Controlled Surface Textures of Elastomeric Polyurethane Janus Particles: A Comprehensive Review

Abstract

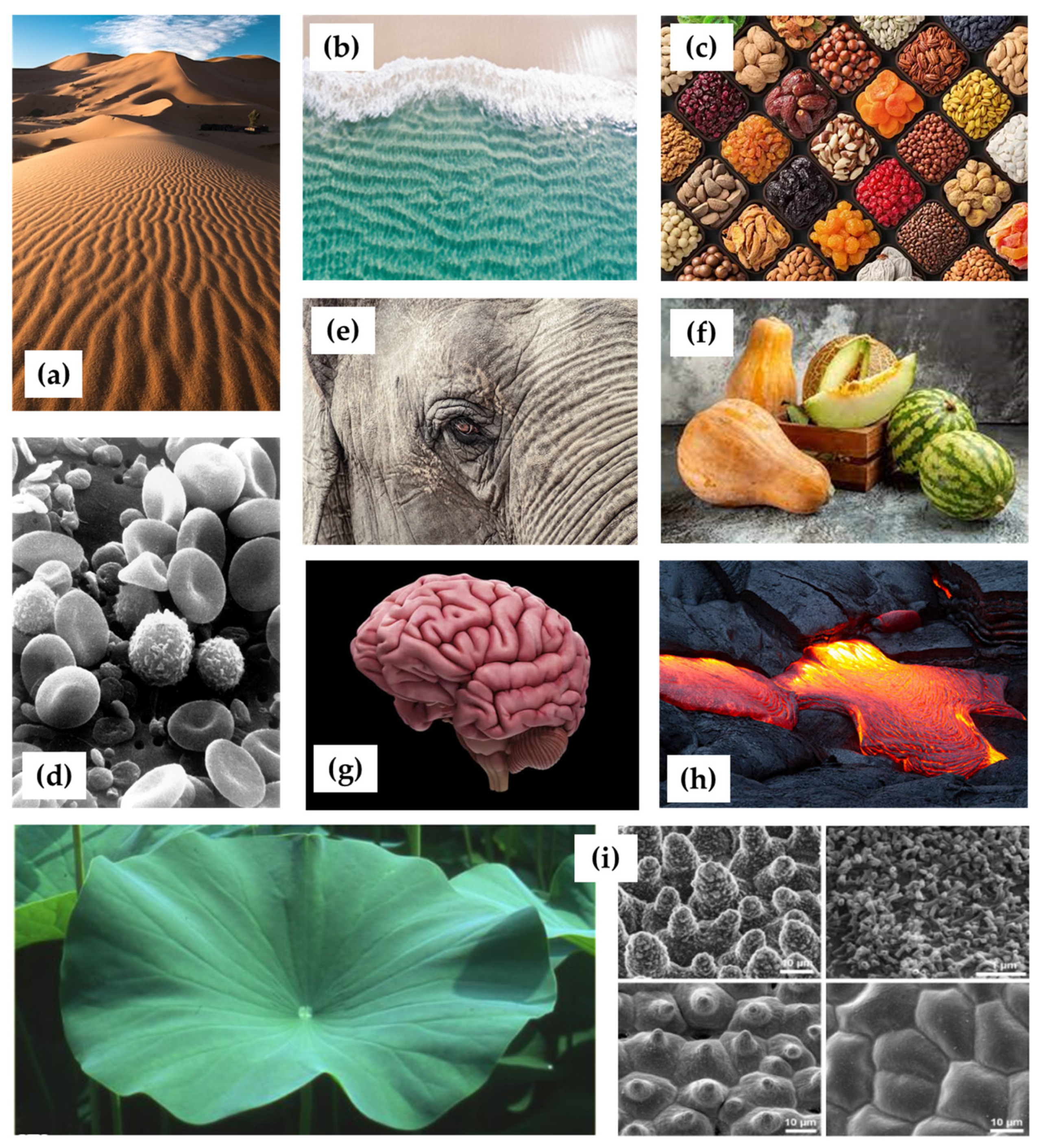

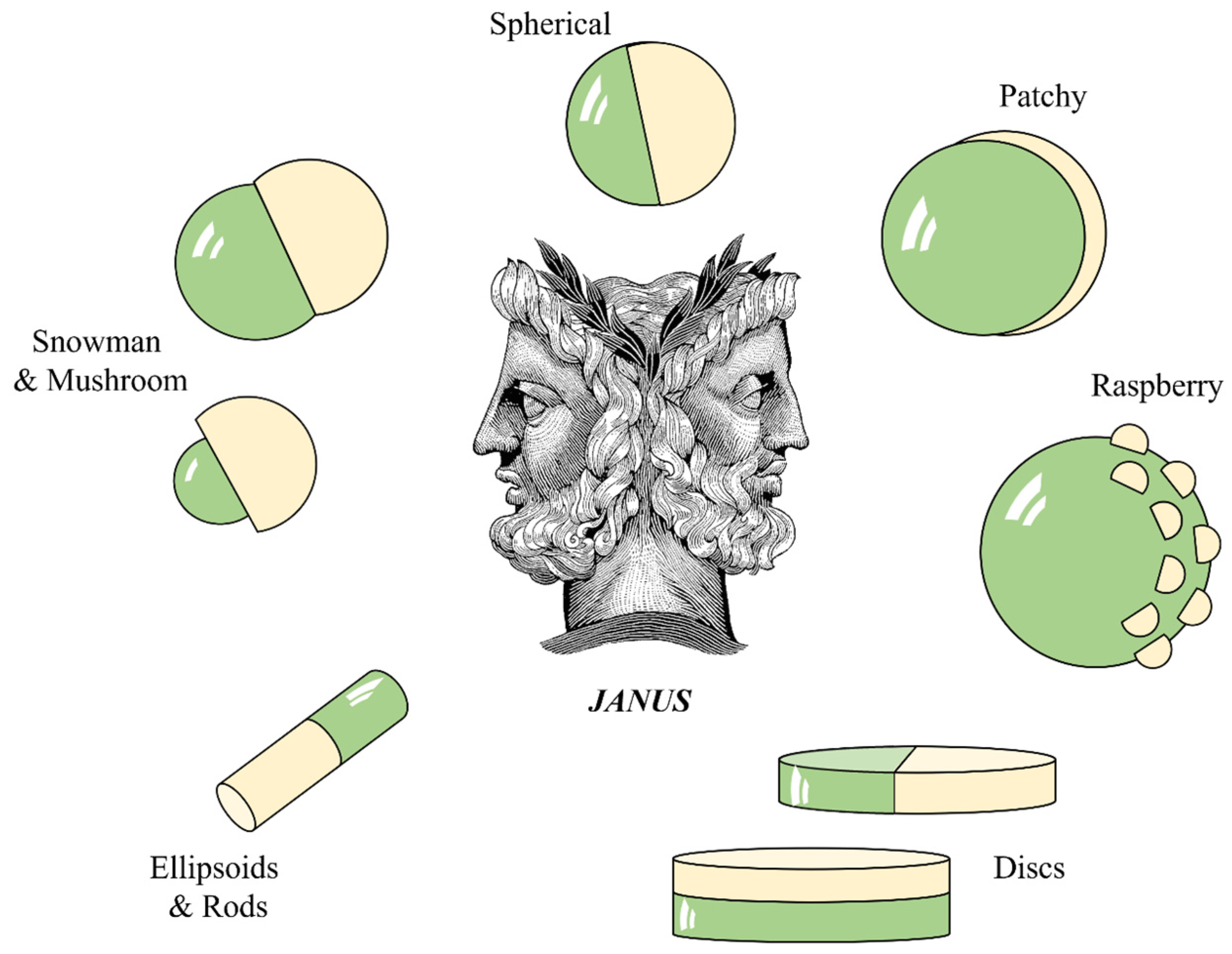

1. Asymmetric Janus Particles: A Short Overview

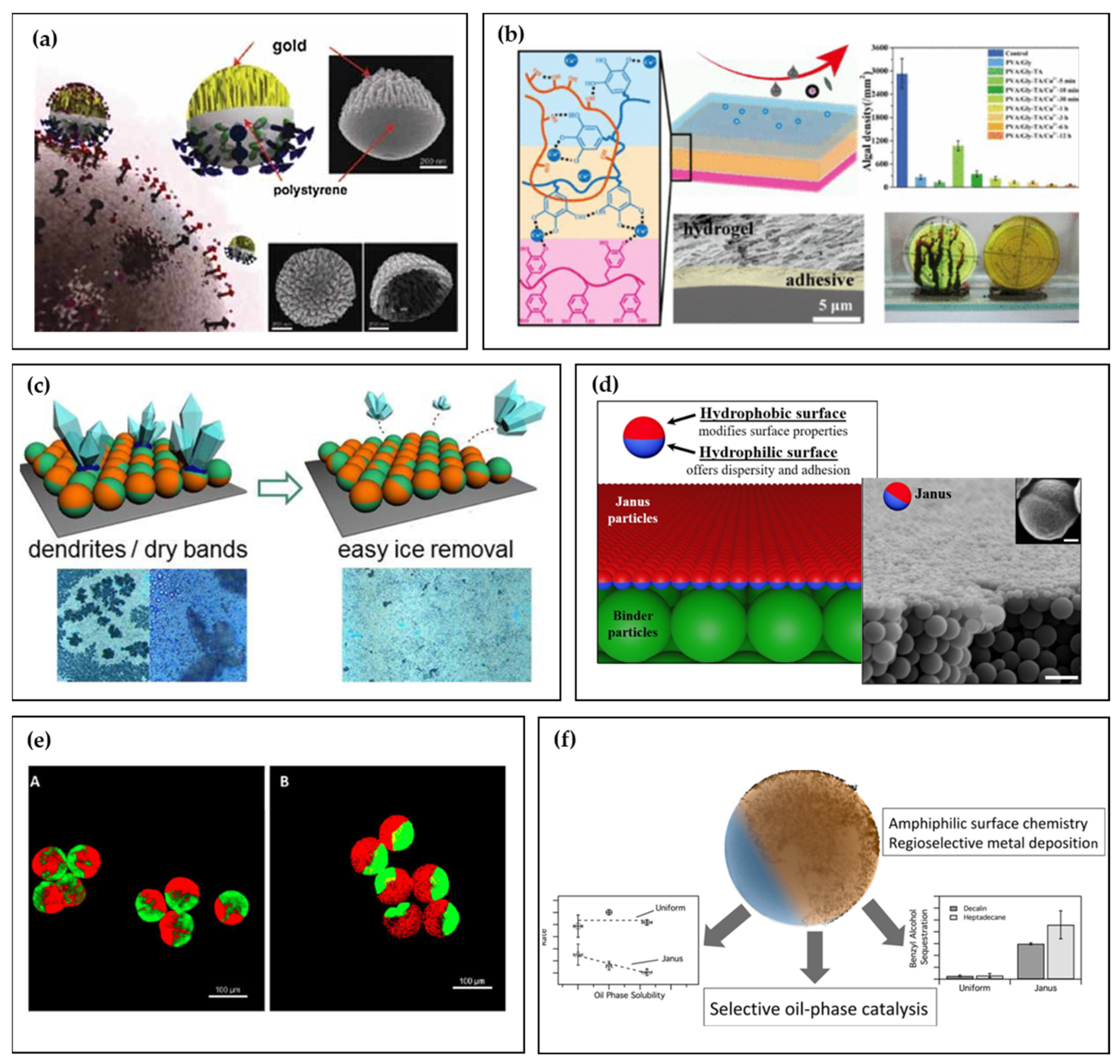

2. Janus Particles: General Synthetic Routes and Applications

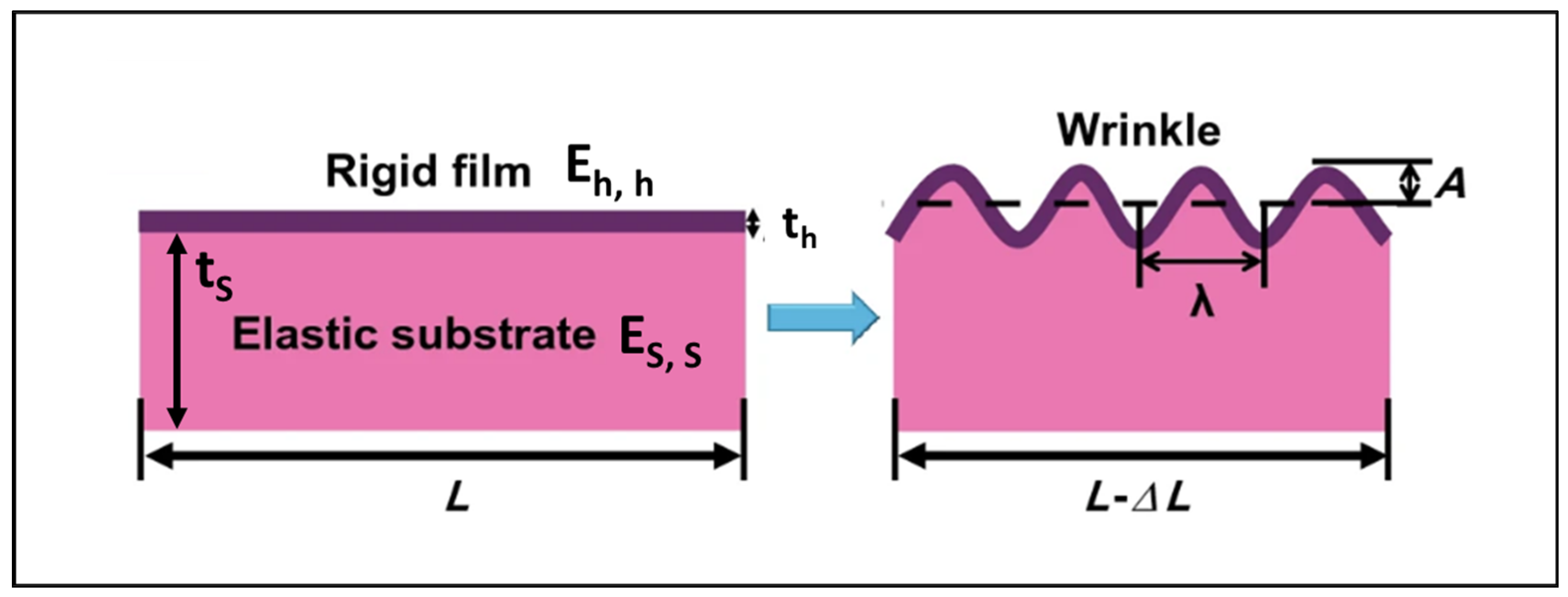

3. Surface Periodic Patterns: Wrinkling and Buckling

4. Controlling Surface Textures of Polyurethane Elastomeric Janus Particles

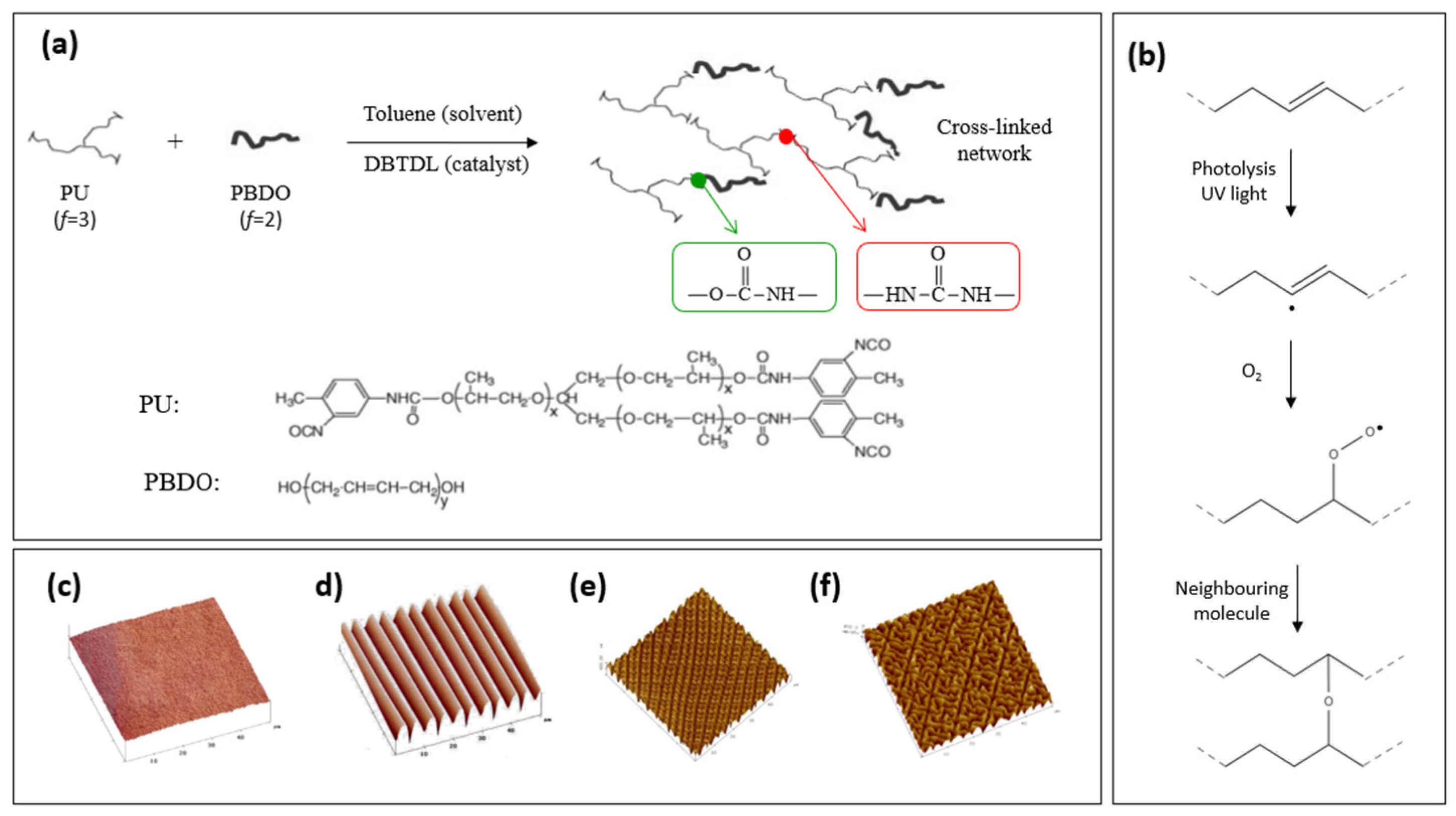

4.1. Wrinkling in Free-Standing Flexible Elastomers

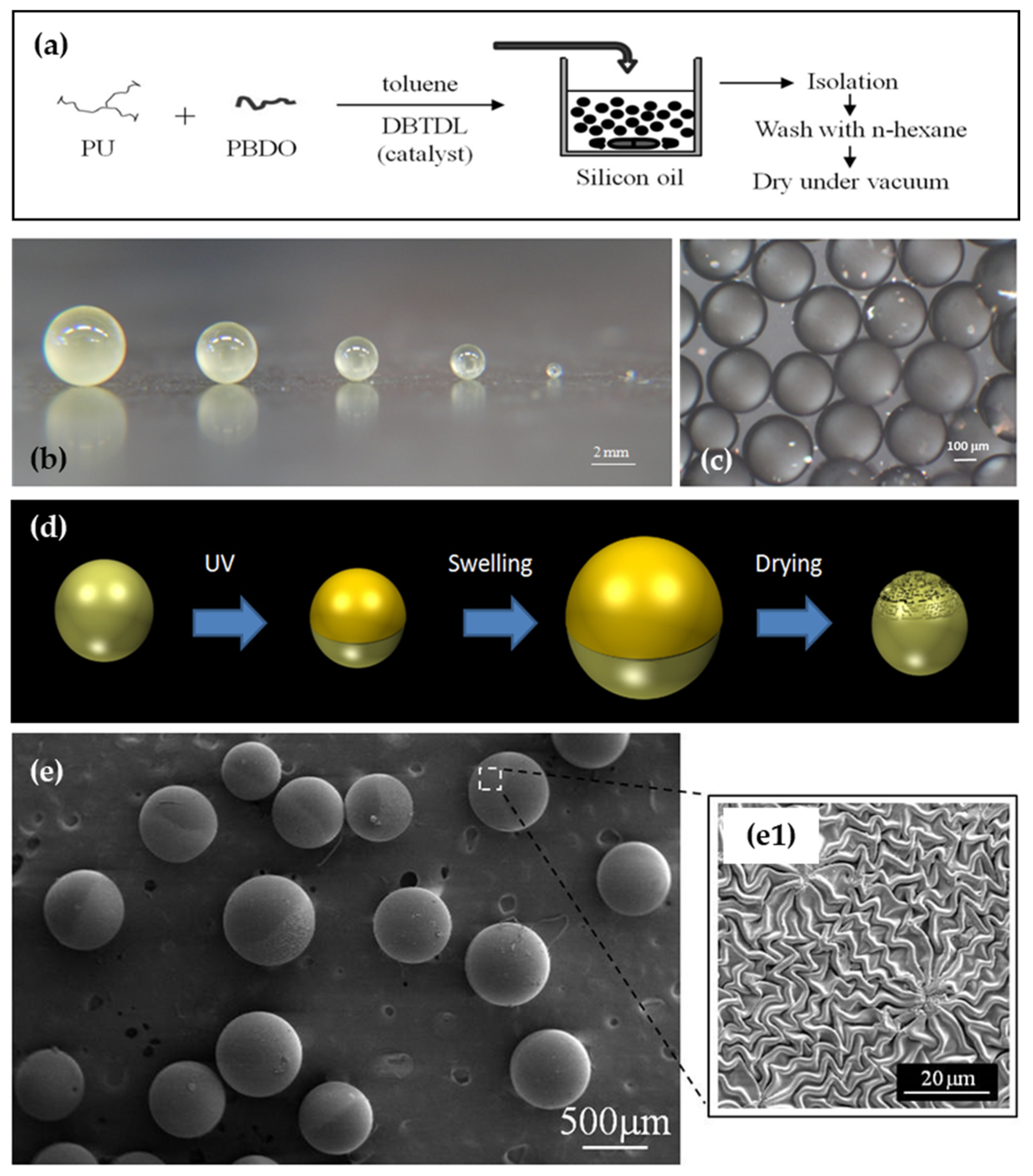

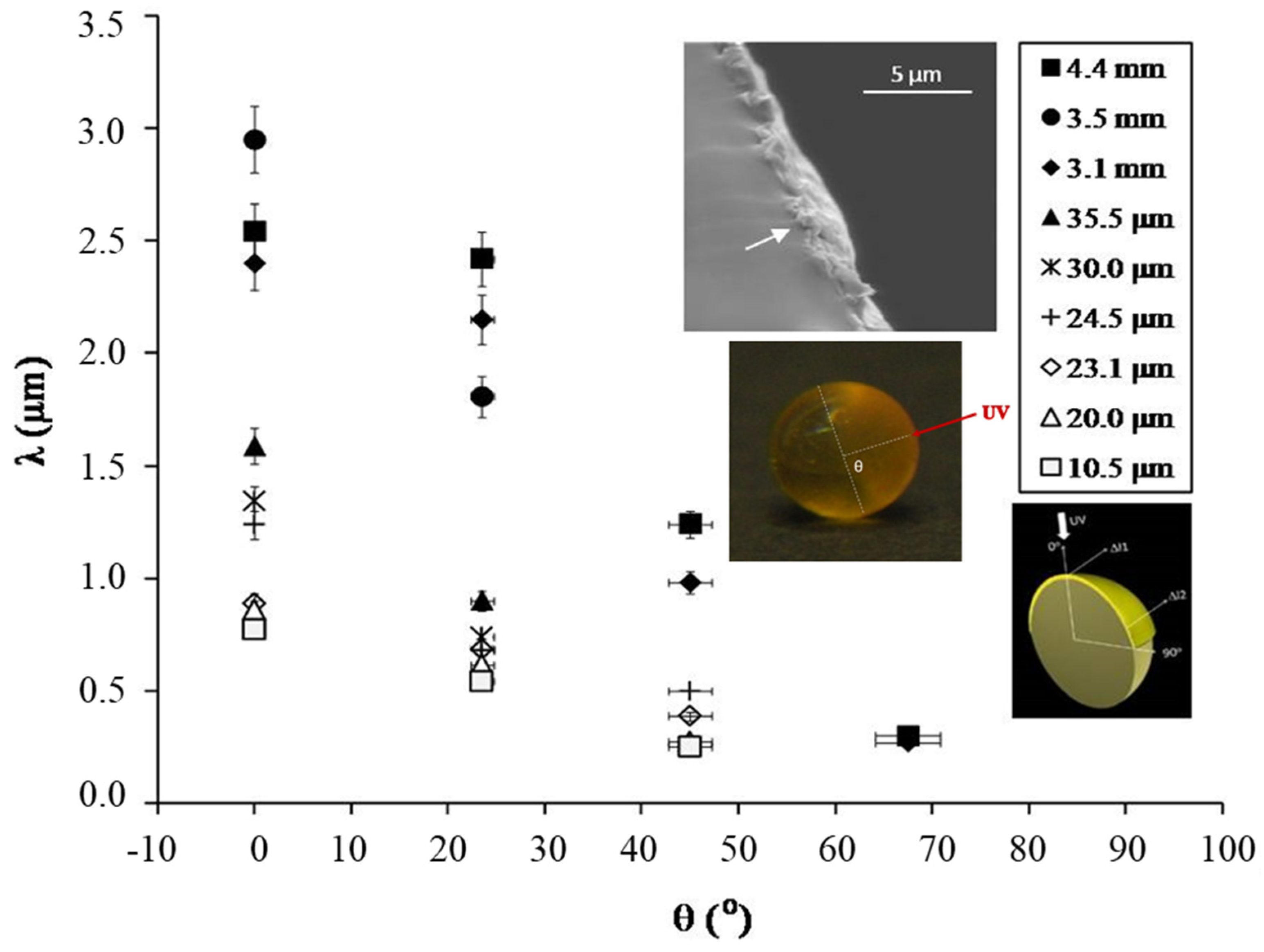

4.2. Janus Wrinkled Spheres

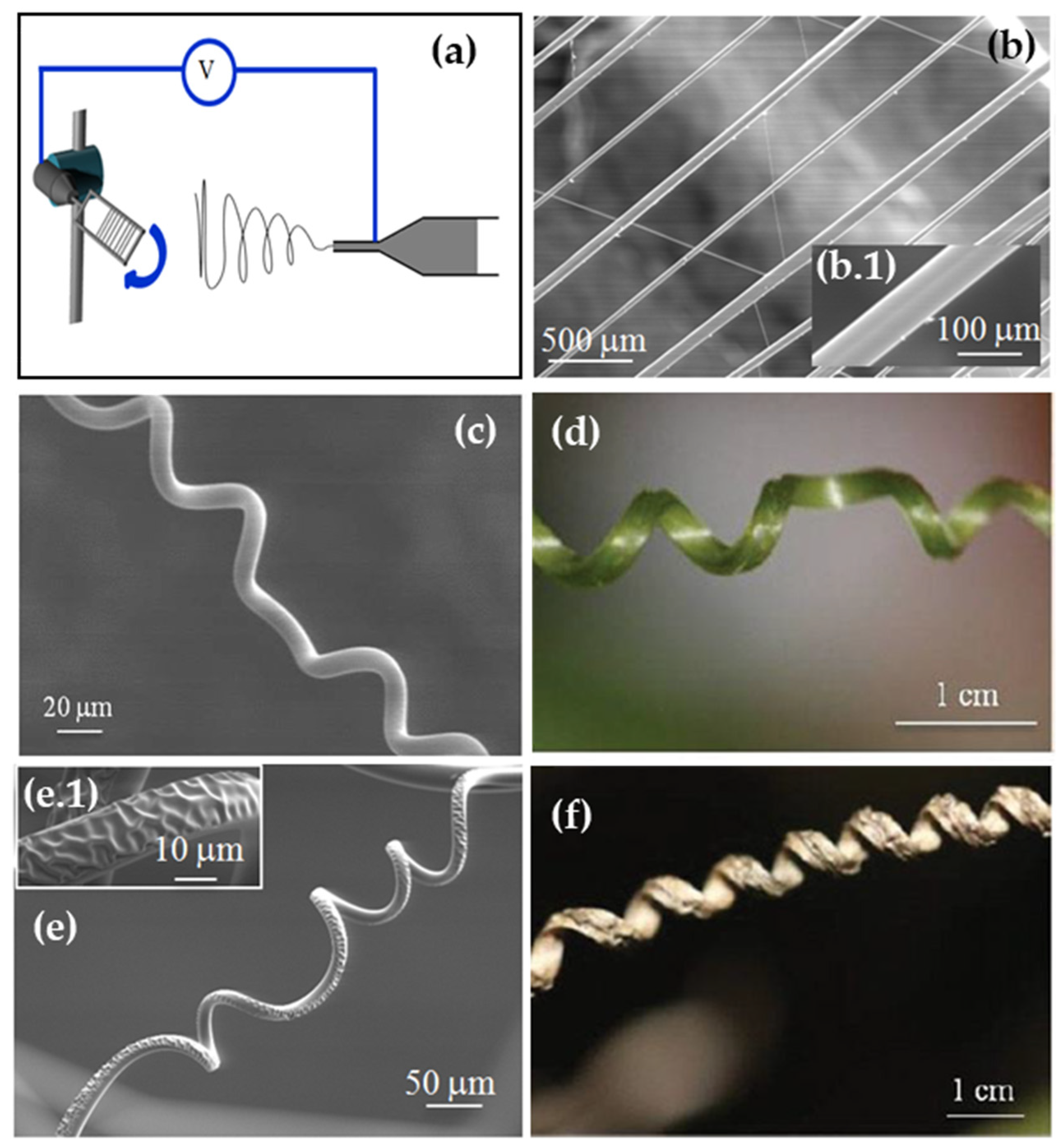

4.3. Janus Wrinkled Fibers

5. Applications and Future Perspectives

6. Challenges and Limitations

7. Conclusions

Funding

Conflicts of Interest

References

- Melville, H.W. Advances in Colloid Science. Nature 1943, 151, 5–6. [Google Scholar] [CrossRef]

- Eisenriegler, E. Anisotropic Colloidal Particles in Critical Fluids. J. Chem. Phys. 2004, 121, 3299–3322. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Schmid, G. Clusters and Colloids: From Theory to Applications; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Lee, K.W.; Cho, I. Effect of Crystallinity on the Mechanical Properties of High-Density Polyethylene/Polystyrene Blends. J. Appl. Polym. Sci. 1985, 30, 1903–1926. [Google Scholar]

- de Gennes, P.G. Soft Matter. Rev. Mod. Phys. 1992, 64, 645–648. [Google Scholar] [CrossRef]

- de Gennes, P.G. Soft Matter. Science 1992, 256, 495–497. [Google Scholar] [CrossRef] [PubMed]

- Hektor, H.J.; Scholtmeijer, K. Hydrophobins: Proteins with Potential. Curr. Opin. Biotechnol. 2005, 16, 434–439. [Google Scholar] [CrossRef] [PubMed]

- Hong, L.; Jiang, S.; Granick, S. Simple Method to Produce Janus Colloidal Particles in Large Quantity. Langmuir 2006, 22, 9495–9499. [Google Scholar] [CrossRef] [PubMed]

- Hong, L.; Cacciuto, A.; Luijten, E.; Granick, S. Clusters of Charged Janus Spheres. Nano Lett. 2006, 6, 2510–2514. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Chen, Q.; Tripathy, M.; Luijten, E.; Schweizer, K.S.; Granick, S. Janus Particle Synthesis and Assembly. Adv. Mater. 2010, 22, 1060–1071. [Google Scholar] [CrossRef] [PubMed]

- Liang, F.; Liu, B.; Cao, Z.; Yang, Z. Janus Colloids toward Interfacial Engineering. Langmuir 2018, 34, 4123–4131. [Google Scholar] [CrossRef]

- Li, X.; Chen, L.; Cui, D.; Jiang, W.; Han, L.; Niu, N. Preparation and Application of Janus Nanoparticles: Recent Development and Prospects. Coord. Chem. Rev. 2022, 454, 214318. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Zhu, H. Symmetry Engineering in Low-Dimensional Materials. Mater. Today 2024, 75, 187–209. [Google Scholar] [CrossRef]

- Tong, H.; Wang, J.; Qi, L.; Gao, Q. Starch-Based Janus Particle: Fabrication, Characterization and Interfacial Properties in Stabilizing Pickering Emulsion. Carbohydr. Polym. 2023, 313, 120867. [Google Scholar] [CrossRef] [PubMed]

- Bradley, L.; Lin, X.; Chen, Y.; Asadinamin, M.; Ai, B.; Zhao, Y. Janus Particles with Flower-like Patches Prepared by Shadow Sphere Lithography. Langmuir 2021, 37, 13637–13644. [Google Scholar] [CrossRef] [PubMed]

- Perro, A.; Reculusa, S.; Ravaine, S.; Bourgeat-Lami, E.; Duguet, E. Design and Synthesis of Janus Micro- and Nanoparticles. J. Mater. Chem. 2005, 15, 3745. [Google Scholar] [CrossRef]

- Hu, J.; Zhou, S.; Sun, Y.; Fang, X.; Wu, L. Fabrication, Properties and Applications of Janus Particles. Chem. Soc. Rev. 2012, 41, 4356. [Google Scholar] [CrossRef] [PubMed]

- Walther, A.; Müller, A.H.E. Janus Particles: Synthesis, Self-Assembly, Physical Properties, and Applications. Chem. Rev. 2013, 113, 5194–5261. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Grzybowski, B.A.; Granick, S. Janus Particle Synthesis, Assembly, and Application. Langmuir 2017, 33, 6964–6977. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.; Carroll, R.L. Design and Fabrication of Bimetallic Colloidal “Janus” Particles. ACS Appl. Mater. Interfaces 2010, 2, 616–620. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, A.; Rastogi, M.; Scheier, P.; Bowen, C.; Kumar, R.V.; Vaish, R. Janus Nanostructures for Heterogeneous Photocatalysis. Appl. Phys. Rev. 2018, 5, 041111. [Google Scholar] [CrossRef]

- Mavukkandy, M.O.; McBride, S.A.; Warsinger, D.M.; Dizge, N.; Hasan, S.W.; Arafat, H.A. Thin Film Deposition Techniques for Polymeric Membranes—A Review. J. Membr. Sci. 2020, 610, 118258. [Google Scholar] [CrossRef]

- Meng, S.; Zhang, Y.; Liu, Y.; Zhang, Z.; Ma, K.; Chen, X.; Gao, Q.; Ma, X.; Wang, W.; Feng, H. The Effect of Particle Size on the Dynamics of Self-Electrophoretic Janus Micromotors, Sputtering Distribution, and Rectifying Voltage. JCIS Open 2022, 5, 100046. [Google Scholar] [CrossRef]

- Jiang, S.; Schultz, M.J.; Chen, Q.; Moore, J.S.; Granick, S. Solvent-Free Synthesis of Janus Colloidal Particles. Langmuir 2008, 24, 10073–10077. [Google Scholar] [CrossRef] [PubMed]

- Braun, F.; Wagner, M.F.P.; Toimil-Molares, M.E.; von Klitzing, R. Comparison of Different Preparation Techniques of Thermophoretic Swimmers and Their Propulsion Velocity. Langmuir 2024, 40, 5606–5616. [Google Scholar] [CrossRef] [PubMed]

- Archer, R.J.; Campbell, A.I.; Ebbens, S.J. Glancing Angle Metal Evaporation Synthesis of Catalytic Swimming Janus Colloids with Well Defined Angular Velocity. Soft Matter 2015, 11, 6872–6880. [Google Scholar] [CrossRef] [PubMed]

- Bin Kim, J.; Lee, S.Y.; Min, N.G.; Lee, S.Y.; Kim, S. Plasmonic Janus Microspheres Created from Pickering Emulsion Drops. Adv. Mater. 2020, 32, e2001384. [Google Scholar] [CrossRef]

- Gu, R.; Yu, Z.; Sun, Y.; Xie, P.; Li, Y.; Cheng, S. Enhancing Stability of Interfacial Solar Evaporator in High-Salinity Solutions by Managing Salt Precipitation with Janus-Based Directional Salt Transfer Structure. Desalination 2022, 524, 115470. [Google Scholar] [CrossRef]

- Du, J.; O’Reilly, R.K. Anisotropic Particles with Patchy, Multicompartment and Janus Architectures: Preparation and Application. Chem. Soc. Rev. 2011, 40, 2402. [Google Scholar] [CrossRef] [PubMed]

- Nie, Z.; Li, W.; Seo, M.; Xu, S.; Kumacheva, E. Janus and Ternary Particles Generated by Microfluidic Synthesis: Design, Synthesis, and Self-Assembly. J. Am. Chem. Soc. 2006, 128, 9408–9412. [Google Scholar] [CrossRef] [PubMed]

- Nisisako, T. Recent Advances in Microfluidic Production of Janus Droplets and Particles. Curr. Opin. Colloid Interface Sci. 2016, 25, 1–12. [Google Scholar] [CrossRef]

- Luo, G.; Du, L.; Wang, Y.; Lu, Y.; Xu, J. Controllable Preparation of Particles with Microfluidics. Particuology 2011, 9, 545–558. [Google Scholar] [CrossRef]

- Seiffert, S.; Romanowsky, M.B.; Weitz, D.A. Janus Microgels Produced from Functional Precursor Polymers. Langmuir 2010, 26, 14842–14847. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.; Wang, X. Photodeformable Azo Polymer Janus Particles Obtained upon Nonsolvent-Induced Phase Separation and Asynchronous Aggregation. Langmuir 2022, 38, 12466–12479. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Zheng, Y.; Lin, L.; Sun, Y.; Xing, G.; Lin, H.; Lin, J.-M. Multicompartmental Hydrogel Microspheres as a Tool for Multicomponent Analysis. Anal. Chem. 2023, 95, 11047–11051. [Google Scholar] [CrossRef] [PubMed]

- Liang, F.; Zhang, C.; Yang, Z. Rational Design and Synthesis of Janus Composites. Adv. Mater. 2014, 26, 6944–6949. [Google Scholar] [CrossRef] [PubMed]

- Roh, K.-H.; Martin, D.C.; Lahann, J. Biphasic Janus Particles with Nanoscale Anisotropy. Nat. Mater. 2005, 4, 759–763. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, S.; Villa, C.H.; Dishman, A.F.; Grabowski, M.E.; Pan, D.C.; Durmaz, H.; Misra, A.C.; Colón-Meléndez, L.; Solomon, M.J.; Muzykantov, V.R.; et al. Long-Circulating Janus Nanoparticles Made by Electrohydrodynamic Co-Jetting for Systemic Drug Delivery Applications. J. Drug Target. 2015, 23, 750–758. [Google Scholar] [CrossRef] [PubMed]

- Walther, A.; Muller, A.H.E. Janus Particles. Soft Matter 2008, 4, 663–668. [Google Scholar] [CrossRef] [PubMed]

- Il So, J.; Shin, D.H.; Kim, J.B.; Jeong, H.W.; Kim, C.H.; Choi, J.; Shim, S.E.; Qian, Y. One-Pot Synthesis of Bifunctional Polyhedral Oligomeric Silsesquioxane: Full Spectrum Ratio of Vinyl Groups from 0 to 100%. J. Ind. Eng. Chem. 2022, 113, 502–512. [Google Scholar] [CrossRef]

- Akbaşak, T.; Kodal, M.; Mert, O.; Özkoç, G. Novel and Eco-Friendly Hydrophobic Treatment of Cotton and Polyester Fabrics Based-on Octavinyl and Aminopropylisobutyl Polyhedral Oligomeric Silsesquioxanes (OL-POSS and AM-POSS). Polymer 2023, 268, 125723. [Google Scholar] [CrossRef]

- Mrzygłód, A.; García Armada, M.P.; Rzonsowska, M.; Dudziec, B.; Nowicki, M. Metallodendrimers Unveiled: Investigating the Formation and Features of Double-Decker Silsesquioxane-Based Silylferrocene Dendrimers. Inorg. Chem. 2023, 62, 16932–16942. [Google Scholar] [CrossRef] [PubMed]

- Mrzygłód, A.; Rzonsowska, M.; Dudziec, B. Exploring Polyol-Functionalized Dendrimers with Silsesquioxane Cores. Inorg. Chem. 2023, 62, 21343–21352. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, Z.; Hu, J.; Feng, X.; Zhang, M.; Duan, G.; Zhang, R.; Li, Y. Self-Assembly of Poly(Janus Particle)s into Unimolecular and Oligomeric Spherical Micelles. ACS Macro Lett. 2021, 10, 1563–1569. [Google Scholar] [CrossRef] [PubMed]

- Walther, A.; Hoffmann, M.; Müller, A.H.E. Emulsion Polymerization Using Janus Particles as Stabilizers. Angew. Chem. 2008, 120, 723–726. [Google Scholar] [CrossRef]

- Pei, X.; Tan, Y.; Xu, K.; Liu, C.; Lu, C.; Wang, P. Pickering Polymerization of Styrene Stabilized by Starch-Based Nanospheres. Polym. Chem. 2016, 7, 3325–3333. [Google Scholar] [CrossRef]

- Tang, J.; Quinlan, P.J.; Tam, K.C. Stimuli-Responsive Pickering Emulsions: Recent Advances and Potential Applications. Soft Matter 2015, 11, 3512–3529. [Google Scholar] [CrossRef] [PubMed]

- Plucinski, A.; Lyu, Z.; Schmidt, B.V.K.J. Polysaccharide Nanoparticles: From Fabrication to Applications. J. Mater. Chem. B 2021, 9, 7030–7062. [Google Scholar] [CrossRef] [PubMed]

- Low, L.E.; Siva, S.P.; Ho, Y.K.; Chan, E.S.; Tey, B.T. Recent Advances of Characterization Techniques for the Formation, Physical Properties and Stability of Pickering Emulsion. Adv. Colloid Interface Sci. 2020, 277, 102117. [Google Scholar] [CrossRef] [PubMed]

- Ni, L.; Yu, C.; Wei, Q.; Liu, D.; Qiu, J. Pickering Emulsion Catalysis: Interfacial Chemistry, Catalyst Design, Challenges, and Perspectives. Angew. Chem. 2022, 134, e202115885. [Google Scholar] [CrossRef]

- Casagrande, C.; Fabre, P.; Raphael, E.; Veyssié, M. “Janus Beads”: Realization and Behaviour at Water/Oil Interfaces. Europhys. Lett. 1989, 9, 251–255. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, Y. How Half-Coated Janus Particles Enter Cells. J. Am. Chem. Soc. 2013, 135, 19091–19094. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.; Tanaka, M. Designing Smart Biomaterials for Tissue Engineering. Int. J. Mol. Sci. 2017, 19, 17. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, P.; Zhang, S.; Zhu, K.; Shangguan, X.; Liu, L.; Zhang, S. Application of Janus Particles in Point-of-Care Testing. Biosensors 2022, 12, 689. [Google Scholar] [CrossRef]

- Karadkar, S.; Tiwari, A.; Chaskar, A.C. Recent Advancements in Janus Nanoparticle-Based Biosensing Platforms. Int. Nano Lett. 2023, 13, 93–115. [Google Scholar] [CrossRef] [PubMed]

- Jurado-Sánchez, B.; Campuzano, S.; Pingarrón, J.M.; Escarpa, A. Janus Particles and Motors: Unrivaled Devices for Mastering (Bio)Sensing. Microchim. Acta 2021, 188, 416. [Google Scholar] [CrossRef]

- Tan, K.X.; Danquah, M.K.; Jeevanandam, J.; Barhoum, A. Development of Janus Particles as Potential Drug Delivery Systems for Diabetes Treatment and Antimicrobial Applications. Pharmaceutics 2023, 15, 423. [Google Scholar] [CrossRef] [PubMed]

- Khoee, S.; Nouri, A. Preparation of Janus Nanoparticles and Its Application in Drug Delivery. In Design and Development of New Nanocarriers; Elsevier: Amsterdam, The Netherlands, 2018; pp. 145–180. [Google Scholar]

- Liu, Z.; McClements, D.J.; Shi, A.; Zhi, L.; Tian, Y.; Jiao, B.; Liu, H.; Wang, Q. Janus Particles: A Review of Their Applications in Food and Medicine. Crit. Rev. Food Sci. Nutr. 2023, 63, 10093–10104. [Google Scholar] [CrossRef]

- Chen, Z.; Xia, T.; Zhang, Z.; Xie, S.; Wang, T.; Li, X. Enzyme-Powered Janus Nanomotors Launched from Intratumoral Depots to Address Drug Delivery Barriers. Chem. Eng. J. 2019, 375, 122109. [Google Scholar] [CrossRef]

- Khoee, S.; Soleymani, M. Janus Arrangement of Smart Polymer on Magnetite Nanoparticles through Solvent Evaporation from Emulsion Droplets. Appl. Surf. Sci. 2019, 494, 805–816. [Google Scholar] [CrossRef]

- Komazaki, Y.; Hirama, H.; Torii, T. Electrically and Magnetically Dual-Driven Janus Particles for Handwriting-Enabled Electronic Paper. J. Appl. Phys. 2015, 117, 154506. [Google Scholar] [CrossRef]

- Panda, S.K.; Debata, S.; Singh, D.P. Characterizing the Janus Colloidal Particles in AC Electric Field and a Step towards Label-Free Cargo Manipulation. Chem. Phys. Impact 2024, 8, 100588. [Google Scholar] [CrossRef]

- Marschelke, C.; Fery, A.; Synytska, A. Janus Particles: From Concepts to Environmentally Friendly Materials and Sustainable Applications. Colloid Polym. Sci. 2020, 298, 841–865. [Google Scholar] [CrossRef]

- Ma, X.; Jannasch, A.; Albrecht, U.-R.; Hahn, K.; Miguel-López, A.; Schäffer, E.; Sánchez, S. Enzyme-Powered Hollow Mesoporous Janus Nanomotors. Nano Lett. 2015, 15, 7043–7050. [Google Scholar] [CrossRef] [PubMed]

- Schattling, P.S.; Ramos-Docampo, M.A.; Salgueiriño, V.; Städler, B. Double-Fueled Janus Swimmers with Magnetotactic Behavior. ACS Nano 2017, 11, 3973–3983. [Google Scholar] [CrossRef] [PubMed]

- Wang, W. Open Questions of Chemically Powered Nano- and Micromotors. J. Am. Chem. Soc. 2023, 145, 27185–27197. [Google Scholar] [CrossRef] [PubMed]

- Guix, M.; Weiz, S.M.; Schmidt, O.G.; Medina-Sánchez, M. Self-Propelled Micro/Nanoparticle Motors. Part. Part. Syst. Charact. 2018, 35, 1700382. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, H.; Cao, W.; Xie, S.; Ran, P.; Wei, K.; Li, X. Ultrasound-Chargeable Persistent Luminescence Nanoparticles to Generate Self-Propelled Motion and Photothermal/NO Therapy for Synergistic Tumor Treatment. ACS Nano 2023, 17, 16089–16106. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Yan, J.; Granick, S. Directed Self-Assembly Pathways of Active Colloidal Clusters. Angew. Chem. Int. Ed. 2016, 55, 5166–5169. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Han, M.; Zhang, J.; Xu, C.; Luijten, E.; Granick, S. Reconfiguring Active Particles by Electrostatic Imbalance. Nat. Mater. 2016, 15, 1095–1099. [Google Scholar] [CrossRef] [PubMed]

- Baran, Ł.; Borówko, M.; Rżysko, W.; Smołka, J. Amphiphilic Janus Particles Confined in Symmetrical and Janus-Like Slits. ACS Omega 2023, 8, 18863–18873. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Liang, K. Self-Propelled Nanoswimmers in Biomedical Sensing. Adv. Sens. Res. 2023, 2, 2300056. [Google Scholar] [CrossRef]

- Roh, K.-H.; Yoshida, M.; Lahann, J. Water-Stable Biphasic Nanocolloids with Potential Use as Anisotropic Imaging Probes. Langmuir 2007, 23, 5683–5688. [Google Scholar] [CrossRef] [PubMed]

- Yi, Y.; Sanchez, L.; Gao, Y.; Yu, Y. Janus Particles for Biological Imaging and Sensing. Analyst 2016, 141, 3526–3539. [Google Scholar] [CrossRef] [PubMed]

- Yánez-Sedeño, P.; Campuzano, S.; Pingarrón, J.M. Janus Particles for (Bio)Sensing. Appl. Mater. Today 2017, 9, 276–288. [Google Scholar] [CrossRef]

- He, Q.; Vijayamohanan, H.; Li, J.; Swager, T.M. Multifunctional Photonic Janus Particles. J. Am. Chem. Soc. 2022, 144, 5661–5667. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.Y.; Ross, B.M.; Hong, S.; Lee, L.P. Bioinspired Nanocorals with Decoupled Cellular Targeting and Sensing Functionality. Small 2010, 6, 503–507. [Google Scholar] [CrossRef]

- Hu, S.-H.; Gao, X. Nanocomposites with Spatially Separated Functionalities for Combined Imaging and Magnetolytic Therapy. J. Am. Chem. Soc. 2010, 132, 7234–7237. [Google Scholar] [CrossRef]

- Jiang, J.; Gu, H.; Shao, H.; Devlin, E.; Papaefthymiou, G.C.; Ying, J.Y. Bifunctional Fe3O4–Ag Heterodimer Nanoparticles for Two-Photon Fluorescence Imaging and Magnetic Manipulation. Adv. Mater. 2008, 20, 4403–4407. [Google Scholar] [CrossRef]

- Yang, T.; Wei, L.; Jing, L.; Liang, J.; Zhang, X.; Tang, M.; Monteiro, M.J.; Chen, Y.; Wang, Y.; Gu, S.; et al. Dumbbell-Shaped Bi-component Mesoporous Janus Solid Nanoparticles for Biphasic Interface Catalysis. Angew. Chem. Int. Ed. 2017, 56, 8459–8463. [Google Scholar] [CrossRef] [PubMed]

- Kirillova, A.; Schliebe, C.; Stoychev, G.; Jakob, A.; Lang, H.; Synytska, A. Hybrid Hairy Janus Particles Decorated with Metallic Nanoparticles for Catalytic Applications. ACS Appl. Mater. Interfaces 2015, 7, 21218–21225. [Google Scholar] [CrossRef]

- Faria, J.; Ruiz, M.P.; Resasco, D.E. Phase-Selective Catalysis in Emulsions Stabilized by Janus Silica-Nanoparticles. Adv. Synth. Catal. 2010, 352, 2359–2364. [Google Scholar] [CrossRef]

- Wei, D.; Yin, N.; Xu, D.; Ge, L.; Guo, R. Dynamically Reconfigurable Complex Emulsion Droplets as Intelligent Microreactors. ACS Sustain. Chem. Eng. 2024, 12, 5129–5138. [Google Scholar] [CrossRef]

- Kim, J.-W.; Larsen, R.J.; Weitz, D.A. Synthesis of Nonspherical Colloidal Particles with Anisotropic Properties. J. Am. Chem. Soc. 2006, 128, 14374–14377. [Google Scholar] [CrossRef] [PubMed]

- Marković, D.; Gros, C. Power Laws and Self-Organized Criticality in Theory and Nature. Phys. Rep. 2014, 536, 41–74. [Google Scholar] [CrossRef]

- Bak, P.; Chen, K.; Creutz, M. Self-Organized Criticality in the “Game of Life”. Nature 1989, 342, 780–782. [Google Scholar] [CrossRef]

- Available online: https://Img.Freepik.Com/Free-Photo/Vertical-Shot-Patterns-Beautiful-Sand-Dunes-Desert_181624-23323.jpg (accessed on 25 June 2024).

- Available online: https://www.orchidsinternationalschool.com/maths-concepts/wave-pattern (accessed on 25 June 2024).

- Available online: https://media.istockphoto.com/id/1370738891/photo/assorted-candied-berries-dried-fruits-nuts-and-seeds-top-view-healthy-food-background.jpg?s=1024x1024&w=is&k=20&c=83MVo6ootEmZ7qwCkm6e8prMEbvoh0zzFlq4YxhaE2M= (accessed on 25 June 2024).

- Available online: https://en.wikipedia.org/wiki/White_blood_cell (accessed on 25 June 2024).

- Available online: https://cdn.pixabay.com/photo/2016/08/17/06/20/elephant-1599763_640.jpg (accessed on 25 June 2024).

- Available online: https://img.freepik.com/Free-Photo/Front-View-Fresh-Melon-with-Pumpkin-Watermelon-Dark-Background_140725-91708.jpg (accessed on 25 June 2024).

- Available online: https://media.istockphoto.com/id/484757150/pt/foto/o-c%C3%A9rebro.jpg?s=1024x1024&w=is&k=20&c=JFbPgOU3CFMVdpyvTuHGsTPIV1akD73XO3loABBpc2Q= (accessed on 25 June 2024).

- Available online: https://media.gettyimages.com/id/155375562/photo/lava.webp?s=2048x2048&w=gi&k=20&c=sxWVBTTKoTxd_qldABnrs3Gq7AgwzYgWShXq1oB3oxQ= (accessed on 25 June 2024).

- Ensikat, H.J.; Ditsche-Kuru, P.; Neinhuis, C.; Barthlott, W. Superhydrophobicity in Perfection: The Outstanding Properties of the Lotus Leaf. Beilstein J. Nanotechnol. 2011, 2, 152–161. [Google Scholar] [CrossRef] [PubMed]

- Okayasu, T.; Zhang, H.-L.; Bucknall, D.G.; Briggs, G.A.D. Spontaneous Formation of Ordered Lateral Patterns in Polymer Thin-Film Structures. Adv. Funct. Mater. 2004, 14, 1081–1088. [Google Scholar] [CrossRef]

- Genzer, J.; Groenewold, J. Soft Matter with Hard Skin: From Skin Wrinkles to Templating and Material Characterization. Soft Matter 2006, 2, 310. [Google Scholar] [CrossRef] [PubMed]

- Miller, A.F. Exploiting Wrinkle Formation. Science 2007, 317, 605–606. [Google Scholar] [CrossRef] [PubMed]

- Godinho, M.H.; Trindade, A.C.; Figueirinhas, J.L.; Melo, L.V.; Brogueira, P.; Deus, A.M.; Teixeira, P.I.C. Tuneable Micro- and Nano-Periodic Structures in a Free-Standing Flexible Urethane/Urea Elastomer Film. Eur. Phys. J. E Soft Matter 2006, 21, 319–330. [Google Scholar] [CrossRef]

- Zhao, C.; Norberta de Pinho, M. Design of Polypropylene Oxide/Polybutadiene Bi-Soft Segment Urethane/Urea Polymer for Pervaporation Membranes. Polymer 1999, 40, 6089–6097. [Google Scholar] [CrossRef]

- Godinho, M.H.; Trindade, A.C.; Figueirinhas, J.L.; Melo, L.V.; Brogueira, P. Study of Micro and Nano Surface Structures from UV Irradiated Urethane/Urea Elastomers. Biomol. Eng. 2007, 24, 97–101. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Hu, B.; Song, J.; Chu, Z.; Wu, W. Bioinspired Multiscale Wrinkling Patterns on Curved Substrates: An Overview. Nanomicro Lett. 2020, 12, 101. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, P.; Trindade, A.C.; Godinho, M.H.; Azeredo, J.; Oliveira, R.; Fonseca, J.G. Staphylococcus Epidermidis Adhesion on Modified Urea/Urethane Elastomers. J. Biomater. Sci. Polym. Ed. 2006, 17, 239–246. [Google Scholar] [CrossRef][Green Version]

- Yin, J.; Lu, C. Hierarchical Surface Wrinkles Directed by Wrinkled Templates. Soft Matter 2012, 8, 6528. [Google Scholar] [CrossRef]

- Liu, L.; Ren, M.; Yang, W. Preparation of Polymeric Janus Particles by Directional UV-Induced Reactions. Langmuir 2009, 25, 11048–11053. [Google Scholar] [CrossRef] [PubMed]

- Cai, X.; Wang, Y.; Wang, X.; Ji, J.; Hong, J.; Pan, F.; Chen, J.; Xue, M. Fabrication of Ultrafine Soft-Matter Arrays by Selective Contact Thermochemical Reaction. Sci. Rep. 2013, 3, 1780. [Google Scholar] [CrossRef]

- Yin, J.; Cao, Z.; Li, C.; Sheinman, I.; Chen, X. Stress-Driven Buckling Patterns in Spheroidal Core/Shell Structures. Proc. Natl. Acad. Sci. USA 2008, 105, 19132–19135. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Hakimi, N.; Perez, R.; Waldman, S.; Kozinski, J.A.; Hwang, D.K. Microarchitecture for a Three-Dimensional Wrinkled Surface Platform. Adv. Mater. 2015, 27, 1880–1886. [Google Scholar] [CrossRef] [PubMed]

- Terwagne, D.; Brojan, M.; Reis, P.M. Smart Morphable Surfaces for Aerodynamic Drag Control. Adv. Mater. 2014, 26, 6608–6611. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Wei, W.; Qu, X.; Yang, Z. Janus Colloids Formed by Biphasic Grafting at a Pickering Emulsion Interface. Angew. Chem. 2008, 120, 4037–4039. [Google Scholar] [CrossRef]

- Yang, Y.; Han, X.; Ding, W.; Jiang, S.; Cao, Y.; Lu, C. Controlled Free Edge Effects in Surface Wrinkling via Combination of External Straining and Selective O 2 Plasma Exposure. Langmuir 2013, 29, 7170–7177. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, M.; Mizukami, K. Well-Ordered Wrinkling Patterns on Chemically Oxidized Poly(Dimethylsiloxane) Surfaces. Macromolecules 2012, 45, 7128–7134. [Google Scholar] [CrossRef]

- Ji, J.; Fuji, M.; Watanabe, H.; Shirai, T. Partially Functionalized Janus ZnO Spheres Prepared by Protecting Mask Techniques. Colloids Surf. A Physicochem. Eng. Asp. 2012, 393, 6–10. [Google Scholar] [CrossRef]

- Choi, S.; Cheong, I.W.; Kim, J.; Xia, Y. Preparation of Uniform Microspheres Using a Simple Fluidic Device and Their Crystallization into Close-Packed Lattices. Small 2009, 5, 454–459. [Google Scholar] [CrossRef] [PubMed]

- Trindade, A.C.; Canejo, J.P.; Pinto, L.F.V.; Patrício, P.; Brogueira, P.; Teixeira, P.I.C.; Godinho, M.H. Wrinkling Labyrinth Patterns on Elastomeric Janus Particles. Macromolecules 2011, 44, 2220–2228. [Google Scholar] [CrossRef]

- Trindade, A.C.; Canejo, J.P.; Patrício, P.; Brogueira, P.; Teixeira, P.I.; Godinho, M.H. Hierarchical Wrinkling on Elastomeric Janus Spheres. J. Mater. Chem. 2012, 22, 22044. [Google Scholar] [CrossRef]

- Bowden, N.; Brittain, S.; Evans, A.G.; Hutchinson, J.W.; Whitesides, G.W. Spontaneous Formation of Ordered Structures in Thin Films of Metals Supported on an Elastomeric Polymer. Nature 1998, 393, 148. [Google Scholar] [CrossRef]

- Cao, G.; Chen, X.; Li, C.; Ji, A.; Cao, Z. Self-Assembled Triangular and Labyrinth Buckling Patterns of Thin Films on Spherical Substrates. Phys. Rev. Lett. 2008, 100, 036102. [Google Scholar] [CrossRef] [PubMed]

- Trindade, A.C.; Canejo, J.P.; Teixeira, P.I.C.; Patrício, P.; Godinho, M.H. First Curl, Then Wrinkle. Macromol. Rapid Commun. 2013, 34, 1618–1622. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Hurd Price, C.-A.; Jing, L.; Tian, Q.; Liu, J.; Qian, K. Janus Particles: Design, Preparation, and Biomedical Applications. Mater. Today Bio 2019, 4, 100033. [Google Scholar] [CrossRef]

- Le, T.C.; Zhai, J.; Chiu, W.-H.; Tran, P.A.; Tran, N. Janus Particles: Recent Advances in the Biomedical Applications. Int. J. Nanomed. 2019, 14, 6749–6777. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Sasic, S.; Liu, K.; Salameh, S.; Ras, R.H.A.; van Ommen, J.R. Nature–Inspired Self–Cleaning Surfaces: Mechanisms, Modelling, and Manufacturing. Chem. Eng. Res. Des. 2020, 155, 48–65. [Google Scholar] [CrossRef]

- Korde, J.M.; Kandasubramanian, B. Fundamentals and Effects of Biomimicking Stimuli-Responsive Polymers for Engineering Functions. Ind. Eng. Chem. Res. 2019, 58, 9709–9757. [Google Scholar] [CrossRef]

- Benko, L.M.; Misko, V.R.; Baraban, L.; Makarov, D.; Maisto, A.; Malsche, W. De Janus Particles in Acoustofluidic Setup: The Interplay between Self-Propulsion and Acoustic Trapping. Micro 2024, 4, 185–195. [Google Scholar] [CrossRef]

- Kirillova, A.; Ionov, L.; Roisman, I.V.; Synytska, A. Hybrid Hairy Janus Particles for Anti-Icing and De-Icing Surfaces: Synergism of Properties and Effects. Chem. Mater. 2016, 28, 6995–7005. [Google Scholar] [CrossRef]

- Zhang, B.; Jiang, Y.; Chen, B.; Li, H.; Mao, Y. Recent Progress of Bioinspired Triboelectric Nanogenerators for Electronic Skins and Human–Machine Interaction. Nanoenergy Adv. 2024, 4, 45–69. [Google Scholar] [CrossRef]

- Walsh, F.C. Janus Particles: Features, Synthesis and Potential Uses, Including Surface Functionalisation. Trans. IMF 2024, 102, 4–8. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Shao, Y.; Deng, R.; Zhu, J.; Yang, Z. Recent Advances in Scalable Synthesis and Performance of Janus Polymer/Inorganic Nanocomposites. Prog. Mater. Sci. 2022, 124, 100888. [Google Scholar] [CrossRef]

- Subasi, B.G.; Xiao, J.; Capanogluo, E. Potential Use of Janus Structures in Food Applications. eFood 2021, 2, 279–287. [Google Scholar] [CrossRef] [PubMed]

- Greydanus, B.; Schwartz, D.K.; Medlin, J.W. Controlling Catalyst-Phase Selectivity in Complex Mixtures with Amphiphilic Janus Particles. ACS Appl. Mater. Interfaces 2020, 12, 2338–2345. [Google Scholar] [CrossRef]

- Liu, H.; Long, Y.; Liang, F. Interfacial Activity of Janus Particle: Unity of Molecular Surfactant and Homogeneous Particle. Chem. Asian J. 2024, 19, e202301078. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Zhang, J.; Yang, W.; Ma, Y.; Wang, R.; Ma, S.; Cai, M.; Yu, B.; Zhou, F. Transparent Janus Hydrogel Wet Adhesive for Underwater Self-Cleaning. ACS Appl. Mater. Interfaces 2021, 13, 50505–50515. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liu, F.; Chen, S.; Tsyrenova, A.; Miller, K.; Olson, E.; Mort, R.; Palm, D.; Xiang, C.; Yong, X.; et al. Self-Stratification of Amphiphilic Janus Particles at Coating Surfaces. Mater. Horiz. 2020, 7, 2047–2055. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trindade, A.C. Controlled Surface Textures of Elastomeric Polyurethane Janus Particles: A Comprehensive Review. Polymers 2024, 16, 1835. https://doi.org/10.3390/polym16131835

Trindade AC. Controlled Surface Textures of Elastomeric Polyurethane Janus Particles: A Comprehensive Review. Polymers. 2024; 16(13):1835. https://doi.org/10.3390/polym16131835

Chicago/Turabian StyleTrindade, Ana Catarina. 2024. "Controlled Surface Textures of Elastomeric Polyurethane Janus Particles: A Comprehensive Review" Polymers 16, no. 13: 1835. https://doi.org/10.3390/polym16131835

APA StyleTrindade, A. C. (2024). Controlled Surface Textures of Elastomeric Polyurethane Janus Particles: A Comprehensive Review. Polymers, 16(13), 1835. https://doi.org/10.3390/polym16131835