Review and Assessment of Material, Method, and Predictive Modeling for Fiber-Reinforced Polymer (FRP) Partially Confined Concrete Columns

Abstract

1. Introduction

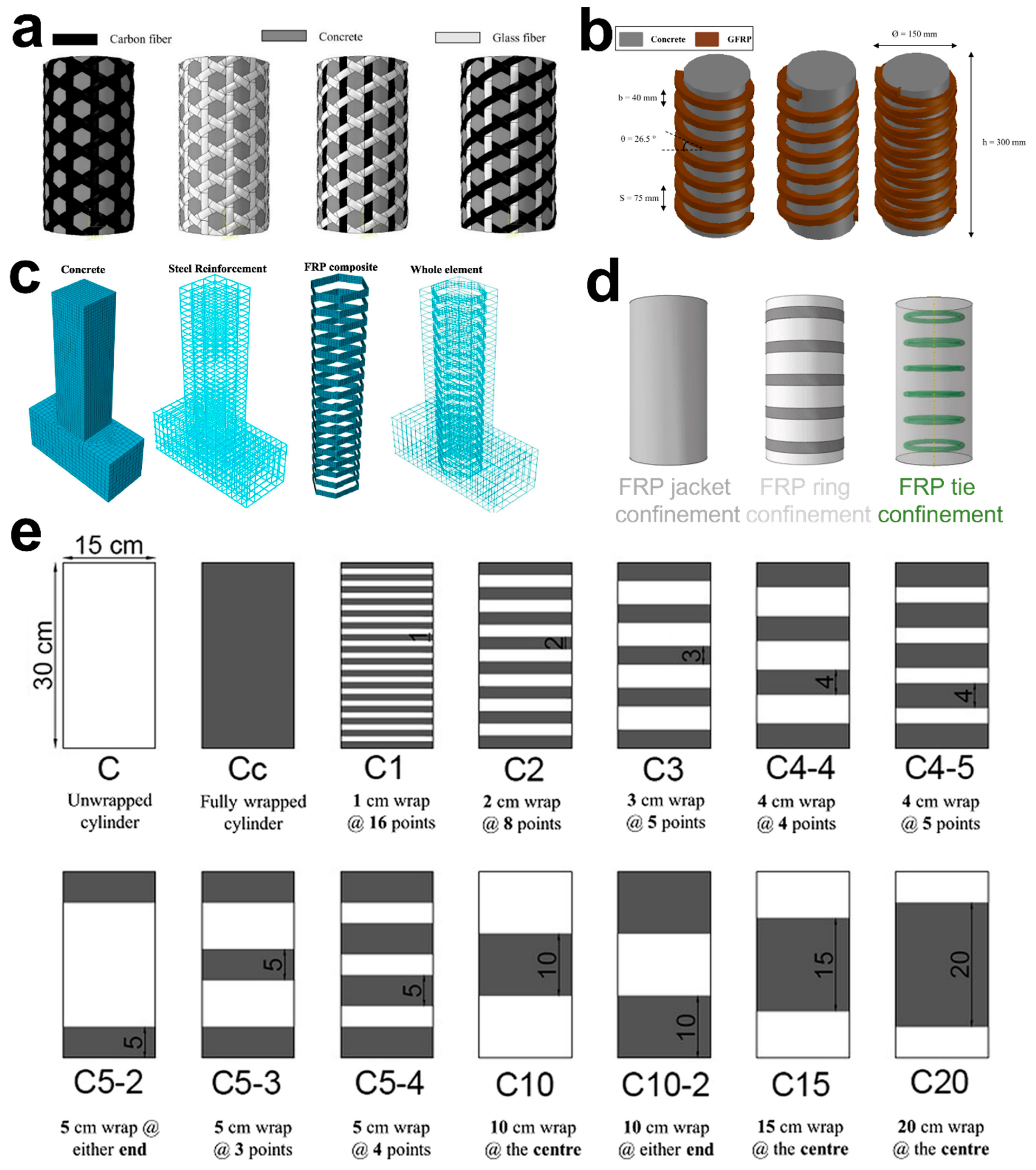

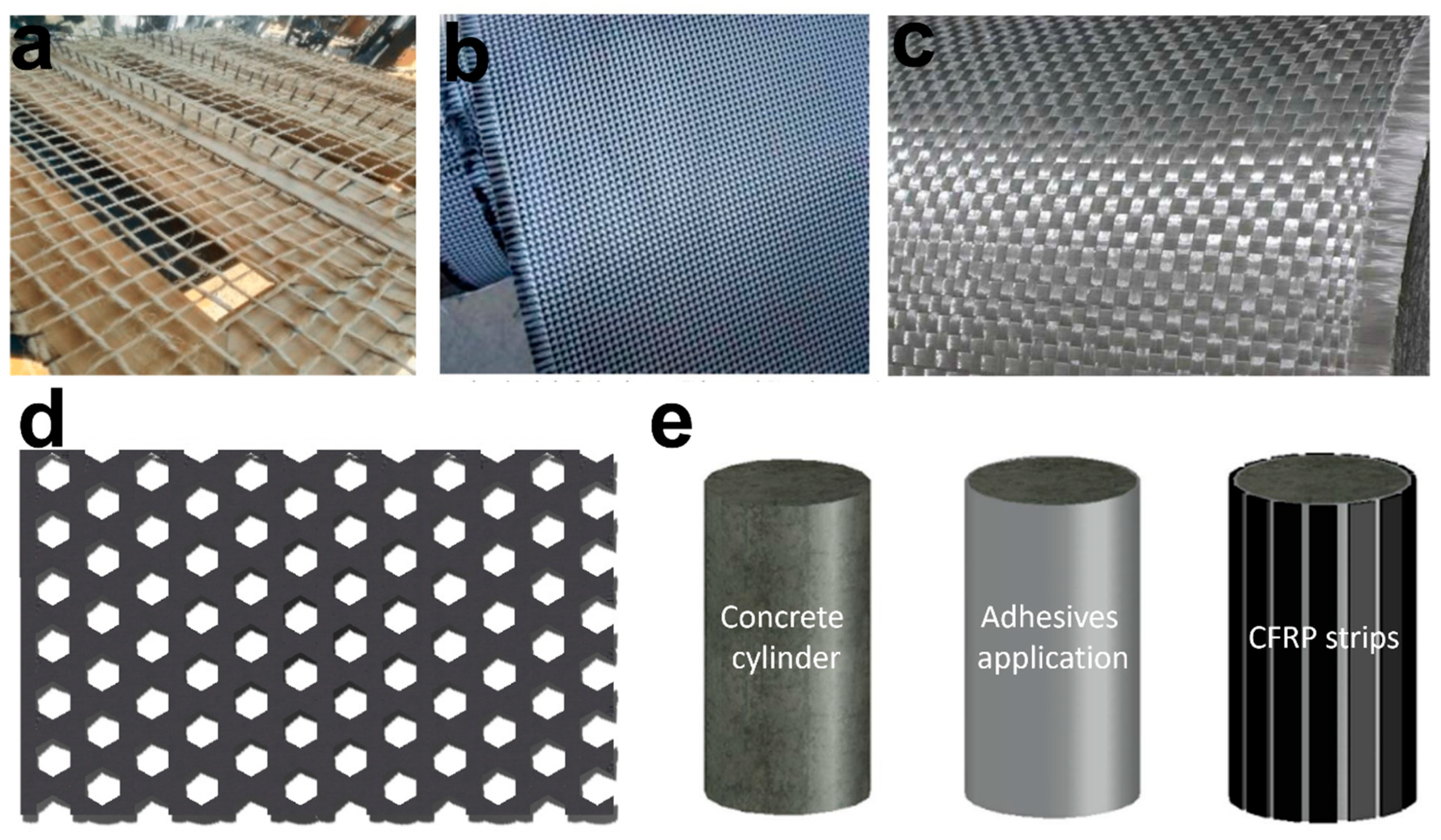

2. Materials for FRP Wrapping and Specimen Strengthening

2.1. Carbon-FRP

2.2. Glass-FRP

2.3. Hybrid Composites

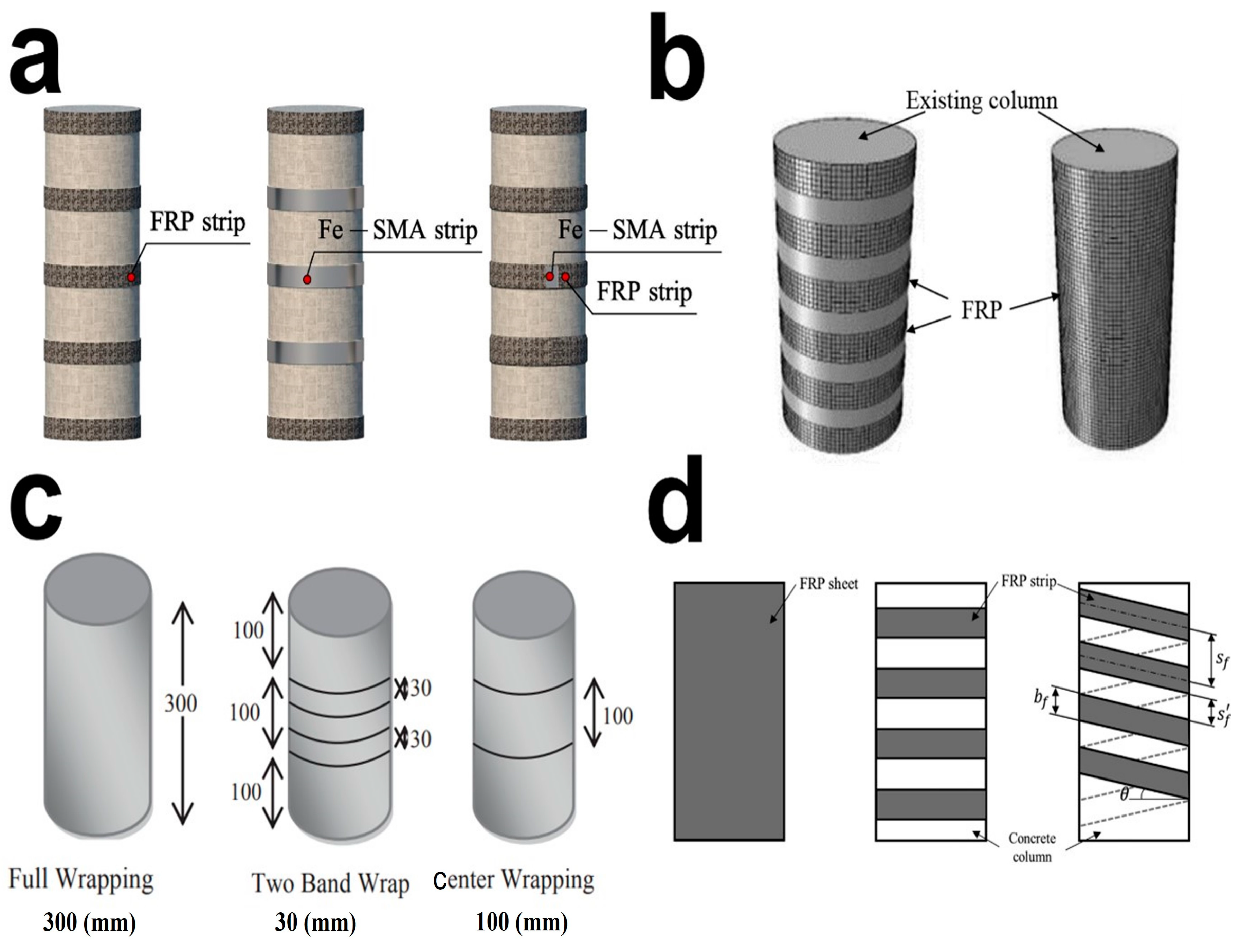

3. Partial Confinement Methods of FRP for Enhancing the Strength of Concrete Columns

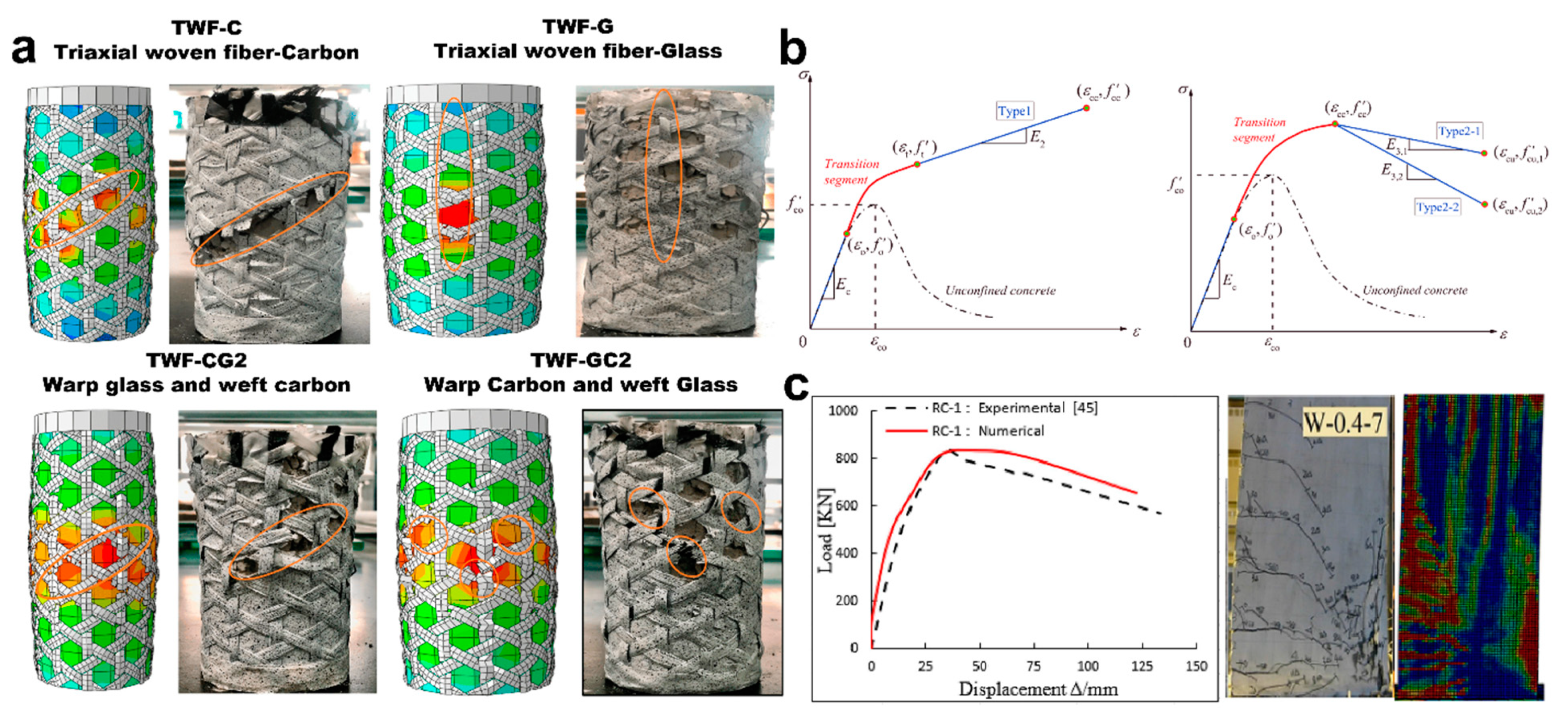

4. Predictive Modelling and Simulation for Partial Confinement of Concrete Columns by FRP Wrappings

5. Comparative Analysis and Correlation between Confinement Materials, Methods of Partial Confinement, and Predictive Modeling and Simulation for Effective Partial Confinement of Concrete Columns

5.1. Overall Challenges and Future Perspective

5.2. Challenges

- There are very few studies on the FRP-concrete bonding behaviors, however, an adequate bonding strength is imperative to ensure the uniform stress transmission between the FRP and concrete columns.

- The research gap in various confinement methods for partial confinement is limiting the selection of most suitable method for long-term applications and bending analysis over a long period. For instance, the certain confinement limits for FRP hoops and spiral strips are unknown to avoid concrete softening.

- There is less data on the fiber orientations and confinement angles for improved ductility under seismic cycle loadings.

- Less work is available on the external environmental factors, and studies on the partial FRP-confined concrete columns are stressed.

- The large-scale database of experimental results for partially FRP-confined concrete columns is not available freely.

- For flexural members like beam-columns joints and bridge girders, the FRP partial confinement adds some challenges including, durability of bonding between surfaces of concrete and FRP material, stress concentration under repeated loadings, and load discontinuity, etc.

5.3. Future Perspective

- 7.

- Under different loading conditions, the bonding analysis, such as the bond-slip relationship of the concrete-FRP, is necessary for long-term performance. Dynamic loading conditions are essential to study bond-slip behavior for a better understanding of FRP-concrete systems. Cyclic loading, fatigue loading, and impact loading can be incorporated into the advanced simulation techniques by considering amplitude, frequency, number of cycles, stress range, mean stress, resistance, peak load, impact, and response to high stress–strain rates along with time-dependent loading conditions, etc.

- 8.

- It is important to perform both experimental and numerical studies on concrete columns partially confined with different configurations of FRP systems to investigate compressive and axial compressive stress–strain behaviors, crack evolution and failure morphology, long-term deflection behavior of flexural concrete structures, etc.

- 9.

- It is essential to study the different fiber orientations of composites for ideally aligning to the internal stress distribution of concrete structures, to enhance the mechanical properties and compressive strength. Horizontal and vertical directional fibers can enhance ductility under seismic loadings, helically wrapped fibers can increase lateral and axial strength. Therefore, various other different orientations should be explored for specific designs.

- 10.

- The simulations and predictive models are required to be extended to incorporate the environmental factors and external stresses for long terms stability of partially confined concrete columns. For further research in this domain, scientists must explore potential modeling techniques including fatigue and fracture mechanics models, Monte Carlo simulations, accelerated aging tests, and coupled multi-physics simulations, etc.

- 11.

- For effective predictive modeling and simulations, it is imperative to develop extensive databases for different configurations, and materials of concrete column confinement. It requires collaborative research projects between academia and industry to build such comprehensive databases. Open-access repositories with standardized protocols can help to promote data collaborations and reproducibility.

- 12.

- Developing hybrid composites of carbon, jute, glass, etc. can add properties of all materials including strength, stiffness, ductility, and toughness. Sustainable plant-based natural fibers can help reduce the environmental impacts if can provide high-performance mechanical properties.

5.4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tsonos, A.G. Effectiveness of CFRP-Jackets and RC-Jackets in Post-Earthquake and Pre-Earthquake Retrofitting of Beam–Column Subassemblages. Eng. Struct. 2008, 30, 777–793. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Lionetto, F. Carbon Fiber Reinforced Polymers. Materials 2021, 14, 5545. [Google Scholar] [CrossRef] [PubMed]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass Fiber-Reinforced Polymer Composites—A Review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Shahawy, M.; Mirmiran, A.; Beitelman, T. Tests and Modeling of Carbon-Wrapped Concrete Columns. Compos. Part B Eng. 2000, 31, 471–480. [Google Scholar] [CrossRef]

- Meyer, M.R.; Friedman, R.J.; Del Schutte, H.; Latour, R.A. Long-Term Durability of the Interface in FRP Composites after Exposure to Simulated Physiologic Saline Environments. J. Biomed. Mater. Res. 1994, 28, 1221–1231. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-Oriented Stress-Strain Model for FRP-Confined Concrete in Rectangular Columns. J. Reinf. Plast. Compos. 2003, 22, 1149–1186. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Nawaz, W.; Abdalla, J.A.; Saqan, E.I. Effect of Flexural CFRP Sheets on Shear Resistance of Reinforced Concrete Beams. Compos. Struct. 2015, 122, 468–476. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Hadi, M.N.S.; Gao, D.; Chen, G. Behaviour of Concrete-Encased Concrete-Filled FRP Tube (CCFT) Columns under Axial Compression. Eng. Struct. 2017, 147, 256–268. [Google Scholar] [CrossRef]

- Barros, J.A.; Ferreira, D.R. Assessing the Efficiency of CFRP Discrete Confinement Systems for Concrete Cylinders. J. Compos. Constr. 2008, 12, 134–148. [Google Scholar] [CrossRef]

- Zeng, J.J.; Guo, Y.C.; Gao, W.Y.; Chen, W.P.; Li, L.J. Stress-Strain Behavior of Concrete in Circular Concrete Columns Partially Wrapped with FRP Strips. Compos. Struct. 2018, 200, 810–828. [Google Scholar] [CrossRef]

- Guo, Y.C.; Xiao, S.H.; Luo, J.W.; Ye, Y.Y.; Zeng, J.J. Confined Concrete in Fiber-Reinforced Polymer Partially Wrapped Square Columns: Axial Compressive Behavior and Strain Distributions by a Particle Image Velocimetry Sensing Technique. Sensors 2018, 18, 4118. [Google Scholar] [CrossRef] [PubMed]

- Kwan, A.K.H.; Dong, C.X.; Ho, J.C.M. Axial and Lateral Stress–Strain Model for FRP Confined Concrete. Eng. Struct. 2015, 99, 285–295. [Google Scholar] [CrossRef]

- Arabshahi, A.; Gharaei-Moghaddam, N.; Tavakkolizadeh, M. Proposition of New Applicable Strength Models for Concrete Columns Confined with Fiber Reinforced Polymers. SN Appl. Sci. 2019, 1, 1677. [Google Scholar] [CrossRef]

- Arabshahi, A.; Gharaei-Moghaddam, N.; Tavakkolizadeh, M. Development of Applicable Design Models for Concrete Columns Confined with Aramid Fiber Reinforced Polymer Using Multi-Expression Programming. Structures 2020, 23, 225–244. [Google Scholar] [CrossRef]

- Shayanfar, J.; Barros, J.A.O.; Rezazadeh, M. Analysis-Oriented Model for Partially FRP-and-Steel-Confined Circular RC Columns under Compression. Eng. Struct. 2023, 276, 115330. [Google Scholar] [CrossRef]

- Ghani, M.U.; Siddique, A.; Abraha, K.G.; Yao, L.; Li, W.; Khan, M.Q.; Kim, I.S. Performance Evaluation of Jute/Glass-Fiber-Reinforced Polybutylene Succinate (PBS) Hybrid Composites with Different Layering Configurations. Materials 2022, 15, 1055. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C.; Vincent, T. FRP-Confined Concrete in Circular Sections: Review and Assessment of Stress–Strain Models. Eng. Struct. 2013, 49, 1068–1088. [Google Scholar] [CrossRef]

- Ghani, M.U.; Sun, T.; Zhang, H.; Abraha, K.G.; Ahmad, N.; Ahmed, K.; Saeed, R.; Sadannavar, M.K.; Li, W. Experimental and Numerical Analysis of Axial Behavior of Triaxial Woven Fabric Confined Concrete Columns. J. Compos. Sci. 2023, 7, 358. [Google Scholar] [CrossRef]

- Pilien, V.P.; Promentilla, M.A.B.; Leaño, J.L.; Oreta, A.W.C.; Ongpeng, J.M.C. Confinement of Concrete Using Banana Geotextile-Reinforced Geopolymer Mortar. Sustainability 2023, 15, 6037. [Google Scholar] [CrossRef]

- Attari, N.; Youcef, Y.S.; Amziane, S. Seismic Performance of Reinforced Concrete Beam–Column Joint Strengthening by Frp Sheets. Structures 2019, 20, 353–364. [Google Scholar] [CrossRef]

- Khorramian, K.; Sadeghian, P. Hybrid System of Longitudinal CFRP Laminates and GFRP Wraps for Strengthening of Existing Circular Concrete Columns. Eng. Struct. 2021, 235, 112028. [Google Scholar] [CrossRef]

- Kaeseberg, S.; Messerer, D.; Holschemacher, K. Experimental Study on Concrete under Combined Frp–Steel Confinement. Materials 2020, 13, 4467. [Google Scholar] [CrossRef] [PubMed]

- Raza, A.; Rafique, U.; Masood, B.; Ali, B.; Asad, M. Performance Evaluation of Hybrid Fiber Reinforced Low Strength Concrete Cylinders Confined with CFRP Wraps. Structures 2021, 31, 182–189. [Google Scholar] [CrossRef]

- Tang, Y.; Lu, X.; Wei, Y.; Hou, S. Experimental Study on Compressive Behavior of Concrete Cylinders Confined by a Novel Hybrid Fiber-Reinforced Polymer Spiral. Polymers 2022, 14, 4750. [Google Scholar] [CrossRef] [PubMed]

- Vijayan, D.S.; Mohan, A.; Daniel, J.J.; Gokulnath, V.; Saravanan, B.; Kumar, P.D. Experimental Investigation on the Ecofriendly External Wrapping of Glass Fiber Reinforced Polymer in Concrete Columns. Adv. Mater. Sci. Eng. 2021, 2021, 2909033. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Hofer, L.; Toska, K.; De Domenico, D.; Pellegrino, C. Confinement of Reinforced Concrete Columns with Glass Fiber Reinforced Cementitious Matrix Jackets. Eng. Struct. 2020, 218, 110847. [Google Scholar] [CrossRef]

- Fedaoui-akmoussi, O.; Taouche-kheloui, F.; Chabane, T.B.; Leklou, N. Effect of the Confinement Type on the Mechanical Performance of Glass Waste Concrete: Experimental and Numerical Modeling. Eng. Fail. Anal. 2023, 143, 106898. [Google Scholar] [CrossRef]

- Li, J.; Mai, Z.; Xie, J.; Lu, Z. Durability of Components of FRP-Concrete Bonded Reinforcement Systems Exposed to Chloride Environments. Compos. Struct. 2022, 279, 114697. [Google Scholar] [CrossRef]

- Shrestha, J.; Zhang, D. Effect of Primer and Surface Preparation on the FRP-Concrete Bond. In Proceedings of the 7th International Conference on FRP Composites in Civil Engineering, Vancouver, BC, Canada, 20–22 August 2014. [Google Scholar]

- Elchalakani, M.; Yang, B.; Mao, K.; Pham, T. Geopolymer Concrete Structures with Steel and FRP Reinforcements: Analysis and Design; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–645. [Google Scholar] [CrossRef]

- Mukhtar, F.M.; Faysal, R.M. A Review of Test Methods for Studying the FRP-Concrete Interfacial Bond Behavior. Constr. Build. Mater. 2018, 169, 877–887. [Google Scholar] [CrossRef]

- Kumar, A.; Arora, H.C.; Kumar, K.; Garg, H. Performance Prognosis of FRCM-to-Concrete Bond Strength Using ANFIS-Based Fuzzy Algorithm. Expert Syst. Appl. 2023, 216, 119497. [Google Scholar] [CrossRef]

- Dirikgil, T. Experimental Investigation of the Effects of Concrete Strength and Axial Load Ratio on the Performances of CFRP-Wrapped and Externally Collared RC Short Columns. Eng. Struct. 2021, 230, 111647. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y. Using Textile Reinforced Engineered Cementitious Composite for Concrete Columns Confinement. Compos. Struct. 2019, 210, 695–706. [Google Scholar] [CrossRef]

- Baasankhuu, B.; Choi, D.; Ha, S. Behavior of Small-Scale Concrete Cylinders in Compression Laterally Confined by Basalt Fiber and PEN Fiber Reinforced Polymer Composites. Int. J. Concr. Struct. Mater. 2020, 14, 8. [Google Scholar] [CrossRef]

- Suhail, R.; Amato, G.; McCrum, D.P. Active and Passive Confinement of Shape Modified Low Strength Concrete Columns Using SMA and FRP Systems. Compos. Struct. 2020, 251, 112649. [Google Scholar] [CrossRef]

- Chen, G.M.; Lan, Z.H.; Xiong, M.X.; Xu, Z. Compressive Behavior of FRP-Confined Steel-Reinforced High Strength Concrete Columns. Eng. Struct. 2020, 220, 110990. [Google Scholar] [CrossRef]

- Woldemariam, A.M.; Oyawa, W.O.; Nyomboi, T. Structural Performance of UPVC Confined Concrete Equivalent Cylinders under Axial Compression Loads. Buildings 2019, 9, 82. [Google Scholar] [CrossRef]

- Ismail, R.; Rashid, R.S.M.; Chan, W.C.; Jaafar, M.S.; Hejazi, F. Compressive Behavior of Concrete Cylinder Fully and Partially Confined by Carbon Fibre-Reinforced Polymer (CFRP). Constr. Build. Mater. 2019, 201, 196–206. [Google Scholar] [CrossRef]

- Liang, J.F.; Zou, W.J.; Wang, Z.L.; Liu, D.W. Compressive Behavior of CFRP-Confined Partially Encased Concrete Columns under Axial Loading. Compos. Struct. 2019, 229, 111479. [Google Scholar] [CrossRef]

- Moussaoui, B.; Bouamra, Y.; Ait Tahar, K.; Ould Amrouche, M.; Ouabed, D. Behavior of Short Concrete Cylinders Partially Confined with GFRP Composites. Procedia Struct. Integr. 2019, 17, 979–985. [Google Scholar] [CrossRef]

- Djenad, S.; Ait Taleb, S.; Si Salem, A. Finite Element Modeling of Partially-Confined Concrete and RC Columns with Embedded Hexagonal-FRP Strips under Axial and Horizontal Loading. Structures 2023, 54, 369–385. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Al-Baali, A.Q.; Hadi, M.N.S. Compressive Behaviour of Partially FRP Confined Concrete: Experimental Observations and Assessment of the Stress-Strain Models. Constr. Build. Mater. 2018, 192, 785–797. [Google Scholar] [CrossRef]

- Liao, J.J.; Zeng, J.J.; Jiang, C.; Li, J.X.; Yuan, J.S. Stress-Strain Behavior and Design-Oriented Model for FRP Spiral Strip-Confined Concrete. Compos. Struct. 2022, 293, 115747. [Google Scholar] [CrossRef]

- Ahmed, C.A.; Salem, A.S. Experimental Behavior and Reliability of Predamaged Concrete Columns Externally Repaired with FRP Spiral Strips under Axial Compression. World J. Eng. 2022, 21, 115–126. [Google Scholar] [CrossRef]

- Zeng, J.J.; Chen, S.P.; Zhuge, Y.; Gao, W.Y.; Duan, Z.J.; Guo, Y.C. Three-Dimensional Finite Element Modeling and Theoretical Analysis of Concrete Confined with FRP Rings. Eng. Struct. 2021, 234, 111966. [Google Scholar] [CrossRef]

- Totonchi, A.; Ansaripour, A.; Shivaei, S. Effect of Different Arrangements of CFRP Wraps on the Axial Stress–Strain Behaviour of Confined Concrete Cylinders: Experimental Study and Numerical Modelling. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2020, 44, 1087–1100. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Wang, Z. Design-Oriented Axial Stress–Strain Model for Partially Fiber-Reinforced-Polymer-Confined Normal-Strength Concrete. Adv. Struct. Eng. 2020, 23, 3481–3495. [Google Scholar] [CrossRef]

- Lin, S.; Zhao, Y.G.; Li, J. An Improved Wrapping Scheme of Axially Loaded Fiber-Reinforced Polymer Confined Concrete Columns. Compos. Struct. 2019, 226, 111242. [Google Scholar] [CrossRef]

- Bashiri, M.; Toufigh, V. Numerical and Experimental Investigation on a BRB Confined with Partially Carbon Fiber Reinforced Polymer (CFRP). Eng. Struct. 2020, 223, 111150. [Google Scholar] [CrossRef]

- Lewangamage, C.S.; Rankoth, C.K.; Jayasinghe, M.T.R. A Study on Reinforced Concrete Columns Partially Confined with Carbon Fibre Reinforced Polymer (CFRP). Eng. J. Inst. Eng. Sri Lanka 2017, 50, 41. [Google Scholar] [CrossRef]

- Zeng, J.J.; Guo, Y.C.; Gao, W.Y.; Li, J.Z.; Xie, J.H. Behavior of Partially and Fully FRP-Confined Circularized Square Columns under Axial Compression. Constr. Build. Mater. 2017, 152, 319–332. [Google Scholar] [CrossRef]

- Al-Tameemi, H.; Akın, E. Improving the Efficiency of FRP-Confined Square Concrete Column by Rounding the Sharp Edges and Circularizing the Flat Sides. Structures 2022, 45, 1762–1773. [Google Scholar] [CrossRef]

- Ghanem, S.Y.; Harik, I.E. Concentrically Loaded Circular RC Columns Partially Confined with FRP. Int. J. Concr. Struct. Mater. 2018, 12, 52. [Google Scholar] [CrossRef]

- Zeng, J.; Guo, Y.; Li, L.; Chen, W. Behavior and Three-Dimensional Finite Element Modeling of Circular Concrete Columns Partially Wrapped with FRP Strips. Polymers 2018, 10, 253. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Dong, Z.; Zhu, H.; Wu, G.; Zhao, X. Compression Behavior of Concrete Columns Combinedly Confined by FRP Externally Wrapped Fe-SMA Strips. Eng. Struct. 2023, 294, 116754. [Google Scholar] [CrossRef]

- Zeng, J.; Zheng, Y.; Liu, F.; Guo, Y.; Hou, C. Behavior of FRP Ring-Con Fi Ned CFST Columns under Axial Compression. Compos. Struct. 2021, 257, 113166. [Google Scholar] [CrossRef]

- Ranolia, K.V.; Thakkar, B.K.; Rathod, J.D. Effect of Different Patterns and Cracking in FRP Wrapping on Compressive Strength of Confined Concrete. Procedia Eng. 2013, 51, 169–175. [Google Scholar] [CrossRef]

- Zeng, J.; Liao, J.; Ye, Y.; Guo, Y.; Zheng, Y.; Tan, L. Behavior of FRP Spiral Strip-Confined Concrete under Cyclic Axial Compression. Constr. Build. Mater. 2021, 295, 123544. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Wang, Z. Axial Compressive Behavior of Partially CFRP Confined Seawater Sea-Sand Concrete in Circular Columns—Part I: Experimental Study. Compos. Struct. 2020, 246, 112373. [Google Scholar] [CrossRef]

- Djenad, S.; Si Salem, A.; Bouzidi, M.A. Performance and Compressive Axial Behavior of New Design Partially Confined Concrete Columns with Encased-FRP/Grid Strips. Asian J. Civ. Eng. 2022, 23, 801–815. [Google Scholar] [CrossRef]

- Al Abadi, H.; Paton-Cole, V.; Patel, V.I.; Thai, H.T. Axial Strength and Elastic Stiffness Behaviour of Partially Confined Concrete Columns. Constr. Build. Mater. 2019, 196, 727–741. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B. Effectiveness of Hybrid and Partially Confined Concrete Subjected to Axial Compressive Loading Using CFRP and GFRP Composite Materials. Slovak J. Civ. Eng. 2020, 28, 8–14. [Google Scholar] [CrossRef]

- Pham, T.M.; Hadi, M.N.S.; Youssef, J. Optimized FRP Wrapping Schemes for Circular Concrete Columns under Axial Compression. J. Compos. Constr. 2015, 19, 04015015. [Google Scholar] [CrossRef]

- Shayanfar, J.; Barros, J.A.; Rezazadeh, M. Unified Model for Fully and Partially FRP Confined Circular and Square Concrete Columns Subjected to Axial Compression. Eng. Struct. 2021, 251, 113355. [Google Scholar] [CrossRef]

- Gharaei-Moghaddam, N.; Arabshahi, A.; Tavakkolizadeh, M. Predictive Models for the Peak Stress and Ultimate Strain of FRP Confined Concrete Cylinders with Inclined Fiber Orientations. Results Eng. 2023, 18, 101044. [Google Scholar] [CrossRef]

- Djenad, S.; Taleb, S.A.; Si Salem, A.; Bouzidi, M.A. NLFEA Based Design Optimization of GFRP Strips in Partially Confined Concrete. Procedia Struct. Integr. 2022, 37, 321–329. [Google Scholar] [CrossRef]

- Deifalla, A.; Salem, N.M. A Machine Learning Model for Torsion Strength of Externally Bonded FRP-Reinforced Concrete Beams. Polymers 2022, 14, 1824. [Google Scholar] [CrossRef]

- Ilyas, I.; Zafar, A.; Afzal, M.T.; Javed, M.F.; Alrowais, R.; Althoey, F.; Mohamed, A.M.; Mohamed, A.; Vatin, N.I. Advanced Machine Learning Modeling Approach for Prediction of Compressive Strength of FRP Confined Concrete Using Multiphysics Genetic Expression Programming. Polymers 2022, 14, 1789. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.; Teng, J.G.; Wong, Y.L.; Dong, S.L. Finite Element Modeling of Confined Concrete-II: Plastic-Damage Model. Eng. Struct. 2010, 32, 680–691. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-Oriented Stress–Strain Model for FRP-Confined Concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Youssef, M.N.; Feng, M.Q.; Mosallam, A.S. Stress–Strain Model for Concrete Confined by FRP Composites. Compos. Part B Eng. 2007, 38, 614–628. [Google Scholar] [CrossRef]

- Popovics, S. A Numerical Approach to the Complete Stress-Strain Curve of Concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Z.; Jia, L.; Zhou, H.; Bai, W.; Li, Y. Flexural Behavior and Size Effect of Normal-Strength RC Columns under Monotonic Horizontal Loading. Eng. Struct. 2018, 166, 251–262. [Google Scholar] [CrossRef]

- Teng, J.G.; Huang, Y.L.; Lam, L.; Ye, L.P. Theoretical Model for Fiber-Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2007, 11, 201–210. [Google Scholar] [CrossRef]

| Concrete Columns Material | Wrapping Material for Concrete | Properties of Wrapped Material | Performance | Reference |

|---|---|---|---|---|

| Reinforced concrete | “Hybrid Composites” carbon fiber fabric wrap, glass fiber fabric and hybrid fiber fabric wrap | CFRP modulus of elasticity = 238 GPa GFRP modulus of elasticity = 76 GPa CFRP tensile strength = 3650 MPa GFRP tensile strength = 2200 MPa Area density (CFRP) = 225 g/m2 Area density (GFRP) = 430 g/m2 | Load bearing capacity increase = 22% Improvement in ductility = 1.65 | [21] |

| RC short columns | “Hybrid Composites” CFRP wrap and steel collar strengthening | Collar Tensile Strength = 452 MPa CFRP Tensile Strength = 1900 MPa Modulus of Elasticity collar = 161,857 MPa Modulus of Elasticity CFRP = 230,000 MPa | Ductility increment for CFRP = 38–108% Ductility increment for collar = 61–100% | [34] |

| BFRP & ECC Confined concrete | “Hybrid Composites” Basalt fiber textile Textile reinforced ECC | Size: 25 × 25 mm weft and wrap formed by monofilaments Density: 120 g/m2 Tensile strength: 658.7 MPa | BFRP and ECC tensile strength = 3.7 MPa BFRP and ECC tensile strain = 0.00657 | [35] |

| Plain concrete | “Hybrid Composites” Polyethylene naphtholate fiber-reinforced polymer (PEN FRP) and Basalt FRP (BFRP) | Density of BFRP fiber = 0.0021 g/mm3 Density of PEN FRP fiber = 0.0014 g/mm3 Tensile strength BFRP = 1226 MPa Tensile strength of PEN FRP = 842 MPa Elastic modulus of BFRP = 68.4 GPa Elastic modulus of PEN FRP = 17.5 GPa | Axial strain for BFRP = 2.1–3.2% Axial strain for PEN FRP = 3.3–5.6% | [36] |

| SMA alloy Spirals and plain concrete | “Hybrid Composites” CFRP and BFRP | BFRP density = 2.75 g/cm3 CFRP density = 1.76 g/cm3 Elastic modulus BFRP = 82 GPa Elastic modulus CFRP = 252 GPa Tensile strength BFRP = 1602 MPa Tensile strength CFRP = 4300 MPa | Strength of BFRP > Strength of CFRP | [37] |

| Steel-reinforced HS concrete | “Hybrid Composites” GFRP tubes | Compressive strength = 161 MPa Axial elastic modulus = 11.5 GPa Hoop Poisson’s ratio = 0.41 | - | [38] |

| Compositional Varied concrete of 4 types | “Hybrid Composites” Un-plasticized polyvinyl chloride (uPVC) tubes | Ultimate tensile strength = 49.5 MPa Young’s modulus = 3.5 GPa Poisson ratio = 0.34 | Strength increment = 1.28–2.35 times ductility factor = 1.84–15.3 times energy absorption increment = 11–243 times | [39] |

| M15 concrete mixture | “Hybrid Composites” Banana geotextile-reinforced geopolymer mortar (BGT-RGM) | Diameter of BFRGM = 13.98 cm Compressive strength = 24.57 MPa Thickness = 13 mm Tensile strength = 0.79 MPa | Tensile strength improvement = 83% Compressive strength improvement = 33% | [20] |

| Steel-reinforced concrete columns | E-glass fiber reinforced cementitious matrix (GFRCM) | Overall area weight = 251 g/m2 Elastic modulus of fiber = 64.4 GPa Ultimate tensile strength = 525 MPa Fiber ultimate tensile strain = 0.9% Equivalent thickness = 0.05 mm | Strength improved = 20–30% | [27] |

| Concrete containing colored waste glass | polypropylene textile | Thickness = 15 mm Width = 55 mm Tensile strength = 1265 MPa Young’s modulus = 8698 MPa | Resistance increases up to = 34.78 MPa | [28] |

| Reinforced concrete | CFRP type (M1, M2, M3) | Axial tensile strength = 4800 MPa Axial modulus of elasticity = 240 GPa Rupture strain(axial) = 2% | Axial strain = 1.9–2.2% | [23] |

| Low-strength hybrid fiber-reinforced concrete | Carbon fiber-reinforced polymer (CFRP) | Density of fiber = 1.65 g/mm2 Fiber thickness = 0.12 mm Tensile strength = 3500 MPa Modulus of elasticity = 28 GPa Ultimate strain = 1.67% | Increase in CS = 113.9% Axial compressive strength = 34 Mpa | [24] |

| Hybrid fiber-reinforced polymer (HFRP) spiral confined concrete | Basalt and carbon fiber | Density of Basalt fiber = 2.6 g/cm3 Density of Carbon fiber = 1.85 g/cm3 Tensile strength of Basalt fiber = 2250 MPa Tensile strength of Carbon fiber = 3000 MPa Elastic modulus of Basalt fiber = 90 GPa Elastic modulus of Carbon fiber = 210 Gpa | Ultimate strain of HFRP spiral > ultimate strain of CFRP bar | [25] |

| FRP Material | Confinement Spacing/Thickness/Width | Strength of Unconfined vs. Partial Confined | Recommended Spacing Ratio/Thickness | Optimum Positioning | References |

|---|---|---|---|---|---|

| Fe-SMA strips and BFRP strips | Strips spacing = 30, 40, 75 mm Number of strips = 3, 5 and 7 | Compressive strength of Fe-SMA with 3 strips increased = 71.10 MPa Compressive strength of FRP with 3 layers = 53 MPa | Narrow net spacing | Strip spacing = 30 mm Number of strip layers = 3 | [57] |

| Carbon fiber-reinforced polymer (CFRP) | Thickness of CFRP layer = 0.25 mm | Strength of proposed confinement = 86–120 MPa | Stronger confinement in the middle with width = 100 cm | Middle zone wrapping with a decrease toward the end | [50] |

| Fiber-reinforced polymer (FRP) | Width of FRP strip = 50 mm | Compressive strength of fully wrapped = 20–30 MPa Compressive strength for partial = 55–70 MPa | Width of strip = 40 mm | increase in number of strips = 1–7 | [55] |

| CFRP | Thickness of layer = 0.37 mm | Max stress in CFRP strip = 490 MPa | Based on a smaller s/L ratio. | M-5 and M-8 coverage area = 50% M-9 coverage area = 40% | [51] |

| CFRP | Width of strips variation range = 1 cm–20 cm | Compressive strength of unconfined = 36 MPa Compressive strength for partial confinement = 40 | Spacing between the strips = 1–2 cm | Wider CFRP wrap in the center | [48] |

| CFRP | Thickness of layer = 0.167 mm | Axial stress of unconfined = 36.4 MPa Axial stress of partially confined = 70 MPa (average) | Spacing between strips = 25–35 cm | Less spacing between strips was recommended | [44] |

| FRP | Thickness of strips range = 0.167–0.334 mm Width of strips = 25, 30 and 35 mm | - | - | More FRP strip width with 4–5 FRP strip | [11] |

| SikWrap-230 C unidirectional CFRP | Thickness of strip = 0.131 mm Width of strip range = 100–600 mm | Elastic stiffness for unconfined = 222 MPa Elastic stiffness for partial confinement = 3000–7900 MPa | Width for the confinement = 300–400 mm | Strips with a confinement width of 500 mm for low-strength concrete | [63] |

| FRP | Width of FRP strip = 25, 30, 35 mm Thickness of strip = 0.167 mm | Compressive Strength for partial confinement = 23–27 MPa | - | Increase in the thickness of the strip increases the compressive strength | [56] |

| CFRP | Thickness of strip = 0.167 mm Number of CFRP layers = 0–3 | Yield displacement = 11–13 mm | Lateral directional confinement of CFRP layer. | Axial bearing capacity of the column increased to 52% by 3 layers of CFRP | [41] |

| Bidirectional fiberglass mat (GFRP) | Hexagonal GFRP strips with width = 30 mm GGFRP strip thickness = 0.35 mm | Compressive strength of hexagonal GFRP = 32 MPa | Spacing between strips = 10 mm | Decrease in spacing of hexagonal strips Increase number and amount of GFRP layer | [62] |

| SikaWrap-301C-CFRP | Spacing of strips = 20, 40 and 60 mm | Compressive strength of horizontal strip Partial-CFRP = 80 MPa Compressive strength of helicoidal strip Partial-CFRP = 68 MPa | Spacing between the strips = 20 mm | partial CFRP confinement with a horizontal strip | [40] |

| Bidirectional GFRP and a unidirectional CFRP | Central zoning confinement with GFRP or CFRP | Compressive strength of partial CFRP = 41–45 MPa Compressive strength of partial GFRP = 40–42 MPa | Partial confinement in the central zone and Partial confinement with hybrid CFRP and GFRP | Two CFRP layers in the central zone or hybrid confinement | [64] |

| GFRP | Spacing between hexagonal strips = 30 mm FRP thickness = 0.35–1.4 mm | Compressive strength of unconfined column = 27.3 MPa Compressive strength of partially confined columns = 30–35 MPa | - | Increase of CFRP layers. | [43] |

| CFRP | Width of CFRP strips = 30, 40, 50, 60 mm Spacing between strips = 30, 60, 75, 90, 105 mm | Average compressive strength for partial confinement = 40 MPa | Width of CFRP strip = 45 mm Spacing between the strips = 30 mm | smaller clear spacing between two adjacent strips | [61] |

| Modeling Approach | Constitutive/Proposed Model | Confinement Method | Key Parameters | Validation Approach | Remarks | References |

|---|---|---|---|---|---|---|

| FE modeling | Concrete damage plastic model (CDPM), as proposed and improved by [71] | Continuous and discontinuous FRP strips | Effective confining pressure, yield function F, hardening function | Comparison of numerical test results with experiments | Few experimental specimens for modeling FE numerical results are not provided for partially FRP concrete columns | [56] |

| Analytical model-an extension of existing stress–strain model | An extension of the existing model with a new coefficient in the model [72] | Partially confined strips with varying gaps | Confinement effective coefficient Ke, Strain hardening and softening, a gap of strip wrapping | Comparison with an experimental database of 76 partially FRP-confined concrete | Limitations in test conditions and complexity in strain distribution. | [44] |

| FEM verification and comparison | Theoretical stress–strain model by [73] | Different wrapping patterns of fibers | Axial stress–strain, confinement pattern thickness, position and ratio, compressive strength | Comparison between FEA, experimental and Youssef et al. | Similar damage patterns by fully and discontinuously wrapped cylinders | [48] |

| Analytical model | Basic framework of axial stress–strain by [74]. Active confinement approach–dilation model | Full and partial | Confinement efficiency factor and stiffness index | Regression analysis technique | The iterative process for R1 and R2 values is not clear | [66] |

| A design-oriented axial stress–strain model | Design-oriented model [11] Separate equations for type 1 and 2 models | Fully and partially | Actual confinement ratio, clear spacing ratio, hoop rupture strain of FRP | A large experimental database of FRP partially wrapped normal strength concrete columns | Emphasize the material properties, geometric parameters, and some specific ratios. | [49] |

| Analysis oriented model | Unified dilation model for axial deformations due to damage in unwrapped areas | FRP full and partial | Spacing, steel hoop/spiral, FRP confinement stiffness | Existing experimental results, previous model and confinement efficiency factor | Recalibration is required to adapt this model for new material and confinement types | [16] |

| FEM-an innovative configuration of embedded strips | 3D simulations were tested on the basis of [75] | Hexagonal GFRP strips wrapped on discontinuous steel grid within the concrete column | Failure mode, lateral carrying load capacity, concrete strength, ratio | By experimental and analytical data for axial stress–strain and failure parameters | Simulation and data of large-scale RC columns needed for further optimization | [43] |

| Existing stress–strain model with advanced FE approach | Revised analysis model based on [76], Proposed arching action angle model, Improved CDPM by [71] | Concrete confined with FRP rings/ties | Confinement coefficient Kv,new = Ve/Vv Unconfined concrete strength, FRP width and thickness, | Comparing experimental evidence as stress–strain curves, failure mode, ultimate axial stress–strain distribution | Varied axial stress distribution in columns having the same confinement coefficient | [47] |

| Analytical and numerical (Design oriented) | Proposed factors based on the relations proposed by [15] | FRP inclined wrappings | Peak stress, ultimate strain, modification factors β1 and β2 as fiber angles | Experimental database 70% for modification and 30% for validation | Improvements for existing models but new models not presented | [67] |

| Non-linear Finite element approach (NLFEA) | CDPM, Tsai-Wu failure criteria | FRP stirrups | Strips spacing/width/thickness/rate of confinement | Comparison with numerical results of already available experimental data | Ensuring optimal adhesion in the bonded area is critical for repairment | [68] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghani, M.U.; Ahmad, N.; Abraha, K.G.; Manj, R.Z.A.; Sharif, M.H.; Wei, L. Review and Assessment of Material, Method, and Predictive Modeling for Fiber-Reinforced Polymer (FRP) Partially Confined Concrete Columns. Polymers 2024, 16, 1367. https://doi.org/10.3390/polym16101367

Ghani MU, Ahmad N, Abraha KG, Manj RZA, Sharif MH, Wei L. Review and Assessment of Material, Method, and Predictive Modeling for Fiber-Reinforced Polymer (FRP) Partially Confined Concrete Columns. Polymers. 2024; 16(10):1367. https://doi.org/10.3390/polym16101367

Chicago/Turabian StyleGhani, Muhammad Usman, Nauman Ahmad, Kahsay Gebresilassie Abraha, Rana Zafar Abbas Manj, Muhammad Haroon Sharif, and Li Wei. 2024. "Review and Assessment of Material, Method, and Predictive Modeling for Fiber-Reinforced Polymer (FRP) Partially Confined Concrete Columns" Polymers 16, no. 10: 1367. https://doi.org/10.3390/polym16101367

APA StyleGhani, M. U., Ahmad, N., Abraha, K. G., Manj, R. Z. A., Sharif, M. H., & Wei, L. (2024). Review and Assessment of Material, Method, and Predictive Modeling for Fiber-Reinforced Polymer (FRP) Partially Confined Concrete Columns. Polymers, 16(10), 1367. https://doi.org/10.3390/polym16101367