Hybrid Steel/NSM/GFRP System versus GFRP Wrapping for Upgrading RC Wall-like Columns

Abstract

1. Introduction

2. Experimental Study

2.1. Test Specimens

| Specimen ID | Upgrading Scheme | No. of Specimens |

|---|---|---|

| C1, C2 | Control (unstrengthened) specimen (see Figure 1) | 2 |

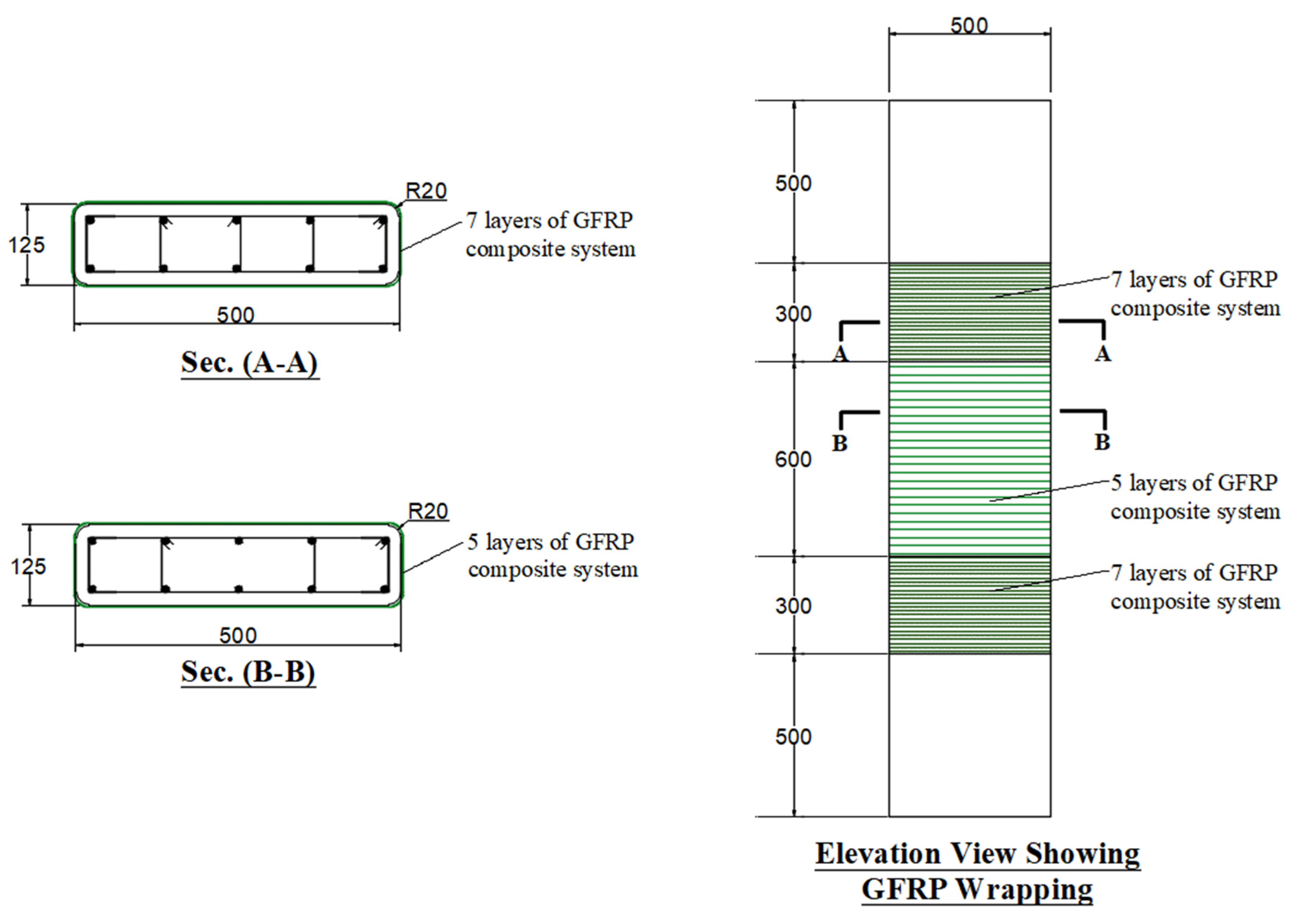

| S1 | GFRP wrapping (see Figure 2) | 1 |

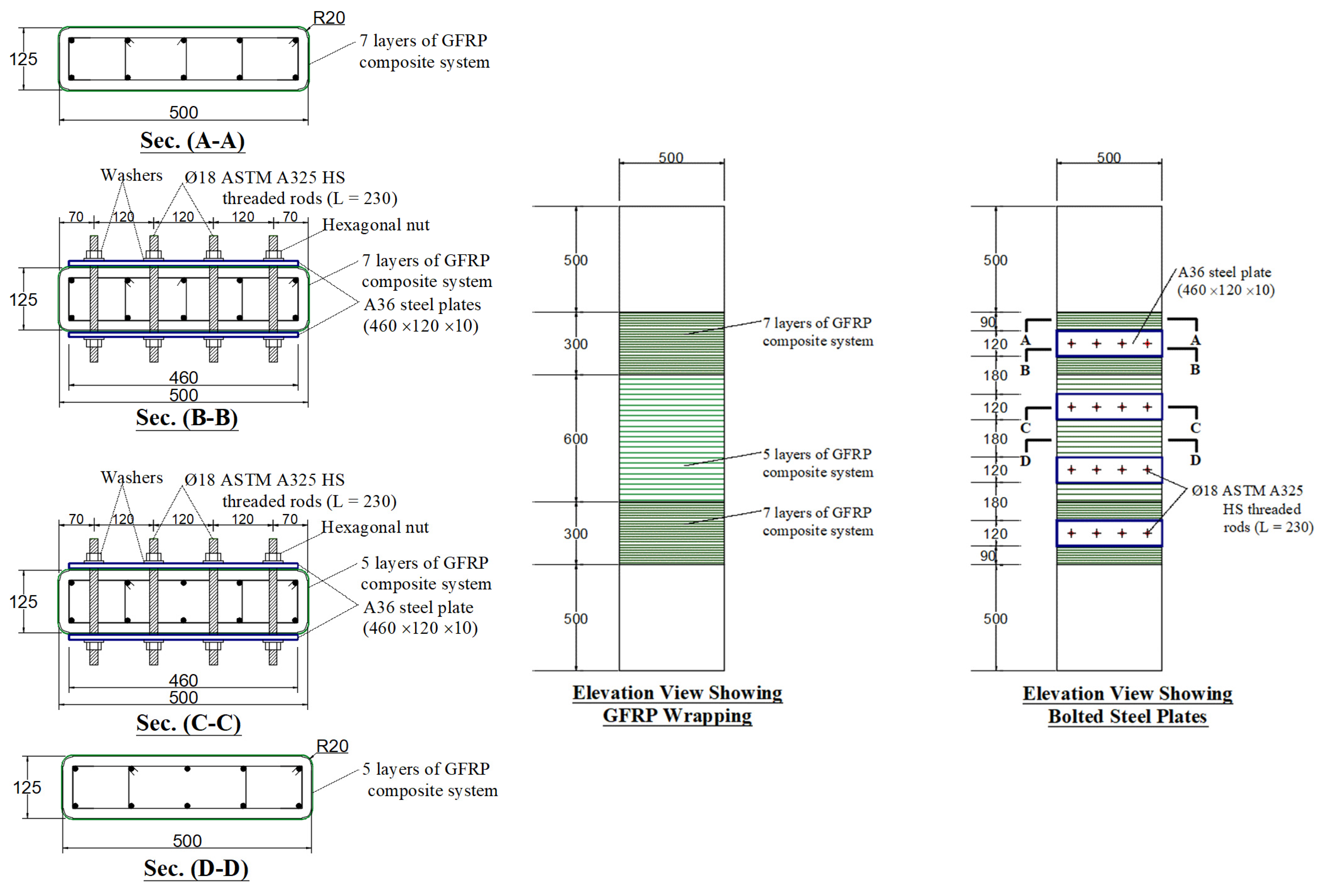

| S2 | GFRP wrapping + bolted steel plates (see Figure 3) | 1 |

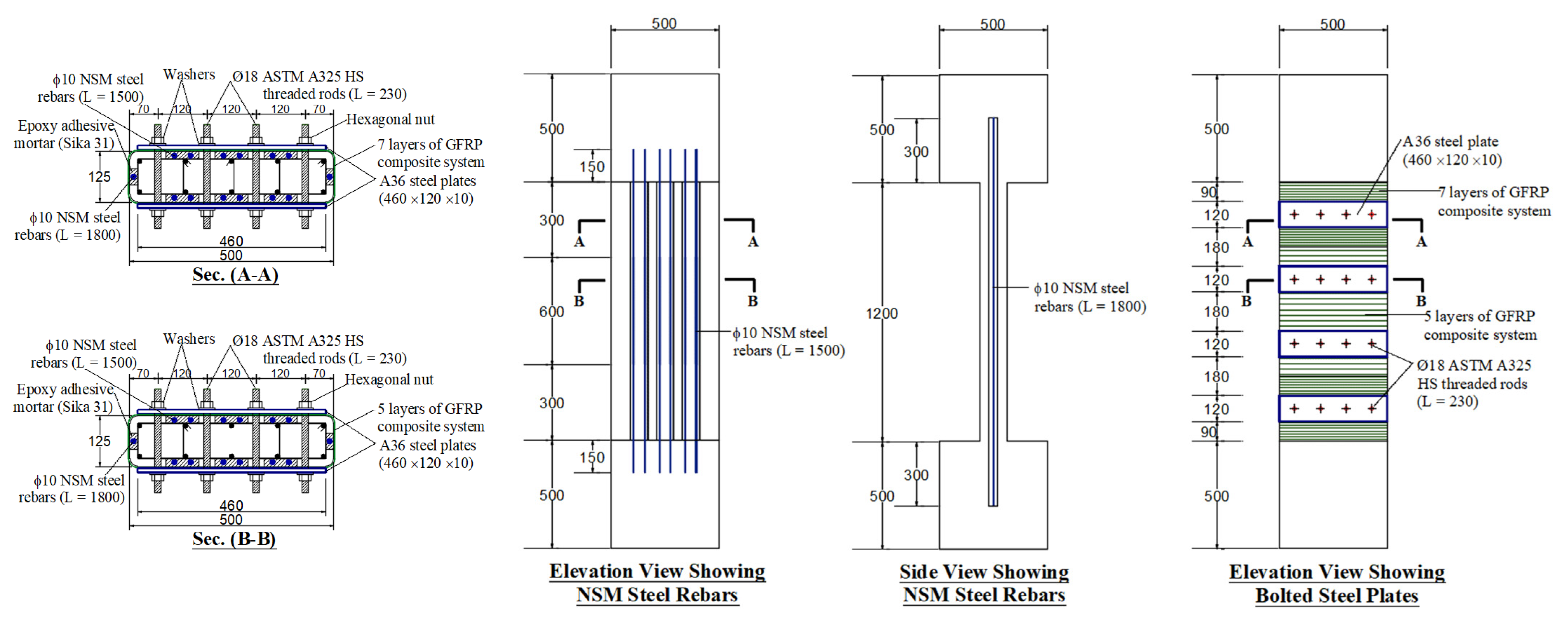

| S3 | GFRP wrapping + bolted steel plates + connected NSM steel bars (see Figure 4) | 1 |

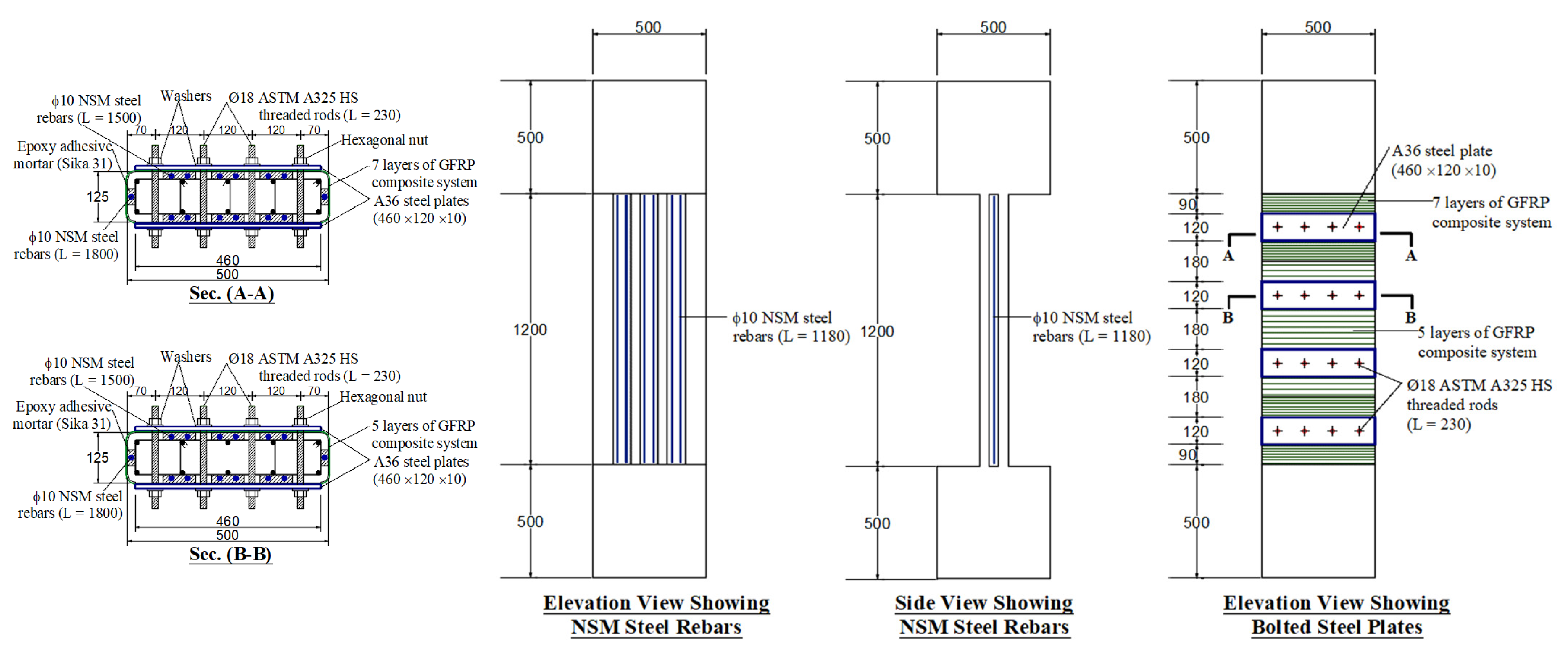

| S4 | GFRP wrapping + bolted steel plates + disconnected NSM steel bars (see Figure 5) | 1 |

| Total No. of columns = | 6 |

2.2. Material Properties

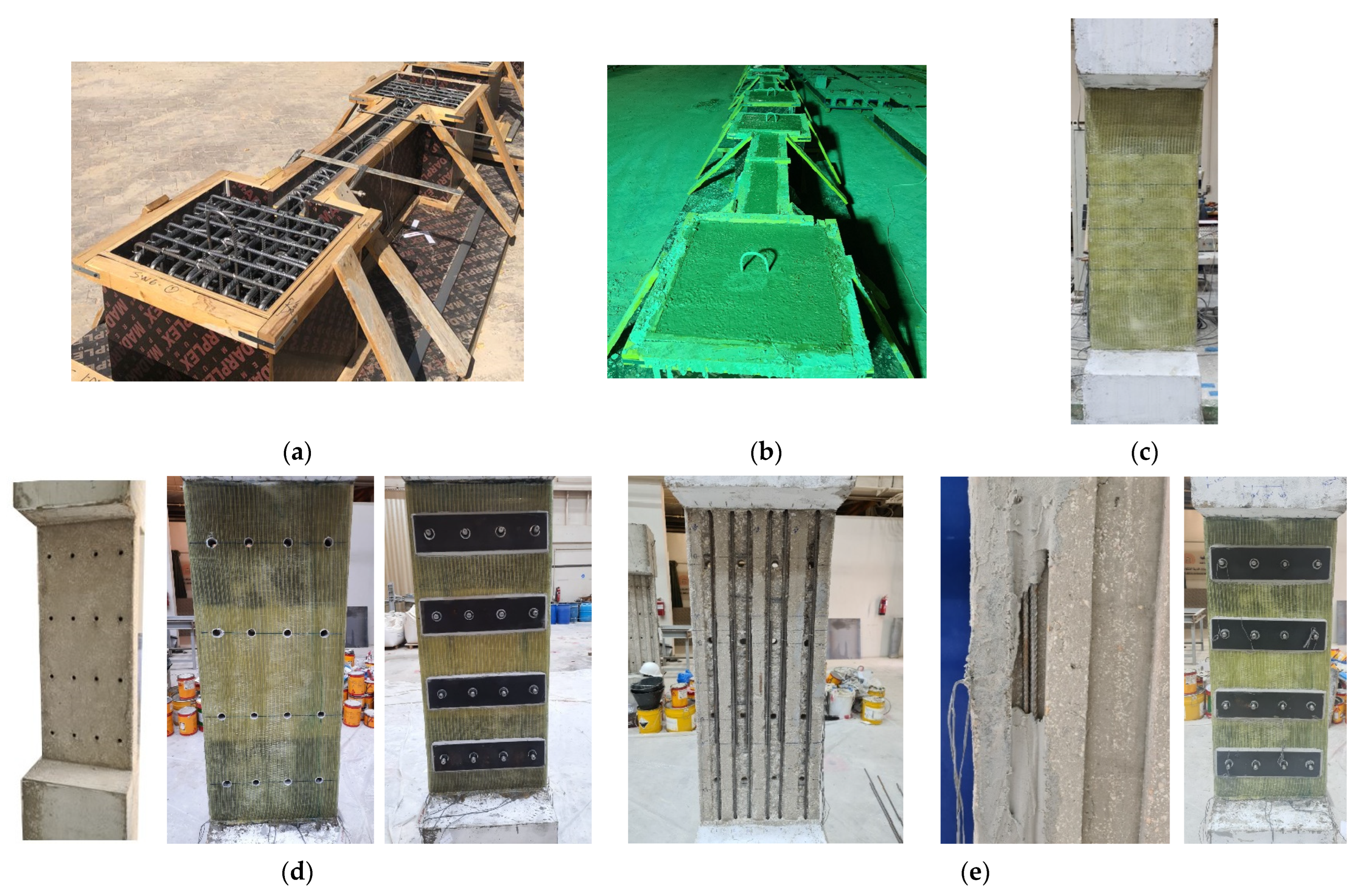

2.3. Preparation of Column Specimens

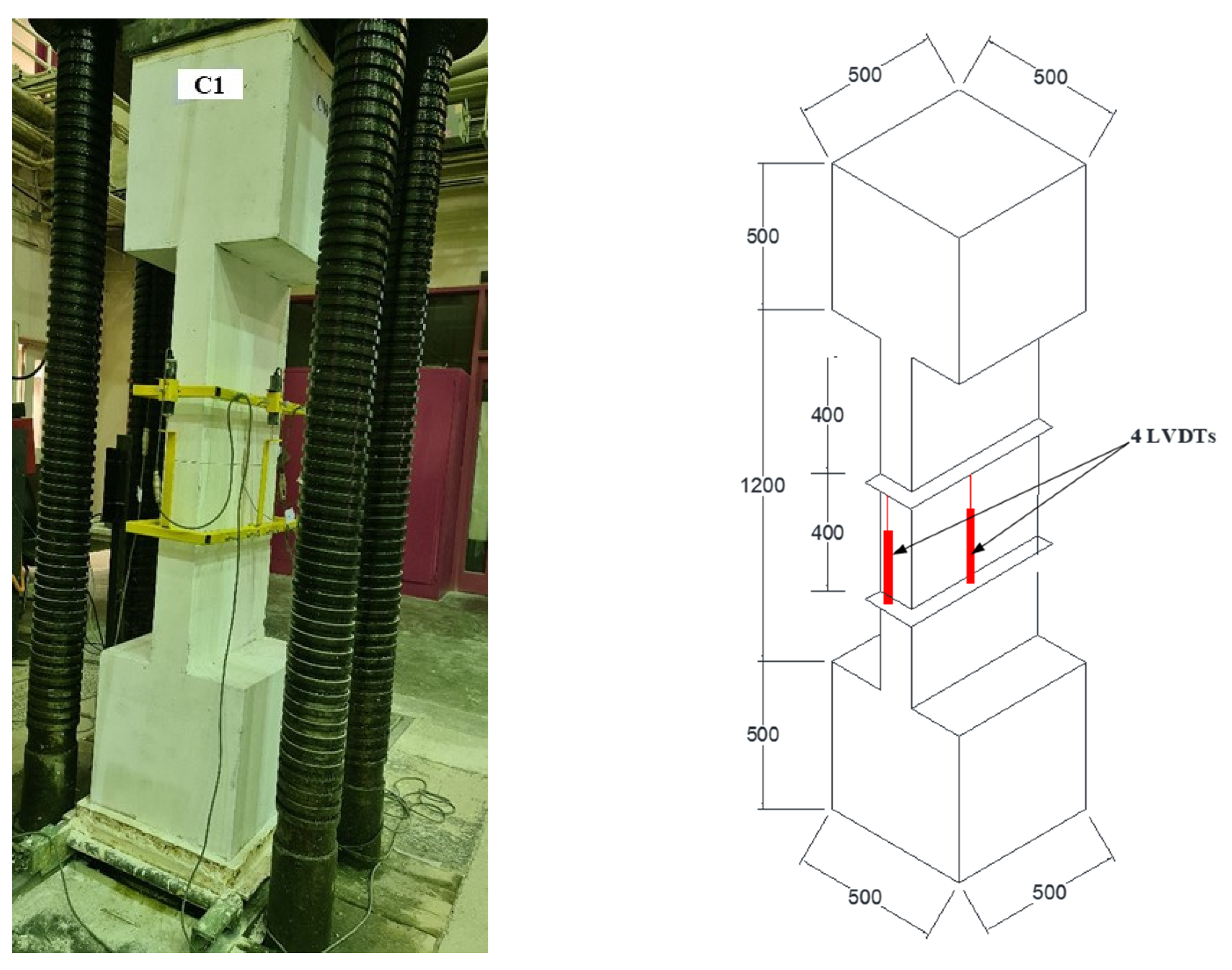

2.4. Sensor Layout and Test Setup

3. Discussion of Test Results

3.1. Control Specimens

3.2. Strengthened Specimens

3.2.1. Column S1

3.2.2. Column S2

3.2.3. Column S3

3.2.4. Column S4

4. Analytical Study

4.1. Approach 1

4.2. Approach 2

5. FE Analysis

5.1. FE Mesh

5.2. Constitutive Models

5.3. Modeling of Supports and Loading Protocol

6. Discussion of Numerical Results

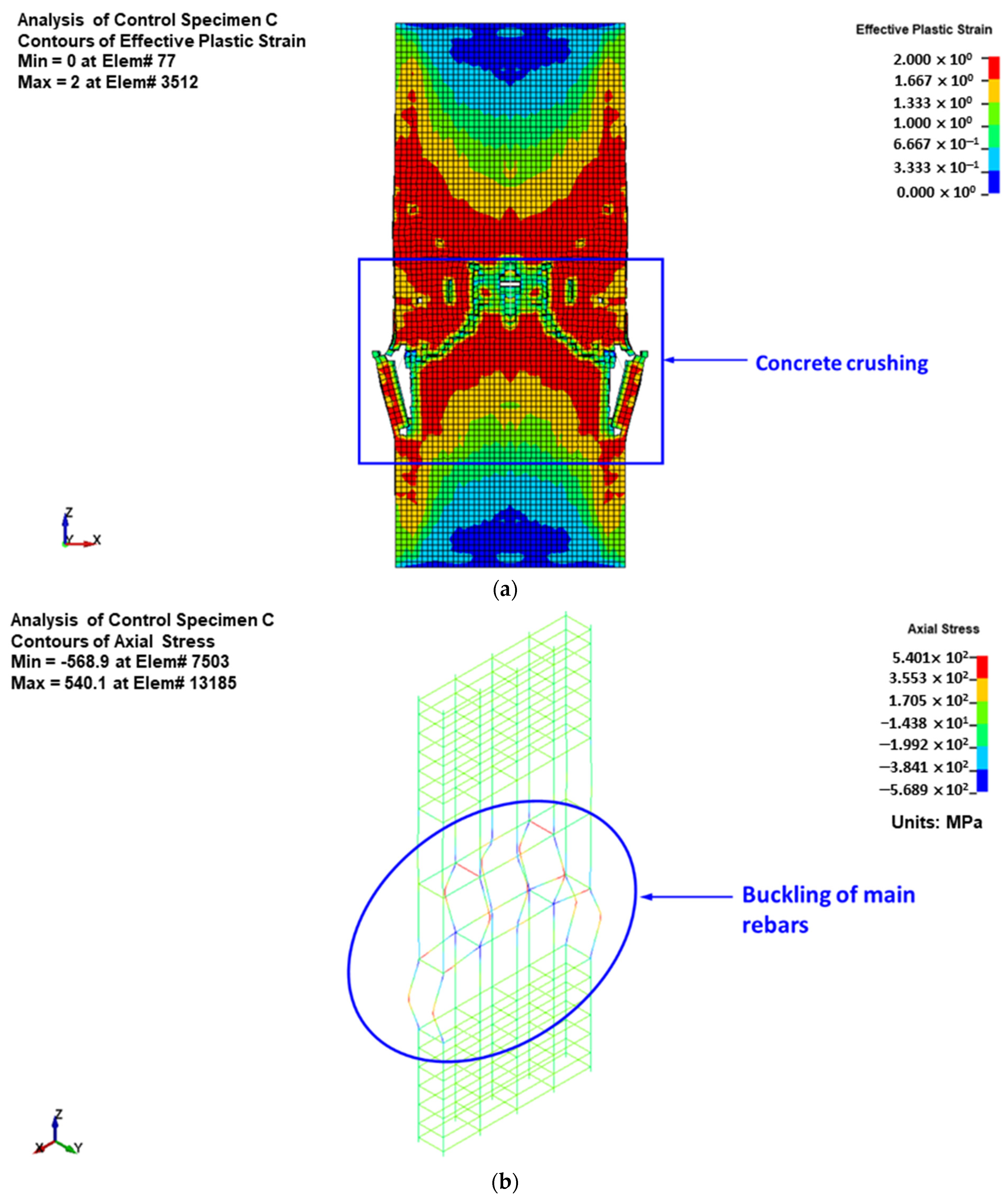

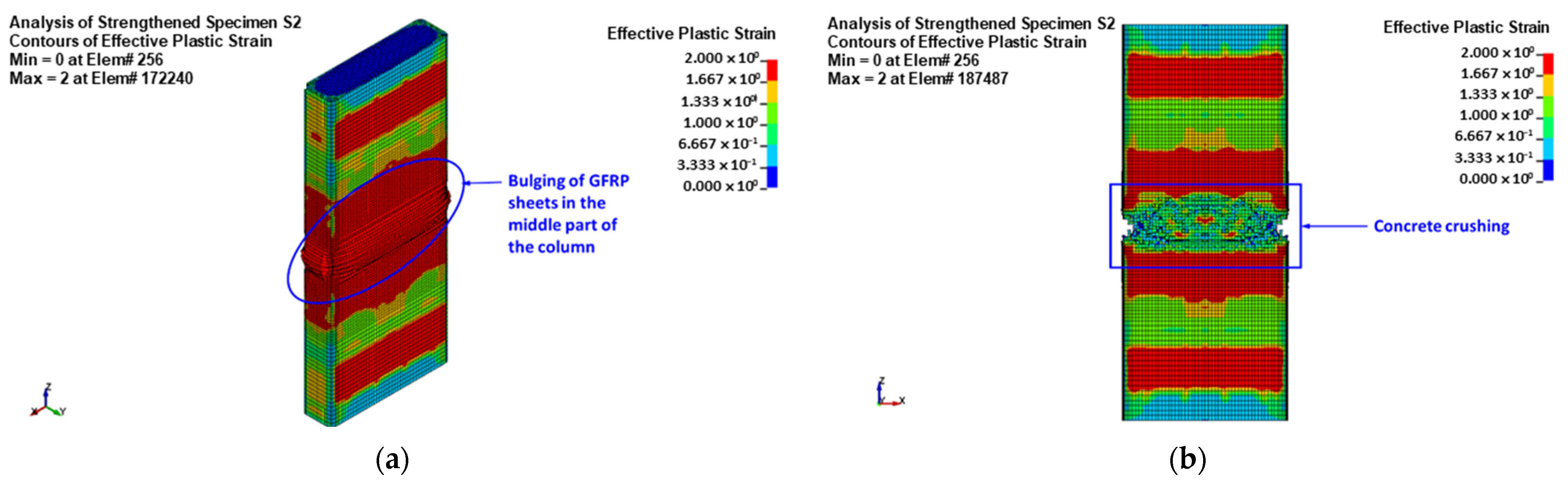

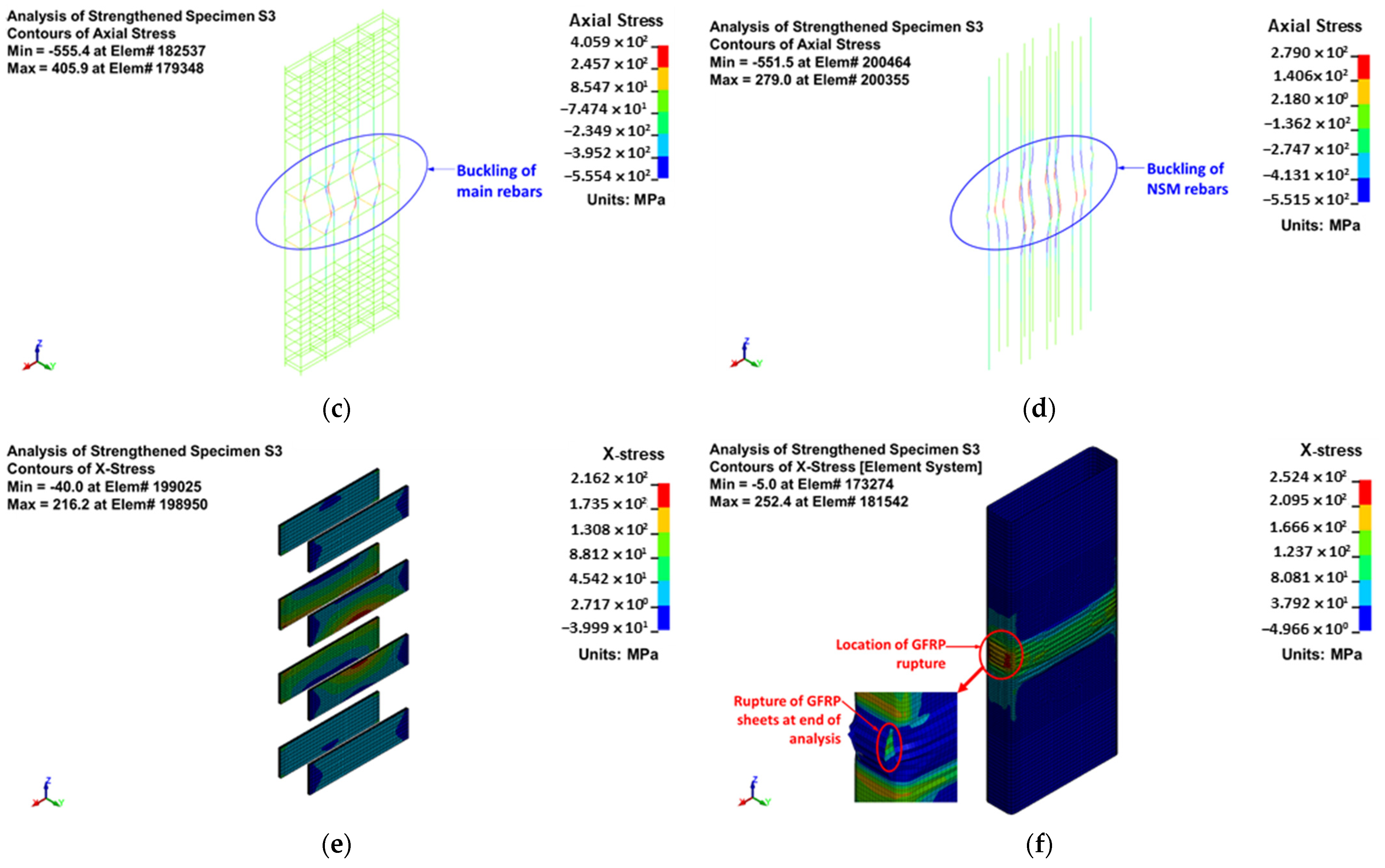

6.1. Modes of Failure

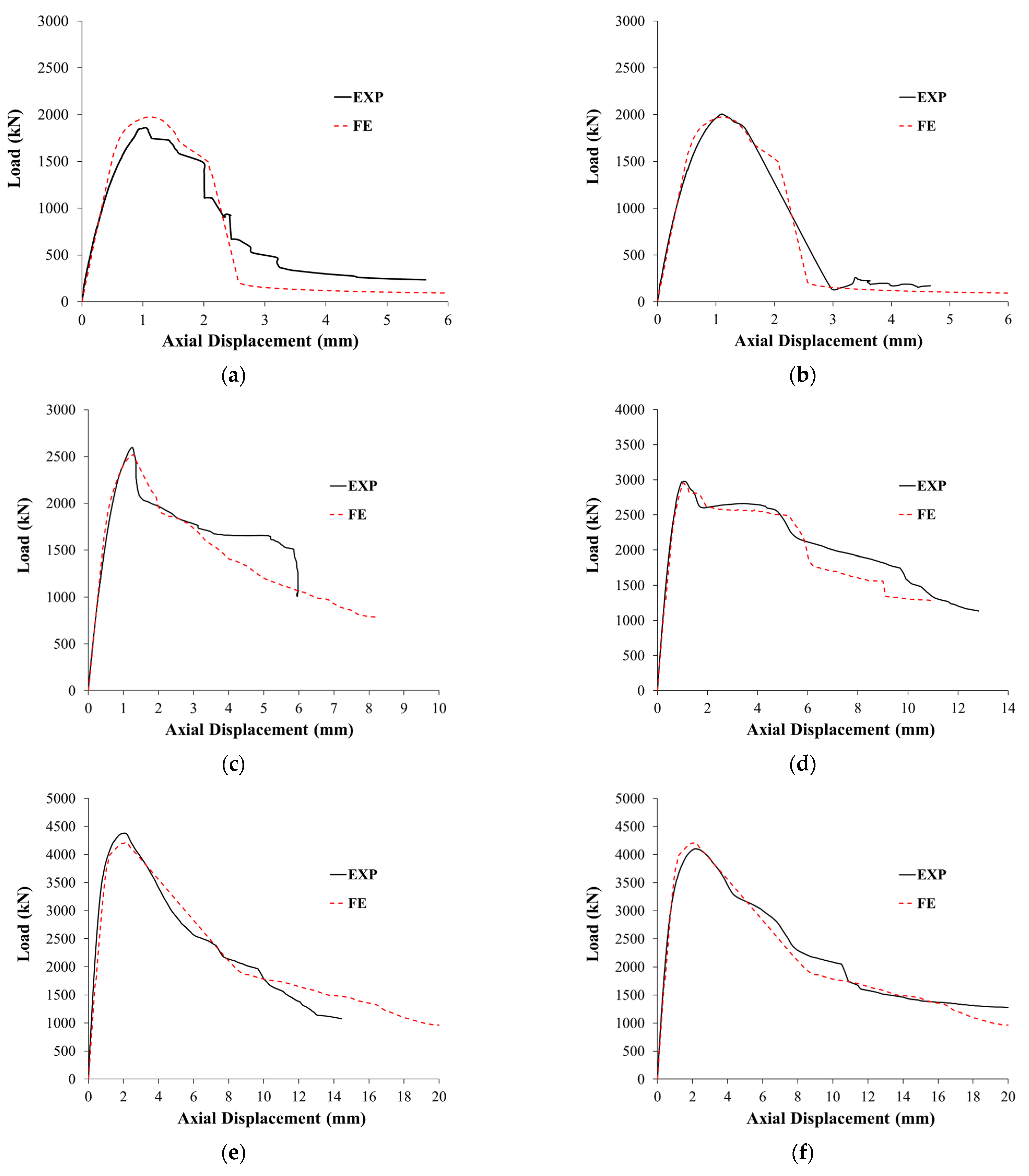

6.2. Load versus Displacement Curves

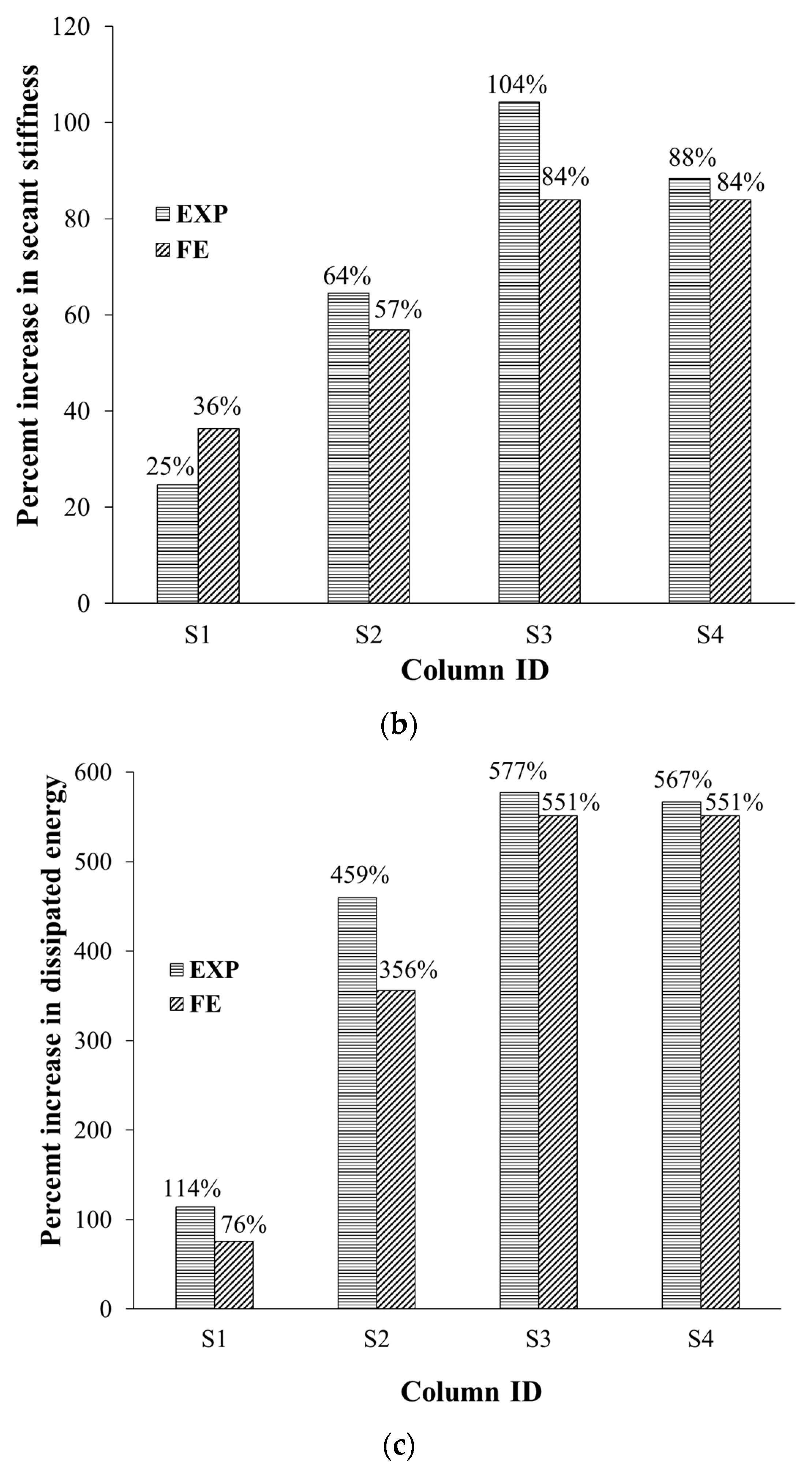

7. Evaluation of Upgrading Schemes

8. Conclusions

- The strengthening schemes proposed in this research for RC wall-like columns were designed so that the dimensions of the column cross-section are not increased. Accordingly, they are favored by architects, especially in buildings constructed in congested and expensive areas of metropolitan cities.

- Control specimens had a common brittle failure mode that started with cover spalling, resulting in buckling of vertical bars, and the failure was concluded by crushing concrete in the middle part of the height. For all strengthened columns, the failure started with the bulging of the GFRP sheets in the middle part of the column height, and it was followed by the buckling of both NSM bars (if any) and main steel bars. Then, the failure was concluded by rupture of GFRP wrapping at (or close to) the corners.

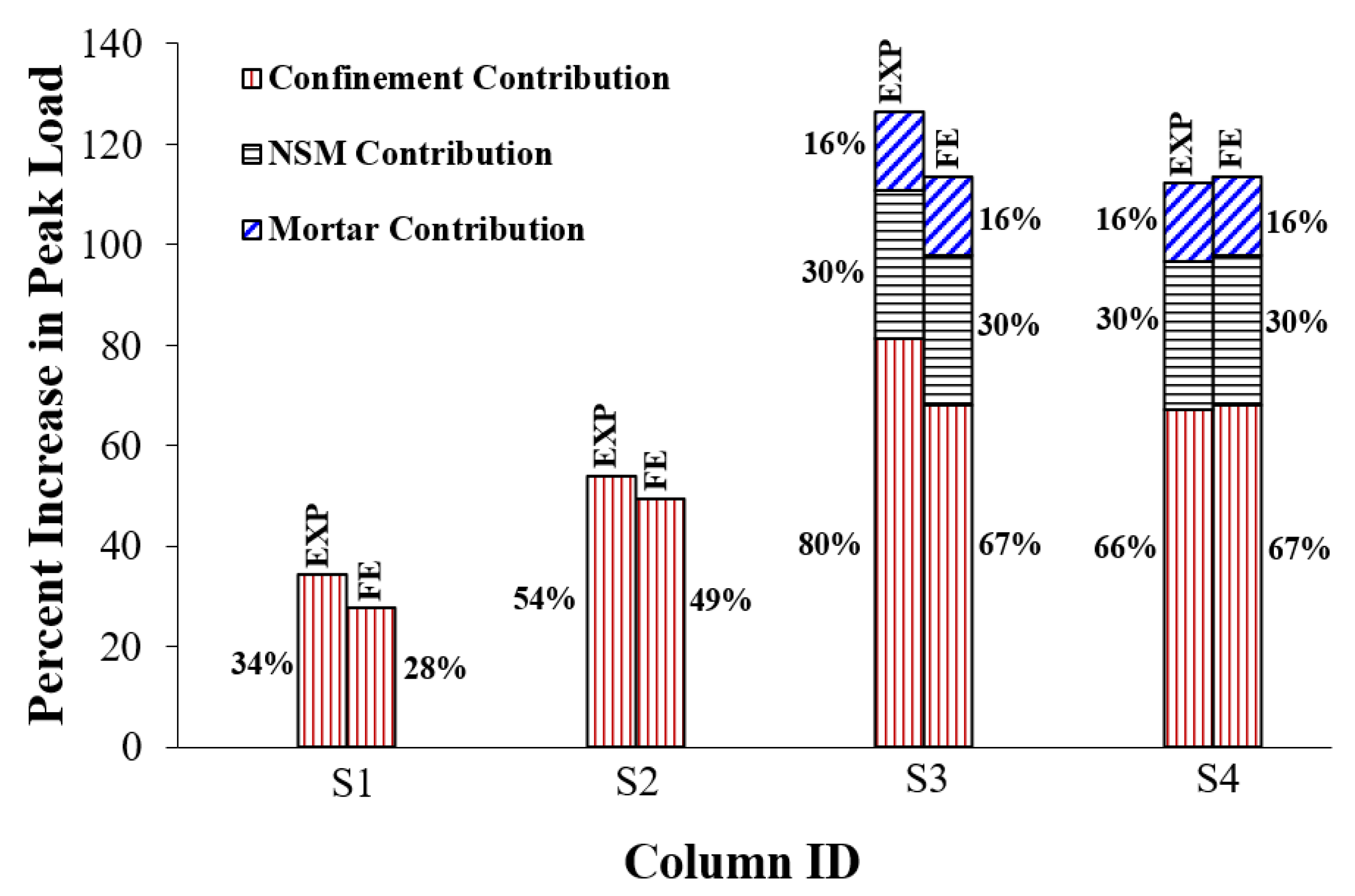

- Upgrading of wall-like columns by GFRP wrapping in scheme 1 was moderately efficient in increasing the maximum load by 34% and 28%, respectively, for test and numerical results. It also had a small influence on increasing the axial column stiffness (the enhancements were 25% and 36% for test and numerical results, respectively).

- Combining bolted steel plates with GFRP wrapping in scheme 2 was effective at improving the ultimate load by 54% and 49% for test and numerical results, respectively. It was also effective at increasing the axial stiffness of the column by 64% and 57% for test and FE results, respectively.

- Among the four studied schemes, the use of the hybrid system (GFRP wrapping along with bolted steel plates and NSM bars) in schemes 3 and 4 was the most effective at increasing the maximum experimental load by 126% (113% for FE results) and 112% (113% for FE results), respectively. The best performance of schemes 3 and 4 could be owing to the enhanced concrete confinement provided by all of the GFRP composites, steel plates, and NSM bars, along with the increased axial load resisted by the NSM bars. In addition, the use of the hybrid system in specimens S3 and S4 was very effective at upgrading the experimental axial stiffness by 104% (84% for FE results) and 88% (84% for FE results), respectively.

- Schemes 2, 3, and 4, which involved the use of bolted steel plates combined with GFRP wrapping, had substantial enhancement in the ultimate axial displacement of the columns. Compared with control columns, ultimate displacement enhancements of 157% to 253% and 179% to 191% were provided by schemes 2, 3, and 4 for experimental and FE results, respectively.

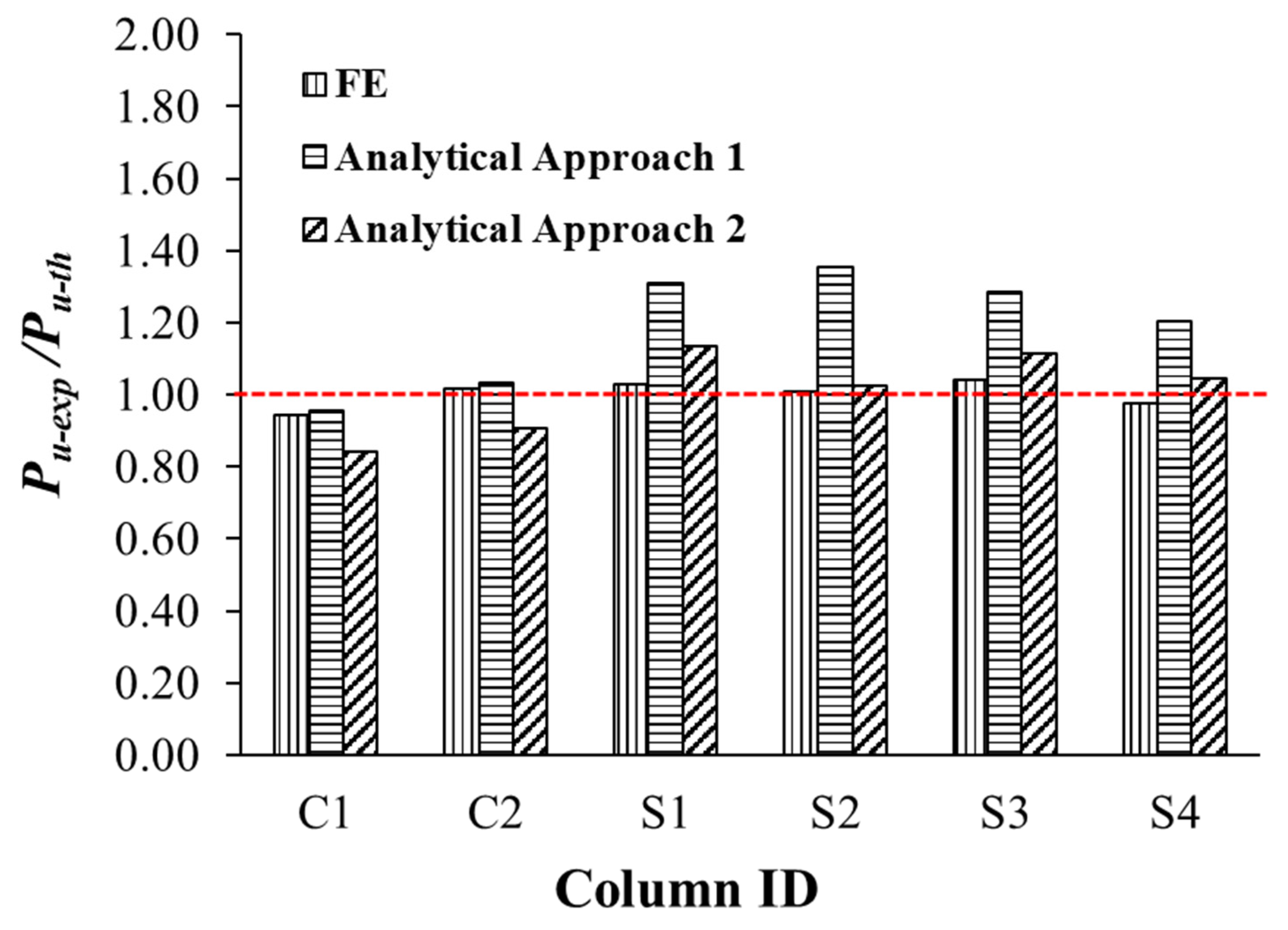

- Two analytical approaches were developed for computing the ultimate load of control and upgraded RC wall-like columns. Then, the calculated loads were compared with the test values. The first analytical approach predicted the maximum load of control columns more precisely than the second one. Nevertheless, Approach 2 predicted the maximum load of upgraded columns more accurately than Approach 1. For upgraded columns, the prediction errors of Approach 1 were 20% to 35%; nevertheless, the errors of Approach 2 were 3% to 14%.

- The FE results with regard to failure modes and load–displacement behavior accurately matched the test results. This validates the employed models of constitutive materials (concrete, GFRP sheets, and steel). Thus, the conducted FE analysis can be utilized in forthcoming studies on the strengthening of RC columns.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Nomenclature

| Ag | gross area of column section |

| Agrooves | area of grooves for NSM bars |

| ANSM | area NSM bars |

| Ast | area of parent steel bars |

| bp | width of steel plates |

| B | width of column cross-section |

| De | diagonal of the rectangular column cross-section |

| Ef | modulus of elasticity of GFRP sheets |

| Es | Young’s modulus of steel plates |

| unconfined compressive strength of concrete | |

| maximum actual concrete strength | |

| maximum average concrete strength | |

| confined compressive strength of concrete | |

| confined grout mortar strength (used in the NSM grooves) | |

| peak lateral confining pressure exerted on concrete | |

| compressive strength of mortar | |

| fy-NSM | yield strength of NSM bars |

| fy-st | yield strength of parent steel bars |

| H | depth of column cross-section |

| ka | FRP confinement efficiency factor |

| ks | axial secant stiffness |

| Ps | service load |

| Pu | peak load |

| Pu-exp | ultimate experimental load |

| Pu-ana | ultimate analytical load |

| Sp | spacing of steel plates measured on centers |

| rc | radius of corner of column cross-section |

| tf | total thickness of GFRP layers |

| tp | thickness of steel plates |

| P | increase in load carrying capacity of column due to upgrading |

| PNSM | increase in load carrying capacity of column due to NSM bars |

| Pmortar | increase in load carrying capacity of column due to mortar |

| Pconf | increase in load carrying capacity of column due to confinement |

| η | equivalent rectangular stress block parameter |

| Ψf | strength reduction factor for FRP confinement (=0.95) |

| Δs | axial displacement at service load |

| εfe | effective strain of GFRP sheets (=55% of the rupture strain) |

| ρg | reinforcement ratio of longitudinal steel bars = Ast/BH |

References

- Bett, B.J.; Klingner, R.E.; Jisra, J.O. Lateral load response of strengthened and repaired reinforced concrete columns. ACI Struct. J. 1988, 85, 499–508. [Google Scholar]

- Rodriguey, M.; Park, R. Seismic load tests on reinforced concrete columns strengthened by jacketing. ACI Struct. J. 1994, 91, 150–159. [Google Scholar]

- Campione, G. Load carrying capacity of RC compressed columns strengthened with steel angles and strips. Eng. Struct. 2012, 40, 457–465. [Google Scholar] [CrossRef]

- Khalifa, E.S.; Al-Tersawy, S.H. Experimental and analytical behavior of strengthened reinforced concrete columns with steel angles and strips. Int. J. Adv. Struct. Eng. 2014, 6, 6. [Google Scholar] [CrossRef]

- Tarabia, A.M.; Albakry, H.F. Strengthening of RC columns by steel angles and strips. Alex. Eng. J. 2014, 53, 615–626. [Google Scholar] [CrossRef]

- Abdel-Hay, A.S.; Fawzy, Y.A.G. Behavior of partially defected R.C columns strengthened using steel jackets. HBRC J. 2015, 11, 194–200. [Google Scholar] [CrossRef]

- Salah, A.; Elsanadedy, H.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of axially loaded L-shaped RC columns strengthened using steel jacketing. J. Build. Eng. 2022, 47, 103870. [Google Scholar] [CrossRef]

- Tan, K.H. Strength enhancement of rectangular RC columns using FRP. J. Compos. Constr. ASCE 2002, 6, 175–183. [Google Scholar] [CrossRef]

- Hosny, A.; Shaheen, H.; Abdelrahman, A.; Elafandy, T. Uniaxial tests on rectangular columns strengthened with CFRP. In Proceedings of the 3rd Middle East Symposium on Structural Composites for Infrastructure Applications, Aswan, Egypt, 17 December 2002. [Google Scholar]

- Tanwongsval, S.; Maalej, M.; Paramasivam, P. Strengthening of RC wall-like columns with FRP under sustained loading. RILEM Mater. Struct. 2003, 36, 282–290. [Google Scholar] [CrossRef]

- Maalej, M.; Tanwongsval, S.; Paramasivam, P. Modelling of rectangular RC columns strengthened with FRP. Cem. Concr. Compos. 2003, 25, 263–276. [Google Scholar] [CrossRef]

- Prota, A.; Manfredi, G.; Cosenza, E. Ultimate behavior of axially loaded RC wall-like columns confined with GFRP. Compos. Part B 2006, 37, 670–678. [Google Scholar] [CrossRef]

- De Luca, A.; Nardone, F.; Lignola, G.P.; Prota, A.; Nanni, A. Wall-like reinforced concrete columns externally confined by means of glass FRP laminates. Adv. Struct. Eng. 2013, 16, 593–603. [Google Scholar] [CrossRef]

- Alsayed, S.H.; Almusallam, T.H.; Ibrahim, S.M.; Al-Hazmi, N.M.; Al-Salloum, Y.A.; Abbas, H. Experimental and numerical investigation for compression response of CFRP strengthened shape modified wall-like RC column. Constr. Build. Mater. 2014, 63, 72–80. [Google Scholar] [CrossRef]

- Abbas, H.; Ibrahim, S.M.; Al-Hazmi, N.; Elsanadedy, H.; Almusallam, T.; Al-Salloum, Y. Axial Compression Behavior of Wall-like Reinforced Concrete Columns Retrofitted Using Different FRP Schemes. Buildings 2022, 13, 26. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Choutopoulou, E.; Fotaki, E.; Skorda, M.; Stathopoulou, M.; Karlos, K. FRP confinement of wall-like reinforced concrete columns. Mater. Struct. 2016, 49, 651–664. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. ASCE 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Wang, Y.C.; Resrepo, J.I. Investigations of concentrically loaded reinforced concrete columns confined with glass fiber-reinforced polymer jackets. ACI Struct. J. 2001, 98, 377–385. [Google Scholar]

- Saatcioglu, M.; Razvi, S.R. Strength and ductility of confined concrete. J. Struct. Eng. 1992, 118, 590–607. [Google Scholar] [CrossRef]

- Yalcim, C.; Saatcioglu, M. Inelastic analysis of reinforced concrete columns. Comput. Struct. 2000, 77, 539–555. [Google Scholar] [CrossRef]

- Elsanadedy, H.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Performance of Concentrically Loaded RC Wall-like Columns Upgraded with Innovative Hybrid NSM/CFRP System. Polymers 2023, 15, 378. [Google Scholar] [CrossRef]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018.

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2016.

- ASTM D3039/D3039M; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2014.

- ACI 440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Detroit, MI, USA, 2017.

- ASTM A370–16; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- Al-Salloum, Y.A.; Almusallam, T.H.; Elsanadedy, H.M.; Iqbal, R.A. Effect of elevated temperature environments on the residual axial capacity of RC columns strengthened with different techniques. Constr. Build. Mater. 2016, 115, 345–361. [Google Scholar] [CrossRef]

- Elsanadedy, H.; Almusallam, T.; Al-Salloum, Y.; Iqbal, R. Effect of high temperature on structural response of reinforced concrete circular columns strengthened with fiber reinforced polymer composites. J. Compos. Mater. 2017, 51, 333–355. [Google Scholar] [CrossRef]

- ACI Committee 318; Building Code Requirements for Structural Concrete (ACI 318-19): An ACI Standard: Commentary on Building code Requirements for Structural Concrete (ACI 318R-19). American Concrete Institute: Farmington Hills, MI, USA, 2019.

- SBC 304; Concrete Structures Requirements—SBC 304. Saudi Building Code National Committee (SBCNC): Riyadh, Saudi Arabia, 2007.

- EN 1992-1-1; EN 1992-1-1 Eurocode 2: Design of Concrete Structures-Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Livermore Software Technology Corporation (LSTC). LS-DYNA Keyword User’s Manual, Version R11; LSTC: Livermore, CA, USA, 2018; Volume 1–3. [Google Scholar]

- Malvar, L.J.; Crawford, J.E.; Wesevich, J.W.; Simons, D. A plasticity concrete material model for DYNA 3D. Int. J. Impact Eng. 1997, 19, 847–873. [Google Scholar] [CrossRef]

- Malvar, L.J.; Crawford, J.E.; Morrill, K.B. K&C Concrete Material Model Release III–Automated Generation of Material Input; K&C Technical Report TR-99-24-B1; Karagozian and Case: Glendale, CA, USA, 2000. [Google Scholar]

- Magallanes, J.M.; Wu, Y.; Malvar, L.J.; Crawford, J.E. Recent improvements to release III of the K&C concrete model. In Proceedings of the 11th International LS-DYNA Users Conference, Detroit, MI, USA, 6–8 June 2010. [Google Scholar]

- Chang, F.K. A progressive damage model for laminated composites containing stress concentration. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

| Concrete and Mortar | Concrete | Epoxy-Based Mortar | ||

| Model No. | 72R3 | |||

| Model type | Concrete damage | |||

| Compressive strength | 29.2 MPa | 65.0 MPa | ||

| Aggregate size | 10.0 mm | 5.0 mm | ||

| Steel reinforcing bars, rods, and plates | Φ8 mm bars | Φ10 mm bars | Φ18 mm rods | Plates |

| Model No. | 24 | |||

| Model type | Piecewise linear plasticity | |||

| Modulus of elasticity | 2 × 105 MPa | |||

| Yield strength | 548.0 MPa | 531.0 MPa | 711.0 MPa | 230.0 MPa |

| Tangent modulus | 86.4 MPa | 133.8 MPa | 0.0 | 0.0 |

| Plastic fracture strain | 9.72% | 9.73% | 6.64% | 19.89% |

| GFRP sheets | ||||

| Model No. | 54–55 | |||

| Model type | Enhanced composite damage | |||

| Density | 1740 kg/m3 | |||

| Thickness per layer | 1.30 mm | |||

| Elastic modulus in the fiber direction | 20.90 × 103 MPa | |||

| Elastic modulus in the transverse direction | 1.05 × 103 MPa | |||

| Tensile strength in the fiber direction | 253.0 MPa | |||

| Tensile strength in the transverse direction | 25.30 MPa | |||

| Specimen ID | Results | Yield Load (kN) | Peak Load (kN) | Axial Displacement (mm) at | Axial Stiffness (kN/mm) | Dissipated Energy (kN.mm) | |||

|---|---|---|---|---|---|---|---|---|---|

| Service Load | Yield Load | Peak Load | Ultimate State | ||||||

| Control specimens | |||||||||

| C1 | TEST | 1846 | 1862 | 0.27 | 0.93 | 1.05 | 2.01 | 2810 | 2866 |

| FEM | 1969 | 1974 | 0.29 | 1.04 | 1.09 | 2.15 | 2693 | 3220 | |

| TEST/FEM | 0.94 | 0.94 | 0.90 | 0.89 | 0.96 | 0.93 | 1.04 | 0.89 | |

| C2 | TEST | 1919 | 2006 | 0.29 | 0.93 | 1.11 | 1.97 | 2815 | 3157 |

| FEM | 1969 | 1974 | 0.29 | 1.04 | 1.09 | 2.15 | 2693 | 3220 | |

| TEST/FEM | 0.97 | 1.02 | 0.97 | 0.89 | 1.02 | 0.92 | 1.05 | 0.98 | |

| Mean of C1 and C2 | TEST | 1883 | 1934 | 0.24 | 0.93 | 1.08 | 1.99 | 3309 | 3012 |

| FEM | 1969 | 1974 | 0.25 | 1.04 | 1.09 | 2.15 | 3154 | 3220 | |

| TEST/FEM | 0.96 | 0.98 | 0.94 | 0.89 | 0.99 | 0.93 | 1.05 | 0.94 | |

| Strengthened specimens | |||||||||

| S1 | TEST | 2470 | 2596 | 0.30 | 1.06 | 1.25 | 3.5 | 3505 | 6450 |

| FEM | 2391 | 2519 | 0.27 | 0.98 | 1.29 | 2.96 | 3673 | 5663 | |

| TEST/FEM | 1.03 | 1.03 | 1.08 | 1.08 | 0.97 | 1.17 | 0.95 | 1.14 | |

| S2 | TEST | 2637 | 2978 | 0.26 | 0.73 | 1.11 | 7.02 | 4626 | 16,845 |

| FEM | 2807 | 2950 | 0.28 | 0.89 | 1.02 | 6.01 | 4225 | 14,678 | |

| TEST/FEM | 0.94 | 1.01 | 0.92 | 0.82 | 1.08 | 1.17 | 1.09 | 1.15 | |

| S3 | TEST | 3647 | 4379 | 0.31 | 0.84 | 2.06 | 5.11 | 5743 | 20,396 |

| FEM | 3753 | 4212 | 0.34 | 1.03 | 2.20 | 6.25 | 4954 | 20,967 | |

| TEST/FEM | 0.97 | 1.04 | 0.90 | 0.82 | 0.94 | 0.82 | 1.16 | 0.97 | |

| S4 | TEST | 3350 | 4105 | 0.31 | 0.94 | 2.20 | 6.00 | 5297 | 20,073 |

| FEM | 3753 | 4212 | 0.34 | 1.03 | 2.20 | 6.25 | 4954 | 20,967 | |

| TEST/FEM | 0.89 | 0.97 | 0.91 | 0.92 | 1.00 | 0.96 | 1.07 | 0.96 | |

| Specimen ID | Results | Average Peak Stress (MPa) | Actual Peak Stress (MPa) | Concrete Strain at Peak Stress (με) | Ultimate Concrete Strain (με) | Strain in Main Bars at Peak Load (με) | Strain in NSM Bars at Peak Load (με) | Peak GFRP Strain (με) | Peak Steel Plate Strain (με) |

|---|---|---|---|---|---|---|---|---|---|

| Control specimens | |||||||||

| C1 | TEST | 29.79 | 23.41 | 2600 | 5000 | 3400 | - | - | - |

| FEM | 31.59 | 25.23 | 2700 | 5400 | 3300 | - | - | - | |

| TEST/FEM | 0.94 | 0.93 | 0.96 | 0.93 | 1.04 | - | - | - | |

| C2 | TEST | 32.09 | 25.74 | 2800 | 4900 | 3100 | - | - | - |

| FEM | 31.59 | 25.23 | 2700 | 5400 | 3300 | - | - | - | |

| TEST/FEM | 1.02 | 1.02 | 1.02 | 0.92 | 0.95 | - | - | - | |

| Mean of C1 and C2 | TEST | 30.94 | 24.58 | 2700 | 4950 | 3250 | |||

| FEM | 31.59 | 25.23 | 2700 | 5400 | 3300 | ||||

| TEST/FEM | 0.98 | 0.97 | 1.00 | 0.92 | 0.98 | ||||

| Strengthened specimens | |||||||||

| S1 | TEST | 41.77 | 35.51 | 3128 | 8678 | 3195 | - | 10,274 | - |

| FEM | 40.30 | 34.25 | 3230 | 7392 | 3579 | - | 12,088 | - | |

| TEST/FEM | 1.04 | 1.04 | 0.97 | 1.17 | 0.89 | - | 0.85 | - | |

| S2 | TEST | 47.91 | 41.73 | 2763 | 17,544 | 6205 | - | 12,451 | 4033 |

| FEM | 47.21 | 41.28 | 2550 | 15,016 | 6648 | - | 12,083 | 3558 | |

| TEST/FEM | 1.01 | 1.01 | 1.08 | 1.17 | 0.93 | - | 1.03 | 1.13 | |

| S3 | TEST | 70.45 | 56.05 | 5147 | 12,763 | 11,357 | 12,376 | 14,369 | 3432 |

| FEM | 67.39 | 53.29 | 5488 | 15,622 | 12,269 | 13,669 | 12,075 | 3845 | |

| TEST/FEM | 1.05 | 1.05 | 0.94 | 0.82 | 0.93 | 0.91 | 1.19 | 0.89 | |

| S4 | TEST | 66.04 | 51.51 | 5509 | 15,003 | 13,491 | 13,184 | 11,543 | 3225 |

| FEM | 67.39 | 53.29 | 5488 | 15,622 | 12,269 | 13,669 | 12,075 | 3845 | |

| TEST/FEM | 0.98 | 0.97 | 1.00 | 0.96 | 1.10 | 0.96 | 0.96 | 0.84 | |

| Specimen ID | Approach 1 | Approach 2 | ||

|---|---|---|---|---|

| Pu-ana (kN) | Pu-exp/Pu-ana | Pu-ana (kN) | Pu-exp/Pu-ana | |

| C1 | 1946 | 0.96 | 2216 | 0.84 |

| C2 | 1946 | 1.03 | 2216 | 0.91 |

| Mean of C1 and C2 | 1946 | 0.99 | 2216 | 0.87 |

| S1 | 1983 | 1.31 | 2285 | 1.14 |

| S2 | 2198 | 1.35 | 2902 | 1.03 |

| S3 | 3413 | 1.28 | 3927 | 1.11 |

| S4 | 3413 | 1.20 | 3927 | 1.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsanadedy, H.; Abbas, H.; Siddiqui, N.; Almusallam, T.; Al-Salloum, Y. Hybrid Steel/NSM/GFRP System versus GFRP Wrapping for Upgrading RC Wall-like Columns. Polymers 2023, 15, 1886. https://doi.org/10.3390/polym15081886

Elsanadedy H, Abbas H, Siddiqui N, Almusallam T, Al-Salloum Y. Hybrid Steel/NSM/GFRP System versus GFRP Wrapping for Upgrading RC Wall-like Columns. Polymers. 2023; 15(8):1886. https://doi.org/10.3390/polym15081886

Chicago/Turabian StyleElsanadedy, Hussein, Husain Abbas, Nadeem Siddiqui, Tarek Almusallam, and Yousef Al-Salloum. 2023. "Hybrid Steel/NSM/GFRP System versus GFRP Wrapping for Upgrading RC Wall-like Columns" Polymers 15, no. 8: 1886. https://doi.org/10.3390/polym15081886

APA StyleElsanadedy, H., Abbas, H., Siddiqui, N., Almusallam, T., & Al-Salloum, Y. (2023). Hybrid Steel/NSM/GFRP System versus GFRP Wrapping for Upgrading RC Wall-like Columns. Polymers, 15(8), 1886. https://doi.org/10.3390/polym15081886