Effect of Hydrothermal Aging on the Tribological Performance of Nitrile Butadiene Rubber Seals

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

2.2. Hydrothermal Aging Test

2.3. Hydrothermal Aged NBR Characterization

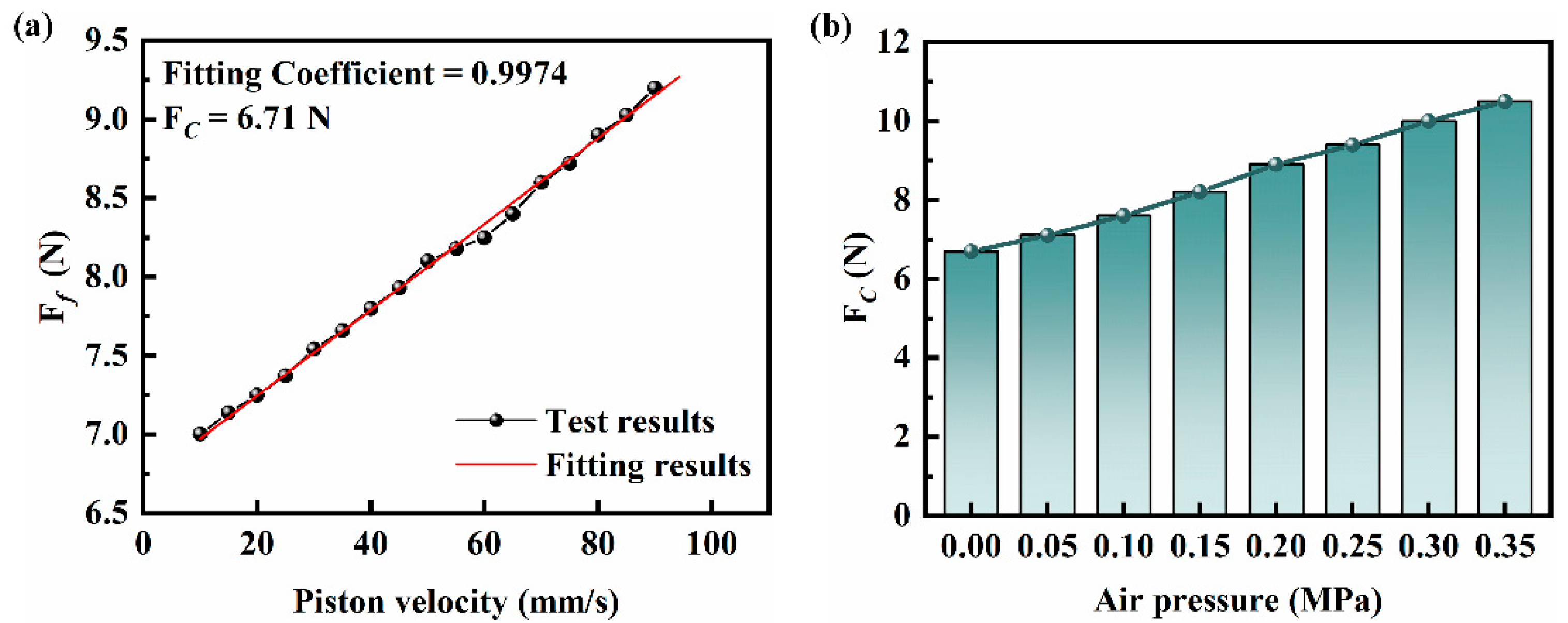

2.4. Friction Experiment

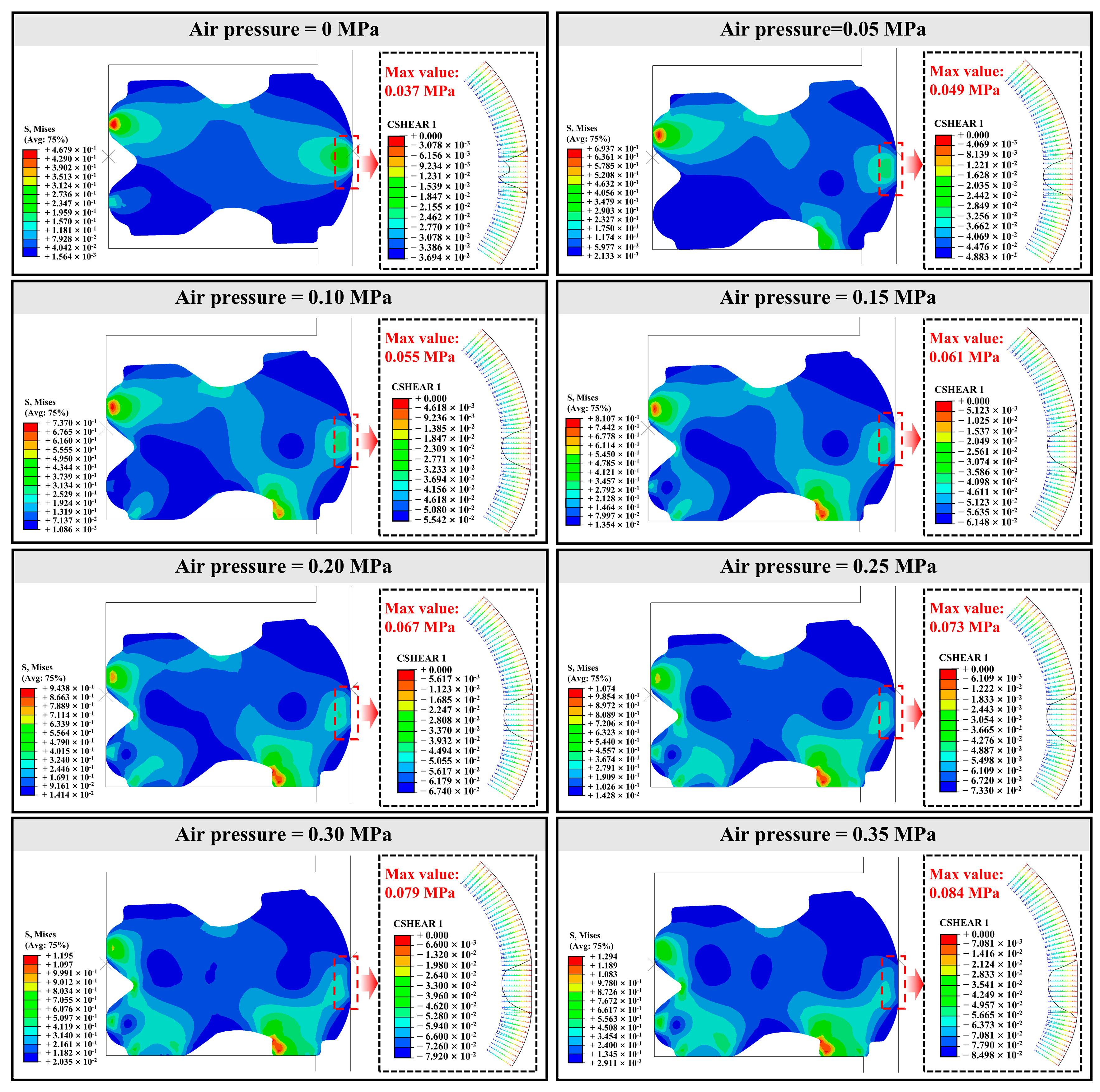

3. Finite Element Analysis of the NBR Seals Friction Process

4. Results and Discussions

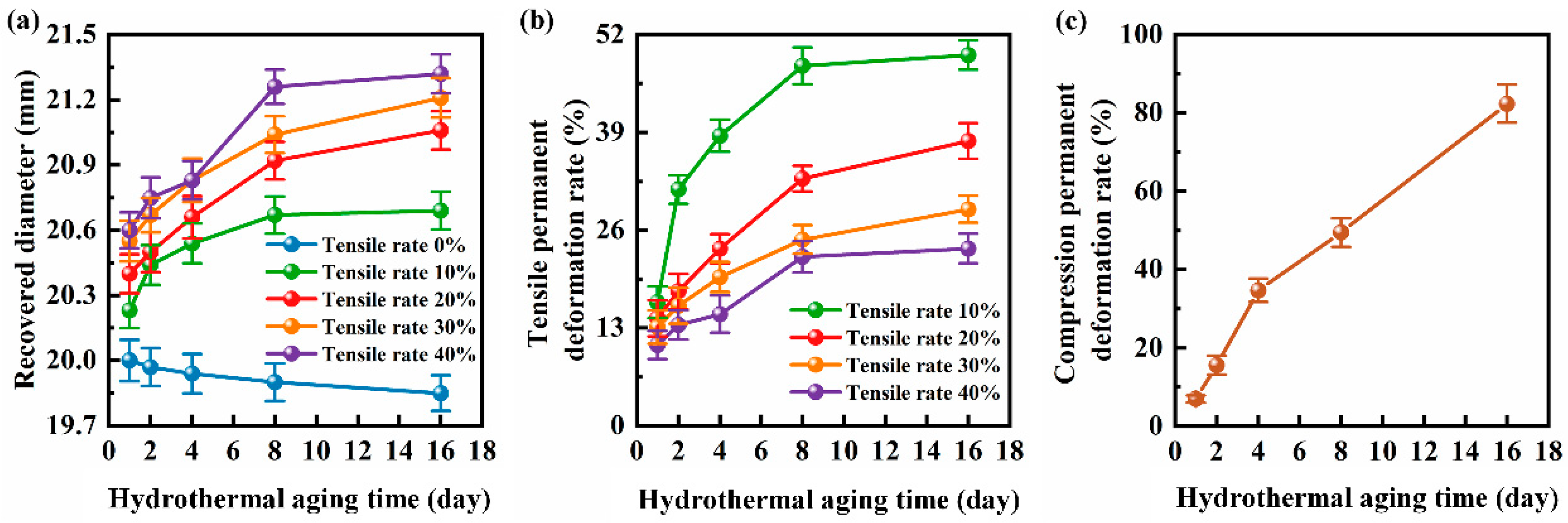

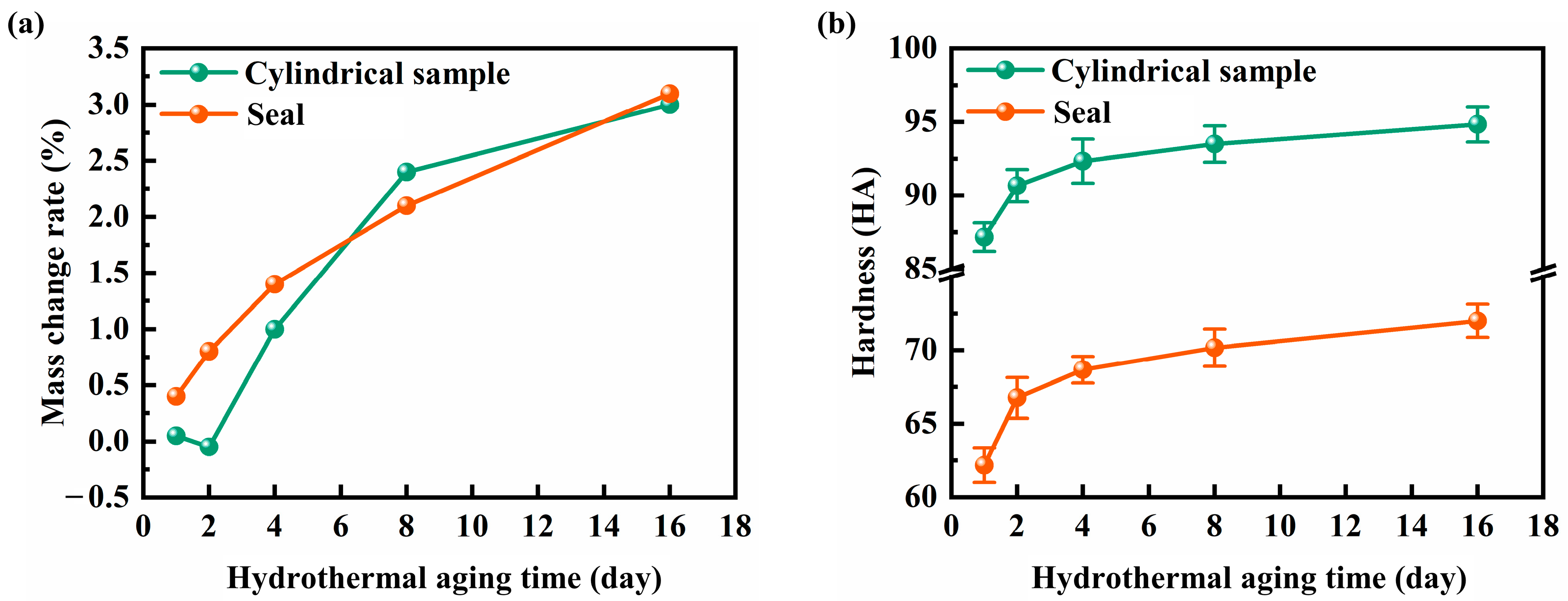

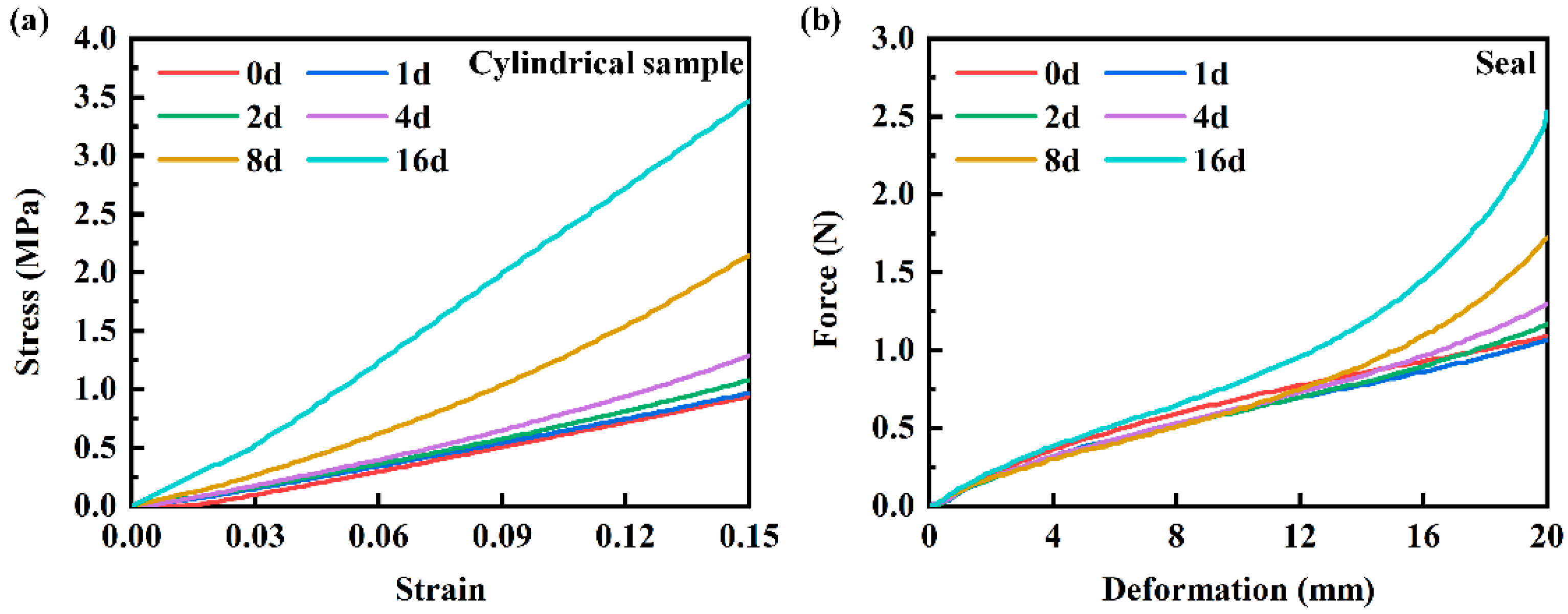

4.1. Mechanical Properties

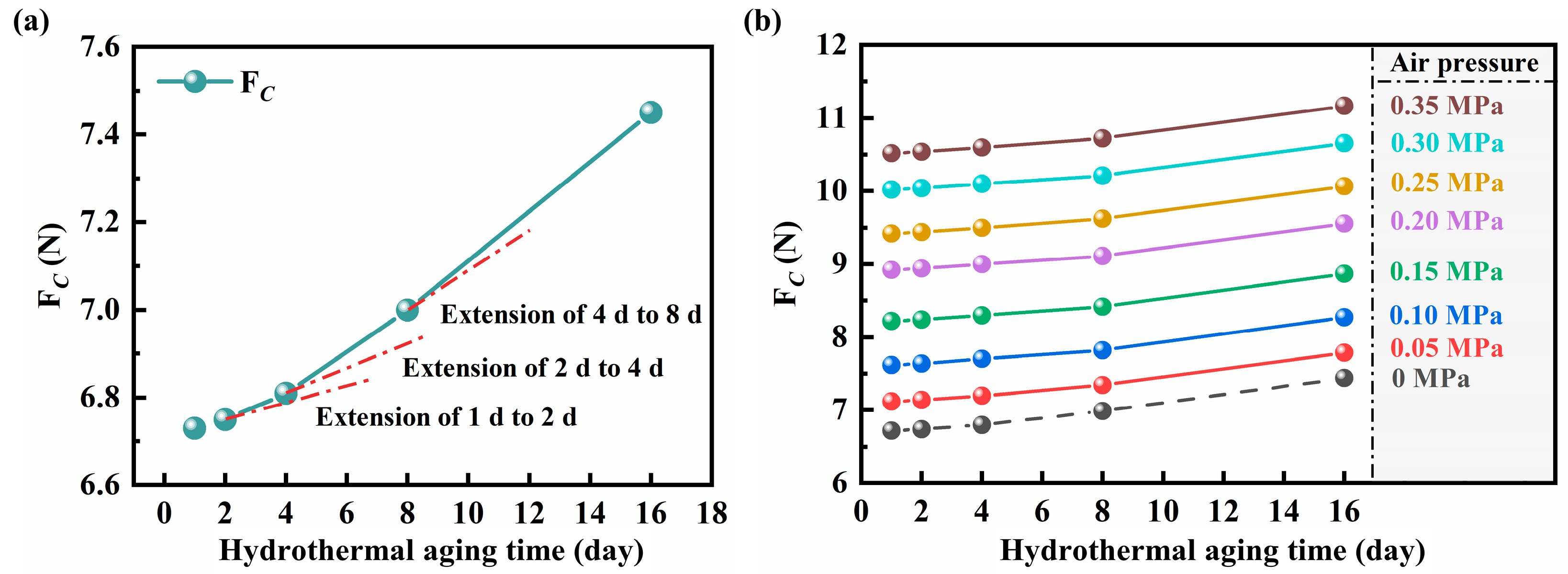

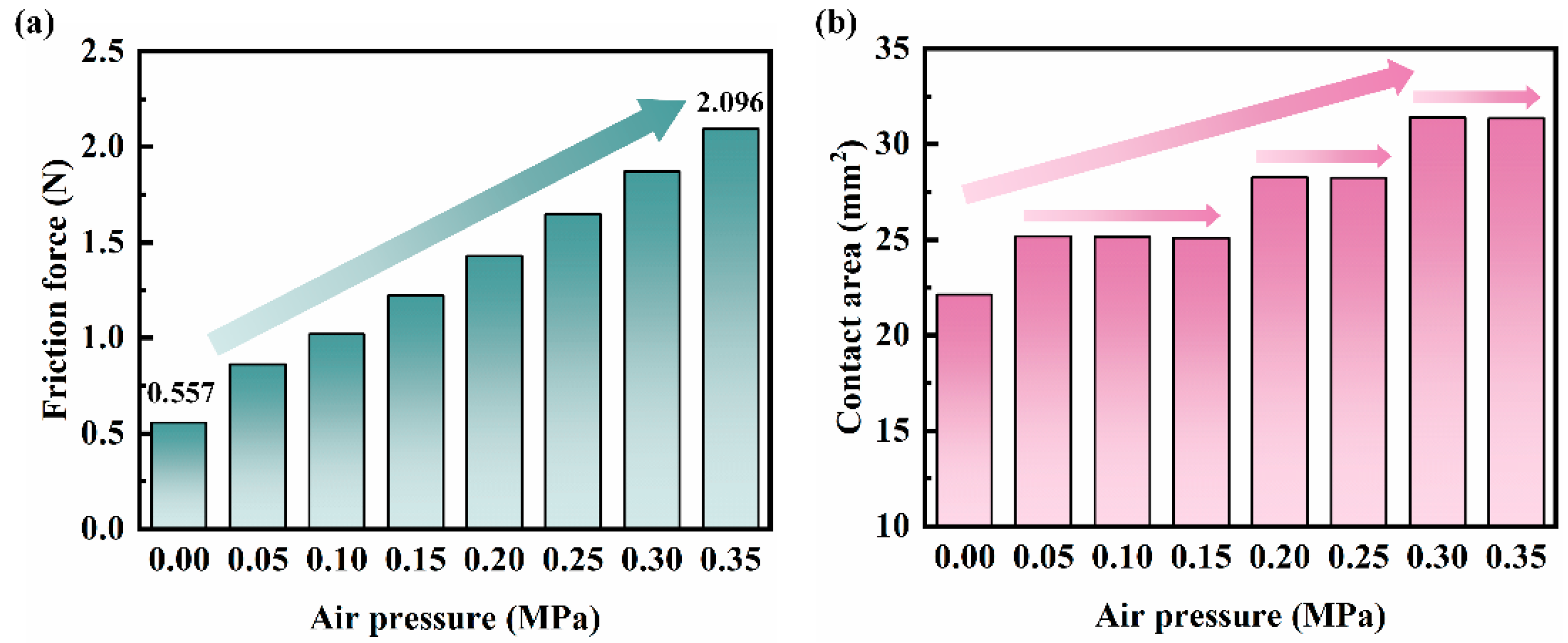

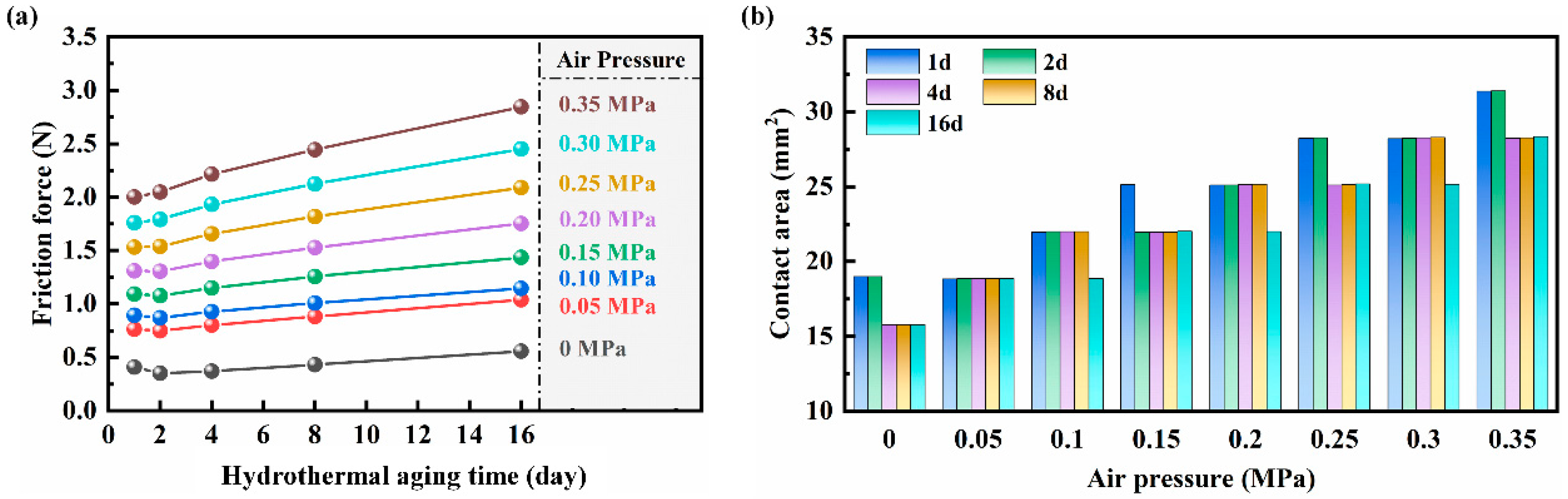

4.2. Tribological Behavior of Hydrothermal Aging

5. Conclusions

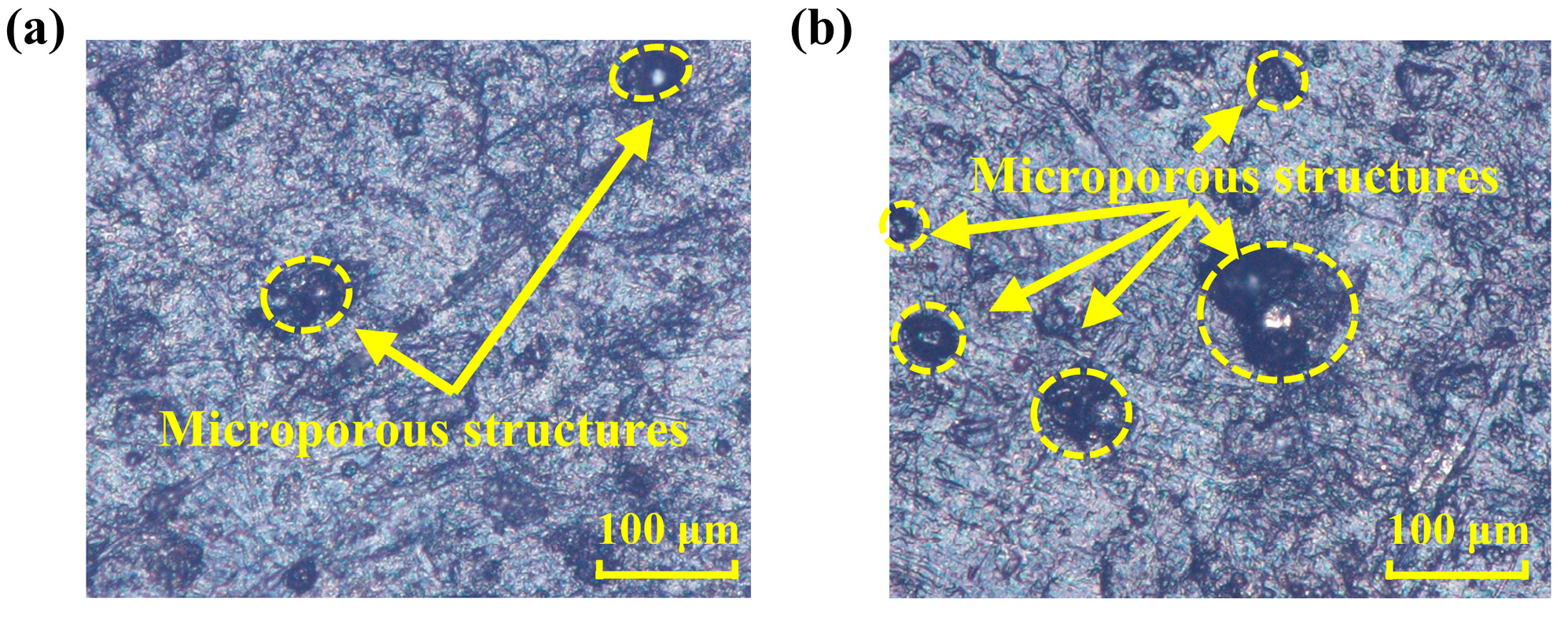

- NBR undergoes oxidation, cross-linking, chain-breaking, etc. in the hydrothermal aging environment, which leads to changes in the chemical structure. Moreover, the internal additives precipitate out onto its surface, which causes the appearance of surface micropores. The number and size of these micropores increase with the hydrothermal aging time.

- The cross-link density between molecules of NBR increases in the hydrothermal aging environment, and the strength of the connection between molecular chains is enhanced, resulting in increased hardness, tensile and compressive resistance, and weakened elastic deformation. Therefore, the NBR seals shrink in the hydrothermal aging environment, which reduces the contact pressure between them and the cylinder wall.

- The increase in loading air pressure in the cylinder causes an increase in dynamic friction and does not affect the effect of hydrothermal aging time on the tribological performance of NBR seals. The dynamic friction of the NBR seals in the cylinder gradually increases with the increase of the hydrothermal aging time, which is mainly due to the increase in the number and size of surface micropores caused by the volatilization of additives inside the NBR in the damp aging environment. The deterioration of the surface quality leads to the degradation of the tribological performance of the NBR seals, and shrinkage of the NBR seals due to hydrothermal aging suppresses the degradation of the tribological performance.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Saravanakumar, D.; Mohan, B.; Muthuramalingam, T.; Sakthivel, G. Performance evaluation of interconnected pneumatic cylinders positioning system. Sens. Actuat. A Phys. 2018, 274, 155–164. [Google Scholar]

- Taghizadeh, M.; Ghaffari, A.; Najafi, F. Improving dynamic performances of PWM-driven servo-pneumatic systems via a novel pneumatic circuit. ISA Trans. 2009, 48, 512–518. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Cai, M.; Xu, W.; Wang, Y.J. Methods to Evaluate and Measure Power of Pneumatic System and Their Applications. Chin. J. Mech. Eng. 2019, 32, 322019. [Google Scholar]

- Shen, M.X.; Peng, X.D.; Meng, X.K.; Zheng, J.P.; Zhu, M.H. Fretting wear behavior of acrylonitrile–butadiene rubber (NBR) for mechanical seal applications. Tribol. Int. 2016, 93, 419–428. [Google Scholar] [CrossRef]

- Bai, C.; Gong, Z.; An, L.; Qiang, L.; Zhang, J.; Yushkov, G.; Nikolaev, A.; Shandrikov, M.; Zhang, B. Adhesion and friction performance of DLC/rubber: The influence of plasma pretreatment. Friction 2021, 9, 627–641. [Google Scholar] [CrossRef]

- Bai, C.; Qiang, L.; Zhang, B.; Gao, K.; Zhang, J. Optimizing the tribological performance of DLC-coated NBR rubber: The role of hydrogen in films. Friction 2021, 10, 866–877. [Google Scholar] [CrossRef]

- Qu, C.; Zhang, N.; Wang, C.; Wang, T.; Wang, Q.; Li, S.; Chen, S. MoS2/CF synergistic reinforcement on tribological properties of NBR/PU/EP interpenetrating polymer networks. Tribol. Int. 2022, 167, 107384. [Google Scholar] [CrossRef]

- Bauer, D.R.; Baldwin, J.M.; Ellwood, K.R. Rubber aging in tires. Part 2: Accelerated oven aging tests. Polym. Degrad. Stabil. 2007, 92, 110–117. [Google Scholar] [CrossRef]

- Sridharan, H.; Chanda, J.; Ghosh, P.; Mukhopadhyay, R. Rubber blend and filler effects on damage mechanisms under monotonic and fatigue loading. Rubber. Chem. Tech. 2019, 92, 415–430. [Google Scholar] [CrossRef]

- Lucas, P.; Baba, M.; Lacoste, J.; Gardette, J.L. Crosslinking of dienic elastomers resulting from ageing: X-ray diffraction and refractometry measurements. Polym. Degrad. Stabil. 2002, 76, 449–453. [Google Scholar] [CrossRef]

- Woo, C.S.; Ki, W.D.; Kwon, J.D. A study on the material properties and fatigue life prediction of natural rubber component. Mat. Sci. Eng. A 2008, 376, 483–484. [Google Scholar] [CrossRef]

- Wu, J.; Dong, J.; Wang, Y.; Gond, B.K. Thermal oxidation ageing effects on silicone rubber sealing performance. Polym. Degrad. Stabil. 2017, 135, 43–53. [Google Scholar] [CrossRef]

- Le Huy, M.; Evrard, G. Methodologies for lifetime predictions of rubber using Arrhenius and WLF models. Angew. Makromol. Chem. 1998, 261, 135–142. [Google Scholar] [CrossRef]

- Bernstein, R.; Gillen, K.T. Predicting the lifetime of fluorosilicone o-rings. Polym. Degrad. Stabil. 2009, 94, 2107–2113. [Google Scholar] [CrossRef]

- Woo, C.S.; Park, H.S. Useful lifetime prediction of rubber component. Eng. Fail. Anal. 2011, 18, 1645–1651. [Google Scholar] [CrossRef]

- Woo, C.S.; Kim, W.D.; Lee, S.H.; Choi, B.I.; Park, H.S. Fatigue life prediction of vulcanized natural rubber subjected to heat-aging. Procedia Eng. 2009, 1, 9–12. [Google Scholar] [CrossRef]

- He, S.; Bai, F.; Liu, S.; Ma, H.; Hu, J.; Chen, L.; Lin, J.; Wei, G.; Du, X. Aging properties of styrene-butadiene rubber nanocomposites filled with carbon black and rectorite. Polym. Test. 2017, 64, 92–100. [Google Scholar] [CrossRef]

- Roland, C.M.; Mott, P.H. Aging of Natural Rubber in Air and Seawater. Rubber. Chem. Techn 2001, 74, 79. [Google Scholar]

- Woo, C.S.; Choi, S.S.; Lee, S.B.; Kim, H.S. Useful lifetime prediction of rubber components using accelerated testing. IEEE. Trans. Reliab. 2010, 59, 11–17. [Google Scholar] [CrossRef]

- Moon, B.; Lee, J.; Park, S.; Seok, C.-S. Study on the Aging Behavior of Natural Rubber/Butadiene Rubber (NR/BR) Blends Using a Parallel Spring Model. Polymers 2018, 10, 658. [Google Scholar] [CrossRef]

- Alcock, B.; Jørgensen, J.K. The mechanical properties of a model hydrogenated nitrile butadiene rubber (HNBR) following simulated sweet oil exposure at elevated temperature and pressure. Polym. Test. 2015, 46, 50–58. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Xu, L.; Zhang, P. Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym. Test. 2016, 54, 59–66. [Google Scholar] [CrossRef]

- Zou, Y.; Sun, Y.; Zhang, Y.; He, J.; Tang, Z.; Zhu, L.; Luo, Y.; Liu, F. Antioxidative behavior of a novel samarium complex in styrene-butadiene rubber/silica composites. Polym. Degrad. Stabil. 2016, 133, 201–210. [Google Scholar] [CrossRef]

- Nabil, H.; Ismail, H.; Azura, A.R. Comparison of thermo-oxidative ageing and thermal analysis of carbon black-filled NR/Virgin EPDM and NR/Recycled EPDM blends. Polym. Test. 2013, 32, 631–639. [Google Scholar] [CrossRef]

- Choudhury, A.; Bhowmick, A.K.; Soddemann, M. Effect of organo-modified clay on accelerated aging resistance of hydrogenated nitrile rubber nanocomposites and their life time prediction. Polym. Degrad. Stabil. 2010, 95, 2555–2562. [Google Scholar] [CrossRef]

- Liu, X.R.; Zhang, W.F.; Lou, W.T.; Huang, Y.X.; Dai, W. Investigation on thermal oxidative aging of nitrile rubber (NBR) O-rings under compression stress. IOP. Conf. Ser. Mater. Sci. Eng. 2017, 265, 012003. [Google Scholar] [CrossRef]

- Choi, S.S.; Chung, H.S.; Joo, Y.T.; Yang, K.M.; Lee, S.H. Analysis of whitening phenomenon of EPDM article by humid aging. J. Appl. Polym. Sci. 2012, 123, 2451–2457. [Google Scholar] [CrossRef]

- Patel, M.; Skinner, A.R. Thermal ageing studies on room-temperature vulcanised polysiloxane rubbers. Polym. Degrad. Stabil. 2001, 73, 399–402. [Google Scholar] [CrossRef]

- Liu, S.; Cui, Z.; Su, Z.; Zhu, B.; He, S.; Su, B.; Wu, J.; Wang, Y. Sliding characteristics of bioinspired polydimethylsiloxane micropillars under bending states. Tribol. Int. 2022, 175, 107808. [Google Scholar] [CrossRef]

- Teng, F.; Wu, J.; Su, B.; Wang, Y. High-speed tribological properties of Eucommia ulmoides gum/natural rubber blends: Experimental and molecular dynamics simulation study. Tribol. Int. 2022, 171, 107542. [Google Scholar] [CrossRef]

- Dong, C.L.; Yuan, C.Q.; Bai, X.Q.; Yan, X.P.; Peng, Z. Tribological properties of aged nitrile butadiene rubber under dry sliding conditions. Wear 2015, 322, 226–237. [Google Scholar] [CrossRef]

- Han, R.; Quan, X.; Shao, Y.; Niu, K. Tribological properties of phenyl-silicone rubber composites with nano-CeO2 and graphene under thermal-oxidative aging. Appl. Nanosci. 2020, 10, 2129–2138. [Google Scholar] [CrossRef]

- He, Q.; Wang, G.; Zhang, Y.; Li, Z.; Kong, L.; Zhou, W. Thermo-oxidative ageing behavior of cerium oxide/silicone rubber. J. Rare Earths 2020, 38, 436–444. [Google Scholar] [CrossRef]

- Luo, H.; Wu, J.; Teng, F.; Su, B.; Li, H.; Lin, A.; Li, Z.; Wang, Y. Multiscale simulation on dynamic friction behavior of cylinder sealing rings under hydrothermal aging. J. Appl. Polym. Sci. 2021, 138, 50453. [Google Scholar] [CrossRef]

- ISO 188:2023; Rubber, Vulcanized or Thermoplastic—Accelerated Ageing and Heat Resistance Tests. ISO: Geneva, Switzerland, 2023.

- ISO 2285:2019; Rubber, Vulcanized or Thermoplastic—Determination of Tension Set under Constant Elongation, and of Tension Set, Elongation and Creep under Constant Tensile Load. ISO: Geneva, Switzerland, 2019.

- ISO 815-1:2019; Rubber, Vulcanized or Thermoplastic: Determination of Compression Set—Part 1: At Ambient or Elevated Temperatures. ISO: Geneva, Switzerland, 2019.

- ISO 7743:2017; Rubber, Vulcanized or Thermoplastic: Determination of Compression Stress-Strain Properties. ISO: Geneva, Switzerland, 2017.

- Bazaei, A.; Moallem, M. Prestiction friction modeling and position control in an actuated rotary arm. IEEE. Trans. Instrum. Meas. 2010, 59, 131–139. [Google Scholar] [CrossRef]

- Jiménez, R.; Álvarez-Icaza, L. LuGre friction model for a magnetorheological damper. Struct. Control. Health Monitor. 2005, 12, 91–116. [Google Scholar] [CrossRef]

- Muvengei, O.; Kihiu, J.; Ikua, B. Dynamic analysis of planar multi-body systems with LuGre friction at differently located revolute clearance joints. Multibody Syst. Dyn. 2012, 28, 369–393. [Google Scholar] [CrossRef]

- Li, B.; Li, S.X.; Shen, M.X.; Xiao, Y.L.; Zhang, J.; Xiong, G.Y.; Zhang, Z.N. Tribological behaviour of acrylonitrile-butadiene rubber under thermal oxidation ageing. Polym. Test. 2021, 93, 106954. [Google Scholar] [CrossRef]

| Aging Time (Day) | Loading Air Pressure (MPa) | Piston Velocity (mm/s) |

|---|---|---|

| 0 | 0, 0.05, 0.1, 0.15, 0.2, 0.25, 0.3, 0.35 | 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90 |

| 1 | ||

| 2 | ||

| 4 | ||

| 8 | ||

| 16 |

| Aging Time (Day) | Loading Air Pressure (MPa) |

|---|---|

| 0 | 0, 0.05, 0.1, 0.15, 0.2, 0.25, 0.3, 0.35 |

| 1 | |

| 2 | |

| 4 | |

| 8 | |

| 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, G.; Chen, Z.; Wu, J.; Lin, A.; Liu, Q.; Liu, S.; Su, B.; Wang, Y. Effect of Hydrothermal Aging on the Tribological Performance of Nitrile Butadiene Rubber Seals. Polymers 2024, 16, 81. https://doi.org/10.3390/polym16010081

Huang G, Chen Z, Wu J, Lin A, Liu Q, Liu S, Su B, Wang Y. Effect of Hydrothermal Aging on the Tribological Performance of Nitrile Butadiene Rubber Seals. Polymers. 2024; 16(1):81. https://doi.org/10.3390/polym16010081

Chicago/Turabian StyleHuang, Gege, Zhihao Chen, Jian Wu, Ange Lin, Qinxiu Liu, Shouyao Liu, Benlong Su, and Youshan Wang. 2024. "Effect of Hydrothermal Aging on the Tribological Performance of Nitrile Butadiene Rubber Seals" Polymers 16, no. 1: 81. https://doi.org/10.3390/polym16010081

APA StyleHuang, G., Chen, Z., Wu, J., Lin, A., Liu, Q., Liu, S., Su, B., & Wang, Y. (2024). Effect of Hydrothermal Aging on the Tribological Performance of Nitrile Butadiene Rubber Seals. Polymers, 16(1), 81. https://doi.org/10.3390/polym16010081