3.1. Rheological Characteristics of Binary Bitumen–Additive Systems

The results of studying the rheological properties of bitumen compositions at 130 °C depending on the concentration of modifiers (0–2.0 g/dm

3) are presented in

Table 2.

As evidenced by experimental data obtained at t = 130 °C, the introduction of 0.5 g/dm

3 of all types of additives into the binder leads to a decrease in viscosity values relative to unmodified bitumen (

Table 2).

The greatest decrease in specific viscosity in isoconcentration (C = 0.5 g/dm

3) binary compositions occurs in the presence of AS-1 (

ηsp = −0.62), i.e., the lowest molecular weight additive (M = 250 amu). As the molecular weights of the modifiers increased, the depth of viscosity changes decreased. Thus, in the composition with AMDOR-10 (M = 2260 amu), the specific viscosity had a value of −0.48, and with the higher molecular weight of AG-4I (M = 5400 amu), the decrease of relative viscosity (

ηsp = −0.28) was even less (

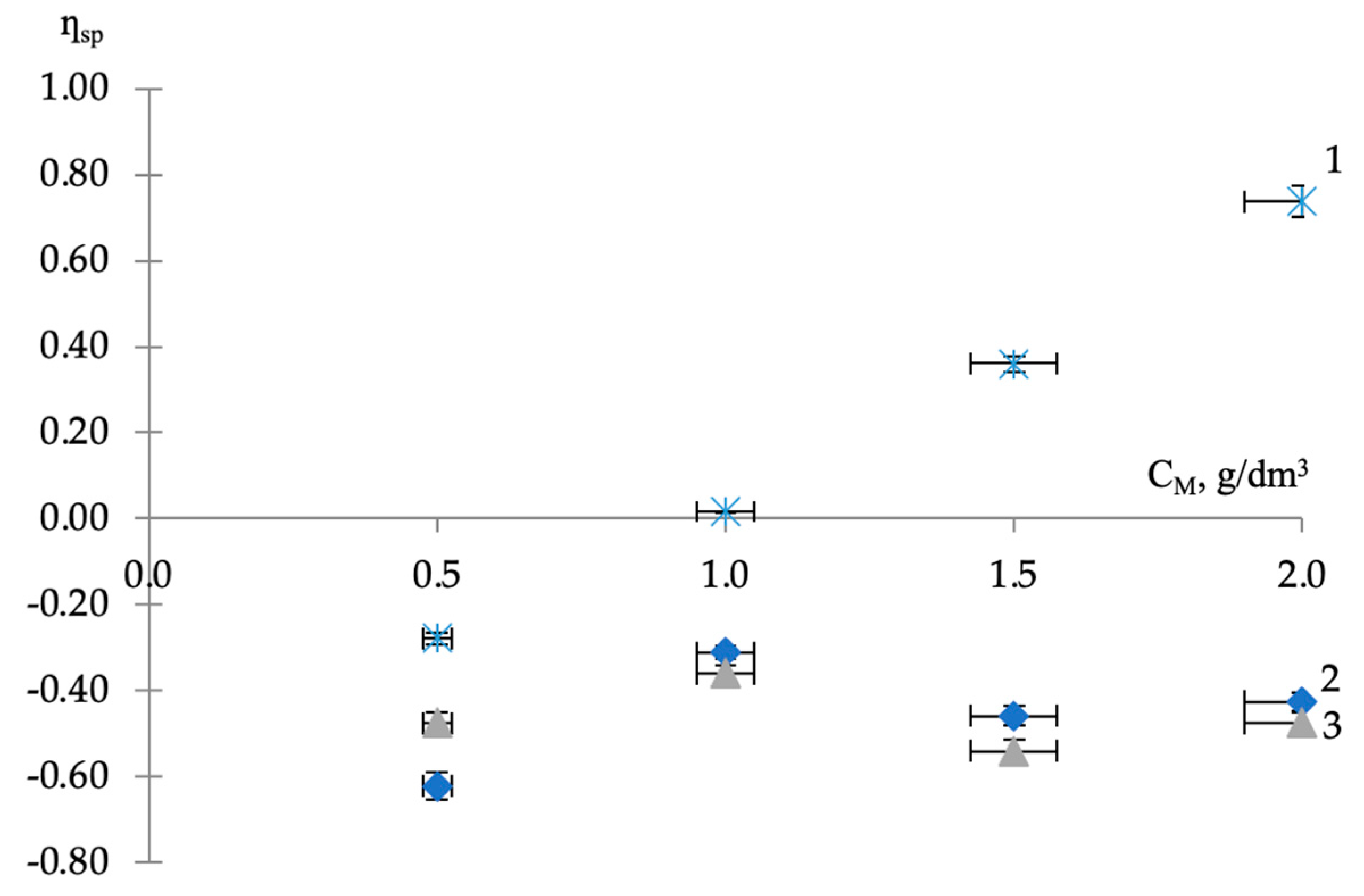

Figure 2).

With further dosing of additives into bitumen (C

M ≥ 1.0 g/dm

3), the concentration dependence of the specific viscosity of the composition with a sealing liquid (

Figure 2, curve 1) and with amphiphilic compounds (

Figure 2, curves 2 and 3) have a completely different character and reflect two different mechanisms of intermolecular and interfacial interactions in the volumetric phase of bitumen. So, if with AG-4I (

Figure 2, curve 1) the increment in bitumen viscosity due to the dissolved substance in the concentration range from 1.0 to 2.0 g/dm

3 increases positively and invariably, then with AS-1 and AMDOR-10 it is the same and does not go into the region of positive values (

Figure 2, curves 2 and 3). These differences are associated both with the dispersed structure of bitumen (core-asphaltenes, shell-resins, medium-oil) [

1] and with the characteristics (composition, structure, spatial orientation) of the modifiers themselves.

Based on the results of numerous studies [

1,

30,

31,

32,

33], it is known that the structural unit of resinous-asphaltene substances is condensed benzene rings with heteroatoms, forming a flat geometric figure with side substituents in the form of alkyl chains and naphthenic rings. Located parallel to each other, such structures form microassociates (packs, globules, micromicelles), separated from each other by an oil layer. When AG-4I (a solution of polyisobutylene in petroleum oil) is introduced into bitumen, the oil layer expands, which causes a restructuring of microassociates, and some of the molecules pass into the solution, providing the entire system with surface activity, which we previously proved by measuring surface tension [

26]. As a consequence, the destruction processes developed under the influence of petroleum oils cause the observed decrease in specific viscosity in this concentration area (

ηsp = −0.28). In parallel with this process, another component of AG-4I—polyisobutylene, spreading between bitumen microassociates, forms an intermolecular polymer network inside the bulk phase of the dispersed system. The development of homoassociation processes in the concentration range of 1.0–2.0 g/dm

3 AG-4I (

Figure 2, curve 1) is confirmed by the results of viscometric analysis: specific viscosity increases from 0.02 to 0.74, i.e., almost 37 times, which corresponds to the results obtained in works [

14,

34].

With the introduction of one of two varieties of amine-containing modifiers (AS-1 or AMDOR-10), the restructuring of the colloidal system of bitumen occurs according to a different mechanism. Part of their molecules concentrate at the bitumen–air interface, reducing surface tension [

26], and the rest are sorbed on bitumen microassociates. Heteroassociation processes weaken the energy of intermolecular interactions in bitumen microassociates, which causes their destruction. This is evidenced by the obtained viscosity indicators of binary compositions with both types of amino derivatives, both AS-1 and AMDOR-10 (

Table 2), which are invariably lower than the viscosity indicator of unmodified bitumen throughout the entire range of concentrations studied. The observed fluctuations in specific viscosity are associated with the reversibility of intermolecular formations, the equilibrium characteristics of which are determined by the quantitative content of amphiphilic compounds in the volume of the dispersed system. The lowest degree of destruction was noted in compositions with a modifier concentration of 1.0 g/dm

3, which corresponds to the maximum of their surface activity [

26]. This content corresponds to the highest specific viscosity values. The values of

ηsp for AS-1 and AMDOR-10 were −0.31 and −0.36, respectively (

Figure 2, curves 2 and 3). The maximum effect of destructuring (

ηsp = −0.62) in compositions of the low-molecular AS-1 manifested itself at C

M = 0.5 g/dm

3. In compositions of the high-molecular AMDOR-10, the maximum of this effect (

ηsp = −0.54) was observed at a concentration three times higher (C

M = 1.5 g/dm

3). The latter is apparently associated with the conformational features of AMDOR-10 macromolecules, which cause steric hindrance for all nitrogen atoms to take part in adsorption processes (

Figure 2, curve 3).

Judging by the concentration dependence of the specific viscosity of the binary composition “bitumen-AG-4I” (

Table 3), in the range of additive concentrations C

M ≤ 0.5 g/dm

3, the increasing discreteness of the bitumen system stimulated a decrease in destructuring processes;

ηsp has a value of −0.26 (

Figure 2). A similar pattern in the area of limited concentrations of additives (C

M ≤ 0.5 g/dm

3) was previously stated in the compositions “bitumen-AS-1” and “bitumen-AMDOR-10” (

Table 4). However, in contrast to these compositions with amphiphilic additives, in the “bitumen-AG-4I” compositions, with a further concentration of the sealing liquid (C

M > 0.5 g/dm

3), the specific viscosity invariably increased up to the final (C

M = 2.0 g/dm

3) content (

Table 3).

Another important distinctive feature of the development of the process of homoassociation of polyisobutylene macromolecules was that each subsequent dosing of an additional 0.5 g/dm

3 of AG-4I into bitumen was accompanied by a gradual increase in specific (Δ

ηsp = 0.28–0.38) (

Table 4).

3.2. Rheological Characteristics of Ternary Systems “Bitumen-AG-4I-AS-1”

The results of rheological studies in mixed compositions, including the joint presence of two modifiers in bitumen (AG-4I and AS-1), are presented in

Figure 3. The effect of surfactant concentration on viscosity was determined at a fixed content of AG-4I in bitumen (C

M = 0.5–2.0 g/dm

3) at t = 130 °C.

As a quantitative measure of the processes developing in the volume, along with the experimental indicators (

ηsp.exp), their calculated values for the ternary system (

ηsp.calc) were used as a total value, taking into account the separate contribution of AG-4I and AS-1, i.e., in the absence of intermolecular interactions between them:

where

ηsp.AG-4I—specific viscosity at a fixed content of sealing liquid in the “bitumen-AG-4I” system;

The data obtained show that although the experimental concentration dependences of the specific viscosity of AS-1 in the presence of AG-4I (

Figure 3a–d, curves 1) are largely similar in appearance to the calculated ones (

Figure 3a–d, curves 2), they are, however, shifted towards more high values of

ηsp.

Significant deviations from the additivity rule indicate an increase in the cooperative association of surfactant molecules with bitumen microassociates, which causes an increase in viscosity in the “bitumen-AG-4I-AS-1” systems. The strengthening of the association is associated with the presence in these systems, in addition to the introduced surfactant (AS-1), bitumen surfactants delocalized under the influence of the sealing liquid [

26]. Part of them are adsorbed on the bitumen–air surface, reducing surface tension, and the rest are concentrated on bitumen microassociates, increasing intermolecular interactions and, accordingly,

ηsp. As experimental data show, for the formation of cross-links due to the cationic substance AS-1 and predominantly anionic bitumen surfactants, i.e., to manifest the viscous effect, a certain concentration ratio of the components is required. Depending on this, the association may increase or decrease.

At limited contents of AG-4I (CM < 1.0 g/dm3), surfactants have a priority effect on association processes, and at increased concentrations (CM ≥ 1.0 g/dm3), the structuring role of the formed intermolecular polyisobutylene network increases.

The greatest influence of surfactants on the viscosity effect was noted in the composition “bitumen-AG-4I-AS-1” with a minimum content of AG-4I (0.5 g/dm

3). In this system (

Figure 3a, curve 1), the extremum in specific viscosity (

ηsp = 0.34), manifested at C

AS-1 = 1.0 g/dm

3, significantly exceeds the value of the extremum at a similar concentration of AS-1 (

ηsp = −0.31) in the binary system “bitumen-AS-1”. This is clear evidence of the additional impact on the association processes of bitumen surfactants released by the sealing liquid. Further introduction of AS-1 (C > 1.0 g/dm

3) is excessive and has a destructuring effect, even at C

M = 2.0 g/dm

3, specific viscosity values in triple (

ηsp = −0.41) and binary (

ηsp = −0.43) systems are practically leveled off (

Table 3 and

Table 5).

With an increase in AG-4I consumption by two times (1.0 g/dm

3), the maximum in specific viscosity values (

ηsp = +0.15) was observed at a higher concentration of AS-1 (2.0 g/dm

3), and it was lower by 0.16 compared to the previous system (

Figure 3b, curve 1). The decrease in the viscosity effect of the surfactant is associated with the competing influence of the intermolecular network of polyisobutylene, the formation of which was previously recorded in the concentration range of 1.0 ÷ 2.0 g/dm

3 AG-4I in bitumen.

This becomes more obvious in the composition “bitumen-AG-4I-AS-1” containing 1.5 g/dm

3 AG-4I (

Figure 3c, curve 1). In this system, the introduction of AS-1 has practically no effect on the viscosity effect in the concentration range from 0.5 to 1.5 g/dm

3. Each additional dosage of 0.5 g/dm

3 AS-1 led to only minor (Δ

ηsp = ±0.07) deviations of the specific viscosity of the composition from the initial value (Δ

ƞsp = +0.36), determined by the content (1.5 g/dm

3) AG-4I (

Table 4). Only in a narrow range of elevated concentrations of AS-1 (from 1.5 to 2.0 g/dm

3) is the viscous effect of the surfactant manifested, the intensity of which (Δ

ƞsp = 0.13) is minimal.

The viscosity effect of the surfactant is completely neutralized in a system containing 2.0 g/dm

3 AG-4I (

Figure 3d, curve 1). In a composition with a maximum content of free bitumen surfactants, when they, as was established earlier [

26], are absent at the interface between bitumen and air and are completely concentrated in the volume of the disperse system, the additional introduction of 0.5 g/dm

3 AS-1 causes a significant decrease in specific viscosity (Δ

ƞsp = −0.28) relative to the initial value (

ηsp = +0.74). However, this change in specific viscosity is still less than calculated (

Figure 3d, curve 2), as is the intensity of its subsequent concentration fluctuations.

3.3. Modeling of the Effect of Additives Concentration on the Absolute Viscosity of a Bitumen Mixture in Triple System “Bitumen-AG-4I-AS-1”

To determine the effect of the concentration of additives at a temperature of 130 °C on the viscosity (

η, s) of triple systems “bitumen–AG-4I–AS-1”, experiments were carried out according to the orthogonal 5 × 5 plan presented in

Table 6. The input parameters of experimental studies are as follows:

- (1)

Concentration of polymer AG-4I (CAG-4I, g/dm3), taking values 0, 0.5, 1.0, 1.5, or 2.0;

- (2)

The concentration of surfactant AS-1 (CAS-1, g/dm3), taking the values 0, 0.5, 1.0, 1.5, or 2.0.

Table 6 shows the orthogonal plan of the experiment and the results of viscosity measurements. This plan considers all possible combinations of concentrations of additives AG-4I and AS-1 at a temperature of a bitumen mixture of 130 °C.

In accordance with the method of probabilistic deterministic planning [

27], a sample of the experimental array (

Table 5) on partial dependencies in tabular form (

Table 7 and

Table 8) was carried out, and the graphs of partial dependencies were obtained (

Figure 4).

Analyzing the behavior of additives when they are used together in a triple system “bitumen-AG-4I-AS-1” at 130 °C (

Figure 4), it is possible to note a decrease in the viscosity of the bitumen mixture with an increase in the concentration of any of the additives in the range from 0 to 0.5 g/dm

3. It can also be noted that the concentration of AS-1 above 0.5 g/dm

3 has an insignificant effect on the viscosity value. At the same time, with an increase in the concentration of AG-4I from 0.5 to 2.0 g/dm

3 (

Figure 4), the viscosity increases significantly (almost 2.5 times).

The partial dependencies shown in

Figure 4 were approximated by second-order polynomials. Using the obtained polynomials, a two-factor mathematical model based on the generalized Protodyakonov equation [

27] was developed. This model describes the combined effect of the concentration of the polymer AG-4I and the concentration of surfactant AS-1 on the viscosity of the bitumen mixture at a temperature of 130 °C (5):

The coefficient of nonlinear multiple correlation [

27] for this two-factor mathematical model is 0.94. The significance of the obtained nonlinear multiple correlation coefficient was confirmed using the Fisher criterion [

27].

According to the obtained two-parameter mathematical model, nomograms were constructed for the fixed temperature of a bitumen mixture equal to 130 °C (

Figure 5). These nomograms allowing to achieve the required viscosity value (

η takes values of 40, 50, 60, 70, or 80 s, respectively) at different ratios of polymer (C

AG-4I, g/dm

3) and surfactant (C

AS-1, g/dm

3) concentrations. Nomograms allow to select the optimal concentrations of additives to achieve the required viscosity of the bitumen mixture.

Using the obtained two-factor mathematical model, nomograms were constructed to determine the optimal concentrations of polymer AG-4I and surfactant AS-1 to achieve a given viscosity value of the bitumen mixture (

Figure 5). Analyzing the obtained nomograms (

Figure 5), it can be noted that at a fixed concentration of the polymer AG-4I, the given viscosity value, in general, can be achieved at two concentrations of surfactant AS-1. If one value of the concentration of surfactant AS-1 less than 1.0 g/dm

3 for a certain fixed value (less than 0.6 g/dm

3) was selected, then the second value of the concentration of surfactant AS-1, corresponding to a given value of viscosity and concentration of polymer AG-4I, will be higher than the concentration of 1.4 g/dm

3 by approximately the same certain fixed value. For example, the concentration of surfactant AS-1 equal to 0.8 g/dm

3 will approximately correspond to the concentration of surfactant AS-1 equal to 1.6 g/dm

3, and the concentration of 0.5 g/dm

3 will approximately correspond to the concentration of surfactant AS-1 equal to 1.9 g/dm

3. The maximum concentration of AG-4I at a given viscosity value corresponds to the concentration of AS-1 in the range of approximately 1.1 to 1.3 g/dm

3.

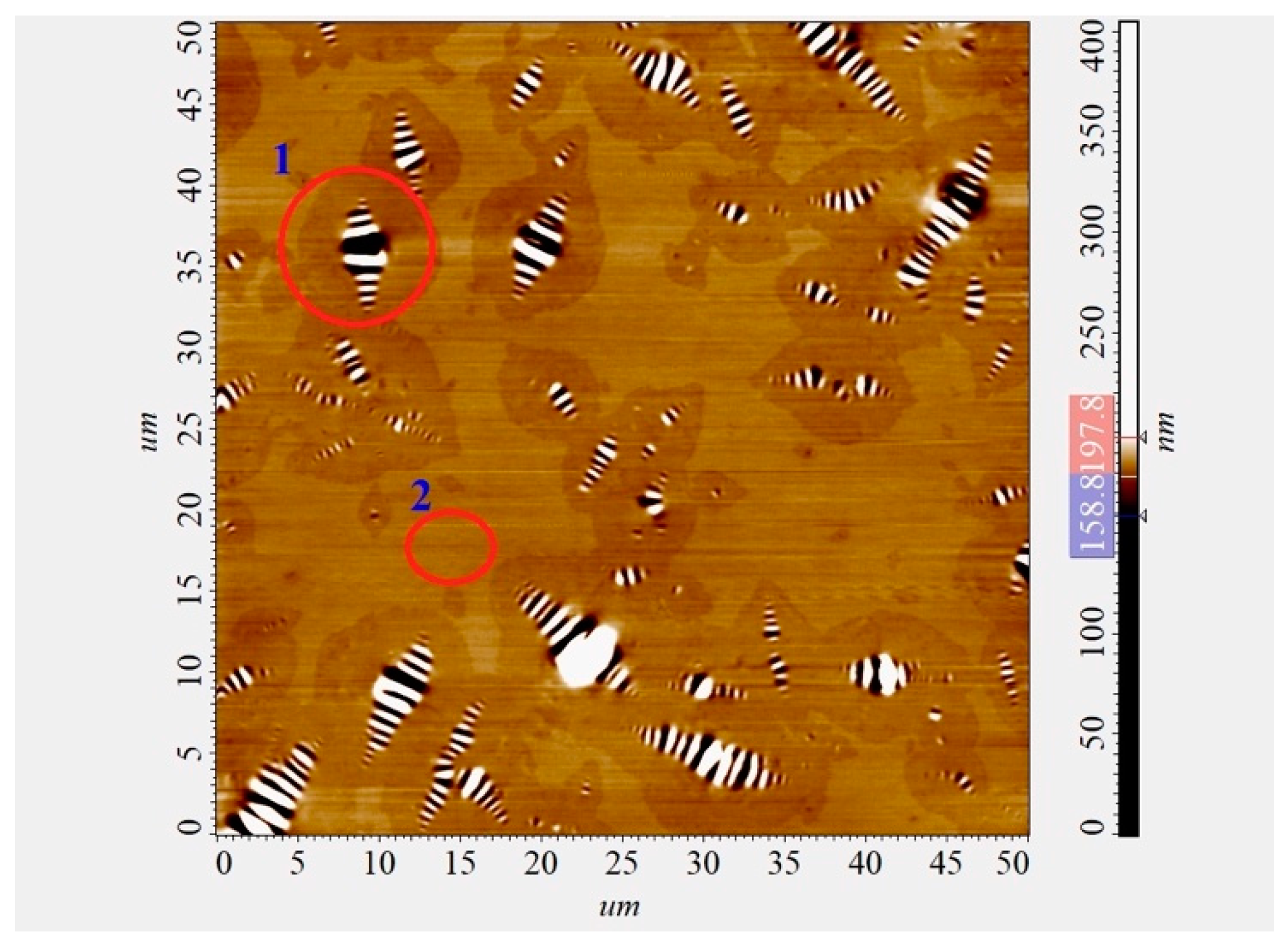

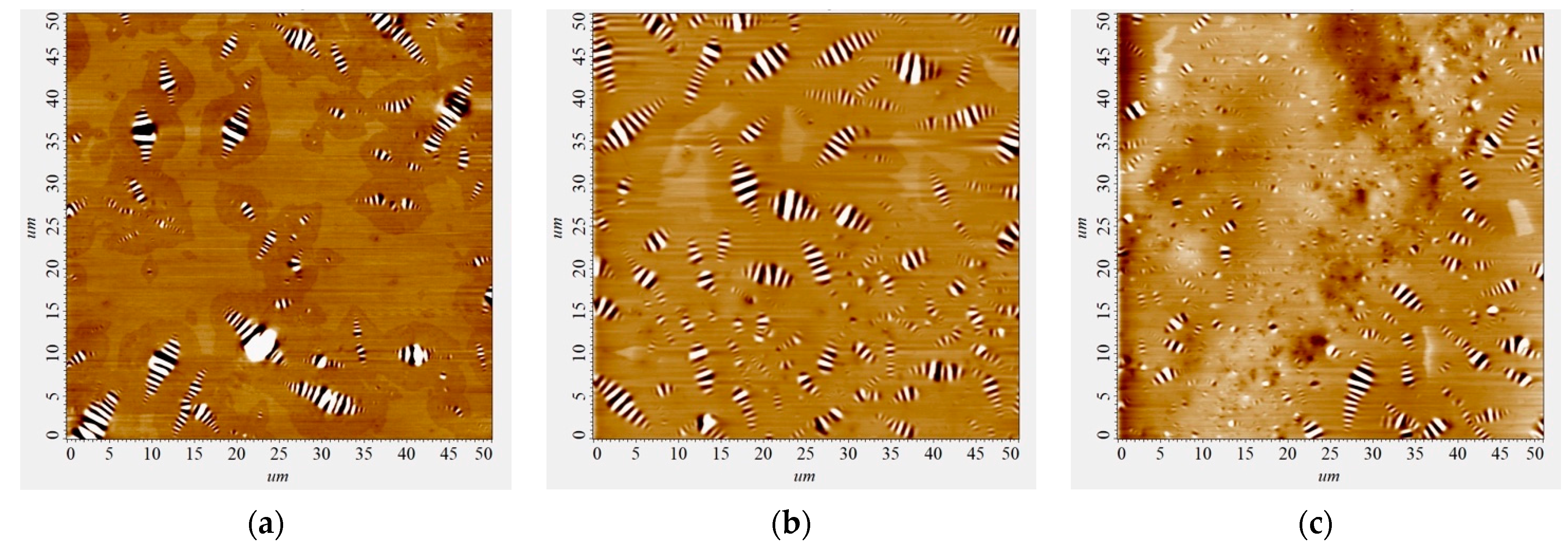

3.4. Study of the Microstructure of Modified Bitumen

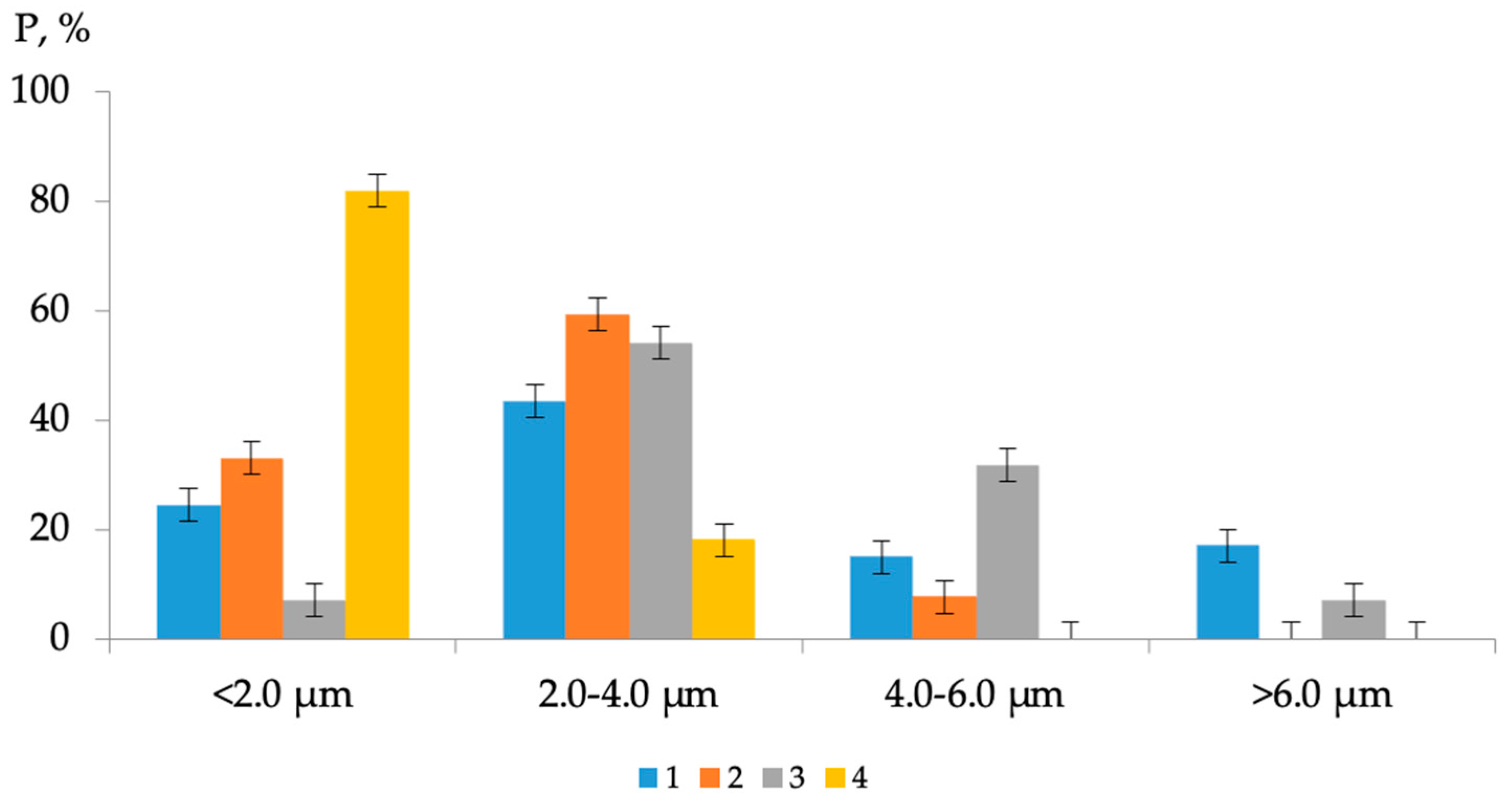

The results of AFM of binary bitumen compositions are presented in

Figure 6 as well as diagrams of the distribution of bitumen microdispersions in the original bitumen and modified samples (

Figure 7).

Comparing images

Figure 6a–c it can be noted that when the polymer additive AG-4I is introduced into bitumen, a significant change in the microstructure of the bitumen occurs (

Figure 6). As follows from the distribution diagram of bitumen microdispersions, in the absence of an additive (

Figure 7, composition No 1), fractions ranging in size from 2.0 to 4.0 microns (P = 43.40%) predominate. The content of fine fractions (particle size ≤ 2.0 µm) does not exceed 24.50%, and large aggregates, larger than 6.0 µm, account for 17.10%. The average size (

aav) of bee-like structures in unmodified bitumen was 3.69 µm.

When 0.5 g/dm

3 AG-4I was introduced into bitumen, the average particle size decreased to 2.23 µm, and the content of fine fractions (≤2.0 µm) increased 1.7 times and amounted to 42.20% (

Figure 7, composition No 2). The presented diagram clearly demonstrates that AG-4I increases the number of small (≤2.0 µm) and medium (≤2.0–4.0 µm) particles due to the absolute destruction of the largest dispersions (>6.0 µm) and partially aggregates ranging in size from 4.0 to 6.0 µm. In compositions that are more concentrated (C

AG-4I = 2.0 g/dm

3) in terms of AG-4I content, the effect of the destruction of large bitumen microdispersions (>6.0 µm) remains approximately at the same level: the content of small fractions (≤2.0 µm) increased by 1.5 times and reached 37.20%, and the average particle size was 2.38 µm (

Figure 7, composition No 3). The data obtained serve as a direct confirmation of the above results of rheological studies in isoconcentration binary compositions “bitumen-AG-4I” (

Figure 2).

The introduction of an amphiphilic modifier (AS-1) into bitumen causes a different change in the dispersed composition (

Figure 8).

As a result of the adsorption-propagating action of AS-1 at the same additive concentration (C

AS-1 = 0.5 g/dm

3), the size of the dispersions decreased only to 3.14 µm, and the content of fine fractions (≤2.0 µm) increased to 32.2% (

Figure 9, composition No 2).

With an increase in the concentration of AS-1 from 0.5 to 1.0 g/dm

3, large fractions (>6.0 µm) were destroyed mainly to aggregates measuring 2.0-4.0 µm (ΔP = 11.60%) with a very slight change (ΔP = 2.20%) in fine fractions (compared to the base version without surfactants). The average size of the dispersions was 3.14 µm. A comparison of the presented diagrams (

Figure 7 and

Figure 9) shows that, unlike AG-4I, under the influence of AC-1, there is no complete destruction of large fractions (>6.0 µm). The observed change in the dispersed composition in the binary compositions “bitumen-AS-1” is consistent with the results of viscometrical analysis (

Figure 2, curve 2).

Visualization of the restructuring of the dispersed system of bitumen in the mixed composition “bitumen-AG-4I-AS-1” is presented in

Figure 10.

Based on the results of AFM analysis, it was established that the intensity of the processes of dispersion of microdispersions in the joint presence of both modifiers is maximum at the concentration of C

AG-4I = 1.0 g/dm

3 and C

AS-1 = 1.0 g/dm

3 (

Figure 11); the average size of the dispersions was 1.66 µm, which is the minimum value in the entire studied range of modifier contents.

As a result of simultaneous exposure to AG-4I and AS-1 in these concentration regimes (

Figure 11, composition No 4), not only fractions with sizes from 4.0 to 6.0 µm and higher (>6.0 µm) were completely destroyed, but more than two times much smaller aggregates (2.0–4.0 µm). As a result, in comparison with the base option, the content of fine fractions increased by 57.4% (P = 24.5–81.9%).

To assess the effect of bitumen dispersion on the physical and mechanical characteristics of asphalt concrete pavements, modified bitumen–mineral compositions were studied for compressive strength (

Table 9).

From the data obtained, it follows that asphalt mixture samples using binary “bitumen–additive” compositions have improved strength characteristics, as evidenced by an increase in the values of compressive strength at 20 °C and 50 °C. Asphalt concrete samples made on the basis of original BND 100/130 bitumen according to ST RK 1225-2019 “Mixtures of asphalt concrete road, airfield and asphalt concrete. Technical conditions” must have a compressive strength at 20 °C of at least 2.2 MPa and at 50 °C of at least 1.0 MPa.

In comparison with the strength characteristics of an unmodified asphalt mixture sample at 20 °C (RD = 3.2 MPa), the compressive strength increased by 15.63–21.88% (∆RD = 0.5–0.7 MPa) in the sample using binary composition “bitumen-AG-4I”. The effect of increasing strength in binary compositions “bitumen-AS-1” was 6.25–12.50% compared to the use of the original binder (∆RD = 0.2–0.4 MPa). The maximum increase in compressive strength at 20 °C by 28.13% (∆RD = 0.9 MPa) was achieved in an asphalt concrete sample made on the basis of a ternary bitumen composition, including the combined presence of AG-4I and AS-1 (CAG-4I = 1.0 g/dm3; CAS-1 = 1.0 g/dm3).

A comparative analysis of the physicochemical characteristics of the binder and the structural and mechanical properties of asphalt mixture samples shows that the determining factor for strength is the average size of the bee-like structures of bitumen (

Table 9). In comparison, viscosity is only a detector of associative–dissociative transformations that occur when the modifiers under study are introduced into bitumen. As a result of intermolecular interactions between additives and bee-like structures of bitumen, the size of microassociates, the density of their distribution in the dispersion medium of the binder, and, accordingly, the strength of asphalt concrete change.