Study of Prepared Lead-Free Polymer Nanocomposites for X- and Gamma-ray Shielding in Healthcare Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Polymer Nanocomposites

2.2. Characterization of Fabricated Polymer Nanocomposites

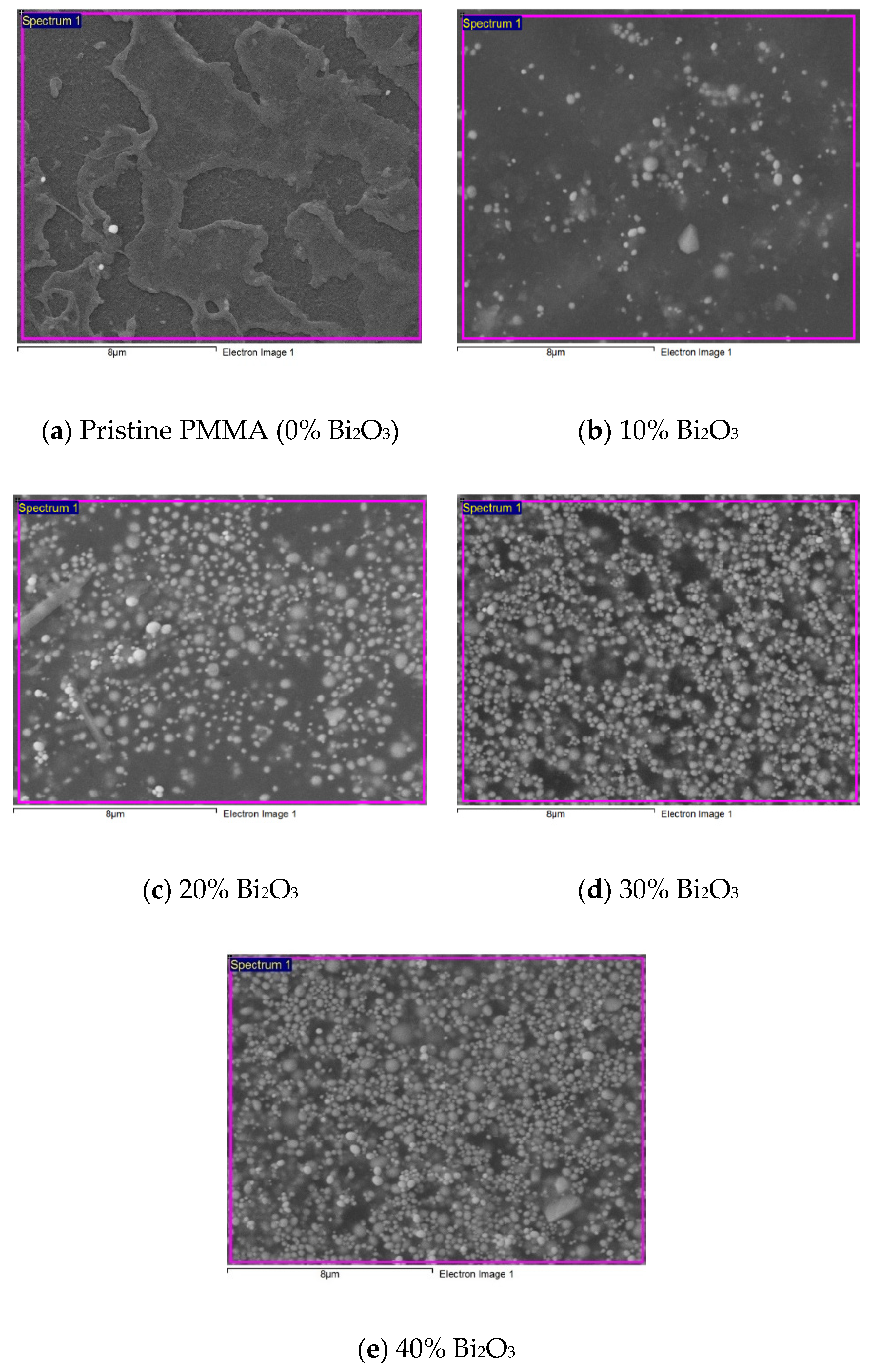

2.2.1. Scanning Electron Microscopy

2.2.2. X-ray Diffraction

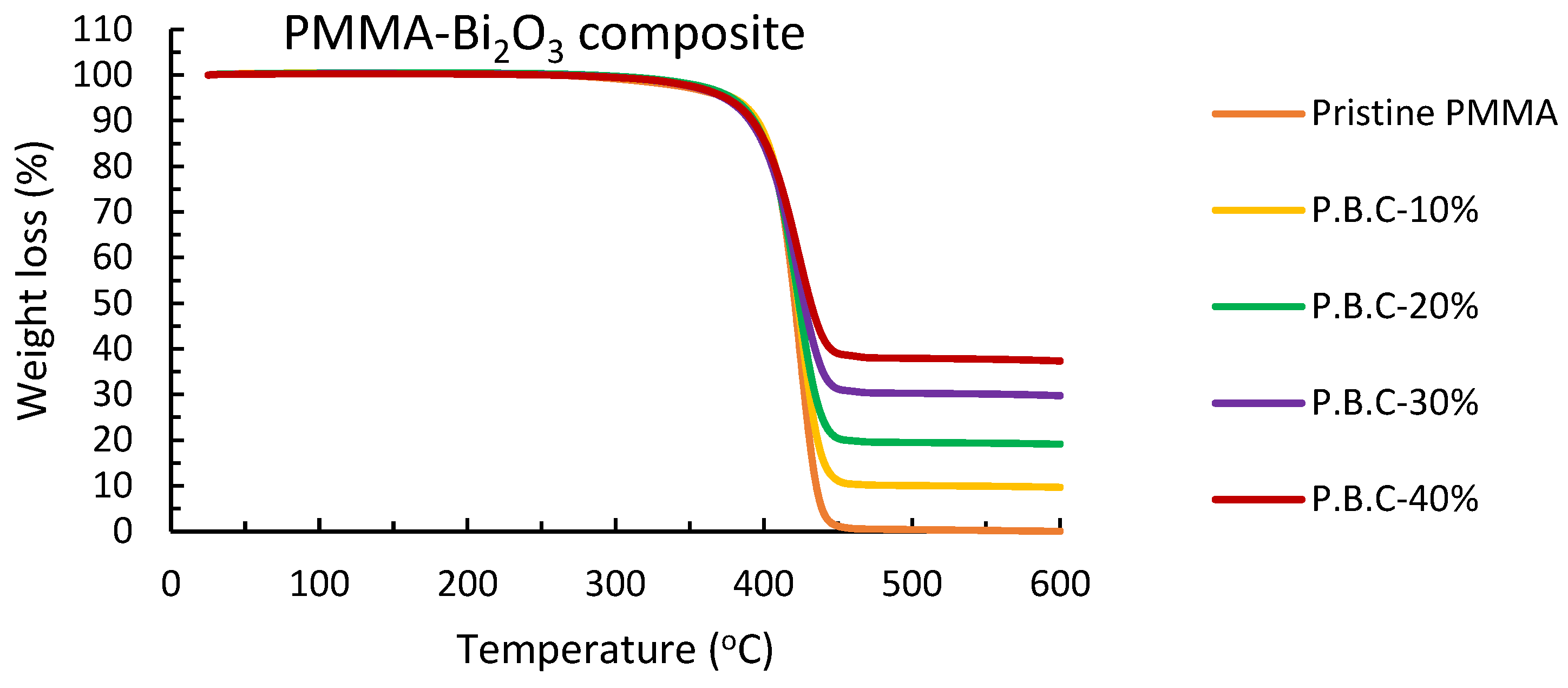

2.2.3. TGA Analysis

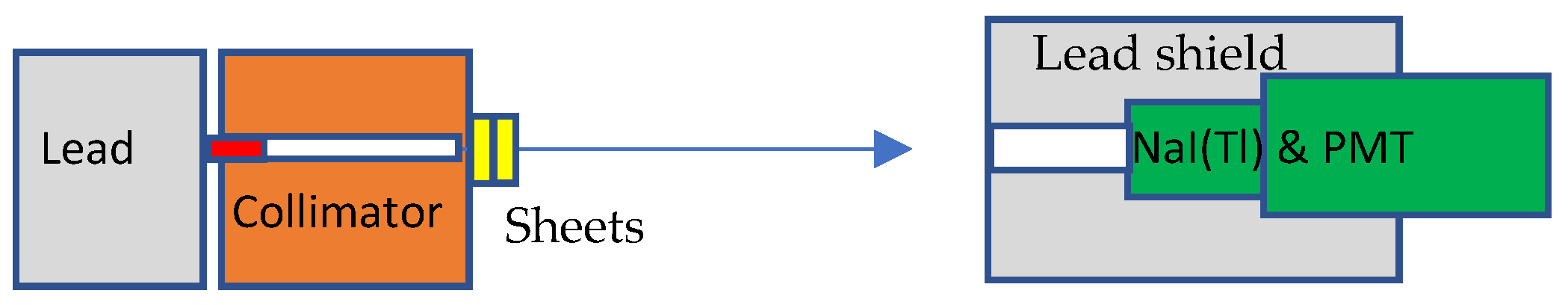

2.3. Gamma-Ray Shielding Properties of Fabricated Polymer Nanocomposites

2.3.1. Theoretical Overview

2.3.2. Experimental Determination of Gamma Rays Attenuation Coefficients

3. Results

3.1. Characterization

3.1.1. Scanning Electron Microscopy

3.1.2. X-ray Diffraction Analysis

3.1.3. TGA Analysis

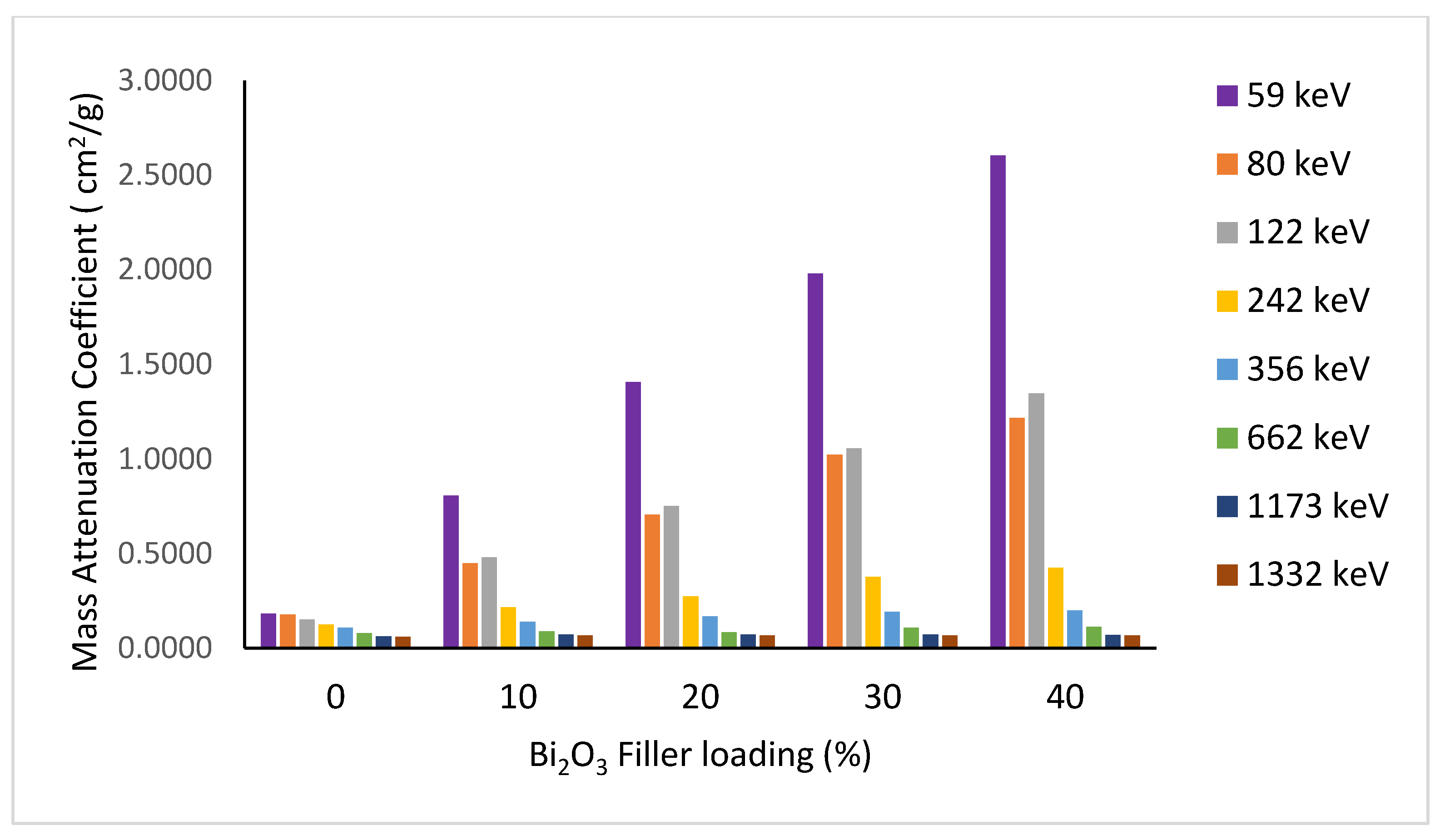

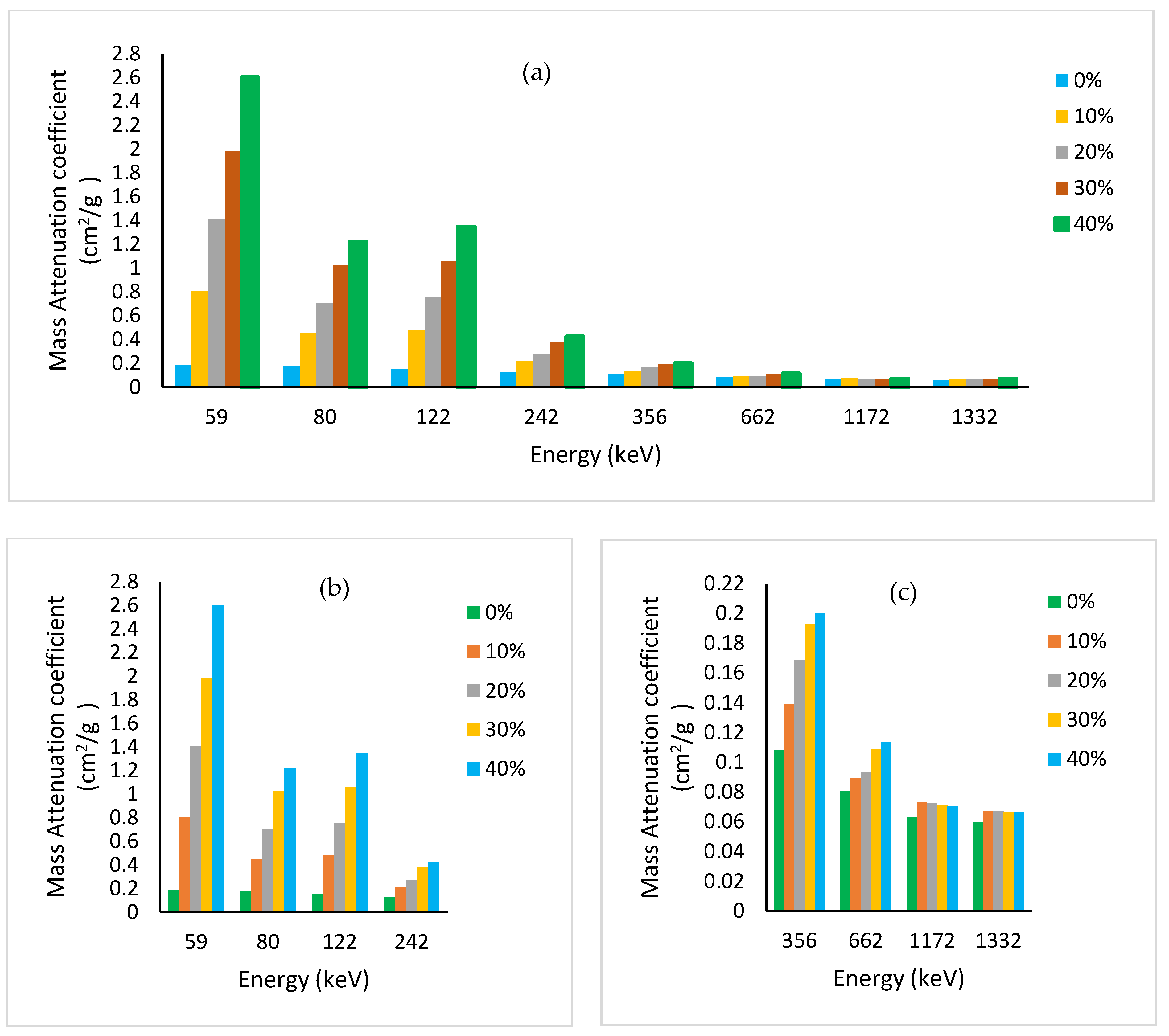

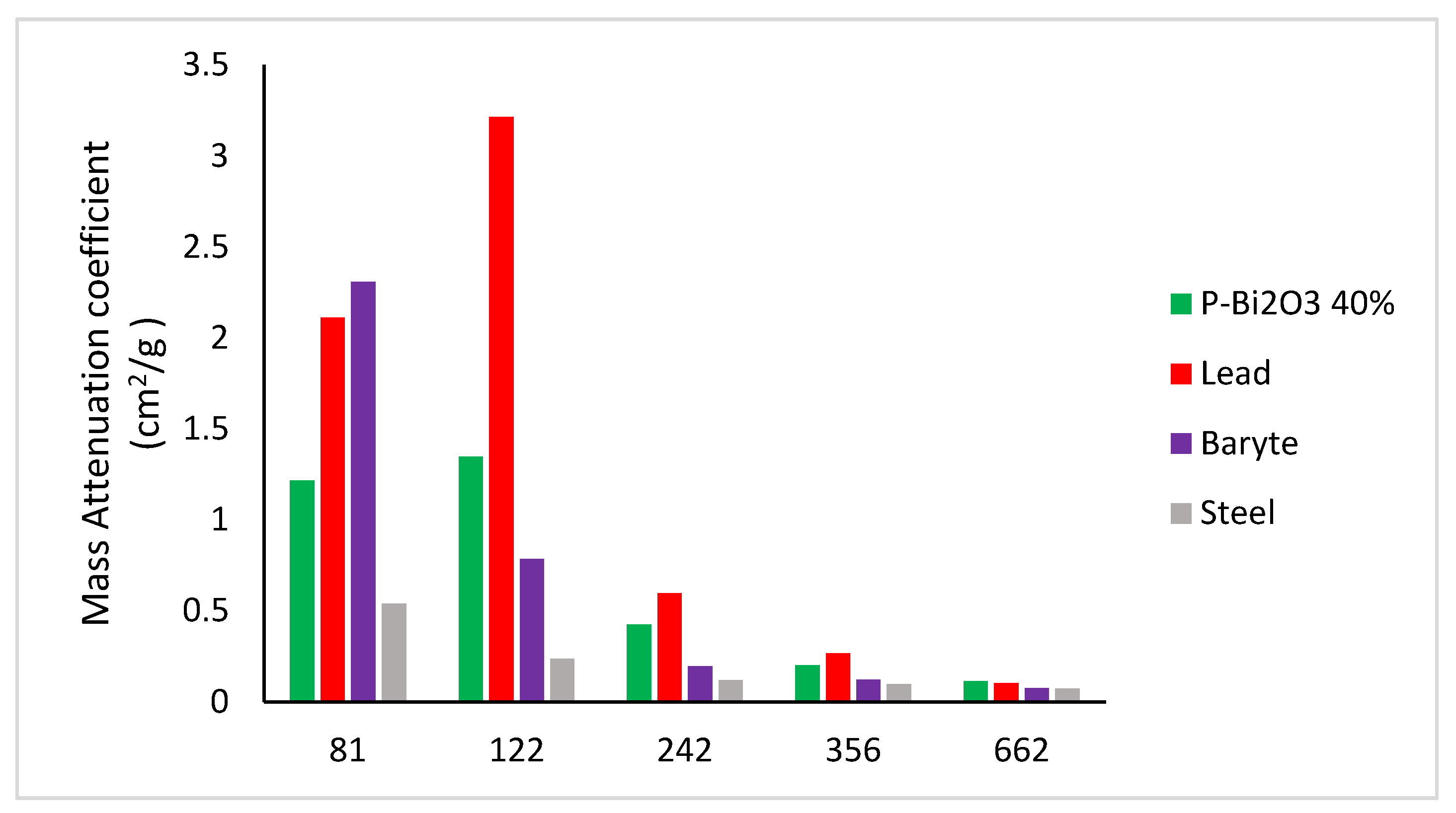

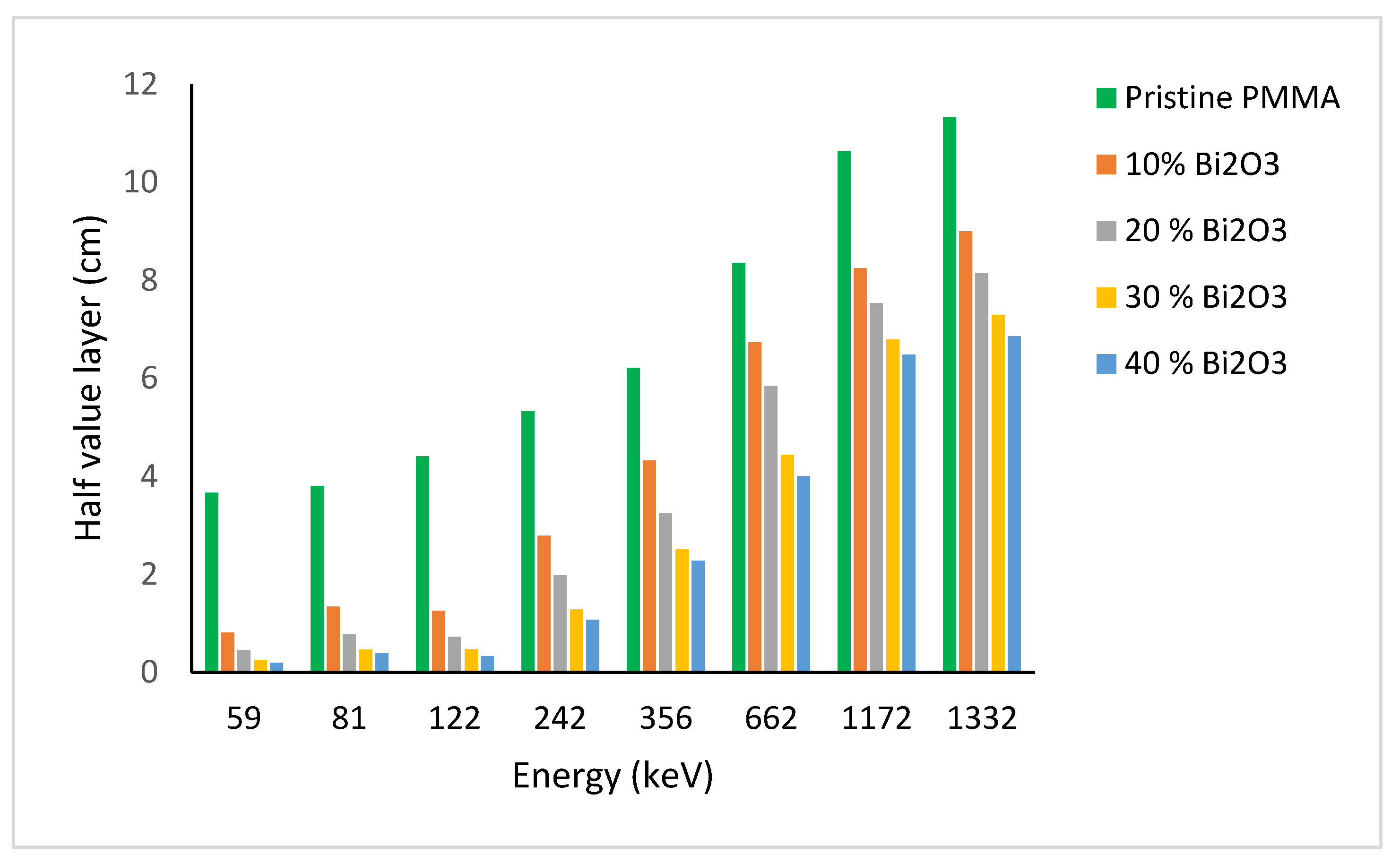

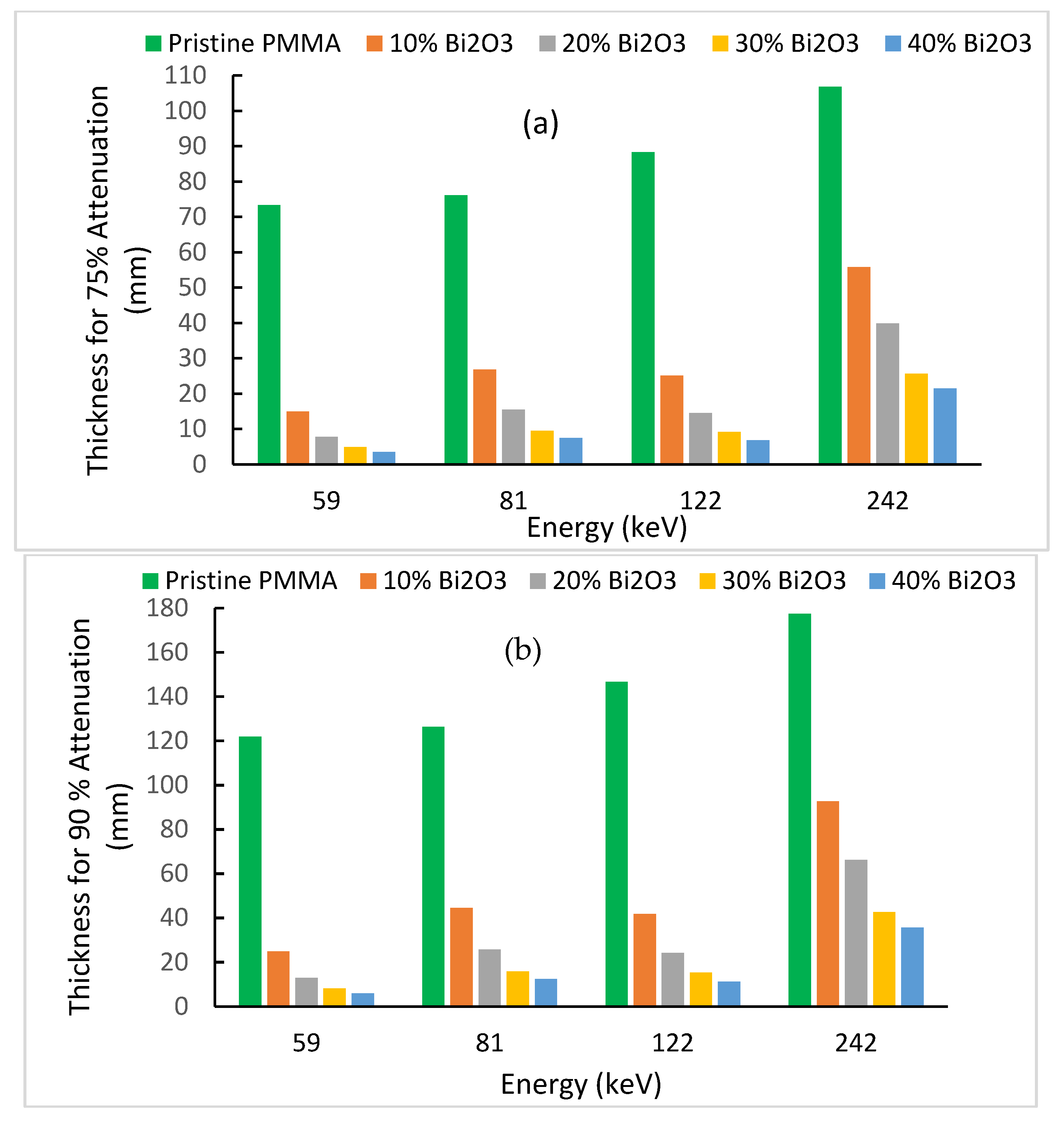

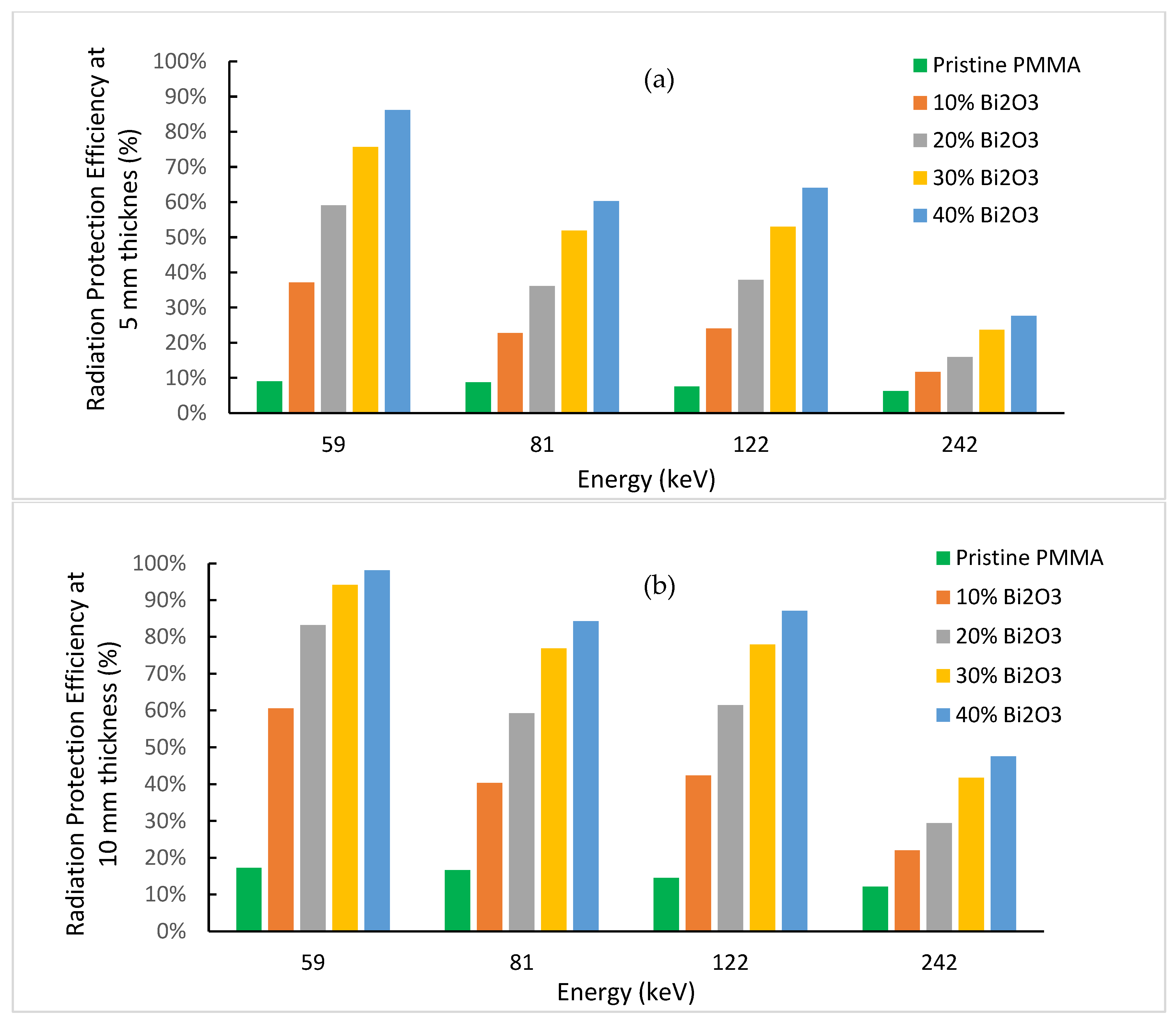

3.2. Gamma Ray Attenuation Coefficients Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mazrani, W.; McHugh, K.; Marsden, P.J. The Radiation Burden of Radiological Investigations. Arch. Dis. Child. 2007, 92, 1127–1131. [Google Scholar] [CrossRef] [PubMed]

- Klein, L.W.; Miller, D.L.; Balter, S.; Laskey, W.; Haines, D.; Norbash, A.; Mauro, M.A.; Goldstein, J.A. Occupational Health Hazards in the Interventional Laboratory: Time for a Safer Environment. Radiology 2009, 250, 538–544. [Google Scholar] [CrossRef]

- Johnson, T.E.; Cember, H. Introduction to Health Physics, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2017; ISBN 978-0-07-183527-5. [Google Scholar]

- National Council on Radiation Protection and Measurements (Ed.) Structural Shielding Design for Medical X-Ray Imaging Facilities; NCRP Report; National Council on Radiation Protection and Measurement: Bethesda, MD, USA, 2004; ISBN 978-0-929600-83-3. [Google Scholar]

- Charkiewicz, A.E.; Backstrand, J.R. Lead Toxicity and Pollution in Poland. Int. J. Environ. Res. Public Heal. 2020, 17, 4385. [Google Scholar] [CrossRef] [PubMed]

- Krzywy, I.; Krzywy, E.; Pastuszak-Gabinowska, M.; Brodkiewicz, A. Lead--is there something to be afraid of? Ann. Acad. Med. Stetin. 2010, 56, 118–128. [Google Scholar] [PubMed]

- Wani, A.L.; Ara, A.; Usmani, J.A. Lead Toxicity: A Review. Interdiscip. Toxicol. 2015, 8, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Dignam, T.; Kaufmann, R.B.; LeStourgeon, L.; Brown, M.J. Control of Lead Sources in the United States, 1970-2017: Public Health Progress and Current Challenges to Eliminating Lead Exposure. J. Public Health Manag. Pract. 2019, 25 (Suppl. S1), S13–S22. [Google Scholar] [CrossRef]

- Adlienė, D.; Gilys, L.; Griškonis, E. Development and Characterization of New Tungsten and Tantalum Containing Composites for Radiation Shielding in Medicine. Nucl. Instruments Methods Phys. Res. Sect. B: Beam Interact. Mater. Atoms 2020, 467, 21–26. [Google Scholar] [CrossRef]

- Mittal, V. Synthesis Techniques for Polymer Nanocomposites; Polymer Nano-, Micro- & Macrocomposites Series; Wiley-VCH: Weinheim, Germany, 2015. [Google Scholar]

- Sayyed, M.I.; Al-Ghamdi, H.; Almuqrin, A.H.; Yasmin, S.; Elsafi, M. A Study on the Gamma Radiation Protection Effectiveness of Nano/Micro-MgO-Reinforced Novel Silicon Rubber for Medical Applications. Polymers 2022, 14, 2867. [Google Scholar] [CrossRef]

- Li, Q.; Wei, Q.; Zheng, W.; Zheng, Y.; Okosi, N.; Wang, Z.; Su, M. Enhanced Radiation Shielding with Conformal Light-Weight Nanoparticle–Polymer Composite. ACS Appl. Mater. Interfaces 2018, 10, 35510–35515. [Google Scholar] [CrossRef]

- AbuAlRoos, N.J.; Baharul Amin, N.A.; Zainon, R. Conventional and New Lead-Free Radiation Shielding Materials for Radiation Protection in Nuclear Medicine: A Review. Radiat. Phys. Chem. 2019, 165, 108439. [Google Scholar] [CrossRef]

- Wasel, O.; Freeman, J. Comparative Assessment of Tungsten Toxicity in the Absence or Presence of Other Metals. Toxics 2018, 6, 66. [Google Scholar] [CrossRef]

- El-Khatib, A.M.; Abbas, M.I.; Elzaher, M.A.; Badawi, M.S.; Alabsy, M.T.; Alharshan, G.A.; Aloraini, D.A. Gamma Attenuation Coefficients of Nano Cadmium Oxide/High Density Polyethylene Composites. Sci. Rep. 2019, 9, 16012. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Wang, Y.; Yang, Z.; Li, M.; Zhang, Z. Effect of Particle Size on Gamma Radiation Shielding Property of Gadolinium Oxide Dispersed Epoxy Resin Matrix Composite. Mater. Res. Express 2017, 4, 035035. [Google Scholar] [CrossRef]

- Noor Azman, N.Z.; Siddiqui, S.A.; Hart, R.; Low, I.M. Effect of Particle Size, Filler Loadings and X-ray Tube Voltage on the Transmitted X-ray Transmission in Tungsten Oxide—Epoxy Composites. Appl. Radiat. Isot. 2013, 71, 62–67. [Google Scholar] [CrossRef] [PubMed]

- Abu Saleem, R.; Abdelal, N.; Alsabbagh, A.; Al-Jarrah, M.; Al-Jawarneh, F. Radiation Shielding of Fiber Reinforced Polymer Composites Incorporating Lead Nanoparticles—An Empirical Approach. Polymers 2021, 13, 3699. [Google Scholar] [CrossRef] [PubMed]

- Kucuk, N.; Cakir, M.; Isitman, N.A. Mass Attenuation Coefficients, Effective Atomic Numbers and Effective Electron Densities for Some Polymers. Radiat. Prot. Dosim. 2013, 153, 127–134. [Google Scholar] [CrossRef]

- Pituru, S.M.; Greabu, M.; Totan, A.; Imre, M.; Pantea, M.; Spinu, T.; Tancu, A.M.C.; Popoviciu, N.O.; Stanescu, I.-I.; Ionescu, E. A Review on the Biocompatibility of PMMA-Based Dental Materials for Interim Prosthetic Restorations with a Glimpse into Their Modern Manufacturing Techniques. Materials 2020, 13, 2894. [Google Scholar] [CrossRef]

- Alshahri, S.; Alsuhybani, M.; Alosime, E.; Almurayshid, M.; Alrwais, A.; Alotaibi, S. LDPE/Bismuth Oxide Nanocomposite: Preparation, Characterization and Application in X-Ray Shielding. Polymers 2021, 13, 3081. [Google Scholar] [CrossRef]

- Ambika, M.R.; Nagaiah, N.; Suman, S.K. Role of Bismuth Oxide as a Reinforcer on Gamma Shielding Ability of Unsaturated Polyester Based Polymer Composites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Ambika, M.R.; Nagaiah, N.; Harish, V.; Lokanath, N.K.; Sridhar, M.A.; Renukappa, N.M.; Suman, S.K. Preparation and Characterisation of Isophthalic-Bi2O3 Polymer Composite Gamma Radiation Shields. Radiat. Phys. Chem. 2017, 130, 351–358. [Google Scholar] [CrossRef]

- Mehrara, R.; Malekie, S.; Kotahi, S.M.S.; Kashian, S. Introducing a Novel Low Energy Gamma Ray Shield Utilizing Polycarbonate Bismuth Oxide Composite. Sci. Rep. 2021, 11, 10614. [Google Scholar] [CrossRef]

- Cao, D.; Yang, G.; Bourham, M.; Moneghan, D. Gamma Radiation Shielding Properties of Poly (Methyl Methacrylate)/Bi2O3 Composites. Nucl. Eng. Technol. 2020, 52, 2613–2619. [Google Scholar] [CrossRef]

- Abbas, M.I.; El-Khatib, A.M.; Dib, M.F.; Mustafa, H.E.; Sayyed, M.I.; Elsafi, M. The Influence of Bi2O3 Nanoparticle Content on the γ-Ray Interaction Parameters of Silicon Rubber. Polymers 2022, 14, 1048. [Google Scholar] [CrossRef]

- Pavlenko, V.I.; Cherkashina, N.I.; Yastrebinsky, R.N. Synthesis and Radiation Shielding Properties of Polyimide/Bi2O3 Composites. Heliyon 2019, 5, e01703. [Google Scholar] [CrossRef] [PubMed]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric Composite Materials for Radiation Shielding: A Review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef]

- Berger, M.J.; Hubbell, J.H.; Seltzer, S.M.; Chang, J.; Coursey, J.S.; Sukumar, R.; Zucker, D.S.; Olsen, K. XCOM: Photon Cross Sections Database, NIST Standard Reference Database (XGAM). 2010. Available online: https://www.nist.gov/pml/xcom-photon-cross-sections-database (accessed on 15 January 2023).

- Tokar, E.J.; Boyd, W.A.; Freedman, J.H.; Waalkes, M.P. Toxic Effects of Metals. In Casarett and Doull’s Toxicology: The Basic Science of Poisons, 8th ed.; Klaassen, C.D., Ed.; McGraw Hill: New York NY, USA, 2013; Available online: https://accesspharmacy.mhmedical.com/content.aspx?bookid=958§ionid=53483748 (accessed on 20 April 2023).

- Shahzad, K.; Kausar, A.; Manzoor, S.; Rakha, S.A.; Uzair, A.; Sajid, M.; Arif, A.; Khan, A.F.; Diallo, A.; Ahmad, I. Views on Radiation Shielding Efficiency of Polymeric Composites/Nanocomposites and Multi-Layered Materials: Current State and Advancements. Radiation 2022, 3, 1–20. [Google Scholar] [CrossRef]

- Hoogeveen, R.C.; Hazenoot, B.; Sanderink, G.C.H.; Berkhout, W.E.R. The Value of Thyroid Shielding in Intraoral Radiography. Dentomaxillofacial Radiol. 2016, 45, 20150407. [Google Scholar] [CrossRef]

- Gregory Von, W., II; Rajan, T.; Lysle M., S.; Mathias C, C.; Robert, B. An Overview of Basic Radiation Effects on Polymers and Glasses. Available online: https://www.osti.gov/servlets/purl/1671997 (accessed on 20 April 2023).

- Naikwadi, A.T.; Sharma, B.K.; Bhatt, K.D.; Mahanwar, P.A. Gamma Radiation Processed Polymeric Materials for High Performance Applications: A Review. Front. Chem. 2022, 10, 837111. [Google Scholar] [CrossRef] [PubMed]

- Knoll, G.F. Radiation Detection and Measurement, 4th ed.; John Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Abasi, C.Y.; Wankasi, D.; Dikio, E.D. Adsorption Study of Lead (II) Ions on Poly (Methyl Methacrylate) Waste Material. Asian J. Chem. 2018, 30, 859–867. [Google Scholar] [CrossRef]

- Hou, J.; Yang, C.; Wang, Z.; Zhou, W.; Jiao, S.; Zhu, H. In Situ Synthesis of α–β Phase Heterojunction on Bi2O3 Nanowires with Exceptional Visible-Light Photocatalytic Performance. Appl. Catal. B: Environ. 2013, 142, 504–511. [Google Scholar] [CrossRef]

- Dias, L.P.; Correia, F.C.; Ribeiro, J.M.; Tavares, C.J. Photocatalytic Bi2O3/TiO2:N Thin Films with Enhanced Surface Area and Visible Light Activity. Coatings 2020, 10, 445. [Google Scholar] [CrossRef]

- Lunca Popa, P.; Sønderby, S.; Kerdsongpanya, S.; Lu, J.; Arwin, H.; Eklund, P. Structural, Morphological, and Optical Properties of Bi2O3 Thin Films Grown by Reactive Sputtering. Thin Solid Films 2017, 624, 41–48. [Google Scholar] [CrossRef]

- ISO 11358-1:2022; Plastics—Thermogravimetry (TG) of polymers—Part 1: General Principles. ISO: Geneva, Switzerland, 2022.

- Manjunatha, H.C. A Study of Gamma Attenuation Parameters in Poly Methyl Methacrylate and Kapton. Radiat. Phys. Chem. 2017, 137, 254–259. [Google Scholar] [CrossRef]

- Tekin, H.O.; Singh, V.P.; Manici, T. Effects of Micro-Sized and Nano-Sized WO 3 on Mass Attenuation Coefficients of Concrete by Using MCNPX Code. Appl. Radiat. Isotopes 2017, 121, 122–125. [Google Scholar] [CrossRef]

- ISO 4037-1:2019; Radiological Protection—X and Gamma Reference Radiation for Calibrating Dosemeters and Doserate Meters and for Determining Their Response as a Function of Photon Energy—Part 1: Radiation Characteristics and Production Methods. ISO: Geneva, Switzerland, 2019.

| Sample | Crystallite Size D (nm) |

|---|---|

| PMMA + 10% Bi2O3 | 24(±2) |

| PMMA + 20% Bi2O3 | 27(±2) |

| PMMA + 30% Bi2O3 | 25(±2) |

| PMMA + 40% Bi2O3 | 25(±3) |

| Average | 26(±2) |

| Sample | Bi2O3 Loading (%) | Extrapolated Onset Temperature (°C) | High Peak Temperature (°C) | Weight (%) at 600 °C |

|---|---|---|---|---|

| Pure PMMA | 0 | 405.7 | 422.9 | 0.03 |

| P.B.C-10% | 10 | 403.5 | 423.0 | 9.68 |

| P.B.C-20% | 20 | 399.0 | 423.1 | 19.12 |

| P.B.C-30% | 30 | 395.4 | 423.2 | 29.75 |

| P.B.C-40% | 40 | 393.1 | 423.1 | 37.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsaab, A.H.; Zeghib, S. Study of Prepared Lead-Free Polymer Nanocomposites for X- and Gamma-ray Shielding in Healthcare Applications. Polymers 2023, 15, 2142. https://doi.org/10.3390/polym15092142

Alsaab AH, Zeghib S. Study of Prepared Lead-Free Polymer Nanocomposites for X- and Gamma-ray Shielding in Healthcare Applications. Polymers. 2023; 15(9):2142. https://doi.org/10.3390/polym15092142

Chicago/Turabian StyleAlsaab, Abdulrhman Hasan, and Sadek Zeghib. 2023. "Study of Prepared Lead-Free Polymer Nanocomposites for X- and Gamma-ray Shielding in Healthcare Applications" Polymers 15, no. 9: 2142. https://doi.org/10.3390/polym15092142

APA StyleAlsaab, A. H., & Zeghib, S. (2023). Study of Prepared Lead-Free Polymer Nanocomposites for X- and Gamma-ray Shielding in Healthcare Applications. Polymers, 15(9), 2142. https://doi.org/10.3390/polym15092142