Effect of Mortise and Tenon Structure on the Properties of Wood Flour Polyvinyl Chloride-Laminated Veneer Lumber Co-Extruded Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

2.2.1. Preparation of WPVC

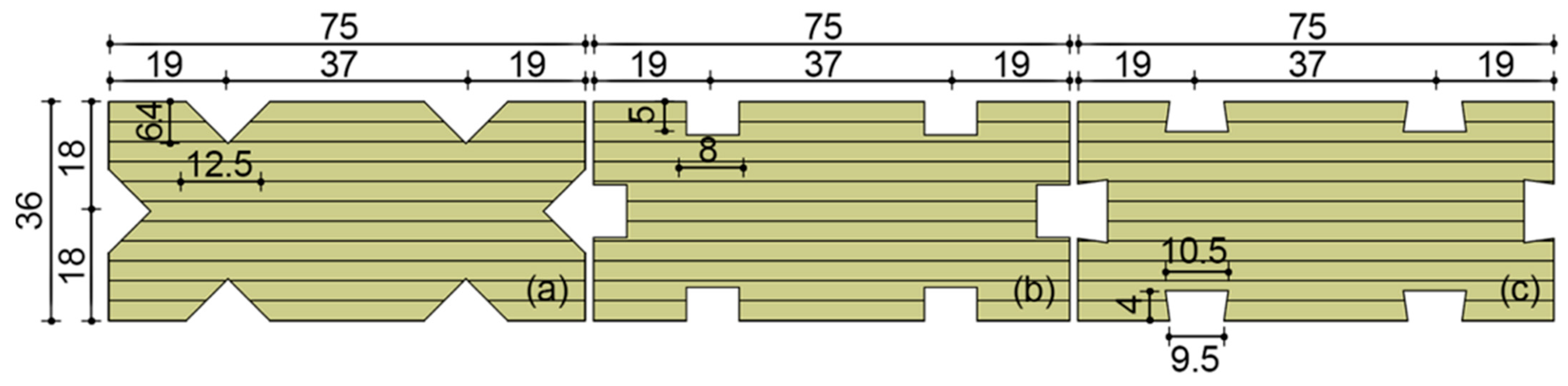

2.2.2. Groove Milling on Poplar LVL

2.2.3. Preparation of WPVC–LVL Wood–Plastic Co-Extrusion Composites

3. Characterization Methods

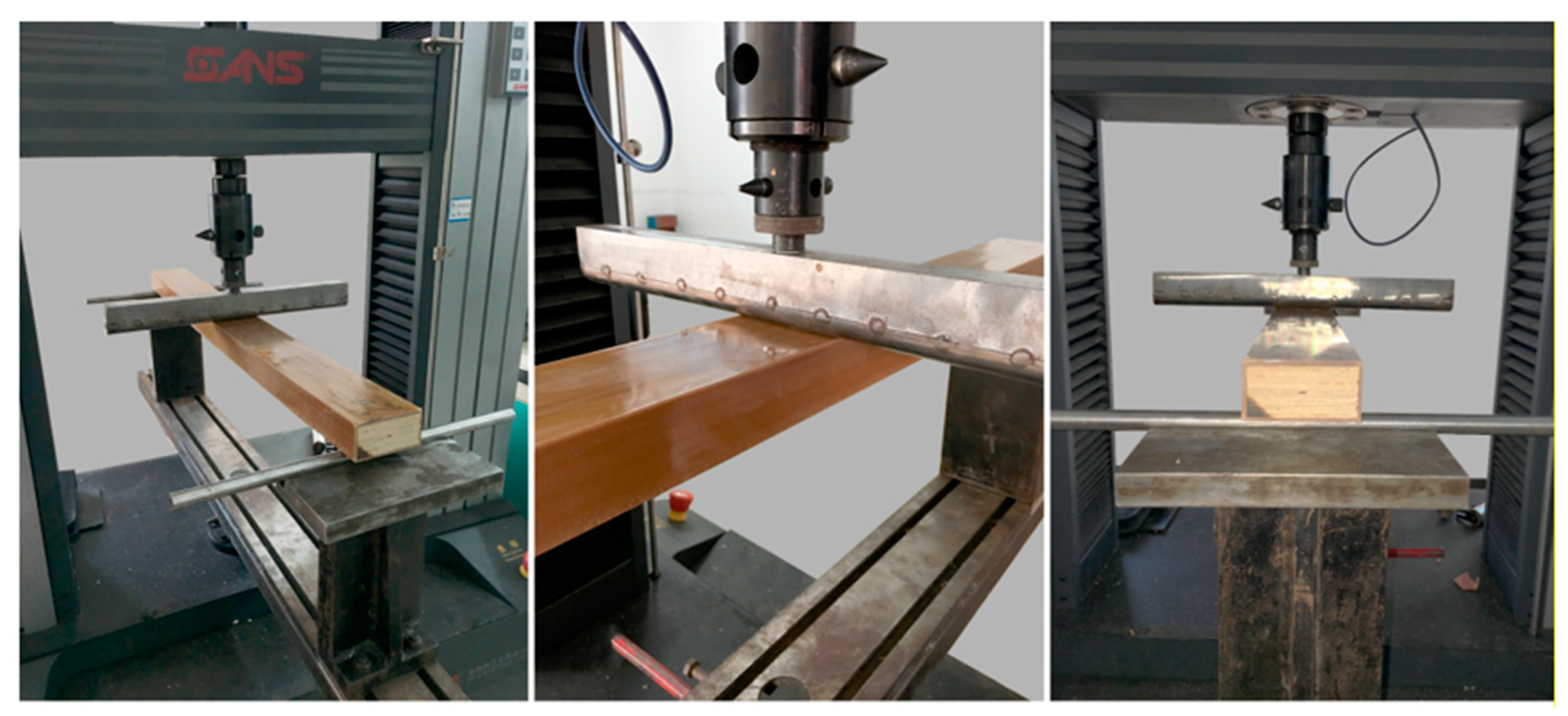

3.1. Bending Performance

3.2. Long-Term Creep Performance

3.3. Interface Bonding Performance

3.4. Dimensional Stability

3.4.1. Water Absorption Expansion Test

3.4.2. Water Absorption Weight Gain

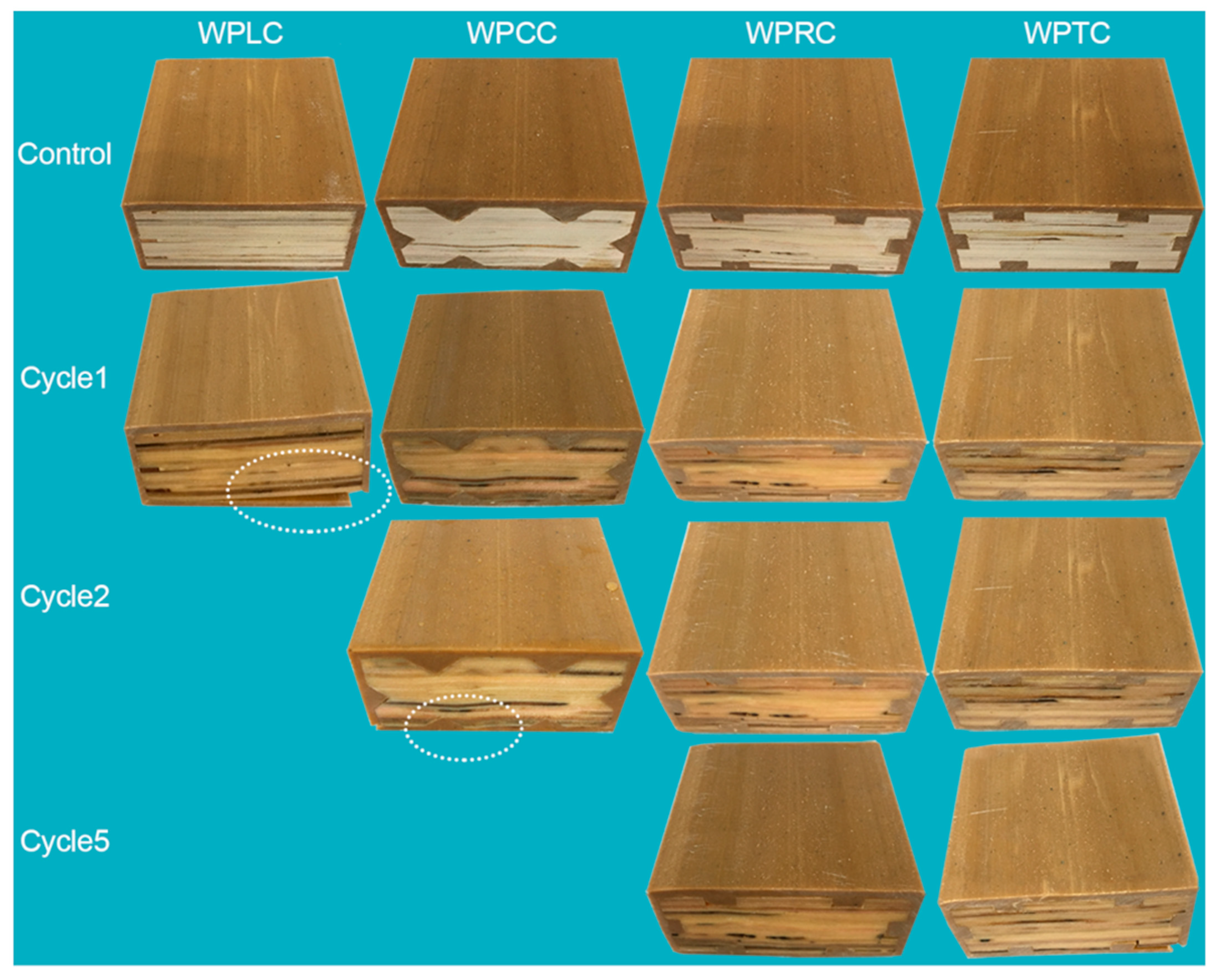

3.4.3. Morphological Analysis after Water Absorption

4. Results and Discussion

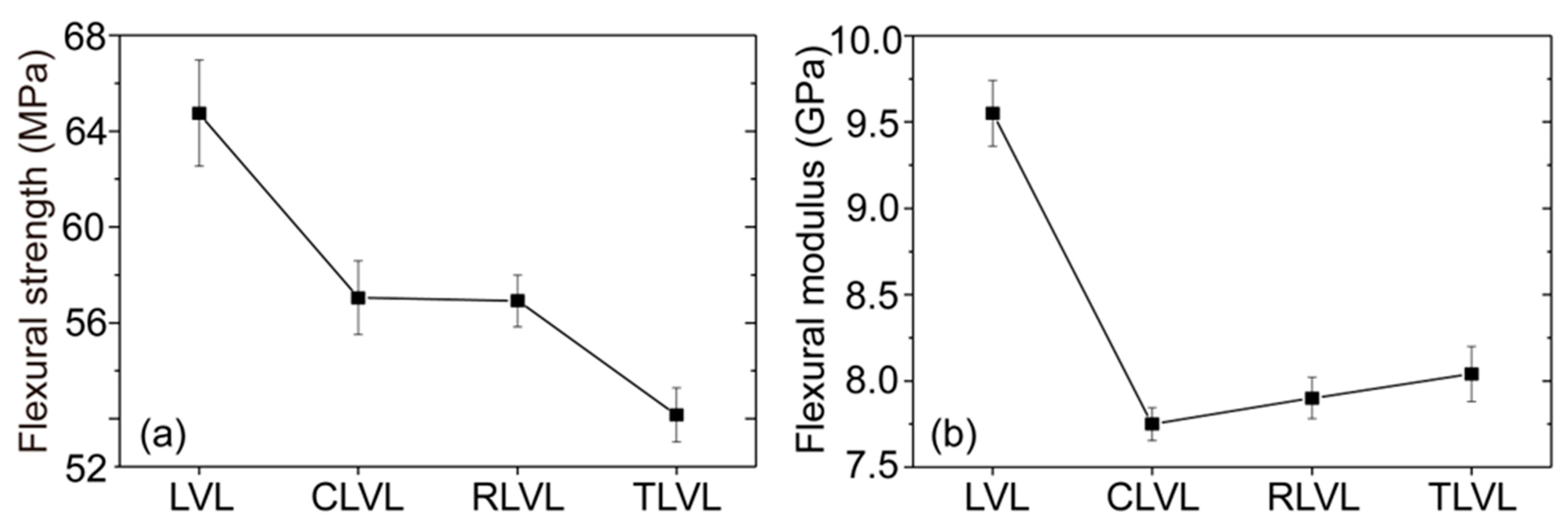

4.1. Bending Performance Analysis

4.2. Analysis of Long-Term Creep Performance

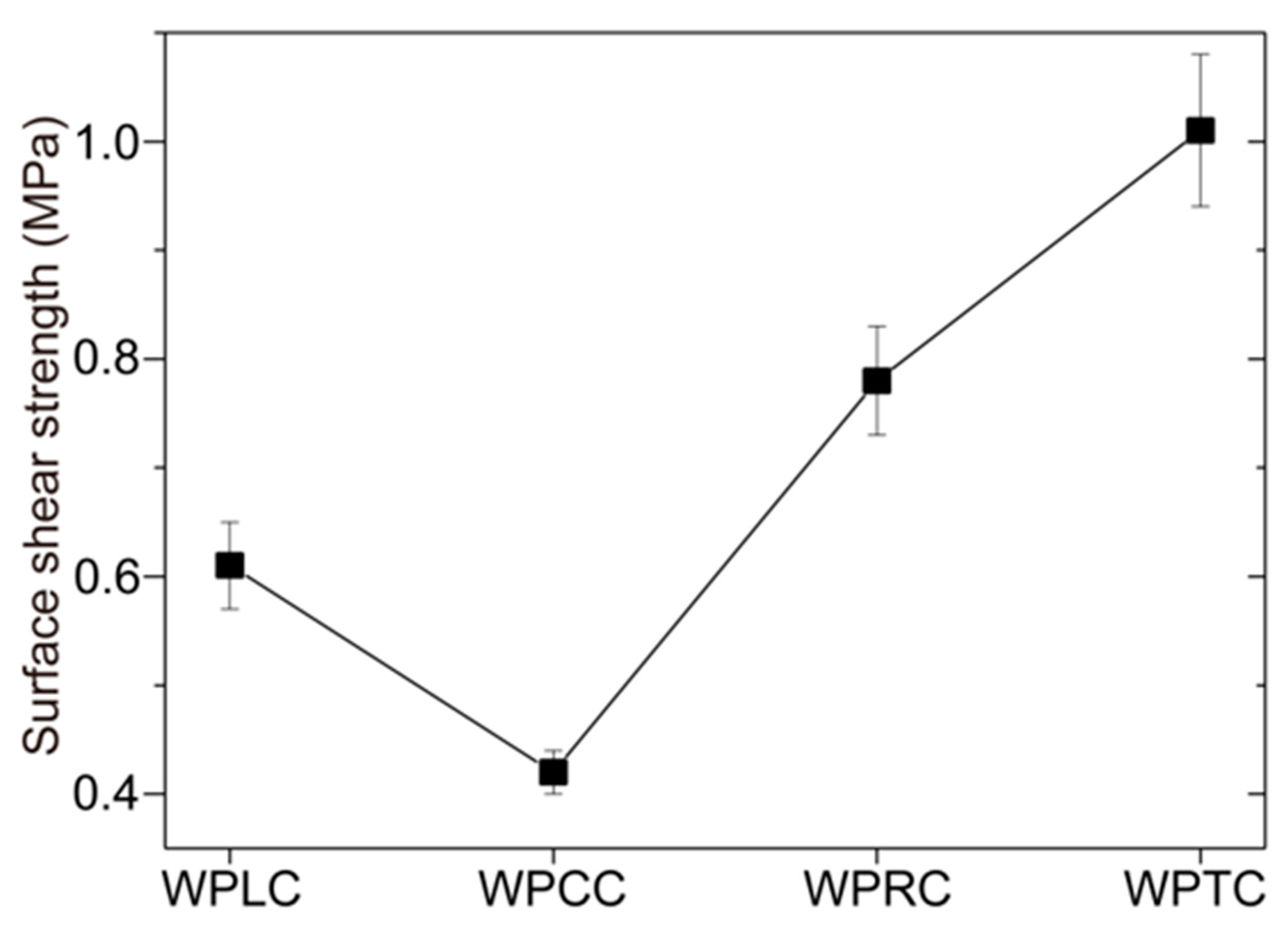

4.3. Analysis of Interface Bonding Performance

4.4. Analysis of Dimensional Stability

5. Conclusions

- (1)

- The bending properties of LVL decreased significantly due to the decrease in the volume of poplar LVL in the core layer and the damage to the structure during milling. The co-extrusion of milled LVL and WPVC could effectively compensate for the performance degradation caused by LVL milling. The bending performance of WPTC exceeded that of WPLC. At the same time, based on the effective reinforcement of mortise and tenon structure, the creep performance of milled LVL and WPVC after co-extrusion for 1500 h improved significantly.

- (2)

- The mortise and tenon structure could provide greater bonding stress to inhibit the separation of the two layers when they were pulled out. Among these, the trapezoidal mortise and tenon structure could form the mechanical interlock, which had the largest interface bonding force compared with the conical and rectangular mortise and tenon structures, and had more advantages in realizing the physical bonding between the outer shell layer and the inner core layer.

- (3)

- The coating of the outer shell layer WPVC on the inner shell layer LVL could slow down the water absorption by the LVL. The milling process reduced the volume of the LVL, which could reduce the water absorption capacity of the sample. Moreover, the mechanical interlocking formed by trapezoidal mortise and tenon structure could disperse the stress of the core layer LVL after water absorption and expansion, thus significantly improving the dimensional stability of the co-extrusion composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Acosta, A.; Aramburu, A.B.; Beltrame, R.; Gatto, D.A.; Amico, S.; Labidi, J.; Delucis, R.D.A. Wood Flour Modified by Poly(furfuryl alcohol) as a Filler in Rigid Polyurethane Foams: Effect on Water Uptake. Polymers 2022, 14, 5510. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.Z.; Srivastava, S.K.; Gupta, M. A state-of-the-art review on particulate wood polymer composites: Processing, properties and applications. Polym. Test. 2020, 89, 106721. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Fu, H.; Dun, M.; Chen, B.; Zhou, Z.; Wang, H.; Wang, W.; Xie, Y.; Wang, Q. Compression rheological behavior of ultrahighly filled wood flour-polyethylene composites. Compos. Part B Eng. 2021, 215, 108766. [Google Scholar] [CrossRef]

- Hao, J.; Wang, H.; Song, Y.; Wang, W. Simultaneously improving the toughness and stiffness of wood flour/polypropylene composites using elastomer A669/talcum blends. Polym. Compos. 2018, 40, 1335–1341. [Google Scholar] [CrossRef]

- Fu, H.; Dun, M.; Wang, H.; Wang, W.; Wang, Q. Rheological behavior, internal stress and structural changes of ultra-high-filled wood-flour/high-density polyethylene composite in shear flow field. J. Mater. Res. Technol. 2021, 14, 1191–1202. [Google Scholar] [CrossRef]

- Luo, S.; Lv, C.; Chang, L.; Guo, W. Enhancing Crystallization and Toughness of Wood Flour/Polypropylene Composites via Matrix Crystalline Modification: A Comparative Study of Two beta-Nucleating Agents. Polymers 2022, 14, 3561. [Google Scholar] [CrossRef]

- Miao, W.; Cheng, W.; Song, W. The influence of poly(maleic anhydride-co-vinyl acetate) on polylactide/wood flour/calcium carbonate composites. Polym. Test. 2023, 120, 107945. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Lopez-Anido, R.A.; Gardner, D.J.; Tajvidi, M.; Han, Y. Experimental investigation of the hygrothermal creep strain of wood–plastic composite lumber made from thermally modified wood. J. Thermoplast. Compos. Mater. 2019, 33, 1248–1268. [Google Scholar] [CrossRef]

- Feng, L.; Zhao, C. Analysis of Creep Properties and Factors Affecting Wood Plastic Composites. Polymers 2022, 14, 2814. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Lopez-Anido, R.A.; Gardner, D.J. Flexural Creep Behavior of High-Density Polyethylene Lumber and Wood Plastic Composite Lumber Made from Thermally Modified Wood. Polymers 2020, 12, 262. [Google Scholar] [CrossRef] [PubMed]

- Hao, X.; Zhou, H.; Mu, B.; Chen, L.; Guo, Q.; Yi, X.; Sun, L.; Wang, Q.; Ou, R. Effects of fiber geometry and orientation distribution on the anisotropy of mechanical properties, creep behavior, and thermal expansion of natural fiber/HDPE composites. Compos. Part B Eng. 2020, 185, 107778. [Google Scholar] [CrossRef]

- Hao, X.; Xu, J.; Zhou, H.; Tang, W.; Li, W.; Wang, Q.; Ou, R. Interfacial adhesion mechanisms of ultra-highly filled wood fiber/polyethylene composites using maleic anhydride grafted polyethylene as a compatibilizer. Mater. Des. 2021, 212, 110182. [Google Scholar] [CrossRef]

- Xu, J.; Hao, X.; Tang, W.; Zhou, H.; Chen, L.; Guo, C.; Wang, Q.; Ou, R. Mechanical properties, morphology, and creep resistance of ultra-highly filled bamboo fiber/polypropylene composites: Effects of filler content and melt flow index of polypropylene. Constr. Build. Mater. 2021, 310, 125289. [Google Scholar] [CrossRef]

- Zhou, H.; Li, W.; Hao, X.; Zong, G.; Yi, X.; Xu, J.; Ou, R.; Wang, Q. Recycling end-of-life WPC products into ultra-high-filled, high-performance wood fiber/polyethylene composites: A sustainable strategy for clean and cyclic processing in the WPC industry. J. Mater. Res. Technol. 2022, 18, 1–14. [Google Scholar] [CrossRef]

- Tang, W.; Xu, J.; Fan, Q.; Li, W.; Zhou, H.; Liu, T.; Guo, C.; Ou, R.; Hao, X.; Wang, Q. Rheological behavior and mechanical properties of ultra-high-filled wood fiber/polypropylene composites using waste wood sawdust and recycled polypropylene as raw materials. Constr. Build. Mater. 2022, 351, 128977. [Google Scholar] [CrossRef]

- Fu, H.; Dun, M.; Wang, H.; Wang, W.; Ou, R.; Wang, Y.; Liu, T.; Wang, Q. Creep response of wood flour-high-density polyethylene/laminated veneer lumber coextruded composites. Constr. Build. Mater. 2020, 237, 117499. [Google Scholar] [CrossRef]

- Hao, X.; Yi, X.; Sun, L.; Tu, D.; Wang, Q.; Ou, R. Mechanical properties, creep resistance, and dimensional stability of core/shell structured wood flour/polyethylene composites with highly filled core layer. Constr. Build. Mater. 2019, 226, 879–887. [Google Scholar] [CrossRef]

- Purba, C.Y.C.; Pot, G.; Viguier, J.; Ruelle, J.; Denaud, L. The influence of veneer thickness and knot proportion on the mechanical properties of laminated veneer lumber (LVL) made from secondary quality hardwood. Eur. J. Wood Wood Prod. 2019, 77, 393–404. [Google Scholar] [CrossRef]

- Sözen, E.; Kayahan, K.; Bardak, T.; Bardak, S. The effects of the moisture content of laminated veneer lumber on bending strength and deformation determination via two-dimensional digital image correlation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 5603–5615. [Google Scholar] [CrossRef]

- Fabbri, A.; Minghini, F.; Tullini, N. Monotonic and cyclic pull-pull tests on dowel-nut connector in laminated veneer lumber made of European beech wood. Constr. Build. Mater. 2022, 359, 129461. [Google Scholar] [CrossRef]

- Jucienė, M.; Dobilaitė, V.; Albrektas, D. An Investigation of the Impact of Water on Certain of the Mechanical and Physical Properties of Laminated Veneer Lumber (LVL) as Used in Construction. Appl. Sci. 2023, 13, 925. [Google Scholar] [CrossRef]

- Ahmed, J.; Mulla, M.Z.; Vohra, A. High-pressure treatment of water-filled co-extruded polylactide films: Effect on microstructure, barrier, thermal, and rheological properties. J. Food Sci. 2022, 87, 1754–1766. [Google Scholar] [CrossRef] [PubMed]

- Oreski, G.; Eder, G.; Voronko, Y.; Omazic, A.; Neumaier, L.; Mühleisen, W.; Ujvari, G.; Ebner, R.; Edler, M. Performance of PV modules using co-extruded backsheets based on polypropylene. Sol. Energy Mater. Sol. Cells 2021, 223, 110976. [Google Scholar] [CrossRef]

- Su, J.; Yang, M.; Zhang, X.; Fang, C.; Zheng, Y.; Pei, L.; Liu, M. Preparation and Properties of Waste Corrugated Paper Fiber/Polylactic Acid Co-Extruded Composite. Polymers 2022, 14, 4569. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Zhang, X.; Zhou, C. Mechanical, flammable, and thermal performances of co-extruded wood polymer composites with core–shell structure containing barite-filled shells. Wood Sci. Technol. 2020, 54, 1299–1318. [Google Scholar] [CrossRef]

- Rathner, R.; Leimhofer, C.; Roland, W.; Hammer, A.; Löw-Baselli, B.; Steinbichler, G.; Hild, S. Improving Layer Adhesion of Co-Extruded Polymer Sheets by Inducing Interfacial Flow Instabilities. Polymers 2022, 14, 587. [Google Scholar] [CrossRef]

- Tucci, F.; Vedernikov, A. Design Criteria for Pultruded Structural Elements. Encycl. Mater. Compos. 2021, 3, 51–68. [Google Scholar]

- Özkılıç, Y.O.; Gemi, L.; Madenci, E.; Aksoylu, C.; Kalkan, İ. Effect of the GFRP wrapping on the shear and bending Behavior of RC beams with GFRP encasement. Steel Compos. Struct. 2022, 45, 193–204. [Google Scholar]

| Samples | PVC (wt%) | Wood Flour (wt%) | Calcium–Zinc Stabilizer (wt%) | ACR (wt%) | PE Wax (wt%) | Stearic Acid (wt%) | Calcium Stearate (wt%) |

|---|---|---|---|---|---|---|---|

| WPVC | 100 | 40 | 6 | 4 | 0.6 | 0.4 | 0.3 |

| Heating Process | Temperature of Different Heating Stages (°C) | Feed Speed (kg h−1) | Extruded Velocity (rpm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | Handpiece | |||

| Twin-screw granulator | 150 | 160 | 170 | 180 | 180 | 170 | 170 | 170 | 3 | 55 |

| Heating Process | Temperature of Different Heating Stages (°C) | Feed Speed (kg h−1) | Extruded Velocity (rpm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | Mold | |||

| Co-extruder | 165 | 170 | 175 | 178 | 178 | 178 | 170 | 180 | 45 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zong, G.; Zhou, J.; Zhang, M.; Ma, Y.; Zhao, Y.; He, X.; Hao, J.; Wang, F. Effect of Mortise and Tenon Structure on the Properties of Wood Flour Polyvinyl Chloride-Laminated Veneer Lumber Co-Extruded Composites. Polymers 2023, 15, 2151. https://doi.org/10.3390/polym15092151

Zong G, Zhou J, Zhang M, Ma Y, Zhao Y, He X, Hao J, Wang F. Effect of Mortise and Tenon Structure on the Properties of Wood Flour Polyvinyl Chloride-Laminated Veneer Lumber Co-Extruded Composites. Polymers. 2023; 15(9):2151. https://doi.org/10.3390/polym15092151

Chicago/Turabian StyleZong, Guanggong, Jinjiang Zhou, Mengyan Zhang, Yanqiu Ma, Yang Zhao, Xiaoyan He, Jianxiu Hao, and Fangfang Wang. 2023. "Effect of Mortise and Tenon Structure on the Properties of Wood Flour Polyvinyl Chloride-Laminated Veneer Lumber Co-Extruded Composites" Polymers 15, no. 9: 2151. https://doi.org/10.3390/polym15092151

APA StyleZong, G., Zhou, J., Zhang, M., Ma, Y., Zhao, Y., He, X., Hao, J., & Wang, F. (2023). Effect of Mortise and Tenon Structure on the Properties of Wood Flour Polyvinyl Chloride-Laminated Veneer Lumber Co-Extruded Composites. Polymers, 15(9), 2151. https://doi.org/10.3390/polym15092151