Proposal of Evaluation Method for Crack Propagation Behaviors of Second-Generation Acrylic Adhesives under Mode I Static Loading

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

2.2. Specimens and Test Conditions of Loading–Unloading Test

2.3. FEM Analysis

3. Results and Discussion

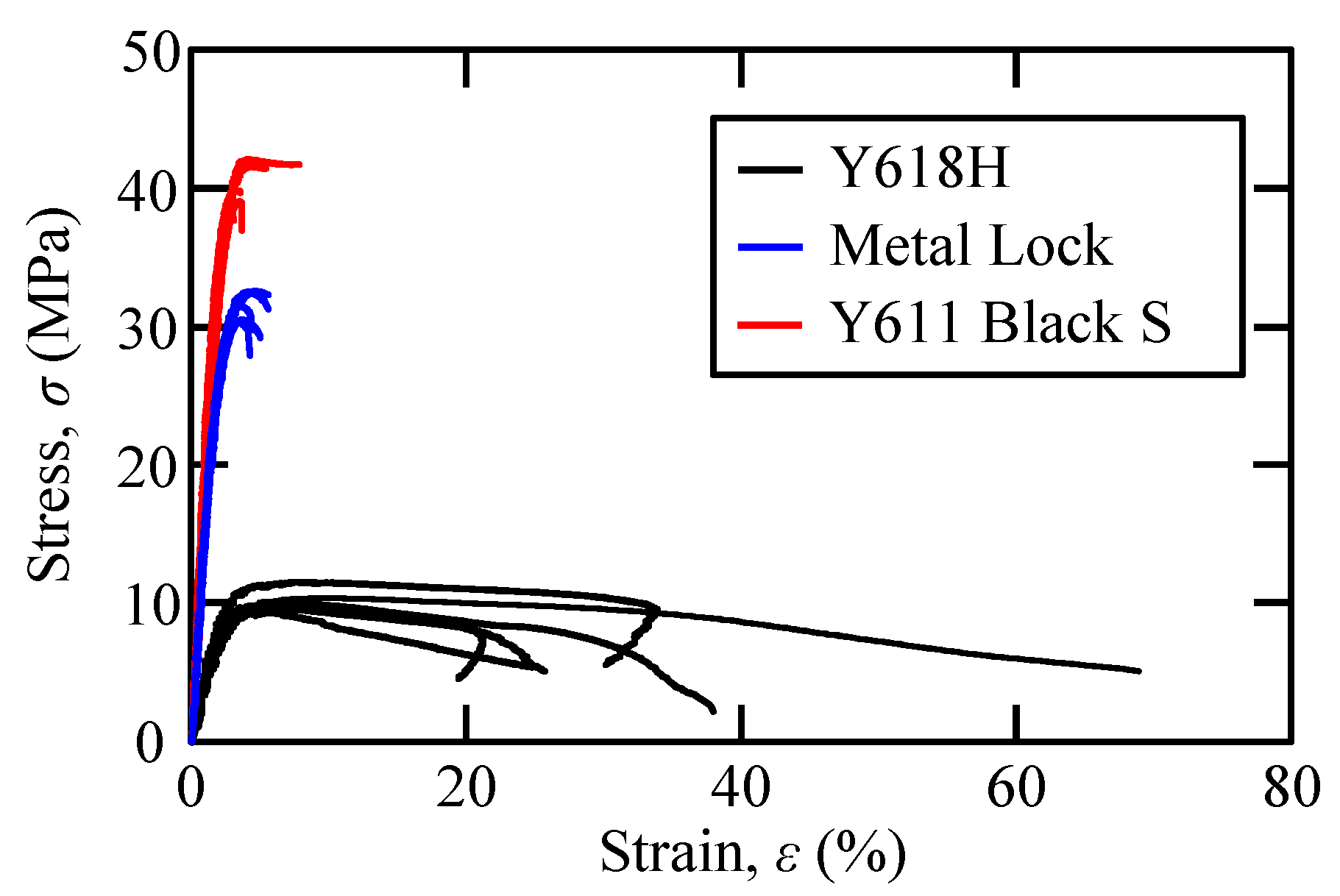

3.1. Tensile Testing of SGA Adhesive

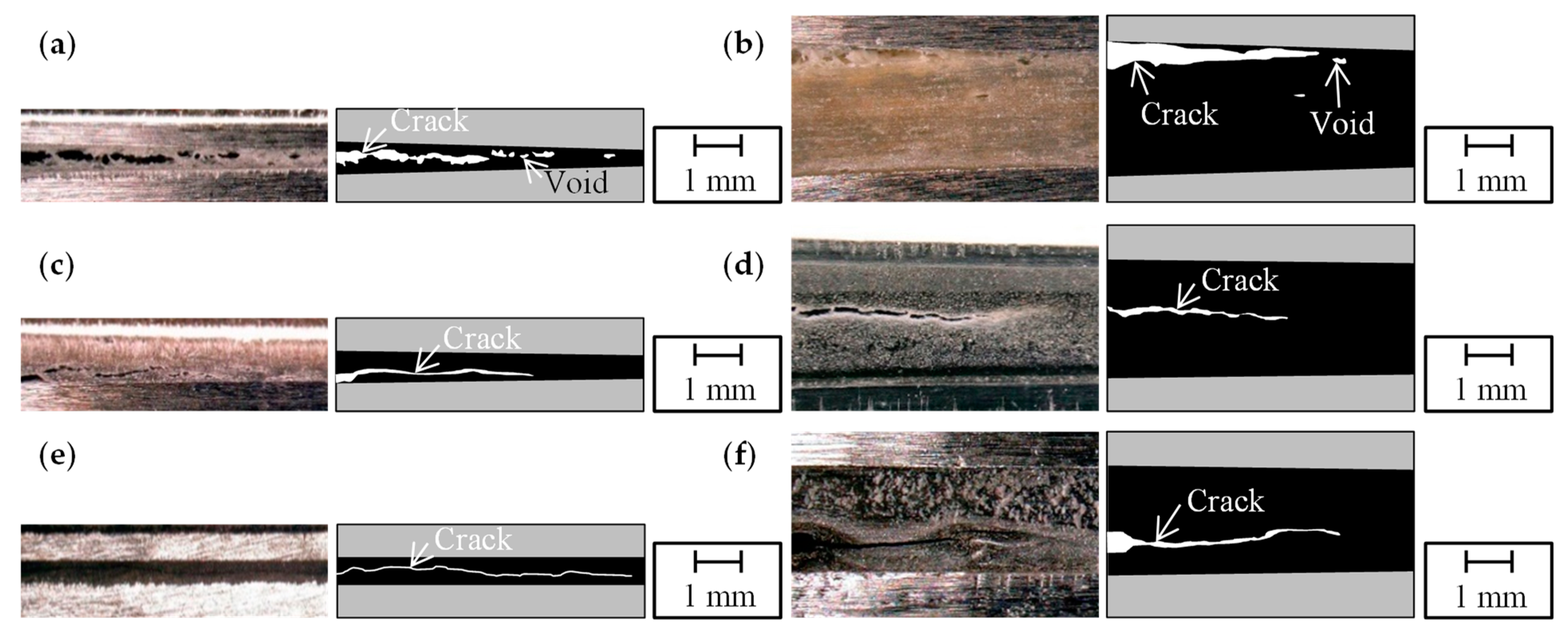

3.2. Loading–Unloading Tests

3.3. FEM Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bouaziz, O.; Zurob, H.; Huang, M. Driving force and logic of development of advanced high strength steels for automotive applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Hirscha, J.; Al-Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Driving force and logic of development of advanced high strength steels for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Sun, M.; Behravesh, S.B.; Wu, L.; Zhou, Y.; Jahed, H. Fatigue behavior of dissimilar Al 5052 and Mg AZ31 resistance spot welds with Sn-coated steel interlayer. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1048–1058. [Google Scholar] [CrossRef]

- Maggiore, S.; Banea, M.D.; Stagnaro, P.; Luciano, G. A Review of Structural Adhesive Joints in Hybrid Joining Processes. Polymers 2021, 13, 3961. [Google Scholar] [CrossRef] [PubMed]

- Machado, J.J.M.; Marques, E.A.S.; Barbosa, A.Q.; da Silva, L.F.M. Fatigue performance of single lap joints with CFRP and aluminium substrates prior and after hygrothermal aging. Fatigue Fract. Eng. Mater. Struct. 2020, 42, 2325–2339. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology, 2nd ed.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Pethrick, R.A. Design and ageing of adhesives for structural adhesive bonding—A review. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2015, 229, 349–379. [Google Scholar] [CrossRef]

- Avendano, R.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M.; Fernandes, A.A. Effect of temperature and strain rate on single lap joints with dissimilar lightweight adherends bonded with an acrylic adhesive. Compos. Struct. 2016, 152, 34–44. [Google Scholar] [CrossRef]

- Angelovici, M.; Dodiuk, H.; Kenig, S. Effect of surface preparation on performance of acrylic adhesive joints: Part II. Int. J. Adhes. Adhes. 1991, 11, 43–49. [Google Scholar] [CrossRef]

- Haraga, K.; Taguchi, K.; Yoda, K.; Nakashima, Y. Assembly technique for control panel enclosures with the combined use of adhesive and rivets and the reduction of energy consumption. Int. J. Adhes. Adhes. 2003, 23, 371–376. [Google Scholar] [CrossRef]

- Kawasaki, S.; Nakajima, G.; Haraga, K.; Sato, C. Functionally Graded Adhesive Joints Bonded by Honeymoon Adhesion Using Two Types of Second Generation Acrylic Adhesives of Two Components. J. Adhes. 2016, 92, 517–534. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Nakanouchi, M.; Haraga, K.; Takasaki, I.; Sato, C. Experimental investigation on strength of stepwise tailored single lap adhesive joint using second-generation acrylic adhesive via shear and low-cycle shear tests. Int. J. Adhes. Adhes. 2019, 95, 102438. [Google Scholar] [CrossRef]

- Aronovich, D.A.; Boinovich, L.B. Structural Acrylic Adhesives: A Critical Review. Rev. Adhes. Adhes. 2021, 9, 65–122. [Google Scholar]

- Kamiyama, K.; Mikuni, M.; Matsumoto, T.; Matsuda, S.; Kishi, H. Crack growth mechanism on SGA adhesive joints. Int. J. Adhes. Adhes. 2020, 103, 102690. [Google Scholar] [CrossRef]

- Hayashi, A.; Sekiguchi, Y.; Sato, C. AFM observation of sea-island structure formed by second generation acrylic adhesive. J. Adhes. 2021, 97, 155–171. [Google Scholar] [CrossRef]

- Kim, H.B.; Naito, K.; Oguma, H. Double cantilever-beam test comparisons of Mode I fracture toughness of adherends bonded using DP8010 and DP8005 acrylic-based adhesives. Int. J. Adhes. Adhes. 2018, 82, 173–183. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Hayashi, A.; Sato, C. Analytical determination of adhesive layer deformation for adhesively bonded double cantilever beam test considering elastic-plastic deformation. J. Adhes. 2020, 96, 647–664. [Google Scholar] [CrossRef]

- Dasilva, S.; Jimenez-Suarez, A.; Rodríguez, E.; Prolongo, S.G. Influence of Manufacturing Process in Structural Health Monitoring and Mechanical Behaviour of CNT Reinforced CFRP and Ti6Al4V Multi-Material Joints. Polymers 2021, 13, 2488. [Google Scholar] [CrossRef]

- Kim, H.B.; Naito, K.; Oguma, H. Mode II fracture toughness of two-part acrylic-based adhesive in an adhesively bonded joint: End-notched flexure tests under static loading. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1795–1808. [Google Scholar] [CrossRef]

- Kamiyama, K.; Mikuni, M.; Matsumoto, T. Fracture propagation analysis on two component type acrylic adhesive joints. Int. J. Adhes. Adhes. 2018, 83, 76–86. [Google Scholar] [CrossRef]

- Imanaka, M.; Omiya, M.; Taguchi, N. Estimation of static strength of adhesively bonded single lap joints with an acrylic adhesive under tensile shear condition based on cohesive zone model. J. Adhes. Sci. Technol. 2019, 33, 660–674. [Google Scholar] [CrossRef]

- Rocha, A.V.M.; Akhava-Safar, A.; Carbas, R.; Marques, E.A.S.; Goyal, R.; El-zein, M.; da Silva, L.F.M. Fatigue crack growth analysis of different adhesive systems: Effects of mode mixity and load level. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 330–341. [Google Scholar] [CrossRef]

- Tobata, Y.; Naito, K.; Tanks, J. Direct measurement and verification of cohesive zone model parameters for basalt/PP rods using the transverse tensile test and virtual double cantilever beam test. Polym. Compos. 2022, 44, 954–962. [Google Scholar] [CrossRef]

- Ogawa, Y.; Naito, K.; Harada, K.; Oguma, H. Evaluation of crack growth behaviors under Mode I static loading for two-part polyurethane adhesives. Int. J. Adhes. Adhes. 2022, 117, 103172. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Rodrigues, T.N.S.S.; Figureueiredo, M.A.V.; de Moura, M.F.S.F.; Chousal, J.A.G. Effect of adhesive type and thickness on the lap shear strength. J. Adhes. 2006, 82, 1091–1115. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Campilho, R.D.S.G. The Effect of Adhesive Thickness on the Mechanical Behavior of a Structural Polyurethane Adhesive. J. Adhes. 2015, 91, 331–346. [Google Scholar] [CrossRef]

- Iwata, T.; Hayashibara, H. Durability and flammability evaluation of SGA structural adhesive joints consisting of a thick adhesive layer for shipbuilding. J. Adhes. 2019, 95, 614–631. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Sato, C. Experimental investigation of the effects of adhesive thickness on the fracture behavior of structural acrylic adhesive joints under various loading rates. Int. J. Adhes. Adhes. 2021, 105, 102782. [Google Scholar] [CrossRef]

- Japanese Industrial Standards Committee. Rubber, Vulcanized or Thermoplastics-Determination of Tensile Stress–Strain Properties. JIS K 6251. 2010. Available online: https://dokumen.tips/documents/jis-k-6251-rubber-vulcanized-or-thermoplastics-determination-of-tensile.html?page=1 (accessed on 24 February 2023).

- Testing Methods for Interlaminar Fracture Toughness of Carbon Fibre Reinforced Plastics. JIS K 7086. 1993. Available online: https://www.beuth.de/en/standard/jis-k-7086/14292425 (accessed on 24 February 2023).

- Tobata, Y.; Naito, K.; Tanks, J. Investigation of a critical separation criterion for mode I-Governed fracture of basalt fiber/polypropylene rods via a modified double cantilever beam test. Compos. Struct. 2021, 279, 114778. [Google Scholar] [CrossRef]

- Lopes, R.M.; Campilho, R.D.S.G.; da Silva, F.J.G.; Faneco, T.M.S. Comparative evaluation of the Double-Cantilever Beam and Tapered Double-Cantilever Beam tests for estimation of the tensile fracture toughness of adhesive joints. Int. J. Adhes. Adhes. 2016, 67, 103–111. [Google Scholar] [CrossRef]

- Williams, J.G. The fracture mechanics of delamination tests. J. Strain Anal. Eng. Des. 1989, 24, 207–214. [Google Scholar] [CrossRef]

| Adhesive | Tensile Strength (MPa) | Tensile Modulus (MPa) | Strain at Failure (%) |

|---|---|---|---|

| Y618H | 10.2 (0.7) | 434 (37) | 34.2 (16.3) |

| Metal Lock | 31.7 (1.1) | 1527 (120) | 5.7 (2.3) |

| Y611 Black S | 40.1 (1.7) | 2017 (226) | 4.6 (2.0) |

| Adhesive | Critical Separation Energy, SEIC or SEIC-rapid (J m−2) | ||

|---|---|---|---|

| Zero Thickness | 0.3 mm | 3.0 mm | |

| Y618H (SEIC) | 393 | 499 (92) | 1456 (138) |

| Metal Lock (SEIC-rapid) | 646 | 673 (51) | 918 (111) |

| Y611 Black S (SEIC-rapid) | 547 | 568 (99) | 761 (81) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogawa, Y.; Naito, K.; Harada, K.; Oguma, H. Proposal of Evaluation Method for Crack Propagation Behaviors of Second-Generation Acrylic Adhesives under Mode I Static Loading. Polymers 2023, 15, 1878. https://doi.org/10.3390/polym15081878

Ogawa Y, Naito K, Harada K, Oguma H. Proposal of Evaluation Method for Crack Propagation Behaviors of Second-Generation Acrylic Adhesives under Mode I Static Loading. Polymers. 2023; 15(8):1878. https://doi.org/10.3390/polym15081878

Chicago/Turabian StyleOgawa, Yuki, Kimiyoshi Naito, Keisuke Harada, and Hiroyuki Oguma. 2023. "Proposal of Evaluation Method for Crack Propagation Behaviors of Second-Generation Acrylic Adhesives under Mode I Static Loading" Polymers 15, no. 8: 1878. https://doi.org/10.3390/polym15081878

APA StyleOgawa, Y., Naito, K., Harada, K., & Oguma, H. (2023). Proposal of Evaluation Method for Crack Propagation Behaviors of Second-Generation Acrylic Adhesives under Mode I Static Loading. Polymers, 15(8), 1878. https://doi.org/10.3390/polym15081878