Study on the Relationship between Electron Transfer and Electrical Properties of XLPE/Modification SR under Polarity Reversal

Abstract

:1. Introduction

2. Sample Preparation and Experimental Methods

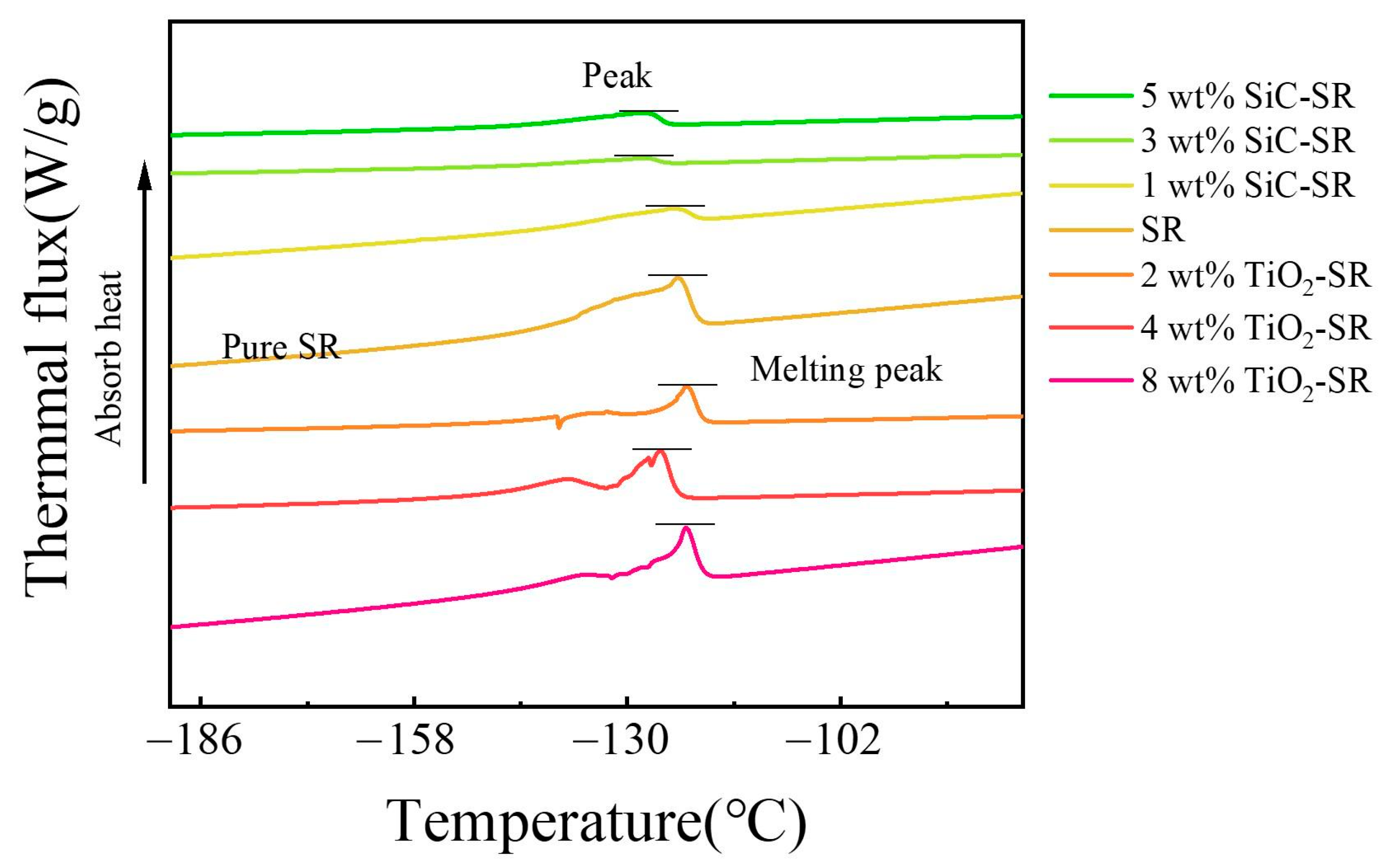

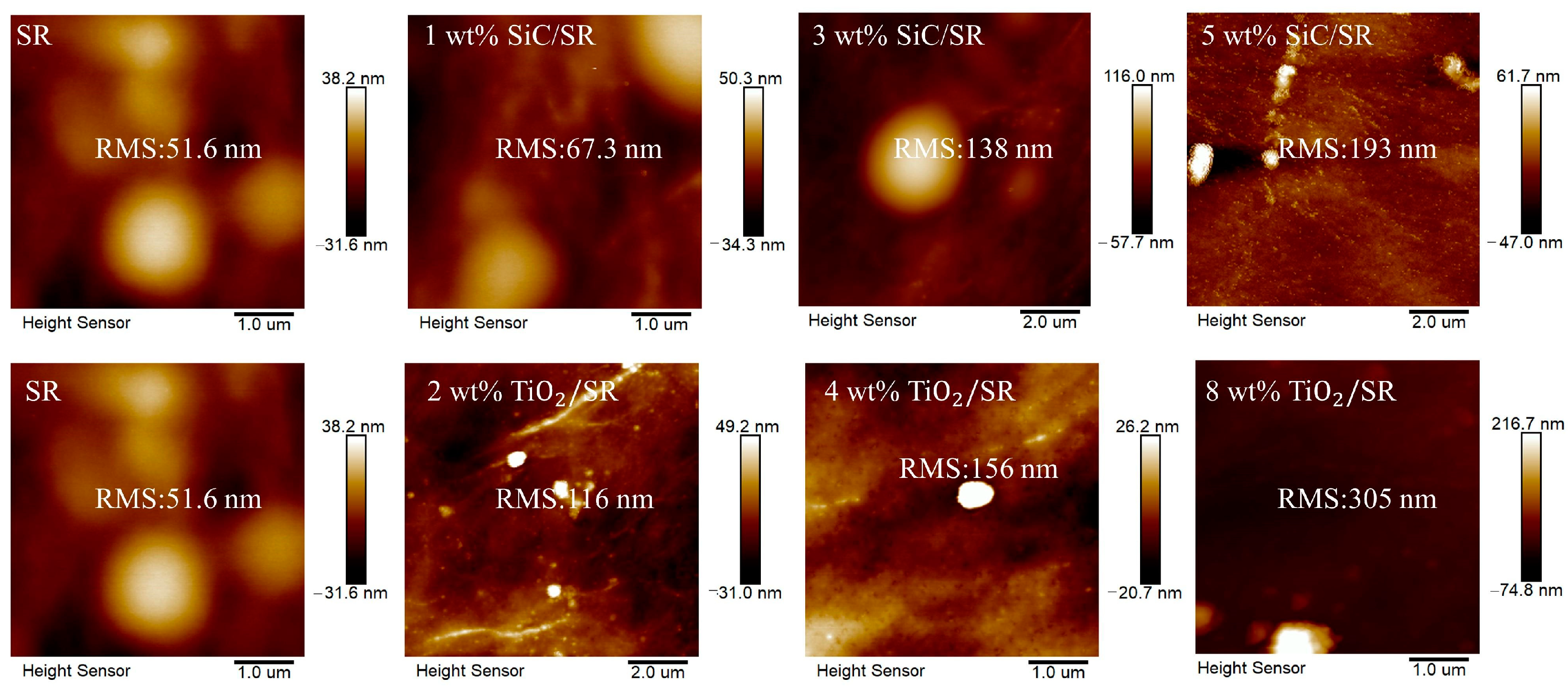

2.1. Preparation of Nano-Doped SiC-SR and TiO2-SR Composite Materials

2.2. Preparation of Sheet-like Specimens of XLPE and SiC-SR, TiO2-SR Nanocomposites

2.2.1. Preparation of XLPE Sheet-like Specimens

2.2.2. Preparation of SiC-SR and TiO2-SR Sheet-like Specimens

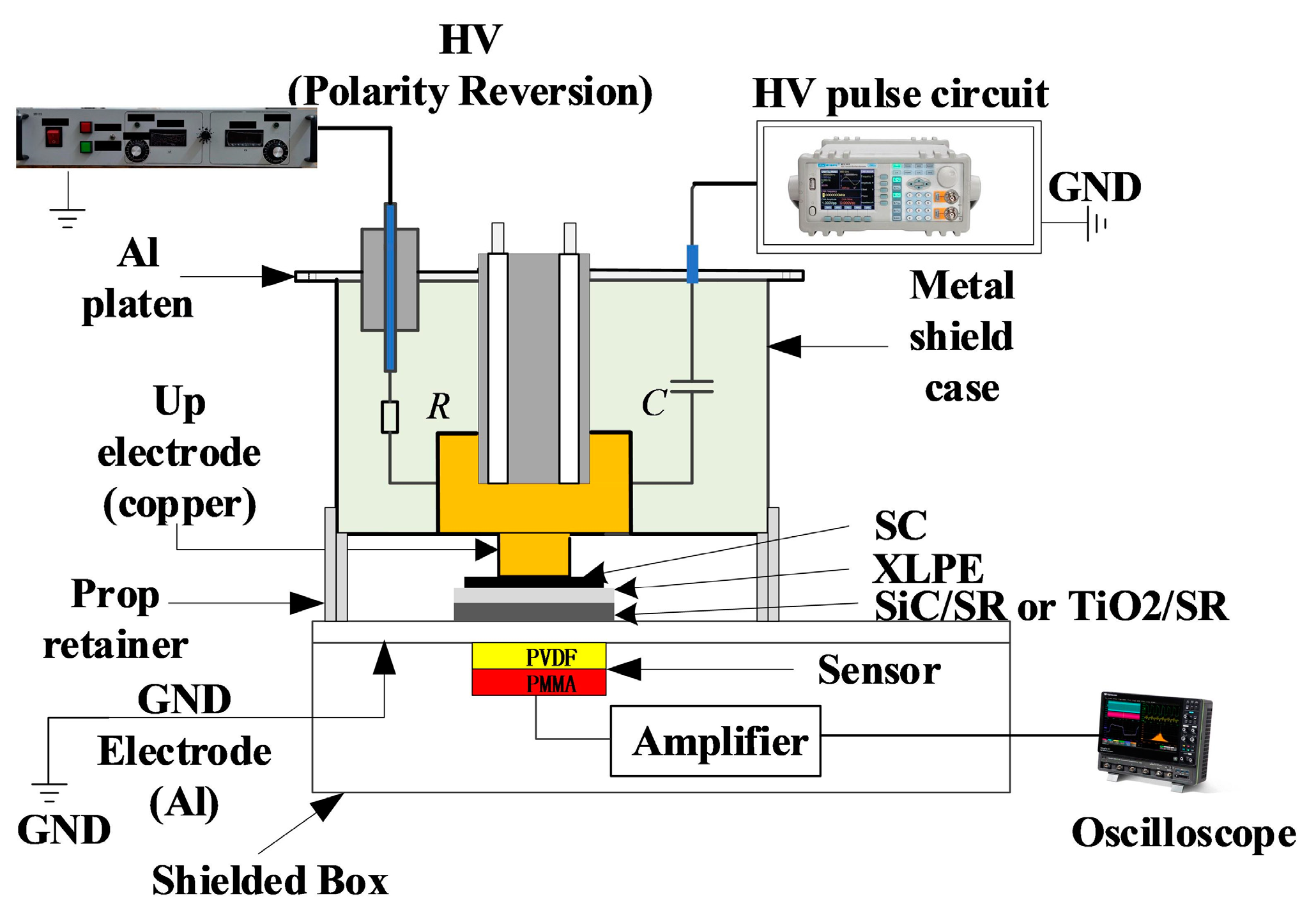

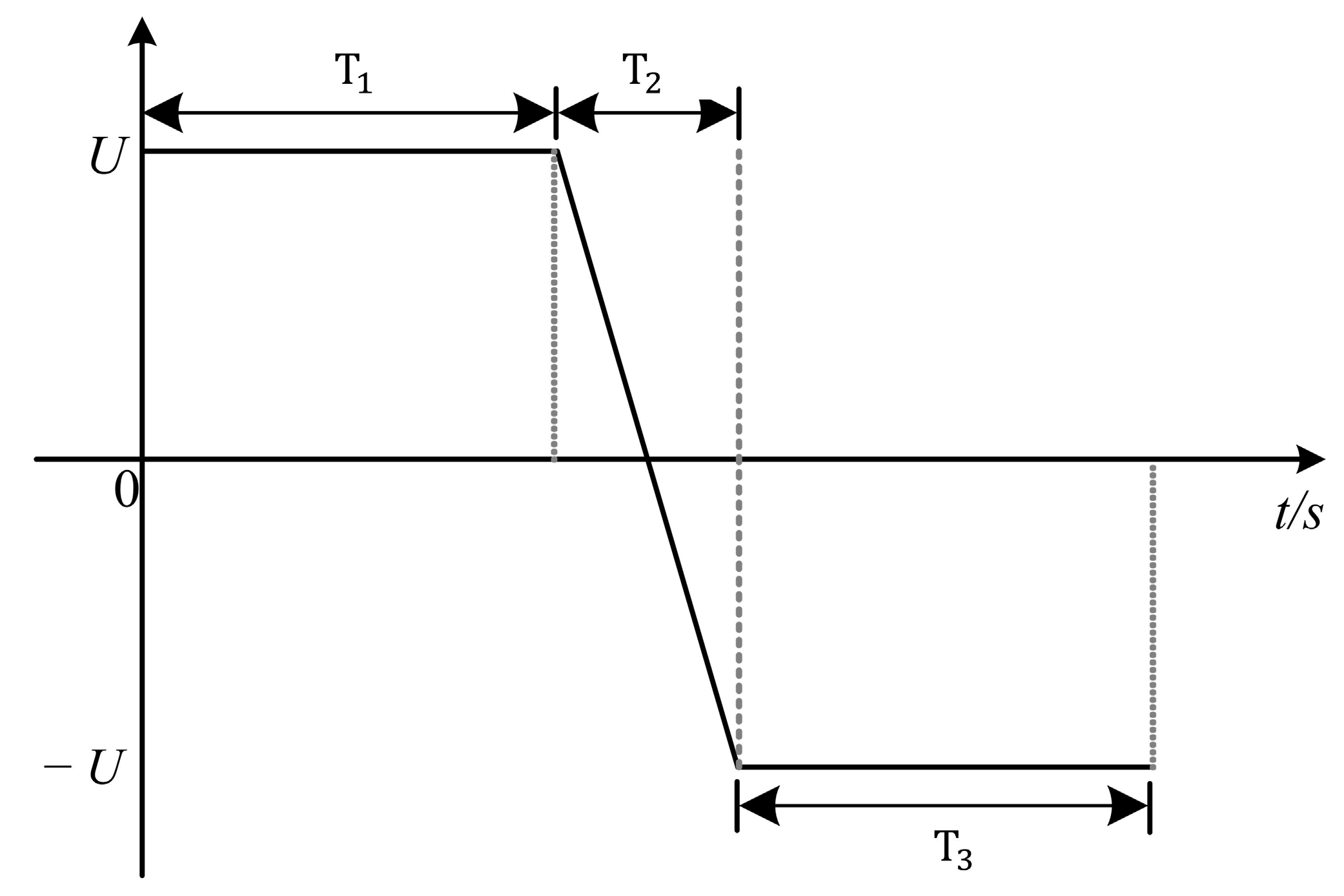

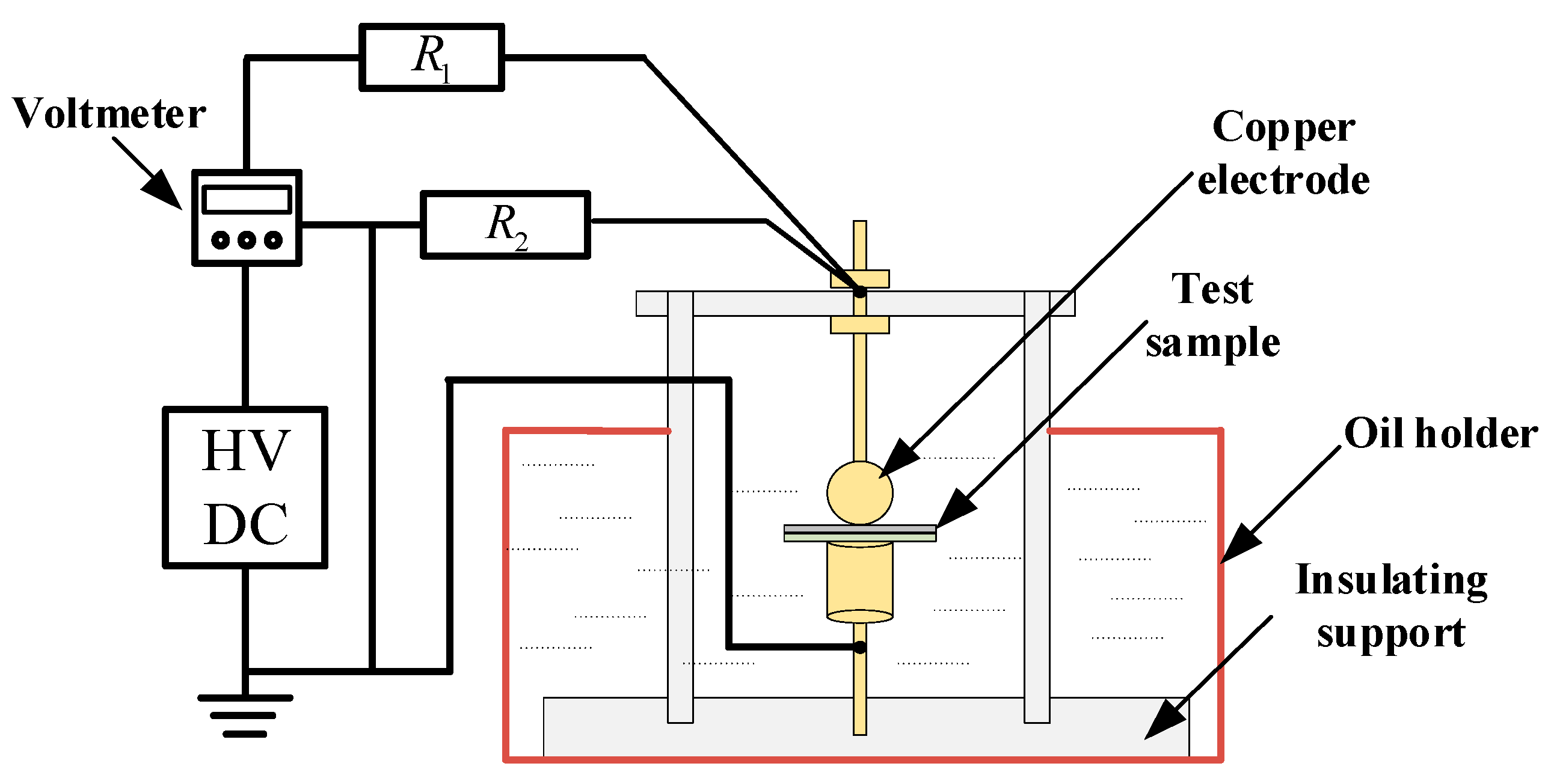

2.3. Polarity Reversal PEA Testing Platform and Testing Methods

2.4. Breakdown Testing Platform and Testing Methods

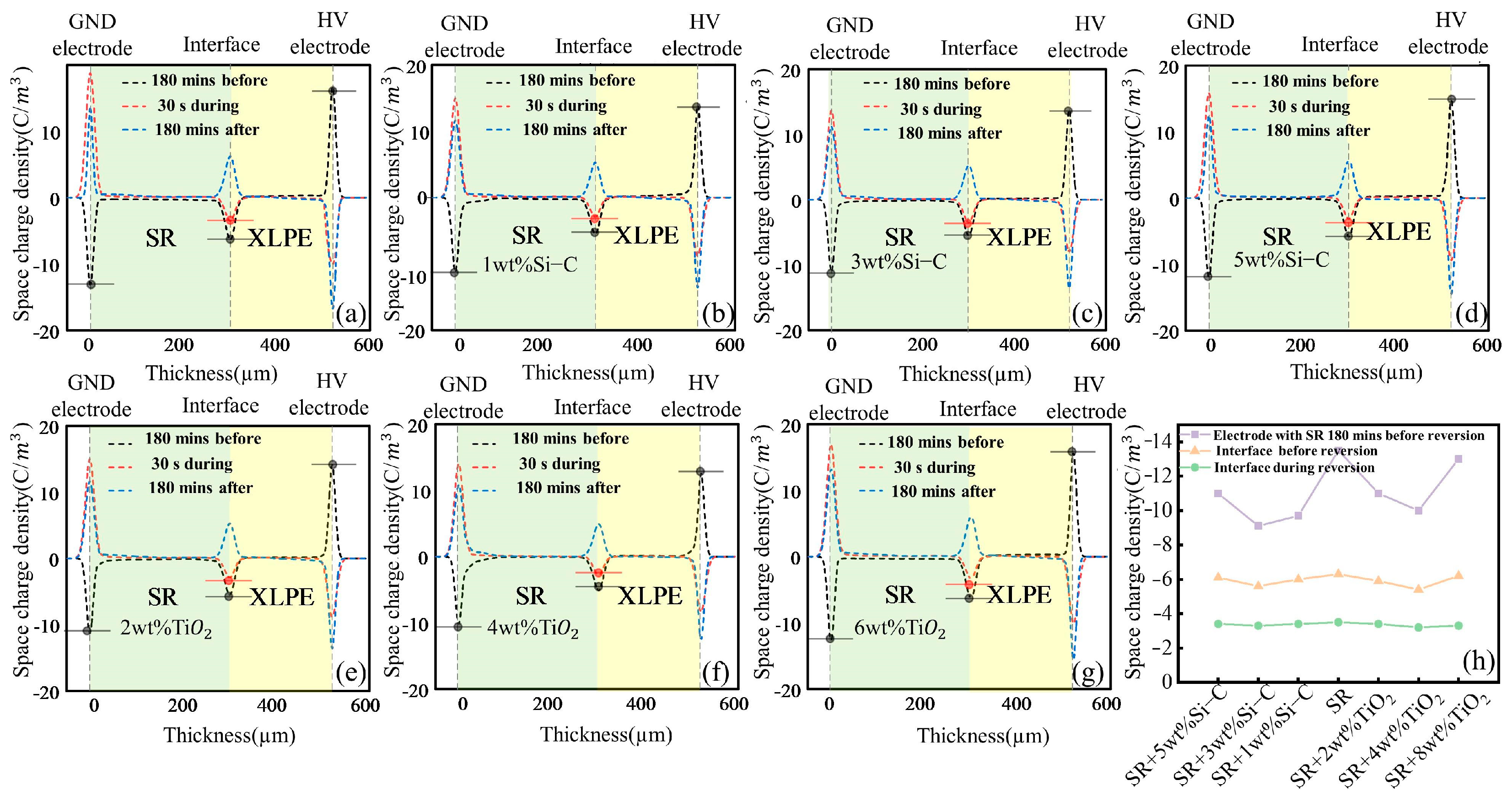

3. Space Charge Distribution under Polarity Reversal

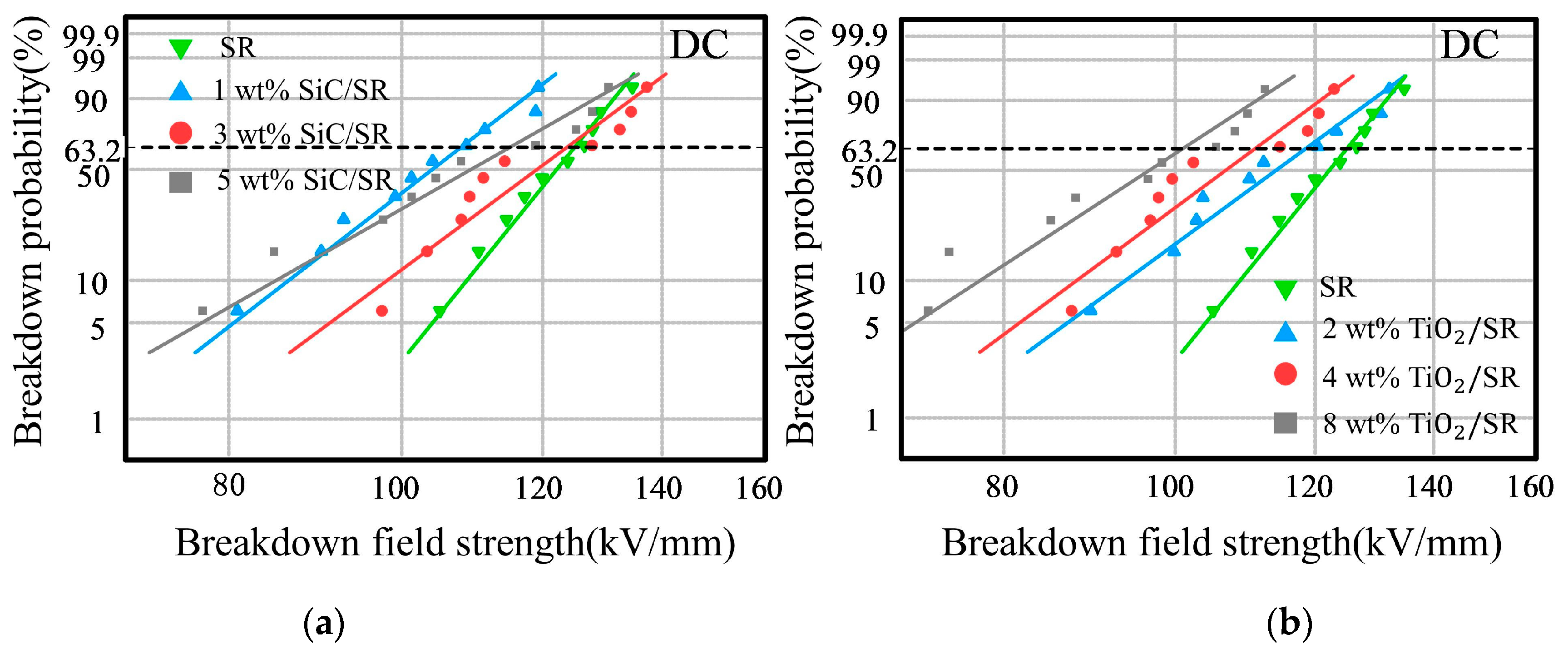

4. Macroscopic Electrical Properties under Polarity Reversal

5. Conclusions

- (1)

- Doping nanoparticles does not alter the overall trend of space charge distribution in double-layer media under polarity reversal conditions.

- (2)

- Doping nanoparticles reduces the variation in space charge at the interface of the double-layer SR/XLPE under polarity reversal, making the “hysteresis effect” more pronounced. Specifically, the time required for space charge to accumulate at the interface after polarity reversal is shorter.

- (3)

- Within the doping concentration limits, increased doping concentration leads to a decrease in interface charge accumulation. SiC particles at 3 wt% exhibit a significant inhibitory effect on interface charge accumulation, while the TiO2 at 4 wt% concentration effectively reduces the maximum distorted electric field intensity, which correlates with enhanced macroscopic breakdown strength.

- (4)

- Doping nanoparticles improved the breakdown strength of the double-layer SR/XLPE, with notable improvements under polarity reversal conditions. Specifically, doping concentration with 4 wt% TiO2 increased the breakdown strength of the double-layer medium under polarity reversal by 21.38%.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Du, B.; Han, C.; Li, J. Research status of polyethylene insulation materials for high-voltage DC cables. Trans. China Electrotech. Soc. 2019, 34, 179–191. [Google Scholar]

- Zhao, J.; Zhao, P.; Chen, Z. Review of research progress on insulation materials for high-voltage DC cables. High Volt. Eng. 2017, 43, 3490–3503. [Google Scholar]

- He, J.; Dang, B.; Zhou, Y. Research progress and key technology review of extruded high-voltage direct current cables. High Volt. Eng. 2015, 41, 1417–1429. [Google Scholar]

- Tang, G.; Pang, H.; He, Z. Development and Application of Advanced AC/DC Transmission Technology in China. Proceeding CSEE 2016, 36, 1760–1771. [Google Scholar]

- Morshuis, P.; Cavallini, A.; Fabiani, D.; Montanari, G.C.; Azcarraga, C. Stress conditions in HVDC equipment and routes to in service failure. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 81–91. [Google Scholar] [CrossRef]

- Luo, S. Study on Space Charge of Carbon Black/Polyethylene Composite under Polarity Reversal; North China Electric Power University: Beijing, China, 2017. [Google Scholar]

- Li, G.; An, T.; Liang, J.; Liu, W.; Joseph, T.; Lu, J.; Szechtman, M.; Andersen, B.R.; Lan, Y. Power reversal strategies for hybrid LCC/MMC HVDC systems. CSEE J. Power Energy Syst. 2020, 6, 203–212. [Google Scholar]

- Lan, L. The Effect of Temperature on Space Charge Behavior in Polymer Insulation; Shanghai Jiaotong University: Shanghai, China, 2015. [Google Scholar]

- Wang, X.; Liu, X.; Zheng, M. He mechanism of space charge formation at the interface between silicone rubber and cross-linked polyethylene under temperature gradient field. High Volt. Eng. 2011, 37, 2424–2430. [Google Scholar]

- Du, B.X.; Yang, Z.R.; Li, Z.L.; Li, J. Nonlinear conductivity and charge transport characteristics of silicone rubber/SiC composites under impulse superimposed on DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 776–783. [Google Scholar] [CrossRef]

- Qin, J. Study on the Dielectric and Space Charge Characteristics of Liquid Silicone Rubber Modified with Nano-TiO2; Harbin University of Science and Technology: Harbin, China, 2018. [Google Scholar]

- Chen, X.; Wu, K.; Wang, X. Research on Nanoparticle Modified Polyethylene DC Cable Insulation Materials(I). High Volt. Eng. 2012, 38, 2691–2697. [Google Scholar]

- Fu, M.; Dissado, L.A.; Chen, G.; Fothergill, J.C. Space charge formation and its modified electric field under applied voltage reversal and temperature gradient in XLPE cable. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 851–860. [Google Scholar] [CrossRef]

- Xiang, M. Study on the AC/DC Superposition and Polarity Reversal Characteristics of Nano Al2O3 Modified Paper at Different Heat Aging Stages; Chongqing University: Chongqing, China, 2018. [Google Scholar]

- Yang, J.; Wang, X.; Han, B. The DC conductivity characteristics of LDPE nanocomposite media and its influence on the electric field distribution in high-voltage DC cables. Proceeding CSEE 2014, 34, 1454–1461. [Google Scholar]

- Grunlan, J.C.; Bloom, F.L.; Gerberich, W.W.; Francis, L.F. Effect of dispersing aid on electrical and mechanical behavior of carbon black-filled latex. J. Mater. Sci. Lett. 2001, 20, 1523–1526. [Google Scholar] [CrossRef]

- Xia, J.; Li, Z.; Nasreen, S.; Ronzello, J.; Teng, H.; Jacobs, L.; Cao, Y. Discharge Resistant Nano-Coatings. In Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21–24 October 2018. [Google Scholar]

- Choi, J.H.; Kim, S.H.; Jang, K.; Hikita, M.; Lee, S.-H. Finite-element analysis for surface discharge due to interfacial polarization at the oil-nanocomposite interface. IEEE Trans. Magn. 2017, 54, 1–4. [Google Scholar] [CrossRef]

- Preetha, P.; Alapati, S.; Singha, S.; Venkatesulu, B.; Thomas, M.J. Electrical discharge resistant characteristics of epoxy nanocomposites. In Proceedings of the 2008 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008. [Google Scholar]

- Zhang, X.; Jiang, J.; Shen, Z.; Dan, Z.; Li, M.; Lin, Y.; Nan, C.; Chen, L.; Shen, Y. Polymer nanocomposites with ultrahigh energy density and high discharge efficiency by modulating their nanostructures in three dimensions. Adv. Mater. 2018, 30, e1707269. [Google Scholar] [CrossRef]

- Shang, N.; Chen, Q.; Wei, X. Preparation and dielectric properties of SiC/LSR nanocomposites for insulation of high voltage direct current cable accessories. Materials 2018, 11, 403. [Google Scholar] [CrossRef]

- Taj, M.N.; Darukaprasad, B.; Rao, N.R.; Nagabhushana, H.; Anantharaju, K.S.; Murugendrappa, M.V. Polymer-silicate nanocomposities: Package material for nanodevices as an EMI shielding. Mater. Today Proc. 2021, 46, 6017–6021. [Google Scholar]

- Ismail, N.H.; Mustapha, M. A review of thermoplastic elastomeric nanocomposites for high voltage insulation applications. Polym. Eng. Sci. 2018, 58, E36–E63. [Google Scholar] [CrossRef]

- Xu, M.; Cao, X.; Yu, B. Study on the Properties of Nano SiO2/Epoxy Resin Composite System (II) Dielectric and Mechanical Properties of Composite Materials. Polym. Mater. Sci. Eng. 2005, 21, 156–159. [Google Scholar]

- Liang, M.; Wong, K.L. Improving the long-term performance of composite insulators use nanocomposite: A review. Energy Procedia 2017, 110, 168–173. [Google Scholar] [CrossRef]

- Zou, J.; Liu, D.; Zhao, J.; Hou, L.; Liu, T.; Zhang, X.; Zhao, Y.; Zhu, Y.T.; Li, Q. Ni nanobuffer layer provides light-weight CNT/Cu fibers with superior robustness, conductivity, and ampacity. ACS Appl. Mater. Interfaces 2018, 10, 8197–8204. [Google Scholar] [CrossRef] [PubMed]

- Abdul-Hussein, A.B.; Kareem, E.S.A.; Atallah, M.S. Effect of carbon nano tubes on erosion wear of carbon fiber, glass fiber & kevlar fiber reinforced unsaturated polyester composites. J. Eng. Sustain. Dev. 2018, 22, 74–89. [Google Scholar]

- Yang, L.; Zhang, M.; Hou, B.; Mi, M.; Wu, M.; Zhu, Q.; Zhu, J.; Lu, Y.; Chen, L.; Zhou, X.; et al. High channel conductivity, breakdown field strength, and low current collapse in AlGaN/GaN/Si-Doped AlGaN/GaN: C HEMTs. IEEE Trans. Electron Devices 2019, 66, 1202–1207. [Google Scholar] [CrossRef]

- Weerasinghe, J.L. Dynamical Properties of Ferroelectric Perovskites (Barium, Strontium) Titanate and Lead (Zirconium, Titanium) Oxide Systems from First Principles; University of Arkansas: Fayetteville, NC, USA, 2012. [Google Scholar]

- Bousquet, E.; Fava, M.; Romestan, Z.; Gómez-Ortiz, F.; McCabe, E.E.; Romero, A.H. Structural chirality and related properties in the periodic inorganic solids: Review and perspectives. arXiv 2024, arXiv:2406.14684. [Google Scholar]

| Sample Type | Undoped Pure SR | 1 wt% SiC-SR | 3 wt% SiC-SR | 5 wt% SiC-SR |

|---|---|---|---|---|

| Zeta potential (mV) | 52 | 51 | 48 | 42 |

| Sample type | Undoped pure SR | 2 wt% TiO2-SR | 4 wt% TiO2-SR | 8 wt% TiO2-SR |

| Zeta potential (mV) | 44 | 41 | 40 | 39 |

| Accessory | Type |

|---|---|

| DC high-voltage source | BGHX-20 kV |

| protective resistor | 100 MΩ film resistor |

| oscilloscope | Lecroy HDO6054 |

| pulse signal source | RIGOL2017B |

| Sample Type | Undoped Pure SR | 1 wt% SiC−SR | 3 wt% SiC−SR | 5 wt% SiC−SR |

|---|---|---|---|---|

| peak variation (C/m3) | 2.8 | 2.6 | 2.3 | 2.7 |

| Sample type | Undoped pure SR | 2 wt% TiO2−SR | 4 wt% TiO2−SR | 8 wt% TiO2−SR |

| peak variation (C/m3) | 2.8 | 2.5 | 2.2 | 2.9 |

| Sample Type | Undoped Pure SR | 1 wt% SiC-SR | 3 wt% SiC-SR | 5 wt% SiC-SR |

|---|---|---|---|---|

| Shape parameter | 16.21 | 10.14 | 9.72 | 7.47 |

(kV/mm) | 125 | 107.89 | 123.73 | 114.91 |

| Sample Type | Undoped Pure SR | 2 wt% TiO2-SR | 4 wt% TiO2-SR | 8 wt% TiO2-SR |

|---|---|---|---|---|

| Shape parameter | 16.21 | 9.61 | 10.31 | 8.55 |

(kV/mm) | 125 | 118.43 | 111.14 | 100.89 |

| Sample Type | Undoped Pure SR | 1 wt% SiC−SR/XLPE | 3 wt% SiC−SR/XLPE | 5 wt% SiC−SR/XLPE |

|---|---|---|---|---|

| Shape parameter | 7.3 | 11.06 | 15.15 | 10.05 |

(kV/mm) | 139.89 | 149.99 | 181.07 | 152.86 |

| Sample Type | Undoped Pure SR | 2 wt% TiO2-SR/XLPE | 4 wt% TiO2-SR/XLPE | 8 wt% TiO2-SR/XLPE |

|---|---|---|---|---|

| Shape parameter | 7.3 | 12.23 | 9.98 | 6.96 |

(kV/mm) | 139.89 | 165.38 | 169.80 | 126.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.-Y.; Jin, Y.-Z.; Shi, Z.-X.; Wang, Z.-Y.; Wang, W. Study on the Relationship between Electron Transfer and Electrical Properties of XLPE/Modification SR under Polarity Reversal. Polymers 2024, 16, 2356. https://doi.org/10.3390/polym16162356

Wu Z-Y, Jin Y-Z, Shi Z-X, Wang Z-Y, Wang W. Study on the Relationship between Electron Transfer and Electrical Properties of XLPE/Modification SR under Polarity Reversal. Polymers. 2024; 16(16):2356. https://doi.org/10.3390/polym16162356

Chicago/Turabian StyleWu, Zhi-Yuan, Yu-Zhi Jin, Zhe-Xu Shi, Zhi-Yuan Wang, and Wei Wang. 2024. "Study on the Relationship between Electron Transfer and Electrical Properties of XLPE/Modification SR under Polarity Reversal" Polymers 16, no. 16: 2356. https://doi.org/10.3390/polym16162356

APA StyleWu, Z.-Y., Jin, Y.-Z., Shi, Z.-X., Wang, Z.-Y., & Wang, W. (2024). Study on the Relationship between Electron Transfer and Electrical Properties of XLPE/Modification SR under Polarity Reversal. Polymers, 16(16), 2356. https://doi.org/10.3390/polym16162356