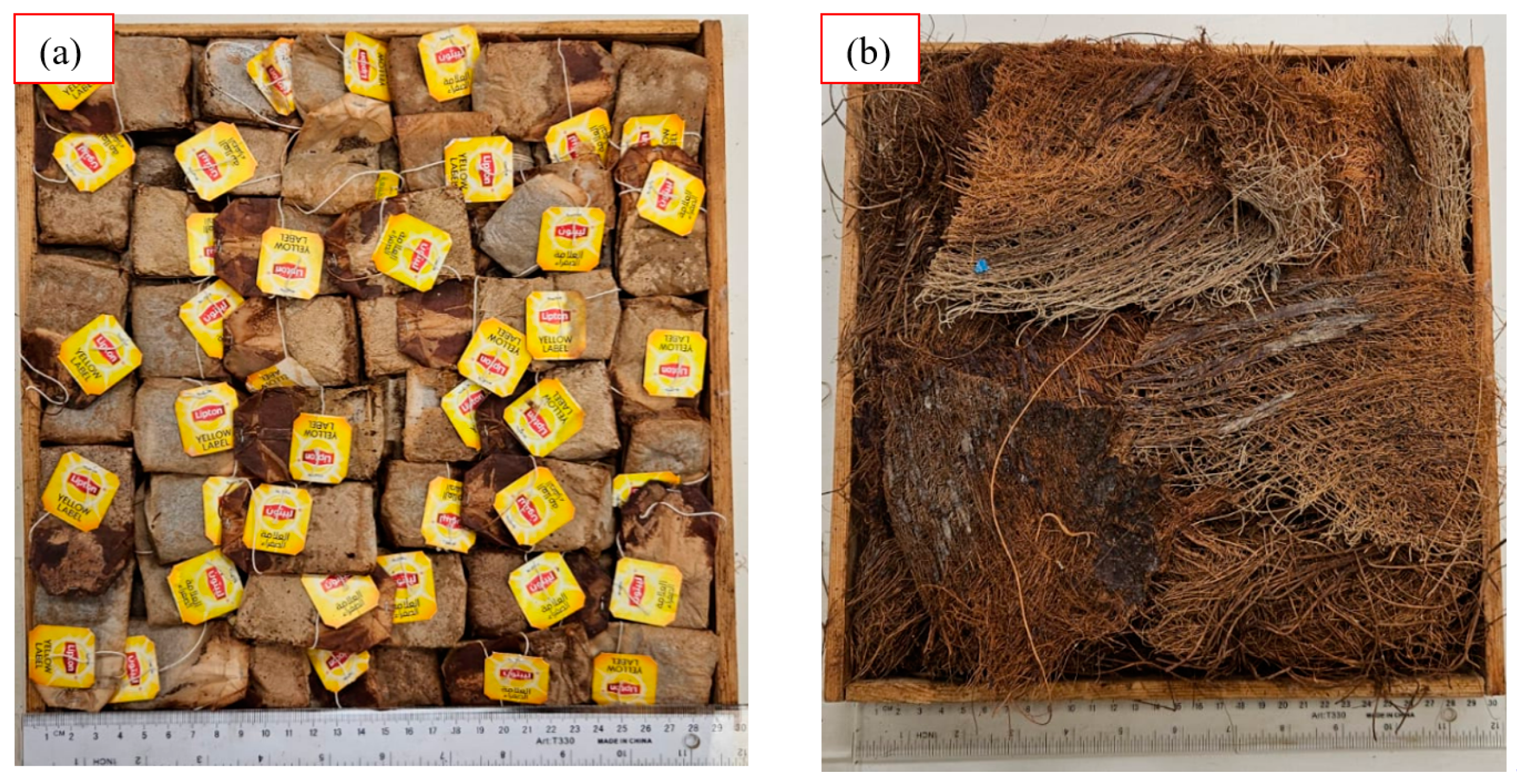

2. Materials and Methods

2.1. Loose Sample Polymer Preparation for Testing

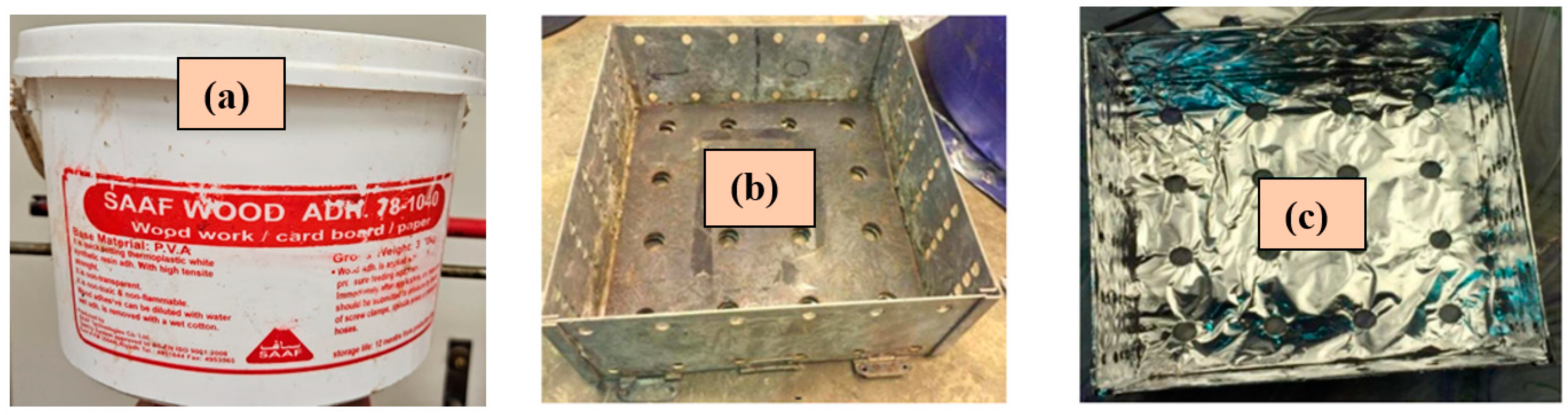

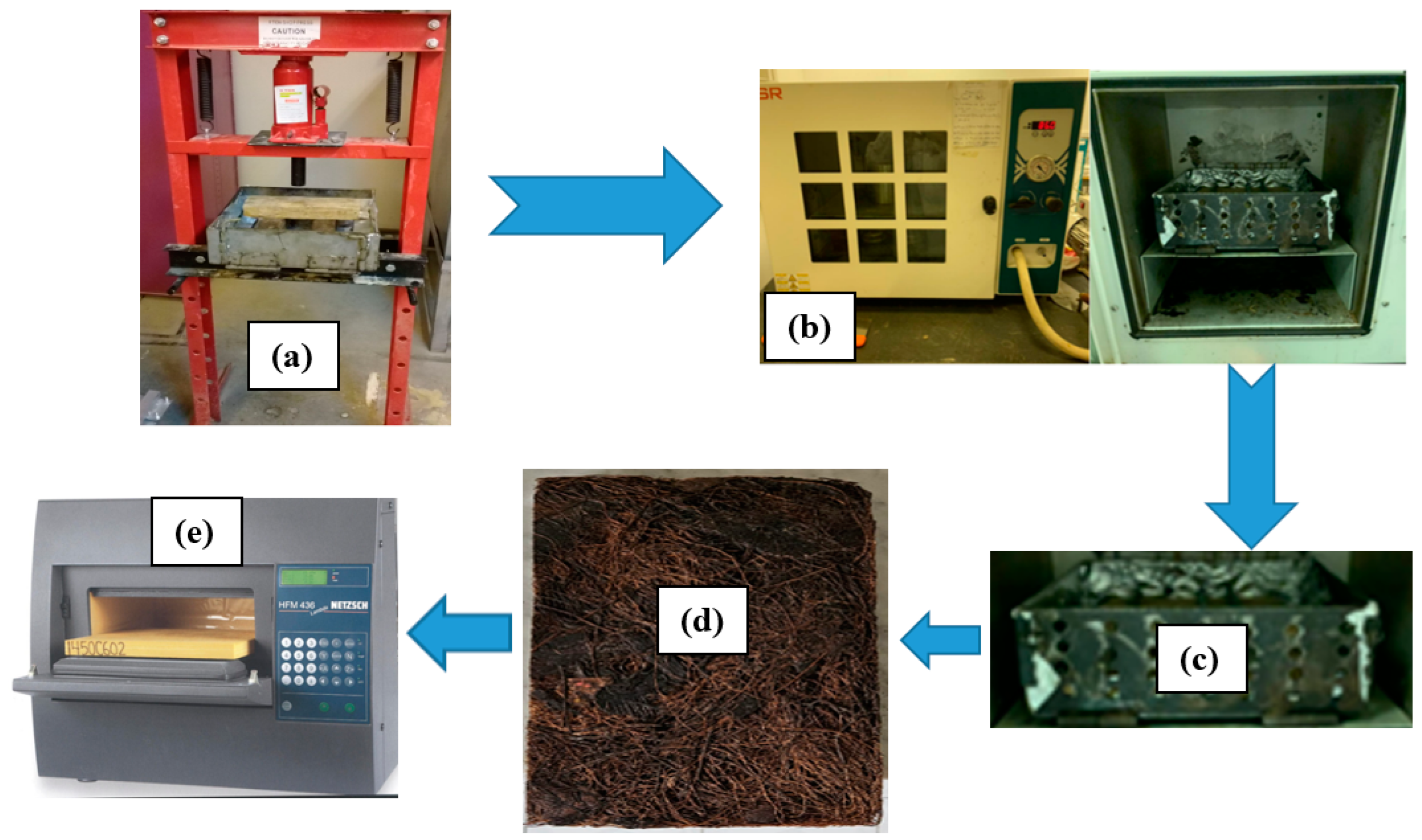

2.2. Composite Bound Sample Preparation for Testing

2.3. Composite Hybrid Sample Preparation for Testing

3. Characterization

3.1. Mechanical Test for Bound and Hybrid Composite Samples

3.2. Thermal Conductivity Coefficient Measurement

3.3. Sound Absorption Coefficient Measurement

3.4. Microstructure Analyses of the Black Tea Bags

3.4.1. Scanning Electron Microscopy Analysis

3.4.2. Energy Dispersive X-Ray (EDX) Spectroscopy Analysis

3.5. Thermal Stability of the Tea Bags

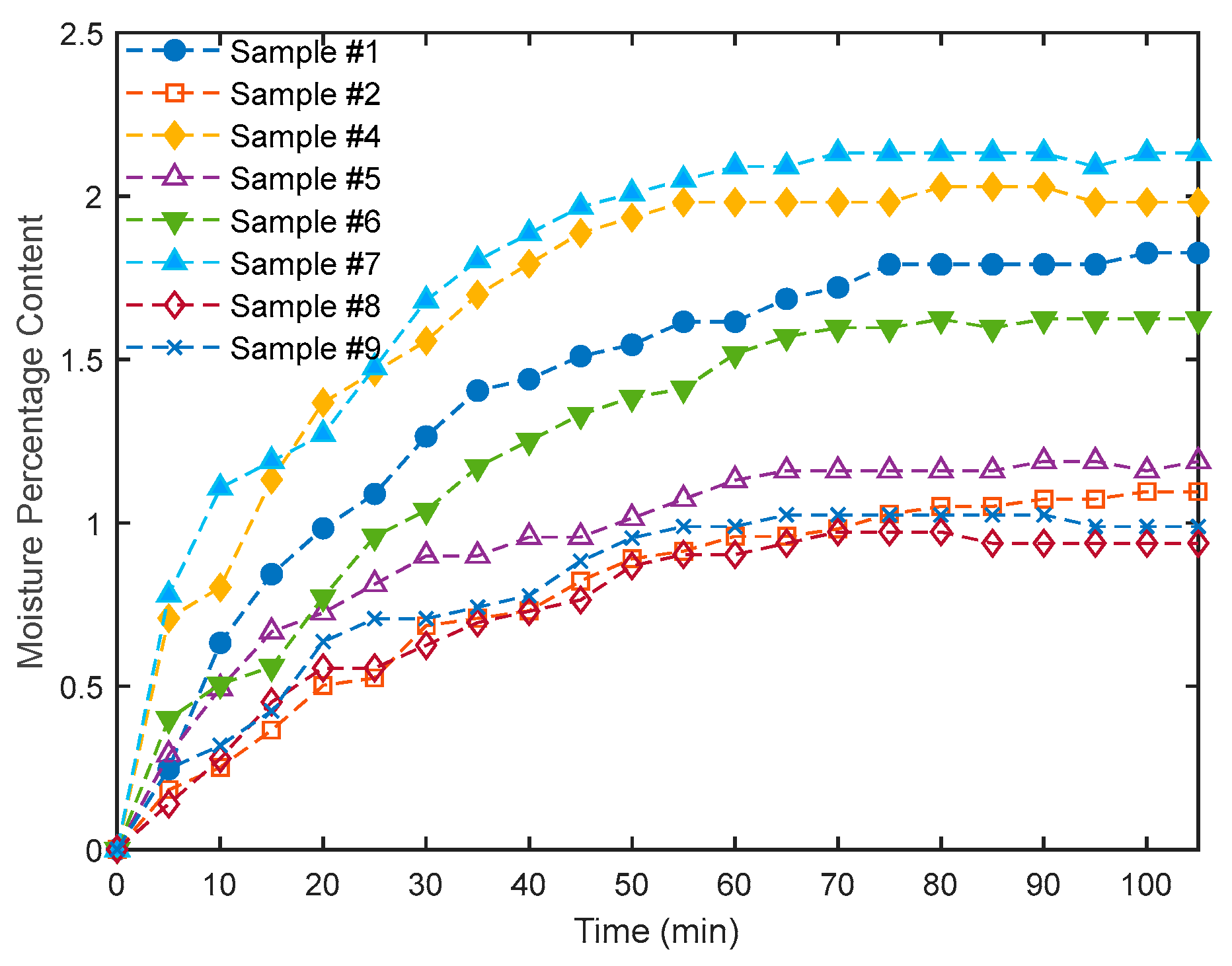

3.6. Moisture Content Test of the Tea Bags

4. Results and Discussion

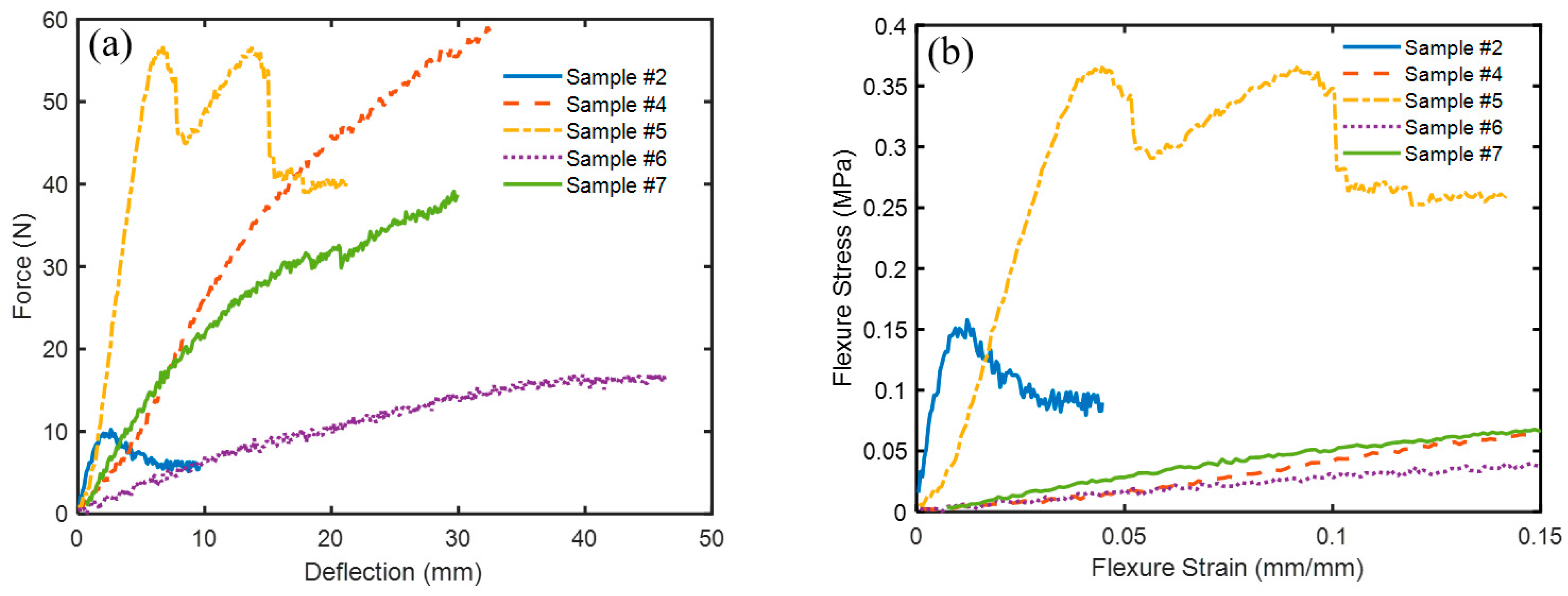

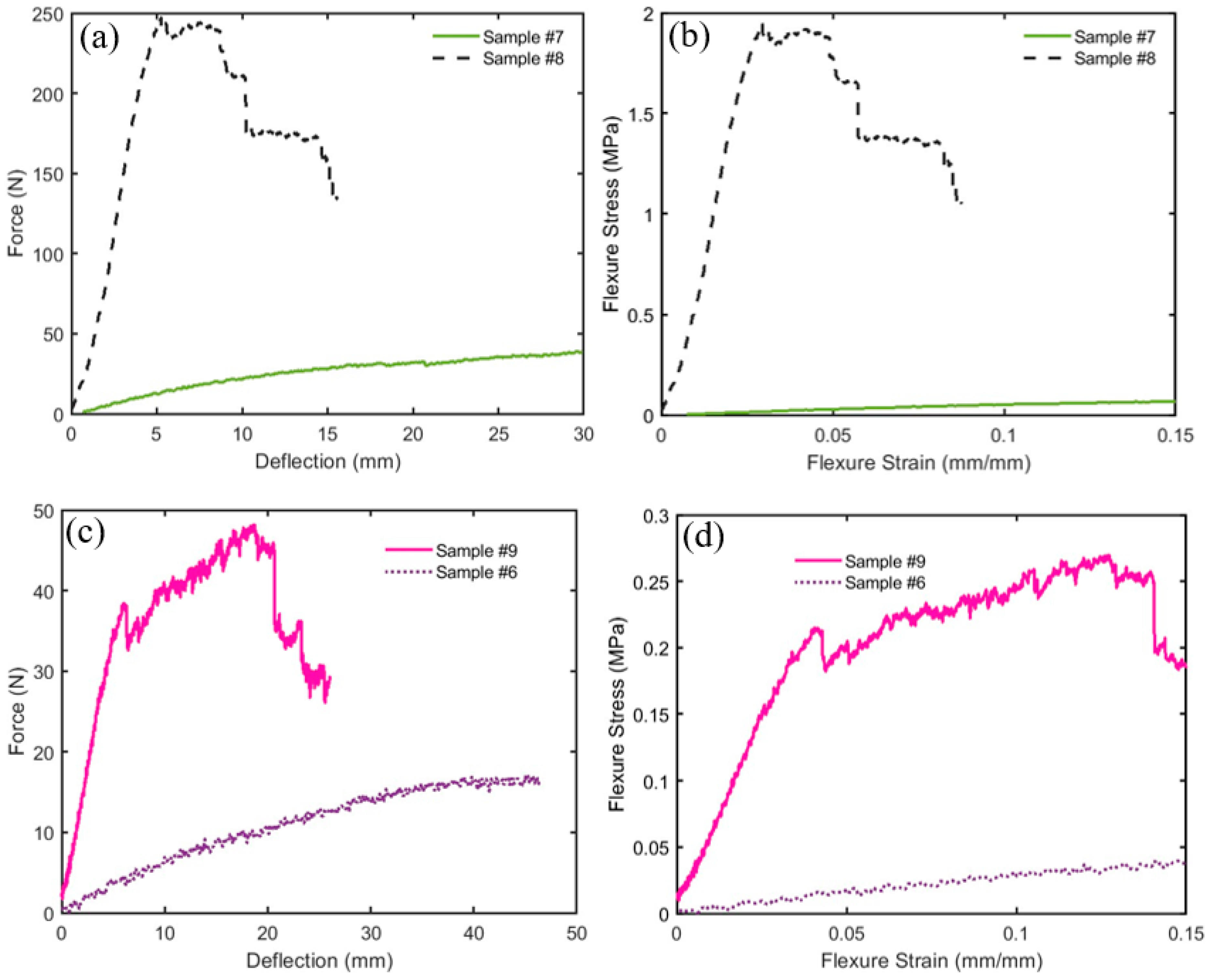

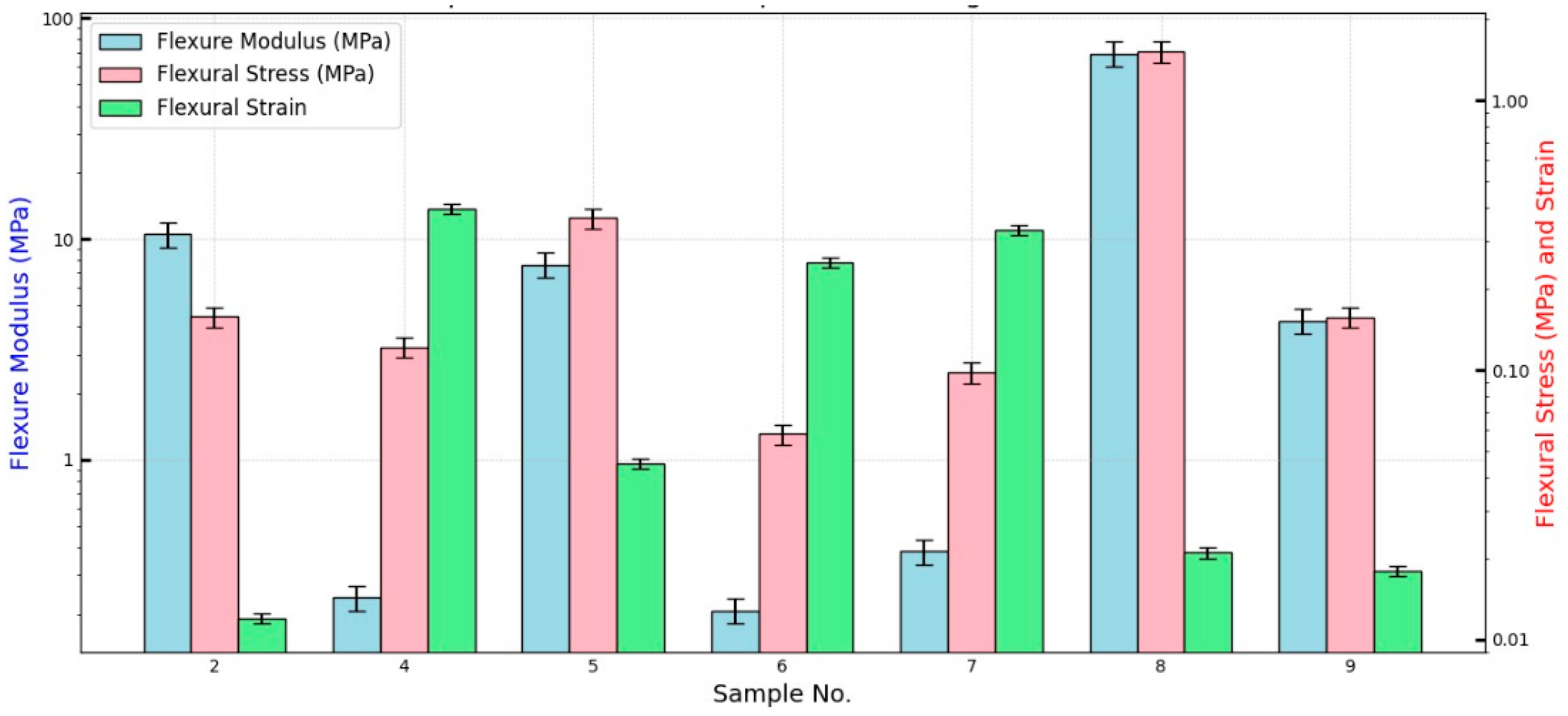

4.1. Three-Point Bending Moment

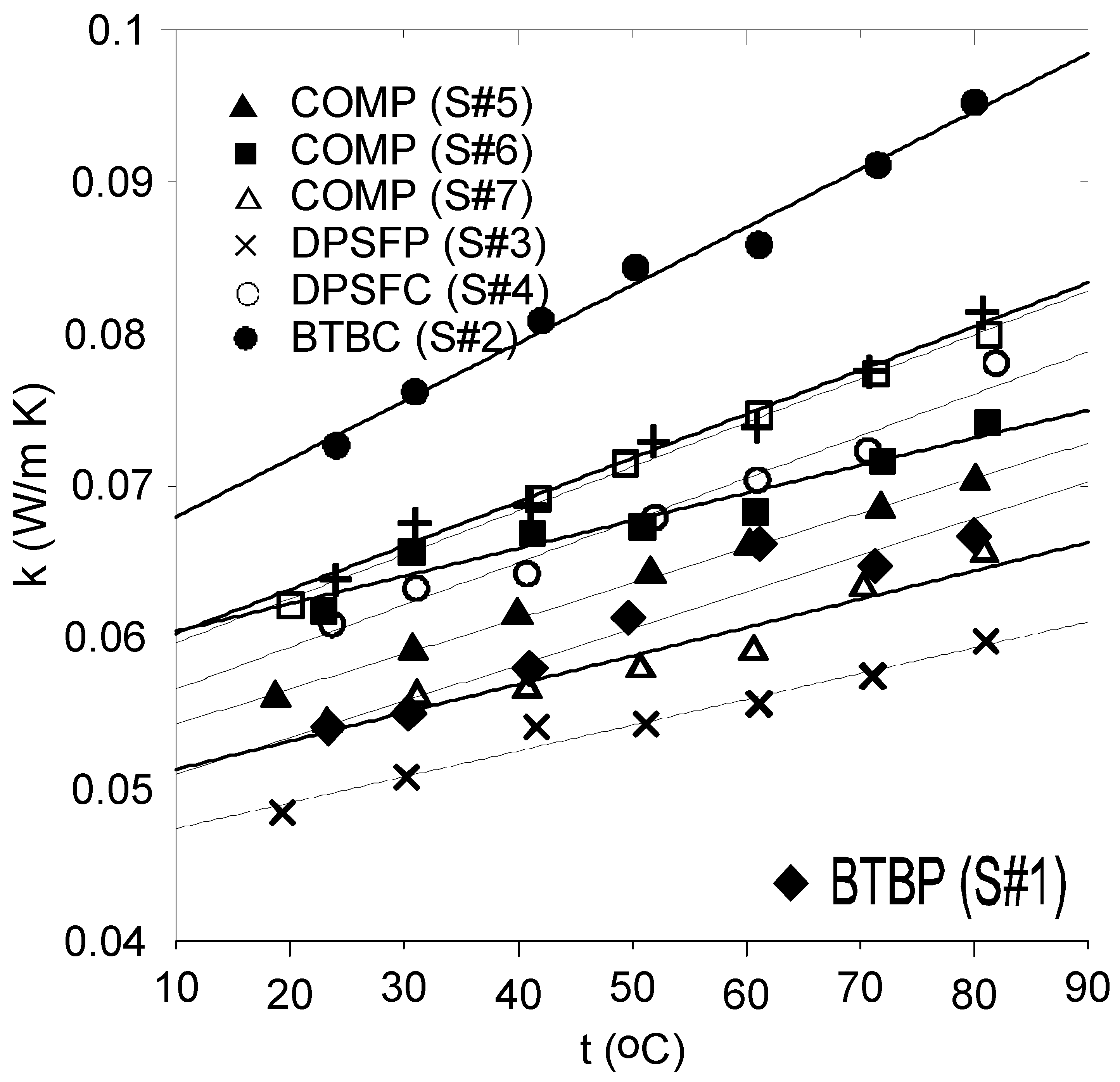

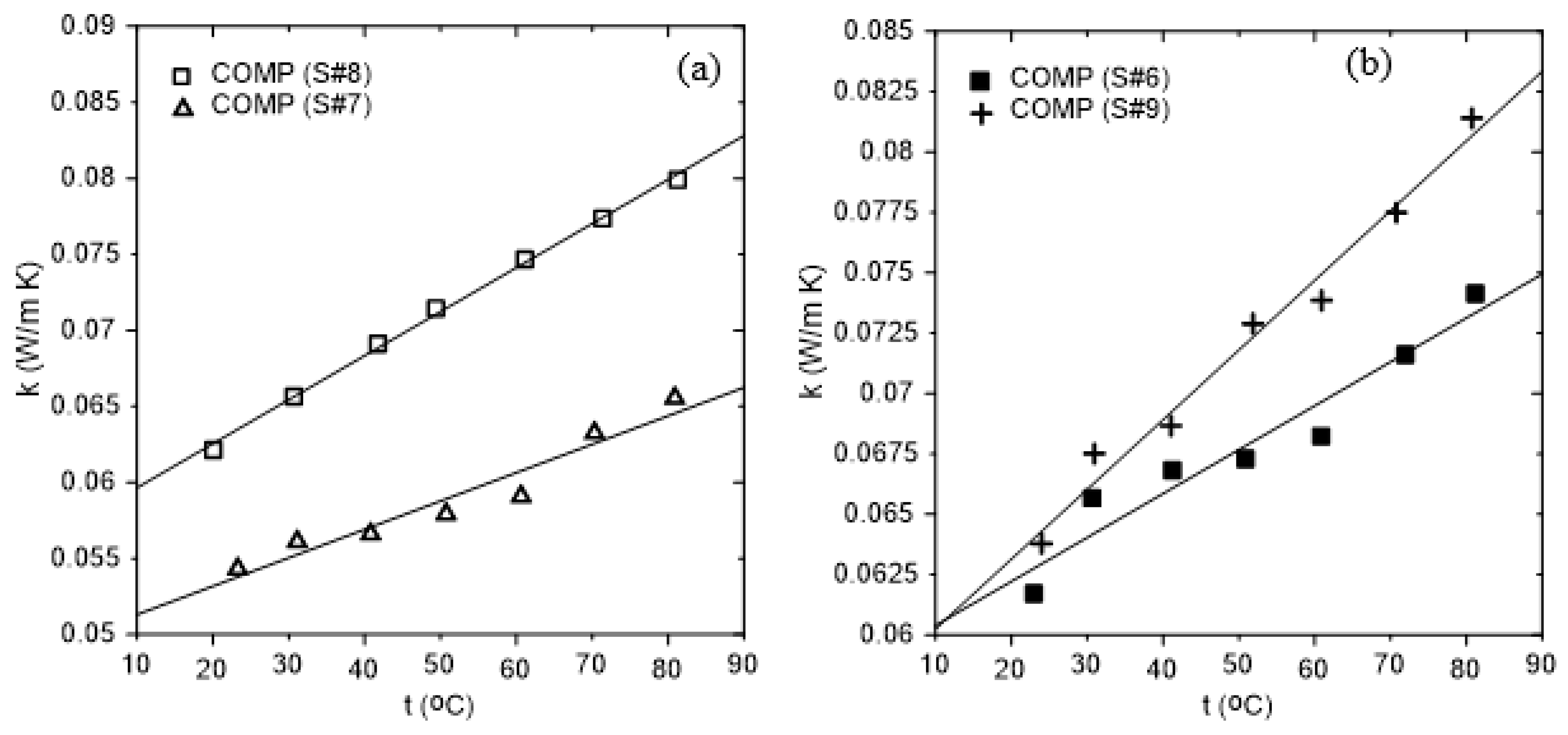

4.2. Thermal Conductivity Measurements

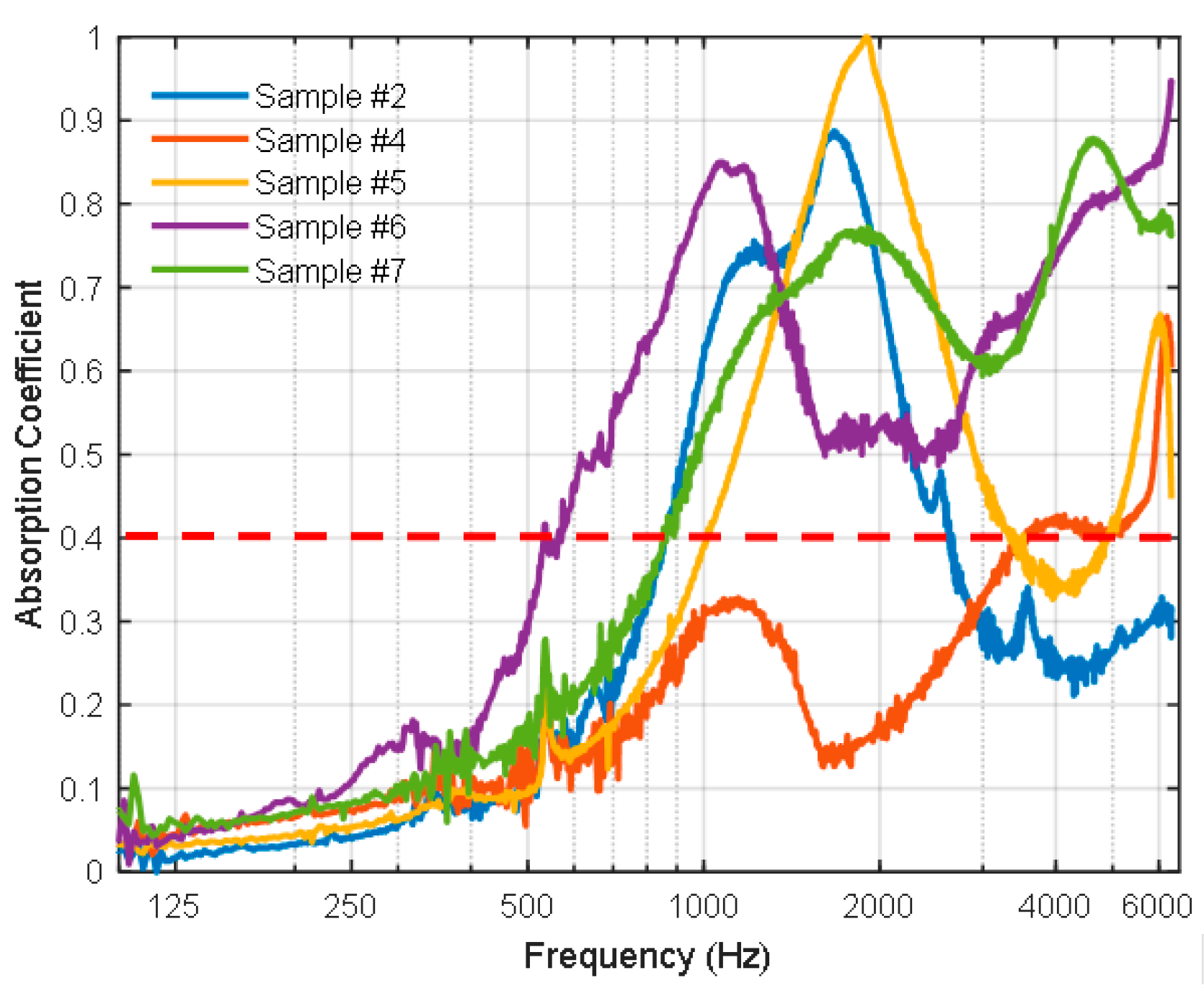

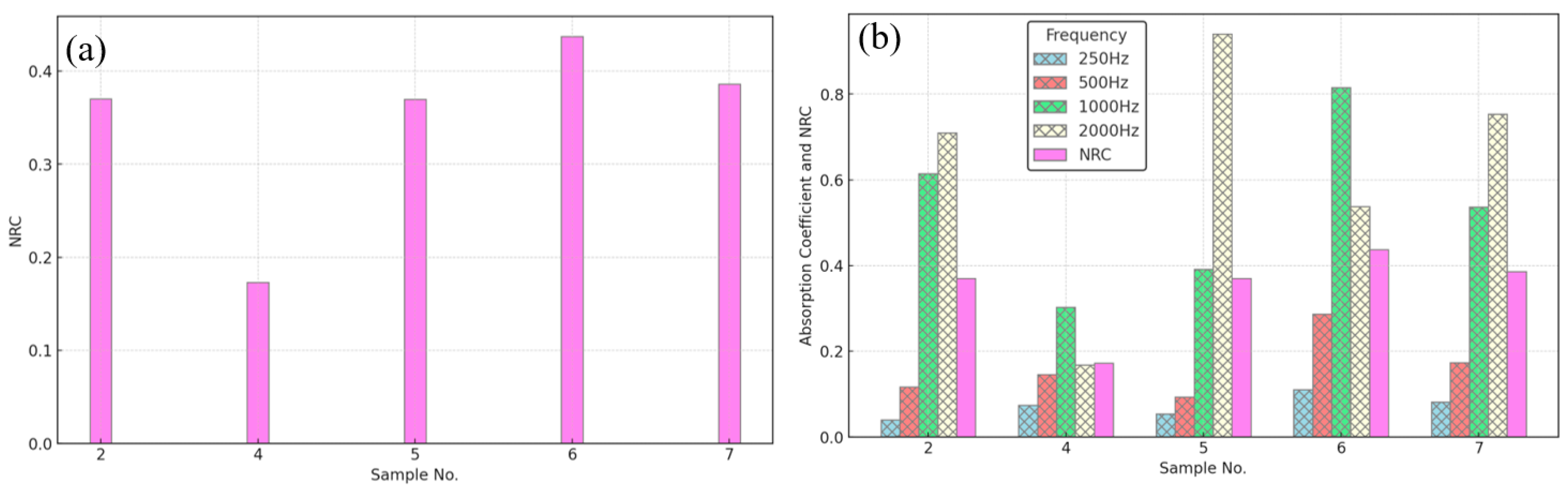

4.3. Sound Absorption and Noise Reduction Coefficients

4.4. Microstructure of the Black Tea Bags

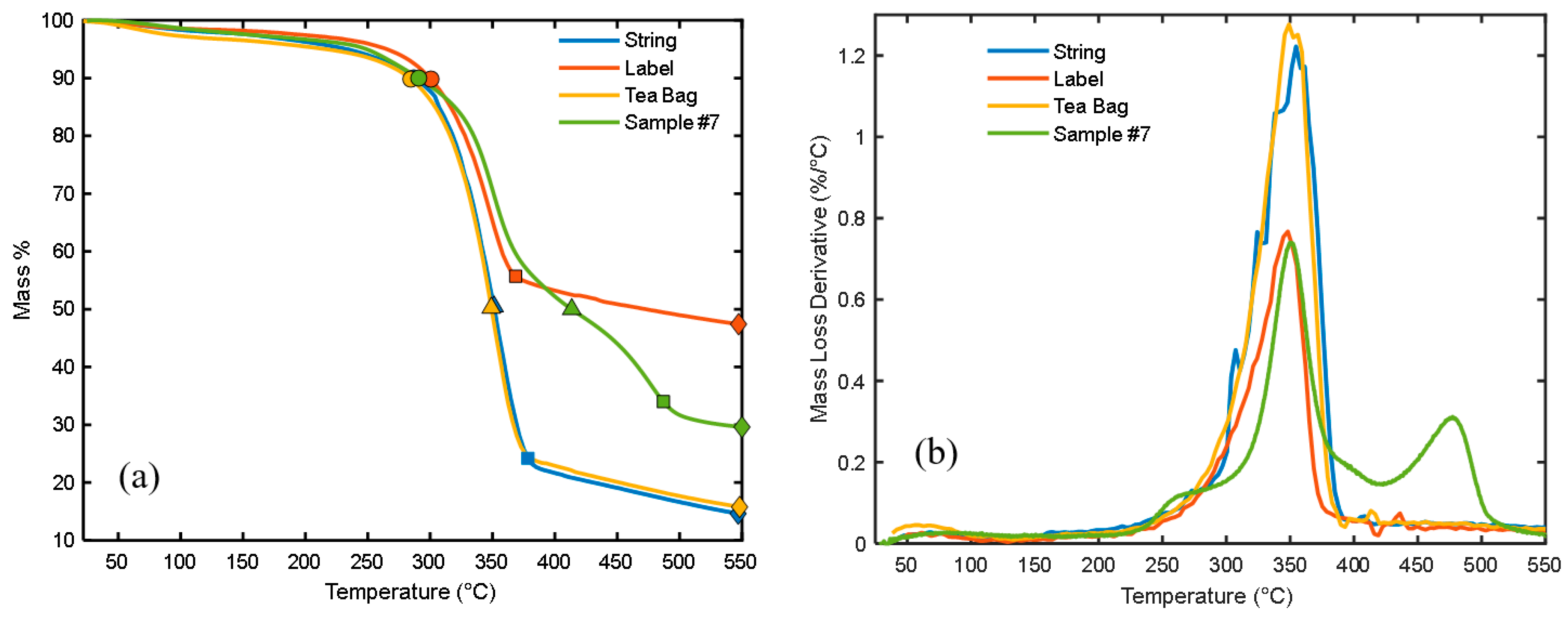

4.5. Thermal Stability of the Tea Bags and Their Composites

4.6. Moisture Content of the Tea Bags

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclatures

| A | Constant |

| B | Constant |

| BTBP | Black tea bag polymer (sample # 1) |

| BTBC | Black tea bag composite (sample # 2) |

| COMP | Composite sample of BTB, DPSF, and the binder |

| DPSFP | Date palm surface fiber polymer (sample # 3) |

| DPSFP | Date palm surface fiber composite (sample # 4) |

| DTGA | Differential thermogravimetric analysis |

| k | Thermal conductivity coefficient |

| NRC | Noise reduction coefficient |

| SAC | Sound absorption coefficient |

| S | Slope |

| t | Temperature (°C) |

| TGA | Thermogravimetric analysis |

References

- Crespo-López, L.; Coletti, C.; Arizzi, A.; Cultrone, G. Effects of using tea waste as an additive in the production of solid bricks in terms of their porosity, thermal conductivity, strength and durability. Sustain. Mater. Technol. 2024, 39, e00859. [Google Scholar] [CrossRef]

- Projected Production: The Twenty-Third Session of the Intergovernmental Group on Tea. 2018. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/26d2c475-f7e3-43d6-a8a7-48e0462a1723/content (accessed on 20 June 2024).

- Hussain, S.; Anjali, K.P.; Hassan, S.T.; Dwivedi, P.B. Waste tea as a novel adsorbent: A review. Appl. Water Sci. 2018, 8, 165. [Google Scholar] [CrossRef]

- Negi, T.; Kumar, Y.; Sirohi, R.; Singh, S.; Tarafdar, A.; Pareek, S.; Awasthi, M.K.; Sagar, N.A. Advances in bioconversion of spent tea leaves to value-added products. Bioresour. Technol. 2022, 346, 126409. [Google Scholar] [CrossRef]

- FAOSTAT. Crop Production, Statistics Division, Food and Agriculture Organization of United Nations; FAO: Rome, Italy, 2010. [Google Scholar]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Wazzan, A.A. The Effect of Surface Treatment on the Strength and Adhesion Characteristics of Phoenix dactylifera-L(Date Palm) Fibers. Int. J. Polym. Mater. Polym. Biomater. 2006, 55, 485–499. [Google Scholar] [CrossRef]

- Alotaibi, M.D.; Alshammari, B.A.; Saba, N.; Alothman, O.Y.; Sanjay, M.; Almutairi, Z.; Jawaid, M. Characterization of natural fiber obtained from different parts of date palm tree (Phoenix dactylifera L.). Int. J. Biol. Macromol. 2019, 135, 69–76. [Google Scholar] [CrossRef]

- Wazzan, A.A. Effect of fiber orientation on the mechanical properties and fracture characteristics of date palm fiber reinforced composites. Int. J. Polym. Mater. Polym. Biomater. 2005, 54, 213–225. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A. Mechanical Properties of Date Palm Fiber Reinforced Composites. Appl. Compos. Mater. 2002, 9, 369–377. [Google Scholar] [CrossRef]

- Hussien, A.; Al Zubaidi, R.; Jannat, N.; Ghanim, A.; Maksoud, A.; Al-Shammaa, A. The effects of tea waste additive on the physical and mechanical characteristics of structural unfired clay bricks. Alex. Eng. J. 2024, 101, 282–294. [Google Scholar] [CrossRef]

- Ibrahim, J.E.F.; Tihtih, M.; Şahin, E.I.; Basyooni, M.A.; Kocserha, I. Sustainable zeolitic tuff incorporating tea waste fired ceramic bricks: Development and investigation. Case Stud. Constr. Mater. 2023, 19, e02238. [Google Scholar] [CrossRef]

- Ozturk, S.; Sutcu, M.; Erdogmus, E.; Gencel, O. Influence of tea waste concentration in the physical, mechanical and thermal properties of brick clay mixtures. Constr. Build. Mater. 2019, 217, 592–599. [Google Scholar] [CrossRef]

- Anjum, F.; Naz, M.; Ghaffar, A.; Shukrullah, S.; AbdEl-Salam, N.; Ibrahim, K. Study of thermal and mechanical traits of organic waste incorporated fired clay porous material. Phys. B Condens. Matter 2020, 599, 412479. [Google Scholar] [CrossRef]

- Debnath, B.; Duarah, P.; Purkait, M.K. Microwave-assisted quick synthesis of microcrystalline cellulose from black tea waste (Camellia sinensis) and characterization. Int. J. Biol. Macromol. 2023, 244, 125354. [Google Scholar] [CrossRef]

- Wong, K.; Ahsan, Q.; Putra, A.; Subramonian, S.; Nor, M.J.M. Preliminary study on the sound absorption behavior of spent tea leaves filled with natural rubber latex binder. J. Teknol. (Sci. Eng.) 2017, 79, 59–64. [Google Scholar] [CrossRef]

- Ersoy, S.; Küçük, H. Investigation of industrial tea-leaf-fibre waste material for its sound absorption properties. Appl. Acoust. 2009, 70, 215–220. [Google Scholar] [CrossRef]

- Ali, M.; Al-Suhaibani, Z.; Almuzaiqer, R.; Albahbooh, A.; Al-Salem, K.; Nuhait, A. New Composites Derived from the Natural Fiber Polymers of Discarded Date Palm Surface and Pineapple Leaf Fibers for Thermal Insulation and Sound Absorption. Polymers 2024, 16, 1002. [Google Scholar] [CrossRef]

- Raza, M.; Al Abdallah, H.; Kozal, M.; Al Khaldi, A.; Ammar, T.; Abu-Jdayil, B. Development and characterization of Polystyrene–Date palm surface fibers composites for sustainable heat insulation in construction. J. Build. Eng. 2023, 75, 106988. [Google Scholar] [CrossRef]

- Raza, M.; Al Abdallah, H.; Abdullah, A.; Abu-Jdayil, B. Date Palm Surface Fibers for Green Thermal Insulation. Buildings 2022, 12, 866. [Google Scholar] [CrossRef]

- Ali, M.E.; Alabdulkarem, A. On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Constr. Build. Mater. 2017, 138, 276–284. [Google Scholar] [CrossRef]

- Alabdulkarem, A.; Ali, M.; Iannace, G.; Sadek, S.; Almuzaiqer, R. Thermal analysis, microstructure and acoustic characteristics of some hybrid natural insulating materials. Constr. Build. Mater. 2018, 187, 185–196. [Google Scholar] [CrossRef]

- Fouladi, M.H.; Nassir, M.H.; Ghassem, M.; Shamel, M.; Peng, S.Y.; Wen, S.Y.; Xin, P.Z.; Nor, M.J.M. Utilizing Malaysian natural fibers as sound absorber. In Modeling and Measurement Methods for Acoustic Waves and for Acoustic Microdevices; BoD—Books on Demand: Norderstedts, Germany, 2013; pp. 161–170. [Google Scholar]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Available online: https://www.gulfindustrialgroup.com/saaf/wp-content/uploads/2016/08/WOOD-ADHESIVE-78-1040-MSDS.pdf (accessed on 10 June 2024).

- ASTM D790-03; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- ASTM-C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus (C 518). American Society of Testing and Materials (ASTM): West Conshohocken, PA, USA, 2010; pp. 152–166.

- Ali, M.; Almuzaiqer, R.; Al-Salem, K.; Alabdulkarem, A.; Nuhait, A. New novel thermal insulation and sound-absorbing materials from discarded facemasks of COVID-19 pandemic. Sci. Rep. 2021, 11, 23240. [Google Scholar] [CrossRef] [PubMed]

- ISO 10534-1; Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 1: Method Using Standing Wave Ratio. ISO: Geneva, Switzerland, 1996.

- ISO 10534-2; Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method. ISO: Geneva, Switzerland, 1998.

- ASTM D2974—07A ASTM D2974-07; Standard Test Methods for Moisture, Ash, and Organic Matter of Peat and Other Organic Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- RILEM-TC. Test for the determination of modulus of rupture and limit of proportionality of thin fibre reinforced cement sections. In RILEM Recommendations for the Testing and Use of Constructions Materials; RILEM, Ed.; E & F SPON: London, UK, 1984; pp. 161–163. ISBN 2351580117. [Google Scholar]

- Nguyen, D.M.; Grillet, A.-C.; Diep, T.M.H.; Bui, Q.B.; Woloszyn, M. Influence of thermo-pressing conditions on insulation materials from bamboo fibers and proteins based bone glue. Ind. Crops Prod. 2018, 111, 834–845. [Google Scholar] [CrossRef]

- Dukhan, N.; Rayess, N.; Hadley, J. Characterization of aluminum foam–polypropylene interpenetrating phase composites: Flexural test results. Mech. Mater. 2010, 42, 134–141. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Intini, F.; Kühtz, S. Recycling in buildings: An LCA case study of a thermal insulation panel made of polyester fiber, recycled from post-consumer PET bottles. Int. J. Life Cycle Assess. 2011, 16, 306–315. [Google Scholar] [CrossRef]

- Martwong, E.; Yingshataporn-A-Nan, T.; Minanandana, T.; Puksuwan, K.; Junthip, J.; Sukhawipat, N. Sound absorption and thermal insulation materials from waste palm oil for housing application: Green polyurethane/water hyacinth fiber sheet composite. Constr. Build. Mater. 2024, 438, 137007. [Google Scholar] [CrossRef]

- Danihelová, A.; Němec, M.; Gergeľ, T.; Gejdoš, M.; Gordanová, J.; Sčensný, P. Usage of Recycled Technical Textiles as Thermal Insulation and an Acoustic Absorber. Sustainability 2019, 11, 2968. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, Y.; Li, W.; Yue, X. Functional modification of softwood fiber and its application in natural fiber-based sound-absorbing composite. Ind. Crops Prod. 2024, 218, 119044. [Google Scholar] [CrossRef]

- Sharma, S.K.; Shukla, S.R.; Sethy, A.K. Acoustical behaviour of natural fibres-based composite boards as sound-absorbing materials. J. Indian Acad. Wood Sci. 2020, 17, 66–72. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.; Gong, J.; Chen, J.; Li, Z.; Li, Q.; Cheng, M.; Li, X.; Zhang, J. The review of fiber-based sound-absorbing structures. Text. Res. J. 2023, 93, 434–449. [Google Scholar] [CrossRef]

- Nandanwar, A.; Kiran, M.C.; Varadarajulu, K.C. Influence of Density on Sound Absorption Coefficient of Fibre Board. Open J. Acoust. 2017, 7, 73876. [Google Scholar] [CrossRef]

- Na, Y.; Lancaster, J.; Casali, J.; Cho, G. Sound Absorption Coefficients of Micro-fiber Fabrics by Reverberation Room Method. Text. Res. J. 2007, 77, 330–335. [Google Scholar] [CrossRef]

- Shahid NS, M.; Ahmad, M.A.; Tahir, F.L. Sound Absorption Coefficient of Different Green Materials Polymer on Noise Redction. Int. J. Innov. Tech. Explor. Eng 2020, 9, 2773–2777. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Biocomposites from wheat straw nanofibers: Morphology, thermal and mechanical properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal stability of natural fibers and their polymer composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Bainbridge, D.A. High performance low cost buildings of straw. Agric. Ecosyst. Environ. 1986, 16, 281–284. [Google Scholar] [CrossRef]

| Material Specifications | Sample Number | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| BTBP (# 1) | BTBC (# 2) | DPSFP (# 3) | DPSFC (# 4) | COMP (# 5) | COMP (# 6) | COMP (# 7) | COMP (# 8) | COMP (# 9) | |

| BTB % | 100 | 65.4 | 0.0 | 0.0 | 64 | 39.0 | 19.0 | 13.5 | 34.0 |

| DPSF % | 0.0 | 0.0 | 100 | 81.3 | 21 | 39.0 | 57.0 | 40.5 | 34.0 |

| Ratio of polymerized (PVA) resin to total mass % | 0.0 | 34.6 | 0.0 | 18.7 | 15.0 | 22.0 | 24.0 | 46.0 | 32.0 |

| Thickness, δ (mm) | 41.0 | 18.0 | 46.0 | 46.0 | 25.0 | 32.0 | 42.0 | 25.0 | 29.0 |

| The sample’s volume (cm3) | 3330 | 1620 | 4132 | 4140 | 2250 | 2880 | 3780 | 2250 | 2610 |

| BTB’s mass (g) | 439 | 500 | 0.0 | 0.0 | 375 | 250 | 125 | 100 | 250 |

| DPSF’ mass (g) | 0.0 | 0.0 | 500 | 500 | 125 | 250 | 375 | 300 | 250 |

| Resin’s mass (g) | 0.0 | 265 | 0.0 | 115 | 86 | 148 | 158 | 341 | 234 |

| Figure # | 2(a) | 5(a) | 2(b) | 5(b) | 5(c) | 5(d) | 5(e) | 5(f) | 5(g) |

| Apparent density of dried samples (kg/m3) | 132 | 472 | 121 | 149 | 260 | 225 | 174 | 329 | 281 |

| Total dried mass (g) | 439 | 765 | 500 | 615 | 586 | 648 | 658 | 741 | 734 |

| Specimens’ Number | Thickness (δ) (mm) | Width (b) (mm) | Span (L) (mm) | Slope (S) (N/mm) |

|---|---|---|---|---|

| 2 | 18.0 | 47.0 | 150.0 | 3.2 |

| 4 | 46.0 | 51.0 | 150.0 | 1.4 |

| 5 | 25.0 | 55.0 | 150.0 | 7.9 |

| 6 | 32.0 | 53.0 | 150.0 | 0.45 |

| 7 | 42.0 | 51.0 | 150.0 | 1.7 |

| 8 | 25.0 | 53.0 | 160.0 | 49.0 |

| 9 | 29.0 | 51.0 | 160.0 | 5.2 |

| Fabricated Specimen No. | Slope (S) (N/mm) | Thickness (δ) (mm) | Density, (kg/m3) | Polymerized (PVA) Resin to the Total Mass % | Flexure Modulus (MPa), Ef | Flexural Stress (MPa), σf | Flexural Strain at Flexural Strength, εf |

|---|---|---|---|---|---|---|---|

| 2 | 3.2 | 18.0 | 472.0 | 34.6 | 10.5 ± 1.4 | 0.16 ± 0.01 | 0.01 ± 0.0005 |

| 4 | 1.4 | 46.0 | 149.0 | 18.7 | 0.24 ± 0.03 | 0.12 ± 0.01 | 0.4 ± 0.018 |

| 5 | 7.9 | 25.0 | 260.0 | 15.0 | 7.6 ± 0.98 | 0.37 ± 0.03 | 0.05 ± 0.002 |

| 6 | 0.45 | 32.0 | 225.0 | 22.0 | 0.21 ± 0.03 | 0.06 ± 0.005 | 0.25 ± 0.011 |

| 7 | 1.7 | 42.0 | 174.0 | 24.0 | 0.39 ± 0.05 | 0.10 ± 0.008 | 0.33 ± 0.015 |

| 8 | 49.0 | 25.0 | 329.0 | 46.0 | 68.9 ± 8.87 | 1.52 ± 0.13 | 0.02 ± 0.0009 |

| 9 | 5.2 | 29.0 | 281.0 | 32.0 | 4.3 ± 0.55 | 0.16 ± 0.014 | 0.02 ± 0.0008 |

| Equation (3) | k = A + B × t | ||||

|---|---|---|---|---|---|

| Sample # | Symbol | A | B | R2, % | Density, kg/m3 |

| 1 (BTBP) | ♦ | 0.049 | 0.0002 | 92.6 | 132.0 |

| 2 (BTBC) | ● | 0.064 | 0.0004 | 98.7 | 472.0 |

| 3 (DPSFP) | × | 0.046 | 0.0002 | 97.2 | 121.0 |

| 4 (DPSFC) | ο | 0.054 | 0.0003 | 97.4 | 149.0 |

| 5 (COMP) | ▲ | 0.052 | 0.0002 | 99.8 | 260.0 |

| 6 (COMP) | ■ | 0.059 | 0.0002 | 93.0 | 225.0 |

| 7 (COMP) | Δ | 0.049 | 0.0002 | 94.0 | 174.0 |

| 8 (COMP) | □ | 0.057 | 0.0003 | 99.7 | 329.0 |

| 9 (COMP) | + | 0.057 | 0.0003 | 98.1 | 281.0 |

| Materials | Density (kg/m3) | Thermal Conductivity (W/mK) | References |

|---|---|---|---|

| BTBP (# 1) | 132 | 0.05405–0.0666 | This study |

| BTBC (# 2) | 472 | 0.072636–0.095211 | This study |

| DPSFP (# 3) | 121 | 0.048461–0.059728 | This study |

| DPSFC (# 4) | 149 | 0.060877–0.078064 | This study |

| COMP (# 5) | 260 | 0.05597–0.0703 | This study |

| COMP (# 6) | 225 | 0.0617–0.0741 | This study |

| COMP (# 7) | 174 | 0.0543–0.0655 | This study |

| COMP (# 8) | 329 | 0.062125–0.079914 | This study |

| COMP (# 9) | 281 | 0.063792–0.081400 | This study |

| Recycled polyethylene terephthalate (PET) | 30 | 0.0355 | [36] |

| Recycled (PET) (commercialized) | 15–60 | 0.034–0.039 | [35] |

| Recycled glass fibers (commercialized) | 100–165 | 0.038–0.050 | [35] |

| Polyurethane foam | 30–80 | 0.02–0.027 | |

| Rock wool | 40–200 | 0.033–0.040 | [35] |

| Expanded polystyrene (XPS) | 15–35 | 0.031–0.038 | [35] |

| Extruded polystyrene (EPS) | 32–40 | 0.032–0.037 | [35] |

| Kenaf | 30–180 | 0.034–0.043 | [35] |

| Sheep wool | 10–25 | 0.038–0.054 | [35] |

| Sample Number | Density, kg/m3 | Frequency (Hz) | NRC | |||

|---|---|---|---|---|---|---|

| 250 | 500 | 1000 | 2000 | |||

| Sound Absorption Coefficients (SAC) | ||||||

| 2 | 472 | 0.0397 | 0.1162 | 0.6149 | 0.7098 | 0.35 |

| 4 | 149 | 0.0736 | 0.1459 | 0.3029 | 0.1683 | 0.15 |

| 5 | 260 | 0.054 | 0.0933 | 0.391 | 0.9402 | 0.35 |

| 6 | 225 | 0.1097 | 0.2862 | 0.8149 | 0.5376 | 0.45 |

| 7 | 174 | 0.0818 | 0.1736 | 0.5362 | 0.7534 | 0.40 |

| Materials | Density (kg/m3) | Thickness of the Board or Fiber (m) | Sound Absorption Coefficient, SAC | NRC | References | |||

|---|---|---|---|---|---|---|---|---|

| Frequency, Hz | ||||||||

| 250 | 500 | 1000 | 2000 | |||||

| BTBC (# 2) | 472 | 0.018 | 0.0397 | 0.1162 | 0.6149 | 0.7098 | 0.35 | This study |

| DPSFC (# 4) | 149 | 0.046 | 0.0736 | 0.1459 | 0.3029 | 0.1683 | 0.15 | This study |

| COMP (# 5) | 260 | 0.025 | 0.054 | 0.0933 | 0.391 | 0.9402 | 0.35 | This study |

| COMP (# 6) | 225 | 0.032 | 0.1097 | 0.2862 | 0.8149 | 0.5376 | 0.45 | This study |

| COMP (# 7) | 174 | 0.042 | 0.0818 | 0.1736 | 0.5362 | 0.7534 | 0.40 | This study |

| Polyurethane foam | 95 | ------------ | 0.02 | 0.01 | 0.11 | 0.16 | 0.08 | [37] |

| Kenaf (light) | 50 | 0.06 | 0.19 | 0.33 | 0.68 | 0.9 | 0.55 | [24] |

| Wood (fibers) | 100 | 0.04 | 0.40 | 0.50 | 0.65 | 0.91 | 0.60 | [24] |

| Coconut | 60 | 0.04/0.06 | 0.2 | 0.34 | 0.67 | 0.79 | 0.50 | [24] |

| Cork | 100 | 0.03 | 0.02 | 0.10 | 0.30 | 0.86 | 0.30 | [24] |

| Cane (only wooden) | 400 | 0.04 | 0.06 | 0.12 | 0.47 | 0.43 | 0.25 | [24] |

| Fleece (100% polyester) fiber | 60 | 0.0035 | 0.08 | 0.12 | 0.19 | 0.21 | 0.15 | [42] |

| Queenscord fiber | 160 | 0.0019 | 0.05 | 0.14 | 0.34 | 0.30 | 0.20 | [42] |

| Mesh fiber | 100 | 0.0033 | 0.18 | 0.02 | 0.05 | 0.07 | 0.10 | [42] |

| Suede fiber | 300 | 0.0006 | 0.09 | 0.13 | 0.24 | 0.28 | 0.20 | [42] |

| Wood fiberboard | 480 | 0.018 | 0.11 | 0.14 | 0.21 | 0.34 | 0.20 | [43] |

| Palm oil leaves | 152 | 0.010 | --- | 0.05 | 0.08 | 0.19 | 0.10 | [44] |

| Lemongrass | 201 | 0.010 | --- | 0.06 | 0.15 | 0.45 | 0.20 | [44] |

Tea Bag, | |||||||

| Thermally Stable Zone | T50% Degradation | End of Major Degradation | Char Formation | ||||

| Mass % 90 | Temp. (°C) 284.5 | Mass % 50 | Temp. (°C) 349.0 | Mass % 24.3 | Temp. (°C) 379.5 | Mass % 16 | Temp. (°C) 548.0 |

String, | |||||||

| Mass % 90 | Temp. (°C) 287.0 | Mass % 50 | Temp. (°C) 351.0 | Mass % 24 | Temp. (°C) 378.0 | Mass % 15 | Temp. (°C) 547.0 |

Label, | |||||||

| Mass % 90 | Temp. (°C) 300.7 | Mass % 50 | Temp. (°C) 473.0 | Mass % 56 | Temp. (°C) 368.6 | Mass % ------- | Temp. (°C) ------- |

Composite Sample # 7, | |||||||

| Mass % 90 | Temp. (°C) 291.0 | Mass % 50 | Temp. (°C) 413.5 | Mass % 34 | Temp. (°C) 487.0 | Mass % 20.4 | Temp. (°C) 800.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.; Almuzaiqer, R.; Al-Salem, K.; Alshehri, H.; Nuhait, A.; Alabdullatif, A.; Almubayrik, A. New Eco-Friendly Thermal Insulation and Sound Absorption Composite Materials Derived from Waste Black Tea Bags and Date Palm Tree Surface Fibers. Polymers 2024, 16, 2989. https://doi.org/10.3390/polym16212989

Ali M, Almuzaiqer R, Al-Salem K, Alshehri H, Nuhait A, Alabdullatif A, Almubayrik A. New Eco-Friendly Thermal Insulation and Sound Absorption Composite Materials Derived from Waste Black Tea Bags and Date Palm Tree Surface Fibers. Polymers. 2024; 16(21):2989. https://doi.org/10.3390/polym16212989

Chicago/Turabian StyleAli, Mohamed, Redhwan Almuzaiqer, Khaled Al-Salem, Hassan Alshehri, Abdullah Nuhait, Abdullah Alabdullatif, and Abdulrahman Almubayrik. 2024. "New Eco-Friendly Thermal Insulation and Sound Absorption Composite Materials Derived from Waste Black Tea Bags and Date Palm Tree Surface Fibers" Polymers 16, no. 21: 2989. https://doi.org/10.3390/polym16212989

APA StyleAli, M., Almuzaiqer, R., Al-Salem, K., Alshehri, H., Nuhait, A., Alabdullatif, A., & Almubayrik, A. (2024). New Eco-Friendly Thermal Insulation and Sound Absorption Composite Materials Derived from Waste Black Tea Bags and Date Palm Tree Surface Fibers. Polymers, 16(21), 2989. https://doi.org/10.3390/polym16212989