CNN-Optimized Electrospun TPE/PVDF Nanofiber Membranes for Enhanced Temperature and Pressure Sensing

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Reagents

2.2. Fabrication of PVDF Electrospinning Solutions and TPE-Doped PVDF Electrospinning Solutions

2.3. Fabrication of PVDF and TPE-Doped PVDF Nanofiber Membranes

2.4. Characterization

2.5. Training of Neural Network for Fiber Diameter Prediction

2.6. Gray Value Method for Thermal Sensitivity Measurement

3. Results and Discussion

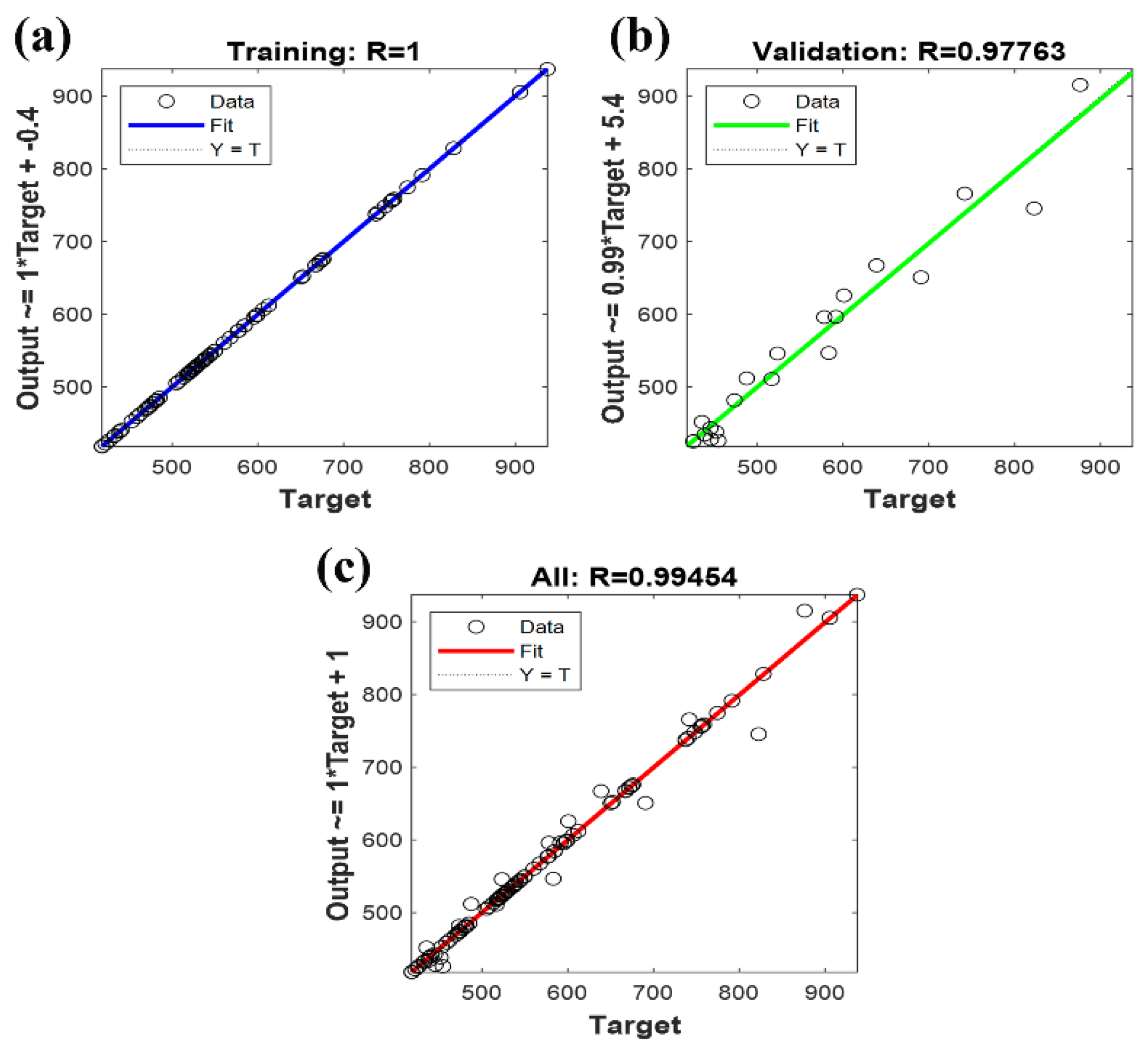

3.1. Comparison of Different Neural Network Prediction Results

3.2. Interactions among Electrospinning Process Parameters

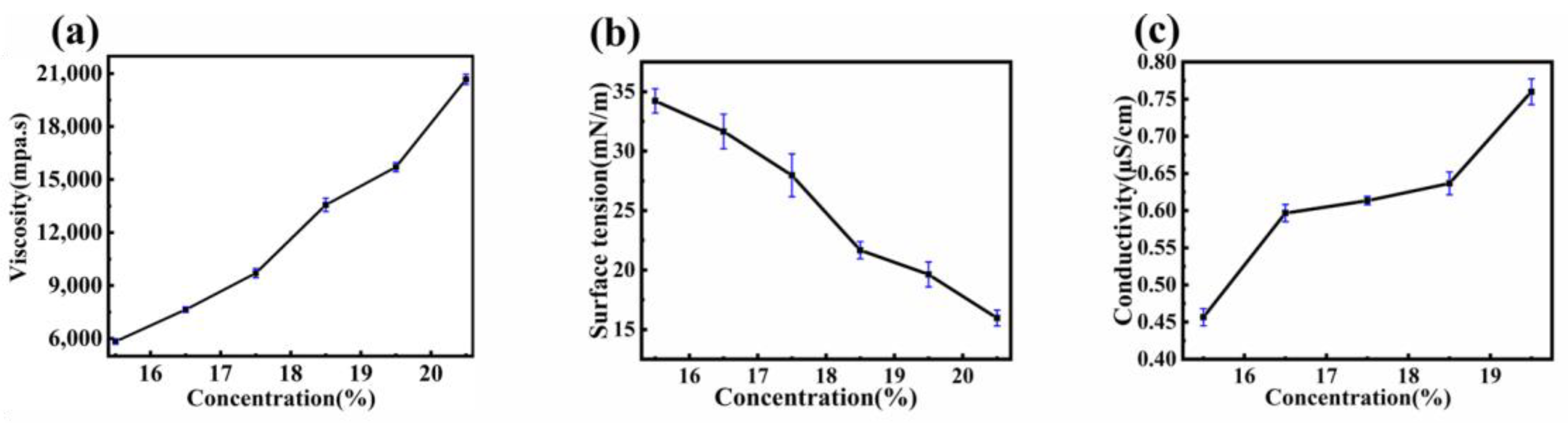

3.3. Effect of PVDF Concentration on Viscosity, Surface Tension, and Conductivity of Spinning Solutions

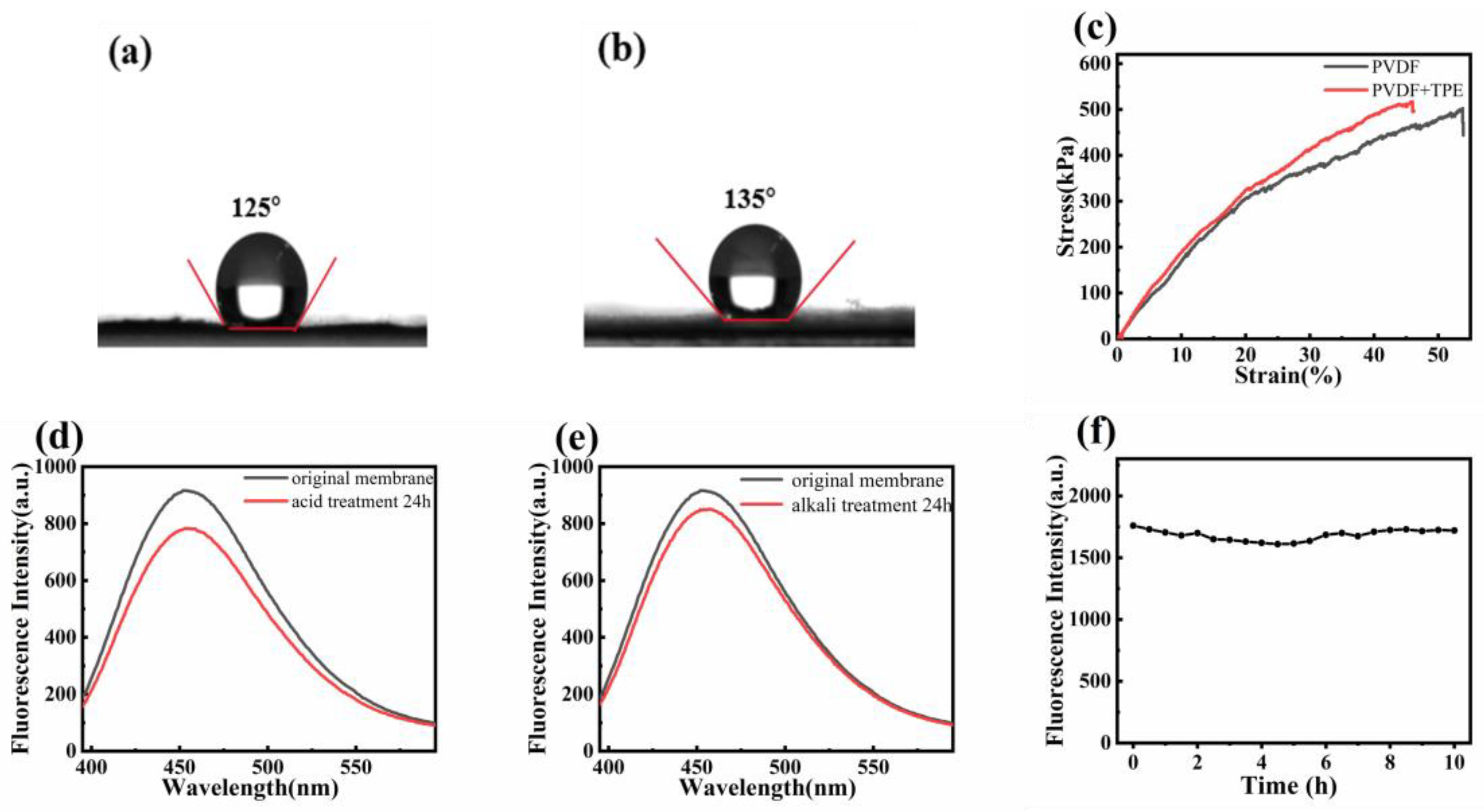

3.4. Surface and Stability Properties of Nanofiber Membranes

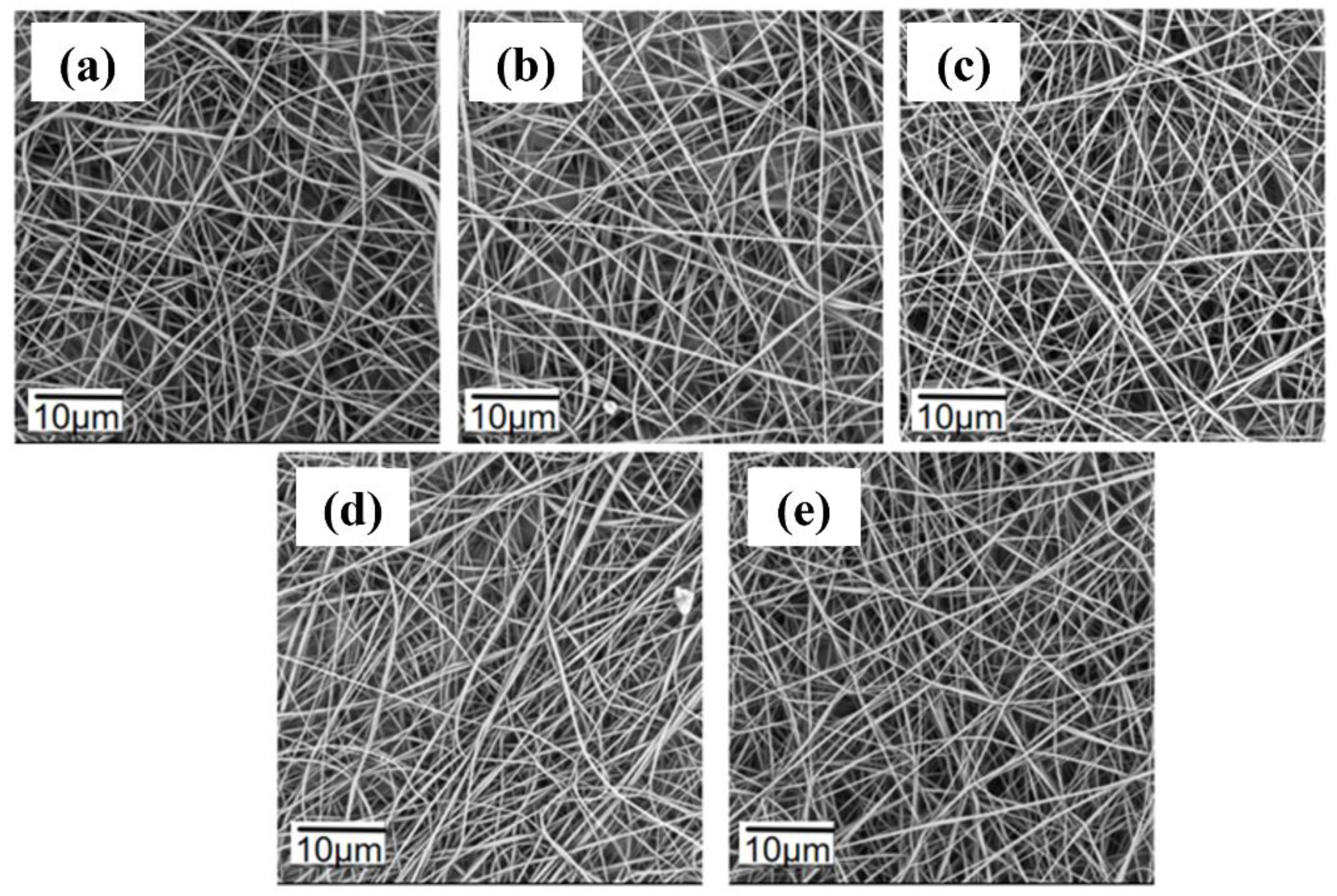

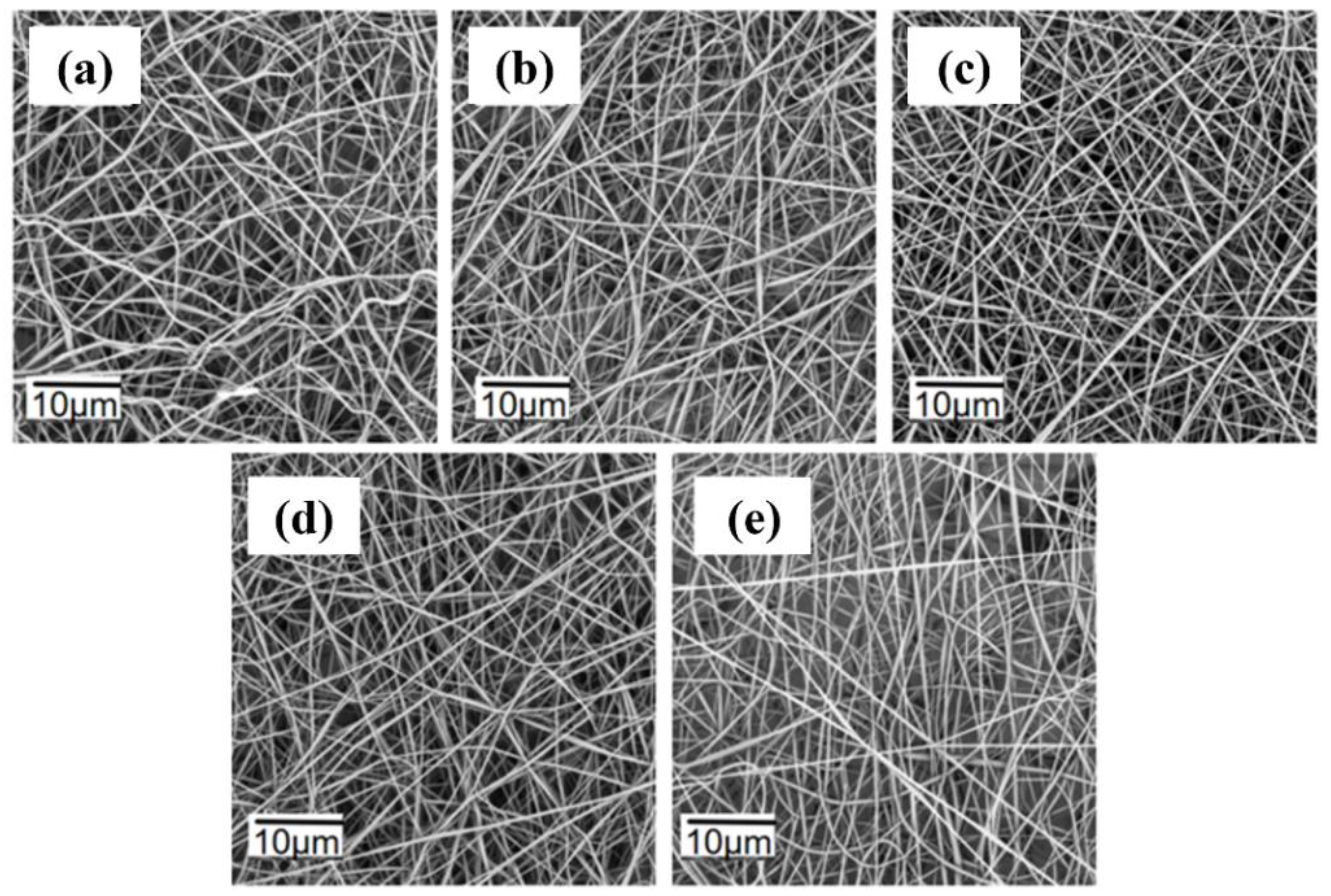

3.5. Morphological Analysis of Fluorescent Nanofiber Membranes

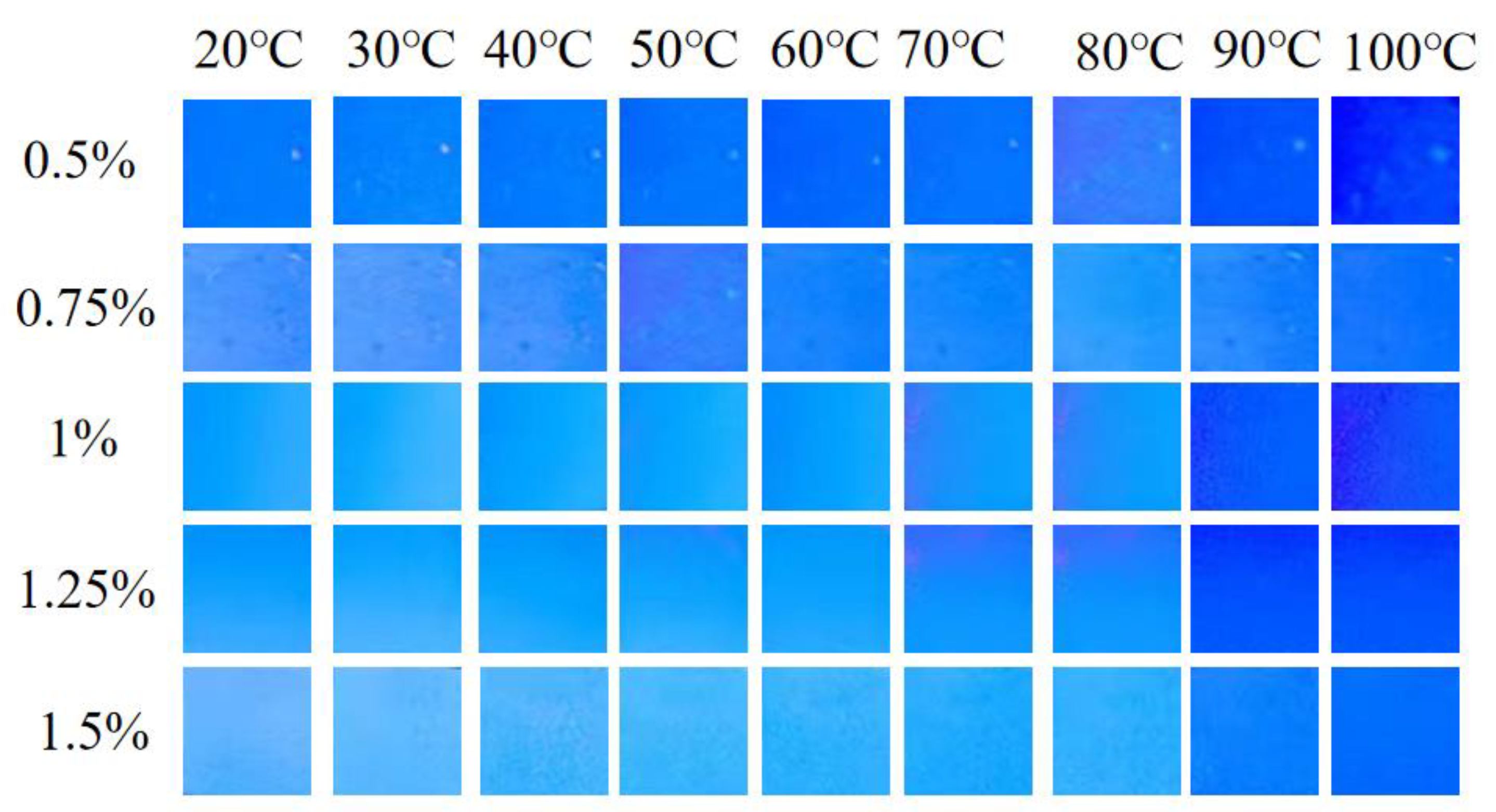

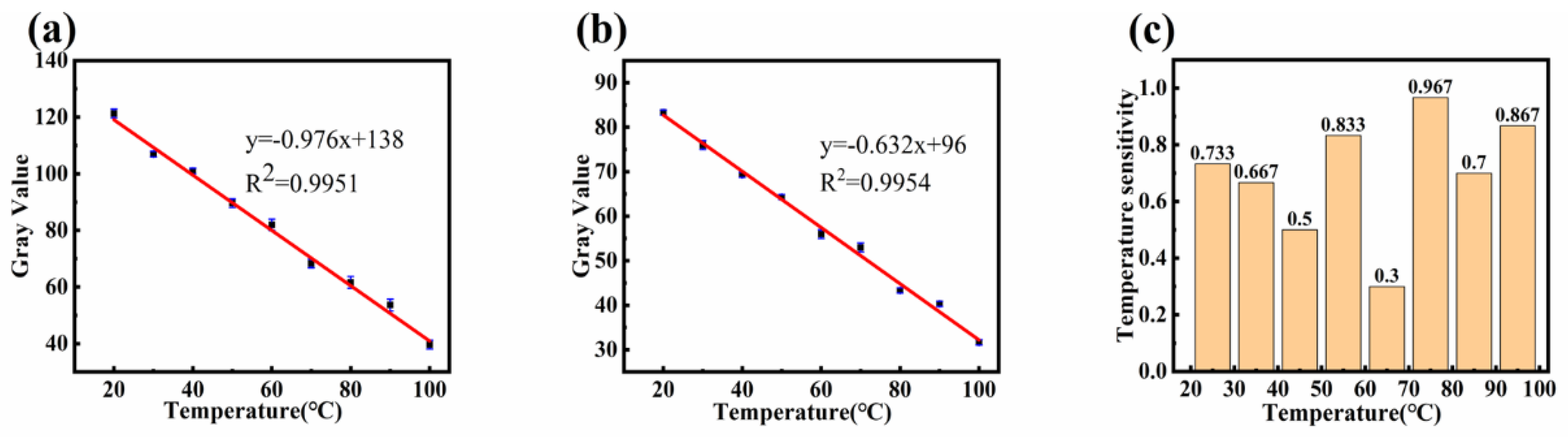

3.6. Thermal Sensitivity Analysis of Fluorescent Nanofiber Membranes

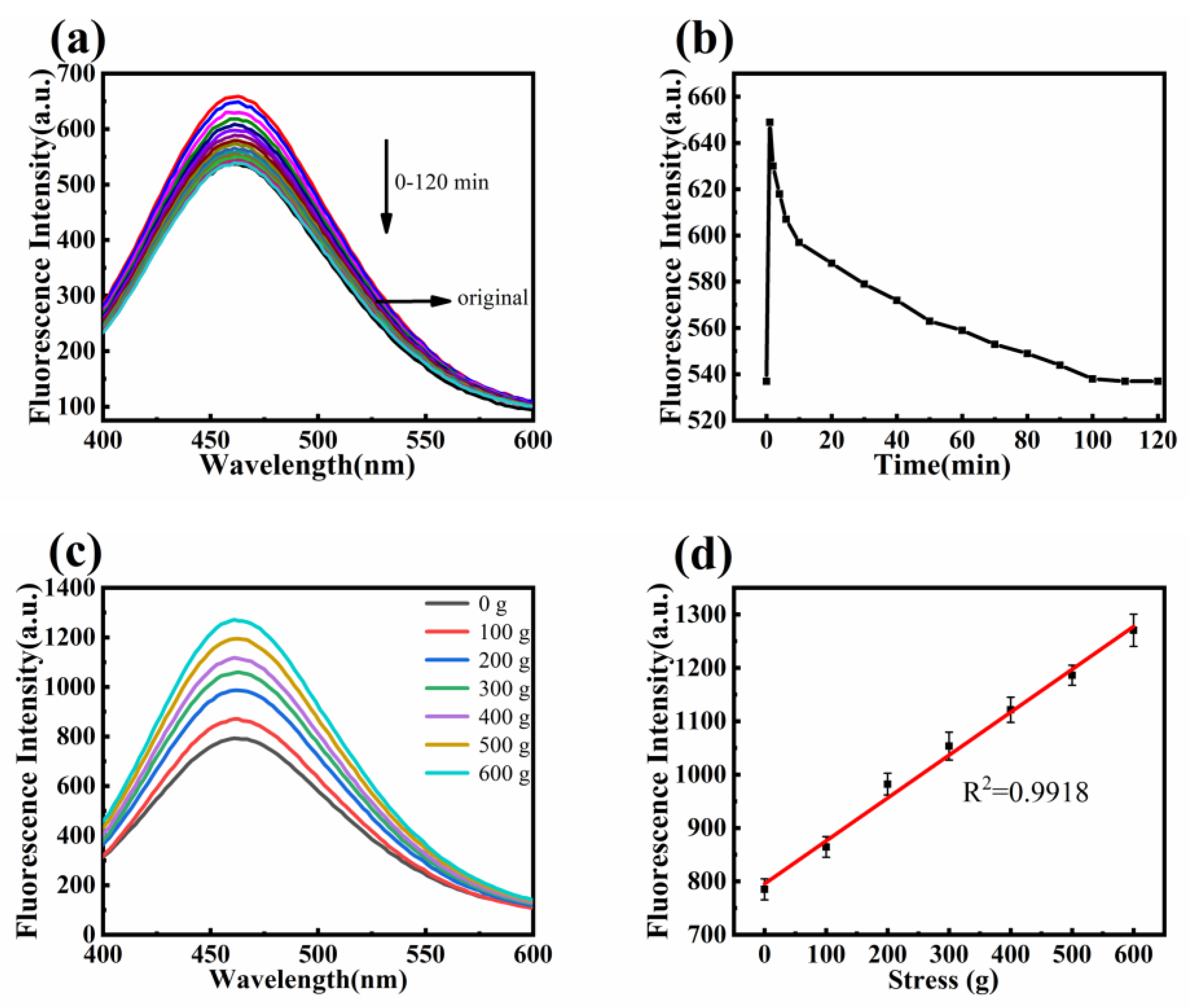

3.7. Pressure Sensitivity Analysis of Fluorescent Nanofiber Membranes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, M.X.; Song, W.L.; Tang, Y.X.; Xu, X.Z.; Huang, Y.N.; Yu, D.G. Polymer-Based Nanofiber-Nanoparticle Hybrids and Their Medical Applications. Polymers 2022, 14, 351. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.T.; Liu, Y.W.; Lin, J.H.; Su, J.T.; Redshaw, C.; Feng, X.; Min, Y.G. Novel pyrene-based aggregation-induced emission luminogen (AIEgen) composite phase change fibers with satisfactory fluorescence anti-counterfeiting, temperature sensing, and high-temperature warning functions for solar-thermal energy storage. Adv. Compos. Hybrid. Mater. 2023, 6, 15. [Google Scholar] [CrossRef]

- Yang, Y.F.; Zhao, C.L.; Chen, X.D.; Yang, S.X.; Zhang, R.M.; Wang, Y.Q.; Wang, K.; Qian, J.; Long, L.L. Development of near-infrared fluorescent sensor and portable measuring device for on-site quantitation of Cys in food samples. Sens. Actuator B Chem. 2024, 414, 7. [Google Scholar] [CrossRef]

- Xue, K.; Wang, C.; Wang, J.X.; Lv, S.Y.; Hao, B.Y.; Zhu, C.L.; Tang, B.Z. A Sensitive and Reliable Organic Fluorescent Nanothermometer for Noninvasive Temperature Sensing. J. Am. Chem. Soc. 2021, 143, 14147–14157. [Google Scholar] [CrossRef]

- Hardianto, H.; Malengier, B.; De Mey, G.; Van Langenhove, L.; Hertleer, C. Textile yarn thermocouples for use in fabrics. J. Eng. Fiber Fabr. 2019, 14, 1558925019836092. [Google Scholar] [CrossRef]

- Mala, S.; Latha, H.K.E.; Udayakumar, A. Design and Fabrication of Indium Tin Oxide Based Thin Film Piezoresistive Pressure Sensor. Exp Tech. 2024, 14, 1–13. [Google Scholar] [CrossRef]

- Qi, F.X.; Xu, L.; He, Y.; Yan, H.; Liu, H. PVDF-Based Flexible Piezoelectric Tactile Sensors: Review. Cryst. Res. Technol. 2023, 58, 17. [Google Scholar] [CrossRef]

- Hujer, J.; Dancova, P.; Korinek, T.; Muller, M. Photolithographically Home-Made PVDF Sensor for Cavitation Impact Load Measurement. Processes 2021, 9, 1761. [Google Scholar] [CrossRef]

- Hari, M.A.; Karumuthil, S.C.; Rajan, L. Optimization of PVDF nanocomposite based flexible piezoelectric tactile sensors: A comparative investigation. Sens. Actuator A Phys. 2023, 353, 7. [Google Scholar]

- Hernández-Rivera, D.; Rodríguez-Roldán, G.; Mora-Martínez, R.; Suaste-Gómez, E. A Capacitive Humidity Sensor Based on an Electrospun PVDF/Graphene Membrane. Sensors 2017, 17, 1009. [Google Scholar] [CrossRef]

- Ooyama, Y.; Sugino, M.; EnoKi, T.; Yamamoto, K.; Tsunoji, N.; Ohshita, J. Aggregation-induced emission (AIE) characteristic of water-soluble tetraphenylethene (TPE) bearing four sulfonate salts. New J. Chem. 2017, 41, 4747–4749. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Qin, W.; Leung, N.L.C.; Arseneault, M.; Lam, J.W.Y.; Liang, G.D.; Sung, H.H.Y.; Williams, I.D.; Tang, B.Z. A mechanistic study of AIE processes of TPE luminogens: Intramolecular rotation vs. configurational isomerization. J. Mater. Chem. C 2016, 4, 99–107. [Google Scholar] [CrossRef]

- Wang, N.; Yao, H.; Tao, Q.; Sun, J.; Ma, H.; Wang, Y.; Zhou, C.C.; Fan, H.Y.; Shao, H.X.; Qin, A.J.; et al. TPE based aggregation induced emission fluorescent sensors for viscosity of liquid and mechanical properties of hydrogel. Chin. Chem. Lett. 2022, 33, 252–256. [Google Scholar] [CrossRef]

- Ji, F.Y.; Wang, P.L.; Li, Z.R.; Ji, K.X.; Wang, D.Y.; Ma, Q. Cu superparticle-based aggregation induced enhancement strategy with PVDF-HFP/CeVO4 NP sensing interface for miR-103a detection. Talanta 2024, 276, 9. [Google Scholar] [CrossRef]

- Sobhan, M.A.; Lebedev, A.; Chng, L.L.; Anariba, F. Rapid Fabrication of Photoluminescent Electrospun Nanofibers without the Need of Chemical Polymeric Backbone Modifications. J. Nanomater. 2018, 7, 1–7. [Google Scholar] [CrossRef]

- Peng, X.; Dai, Z.; Zhang, Q.; Gao, S.; Li, N. Intelligent microsphere-gel structures: Pioneering multi-range temperature sensing technology. Appl. Mater. Today 2024, 38, 102244. [Google Scholar] [CrossRef]

- Al-Abduljabbar, A.; Farooq, I. Electrospun Polymer Nanofibers: Processing, Properties, and Applications. Polymers 2022, 15, 65. [Google Scholar] [CrossRef] [PubMed]

- Vinh, N.; Kim, H.-M. Electrospinning Fabrication and Performance Evaluation of Polyacrylonitrile Nanofiber for Air Filter Applications. Appl. Sci. 2016, 6, 235. [Google Scholar] [CrossRef]

- Choi, S.Y.; Han, E.M.; Park, K.H. Porosity Control of Electrospun PAN/PMMA Nanofiber Webs. Mol. Cryst. Liq. Cryst. 2019, 688, 68–74. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, R.; Peng, X.; Li, N.; Dai, Z. Development of Support Layers and Their Impact on the Performance of Thin Film Composite Membranes (TFC) for Water Treatment. Polymers 2023, 15, 3290. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, W.; Yang, Z.; Chen, X.; Yu, D.-G.; Shao, J. Hybrid Films Prepared from a Combination of Electrospinning and Casting for Offering a Dual-Phase Drug Release. Polymers 2022, 14, 2132. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Milam-Guerrero, J.; Tai, Y.; Yang, S.; Choi, Y.Y.; Nam, J.; Myung, N.V. Maximizing Polyacrylonitrile Nanofiber Piezoelectric Properties through the Optimization of Electrospinning and Post-thermal Treatment Processes. Appl. Polym. Mater. 2021, 4, 635–644. [Google Scholar] [CrossRef]

- de Almeida, D.S.; Duarte, E.H.; Hashimoto, E.M.; Turbiani, F.R.B.; Muniz, E.C.; de Souza, P.R.; Gimenes, M.L.; Martins, L.D. Development and characterization of electrospun cellulose acetate nanofibers modified by cationic surfactant. Polym. Test. 2020, 81, 106206. [Google Scholar] [CrossRef]

- Shi, S.; Si, Y.; Han, Y.; Wu, T.; Iqbal, M.I.; Fei, B.; Li, R.K.Y.; Hu, J.; Qu, J. Recent Progress in Protective Membranes Fabricated via Electrospinning: Advanced Materials, Biomimetic Structures, and Functional Applications. Adv. Mater. 2022, 34, 2107938. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Zheng, Y.-M.; Zhang, B.-G.; Dai, Y.-R. A critical review on the electrospun nanofibrous membranes for the adsorption of heavy metals in water treatment. J. Hazard. Mater. 2021, 401, 123608. [Google Scholar] [CrossRef]

- Bhatta, T.; Sharma, S.; Shrestha, K.; Shin, Y.; Seonu, S.; Lee, S.; Kim, D.; Sharifuzzaman, M.; Rana, S.M.S.; Park, J.Y. Siloxene/PVDF Composite Nanofibrous Membrane for High-Performance Triboelectric Nanogenerator and Self-Powered Static and Dynamic Pressure Sensing Applications. Adv. Funct. Mater. 2022, 32, 15. [Google Scholar] [CrossRef]

- Xiong, J.P.; Wang, L.; Liang, F.H.; Li, M.Y.; Yabuta, Y.; Iqbal, M.A.; Mayakrishnan, G.; Shi, J.; Kim, I.S. Flexible Piezoelectric Sensor Based on Two-Dimensional Topological Network of PVDF/DA Composite Nanofiber Membrane. Adv. Fiber Mater. 2024, 17, 1212–1228. [Google Scholar] [CrossRef]

- Chen, H.; Li, N.; Lin, Y.S.; Dai, Z. Research progress on nanofiber-based support layers in forward/osmosis composite membranes. Fine Chem. 2023. [Google Scholar] [CrossRef]

- Wang, T.; Kumar, S. Electrospinning of polyacrylonitrile nanofibers. J. Appl. Polym. Sci. 2006, 102, 1023–1029. [Google Scholar] [CrossRef]

- Du, J.; Shintay, S.; Zhang, X. Diameter control of electrospun polyacrylonitrile/iron acetylacetonate ultrafine nanofibers. J. Polym. Sci. Pol. Phys. 2008, 46, 1611–1618. [Google Scholar] [CrossRef]

- Chang, W.M.; Wang, C.C.; Chen, C.Y. The combination of electrospinning and forcespinning: Effects on a viscoelastic jet and a single nanofiber. Chem. Eng. J. 2014, 244, 540–551. [Google Scholar] [CrossRef]

- Papkov, D.; Delpouve, N.; Delbreilh, L.; Araujo, S.; Stockdale, T.; Mamedov, S.; Maleckis, K.; Zou, Y.; Andalib, M.N.; Dargent, E.; et al. Quantifying Polymer Chain Orientation in Strong and Tough Nanofibers with Low Crystallinity: Toward Next Generation Nanostructured Superfibers. ACS Nano 2019, 13, 4893–4927. [Google Scholar] [CrossRef]

- Kirecci, A.; Özkoç, Ü.; Içoglu, H.I. Determination of optimal production parameters for polyacrylonitrile nanofibers. J. Appl. Polym. Sci. 2012, 124, 4961–4968. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Asteris, P.G. A comparative study of ANN and ANFIS models for the prediction of cement-based mortar materials compressive strength. Neural Comput. Appl. 2020, 33, 4501–4532. [Google Scholar] [CrossRef]

- Premasudha, M.; Bhumi Reddy, S.R.; Lee, Y.J.; Panigrahi, B.B.; Cho, K.K.; Nagireddy Gari, S.R. Using artificial neural networks to model and interpret electrospun polysaccharide (Hylon VII starch) nanofiber diameter. J. Appl. Polym. Sci. 2020, 138, 50014. [Google Scholar] [CrossRef]

- Santos, A.F.; Aguado, R.; Corazza, M.L.; Tarrés, Q.; Sanchez-Salvador, J.-L.; Blanco, A.; Negro, C.; Delgado-Aguilar, M. Artificial neural network for aspect ratio prediction of lignocellulosic micro/nanofibers. Cellulose 2022, 29, 5609–5622. [Google Scholar] [CrossRef]

- Ahmad, T.; Chen, H.X. A review on machine learning forecasting growth trends and their real-time applications in different energy systems. Sust. Cities Soc. 2020, 54, 27. [Google Scholar] [CrossRef]

- Lakshmi Narayana, P.; Wang, X.S.; Yeom, J.T.; Maurya, A.K.; Bang, W.S.; Srikanth, O.; Harinatha Reddy, M.; Hong, J.K.; Subba Reddy, N.G. Correlating the 3D melt electrospun polycaprolactone fiber diameter and process parameters using neural networks. J. Appl. Polym. Sci. 2021, 138, 50956. [Google Scholar] [CrossRef]

- Samadian, H.; Zakariaee, S.S.; Faridi-Majidi, R. Evaluation of effective needleless electrospinning parameters controlling polyacrylonitrile nanofibers diameter via modeling artificial neural networks. J. Text. Inst. 2019, 110, 477–486. [Google Scholar] [CrossRef]

- Khatti, T.; Naderi-Manesh, H.; Kalantar, S.M. Prediction of diameter in blended nanofibers of polycaprolactone-gelatin using ANN and RSM. Fiber Polym. 2017, 18, 2368–2378. [Google Scholar] [CrossRef]

- Ma, M.; Zhou, H.C.; Gao, S.H.; Li, N.; Guo, W.J.; Dai, Z. Analysis and Prediction of Electrospun Nanofiber Diameter Based on Artificial Neural Network. Polymers 2023, 15, 2813. [Google Scholar] [CrossRef]

- Wang, F.J.; Elbadawi, M.; Tsilova, S.L.; Gaisford, S.; Basit, A.W.; Parhizkar, M. Machine learning to empower electrohydrodynamic processing. Mater. Sci. Eng. C Mater. Biol. Appl. 2022, 132, 14. [Google Scholar] [CrossRef] [PubMed]

- Rubio, J.D. Stability Analysis of the Modified Levenberg-Marquardt Algorithm for the Artificial Neural Network Training. IEEE Trans. Neural Net. Lear 2021, 32, 3510–3524. [Google Scholar] [CrossRef] [PubMed]

- Sherwani, F.; Ibrahim, B.; Asad, M.M. Hybridized classification algorithms for data classification applications: A review. Egypt Inform. J. 2021, 22, 185–192. [Google Scholar] [CrossRef]

- Reddy, B.S.; In, K.H.; Panigrahi, B.B.; Paturi, U.M.R.; Cho, K.K.; Reddy, N.S. Modeling tensile strength and suture retention of polycaprolactone electrospun nanofibrous scaffolds by artificial neural networks. Mater. Today Commun. 2021, 26, 102115. [Google Scholar] [CrossRef]

- Malayeri, M.; Nasiri, F.; Haghighat, F.; Lee, C.S. Optimization of photocatalytic oxidation reactor for air purifier design: Application of artificial neural network and genetic algorithm. Chem. Eng. J. 2023, 462, 12. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Mirzaei, F.; Shariati, M.; Trung, N.T.; Shariati, M.; Trnavac, D. Hybrid ANN-based techniques in predicting cohesion of sandy-soil combined with fiber. Geomech. Eng. 2020, 20, 191–205. [Google Scholar]

- Han, Y.; Liu, B.; Wu, Y.F.; Mao, Y.Y.; Zhao, L.L.; Nan, T.; Wang, J.; Zhang, Y.L.; Tang, R.; Liu, Y.; et al. High-sensitivity high-temperature sensor based on multi-microspheres improved Michelson interferometer. Opt. Commun. 2021, 491, 7. [Google Scholar] [CrossRef]

- Wang, K.; He, Q.; Yang, D.R.; Pi, X.D. Erbium-Hyperdoped Silicon Quantum Dots: A Platform of Ratiometric Near-Infrared Fluorescence. Adv. Opt. Mater. 2022, 10, 9. [Google Scholar] [CrossRef]

- Chen, M.H.; He, Y.C.; Liang, H.H.; Zhou, H.Y.; Wang, X.; Heng, X.B.; Zhang, Z.S.; Gan, J.L.; Yang, Z.M. Stretchable and Strain-Decoupled Fluorescent Optical Fiber Sensor for Body Temperature and Movement Monitoring. ACS Photonics 2022, 9, 1415–1424. [Google Scholar] [CrossRef]

- Listewnik, P.; Bechelany, M.; Wierzba, P.; Szczerska, M. Optical-Fiber Microsphere-Based Temperature Sensors with ZnO ALD Coating-Comparative Study. Sensors 2021, 21, 4982. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, X.B.; Zhang, Q.; Xie, Y.; Wang, Z.J.; Yu, Y.; Wang, Y.; Dong, Y.H.; Huang, Y.; Wang, T.Y. Packaged Temperature Sensor Based on Fluorescent Microsphere With an Embedded Fiber Microlens. IEEE Photonics Technol. Lett. 2023, 35, 398–401. [Google Scholar] [CrossRef]

- Yu, J.B.; Lewis, E.; Brambilla, G.; Wang, P.F. Temperature Sensing Performance of Microsphere Resonators. Sensors 2018, 18, 2515. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.V.; Nguyen, T.D.; Mai, H.H.; Pham, N.V.; Ta, V.D.; Nguyen, T.A. Biological miniature temperature sensor based on monodisperse microsphere lasers fabricated by soft microfluidic technology. J. Phys. D Appl. Phys. 2022, 55, 5. [Google Scholar] [CrossRef]

- Park, T.H.; Park, S.; Yu, S.; Park, S.; Lee, J.; Kim, S.; Jung, Y.; Yi, H. Highly Sensitive On-Skin Temperature Sensors Based on Biocompatible Hydrogels with Thermoresponsive Transparency and Resistivity. Adv. Healthc. Mater. 2021, 10, e2100469. [Google Scholar] [CrossRef]

- Zhuo, C.; Yu, X.; Cheng, Y.; Liu, S.; Zhu, M.; Wang, X. Three-in-One: AIEgen End-Labeling of CO2 Polymer for Visible Fiber Thermometer. Macromolecules 2023, 56, 5610–5618. [Google Scholar] [CrossRef]

| Component Materials | Structure | Average Particle Size | Temperature Measurement Method | Temperature Range | Sensitivity |

|---|---|---|---|---|---|

| SiO2 | Arrays | 220 µm | Ratio of FL | 100–800 °C | 0.15 nm/°C [50] |

| Er3+-Silica | Core–shell | 4 µm | Emission intensity | 4–204 °C | −0.53/K [51] |

| Y2O3@Er3+/Yb3+-Silica | Core–shell | 800 µm | Current ratio | −10–60 °C | 1.3%/°C [52] |

| ZnO-Silica | Shell–core | 100 µm | Peak position | 100–300 °C | 0.019 nm/°C [53] |

| Er3--Yb3+@ Tellurite glass | Hollow | 50 µm | Ratio of FL Intensity | 30–110 °C | 1.11 × 10−2/K [54] |

| PS | Solid | 91.7 µm | WGM Wavelength shift | 20–70 °C | 0.61796 nm/°C [55] |

| PDMS | Solid | 85 µm | Laser wavelength | 25–50 °C | 0.47 nm/°C [56] |

| E-skin | Solid | 3 µm | Resistive | 0–40 °C | 0.0127 °C−1 [55] |

| AIE-PPC | Solid | 576 nm | Laser wavelength | −40–140 | 0.01 mm/°C [56] |

| This work | Solid | 680 nm | Gray value | 20–100 °C | −0.632 gray value/°C |

| This work | Solid | 680 nm | FL emission value | 20–100 °C | −7.3 a.u./°C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, M.; Jin, C.; Yao, S.; Li, N.; Zhou, H.; Dai, Z. CNN-Optimized Electrospun TPE/PVDF Nanofiber Membranes for Enhanced Temperature and Pressure Sensing. Polymers 2024, 16, 2423. https://doi.org/10.3390/polym16172423

Ma M, Jin C, Yao S, Li N, Zhou H, Dai Z. CNN-Optimized Electrospun TPE/PVDF Nanofiber Membranes for Enhanced Temperature and Pressure Sensing. Polymers. 2024; 16(17):2423. https://doi.org/10.3390/polym16172423

Chicago/Turabian StyleMa, Ming, Ce Jin, Shufang Yao, Nan Li, Huchen Zhou, and Zhao Dai. 2024. "CNN-Optimized Electrospun TPE/PVDF Nanofiber Membranes for Enhanced Temperature and Pressure Sensing" Polymers 16, no. 17: 2423. https://doi.org/10.3390/polym16172423

APA StyleMa, M., Jin, C., Yao, S., Li, N., Zhou, H., & Dai, Z. (2024). CNN-Optimized Electrospun TPE/PVDF Nanofiber Membranes for Enhanced Temperature and Pressure Sensing. Polymers, 16(17), 2423. https://doi.org/10.3390/polym16172423