A Study of Plant-Filled Polymer Composites Based on Highly Plasticized Polyvinyl Chloride

Abstract

1. Introduction

2. Materials and Methods

2.1. Polymer Compositions

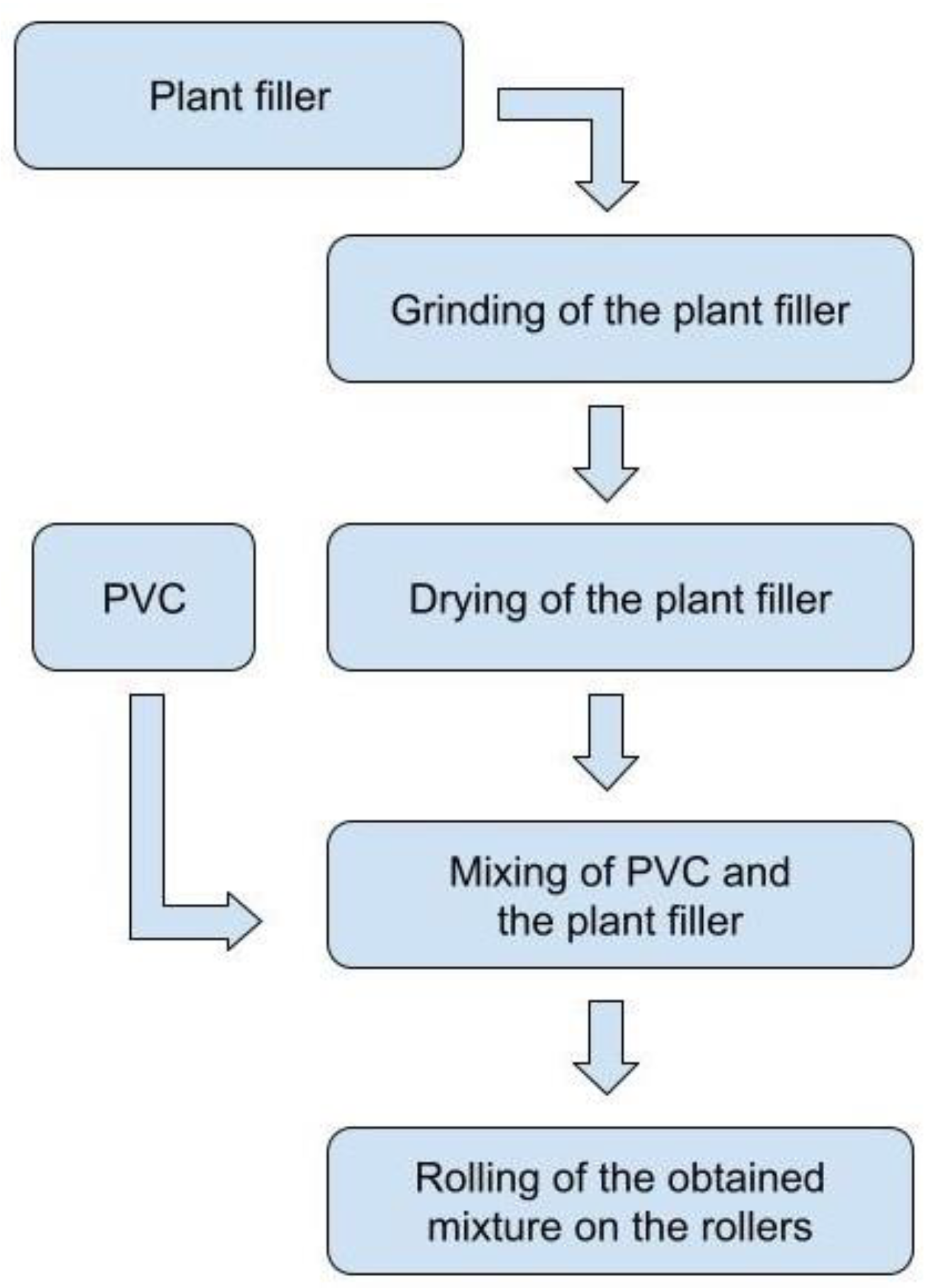

2.2. Polymer Films Fabrication Method

2.3. Investigation Methods

2.3.1. Optical Microscopy

2.3.2. FTIR Spectroscopy

2.3.3. DSC

2.3.4. TGA

2.3.5. Tensile Test

2.3.6. Water Absorption Test

3. Results and Discussion

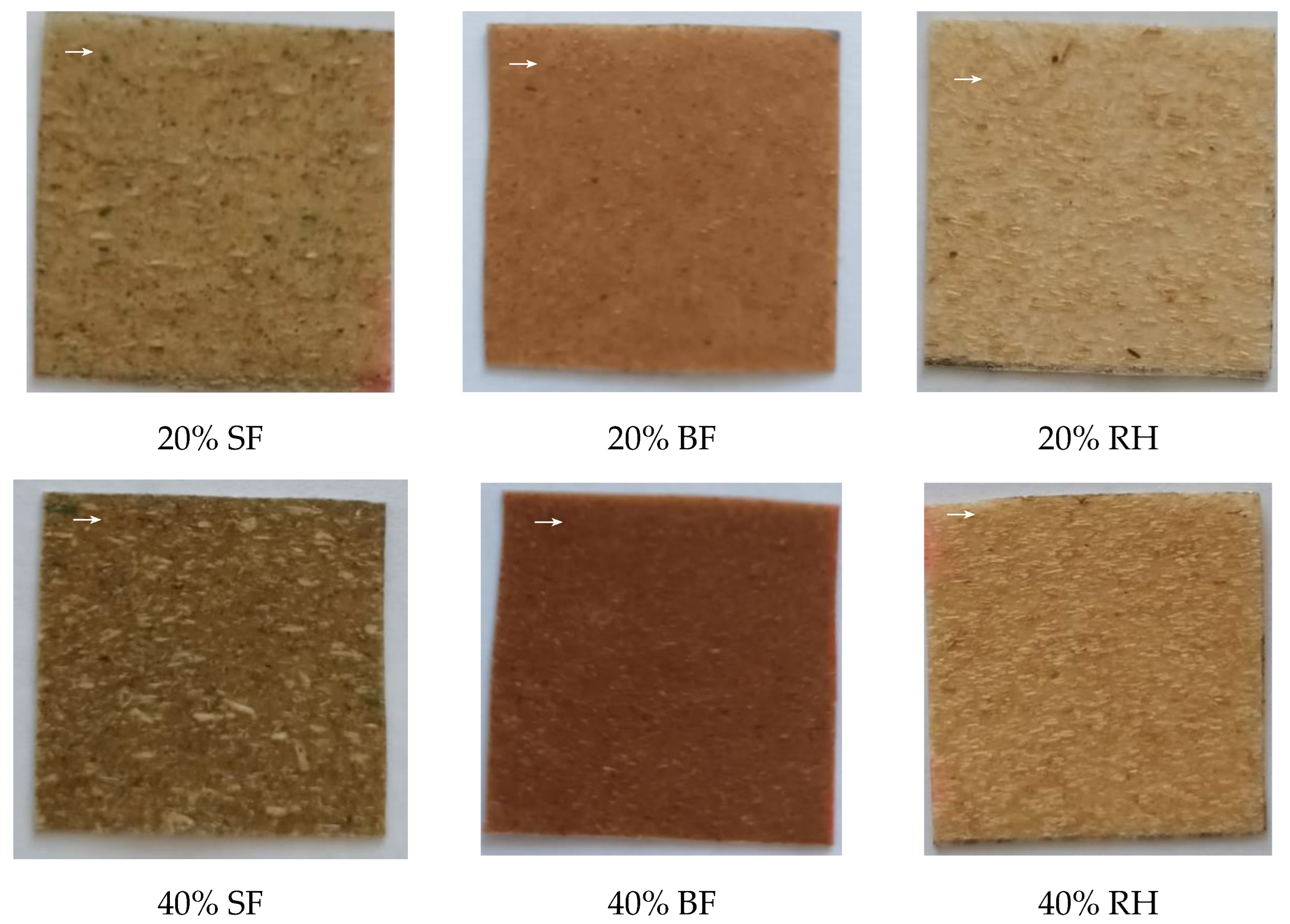

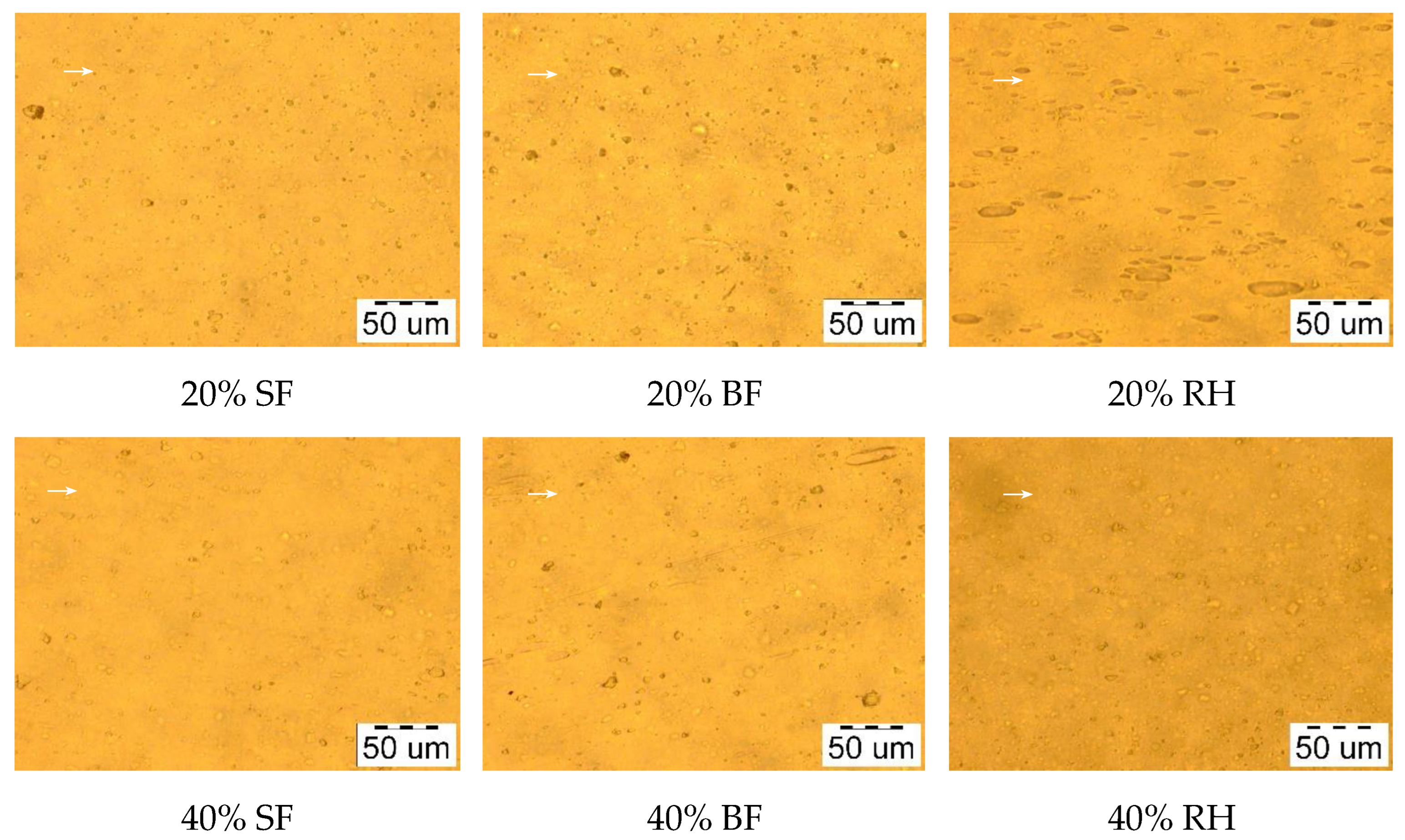

3.1. Optical Measurements

3.2. IR Spectroscopy

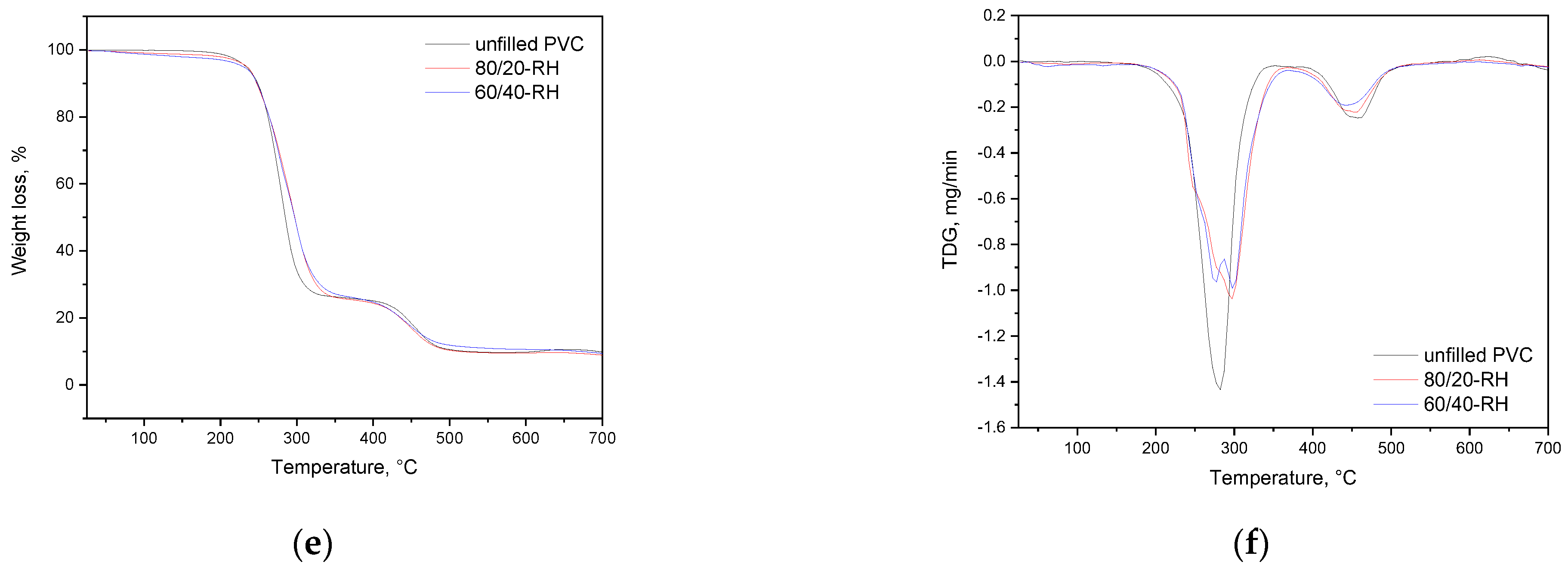

3.3. Thermal Properties

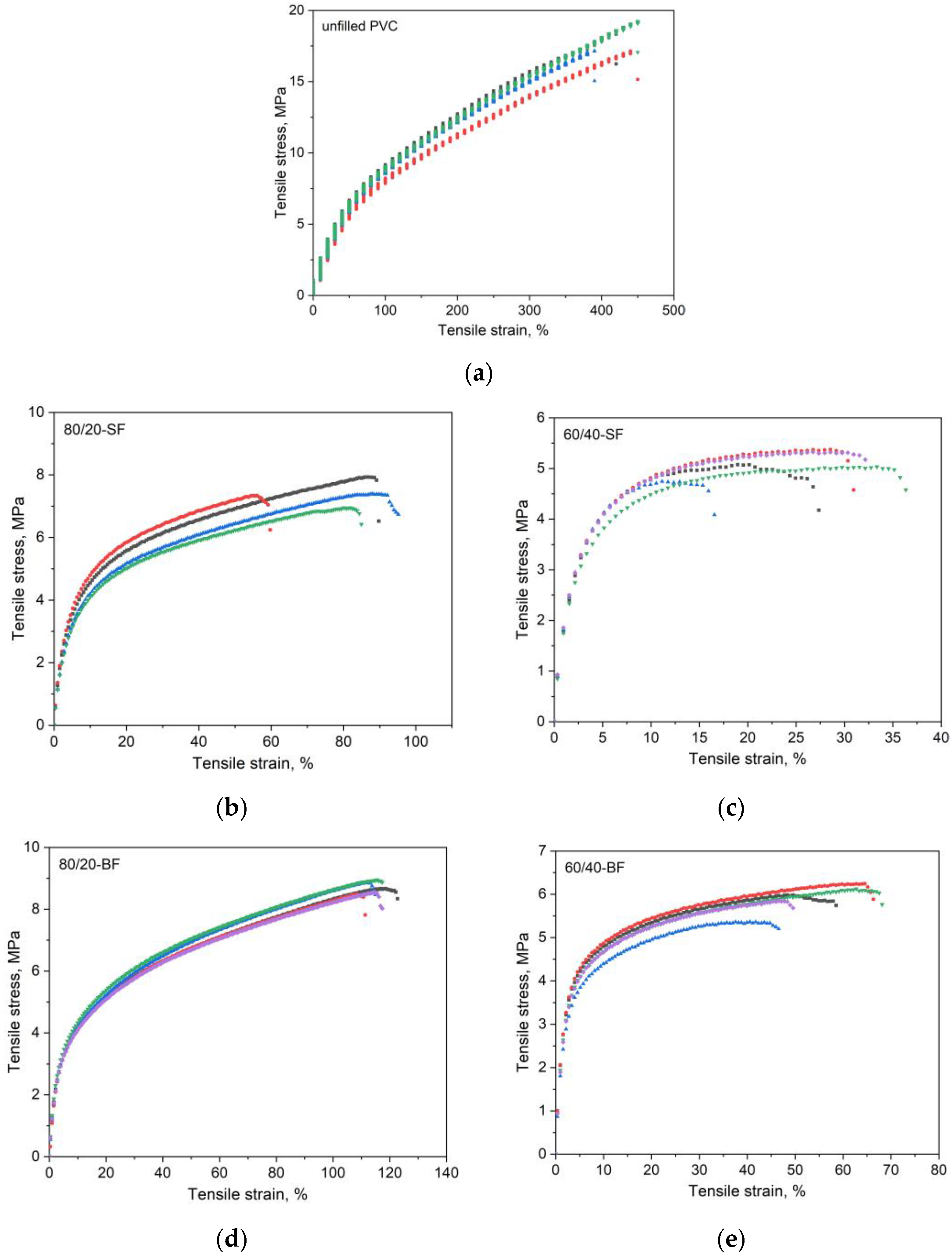

3.4. Mechanical Properties

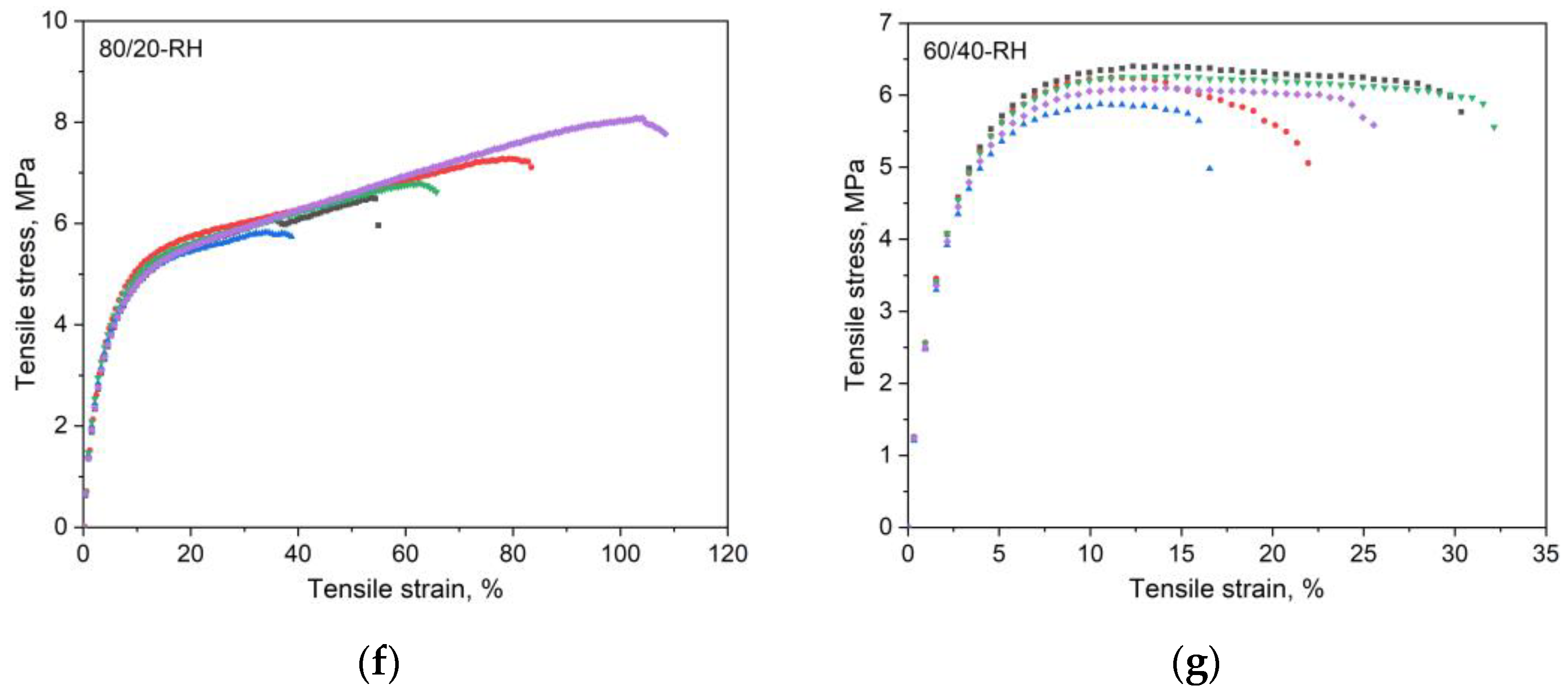

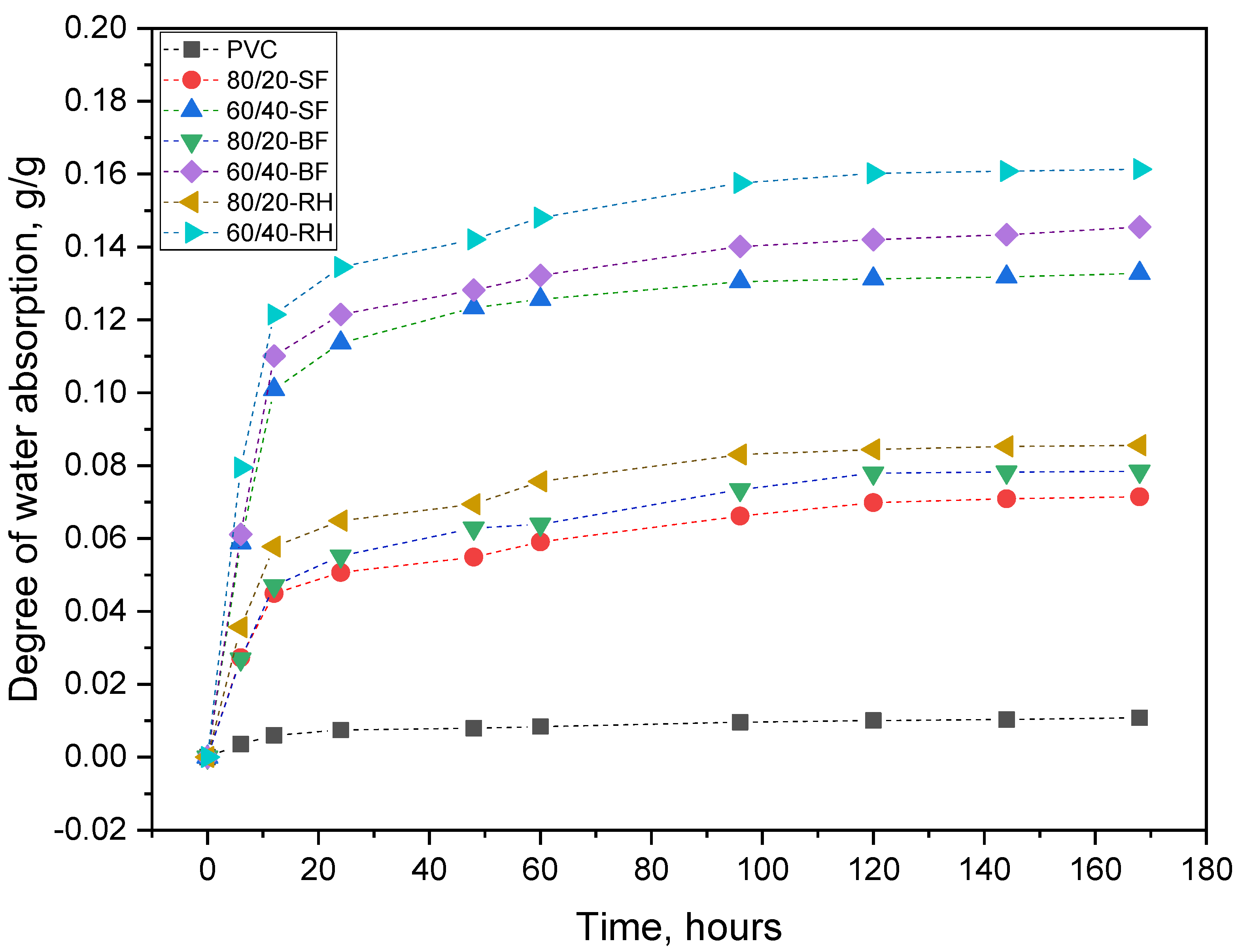

3.5. Water Absorption Test

4. Conclusions

- The relatively low glass transition temperature (below—65 °C) of samples with plant filler allows them to maintain their flexibility and elasticity at negative temperatures, which means such composites can be used in a wide range of temperatures and operating conditions.

- During mechanical tests, it was found that the addition of a plant filler in the amount of 20 wt.% reduces the tensile strength by more than two times, for example, from 18.0 MPa to 7.4 MPa when adding the spruce flour. Increasing the proportion of plant filler in the composites to 40 wt.% leads to a further decrease in tensile strength to 5–6 MPa, depending on the type of filler. A similar situation was observed for elongation strength values. A decrease in elongation at break values by 4–6 times was noted, depending on the type and proportion of filler. To minimize this effect, it is necessary to treat the plant filler with various modifiers.

- The investigation of water absorption of the samples demonstrated the ability of the PVC- filled composites to absorb water. And the highest degree of water absorption was detected for 60/40-RH (up to 160 mg/g). So, these samples cannot be used in conditions of constant contact with water due to their limited hydrophobicity, but they can withstand repeated short-term exposure to water without loss of performance characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Islam, A.; Mobarak, H.; Rimon, I.H.; Al Mahmud, Z.; Ghosh, J.; Ahmed, M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Karki, S.; Hazarika, G.; Yadav, D.; Ingole, P.G. Polymeric membranes for industrial applications: Recent progress, challenges and perspectives. Desalination 2024, 573, 117200. [Google Scholar] [CrossRef]

- Konjarla, A.; Sreekanth, T.; Mallikarjun, A.; Mettu, M.R.; Reddy, M.J. Membrane formation of PVC and PVDF-HFP polymer blend. Mater. Today Proc. 2023, 92, 561–564. [Google Scholar] [CrossRef]

- Kang, J.; Deng, N.; Cheng, B.; Kang, W. Progress in the application of polymer fibers in solid electrolytes for lithium metal batteries. J. Energy Chem. 2024, 92, 26–42. [Google Scholar] [CrossRef]

- Islam, Z.; Fu, Y.; Deb, H.; Hasan, K.; Dong, Y.; Shi, S. Polymer-based low dielectric constant and loss materials for high-speed communication network: Dielectric constants and challenges. Eur. Polym. J. 2023, 200, 112543. [Google Scholar] [CrossRef]

- De Santis, F.; Boragno, L.; Jeremic, D.; Albunia, A.R. Trimodal polyethylene polymer design for more sustainable packaging applications. Polymer 2024, 295, 126740. [Google Scholar] [CrossRef]

- Huang, H.; Ren, P.; Zhong, G.; Olah, A.; Li, Z.; Baer, E.; Zhu, L. Promising strategies and new opportunities for high barrier polymer packaging films. Prog. Polym. Sci. 2023, 144, 101722. [Google Scholar] [CrossRef]

- Dua, S.; Arora, N.; Prakashaiah, B.G.; Saxena, R.C.; Ganguly, S.K.; Senthilkumar, T. Conjugated polymer-based composites for anti-corrosion applications. Prog. Org. Coat. 2024, 188, 108231. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; Barroso de Aguiar, J. Sustainable polymer-based Phase Change Materials for energy efficiency in buildings and their application in aerial lime mortars. Constr. Build. Mater. 2020, 231, 117149. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Z.; Li, Q.; Wang, K.; Jiang, D.; Hou, P.; Huang, Y.; Zhao, P. Insights on the role of particulate filler on the polymer-modified cement-based coating and its application. J. Build. Eng. 2023, 76, 107395. [Google Scholar] [CrossRef]

- Abdulla, N.A. A state-of art-review of materials, methods, and applications of PVC-FRP-confined concrete. Constr. Build. Mater. 2023, 363, 129719. [Google Scholar] [CrossRef]

- Kobayashi, S. Encyclopedia of Polymeric Nanomaterials, 1st ed.; Kobayashi, S., Mullen, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; 2617p. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers; ChemTech Publishing: Toronto, ON, Canada; New York, NY, USA, 2012; p. 696. [Google Scholar] [CrossRef]

- Mijangos, C.; Calafel, I.; Santamaría, A. Poly(vinyl chloride), a historical polymer still evolving. Polymer 2023, 266, 125610. [Google Scholar] [CrossRef]

- Alshammari, A.H.; Alshammari, M.; Ibrahim, M.; Alshammari, K.; Taha, A.M.M. Processing polymer film nanocomposites of polyvinyl chloride—Polyvinylpyrrolidone and MoO3 for optoelectronic applications. Opt. Laser Technol. 2024, 168, 109833. [Google Scholar] [CrossRef]

- Sonia, D.; Malagavelli, V.; Balguri, P.K. Strength Assessment of PVC Pipes Filled with Geo-Polymer Concrete asS lender Column. Mater. Today Proc. 2022, 62, 3001–3005. [Google Scholar] [CrossRef]

- Silva, T.I.B.; Moreira, F.T.C.; Truta, L.A.A.N.A.; Sales, M.G.T. Novel optical PVC probes for on-site detection/determination of fluoroquinolones in a solid/liquid interface: Application to the determination of Norfloxacin in aquaculture water. Biosens. Bioelectron. 2012, 36, 199–206. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, S.J.; Hawaiz, F.E.; Aziz, S.B.; Al-Jaf, S.H. Organic soluble nitrogen-doped carbon dots (ONCDs) to reduce the optical band gap of PVC polymer: Breakthrough in polymer composites with improved optical properties. Opt. Mater. 2024, 149, 115014. [Google Scholar] [CrossRef]

- Li, Y.; Feng, X.; Zhu, L.; Zhang, Z.; Guo, M.; Li, Y.; Minoru Hashimoto, M. High performance fiber-constrained plasticized PVC gel actuators for soft robotics. Sens. Actuators B Chem. 2023, 393, 134177. [Google Scholar] [CrossRef]

- Lang, J.; Stanhope, B.E. Benzoate plasticizer for flexible PVC injection moulded toy applications. Plast. Addit. Compd. 2001, 39, 30–33. [Google Scholar] [CrossRef]

- Simon, M.A.; Kusy, R.P. Plasticizer-level study of poly(viny1 chloride) ion-selective membranes. J. Biomed. Mater. Res. 1996, 30, 313–320. [Google Scholar] [CrossRef]

- Jiaa, P.; Mab, Y.; Song, F.; Hua, Y.; Zhang, C.; Zhoua, Y. Toxic phthalate-free and highly plasticized polyvinyl chloride materials from non-timber forest resources in plantation. React. Funct. Polym. 2019, 144, 104363. [Google Scholar] [CrossRef]

- Pannico, M.; Musto, P. Migration of plasticizers from flexible PVC: Monitoring the concentration profiles by confocal Raman microspectroscopy. Polymer 2024, 294, 126731. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, L.; Qu, L.; Wang, J.; Qiu, Y.; Xi, W.; Ma, Y. Bismuth trioxide replaced diantimony trioxide to obtain polyvinyl chloride leather with high flame retardancy and low flame propagation rate. React. Funct. Polym. 2024, 197, 105864. [Google Scholar] [CrossRef]

- Bajagain, R.; Panthi, G.; Park, J.; Moon, J.; Kwon, J.; Kim, D.Y.; Kwon, J.; Hong, Y. Enhanced migration of plasticizers from polyvinyl chloride consumer products through artificial sebum. Sci. Total Environ. 2023, 874, 162412. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Sochichiu, S.; Kwon, J.-H. Effects of time, temperature, and sebum layer on migration rate of plasticizers in polyvinyl chloride products. Chemosphere 2022, 308, 136478. [Google Scholar] [CrossRef]

- Gulizia, A.M.; Philippa, B.; Zacharuk, J.; Motti, C.A.; Vamvounis, G. Plasticiser leaching from polyvinyl chloride microplastics and the implications for environmental risk assessment. Mar. Pollut. Bull. 2023, 195, 115392. [Google Scholar] [CrossRef] [PubMed]

- Cardarelli, F. Polymers and Elastomers. In Materials Handbook, 3rd ed.; Springer: Basel, Switzerland; Manhattan, NY, USA, 2018; pp. 1013–1092. [Google Scholar] [CrossRef]

- Khalid, A.R.; Shah, T.; Asad, M.; Ali, A.; Samee, E.; Adnan, F.; Bhatti, M.F.; Marhan, S.; Kammann, C.I.; Haider, G. Biochar alleviated the toxic effects of PVC microplastic in a soil-plant system by upregulating soil enzyme activities and microbial abundance. Environ. Pollut. 2023, 332, 1218100. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Kim, J.Y.; Sung, S.; Lee, Y.; Gu, S.; Choi, J.-W.; Yoo, C.-J.; Suh, D.J.; Choi, J.; Ha, J.-M. Chemical upcycling of PVC-containing plastic wastes by thermal degradation and catalysis in a chlorine-rich environment. Environ. Pollut. 2024, 342, 123074. [Google Scholar] [CrossRef]

- Ghosal, K.; Ghosh, S. Biodegradable polymers from lignocellulosic biomass and synthetic plastic waste: An emerging alternative for biomedical applications. Mater. Sci. Eng. R Rep. 2023, 156, 100761. [Google Scholar] [CrossRef]

- Lu, L.; Li, W.; Cheng, Y.; Liu, M. Chemical recycling technologies for PVC waste and PVC-containing plastic waste: A review. Waste Manag. 2023, 166, 245–258. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Xu, F.; Wang, Z. Formation and evolution of PVC waste-derived hydrochar. J. Anal. Appl. Pyrolysis 2023, 175, 106211. [Google Scholar] [CrossRef]

- Meng, J.; Xu, B.; Liu, F.; Li, W.; Sy, N.; Zhou, X.; Yan, B. Effects of chemical and natural ageing on the release of potentially toxic metal additives in commercial PVC microplastics. Chemosphere 2021, 283, 131274. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, S.; Li, Y.; Su, J.; Shangguan, J.; Zhan, M.; Wang, Y.; Su, X.; Li, J.; Zhang, G. The impact of three related emission industries on regional atmospheric chlorinated paraffins pollution. Environ. Pollut. 2023, 316, 120564. [Google Scholar] [CrossRef]

- Li, W.; Bai, Z.; Zhang, T.; Jia, Y.; Hou, Y.; Chen, J.; Guo, Z.; Kong, L.; Bai, J.; Li, W. Comparative study on pyrolysis behaviors and chlorine release of pure PVC polymer and commercial PVC plastics. Fuel 2023, 340, 127555. [Google Scholar] [CrossRef]

- Czégény, Z.; Jakab, E.; Bozi, J.; Blazsó, M. Pyrolysis of wood–PVC mixtures. Formation of chloromethane from lignocellulosic materials in the presence of PVC. J. Anal. Appl. Pyrolysis 2015, 113, 123–132. [Google Scholar] [CrossRef]

- Altaee, N.; El-Hiti, G.A.; Fahdil, A.; Sudesh, K.; Yousif, E. Biodegradation of different formulations of polyhydroxybutyrate films in soil. Springerplus 2016, 5, 762. [Google Scholar] [CrossRef] [PubMed]

- Marceneiro, S.; Lobo, I.; Dias, I.; de Pinho, E.; Dias, A.M.A.; de Sousa, H.C. Eco-friendlier and sustainable natural-based additives for poly(vinyl chloride)-based composites. J. Ind. Eng. Chem. 2022, 10, 248–261. [Google Scholar] [CrossRef]

- Sharma, S.D.; Sowntharya, L.; Kar, K.K. Polymer-Based Composite Structures: Processing and Applications. In Composite Materials, 1st ed.; Kar., K., Ed.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–36. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2017, 172, 349–357. [Google Scholar] [CrossRef]

- Kuyyakanont, A.; Iwata, M. Study of different degradation effects in UV-sensitive polymers using xenon lamp and deuterium lamp to simulate UV irradiation in space environment. Nucl. Instrum. Methods Phys. Res. B 2024, 549, 165267. [Google Scholar] [CrossRef]

- Abdollahi Boraei, S.B.; Bakhshandeh, B.; Mohammadzadeh, F.; Haghighi, D.M.; Mohammadpour, Z. Clay-reinforced PVC composites and nanocomposites. Heliyon 2024, 10, e29196. [Google Scholar] [CrossRef]

- Ivanov, V.; Stabnikov, V. Construction Biotechnological Plastics. In Construction Biotechnology. Green Energy and Technology; Springer: Singapore, 2017; pp. 51–75. [Google Scholar] [CrossRef]

- Subramanian, N. Update on Troubleshooting the PVC Extrusion Process; Smithers Rapra Technology: Shawbury, UK, 2011; 164p. [Google Scholar]

- Yang, A.; Zhang, R.; Xu, Z.; Liu, T.; Fang, Y.; Wang, W.; Xu, M.; Song, Y.; Wang, Q. Preparation of situ microfiber-reinforced co-extruded high-filled wood-plastic composite with excellent mechanical, creep resistance, and water resistance properties. Constr. Build. Mater. 2024, 415, 135002. [Google Scholar] [CrossRef]

- Qi, Z.; Cai, H.; Ren, F.; Liu, L.; Yang, K.; Han, X. In-situ lignin regeneration strategy to improve the interfacial combination, mechanical properties and stabilities of wood-plastic composites. Compos. Sci. Technol. 2024, 246, 110366. [Google Scholar] [CrossRef]

- Yang, R.; Fang, Y.; Zhu, J.; Ren, G.; Lin, B.; Wang, F.; Ou, R.; Wang, Q.; Song, Y. Fabrication ZnO functionalized nano-montmorillonite for enhancing the fire-safety and mechanical properties of wood flour/poly (vinyl chloride) composites. Constr. Build. Mater. 2024, 420, 135522. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S. Effects of Rice Hull Particle Size and Content on the Mechanical Properties and Visual Appearance of Wood Plastic Composites Prepared from Poly(vinyl chloride). J. Bionic. Eng. 2013, 10, 110–117. [Google Scholar] [CrossRef]

- Bai, X.; Wang, Q.; Sui, S.; Zhang, C. The effects of wood-flour on combustion and thermal degradation behaviors of PVC in wood-flour/poly(vinyl chloride) composites. J. Anal. Appl. Pyrolysis 2011, 91, 34–39. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, K.; Chen, D.; Zhang, Y.; Zhang, X.; Yang, Z. Effect of alkali treatment on water absorption deterioration and mechanism of wheat straw/PVC composites. Polym. Test. 2024, 131, 108348. [Google Scholar] [CrossRef]

- Klyosov, A.E. Wood-Plastic Composite; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; 736p, ISBN 978-0-470-14891-4. [Google Scholar]

- Jiang, H.; Kamden, P. Development of Poly(vinyl chloride)/Wood Composites. A Literature Review. J. Vinyl Addit. Technol. 2004, 10, 59–69. [Google Scholar] [CrossRef]

- Joglekar, J.J.; Munde, Y.S.; Jadhav, A.L.; Bhutada, D.S.; Radhakrishnan, S.; Kulkarni, M.B. Studies on effective utilization of Citrus Maxima fibers based PVC composites. Mater. Today Proc. 2021, 42, 578–583. [Google Scholar] [CrossRef]

- Bahari, S.A.; Krause, A. Utilizing Malaysian bamboo for use in thermoplastic composites. J. Clean. Prod. 2016, 110, 16–24. [Google Scholar] [CrossRef]

- Jeamtrakull, S.; Kositchaiyong, A.; Markpin, T.; Rosarpitak, V.; Sombatsompop, N. Effects of wood constituents and content, and glass fiber reinforcement on wear behavior of wood/PVC composites. Compos. B Eng. 2012, 43, 2721–2729. [Google Scholar] [CrossRef]

- Müller, M.; Militz, H.; Krause, A. Thermal degradation of ethanolamine treated poly(vinyl chloride)/wood flour composites. Polym. Degrad. Stab. 2012, 97, 166–169. [Google Scholar] [CrossRef]

- Pulngern, T.; Padyenchean, C.; Rosarpitak, V.; Prapruit, W.; Sombatsompop, N. Flexural and creep strengthening for wood/PVC composite members using flat bar strips. Mater. Des. 2011, 32, 3431–3439. [Google Scholar] [CrossRef]

- Augier, L.; Sperone, G.; Vaca-Garcia, C.; Borredon, M.-E. Influence of the wood fibre filler on the internal recycling of poly(vinyl chloride)-based composites. Polym. Degrad. Stab. 2007, 92, 1169–1176. [Google Scholar] [CrossRef]

- Table of Hardness, Density and Stability of Wood. Available online: https://les-massiv.ru/tverd_plotn_stab (accessed on 25 April 2024).

- ISO 527-3:2018; Plastics—Determination of Tensile Properties. Part 3: Test Test Conditions for Films and Sheets. ISO: Geneva, Switzerland, 2018; 5p.

- ISO 62:2008; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008; 15p.

- Müller, G.; Schöpper, C.; Vos, H.; Kharazipour, A.; Polle, A. FTIR-ATR spectroscopic analyses of changes in wood properties during particleand fibreboard production of hardand softwood trees. BioResources 2009, 4, 49–71. [Google Scholar] [CrossRef]

- Pandey, M.; Joshi, G.M.; Mukherjee, A.; Thomas, P. Electrical properties and thermal degradation of poly(vinyl chloride)/polyvinylidene fluoride/ZnO polymer nanocomposites. Polym. Int. 2016, 65, 1098–1106. [Google Scholar] [CrossRef]

- Wilkie, C.; Summers, J.; Daniels, C. Polyvinylchloride; Professiya: Saint Petersburg, Russia, 2007; 728p. (In Russian) [Google Scholar]

- Jia, P.; Wang, R.; Hu, L.; Zhang, M.; Zhou, Y. Self-Plasticization of PVC via click reaction of a monooctyl phthalate derivative. Polish J. Chem. Technol. 2017, 19, 16–19. [Google Scholar] [CrossRef]

- Hincapie Rojas, D.F.; Pineda Gómez, P.; Rivera, A.R. Production and characterization of silica nanoparticles from rice husk. Adv. Mater. Lett. 2019, 10, 67–73. [Google Scholar] [CrossRef]

- Nörnberg, B.; Borchardt, E.; Luinstra, G.A.; Fromm, J. Wood plastic composites from poly(propylene carbonate) and poplar wood flour—Mechanical, thermal and morphological properties. Eur. Polym. J. 2014, 51, 167–176. [Google Scholar] [CrossRef]

- Raj, S.S.; Elangovan, E.; Arulmozhi, P.; Murugan, N. Selective micro wood reinforcements for bio-wood plastics deliberating mechanical and degradation properties. Mater. Today Proc. 2023, 90, 24–28. [Google Scholar] [CrossRef]

- Khamtree, S.; Ratanawilai, T.; Ratanawilai, S. Determining the optimum conditions for silane treated rubberwood flour-recycled polypropylene composites using response surface methodology. Mater. Today Commun. 2020, 24, 100971. [Google Scholar] [CrossRef]

- Taneli Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, Q.; McNabb, H.S., Jr. Chemical coupling in wood fiber and polymer composites: A review of coupling agents and treatments. Wood Fiber Sci. 2000, 32, 88–104. [Google Scholar]

- Hanafi Ismail, H.; Jaffri, R.M. Physico-mechanical properties of oil palm wood flour filled natural rubber composites. Polym. Test. 1999, 18, 381–388. [Google Scholar] [CrossRef]

- Danyadi, L.; Janecska, T.; Szabo, Z.; Nagy, G.; Moczo, J.; Pukanszky, B. Wood flour filled PP composites: Compatibilization and adhesion. Compos. Sci. Technol. 2007, 67, 2838–2846. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Nógellová, Z.; Mičušík, M.; Novák, I.; Krupa, I. Mechanical, sorption and adhesive properties of composites based on low density polyethylene filled with date palm wood powder. Mater. Des. 2013, 53, 29–37. [Google Scholar] [CrossRef]

- Jiang, L.; Hea, C.; Fua, J.; Chen, D. Wear behavior of straw fiber-reinforced polyvinyl chloride composites under simulated acid rain conditions. Polym. Test. 2017, 62, 373–381. [Google Scholar] [CrossRef]

- Benthien, J.T.; Thoemen, H. Effects of raw materials and process parameters on the physical and mechanical properties of flat pressed WPC panels. Compos. Part A Appl. Sci. Manuf. 2012, 43, 570–576. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Wechsler-Pizarro, A.; Vidal-Vega, M. Mechanical, physical, thermal and morphological properties of polypropylene composite materials developed with particles of peach and cherry stones. SMT 2021, 29, e00300. [Google Scholar] [CrossRef]

- Ashori, A. Hybrid thermoplastic composites using nonwood plant fibers. In Hybrid Polymer Composite Materials; Woodhead Publishing: Sawston, UK, 2017; pp. 39–56. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Mishra, S.; Verma, J. Effect of compatibilizers on water absorption kinetics of polypropylene/wood flour foamed composites. J. Appl. Polym. Sci. 2006, 101, 2530–2537. [Google Scholar] [CrossRef]

- Vlaev, L.; Turmanova, S.; Dimitrova, A. Kinetics and thermodynamics of water adsorption onto rice husks ash filled polypropene composites during soaking. J. Polym. Res. 2009, 16, 151–164. [Google Scholar] [CrossRef]

- Fadele, O.A.; Ata, O. Water absorption properties of sawdust lignin stabilised compressed laterite bricks. Case Stud. Constr. Mater. 2018, 9, e00187. [Google Scholar] [CrossRef]

- Li, M.; Jia, Y.; Shen, X.; Shen, T.; Tan, Z.; Zhuang, W.; Zhao, G.; Zhu, C.; Ying, H. Investigation into lignin modified PBAT/thermoplastic starch composites: Thermal, mechanical, rheological and water absorption properties. Ind. Crops. Prod. 2021, 171, 113916. [Google Scholar] [CrossRef]

| Parameter | Plant Filler | ||

|---|---|---|---|

| SF | BF | RH | |

| Brinell hardness, kgf/mm2 | 2.5 | 3 | - |

| Yankee hardness, ft | 660 | 1260 | - |

| Density, kg/m3 | 400–500 | 540–700 | 735 |

| Tensile strength along/across the fibers, MPa | 98/4.7 | 158/10.6 | - |

| Moisture stability | medium-stable ** | relatively stable * | stable *** |

Organic substances, % [53]:

| |||

| 42 ± 2 | 44 ± 3 | 38 ± 8 | |

| 26 ± 3 | 32 ± 5 | 25 ± 3 | |

| 29 ± 4 | 18 ± 4 | 14 ± 2 | |

| 0.2–0.8 | 0.2–0.8 | 19 | |

| cellulose/lignin | 1.45 | 2.44 | 2.71 |

| Composition of Samples PVC/Plant Filler | Component, wt.% | |||

|---|---|---|---|---|

| PVC Composition | Plant Filler | |||

| Spruce Flour | Birch Flour | Rice Husk | ||

| PVC | 100 | - | - | - |

| 80/20-SF | 80 | 20 | - | - |

| 60/40-SF | 60 | 40 | - | - |

| 80/20-BF | 80 | - | 20 | - |

| 60/40-BF | 60 | - | 40 | - |

| 80/20-RH | 80 | - | - | 20 |

| 60/40-RH | 60 | - | - | 40 |

| Sample | Temperature Value at Mass Loss during the Decomposition (°C) | |||

|---|---|---|---|---|

| Tmax of 1st Stage | 1st Stage Range | Tmax of 2nd Stage | 2nd Stage Range | |

| PVC | 282 | 246–347 | 462 | 425–558 |

| 80/20-SF | 273 | 240–368 | 458 | 418–557 |

| 60/40-SF | 267 | 235–362 | 447 | 416–562 |

| 80/20-BF | 272 | 244–366 | 452 | 424–567 |

| 60/40-BF | 269 | 242–372 | 444 | 415–563 |

| 80/20-RH | 297 | 246–369 | 454 | 414–568 |

| 60/40-RH | 297 | 244–367 | 443 | 414–565 |

| Sample | Thickness of the Samples, mm | Tensile Strength, MPa | Relative Elongation at Break,% | Young’s Modulus, MPa |

|---|---|---|---|---|

| PVC | 0.594 | 18.0 ± 1.0 | 427.4 ± 29.3 | 14.5 ± 0.7 |

| 80/20-SF | 0.501 | 7.4 ± 0.4 | 124.7 ± 28.2 | 94.9 ± 9.1 |

| 60/40-SF | 0.511 | 5.1 ± 0.2 | 62.4 ± 7.6 | 148.2 ± 4.7 |

| 80/20-BF | 0.523 | 8.7 ± 0.2 | 140.0 ± 12.5 | 96.8 ± 8.2 |

| 60/40-BF | 0.483 | 5.9 ± 0.3 | 131.8 ± 11.1 | 162.8 ± 9.7 |

| 80/20-RH | 0.520 | 6.9 ± 0.8 | 126.9 ± 20.4 | 120.4 ± 10.6 |

| 60/40-RH | 0.543 | 6.2 ± 0.2 | 81.6 ± 11.1 | 206.6 ± 4.9 |

| Sample | Water Absorption Degree, g/g | |

|---|---|---|

| After 24 h | After 7 Days | |

| PVC | 0.007 ± 0.002 | 0.011 ± 0.003 |

| 80/20-SF | 0.051 ± 0.018 | 0.071 ± 0.009 |

| 60/40-SF | 0.114 ± 0.011 | 0.133 ± 0.006 |

| 80/20-BF | 0.055 ± 0.007 | 0.078 ± 0.011 |

| 60/40-BF | 0.121 ± 0.015 | 0.145 ± 0.017 |

| 80/20-RH | 0.065 ± 0.009 | 0.086 ± 0.014 |

| 60/40-RH | 0.134 ± 0.011 | 0.161 ± 0.007 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samuilova, E.; Ponomareva, A.; Sitnikova, V.; Zhilenkov, A.; Kichigina, O.; Uspenskaya, M. A Study of Plant-Filled Polymer Composites Based on Highly Plasticized Polyvinyl Chloride. Polymers 2024, 16, 1551. https://doi.org/10.3390/polym16111551

Samuilova E, Ponomareva A, Sitnikova V, Zhilenkov A, Kichigina O, Uspenskaya M. A Study of Plant-Filled Polymer Composites Based on Highly Plasticized Polyvinyl Chloride. Polymers. 2024; 16(11):1551. https://doi.org/10.3390/polym16111551

Chicago/Turabian StyleSamuilova, Evgeniia, Alina Ponomareva, Vera Sitnikova, Anton Zhilenkov, Olga Kichigina, and Mayya Uspenskaya. 2024. "A Study of Plant-Filled Polymer Composites Based on Highly Plasticized Polyvinyl Chloride" Polymers 16, no. 11: 1551. https://doi.org/10.3390/polym16111551

APA StyleSamuilova, E., Ponomareva, A., Sitnikova, V., Zhilenkov, A., Kichigina, O., & Uspenskaya, M. (2024). A Study of Plant-Filled Polymer Composites Based on Highly Plasticized Polyvinyl Chloride. Polymers, 16(11), 1551. https://doi.org/10.3390/polym16111551