Cellulosic Ethanol Production from Weed Biomass Hydrolysate of Vietnamosasa pusilla

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Preparation

2.2. H3PO4 Pretreatment

2.3. Chemical Composition Analysis

2.4. Analytical Methods

2.5. Enzymatic Saccharification

2.6. Determination of Biomass Microstructure

2.7. Crystallinity of Biomass

2.8. Preparation of Biomass Hydrolysate (BH) of V. pusilla

2.9. Ethanol Production

2.10. Statistical Analysis

3. Results

3.1. Compositional Analysis

3.2. Impact of H3PO4 on the Chemical Composition of V. pusilla Biomass

3.3. Enzymatic Saccharification of V. pusilla Biomass

3.4. Scanning Electron Microscopy (SEM) Assessment

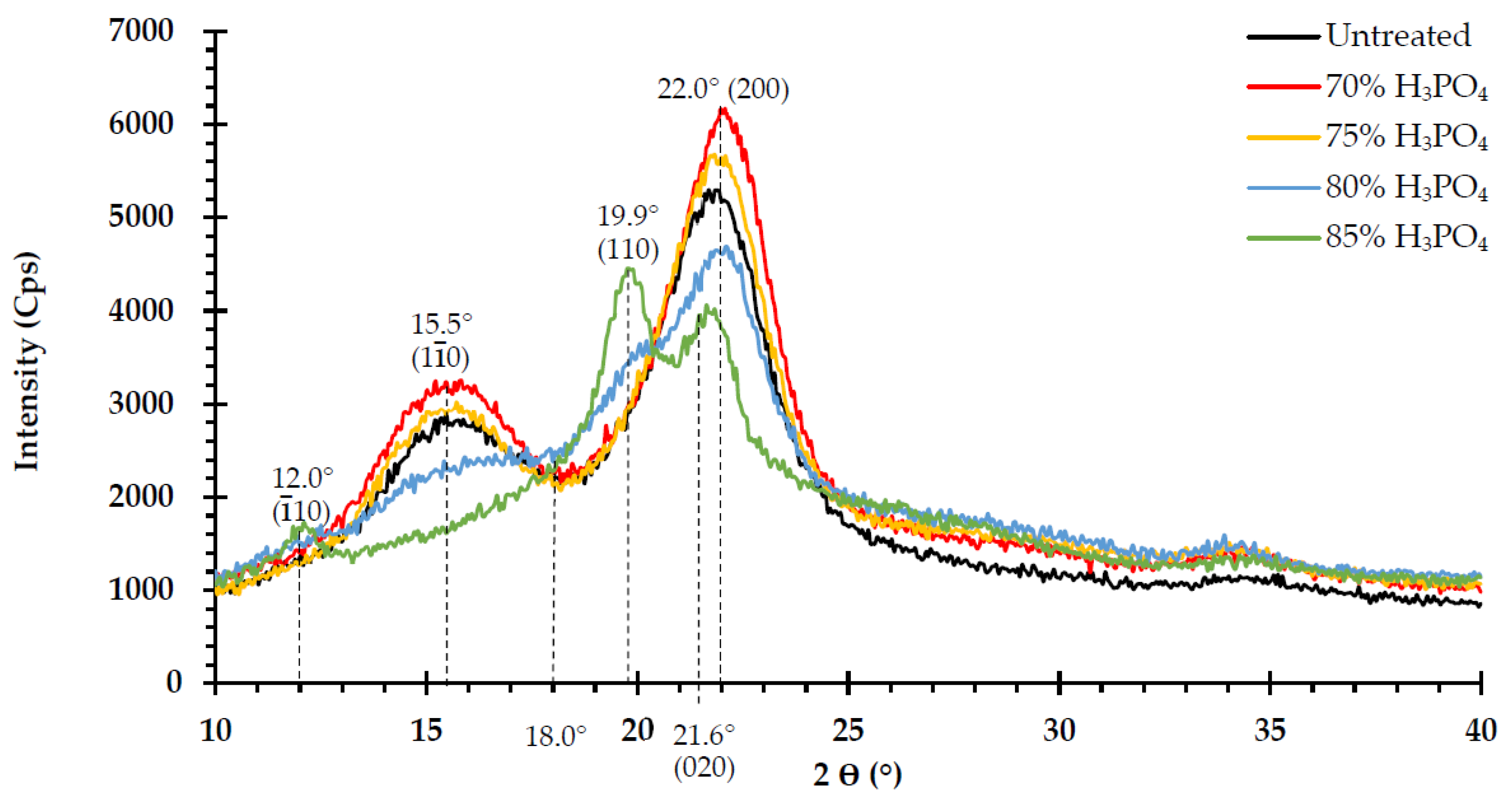

3.5. Effects of H3PO4 on Cellulose Crystalline Structure

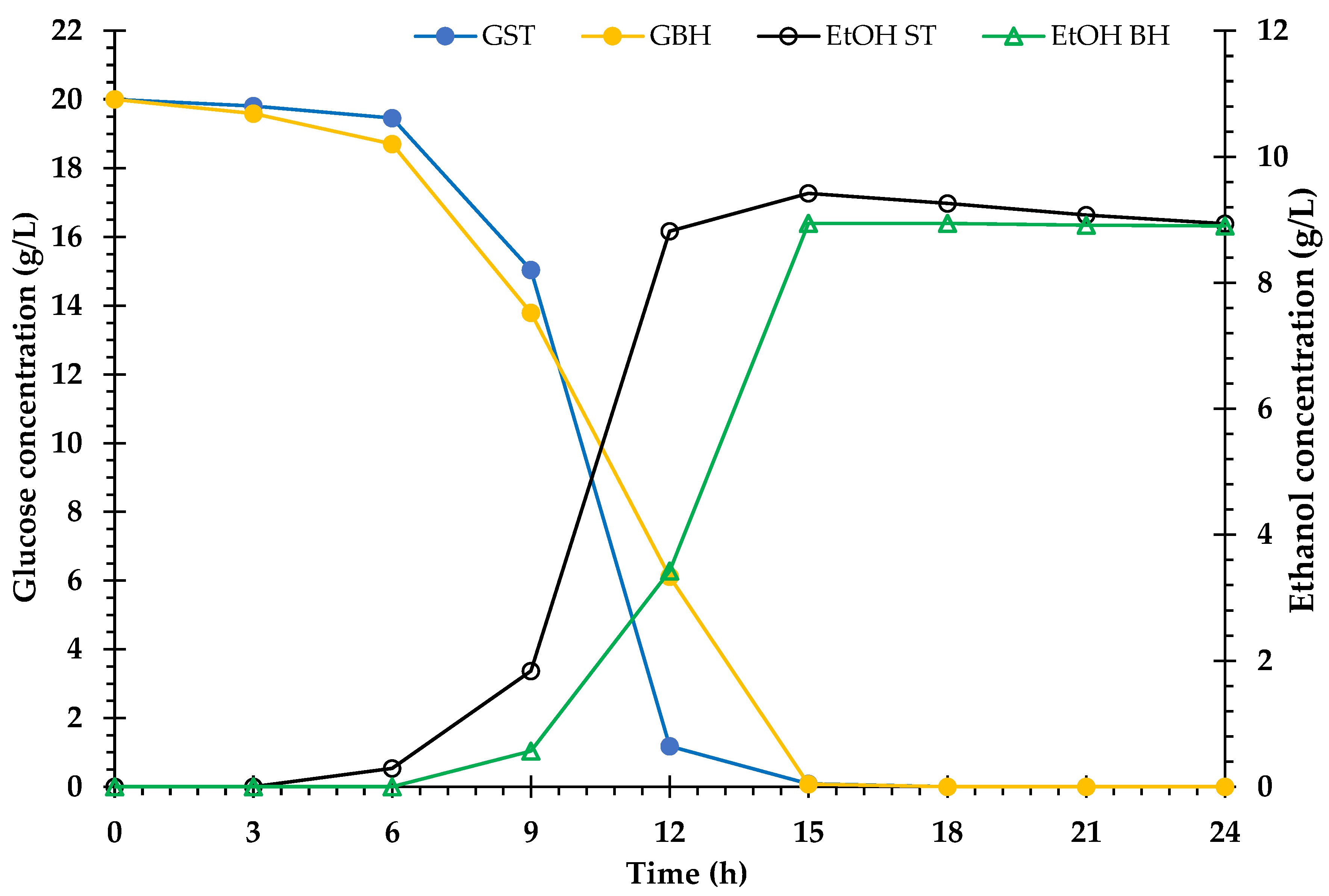

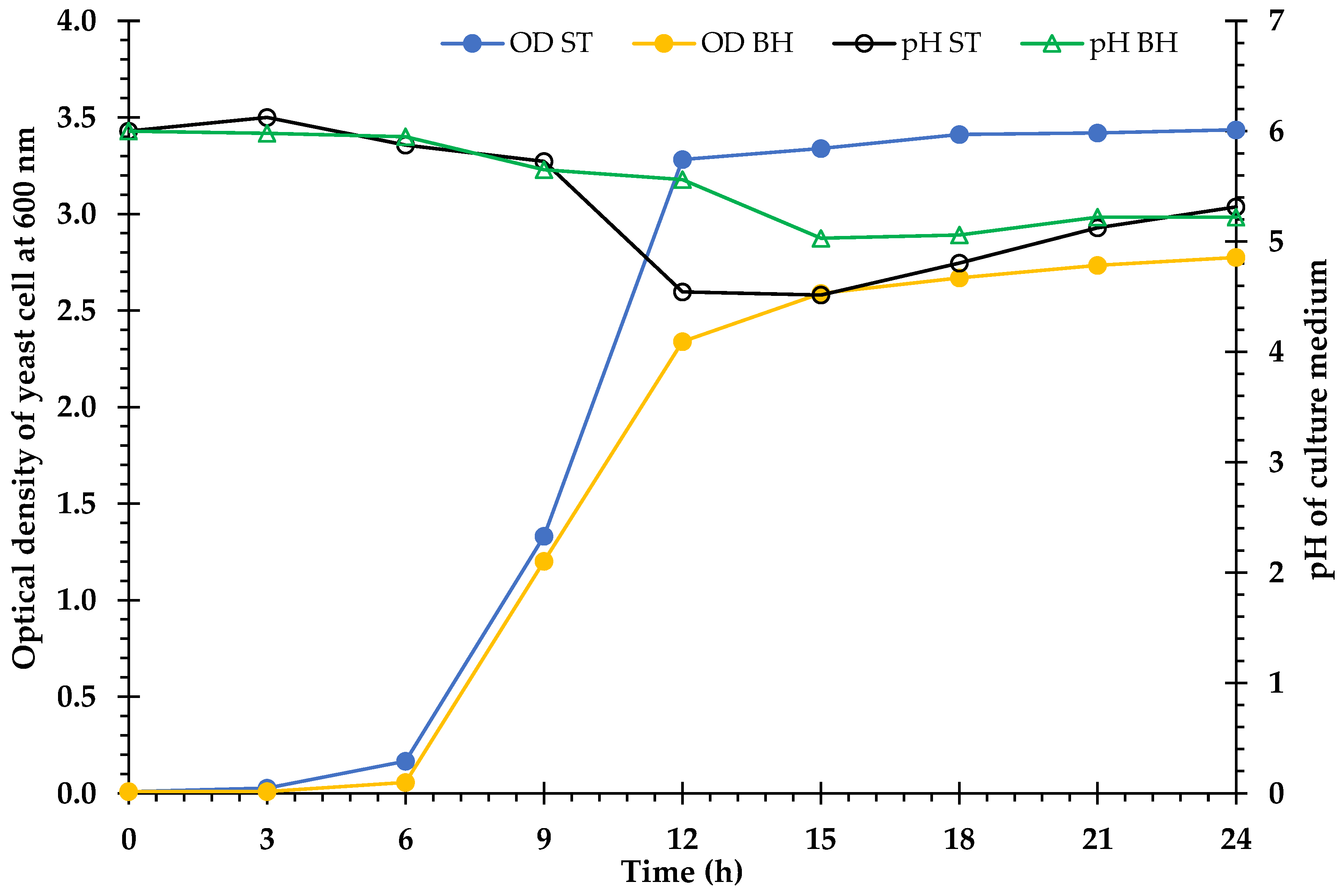

3.6. Ethanol Fermentation

4. Discussion

4.1. Compositional Analysis

4.2. Impact of H3PO4 on the Chemical Composition of V. pusilla Biomass

4.3. Enzymatic Saccharification of V. pusilla Biomass

4.4. SEM Assessment

4.5. Effects of H3PO4 on Cellulose Crystalline Structure

4.6. Bioethanol Fermentation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Chaturvedi, V.; Verma, P. Current perspective on pretreatment technologies using lignocellulosic biomass: An emerging biorefinery concept. Fuel Process. Technol. 2020, 199, 106244. [Google Scholar] [CrossRef]

- Straathof, A.J.; Wahl, S.A.; Benjamin, K.R.; Takors, R.; Wierckx, N.; Noorman, H.J. Grand Research Challenges for Sustainable Industrial Biotechnology. Trends Biotechnol. 2019, 37, 1042–1050. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, Z.-F.; Zhang, C.-C.; Nan, J.; Ren, N.-Q.; Lee, D.-J.; Chen, C. Advances in pretreatment of lignocellulosic biomass for bioenergy production: Challenges and perspectives. Bioresour. Technol. 2022, 343, 126123. [Google Scholar] [CrossRef]

- Patel, A.; Shah, A.R. Integrated lignocellulosic biorefinery: Gateway for production of second generation ethanol and value added products. J. Bioresour. Bioprod. 2021, 6, 108–128. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, B.; Luo, L.; Zhang, F.; Yi, Y.; Shan, Y.; Liu, B.; Zhou, Y.; Wang, X.; Lü, X. A review on recycling techniques for bioethanol production from lignocellulosic biomass. Renew. Sustain. Energy Rev. 2021, 149, 111370. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An overview of integration opportunities for sustainable bioethanol production from first- and second-generation sugar-based feedstocks. J. Clean. Prod. 2019, 245, 118857. [Google Scholar] [CrossRef]

- Satari, B.; Karimi, K.; Kumar, R. Cellulose solvent-based pretreatment for enhanced second-generation biofuel production: A review. Sustain. Energy Fuels 2019, 3, 11–62. [Google Scholar] [CrossRef]

- Kumar, A.K.; Sharma, S. Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour. Bioprocess. 2017, 4, 7. [Google Scholar] [CrossRef]

- Premjet, S.; Pumira, B.; Premjet, D. Determining the Potential of Inedible Weed Biomass for Bio-Energy and Ethanol Production. Bioresources 2013, 8, 701–716. [Google Scholar] [CrossRef]

- Siripong, P.; Duangporn, P.; Takata, E.; Tsutsumi, Y. Phosphoric acid pretreatment of Achyranthes aspera and Sida acuta weed biomass to improve enzymatic hydrolysis. Bioresour. Technol. 2016, 203, 303–308. [Google Scholar] [CrossRef]

- Ji, Z.; Zhang, X.; Ling, Z.; Zhou, X.; Ramaswamy, S.; Xu, F. Visualization of Miscanthus × giganteus cell wall deconstruction subjected to dilute acid pretreatment for enhanced enzymatic digestibility. Biotechnol. Biofuels 2015, 8, 103. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Lee, D.-J.; Zhang, T.; Jiang, D.; Zhang, Z.; Zhang, Q. Effect of enzymolysis time on biohydrogen production from photo-fermentation by using various energy grasses as substrates. Bioresour. Technol. 2020, 305, 123062. [Google Scholar] [CrossRef]

- Thuy, V.T.; Huyen, N.T.; Tu, L.H.; Loi, N.K. Status of bamboos in Binh Duong province, Vietnam: Distribution, species diversity, conservation and utilization. Trees For. People 2021, 6, 100137. [Google Scholar] [CrossRef]

- Pagad, S. Bamboos and Invasiveness-Identifying Which Bamboo Species Pose a Risk to the Natural Environment and What Can Be Done to Reduce This Risk; The International Bamboo and Rattan Organization (INBAR): Beijing, China, 2016; Available online: https://www.researchgate.net/publication/315720069 (accessed on 1 November 2022).

- Jin, Y.; Liu, J.; Yang, H.; Shi, Z.; Zhao, P.; Yang, J. Improving enzymatic saccharification and ethanol production of bamboo residues with sulfomethylation-aided phosphoric acid pretreatment. Ind. Crops Prod. 2021, 170, 113733. [Google Scholar] [CrossRef]

- Zoghlami, A.; Paës, G. Lignocellulosic Biomass: Understanding Recalcitrance and Predicting Hydrolysis. Front. Chem. 2019, 7, 874. [Google Scholar] [CrossRef]

- Chandel, A.K.; Garlapati, V.K.; Singh, A.K.; Antunes, F.A.F.; Da Silva, S.S. The path forward for lignocellulose biorefineries: Bottlenecks, solutions, and perspective on commercialization. Bioresour. Technol. 2018, 264, 370–381. [Google Scholar] [CrossRef]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K. Pretreatment of lignocellulosic biomass: A review on recent advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef]

- Premjet, D.; Wongleang, S.; Premjet, S. Enhancing Glucose Recovery from Hibiscus cannabinus L. through Phosphoric Acid Pretreatment. Energies 2022, 15, 7573. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass. In Technical Report NREL/TP-510-42618; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2012; pp. 1–15. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass. In Technical Report NREL/TP-510-42622; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2008; pp. 1–8. [Google Scholar]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass. In Technical Report NREL/TP-510-42619; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2008; pp. 1–12. [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Siripong, P.; Doungporn, P.; Yoo, H.Y.; Kim, S.W. Improvement of sugar recovery from Sida acuta (Thailand Weed) by NaOH pretreatment and application to bioethanol production. Korean J. Chem. Eng. 2018, 35, 2413–2420. [Google Scholar] [CrossRef]

- Yu, J.; Paterson, N.; Blamey, J.; Millan, M. Cellulose, xylan and lignin interactions during pyrolysis of lignocellulosic biomass. Fuel 2017, 191, 140–149. [Google Scholar] [CrossRef]

- Fortunati, E.; Benincasa, P.; Balestra, G.; Luzi, F.; Mazzaglia, A.; Del Buono, D.; Puglia, D.; Torre, L. Revalorization of barley straw and husk as precursors for cellulose nanocrystals extraction and their effect on PVA_CH nanocomposites. Ind. Crops Prod. 2016, 92, 201–217. [Google Scholar] [CrossRef]

- Zhu, R.; Yadama, V. Isolation and Characterization of Cellulose Micro/Nanofibrils from Douglas Fir. J. Polym. Environ. 2018, 26, 1012–1023. [Google Scholar] [CrossRef]

- Louis, A.C.F.; Venkatachalam, S. Energy efficient process for valorization of corn cob as a source for nanocrystalline cellulose and hemicellulose production. Int. J. Biol. Macromol. 2020, 163, 260–269. [Google Scholar] [CrossRef]

- Li, X.; Sun, C.; Zhou, B.; He, Y. Determination of Hemicellulose, Cellulose and Lignin in Moso Bamboo by Near Infrared Spectroscopy. Sci. Rep. 2015, 5, 17210. [Google Scholar] [CrossRef]

- Vanitjinda, G.; Nimchua, T.; Sukyai, P. Effect of xylanase-assisted pretreatment on the properties of cellulose and regenerated cellulose films from sugarcane bagasse. Int. J. Biol. Macromol. 2019, 122, 503–516. [Google Scholar] [CrossRef]

- Tsegaye, B.; Balomajumder, C.; Roy, P. Alkali pretreatment of wheat straw followed by microbial hydrolysis for bioethanol production. Environ. Technol. 2019, 40, 1203–1211. [Google Scholar] [CrossRef]

- Wang, Y.; Gong, X.; Hu, X.; Zhou, N. Lignin monomer in steam explosion assist chemical treated cotton stalk affects sugar release. Bioresour. Technol. 2019, 276, 343–348. [Google Scholar] [CrossRef]

- Zhang, Q.; Deng, Y.; Tan, X.; Wang, W.; Yu, Q.; Chen, X.; Miao, C.; Guo, Y.; Zhang, Y.; Zhuang, X.; et al. Biphasic fractionation of rice straw under mild condition in acidified 2-phenoxyethanol/water system. Ind. Crops Prod. 2020, 145, 112091. [Google Scholar] [CrossRef]

- Wang, Z.; Hou, X.; Sun, J.; Li, M.; Chen, Z.; Gao, Z. Comparison of ultrasound-assisted ionic liquid and alkaline pretreatment of Eucalyptus for enhancing enzymatic saccharification. Bioresour. Technol. 2018, 254, 145–150. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, Y.; Kwak, S.-Y. Comparing the influence of acetate and chloride anions on the structure of ionic liquid pretreated lignocellulosic biomass. Biomass-Bioenergy 2016, 93, 243–253. [Google Scholar] [CrossRef]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour. Technol. 2018, 262, 310–318. [Google Scholar] [CrossRef]

- Khan, A.S.; Man, Z.; Bustam, M.A.; Nasrullah, A.; Ullah, Z.; Sarwono, A.; Shah, F.U.; Muhammad, N. Efficient conversion of lignocellulosic biomass to levulinic acid using acidic ionic liquids. Carbohydr. Polym. 2018, 181, 208–214. [Google Scholar] [CrossRef]

- Bonfiglio, F.; Cagno, M.; Yamakawa, C.K.; Mussatto, S.I. Production of xylitol and carotenoids from switchgrass and Eucalyptus globulus hydrolysates obtained by intensified steam explosion pretreatment. Ind. Crops Prod. 2021, 170, 113800. [Google Scholar] [CrossRef]

- Mahmood, H.; Moniruzzaman, M.; Iqbal, T.; Khan, M.J. Recent advances in the pretreatment of lignocellulosic biomass for biofuels and value-added products. Curr. Opin. Green Sustain. Chem. 2019, 20, 18–24. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Jagtap, S.S.; Bedekar, A.A.; Bhatia, R.K.; Patel, A.K.; Pant, D.; Banu, J.R.; Rao, C.V.; Kim, Y.-G.; Yang, Y.-H. Recent developments in pretreatment technologies on lignocellulosic biomass: Effect of key parameters, technological improvements, and challenges. Bioresour. Technol. 2020, 300, 122724. [Google Scholar] [CrossRef]

- Woiciechowski, A.L.; Neto, C.J.D.; de Souza Vandenberghe, L.P.; de Carvalho Neto, D.P.; Sydney, A.C.N.; Letti, L.A.J.; Karp, S.G.; Torres, L.A.Z.; Soccol, C.R. Lignocellulosic biomass: Acid and alkaline pretreatments and their effects on biomass recalcitrance—Conventional processing and recent advances. Bioresour. Technol. 2020, 304, 122848. [Google Scholar] [CrossRef]

- Sathitsuksanoh, N.; Zhu, Z.; Zhang, Y.-H.P. Cellulose solvent- and organic solvent-based lignocellulose fractionation enabled efficient sugar release from a variety of lignocellulosic feedstocks. Bioresour. Technol. 2012, 117, 228–233. [Google Scholar] [CrossRef]

- Liu, J.; Gong, Z.; Yang, G.; Chen, L.; Huang, L.; Zhou, Y.; Luo, X. Novel Kinetic Models of Xylan Dissolution and Degradation during Ethanol Based Auto-Catalyzed Organosolv Pretreatment of Bamboo. Polymers 2018, 10, 1149. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Cheng, H.; Zhou, H. Hemicellulose degradation: An overlooked issue in acidic deep eutectic solvents pretreatment of lignocellulosic biomass. Ind. Crops Prod. 2022, 187, 115335. [Google Scholar] [CrossRef]

- Arora, A.; Nandal, P.; Singh, J.; Verma, M.L. Nanobiotechnological advancements in lignocellulosic biomass pretreatment. Mater. Sci. Energy Technol. 2020, 3, 308–318. [Google Scholar] [CrossRef]

- Kucharska, K.; Rybarczyk, P.; Hołowacz, I.; Łukajtis, R.; Glinka, M.; Kamiński, M. Pretreatment of Lignocellulosic Materials as Substrates for Fermentation Processes. Molecules 2018, 23, 2937. [Google Scholar] [CrossRef]

- Yoo, C.G.; Meng, X.; Pu, Y.; Ragauskas, A.J. The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment strategies: A comprehensive review. Bioresour. Technol. 2020, 301, 122784. [Google Scholar] [CrossRef]

- Obeng, A.K.; Premjet, D.; Premjet, S. Fermentable Sugar Production from the Peels of Two Durian (Durio zibethinus Murr.) Cultivars by Phosphoric Acid Pretreatment. Resources 2018, 7, 60. [Google Scholar] [CrossRef]

- Sathitsuksanoh, N.; George, A.; Zhang, Y.-H.P. New lignocellulose pretreatments using cellulose solvents: A review. J. Chem. Technol. Biotechnol. 2013, 88, 169–180. [Google Scholar] [CrossRef]

- Wang, Q.; Shen, F.; Yang, G.; Zhang, Y.; Deng, S.; Hu, Y.; Zhang, J.; Song, C.; Zeng, Y. Pretreating Luffa Sponge (Luffa cylindrica L.) with Concentrated Phosphoric Acid and Subsequent Enzymatic Saccharification. Bioresources 2016, 11, 899–912. [Google Scholar] [CrossRef]

- Premjet, S.; Dana, S.; Obeng, A.K.; Premjet, D. Enzymatic response to structural and chemical transformations in Hibiscus sabdariffa var. altissima bark and core during phosphoric acid pretreatment. Bioresources 2018, 13, 6778–6789. [Google Scholar] [CrossRef]

- Pihlajaniemi, V.; Sipponen, M.H.; Liimatainen, H.; Sirviö, J.A.; Nyyssölä, A.; Laakso, S. Weighing the factors behind enzymatic hydrolyzability of pretreated lignocellulose. Green Chem. 2016, 18, 1295–1305. [Google Scholar] [CrossRef]

- Yuan, Y.; Jiang, B.; Chen, H.; Wu, W.; Wu, S.; Jin, Y.; Xiao, H. Recent advances in understanding the effects of lignin structural characteristics on enzymatic hydrolysis. Biotechnol. Biofuels 2021, 14, 205. [Google Scholar] [CrossRef]

- Yoo, H.Y.; Lee, J.H.; Kim, D.S.; Lee, J.H.; Lee, S.K.; Lee, S.J.; Park, C.; Kim, S.W. Enhancement of glucose yield from canola agricultural residue by alkali pretreatment based on multi-regression models. J. Ind. Eng. Chem. 2017, 51, 303–311. [Google Scholar] [CrossRef]

- Hossain, A.; Rahaman, M.S.; Lee, D.; Phung, T.K.; Canlas, C.G.; Simmons, B.A.; Renneckar, S.; Reynolds, W.T.; George, A.; Tulaphol, S.; et al. Enhanced Softwood Cellulose Accessibility by H3PO4 Pretreatment: High Sugar Yield without Compromising Lignin Integrity. Ind. Eng. Chem. Res. 2020, 59, 1010–1024. [Google Scholar] [CrossRef]

- Moxley, G.; Zhu, Z.; Zhang, Y.-H.P. Efficient Sugar Release by the Cellulose Solvent-Based Lignocellulose Fractionation Technology and Enzymatic Cellulose Hydrolysis. J. Agric. Food Chem. 2008, 56, 7885–7890. [Google Scholar] [CrossRef]

- Luo, Y.; Li, D.; Chen, Y.; Sun, X.; Cao, Q.; Liu, X. The performance of phosphoric acid in the preparation of activated carbon-containing phosphorus species from rice husk residue. J. Mater. Sci. 2019, 54, 5008–5021. [Google Scholar] [CrossRef]

- Chu, G.; Zhao, J.; Huang, Y.; Zhou, D.; Liu, Y.; Wu, M.; Peng, H.; Zhao, Q.; Pan, B.; Steinberg, C.E. Phosphoric acid pretreatment enhances the specific surface areas of biochars by generation of micropores. Environ. Pollut. 2018, 240, 1–9. [Google Scholar] [CrossRef]

- Mund, N.K.; Dash, D.; Barik, C.R.; Goud, V.V.; Sahoo, L.; Mishra, P.; Nayak, N.R. Evaluation of efficient glucose release using sodium hydroxide and phosphoric acid as pretreating agents from the biomass of Sesbania grandiflora (L.) Pers.: A fast growing tree legume. Bioresour. Technol. 2017, 236, 97–105. [Google Scholar] [CrossRef]

- Gourlay, K.; Arantes, V.; Saddler, J.N. Use of substructure-specific carbohydrate binding modules to track changes in cellulose accessibility and surface morphology during the amorphogenesis step of enzymatic hydrolysis. Biotechnol. Biofuels 2012, 5, 51. [Google Scholar] [CrossRef]

- Ling, Z.; Tang, W.; Su, Y.; Huang, C.; Lai, C.; Kirui, A.; Wang, T.; French, A.D.; Yong, Q. Stepwise allomorphic transformations by alkaline and ethylenediamine treatments on bamboo crystalline cellulose for enhanced enzymatic digestibility. Ind. Crops Prod. 2022, 177, 114450. [Google Scholar] [CrossRef]

- Xu, F.; Shi, Y.-C.; Wang, D. X-ray scattering studies of lignocellulosic biomass: A review. Carbohydr. Polym. 2013, 94, 904–917. [Google Scholar] [CrossRef]

- Chundawat, S.P.S.; Bellesia, G.; Uppugundla, N.; Sousa, L.D.C.; Gao, D.; Cheh, A.M.; Agarwal, U.P.; Bianchetti, C.M.; Phillips, J.G.N.; Langan, P.; et al. Restructuring the Crystalline Cellulose Hydrogen Bond Network Enhances Its Depolymerization Rate. J. Am. Chem. Soc. 2011, 133, 11163–11174. [Google Scholar] [CrossRef]

- Hall, M.; Bansal, P.; Lee, J.H.; Realff, M.J.; Bommarius, A.S. Cellulose crystallinity—A key predictor of the enzymatic hydrolysis rate. FEBS J. 2010, 277, 1571–1582. [Google Scholar] [CrossRef]

- Karimi, K.; Taherzadeh, M.J. A critical review of analytical methods in pretreatment of lignocelluloses: Composition, imaging, and crystallinity. Bioresour. Technol. 2016, 200, 1008–1018. [Google Scholar] [CrossRef]

- Zhang, Y.-H.P.; Cui, J.; Lynd, L.R.; Kuang, L.R. A Transition from Cellulose Swelling to Cellulose Dissolution by o-Phosphoric Acid: Evidence from Enzymatic Hydrolysis and Supramolecular Structure. Biomacromolecules 2006, 7, 644–648. [Google Scholar] [CrossRef]

- Yoon, S.-Y.; Kim, B.-R.; Han, S.-H.; Shin, S.-J. Different response between woody core and bark of goat willow (Salix caprea L.) to concentrated phosphoric acid pretreatment followed by enzymatic saccharification. Energy 2015, 81, 21–26. [Google Scholar] [CrossRef]

- Sathitsuksanoh, N.; Zhu, Z.; Wi, S.; Zhang, Y.-H.P. Cellulose solvent-based biomass pretreatment breaks highly ordered hydrogen bonds in cellulose fibers of switchgrass. Biotechnol. Bioeng. 2011, 108, 521–529. [Google Scholar] [CrossRef]

- Arisht, S.N.; Abdul, P.M.; Liu, C.-M.; Lin, S.-K.; Maaroff, R.M.; Wu, S.-Y.; Jahim, J.M. Biotoxicity assessment and lignocellulosic structural changes of phosphoric acid pre-treated young coconut husk hydrolysate for biohydrogen production. Int. J. Hydrogen Energy 2019, 44, 5830–5843. [Google Scholar] [CrossRef]

- Li, Y.-C.; Gou, Z.-X.; Zhang, Y.; Xia, Z.-Y.; Tang, Y.-Q.; Kida, K. Inhibitor tolerance of a recombinant flocculating industrial Saccharomyces cerevisiae strain during glucose and xylose co-fermentation. Braz. J. Microbiol. 2017, 48, 791–800. [Google Scholar] [CrossRef]

| Composition (% DW) | V. pusilla (%) |

|---|---|

| Glucan | 48.1 ± 0.3 |

| Xylan | 19.2 ± 0.4 |

| Arabinan | 1.2 ± 0.1 |

| Ash | 6.1 ± 0.1 |

| Extractive | 18.2 ± 0.2 |

| AIL | 23.5 ± 0.1 |

| ASL | 4.4 ± 0.1 |

| Total lignin | 27.9 ± 0.2 |

| Composition (% DW) | Raw Material | Concentration of H3PO4 (%) | |||

|---|---|---|---|---|---|

| 70 | 75 | 80 | 85 | ||

| Glucan | 48.1 ± 0.3 c | 71.4 ± 0.3 b | 73.6 ± 1.1 a | 71.5 ± 0.7 b | 70.8 ± 0.8 b |

| Xylan | 19.2 ± 0.4 a | 7.6 ± 0.4 b | 4.8 ± 0.3 c | 4.0 ± 0.2 d | n.d. |

| Arabinan | 1.2 ± 0.1 a | n.d. | n.d. | n.d. | n.d. |

| AIL | 23.5 ± 0.1 a | 21.0 ± 0.6 b | 14.8 ± 0.7 c | 13.4 ± 0.3 d | 8.1 ± 0.7 e |

| ASL | 4.4 ± 0.1 a | 2.7 ± 0.1 b | 2.7 ± 0.0 b | 2.6 ± 0.0 b | 2.5 ± 0.0 c |

| Total lignin | 27.9 ± 0.2 a | 23.7 ± 0.6 b | 17.5 ± 0.7 c | 16.0 ± 0.3 d | 10.5 ± 0.7 e |

| Solid recovery | 100 ± 0.0 a | 53.8 ± 1.4 b | 51.1 ± 0.7 c | 50.2 ± 0.4 c | 46.8 ± 1.7 d |

| Glucan recovery | 100 ± 0.0 a | 79.9 ± 0.4 b | 78.3 ± 1.2 c | 74.7 ± 0.7 d | 68.9 ± 0.7 e |

| Xylan recovery | 100 ± 0.0 a | 21.4 ± 1.2 b | 12.8 ± 0.9 c | 10.4 ± 0.6 d | n.d. |

| Arabinan recovery | 100 ± 0.0 a | n.d. | n.d. | n.d. | n.d. |

| AIL recovery | 100 ± 0.0 a | 48.0 ± 1.4 b | 33.1 ± 0.2 c | 28.6 ± 0.6 d | 16.0 ± 1.5 e |

| ASL recovery | 100 ± 0.0 a | 32.7 ± 0.8 b | 30.6 ± 0.2 c | 29.9 ± 0.1 d | 26.0 ± 0.3 e |

| Total lignin recovery | 100 ± 0.0 a | 45.6 ± 1.1 d | 32.0 ± 1.2 c | 28.8 ± 0.5 d | 17.6 ± 1.2 e |

| Total lignin removal | n.d. | 54.4 ± 1.1 d | 68.0 ± 1.2 c | 71.2 ± 0.5 b | 82.4 ± 1.2 a |

| Raw Material | Concentration of H3PO4 (%) | ||||

|---|---|---|---|---|---|

| 70 | 75 | 80 | 85 | ||

| CrI (%) | 59.5 | 65.0 | 63.5 | 49.1 | 42.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wongleang, S.; Premjet, D.; Premjet, S. Cellulosic Ethanol Production from Weed Biomass Hydrolysate of Vietnamosasa pusilla. Polymers 2023, 15, 1103. https://doi.org/10.3390/polym15051103

Wongleang S, Premjet D, Premjet S. Cellulosic Ethanol Production from Weed Biomass Hydrolysate of Vietnamosasa pusilla. Polymers. 2023; 15(5):1103. https://doi.org/10.3390/polym15051103

Chicago/Turabian StyleWongleang, Suwanan, Duangporn Premjet, and Siripong Premjet. 2023. "Cellulosic Ethanol Production from Weed Biomass Hydrolysate of Vietnamosasa pusilla" Polymers 15, no. 5: 1103. https://doi.org/10.3390/polym15051103

APA StyleWongleang, S., Premjet, D., & Premjet, S. (2023). Cellulosic Ethanol Production from Weed Biomass Hydrolysate of Vietnamosasa pusilla. Polymers, 15(5), 1103. https://doi.org/10.3390/polym15051103