Development of Polydiphenylamine@Electrochemically Reduced Graphene Oxide Electrode for the D-Penicillamine Sensor from Human Blood Serum Samples Using Amperometry

Abstract

1. Introduction

2. Experimental

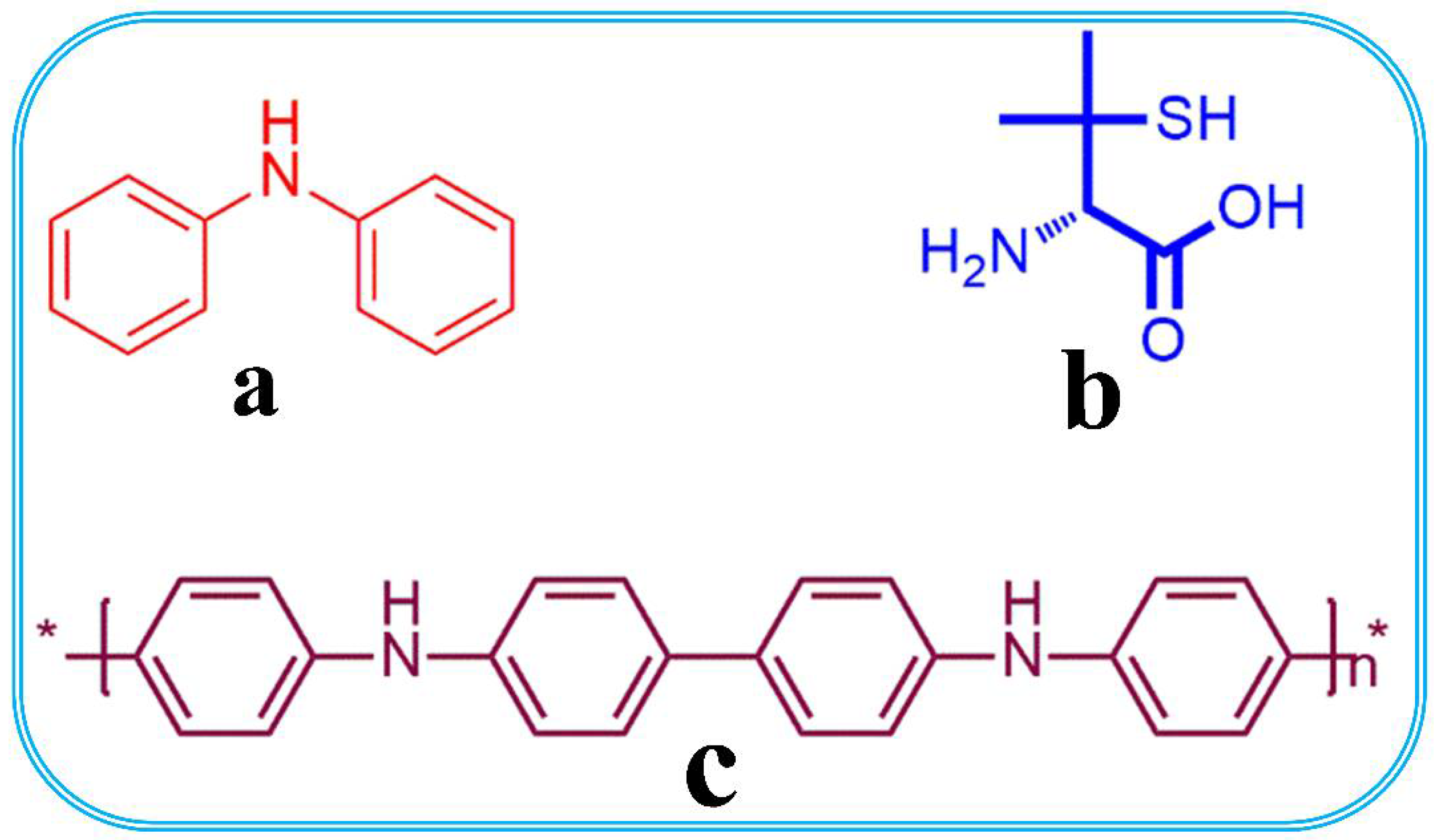

2.1. Materials

2.2. Graphene Oxide Preparation

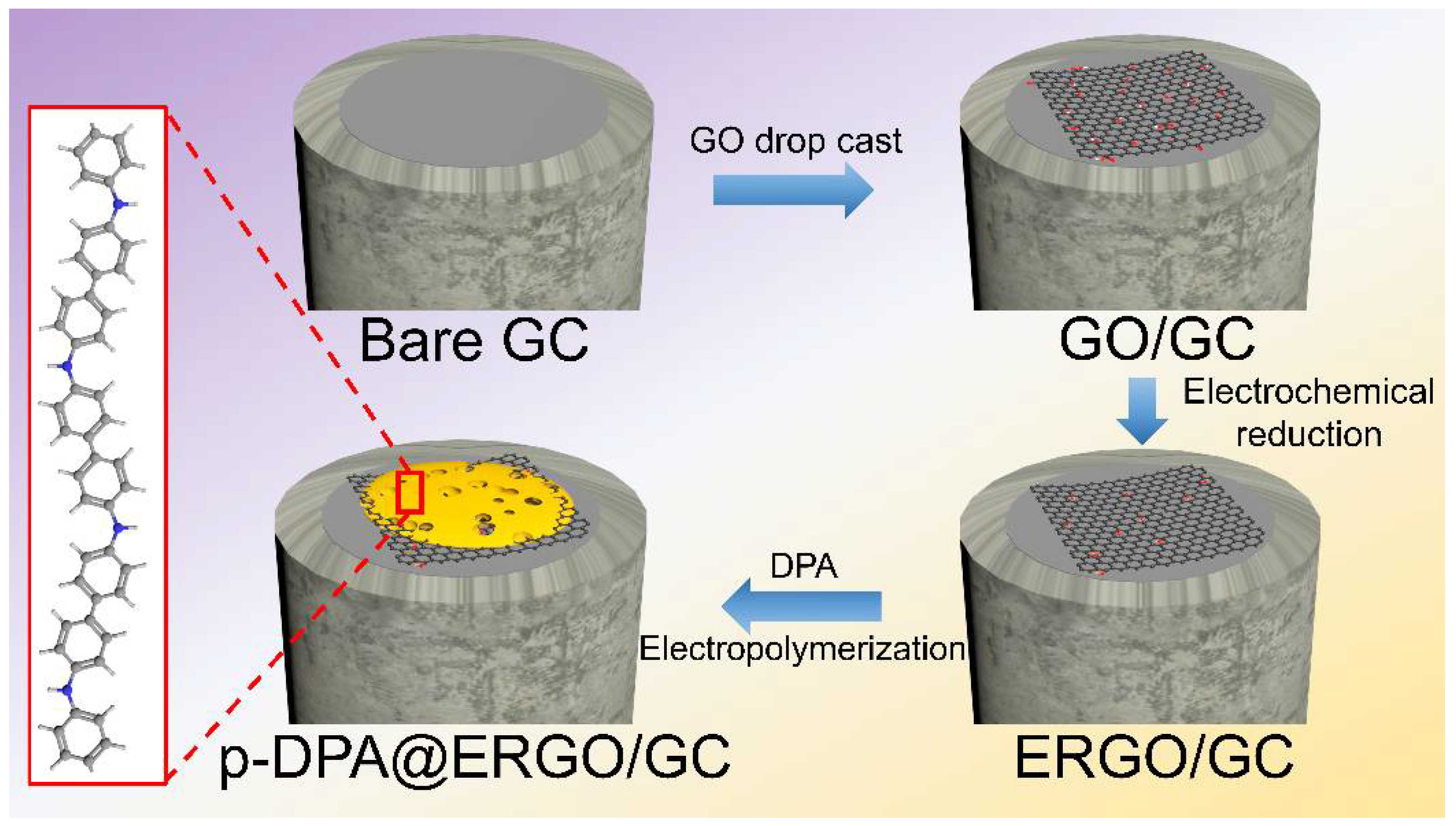

2.3. p-DPA@ERGO/GC Electrode Assembly

2.4. Instrumentation and Analytical Procedure

2.5. Real Sample Analysis Procedure

3. Results and Discussion

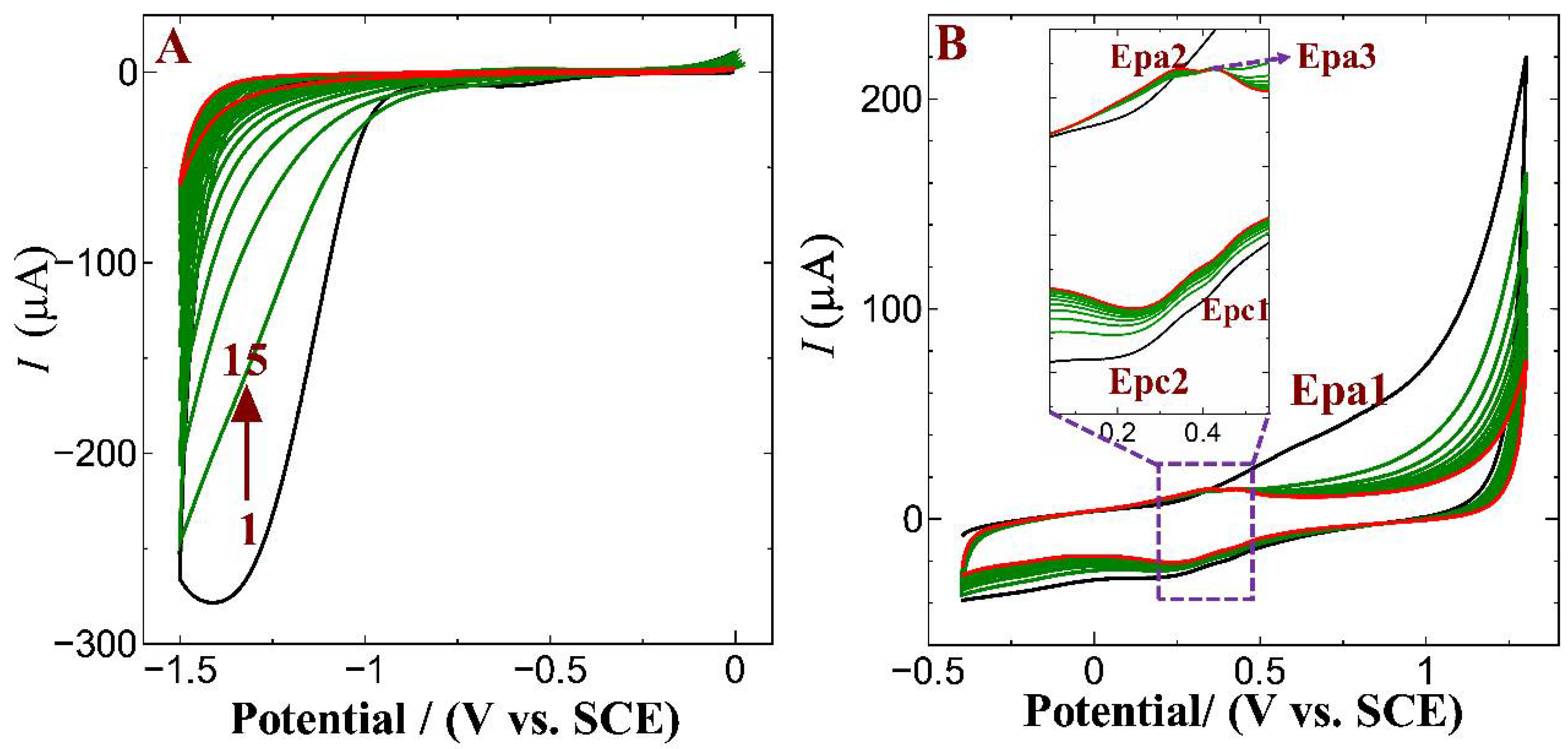

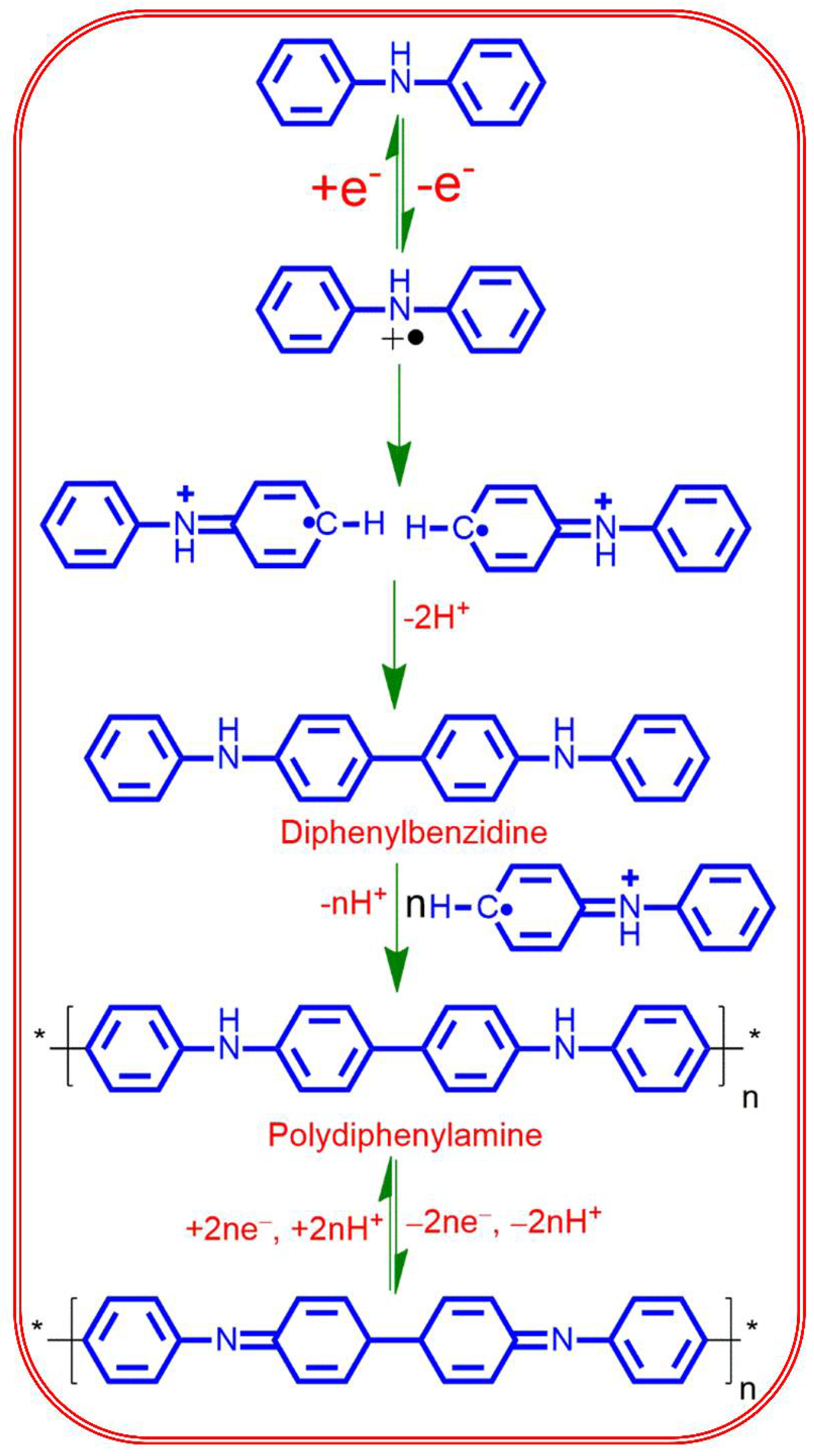

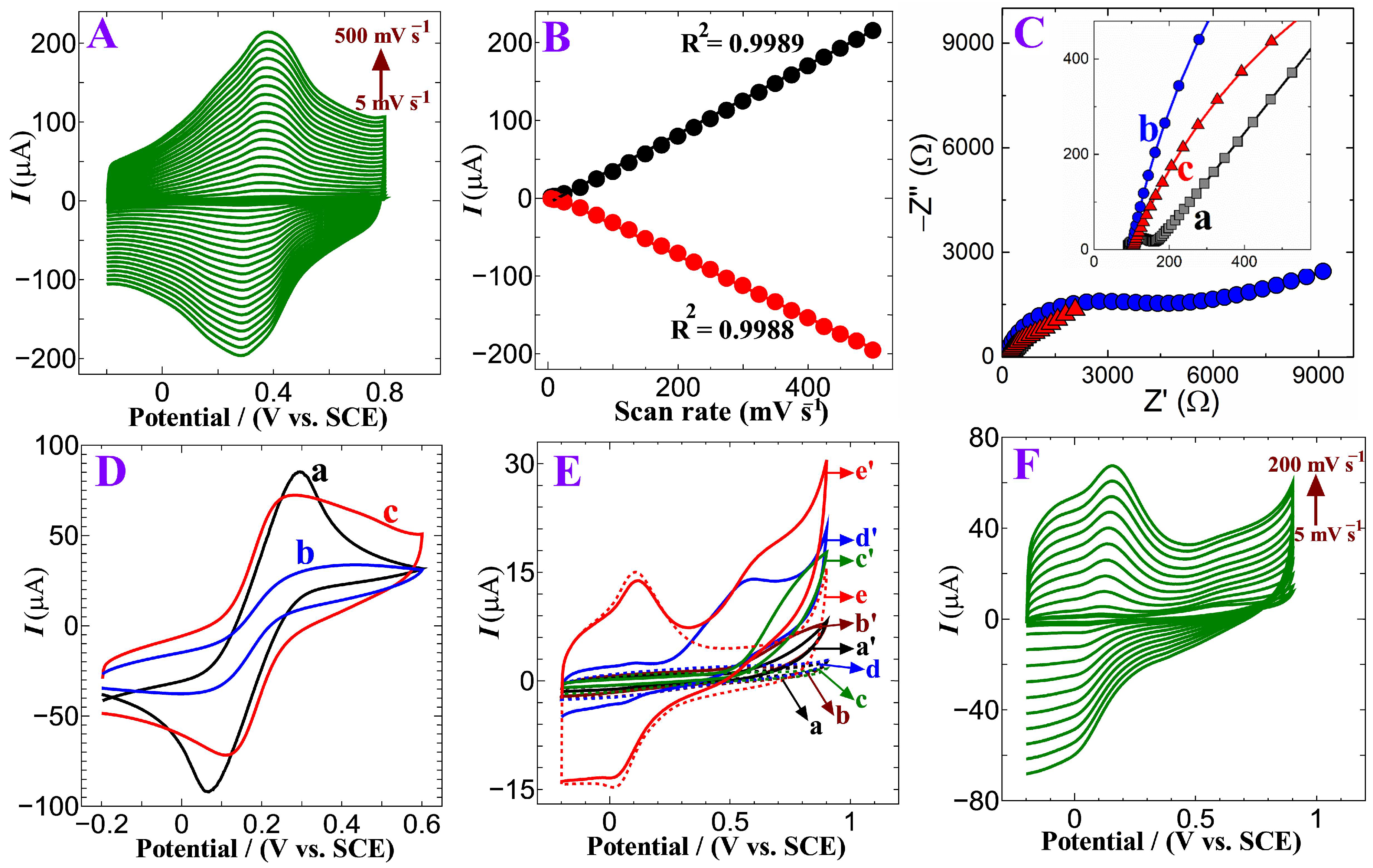

3.1. ERGO/GC and p-DPA@ERGO/GC Electrochemical Studies

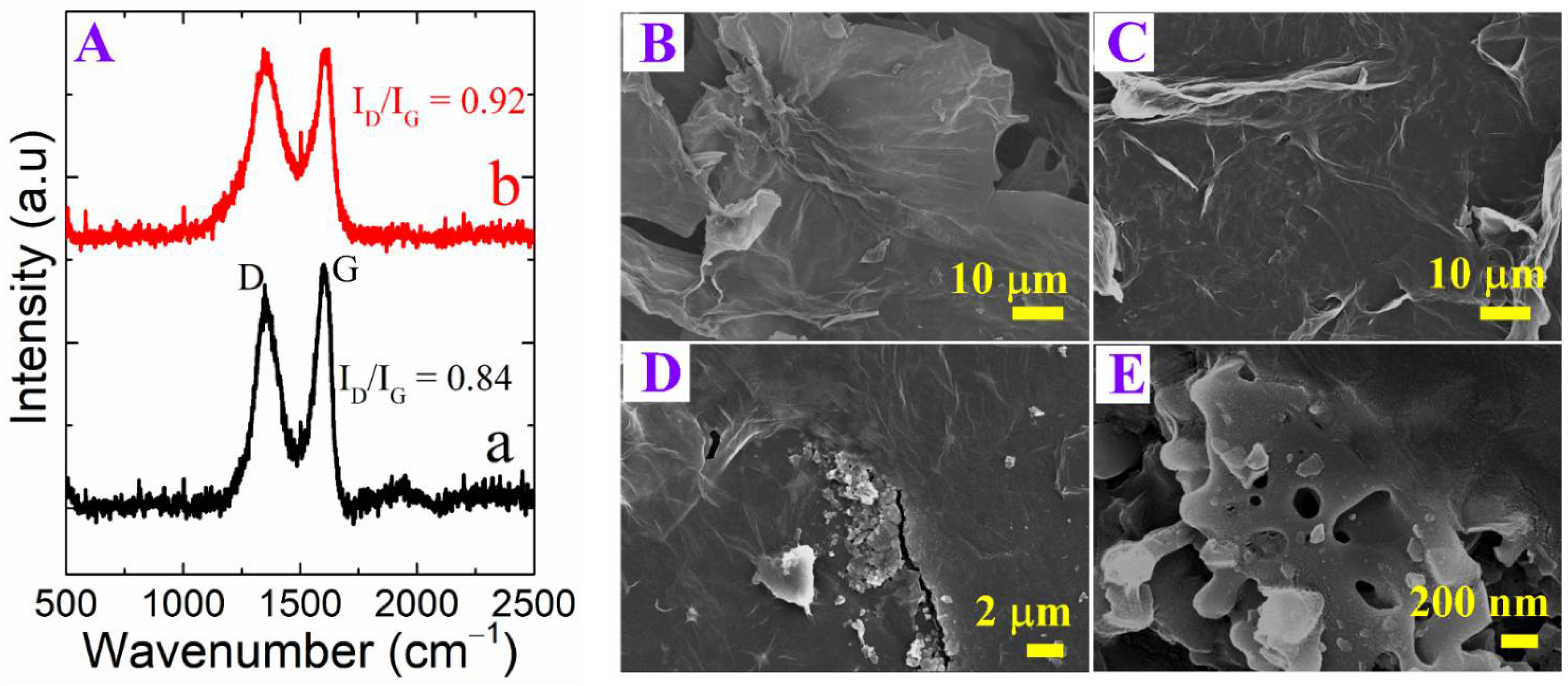

3.2. Structural and Surface Morphological Study

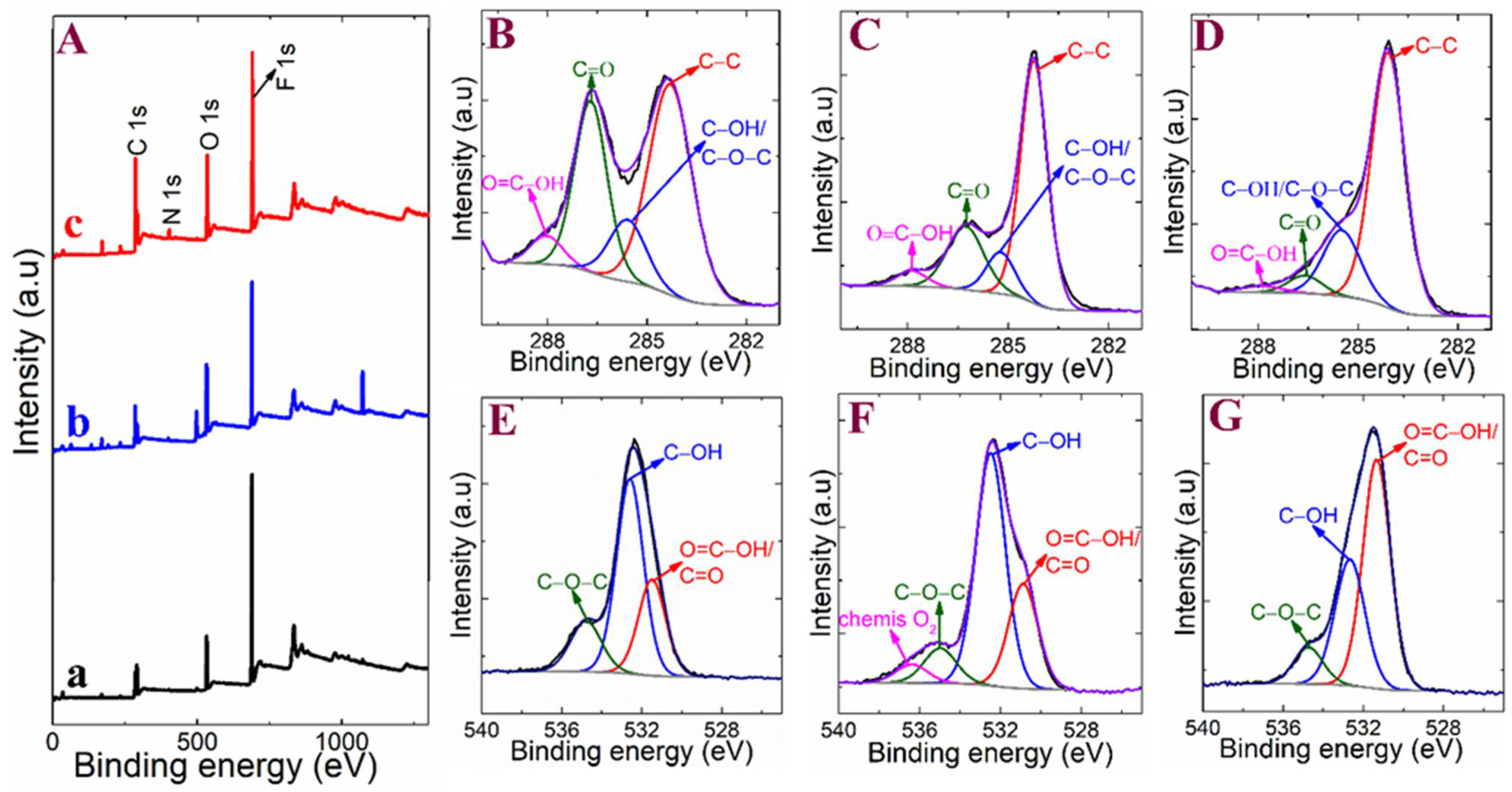

3.3. XRD and XPS Analysis

3.4. p-DPA@ERGO/GC Electrochemical Studies

3.5. Electrochemical Behavior of D-Penicillamine on Modified Electrodes

3.6. DPV and Amperometric Detection of PA

3.7. Selectivity, Repeatability, Reproducibility, and Storage Stability

3.8. Bio-Analytical Applications of p-DPA@ERGO/GC Electrode

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maziz, A.; Özgür, E.; Bergaud, C.; Uzun, L. Progress in conducting polymers for biointerfacing and biorecognition applications. Sens. Actuators Rep. 2021, 3, 100035. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Shao, Y.; Kaner, R.B. Graphene for batteries, supercapacitors and beyond. Nat. Rev. Mater. 2016, 1, 16033. [Google Scholar] [CrossRef]

- Shamkhalichenar, H.; Choi, J.-W. Review—Non-Enzymatic Hydrogen Peroxide Electrochemical Sensors Based on Reduced Graphene Oxide. J. Electrochem. Soc. 2020, 167, 037531. [Google Scholar] [CrossRef]

- He, B.; Yan, D. Au/ERGO nanoparticles supported on Cu-based metal-organic framework as a novel sensor for sensitive determination of nitrite. Food Control 2019, 103, 70–77. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, F.; Qian, L.; Xiao, J.; Wang, S.; Liu, Y. Facile Synthesis of 3D MnO2–Graphene and Carbon Nanotube–Graphene Composite Networks for High-Performance, Flexible, All-Solid-State Asymmetric Supercapacitors. Adv. Energy Mater. 2014, 4, 1400064. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, D. A One-Pot Route for Uniform Deposition of Metal Oxide and Metal Sulfide Nanoparticles on Reduced Graphene Oxide Using Supercritical Alcohols. ECS Meet. Abstr. 2016, MA2016-03, 992. [Google Scholar] [CrossRef]

- Kumar, D.R.; Dhakal, G.; Nguyen, V.Q.; Shim, J.-J. Molecularly imprinted hornlike polymer@electrochemically reduced graphene oxide electrode for the highly selective determination of an antiemetic drug. Anal. Chim. Acta 2021, 1141, 71–82. [Google Scholar] [CrossRef]

- Popov, A.; Aukstakojyte, R.; Gaidukevic, J.; Lisyte, V.; Kausaite-Minkstimiene, A.; Barkauskas, J.; Ramanaviciene, A. Reduced Graphene Oxide and Polyaniline Nanofibers Nanocomposite for the Development of an Amperometric Glucose Biosensor. Sensors 2021, 21, 948. [Google Scholar] [CrossRef]

- Kumar, D.R.; Kesavan, S.; Nguyen, T.T.; Hwang, J.; Lamiel, C.; Shim, J.-J. Polydopamine@electrochemically reduced graphene oxide-modified electrode for electrochemical detection of free-chlorine. Sens. Actuators B 2017, 240, 818–828. [Google Scholar] [CrossRef]

- Smaranda, I.; Benito, A.M.; Maser, W.K.; Baltog, I.; Baibarac, M. Electrochemical Grafting of Reduced Graphene Oxide with Polydiphenylamine Doped with Heteropolyanions and Its Optical Properties. J. Phys. Chem. C 2014, 118, 25704–25717. [Google Scholar] [CrossRef]

- Mu, S. The electrocatalytic oxidative polymerization of o-phenylenediamine by reduced graphene oxide and properties of poly(o-phenylenediamine). Electrochim. Acta 2011, 56, 3764–3772. [Google Scholar] [CrossRef]

- Obrezkov, F.A.; Shestakov, A.F.; Vasil’ev, S.G.; Stevenson, K.J.; Troshin, P.A. Polydiphenylamine as a promising high-energy cathode material for dual-ion batteries. J. Mater. Chem. A 2021, 9, 2864–2871. [Google Scholar] [CrossRef]

- Muthusankar, E.; Ponnusamy, V.K.; Ragupathy, D. Electrochemically sandwiched poly(diphenylamine)/phosphotungstic acid/graphene nanohybrid as highly sensitive and selective urea biosensor. Synth. Met. 2019, 254, 134–140. [Google Scholar] [CrossRef]

- Suganandam, K.; Santhosh, P.; Sankarasubramanian, M.; Gopalan, A.; Vasudevan, T.; Lee, K.-P. Fe3+ ion sensing characteristics of polydiphenylamine—Electrochemical and spectroelectrochemical analysis. Sens. Actuators B 2005, 105, 223–231. [Google Scholar] [CrossRef]

- Pugliese, M.; Biondi, V.; Gugliandolo, E.; Licata, P.; Peritore, A.F.; Crupi, R.; Passantino, A. D-Penicillamine: The State of the Art in Humans and in Dogs from a Pharmacological and Regulatory Perspective. Antibiotics 2021, 10, 648. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, A.P.; Wheeler, N.; Galindo, C.L.; Kim, J.-J. Safety profile of D-penicillamine: A comprehensive pharmacovigilance analysis by FDA adverse event reporting system. Expert Opin. Drug Saf. 2021, 20, 1443–1450. [Google Scholar] [CrossRef]

- Pitman, S.K.; Huynh, T.; Bjarnason, T.A.; An, J.; Malkhasyan, K.A. A case report and focused literature review of d-penicillamine and severe neutropenia: A serious toxicity from a seldom-used drug. Clin. Case Rep. 2019, 7, 990–994. [Google Scholar] [CrossRef]

- Joly, D.; Rieu, P.; Méjean, A.; Gagnadoux, M.-F.; Daudon, M.; Jungers, P. Treatment of cystinuria. Pediatr. Nephrol. 1999, 13, 945–950. [Google Scholar] [CrossRef]

- Dunea, G. Kidney Stones: Medical and Surgical Management. JAMA 1996, 276, 577. [Google Scholar] [CrossRef]

- Kuśmierek, K.; Bald, E. Simultaneous determination of tiopronin and d-penicillamine in human urine by liquid chromatography with ultraviolet detection. Anal. Chim. Acta 2007, 590, 132–137. [Google Scholar] [CrossRef]

- Ge, H.; Zhang, K.; Yu, H.; Yue, J.; Yu, L.; Chen, X.; Hou, T.; Alamry, K.A.; Marwani, H.M.; Wang, S. Sensitive and Selective Detection of Antibiotic D-Penicillamine Based on a Dual-Mode Probe of Fluorescent Carbon Dots and Gold Nanoparticles. J. Fluoresc. 2018, 28, 1405–1412. [Google Scholar] [CrossRef]

- Saracino, M.A.; Cannistraci, C.; Bugamelli, F.; Morganti, E.; Neri, I.; Balestri, R.; Patrizi, A.; Raggi, M.A. A novel HPLC-electrochemical detection approach for the determination of d-penicillamine in skin specimens. Talanta 2013, 103, 355–360. [Google Scholar] [CrossRef]

- Nazifi, M.; Ramezani, A.M.; Absalan, G.; Ahmadi, R. Colorimetric determination of D-penicillamine based on the peroxidase mimetic activity of hierarchical hollow MoS2 nanotubes. Sens. Actuators B 2021, 332, 129459. [Google Scholar] [CrossRef]

- Ibrahim, S.E.; Al-badr, A.A. Application of PMR Spectrometry in Quantitative Analysis of Penicillamine. Spectrosc. Lett. 1980, 13, 471–478. [Google Scholar] [CrossRef]

- Yusof, M.; Neal, R.; Aykin, N.; Ercal, N. High performance liquid chromatography analysis of D-penicillamine by derivatization with N-(1-pyrenyl)maleimide (NPM). Biomed. Chromatogr. 2000, 14, 535–540. [Google Scholar] [CrossRef]

- Rushing, L.G.; Hansen, E.B., Jr.; Thompson, H.C., Jr. Analysis of D-penicillamine by gas chromatography utilizing nitrogen--phosphorus detection. J. Chromatogr. 1985, 337, 37–46. [Google Scholar] [CrossRef]

- Yu, H.; Chen, X.; Yu, L.; Sun, M.; Alamry, K.A.; Asiri, A.M.; Zhang, K.; Zapien, J.A.; Wang, S. Fluorescent MUA-stabilized Au nanoclusters for sensitive and selective detection of penicillamine. Anal. Bioanal. Chem. 2018, 410, 2629–2636. [Google Scholar] [CrossRef]

- Gunjal, D.B.; Gore, A.H.; Naik, V.M.; Pawar, S.P.; Anbhule, P.V.; Shejwal, R.V.; Kolekar, G.B. Carbon dots as a dual sensor for the selective determination of d-penicillamine and biological applications. Opt. Mater. 2019, 88, 134–142. [Google Scholar] [CrossRef]

- Kumar, D.R.; Baynosa, M.L.; Dhakal, G.; Shim, J.-J. Sphere-like Ni3S4/NiS2/MoOx composite modified glassy carbon electrode for the electrocatalytic determination of d-penicillamine. J. Mol. Liq. 2020, 301, 112447. [Google Scholar] [CrossRef]

- Liu, Z.; Kuang, X.; Sun, X.; Zhang, Y.; Wei, Q. Electrochemical enantioselective recognition penicillamine isomers based on chiral C-dots/MOF hybrid arrays. J. Electroanal. Chem. 2019, 846, 113151. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.-Y.; He, X.-W.; Li, W.-Y.; Zhang, Y.-K. Homochiral fluorescence responsive molecularly imprinted polymer: Highly chiral enantiomer resolution and quantitative detection of L-penicillamine. J. Hazard. Mater. 2021, 412, 125249. [Google Scholar] [CrossRef]

- Alkahtani, S.A.; Mahmoud, A.M.; El-Wekil, M.M. Electrochemical sensing of copper-chelator D- penicillamine based on complexation with gold nanoparticles modified copper based-metal organic frameworks. J. Electroanal. Chem. 2022, 908, 116102. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Kairy, P.; Hossain, M.M.; Khan, M.A.R.; Almahri, A.; Rahman, M.M.; Hasnat, M.A. Electrocatalytic oxidation of ascorbic acid in the basic medium over electrochemically functionalized glassy carbon surface. Surf. Interfaces 2022, 33, 102200. [Google Scholar] [CrossRef]

- Islam, M.T.; Hasan, M.M.; Shabik, M.F.; Islam, F.; Nagao, Y.; Hasnat, M.A. Electroless deposition of gold nanoparticles on a glassy carbon surface to attain methylene blue degradation via oxygen reduction reactions. Electrochim. Acta 2020, 360, 136966. [Google Scholar] [CrossRef]

- Tsai, T.-H.; Ku, S.-H.; Chen, S.-M.; Lou, B.-S.; Ali, M.A.; Al-Hemaid, F.M.A. Electropolymerized Diphenylamine on Functionalized Multiwalled Carbon Nanotube Composite Film and Its Application to Develop a Multifunctional Biosensor. Electroanalysis 2014, 26, 399–408. [Google Scholar] [CrossRef]

- Wang, X.; Kholmanov, I.; Chou, H.; Ruoff, R.S. Simultaneous Electrochemical Reduction and Delamination of Graphene Oxide Films. ACS Nano 2015, 9, 8737–8743. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, Y.; Zhai, Y.; Zhai, J.; Ren, W.; Wang, F.; Dong, S. Controlled synthesis of large-area and patterned electrochemically reduced graphene oxide films. Eur. J. Chem. 2009, 15, 6116–6120. [Google Scholar] [CrossRef]

- Toh, S.Y.; Loh, K.S.; Kamarudin, S.K.; Daud, W.R.W. Graphene production via electrochemical reduction of graphene oxide: Synthesis and characterisation. Chem. Eng. J. 2014, 251, 422–434. [Google Scholar] [CrossRef]

- Cançado, L.G.; Takai, K.; Enoki, T.; Endo, M.; Kim, Y.A.; Mizusaki, H.; Jorio, A.; Coelho, L.N.; Magalhães-Paniago, R.; Pimenta, M.A. General equation for the determination of the crystallite size La of nanographite by Raman spectroscopy. Appl. Phys. Lett. 2006, 88, 163106. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Malolepszy, A.; Mazurkiewicz, M.; Mierzwa, B.; Zemek, J.; Jiricek, P.; Bieloshapka, I. Graphene oxide and reduced graphene oxide studied by the XRD, TEM and electron spectroscopy methods. J. Electron. Spectrosc. Relat. Phenom. 2014, 195, 145–154. [Google Scholar] [CrossRef]

- Oh, Y.J.; Yoo, J.J.; Kim, Y.I.; Yoon, J.K.; Yoon, H.N.; Kim, J.-H.; Park, S.B. Oxygen functional groups and electrochemical capacitive behavior of incompletely reduced graphene oxides as a thin-film electrode of supercapacitor. Electrochim. Acta 2014, 116, 118–128. [Google Scholar] [CrossRef]

- Marinho, M.I.C.; Cabral, M.F.; Mazo, L.H. Is the poly (methylene blue)-modified glassy carbon electrode an adequate electrode for the simple detection of thiols and amino acid-based molecules? J. Electroanal. Chem. 2012, 685, 8–14. [Google Scholar] [CrossRef]

- Hatamie, A.; Rahmati, R.; Rezvani, E.; Angizi, S.; Simchi, A. Yttrium Hexacyanoferrate Microflowers on Freestanding Three-Dimensional Graphene Substrates for Ascorbic Acid Detection. ACS Appl. Nano Mater. 2019, 2, 2212–2221. [Google Scholar] [CrossRef]

- Ghaffarinejad, A.; Hashemi, F.; Nodehi, Z.; Salahandish, R. A simple method for determination of d-penicillamine on the carbon paste electrode using cupric ions. Bioelectrochemistry 2014, 99, 53–56. [Google Scholar] [CrossRef]

- Hou, Y.; Liang, J.; Kuang, X.; Kuang, R. Simultaneous electrochemical recognition of tryptophan and penicillamine enantiomers based on MOF-modified β-CD. Carbohydr. Polym. 2022, 290, 119474. [Google Scholar] [CrossRef]

- Parisa, B.; Shishehbore, M.R.; Beitollahi, H.; Sheibani, A. The Application of Ferrocene Derivative and CeO–ZnO Nanocomposite-Modified Carbon Paste Electrode for Simultaneous Detection of Penicillamine and Tryptophan. Russ. J. Electrochem. 2022, 58, 235–247. [Google Scholar] [CrossRef]

- Raoof, J.-B.; Ojani, R.; Majidian, M.; Chekin, F. Voltammetric determination of D-penicillamine based on its homogeneous electrocatalytic oxidation with potassium iodide at the surface of glassy carbon electrode. Russ. J. Electrochem. 2010, 46, 1395–1401. [Google Scholar] [CrossRef]

- Jafari, M.; Tashkhourian, J.; Absalan, G. Electrochemical sensing of D-penicillamine on modified glassy carbon electrode by using a nanocomposite of gold nanoparticles and reduced graphene oxide. J. Iran. Chem. Soc. 2017, 14, 1253–1262. [Google Scholar] [CrossRef]

- Torriero, A.A.J.; Piola, H.D.; Martínez, N.A.; Panini, N.V.; Raba, J.; Silber, J.J. Enzymatic oxidation of tert-butylcatechol in the presence of sulfhydryl compounds: Application to the amperometric detection of penicillamine. Talanta 2007, 71, 1198–1204. [Google Scholar] [CrossRef]

- Mazloum-Ardakani, M.; Beitollahi, H.; Taleat, Z.; Naeimi, H.; Taghavinia, N. Selective voltammetric determination of d-penicillamine in the presence of tryptophan at a modified carbon paste electrode incorporating TiO2 nanoparticles and quinizarine. J. Electroanal. Chem. 2010, 644, 1–6. [Google Scholar] [CrossRef]

| Electrode | Method | Linear Range (µM) | Limit of Detection (µM) | Ref. |

|---|---|---|---|---|

| Cu2+/carbon paste electrode | CV | 1–1000 | 0.1 | [45] |

| β-CD@Ca-sacc/MeOH/GC a | DPV | 100–500 | 0.79 | [46] |

| CeO–ZnO/ILFCPE b | DPV | 0.02–25.0 | 0.01 | [47] |

| KI/GC | DPV | 9.0–120 | 3.5 | [48] |

| AuNPs/RGO c | DPV | 5.0–110 | 3.9 | [49] |

| t-Butylcatecho/GC | Amperometry | 0.02–80 | 0.007 | [50] |

| Quinizarine/TiO2/CPE | SWV d | 0.8–140 | 0.76 | [51] |

| p-DPA@ERGO/GC | Amperometry | 1.4–541 | 0.10 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranjith Kumar, D.; Rajesh, K.; Sayed, M.S.; Milton, A.; Shim, J.-J. Development of Polydiphenylamine@Electrochemically Reduced Graphene Oxide Electrode for the D-Penicillamine Sensor from Human Blood Serum Samples Using Amperometry. Polymers 2023, 15, 577. https://doi.org/10.3390/polym15030577

Ranjith Kumar D, Rajesh K, Sayed MS, Milton A, Shim J-J. Development of Polydiphenylamine@Electrochemically Reduced Graphene Oxide Electrode for the D-Penicillamine Sensor from Human Blood Serum Samples Using Amperometry. Polymers. 2023; 15(3):577. https://doi.org/10.3390/polym15030577

Chicago/Turabian StyleRanjith Kumar, Deivasigamani, Kuppusamy Rajesh, Mostafa Saad Sayed, Ahamed Milton, and Jae-Jin Shim. 2023. "Development of Polydiphenylamine@Electrochemically Reduced Graphene Oxide Electrode for the D-Penicillamine Sensor from Human Blood Serum Samples Using Amperometry" Polymers 15, no. 3: 577. https://doi.org/10.3390/polym15030577

APA StyleRanjith Kumar, D., Rajesh, K., Sayed, M. S., Milton, A., & Shim, J.-J. (2023). Development of Polydiphenylamine@Electrochemically Reduced Graphene Oxide Electrode for the D-Penicillamine Sensor from Human Blood Serum Samples Using Amperometry. Polymers, 15(3), 577. https://doi.org/10.3390/polym15030577