Lignin-Based Composite Film and Its Application for Agricultural Mulching

Abstract

1. Introduction

2. Overview of Lignin

2.1. Structural Units and Linkages of Lignin

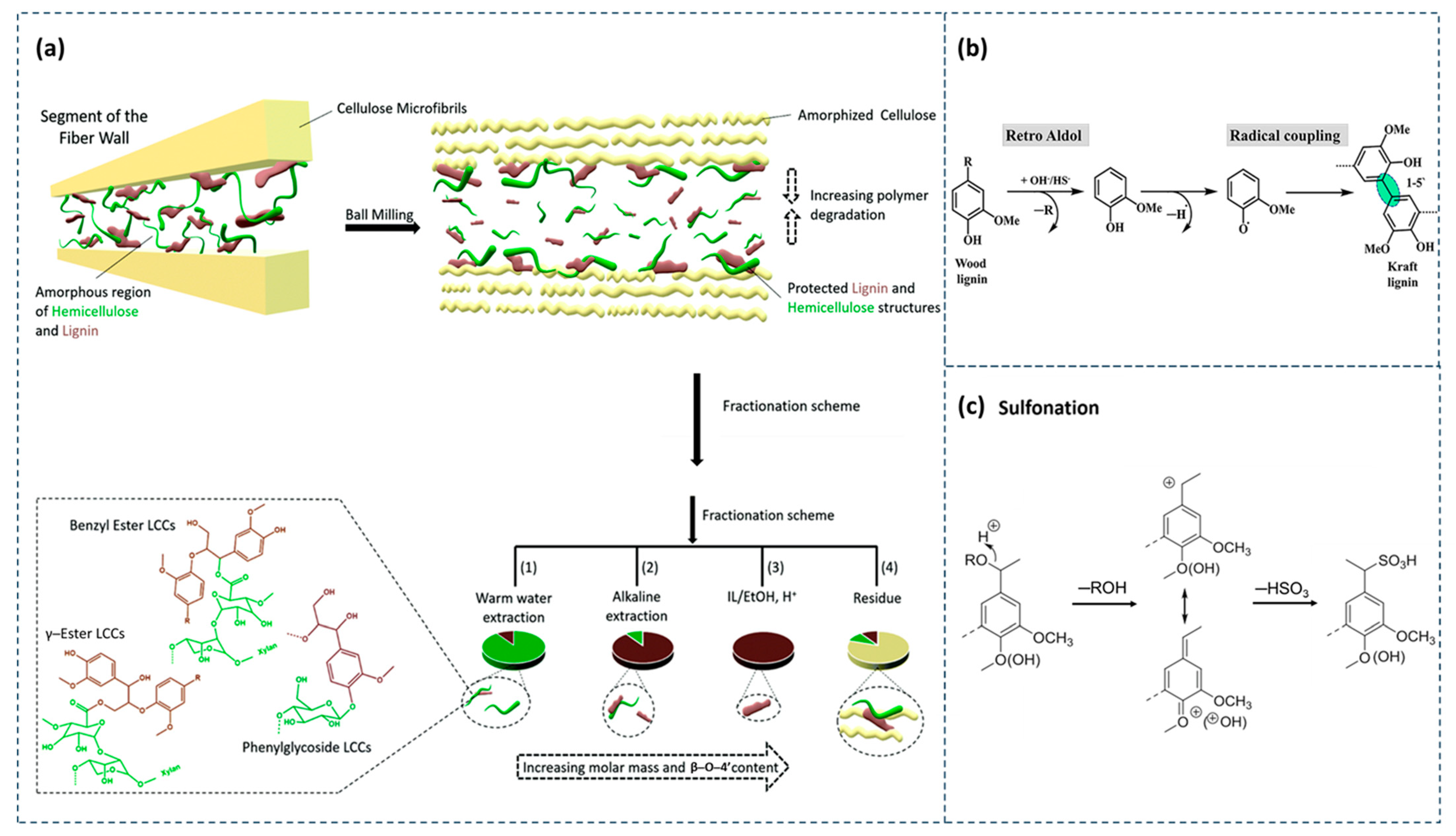

2.2. Lignin Separation Techniques

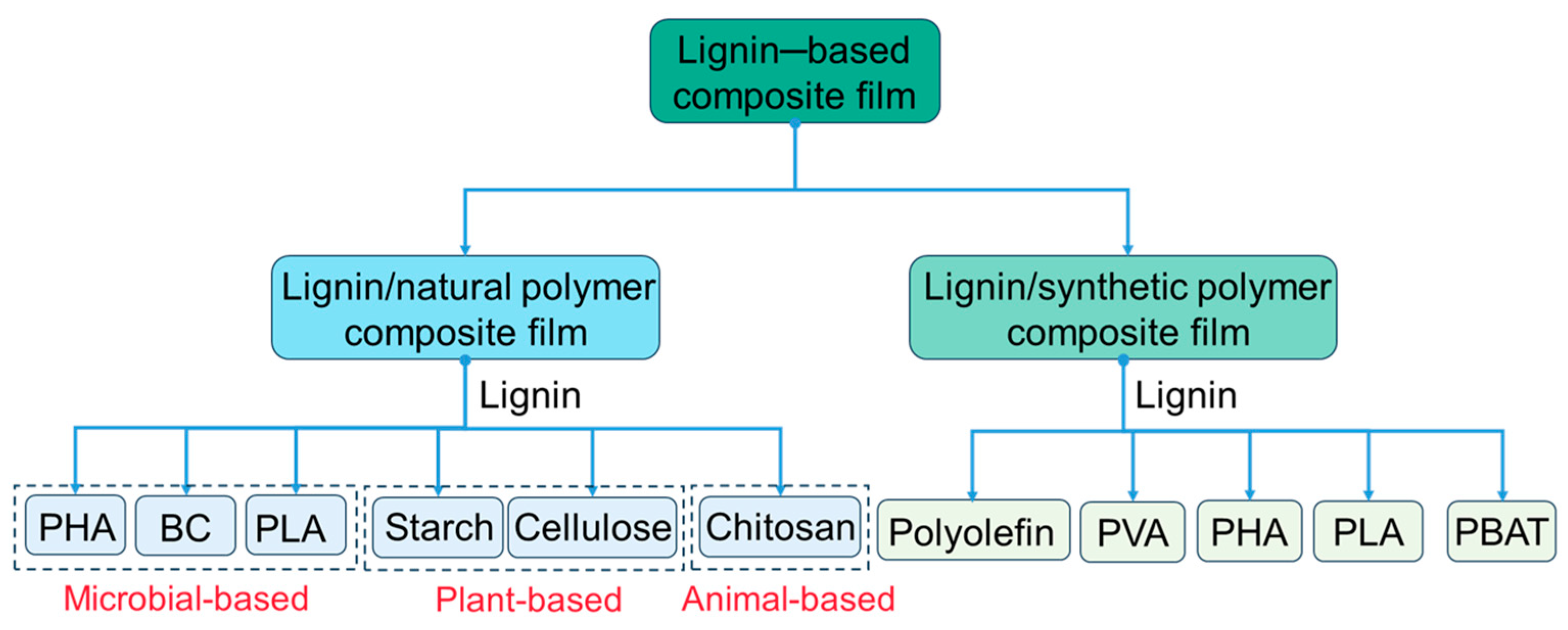

3. Lignin-Based Composite Film Materials

3.1. Lignin/Natural Polymer Composite Film

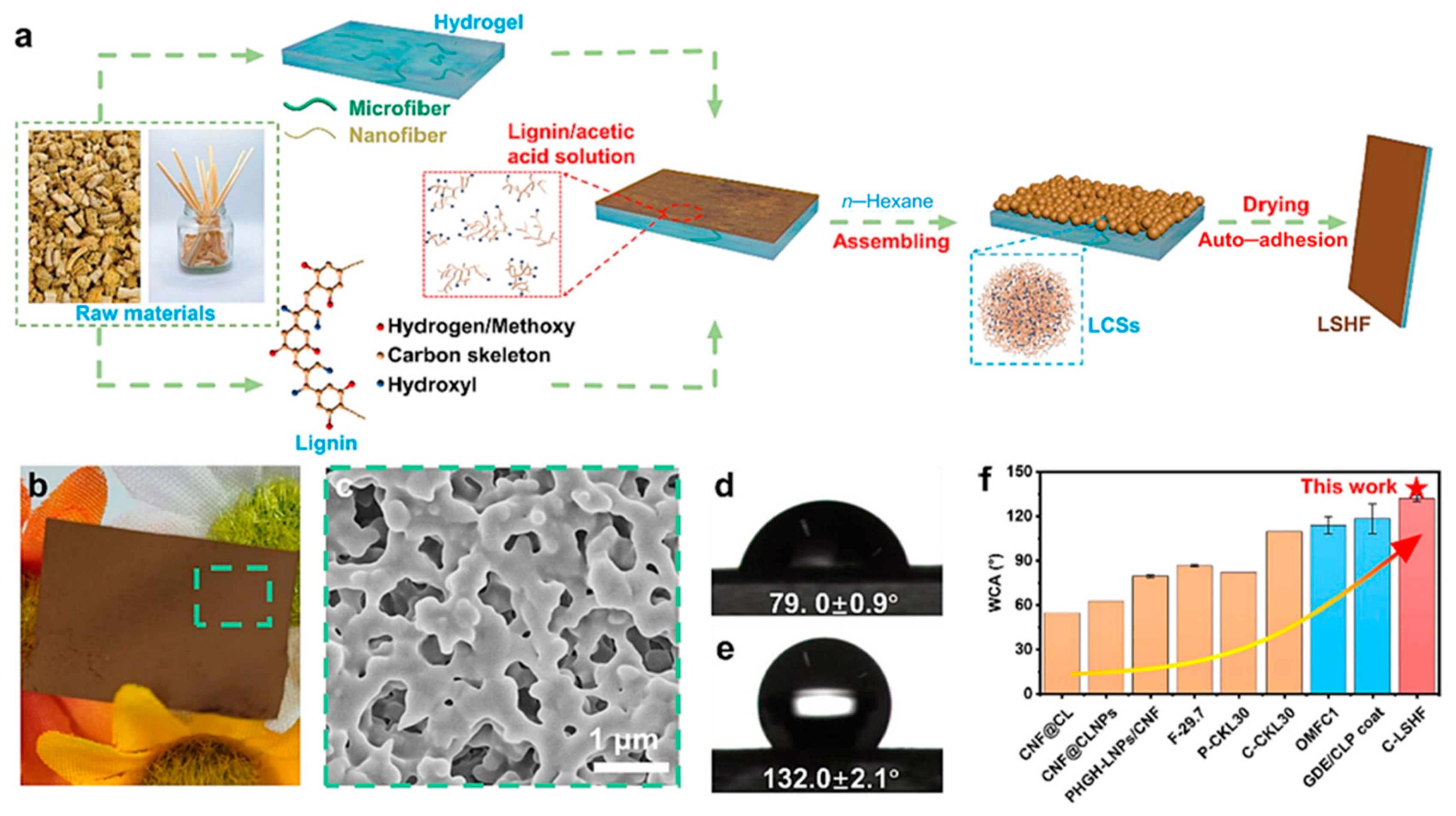

3.1.1. Lignin/Cellulose Composite Film

3.1.2. Lignin/Starch Composite Film

3.1.3. Lignin/Chitosan Composite Film

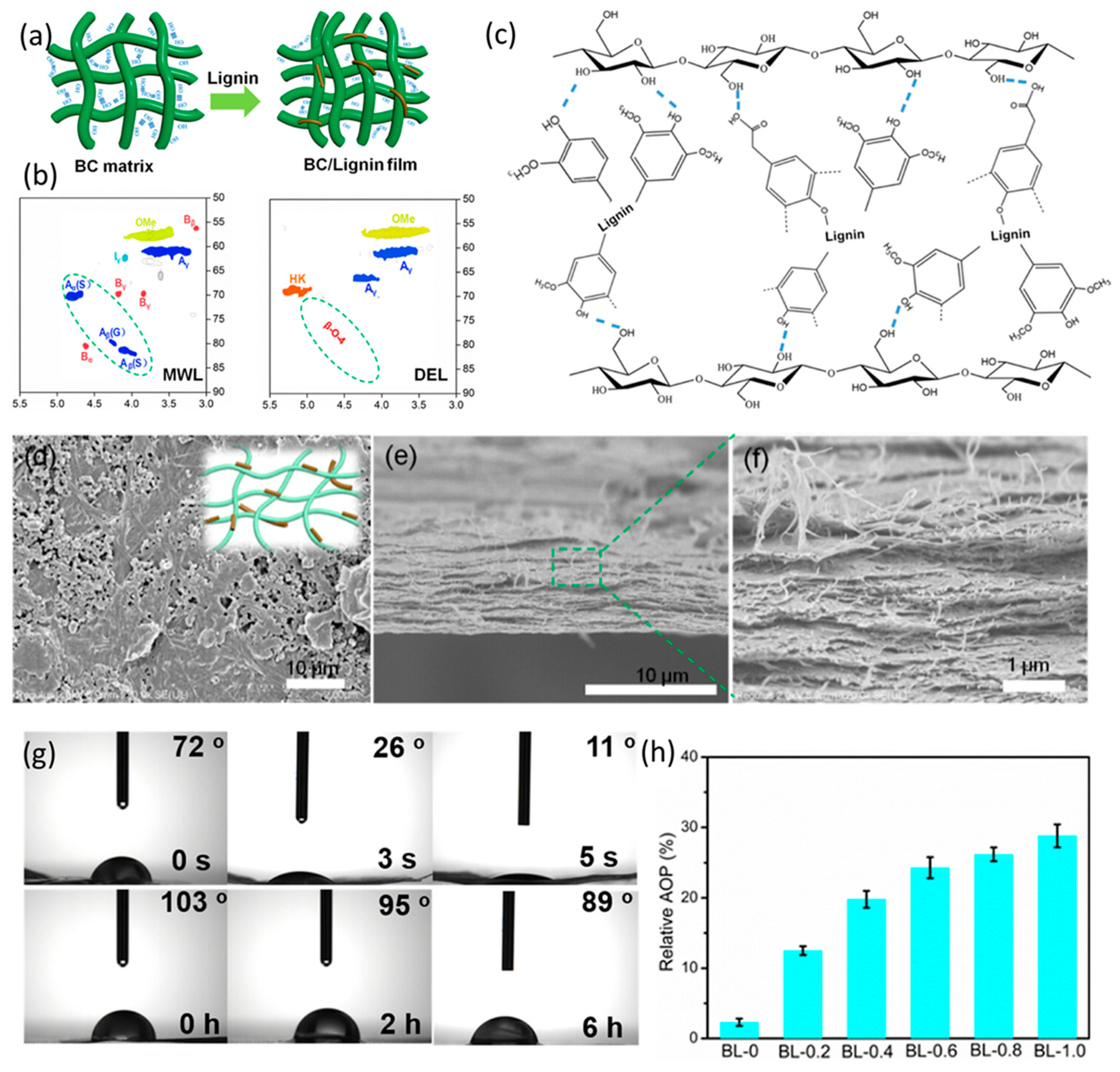

3.1.4. Lignin/Bacterial Cellulose Composite Film

3.2. Lignin/Synthetic Polymer Composite Film

3.2.1. Lignin/Polyolefin Composite Film

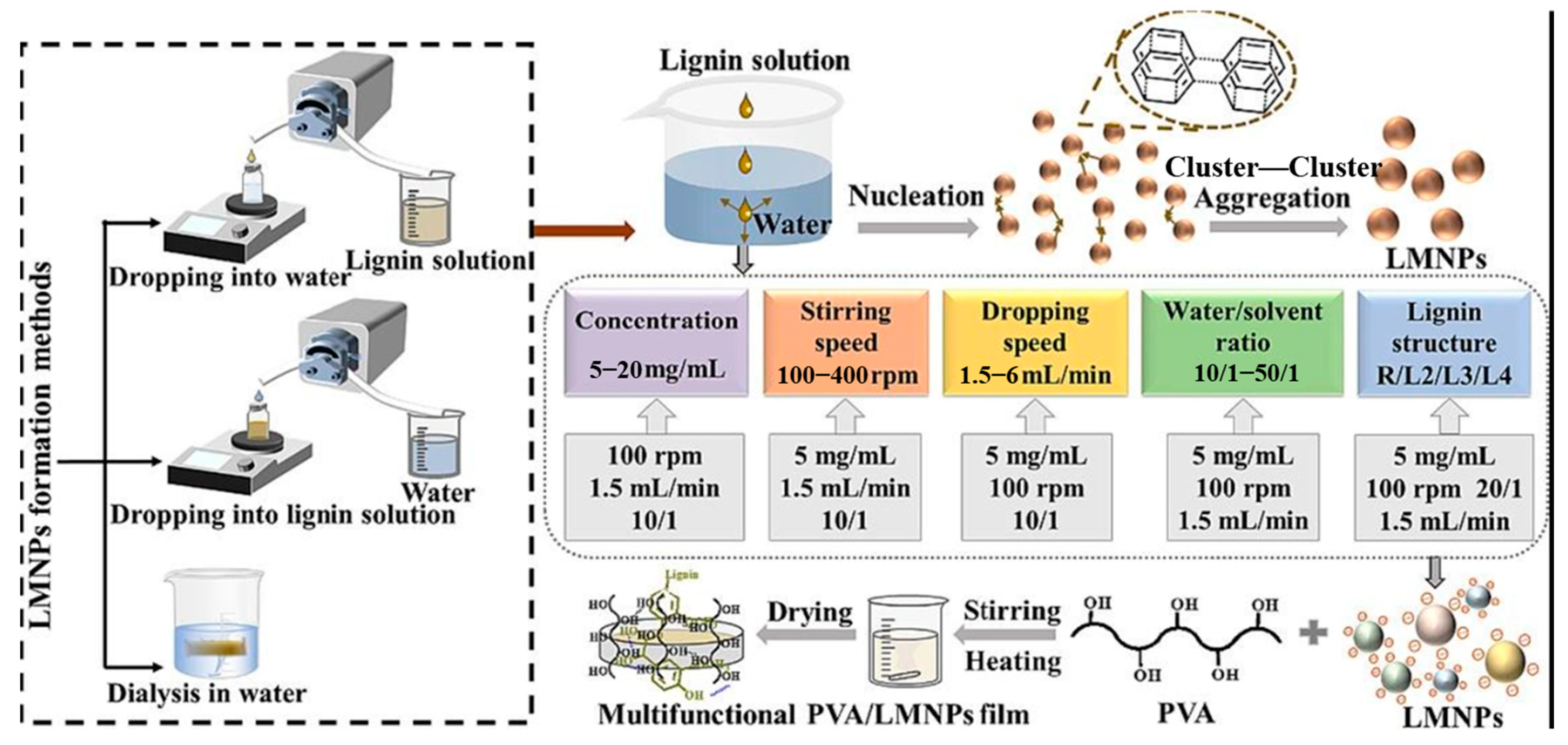

3.2.2. Lignin/Polyvinyl Alcohol (PVA) Composite Film

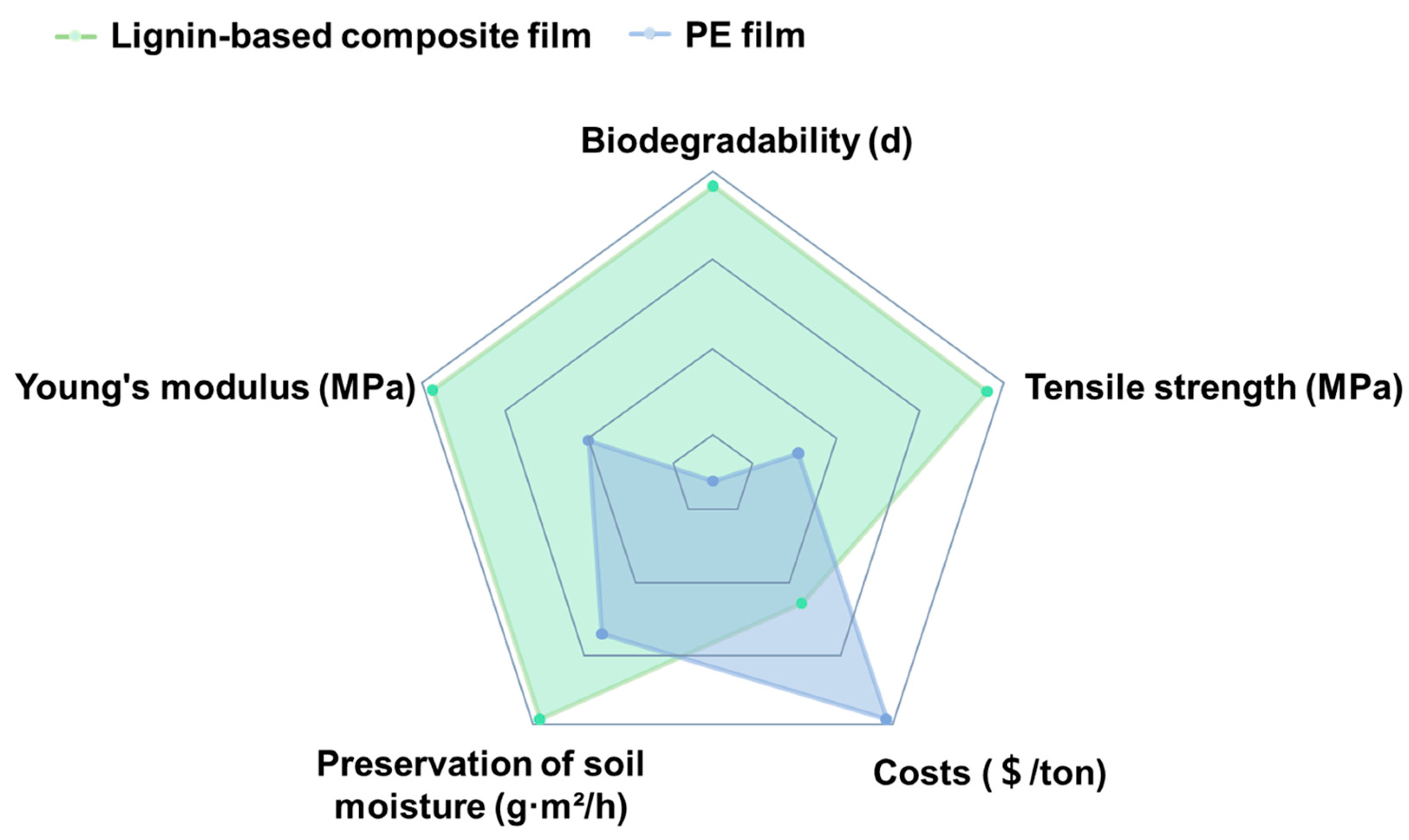

4. Application of Lignin-Based Composite Film in Agriculture

4.1. Agricultural Practice with Mulching

4.1.1. Current Status of Traditional Polyethylene (PE) Mulch Applications

4.1.2. Agricultural Surface Pollution from Traditional Agricultural Mulch

4.2. Prospects for Lignin-Based Agricultural Mulching Film Applications

4.2.1. Covering Performance of Lignin-Based Agricultural Mulching Film

4.2.2. Biodegradability of Lignin-Based Agricultural Mulching Film

4.2.3. Enhancement of Soil Organic Carbon by Lignin-Based Agricultural Film

4.2.4. Economics of Lignin-Based Film Production and Application

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mansoor, Z.; Tchuenbou-Magaia, F.; Kowalczuk, M.; Adamus, G.; Manning, G.; Parati, M.; Radecka, I.; Khan, H. Polymers use as mulch films in agriculture-a review of history, problems and current trends. Polymers 2022, 14, 5062. [Google Scholar] [CrossRef]

- Gao, H.H.; Yan, C.R.; Liu, Q.; Ding, W.L.; Chen, B.Q.; Li, Z. Effects of plastic mulching and plastic residue on agricultural production: A meta-analysis. Sci. Total Environ. 2019, 651, 484–492. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.; Hu, C.S.; Oenema, O. Soil mulching significantly enhances yields and water and nitrogen use efficiencies of maize and wheat: A meta-analysis. Sci. Rep. 2015, 5, 16210. [Google Scholar] [CrossRef]

- Liu, J.L.; Zhan, A.; Chen, H.; Luo, S.S.; Bu, L.D.; Chen, X.P.; Li, S.Q. Response of nitrogen use efficiency and soil nitrate dynamics to soil mulching in dryland maize (Zea mays L.) fields. Nutr. Cycl. Agroecosyst. 2015, 101, 271–283. [Google Scholar] [CrossRef]

- Tindall, J.A.; Beverly, R.B.; Radcliffe, D.E. Mulch effect on soil properties and tomato growth using micro-irrigation. Agron. J. 1991, 83, 1028–1034. [Google Scholar] [CrossRef]

- Abouziena, H.F.; Hafez, O.M.; El-Metwally, I.M.; Sharma, S.D.; Singh, M. Comparison of weed suppression and mandarin fruit yield and quality obtained with organic mulches, synthetic mulches, cultivation, and glyphosate. Hortscience 2008, 43, 795–799. [Google Scholar] [CrossRef]

- Espí, E.; Salmerón, A.; Fontecha, A.; García, Y.; Real, A.I. Plastic films for agricultural applications. J. Plast. Film Sheeting 2006, 22, 85–102. [Google Scholar] [CrossRef]

- Shen, M.C.; Song, B.; Zeng, G.M.; Zhang, Y.X.; Huang, W.; Wen, X.F.; Tang, W.W. Are biodegradable plastics a promising solution to solve the global plastic pollution? Environ. Pollut. 2020, 263, 114469. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Huang, D.; Ouyang, Z.; Guo, X. The effects of microplastics on soil ecosystem: A review. Curr. Opin. Environ. Sci. Health 2022, 26, 100344. [Google Scholar] [CrossRef]

- Garai, S.; Bhattacharjee, C.; Sarkar, S.; Moulick, D.; Dey, S.; Jana, S.; Dhar, A.; Roy, A.; Mondal, K.; Mondal, M.; et al. Microplastics in the soil-water-food nexus: Inclusive insight into global research findings. Sci. Total Environ. 2024, 946, 173891. [Google Scholar] [CrossRef]

- Kannan, K.; Vimalkumar, K. A review of human exposure to microplastics and insights into microplastics as obesogens. Front. Endocrinol. 2021, 12, 724989. [Google Scholar] [CrossRef]

- Michelin, M.; Polizeli, M.; Ruzene, D.S.; Silva, D.; Teixeira, J.A. Application of Lignocelulosic Residues in the Production of Cellulase and Hemicellulases from Fungi, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; p. 34. ISBN 978-042-907-420-2. [Google Scholar]

- Brown, D.E. Lignocellulose hydrolysis. Philos. Trans. R. Soc. B Biol. Sci. 1983, 300, 305–322. [Google Scholar] [CrossRef]

- Brunow, G.; Lundquist, K.; Gellerstedt, G. Lignin. In Analytical Methods in Wood Chemistry, Pulping, and Papermaking; Springer: Berlin/Heidelberg, Germany, 1999; pp. 77–124. [Google Scholar]

- He, W.M.; Fatehi, P. Preparation of sulfomethylated softwood kraft lignin as a dispersant for cement admixture. RSC Adv. 2015, 5, 47031–47039. [Google Scholar] [CrossRef]

- Kazzaz, A.E.; Fatehi, P. Technical lignin and its potential modification routes: A mini-review. Ind. Crop. Prod. 2020, 154, 112732. [Google Scholar] [CrossRef]

- Li, Y.; Liu, C.; Wei, H.Y.; Gai, X.Q.; Lei, T.; Wang, Y.T.; Li, Q.; Xiao, H.N. Recent advances of biodegradable agricultural mulches from renewable resources. ACS Sustain. Chem. Eng. 2023, 11, 14866–14885. [Google Scholar] [CrossRef]

- Ralph, J.; Lapierre, C.; Boerjan, W. Lignin structure and its engineering. Curr. Opin. Biotechnol. 2019, 56, 240–249. [Google Scholar] [CrossRef] [PubMed]

- Vanholme, R.; Demedts, B.; Morreel, K.; Ralph, J.; Boerjan, W. Lignin biosynthesis and structure. Plant Physiol. 2010, 153, 895–905. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhao, X.C.; Wang, A.Q.; Huber, G.W.; Zhang, T. Catalytic Transformation of lignin for the production of chemicals and fuels. Chem. Rev. 2015, 115, 11559–11624. [Google Scholar] [CrossRef]

- Sun, R.C. Lignin source and structural characterization. Chemsuschem 2020, 13, 4385–4393. [Google Scholar] [CrossRef]

- Boeriu, C.G.; Bravo, D.; Gosselink, R.J.; van Dam, J.E. Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind. Crop. Prod. 2004, 20, 205–218. [Google Scholar] [CrossRef]

- Spiridon, I. Extraction of lignin and therapeutic applications of lignin-derived compounds. A review. Environ. Chem. Lett. 2020, 18, 771–785. [Google Scholar] [CrossRef]

- Guerra, A.; Filpponen, I.; Lucia, L.A.; Argyropoulos, D.S. Comparative evaluation of three lignin isolation protocols for various wood species. J. Agric. Food Chem. 2006, 54, 9696–9705. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, S.S.; Zhang, S.C.; Ok, Y.S.; Matsagar, B.M.; Wu, K.C.W.; Tsang, D.C.W. Advances in lignin valorization towards bio-based chemicals and fuels: Lignin biorefinery. Bioresour. Technol. 2019, 291, 121878. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.X.; Gong, Z.G.; Luo, X.L.; Chen, L.H.; Shuai, L. Bonding wood with uncondensed lignins as adhesives. Nature 2023, 621, 511–515. [Google Scholar] [CrossRef] [PubMed]

- Crestini, C.; Lange, H.; Sette, M.; Argyropoulos, D.S. On the structure of softwood kraft lignin. Green Chem. 2017, 19, 4104–4121. [Google Scholar] [CrossRef]

- Giummarella, N.; Lindén, P.r.A.; Areskogh, D.; Lawoko, M. Fractional profiling of kraft lignin structure: Unravelling insights on lignin reaction mechanisms. ACS Sustain. Chem. Eng. 2019, 8, 1112–1120. [Google Scholar] [CrossRef]

- Brudin, S.; Schoenmakers, P. Analytical methodology for sulfonated lignins. J. Sep. Sci. 2010, 33, 439–452. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Production and application of lignosulfonates and sulfonated lignin. ChemSusChem 2017, 10, 1861–1877. [Google Scholar] [CrossRef]

- Yang, S.; Yuan, T.Q.; Sun, R.C. Structural elucidation of whole lignin in cell walls of triploid of populus tomentosa carr. ACS Sustain. Chem. Eng. 2016, 4, 1006–1015. [Google Scholar] [CrossRef]

- Sapouna, I.; Lawoko, M. Deciphering lignin heterogeneity in ball milled softwood: Unravelling the synergy between the supramolecular cell wall structure and molecular events. Green Chem. 2021, 23, 3348–3364. [Google Scholar] [CrossRef]

- Sethupathy, S.; Morales, G.M.; Gao, L.; Wang, H.; Yang, B.; Jiang, J.; Sun, J.; Zhu, D. Lignin valorization: Status, challenges and opportunities. Bioresour. Technol. 2022, 347, 126696. [Google Scholar] [CrossRef] [PubMed]

- Nickerson, R.F.; Habrle, J.A. Cellulose intercrystalline structure study by hydrolytic methods. Ind. Eng. Chem. 1947, 39, 1507–1512. [Google Scholar] [CrossRef]

- Zhong, S.J.; Zhang, J.W.; Yuan, S.X.; Xu, T.Q.; Zhang, X.; Xu, L.; Zuo, T.; Cai, Y.; Yi, L.M. Self-assembling hierarchical flexible cellulose films assisted by electrostatic field for passive daytime radiative cooling. Chem. Eng. J. 2023, 451, 138558. [Google Scholar] [CrossRef]

- Österberg, M.; Vartiainen, J.; Lucenius, J.; Hippi, U.; Seppälä, J.; Serimaa, R.; Laine, J. A fast method to produce strong nfc films as a platform for barrier and functional materials. ACS Appl. Mater. Interfaces 2013, 5, 4640–4647. [Google Scholar] [CrossRef]

- Yu, S.X.; Wang, M.L.; Xie, Y.M.; Qian, W.C.; Bai, Y.W.; Feng, Q.H. Lignin self-assembly and auto-adhesion for hydrophobic cellulose/lignin composite film fabrication. Int. J. Biol. Macromol. 2023, 233, 123598. [Google Scholar] [CrossRef] [PubMed]

- Płotka-Wasylka, J.; De la Guardia, M.; Andruch, V.; Vilková, M.J.M.J. Deep eutectic solvents vs ionic liquids: Similarities and differences. Microchem. J. 2020, 159, 105539. [Google Scholar] [CrossRef]

- Colburn, A.; Vogler, R.J.; Patel, A.; Bezold, M.; Craven, J.; Liu, C.Q.; Bhattacharyya, D. Composite membranes derived from cellulose and lignin sulfonate for selective separations and antifouling aspects. Nanomaterials 2019, 9, 867. [Google Scholar] [CrossRef]

- Baumberger, S.; Lapierre, C.; Monties, B.; Della Valle, G. Use of kraft lignin as filler for starch films. Polym. Degrad. Stabil. 1998, 59, 273–277. [Google Scholar] [CrossRef]

- Baumberger, S.; Lapierre, C.; Monties, B.; Lourdin, D.; Colonna, P. Preparation and properties of thermally moulded and cast lignosulfonates starch blends. Ind. Crop. Prod. 1997, 6, 253–258. [Google Scholar] [CrossRef]

- Ni, S.; Bian, H.; Zhang, Y.; Fu, Y.; Liu, W.; Qin, M.; Xiao, H. Starch-based composite films with enhanced hydrophobicity, thermal stability, and UV-shielding efficacy induced by lignin nanoparticles. Biomacromolecules 2022, 23, 829–838. [Google Scholar] [CrossRef]

- Wu, R.L.; Wang, X.L.; Li, F.; Li, H.Z.; Wang, Y.Z. Green composite films prepared from cellulose, starch and lignin in room-temperature ionic liquid. Bioresour. Technol. 2009, 100, 2569–2574. [Google Scholar] [CrossRef]

- Zhang, S.G.; Li, J.Y.; Li, J.F.; Du, N.; Li, D.H.; Li, F.Y.; Man, J. Application status and technical analysis of chitosan-based medical dressings: A review. RSC Adv. 2020, 10, 34308–34322. [Google Scholar] [CrossRef] [PubMed]

- Sohni, S.; Hashim, R.; Nidaullah, H.; Lamaming, J.; Sulaiman, O. Chitosan/nano-lignin based composite as a new sorbent for enhanced removal of dye pollution from aqueous solutions. Int. J. Biol. Macromol. 2019, 132, 1304–1317. [Google Scholar] [CrossRef]

- Ji, M.; Li, J.; Li, F.; Wang, X.; Man, J.; Li, J.; Zhang, C.; Peng, S. A biodegradable chitosan-based composite film reinforced by ramie fibre and lignin for food packaging. Carbohydr. Polym. 2022, 281, 119078. [Google Scholar] [CrossRef] [PubMed]

- Vedula, S.S.; Yadav, G.D. Wastewater treatment containing methylene blue dye as pollutant using adsorption by chitosan lignin membrane: Development of membrane, characterization and kinetics of adsorption. J. Indian Chem. Soc. 2022, 99, 100263. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, C.L.; Yang, J.Z.; Nie, Y.; Chen, C.T.; Sun, D.P. Recent advances in bacterial cellulose. Cellulose 2014, 21, 1–30. [Google Scholar] [CrossRef]

- Zmejkoski, D.; Spasojevic, D.; Orlovska, I.; Kozyrovska, N.; Sokovic, M.; Glamoclija, J.; Dmitrovic, S.; Matovic, B.; Tasic, N.; Maksimovic, V.; et al. Bacterial cellulose-lignin composite hydrogel as a promising agent in chronic wound healing. Int. J. Biol. Macromol. 2018, 118, 494–503. [Google Scholar] [CrossRef]

- Dai, Q.H.; Bai, Y.H.; Fu, B.; Yang, F. Multifunctional bacterial cellulose films enabled by deep eutectic solvent-extracted lignin. ACS Omega 2023, 8, 7430–7437. [Google Scholar] [CrossRef]

- Tian, D.; Guo, Y.J.; Huang, M.; Zhao, L.; Deng, S.H.; Deng, O.P.; Zhou, W.; Hu, J.G.; Shen, F. Bacterial cellulose/lignin nanoparticles composite films with retarded biodegradability. Carbohydr. Polym. 2021, 274, 118656. [Google Scholar] [CrossRef]

- Wang, H.M.; Yuan, T.Q.; Song, G.Y.; Sun, R.C. Advanced and versatile lignin-derived biodegradable composite film materials toward a sustainable world. Green Chem. 2021, 23, 3790–3817. [Google Scholar] [CrossRef]

- Kun, D.; Pukánszky, B. Polymer/lignin blends: Interactions, properties, applications. Eur. Polym. J. 2017, 93, 618–641. [Google Scholar] [CrossRef]

- Cazacu, G.; Pascu, M.C.; Profire, L.; Kowarski, A.I.; Mihaes, M.; Vasile, C. Lignin role in a complex polyolefin blend. Ind. Crop. Prod. 2004, 20, 261–273. [Google Scholar] [CrossRef]

- Chiappero, L.R.; Bartolomei, S.S.; Estenoz, D.A.; Moura, E.A.B.; Nicolau, V.V. Lignin-based polyethylene films with enhanced thermal, opacity and biodegradability properties for agricultural mulch applications. J. Polym. Environ. 2021, 29, 450–459. [Google Scholar] [CrossRef]

- Kawai, F.; Hu, X.P. Biochemistry of microbial polyvinyl alcohol degradation. Appl. Microbiol. Biotechnol. 2009, 84, 227–237. [Google Scholar] [CrossRef]

- Xu, Y.H.; Li, M.F.; Peng, F. Lignin micro/nanoparticles: Synthesis, properties, and application to endow polyvinyl alcohol film with multi-functionality. Chem. Eng. J. 2023, 473, 145233. [Google Scholar] [CrossRef]

- Mu, C.Y.; Xue, L.Y.; Zhu, J.; Jiang, M.; Zhou, Z.W. Mechanical and thermal properties of toughened poly(l-lactic) acid and lignin blends. BioResources 2014, 9, 5557–5566. [Google Scholar] [CrossRef]

- Xing, Q.Q.; Ruch, D.; Dubois, P.; Wu, L.B.; Wang, W.J. Biodegradable and high-performance poly(butylene adipate-co-terephthalate)-lignin uv-blocking films. ACS Sustain. Chem. Eng. 2017, 5, 10342–10351. [Google Scholar] [CrossRef]

- Vostrejs, P.; Adamcová, D.; Vaverková, M.D.; Enev, V.; Kalina, M.; Machovsky, M.; Sourková, M.; Marova, I.; Kovalcik, A. Active biodegradable packaging films modified with grape seeds lignin. RSC Adv. 2020, 10, 29202–29213. [Google Scholar] [CrossRef]

- Abduwaiti, A.; Liu, X.W.; Yan, C.R.; Xue, Y.H.; Jin, T.; Wu, H.Q.; He, P.C.; Bao, Z.; Liu, Q. Testing biodegradable films as alternatives to plastic-film mulching for enhancing the yield and economic benefits of processed tomato in Xinjiang region. Sustainability 2021, 13, 3093. [Google Scholar] [CrossRef]

- Yan, Z.Y.; Wu, T.; Fang, G.G.; Ran, M.; Shen, K.Z.; Liao, G.F. Self-assembly preparation of lignin-graphene oxide composite nanospheres for highly efficient Cr(vi) removal. RSC Adv. 2021, 11, 4713–4722. [Google Scholar] [CrossRef]

- Raza, T.; Qadir, M.F.; Khan, K.S.; Eash, N.S.; Yousuf, M.; Chatterjee, S.; Manzoor, R.; ur Rehman, S.; Oetting, J.N. Unrevealing the potential of microbes in decomposition of organic matter and release of carbon in the ecosystem. J. Environ. Manag. 2023, 344, 118529. [Google Scholar] [CrossRef]

- Wang, J.W.; Niu, W.Q.; Dyck, M.; Zhang, M.Z.; Li, Y. Drip irrigation with film covering improves soil enzymes and muskmelon growth in the greenhouse. Soil Res. 2018, 56, 59–70. [Google Scholar] [CrossRef]

- Feng, Y.; Gong, D.Z.; Mei, X.R.; Hao, W.P.; Tang, D.H.; Cui, N.B. Energy balance and partitioning in partial plastic mulched and non-mulched maize fields on the Loess Plateau of China. Agric. Water Manag. 2017, 191, 193–206. [Google Scholar] [CrossRef]

- Liang, J.P.; Li, Y.; Si, B.C.; Wang, Y.Z.; Chen, X.G.; Wang, X.F.; Chen, H.R.; Wang, H.R.; Zhang, F.C.; Bai, Y.G.; et al. Optimizing biochar application to improve soil physical and hydraulic properties in saline-alkali soils. Sci. Total Environ. 2021, 771, 144802. [Google Scholar] [CrossRef]

- Fang, S.Y.; Lyu, X.Y.; Tong, T.; Lim, A.I.; Li, T.; Bao, J.M.; Hu, Y.H. Turning dead leaves into an active multifunctional material as evaporator, photocatalyst, and bioplastic. Nat. Commun. 2023, 14, 1203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, W.F.; Liu, W.Q.; Qiu, X.Q. High performance PVA/lignin nanocomposite films with excellent water vapor barrier and UV-shielding properties. Int. J. Biol. Macromol. 2020, 142, 551–558. [Google Scholar] [CrossRef] [PubMed]

- Abd El-Kader, K.; Abdel Hamied, S. Preparation of poly (vinyl alcohol) films with promising physical properties in comparison with commercial polyethylene film. J. Appl. Polym. Sci. 2002, 86, 1219–1226. [Google Scholar] [CrossRef]

- Matsuo, M.; Sawatari, C. Elastic-modulus of polyethylene in the crystal chain direction as measured by x-ray-diffraction. Macromolecules 1986, 19, 2036–2040. [Google Scholar] [CrossRef]

- Cirujeda, A.; Aibar, J.; Anzalone, A.; Martín-Closas, L.; Meco, R.; Moreno, M.M.; Pardo, A.; Pelacho, A.M.; Rojo, F.; Royo-Esnal, A.; et al. Biodegradable mulch instead of polyethylene for weed control of processing tomato production. Agron. Sustain. Dev. 2012, 32, 889–897. [Google Scholar] [CrossRef]

- Orzolek, M.; Lamont, W., Jr. Summary and Recommendations for the Use of Mulch Color in Vegetable Production. Department Horticulture, College of Agricultural Sciences, Penn State University: University Park, PA, USA, 2000. [Google Scholar]

- Teasdale, J.R. Interaction of light, soil-moisture, and temperature with weed suppression by hairy vetch residue. Weed Sci. 1993, 41, 46–51. [Google Scholar] [CrossRef]

- Chopra, M.; Koul, B.J.P.A. Comparative assessment of different types of mulching in various crops: A review. Plant Arch 2020, 20, 1620–1626. [Google Scholar]

- Campanale, C.; Galafassi, S.; Di Pippo, F.; Pojar, I.; Massarelli, C.; Uricchio, V.F. A critical review of biodegradable plastic mulch films in agriculture: Definitions, scientific background and potential impacts. TrAC-Trends Anal. Chem. 2024, 170, 16. [Google Scholar] [CrossRef]

- Wang, K.S.; Jin, T.; Wang, B.; Yuan, Z.M.; Peng, K.W.; Hu, Y. Evolution of hotspots and research trends in agricultural mulch film research: A bibliometric review. Front. Environ. Sci. 2024, 12, 13094808. [Google Scholar] [CrossRef]

- Intelligence, M. Available online: https://www.mordorintelligence.com/zh-CN/industry-reports/north-america-agricultural-films-market (accessed on 25 August 2024).

- Sen, S.K.; Raut, S. Microbial degradation of low density polyethylene (LDPE): A review. J. Environ. Chem. Eng. 2015, 3, 462–473. [Google Scholar]

- Abraham, J.; Ghosh, E.; Mukherjee, P.; Gajendiran, A. Microbial degradation of low density polyethylene. Environ. Prog. Sustain. Energy 2017, 36, 147–154. [Google Scholar] [CrossRef]

- Jiang, X.J.; Liu, W.J.; Wang, E.H.; Zhou, T.Z.; Xin, P. Residual plastic mulch fragments effects on soil physical properties and water flow behavior in the Minqin Oasis, northwestern China. Soil Tillage Res. 2017, 166, 100–107. [Google Scholar] [CrossRef]

- Fan, Y.N.; Zhang, Y.X.; Wan, M.X.; Hu, W.Y.; Chen, Z.K.; Huang, B. Plastic shed production intensified secondary soil salinization in perennial fruit production systems. Agric. Ecosyst. Environ. 2021, 316, 107469. [Google Scholar] [CrossRef]

- Khalid, N.; Aqeel, M.; Noman, A. Microplastics could be a threat to plants in terrestrial systems directly or indirectly. Environ. Pollut. 2020, 267, 115653. [Google Scholar] [CrossRef]

- Liu, B.S.; Li, W.F.; Pan, X.L.; Zhang, D.Y. The persistently breaking trade-offs of three-decade plastic film mulching: Microplastic pollution, soil degradation and reduced cotton yield. J. Hazard. Mater. 2022, 439, 129586. [Google Scholar] [CrossRef]

- Gómez-Hens, A.; Aguilar-Caballos, M.P. Social and economic interest in the control of phthalic acid esters. TrAC-Trends Anal. Chem. 2003, 22, 847–857. [Google Scholar] [CrossRef]

- Jia, Q.M.; Wang, J.; Ali, S.; Chang, S.H.; Zhang, C.; Hou, F.J. Nutrient management and cultivation techniques affect maize production through regulating greenhouse gas intensity and carbon budget under semi-arid climate. J. Clean. Prod. 2020, 276, 124197. [Google Scholar] [CrossRef]

- Briassoulis, D.; Babou, E.; Hiskakis, M.; Scarascia, G.; Picuno, P.; Guarde, D.; Dejean, C. Review, mapping and analysis of the agricultural plastic waste generation and consolidation in Europe. Waste Manag. Res. 2013, 31, 1262–1278. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.S.; Wang, L.Y.; Li, C.; Jiang, C.; Hu, J.W.; Lv, Y.N.; Tao, Y.H.; Lu, J.; Pan, G.F.; Du, J.; et al. Biodegradable and multifunctional black mulch film decorated with darkened lignin induced by iron ions for “green” agriculture. Int. J. Biol. Macromol. 2024, 265, 130981. [Google Scholar] [CrossRef]

- Wang, D.Y.; Li, B.; Ma, J.; Wang, J.; Wang, H.Y.; Li, W.Z. Pseudoplastic liquid mulch film incorporating waste lignin and starch to improve its sprayability and available soil nitrogen. Chem. Eng. J. 2023, 475, 146392. [Google Scholar] [CrossRef]

- Tian, D.; Zhang, J.; Hu, J.G.; Huang, M.; Zhao, L.; Lei, Y.J.; Zou, J.M.; Zhang, S.B.; Shen, F. A new water-soluble lignin incorporation enhanced the barrier performance of liquid mulching film. Chem. Eng. J. 2023, 452, 139383. [Google Scholar] [CrossRef]

- Wang, L.Y.; Ji, X.X.; Cheng, Y.; Tao, Y.H.; Lu, J.; Du, J.; Wang, H.S. All-biodegradable soy protein isolate/lignin composite cross-linked by oxidized sucrose as agricultural mulch films for green farming. Int. J. Biol. Macromol. 2022, 223, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Atiwesh, G.; Parrish, C.C.; Banoub, J.; Le, T.A.T. Lignin degradation by microorganisms: A review. Biotechnol. Prog. 2022, 38, e3226. [Google Scholar] [CrossRef] [PubMed]

- Hall, S.J.; Ye, C.L.; Weintraub, S.R.; Hockaday, W.C. Molecular trade-offs in soil organic carbon composition at continental scale. Nat. Geosci. 2020, 13, 687–692. [Google Scholar] [CrossRef]

- Su, W.Y.; Yang, Z.W.; Wang, H.Y.; Fang, J.; Li, C.L.; Lyu, G.J.; Li, H. Synergistic effect of sodium alginate and lignin on the properties of biodegradable poly(vinyl alcohol) mulch films. ACS Sustain. Chem. Eng. 2022, 10, 11800–11814. [Google Scholar] [CrossRef]

- Rodríguez-Couto, S. Industrial and environmental applications of white-rot fungi. Mycosphere 2017, 8, 456–466. [Google Scholar] [CrossRef]

- Fu, X.; Zheng, Z.; Sha, Z.M.; Cao, H.L.; Yuan, Q.X.; Yu, H.B.; Li, Q. Biorefining waste into nanobiotechnologies revolutionize sustainable agriculture. Trends Biotechnol. 2022, 40, 1503–1518. [Google Scholar] [CrossRef] [PubMed]

- Xu, W. A study on the synthesis, modification and current market status of PBAT. E3S Web Conf. 2023, 385, 04007. [Google Scholar] [CrossRef]

- Ashok, R.P.B.; Oinas, P.; Lintinen, K.; Sarwar, G.; Kostiainen, M.A.; Österberg, M. Techno-economic assessment for the large-scale production of colloidal lignin particles. Green Chem. 2018, 20, 4911–4919. [Google Scholar] [CrossRef]

- Liu, J.L.; Zhu, L.; Luo, S.S.; Bu, L.D.; Chen, X.P.; Yue, S.C.; Li, S.Q. Response of nitrous oxide emission to soil mulching and nitrogen fertilization in semi-arid farmland. Agric. Ecosyst. Environ. 2014, 188, 20–28. [Google Scholar] [CrossRef]

- Zhao, X.P.; Shi, L.; Tian, B.; Li, S.J.; Liu, S.X.; Li, J.; Liu, S.; James, T.D.; Chen, Z.J. Harnessing solar energy for electrocatalytic biorefinery using lignin-derived photothermal materials. J. Mater. Chem. A 2023, 11, 12308–12314. [Google Scholar] [CrossRef]

| Classification | Composite Polymers | Lignin Source | Interfacial Interaction between Polymers | Function of Lignin | Performance | Ref. |

|---|---|---|---|---|---|---|

| Lignin/natural polymer composite film | Lignin/cellulose composite film | Acetic acid lignin | Physical adhesion between ester groups (C=O, O-C=O) | Self-adhesion | Highly hydrophobic film with tensile strength of 37.7 MPa | [37] |

| Lignin/starch composite film | Lignosulfonate | Hydrogen bonding | Plasticizers and surfactants | Highly standard plasticized film with an elongation at break of 208%, Water content of 13.6% | [41] | |

| Lignin/chitosan composite film | Lignin | Hydrogen bonding and van der Waals forces | Provides phenolic groups and a high density of -OH groups | Recyclable film with adsorption capacity, tensile strength of 41.45 MPa | [47] | |

| Lignin/bacterial cellulose composite film | Lignin | Lignin attached to the reticulum of bacterial cellulose and hydrogen bonding | Retard free radical-induced oxidation, enhance mechanical property, and UV-blocking | Stronger interfacially bonded films, tensile strength of 343 MPa | [50] | |

| Lignin/synthetic polymer composite film | Lignin/polyolefin composite film | Hardwood lignin modified by esterification-linear low-density polyethylene | Hydrogen bonding and physically bonded interfacial interactions | Enhance mechanical property, thermal stability and antioxidants, UV absorption | Flexible film, elongation at break of 351.33%, opacity of 46.83% | [55] |

| Lignin/PVA composite film | Lignin micro/nanoparticles | Hydrogen bonding and polar bonding | Improvement of water absorption and heat resistance of composites | High crystallinity film with tensile strength of 99.4 MPa, resilience of 97.1 MJ/m3 | [57] | |

| Lignin/PLA composite film | Lignin in corn stover | Heterogeneous crystallization | Nucleating agent, plasticizer | High toughness film with Young’s modulus of 1589 MPa, tensile strength of 55.1 MPa | [58] | |

| Lignin/PBAT composite film | Alkaline soda lignin | Intermolecular hydrogen bonding | Enhance mechanical property, thermal stability, and UV absorption | Films with excellent UV shielding properties, elongation at break of 689%, Young’s modulus of 63 MPa, tensile strength of 30 MPa | [59] | |

| Lignin/PHA composite film | Grape seeds lignin | Interfacial adhesion | Antioxidant and nucleating agent | Highly antioxidant film with E-modulus of 827 MPa, tensile strength of 82 MPa | [60] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Zhang, Y.; Zhang, C.; Yuan, F.; Gao, H.; Li, Q. Lignin-Based Composite Film and Its Application for Agricultural Mulching. Polymers 2024, 16, 2488. https://doi.org/10.3390/polym16172488

Huang Z, Zhang Y, Zhang C, Yuan F, Gao H, Li Q. Lignin-Based Composite Film and Its Application for Agricultural Mulching. Polymers. 2024; 16(17):2488. https://doi.org/10.3390/polym16172488

Chicago/Turabian StyleHuang, Zujian, Yan Zhang, Chenwei Zhang, Fangting Yuan, Hairong Gao, and Qiang Li. 2024. "Lignin-Based Composite Film and Its Application for Agricultural Mulching" Polymers 16, no. 17: 2488. https://doi.org/10.3390/polym16172488

APA StyleHuang, Z., Zhang, Y., Zhang, C., Yuan, F., Gao, H., & Li, Q. (2024). Lignin-Based Composite Film and Its Application for Agricultural Mulching. Polymers, 16(17), 2488. https://doi.org/10.3390/polym16172488