Thermoplastic Vulcanizates with an Integration of High Wear-Resistant and Anti-Slip Properties Based on Styrene Ethylene Propylene Styrene Block Copolymer/Styrene Ethylene Butylene Styrene Block Copolymer/Solution-Polymerization Styrene-Butadiene Rubber

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials and Equipment

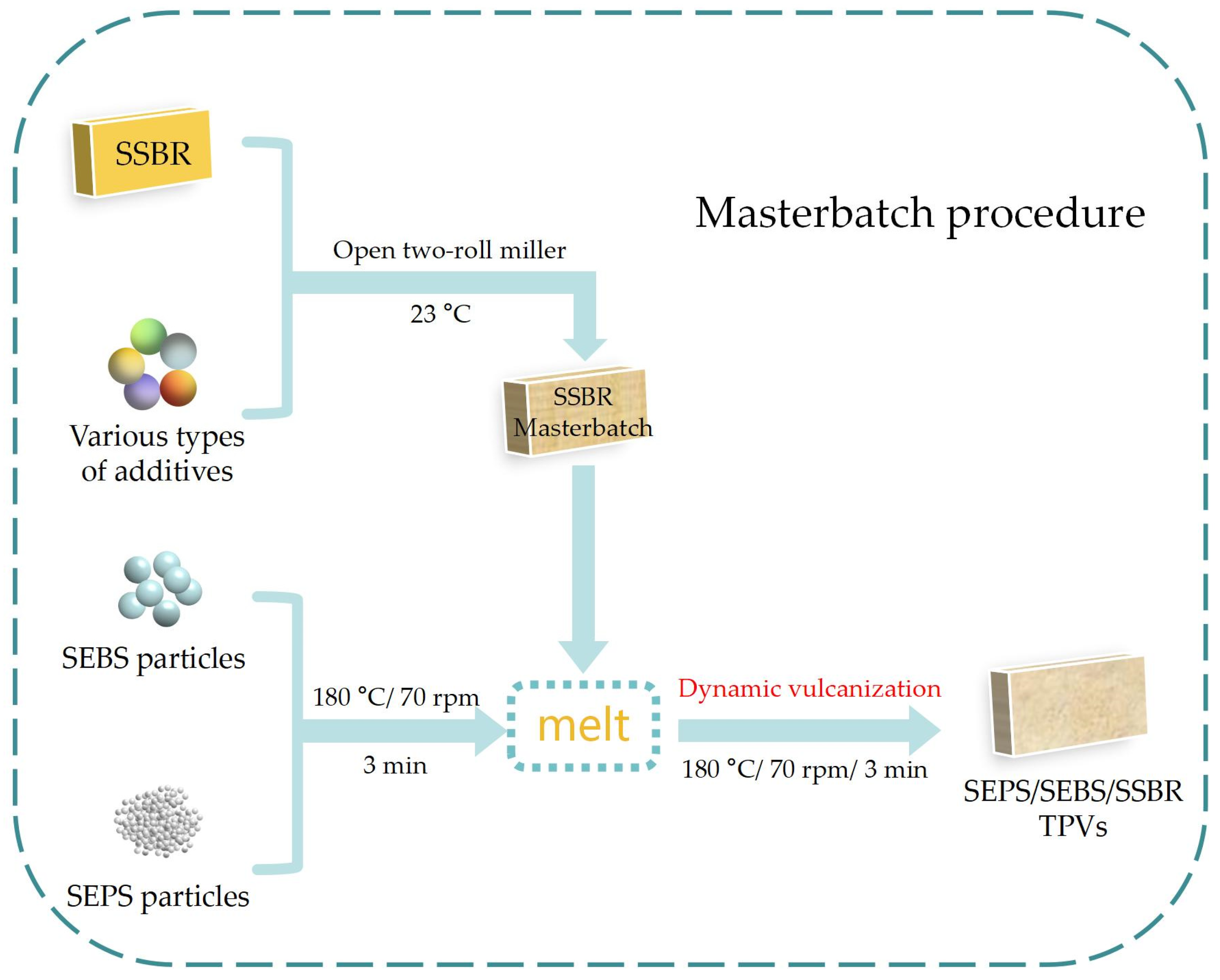

2.2. Sample Preparation

2.2.1. Preparation of SSBR Masterbatch

2.2.2. Preparation of Mixed SEPS/SEBS/SSBR

2.3. Characterization

2.3.1. Mechanical Properties

2.3.2. Torque–Time Curves of DV Process

2.3.3. Melt Flow Rate

2.3.4. Abrasion Resistance

2.3.5. Morphological Analysis

2.3.6. Aging Resistance

2.3.7. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

3.1. Torque Profiles during Preparation of SSBR/TPE TPVs

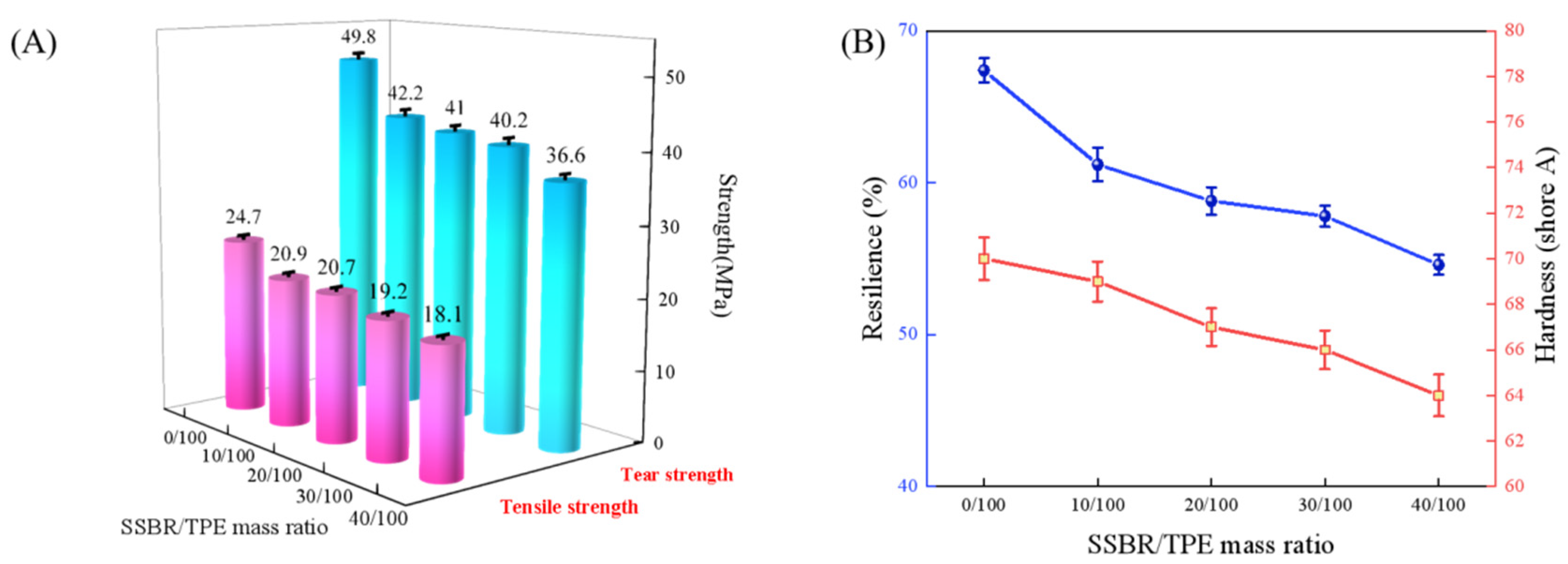

3.2. Mechanical Properties of SSBR/TPE TPVs

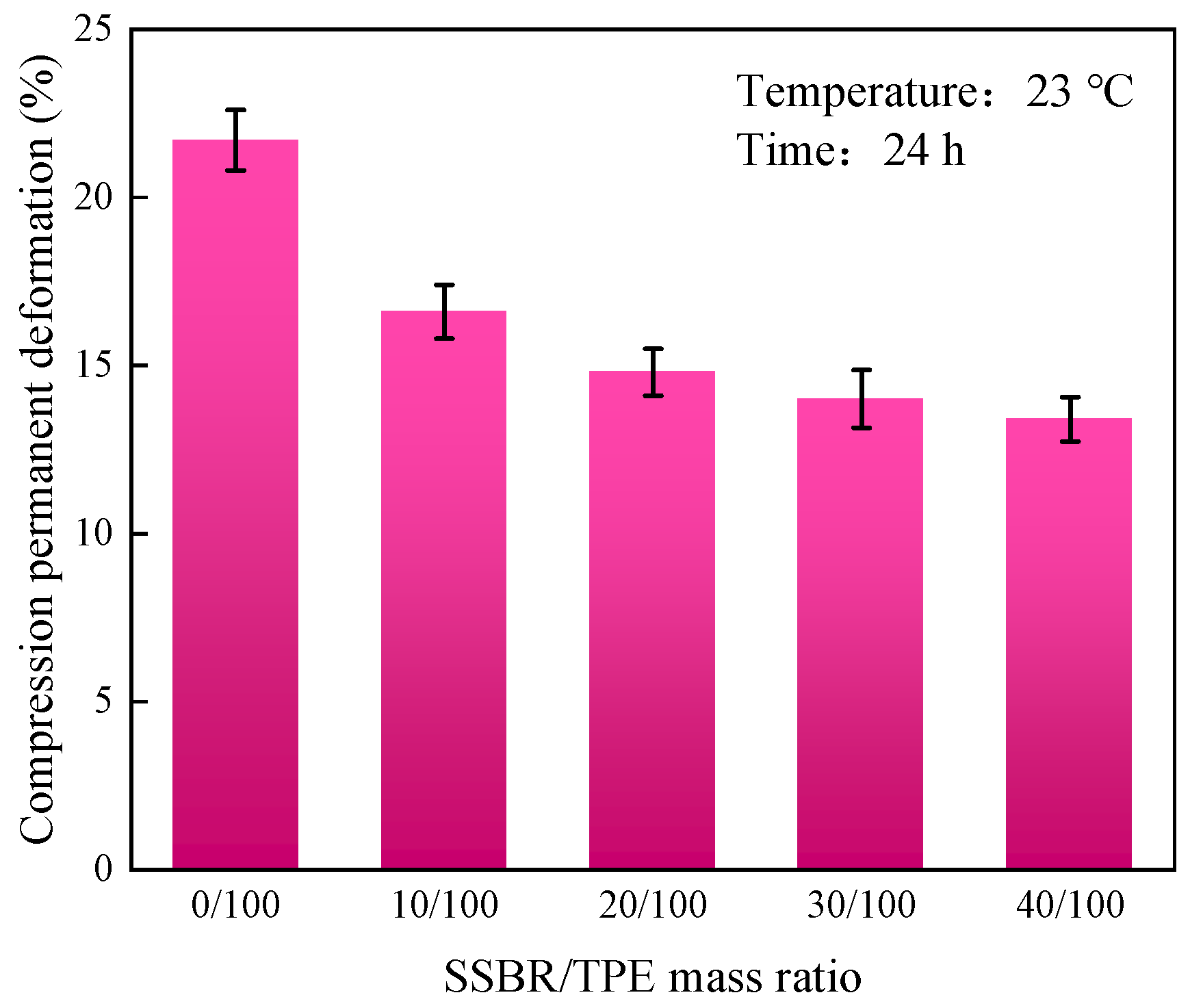

3.3. Compression Permanent Deformation of SSBR/TPE TPVs

3.4. Rheological Properties of SSBR/TPE TPVs

3.5. Wear Resistance of SSBR/TPE TPVs

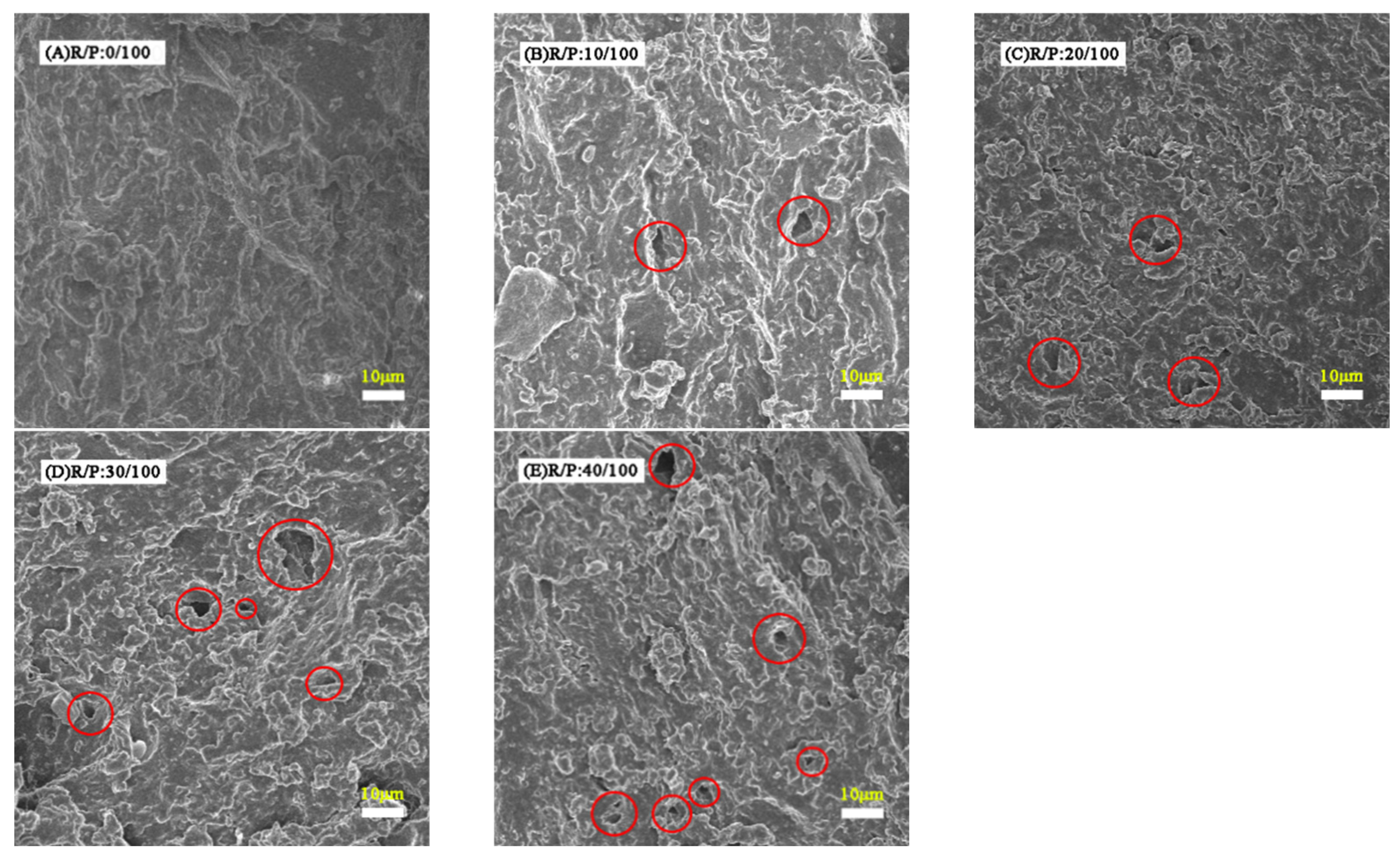

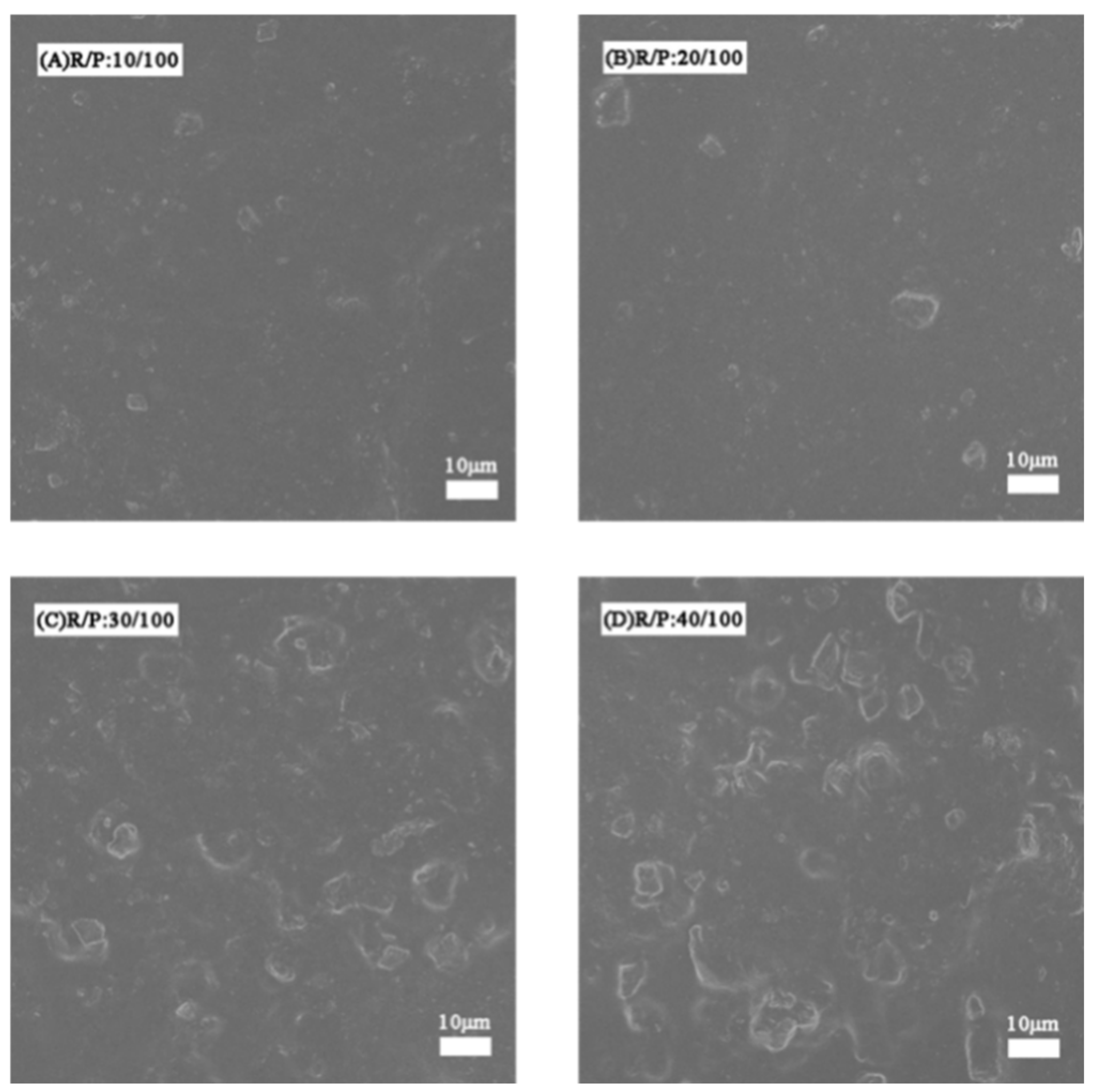

3.6. Morphology of SSBR/TPE TPVs

3.7. Dynamic Mechanical Analysis of SSBR/TPE TPVs

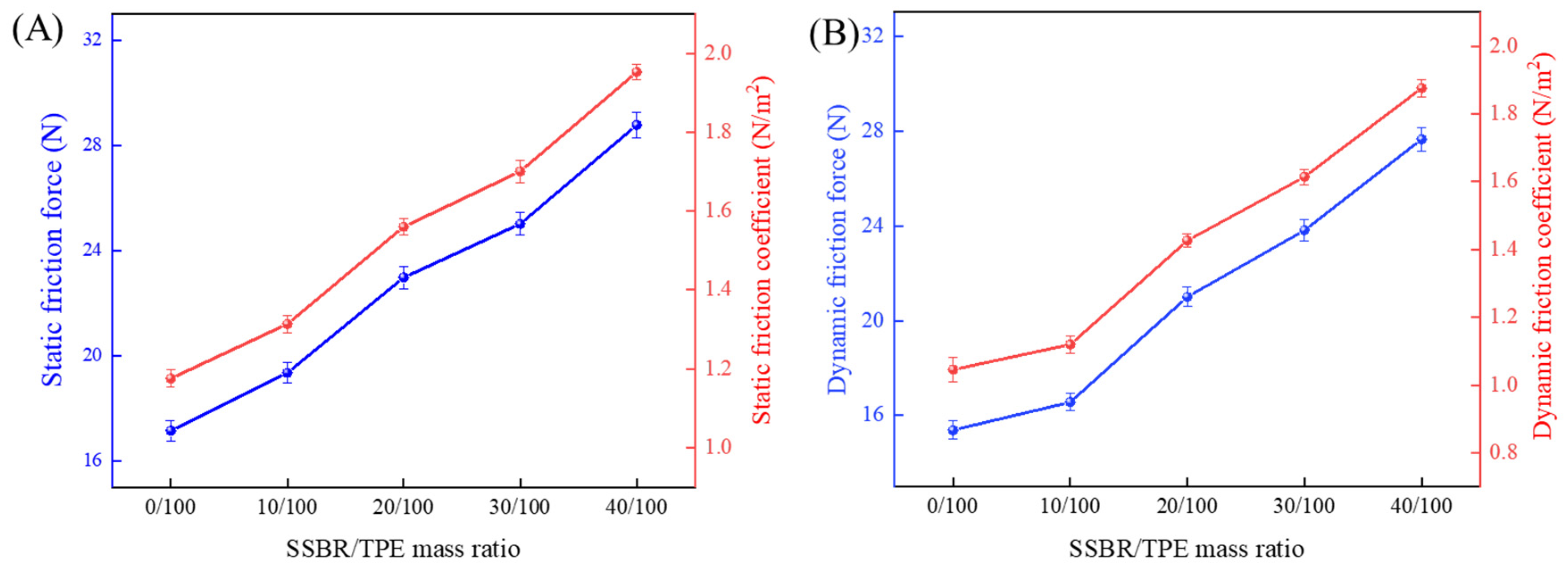

3.8. Skid Resistance of SSBR/TPE TPVs

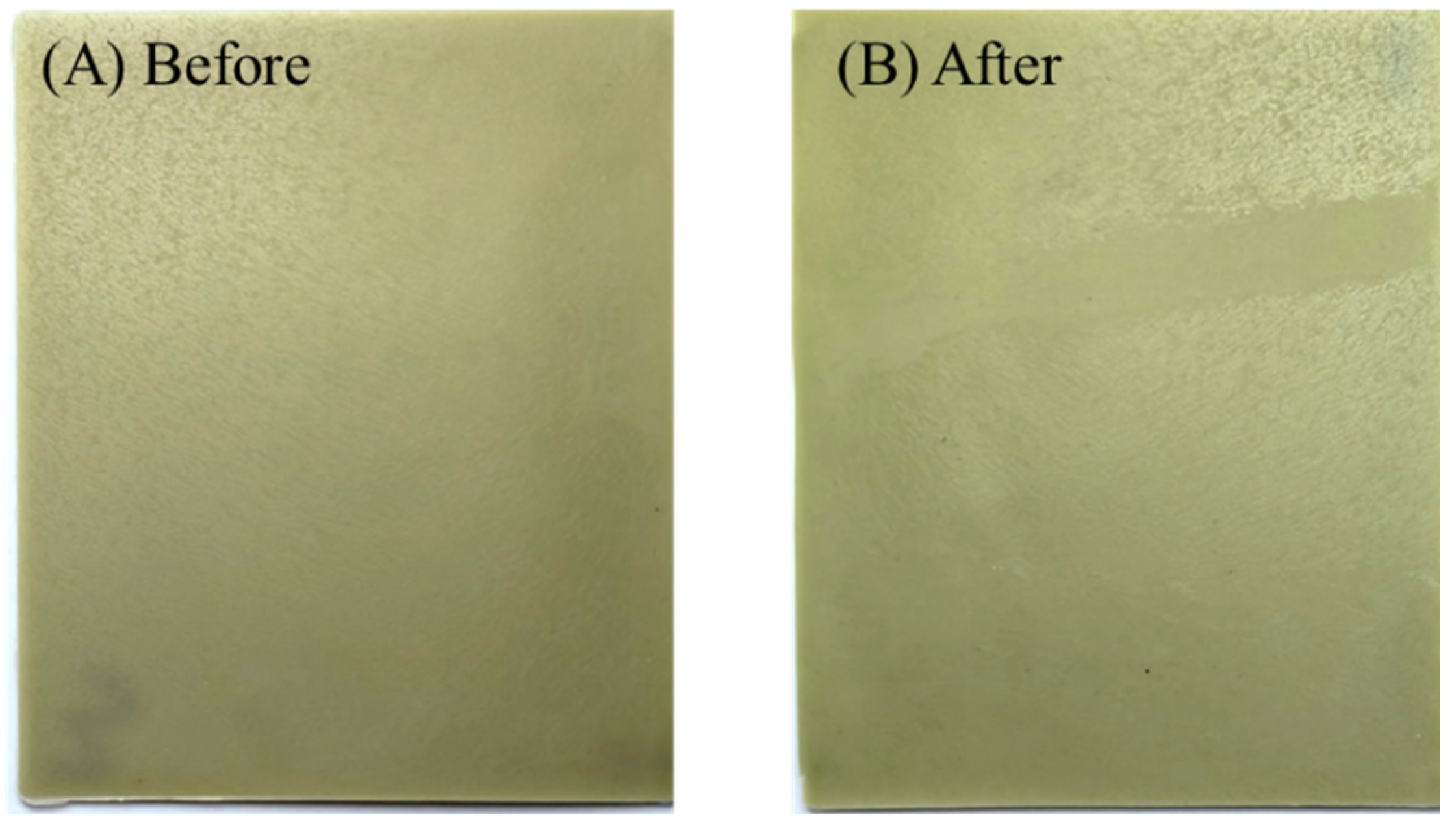

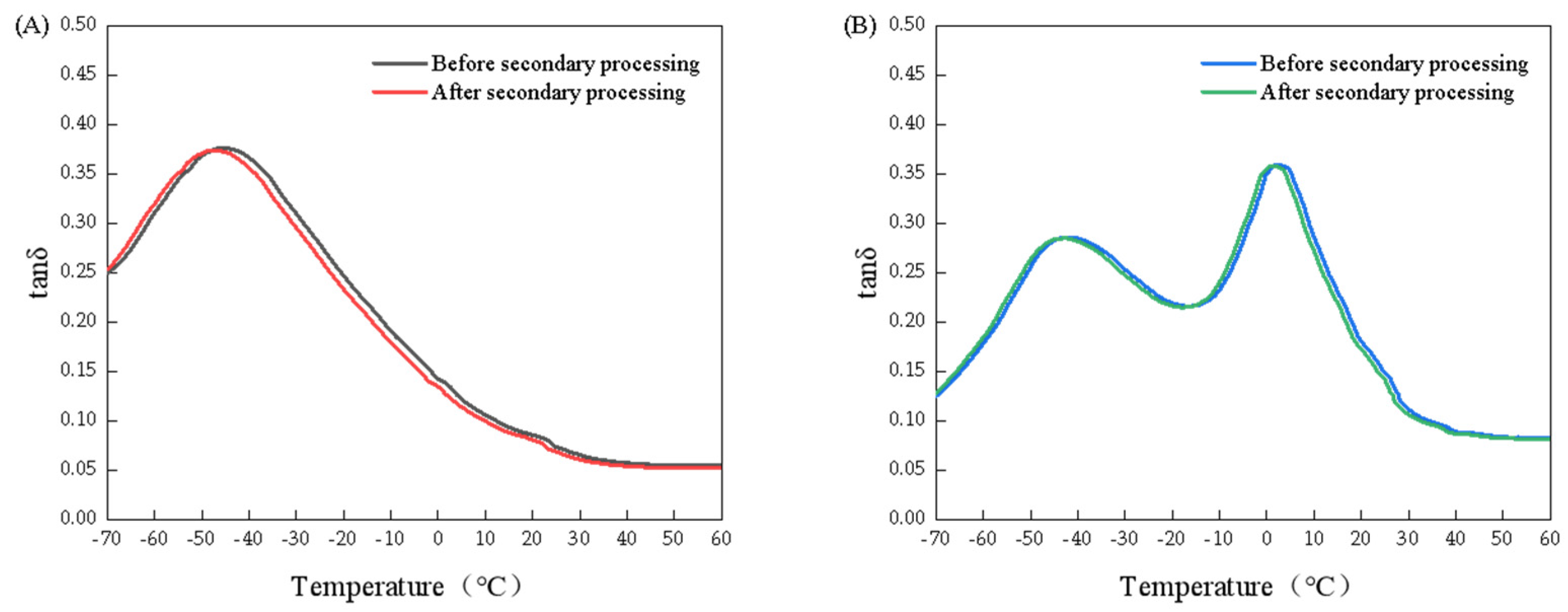

3.9. Secondary Processing Performance of SSBR/TPE TPVs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ning, N.; Li, S.; Wu, H.; Tian, H.; Yao, P.; Hu, G.-H.; Tian, M.; Zhang, L. Preparation, microstructure, and microstructure-properties relationship of thermoplastic vulcanizates (TPVs): A review. Prog. Polym. Sci. 2018, 79, 61–97. [Google Scholar] [CrossRef]

- Tang, Q.; Hu, S.; Han, L.; Zong, C.; Sun, J. Morphological Evolution and Damping Properties of Dynamically Vulcanized Butyl Rubber/Polypropylene Thermoplastic Elastomers. Polymers 2022, 14, 2740. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Tian, M.; Zhang, L.; Tian, H.; Wu, Y.; Ning, N. New understanding of microstructure formation of the rubber phase in thermoplastic vulcanizates (TPV). Soft Matter 2014, 10, 1816–1822. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Tian, H.; Wu, H.; Ning, N.; Tian, M.; Zhang, L. Coupling effect of molecular weight and crosslinking kinetics on the formation of rubber nanoparticles and their agglomerates in EPDM/PP TPVs during dynamic vulcanization. Soft Matter 2020, 16, 2185–2198. [Google Scholar] [CrossRef] [PubMed]

- Babu, R.R.; Naskar, K. Recent Developments on Thermoplastic Elastomers by Dynamic Vulcanization. In Advanced Rubber Composites; Heinrich, G., Ed.; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2011; Volume 239, pp. 219–247. [Google Scholar]

- Wu, H.G.; Tian, M.; Zhang, L.Q.; Tian, H.C.; Wu, Y.P.; Ning, N.Y.; Chan, T.W. New Understanding of Morphology Evolution of Thermoplastic Vulcanizate (TPV) during Dynamic Vulcanization. ACS Sustain. Chem. Eng. 2015, 3, 26–32. [Google Scholar] [CrossRef]

- Xu, C.H.; Lin, B.F.; Liang, X.Q.; Chen, Y.K. Zinc Dimethacrylate Induced in Situ Interfacial Compatibilization Turns EPDM/PP TPVs into a Shape Memory Material. Ind. Eng. Chem. Res. 2016, 55, 4539–4548. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Khajepour, M.; Bayati, A.; Mirasadi, K.; Amin Yousefi, M.; Shegeft, A.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; et al. Advancing sustainable shape memory polymers through 4D printing of polylactic acid-polybutylene adipate terephthalate blends. Eur. Polym. J. 2024, 216, 113289. [Google Scholar] [CrossRef]

- Ali, S.J.A.; Rahmatabadi, D.; Baghani, M.; Baniassadi, M. Design, processing, 3D/4D printing, and characterization of the novel PETG–PBAT blends. J. Mater. Sci. 2024, 59, 9150–9164. [Google Scholar] [CrossRef]

- Dey, P.; Naskar, K.; Nando, G.B. Theoretical and morphological evaluation of dynamic viscoelasticity and thermo-mechanical characteristics of TPV composites. Polymer 2015, 70, 161–172. [Google Scholar] [CrossRef]

- Le Hel, C.; Bounor-Legaré, V.; Catherin, M.; Lucas, A.; Thèvenon, A.; Cassagnau, P. TPV: A New Insight on the Rubber Morphology and Mechanic/Elastic Properties. Polymers 2020, 12, 2315. [Google Scholar] [CrossRef]

- Saha, S.; Bhowmick, A.K. Effect of structure development on the rheological properties of PVDF/HNBR-based thermoplastic elastomer and its vulcanizates. J. Appl. Polym. Sci. 2020, 137, 48758. [Google Scholar] [CrossRef]

- Li, Z.; Kontopoulou, M. Evolution of Rheological Properties and Morphology Development During Crosslinking of Polyolefin Elastomers and Their TPV Blends With Polypropylene. Polym. Eng. Sci. 2009, 49, 34–43. [Google Scholar] [CrossRef]

- Ning, N.; Hua, Y.; Wu, H.; Zhang, L.; Wu, S.; Tian, M.; Tian, H.; Hu, G.-H. Novel heat and oil-resistant thermoplastic vulcanizates based on ethylene-vinyl acetate rubber/poly(vinylidene fluoride). RSC Adv. 2016, 6, 91594–91602. [Google Scholar] [CrossRef]

- Li, S.Q.; Tian, H.C.; Hu, G.H.; Ning, N.Y.; Tian, M.; Zhang, L.Q. Effects of shear during injection molding on the anisotropic microstructure and properties of EPDM/PP TPV containing rubber nanoparticle agglomerates. Polymer 2021, 229, 124008. [Google Scholar] [CrossRef]

- Paul, D.R. Industrial & Engineering Chemistry Research: Looking Back. Ind. Eng. Chem. Res. 2013, 52, 18121–18122. [Google Scholar] [CrossRef]

- Bhattacharya, A.B.; Chatterjee, T.; Naskar, K. Automotive applications of thermoplastic vulcanizates. J. Appl. Polym. Sci. 2020, 137, 49181. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Stefan, A.; Sonmez, M.; Nituica, M.; Georgescu, M. Elasto-Plastic Materials Based on EPDM Rubber, LDPE, Plasticized Starch and OMMT. Mater. Plast. 2024, 61, 131–140. [Google Scholar] [CrossRef]

- Chatterjee, T.; Basu, D.; Das, A.; Wiessner, S.; Naskar, K.; Heinrich, G. Super thermoplastic vulcanizates based on carboxylated acrylonitrile butadiene rubber (XNBR) and polyamide (PA12). Eur. Polym. J. 2016, 78, 235–252. [Google Scholar] [CrossRef]

- Basak, S.; Bandyopadhyay, A. Styrene-butadiene-styrene-based shape memory polymers: Evolution and the current state of art. Polym. Adv. Technol. 2022, 33, 2091–2112. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, S.; Li, A.; Zhang, X. Study on the structure and properties of SSBR with large-volume functional groups at the end of chains. Polymer 2010, 51, 2084–2090. [Google Scholar] [CrossRef]

- Huang, R.M.; Pan, Q.W.; Chen, Z.H.; Feng, K.H. Maleic Anhydride Modified Dicyclopentadiene Resin for Improving Wet Skid Resistance of Silica Filled SSBR/BR Composites. Appl. Sci. 2020, 10, 4478. [Google Scholar] [CrossRef]

- Shi, X.Y.; Liu, J.W.; Zhao, S.G. Properties and Structure of Dynamically Vulcanized TPU/EVM Blends. J. Macromol. Sci. Part B-Phys. 2009, 48, 1263–1274. [Google Scholar] [CrossRef]

- Wu, W.J.; Wan, C.Y.; Zhang, Y. Morphology and mechanical properties of ethylene-vinyl acetate rubber/polyamide thermoplastic elastomers. J. Appl. Polym. Sci. 2013, 130, 338–344. [Google Scholar] [CrossRef]

- Liu, C.C.; Ma, L.F.; He, C.Y.; Xu, X.H. Prediction of comprehensive mechanical properties of thermoplastic vulcanizate (TPV) with various composition ratios based on a micromechanical method. Mod. Phys. Lett. B 2023, 37, 2250230. [Google Scholar] [CrossRef]

- Cui, Z.; Jing, Y.; Wang, L.; Liu, Y.; Du, A. Thermoplastic vulcanizates with an integration of good mechanical performance and excellent resistance to high temperature and oil based on HNBR/TPEE. Polym. Adv. Technol. 2022, 34, 1143–1153. [Google Scholar] [CrossRef]

- Kang, H.L.; Hu, X.R.; Li, M.Q.; Zhang, L.Q.; Wu, Y.P.; Ning, N.Y.; Tian, M. Novel biobased thermoplastic elastomer consisting of synthetic polyester elastomer and polylactide by in situ dynamical crosslinking method. RSC Adv. 2015, 5, 23498–23507. [Google Scholar] [CrossRef]

- Wang, C.C.; Zhang, Y.F.; Wang, Z.B. Mechanical properties, morphology, and Mullins effect of thermoplastic vulcanizates based on ethylene-vinyl acetate copolymer/ethylene-vinyl acetate rubber. J. Thermoplast. Compos. Mater. 2017, 30, 827–839. [Google Scholar] [CrossRef]

- Kunanusont, N.; Samthong, C.; Bowen, F.; Yamaguchi, M.; Somwangthanaroj, A. Effect of Mixing Method on Properties of Ethylene Vinyl Acetate Copolymer/Natural Rubber Thermoplastic Vulcanizates. Polymers 2020, 12, 1739. [Google Scholar] [CrossRef] [PubMed]

- ISO 37: 2024; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2024.

- ISO 48-4:2018; Rubber, Vulcanized or Thermoplastic—Determination of Hardness—Part 4: Indentation Hardness by Durometer Method (Shore Hardness). ISO: Geneva, Switzerland, 2018.

- ISO 4662:2017; Rubber, Vulcanized or Thermoplastic—Determination of Rebound Resilience. ISO: Geneva, Switzerland, 2017.

- ISO 1133-1:2022; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics. ISO: Geneva, Switzerland, 2022.

- ISO 4649:2017; Rubber, Vulcanized or Thermoplastic—Determination of Abrasion Resistance Using a Rotating Cylindrical Drum Device. ISO: Geneva, Switzerland, 2017.

- ISO 188:2023; Rubber, Vulcanized or Thermoplastic—Accelerated Ageing and Heat Resistance Tests. ISO: Geneva, Switzerland, 2023.

- Tang, Y.C.; Lu, K.; Cao, X.J.; Li, Y.J. Nanostructured Thermoplastic Vulcanizates by Selectively Cross-Linking a Thermoplastic Blend with Similar Chemical Structures. Ind. Eng. Chem. Res. 2013, 52, 12613–12621. [Google Scholar] [CrossRef]

- Yao, P.J.; Wu, H.G.; Ning, N.Y.; Zhang, L.Q.; Tian, H.C.; Wu, Y.P.; Hu, G.H.; Chan, T.W.; Tian, M. Microstructure and properties of bromo-isobutylene-isoprene rubber/polyamide 12 thermoplastic vulcanizate toward recyclable inner liners for green tires. RSC Adv. 2016, 6, 30004–30013. [Google Scholar] [CrossRef]

- Im, H.; Jeoung, S. Mechanical Aging Test and Sealing Performance of Thermoplastic Vulcanizate as Sealing Gasket in Automotive Fuel Cell Applications. Polymers 2023, 15, 1872. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.R.; Zhong, M.; Pan, X.L.; Chen, L.; Wu, X.; Kong, Z.Q.; Yuan, Y.; Yan, S.K.; Zhang, J.M.; Duan, Y.X. Fabricating 3D printable BIIR/PP TPV via masterbatch and interfacial compatibilization. Compos. Part B-Eng. 2020, 199, 108220. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Liu, Z.W.; Su, B.; Chen, F.; Fu, Q.; Ning, N.Y.; Tian, M. Property enhancement of PP-EPDM thermoplastic vulcanizates via shear-induced break-up of nano-rubber aggregates and molecular orientation of the matrix. Polymer 2015, 63, 170–178. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.; Wang, Y.; Su, B.; Gond, B. Investigation on Wet Skid Resistance of Tread Rubber. Exp. Tech. 2019, 43, 81–89. [Google Scholar] [CrossRef]

- Markov, D.P. Adhesion at friction and wear. Friction 2022, 10, 1859–1878. [Google Scholar] [CrossRef]

- Li, Y.Z.; Li, S.W.; Bai, P.P.; Jia, W.P.; Xu, Q.; Meng, Y.G.; Ma, L.R.; Tian, Y. Surface wettability effect on aqueous lubrication: Van der Waals and hydration force competition induced adhesive friction. J. Colloid Interface Sci. 2021, 599, 667–675. [Google Scholar] [CrossRef]

- Li, W.Q.; Ma, Q.X. Investigation of Interfacial Friction and Inverse Flowing Behavior under the Adhesive State. Mater. Trans. 2016, 57, 661–668. [Google Scholar] [CrossRef][Green Version]

- Antunes, C.F.; van Duin, M.; Machado, A.V. Effect of crosslinking on morphology and phase inversion of EPDM/PP blends. Mater. Chem. Phys. 2012, 133, 410–418. [Google Scholar] [CrossRef]

- Cossa, M.M.; Sirqueira, A.S.; Soares, B.G. Development of Thermoplastic Elastomers Vulcanized (TPV) with Polypropylene Waste Tire. I-Factorial Design Experiments. Polim.-Cienc. Tecnol. 2009, 19, 190–195. [Google Scholar] [CrossRef][Green Version]

| SEPS/SEBS Mass Ratio | 0/100 | 30/70 | 50/50 | 70/30 | 100/0 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 13.7 | 12.4 | 13.0 | 24.7 | 28.6 |

| Elongation at break/% | 793 | 672 | 676 | 641 | 508 |

| Tear strength/(kN·m−1) | 32.6 | 37.9 | 55.9 | 49.8 | 42.6 |

| Modulus at 100%/MPa | 2.1 | 2.2 | 2.2 | 2.1 | 3.4 |

| Hardness/Shore A | 66 | 66 | 69 | 70 | 79 |

| SSBR/TPE Mass Ratio | 0/100 | 10/100 | 20/100 | 30/100 | 40/100 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 23.2 | 20.3 | 19.6 | 19.4 | 17.9 |

| Tensile strength retention rate/% | 93.9 | 97.1 | 94.7 | 101.4 | 98.9 |

| Tear strength/(kN·m−1) | 48.5 | 39.3 | 38.6 | 37.8 | 36.4 |

| Tear strength retention rate/% | 97.4 | 93.1 | 94.1 | 94.0 | 99.5 |

| Hardness/Shore A | 70 | 68 | 67 | 66 | 64 |

| Hardness retention rate/% | 100 | 98.6 | 100 | 100 | 100 |

| wear volumes/mm3 | 105 | 140 | 147 | 162 | 170 |

| wear volumes retention rate /% | 104.0 | 101.4 | 99.3 | 103.8 | 100.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Xiao, J. Thermoplastic Vulcanizates with an Integration of High Wear-Resistant and Anti-Slip Properties Based on Styrene Ethylene Propylene Styrene Block Copolymer/Styrene Ethylene Butylene Styrene Block Copolymer/Solution-Polymerization Styrene-Butadiene Rubber. Polymers 2024, 16, 2221. https://doi.org/10.3390/polym16152221

Li Z, Xiao J. Thermoplastic Vulcanizates with an Integration of High Wear-Resistant and Anti-Slip Properties Based on Styrene Ethylene Propylene Styrene Block Copolymer/Styrene Ethylene Butylene Styrene Block Copolymer/Solution-Polymerization Styrene-Butadiene Rubber. Polymers. 2024; 16(15):2221. https://doi.org/10.3390/polym16152221

Chicago/Turabian StyleLi, Zhicheng, and Jianbin Xiao. 2024. "Thermoplastic Vulcanizates with an Integration of High Wear-Resistant and Anti-Slip Properties Based on Styrene Ethylene Propylene Styrene Block Copolymer/Styrene Ethylene Butylene Styrene Block Copolymer/Solution-Polymerization Styrene-Butadiene Rubber" Polymers 16, no. 15: 2221. https://doi.org/10.3390/polym16152221

APA StyleLi, Z., & Xiao, J. (2024). Thermoplastic Vulcanizates with an Integration of High Wear-Resistant and Anti-Slip Properties Based on Styrene Ethylene Propylene Styrene Block Copolymer/Styrene Ethylene Butylene Styrene Block Copolymer/Solution-Polymerization Styrene-Butadiene Rubber. Polymers, 16(15), 2221. https://doi.org/10.3390/polym16152221