1. Introduction

Advances in aerospace technology have led to the development of composite materials that feature properties that rival or even surpass those of traditional materials, notably fiber-reinforced polymers (FRPs). FRPs are renowned for their remarkable attributes, including a high strength-to-weight ratio, exceptional durability, stiffness, and resistance to corrosion, wear, and impact. However, these high-performance FRP composite structures face a formidable challenge—vibrations induced by dynamic loads. These vibrations often lead to resonance conditions and the risk of catastrophic failures, exacerbated by insufficient damping characteristics. In response to these critical challenges, the development of smart materials has emerged, with alternative materials aiming to enhance the performance, structural integrity, and overall comfort of composite structures. Among these smart materials, MR materials have gained prominence due to their field-dependent rheological properties [

1,

2].

In the past decade, magneto-rheological materials have gained significant attention, surpassing electrorheological (ER) materials. This shift in interest is attributed to their superior yield strength, resilience to temperature variations, and tolerance to contaminants compared to ER fluids, making them ideal for controlling structural vibrations. Significant research endeavors have focused on evaluating both the properties and practical applications of MR fluids in the domain of structural vibration control [

3,

4]. However, the use of MR fluids is constrained by issues such as the accumulation of iron particles in the absence of a magnetic field and their relatively high production costs. While MR gels and grease offer an exceptional performance, they are susceptible to issues like sedimentation, deposition, environmental pollution, and sealing problems [

5,

6]. In contrast, MR elastomers (MREs), featuring rubber as their matrix material, excel in surmounting these challenges. They exhibit swift and reversible transformations, tunable stiffness, and advantageous viscoelastic properties in response to magnetic field application [

7]. MREs provide several advantages, including lower manufacturing costs and the absence of iron particle accumulation, making them an appealing choice for various engineering applications.

In the development of magnetorheological elastomers (MREs), their composition plays a pivotal role in shaping their characteristics. Chen et al. [

8] emphasized the significant impact of both the applied magnetic field and the iron particle content on MRE damping properties, offering insights into the intricate interplay between magnetic field intensity and material composition. The essential structure of MREs, characterized by a matrix of rubber intricately mixed with dispersed magnetic particles, has been elucidated by various researchers [

9,

10], highlighting the critical role of this composite structure in shaping MRE behavior. Several variables come into play when molding the properties of MREs, including the choice of magnetic filler material, the matrix type, and the compatibility of the magnetic filler with the matrix. Typically, iron particles of diverse shapes and sizes, exhibiting ferromagnetic properties with high magnetic saturation and soft magnetic attributes, emerge as the preferred choice for MREs [

8,

11]. Furthermore, the exceptional magnetorheological performance of MREs can be attributed to the synergy between magnetic fillers and the matrix material [

12]. Chen et al. has demonstrated that natural-rubber-based MREs surpass silicone-rubber-based counterparts in terms of various properties, including their tear strength, tensile strength, resilience factor, and hardness [

13]. Investigating isotropic synthetic-rubber-based MREs, as shown by Gong et al., shows an impressive 26% enhancement in the magnetorheological (MR) effect with the incorporation of a 0.6 volume fraction of carbonyl iron (CI) particles. This enhancement undoubtedly signifies a marked improvement in the material’s rheological behavior. However, it does introduce a trade-off, as it entails a reduction in the material’s elastic properties [

14]. This reduction in elasticity could be of concern, especially in structural applications where the ability to isolate vibrations is of paramount importance. MREs with diminished elastic properties may struggle to obtain the necessary stiffness and structural integrity required to safeguard the overall system’s performance and reliability.

To overcome the limitations posed by the reduced elastic properties in magnetorheological elastomers (MREs), extensive research has focused on incorporating various additives, including plasticizers, silane coupling agents, and nano-sized particles like carbon black, carbon nanotubes, and graphene [

15,

16,

17,

18,

19]. These additives serve to enhance the mechanical properties of MREs by reinforcing the interfacial interactions between fillers and the elastomeric matrix; however, they are not exempt from significant challenges. One of these challenges lies in the propensity of these fillers, particularly when in nano-sized forms, to agglomerate within the elastomeric matrix [

20]. This phenomenon not only complicates the manufacturing process but also increases costs, particularly in the case of nanomaterials [

21]. Ensuring compatibility between the chosen fillers and the matrix material, as well as addressing processing intricacies and potential health and environmental concerns, emerges as crucial considerations in MRE development. Achieving the delicate equilibrium between attaining desired properties and managing these inherent limitations constitutes a challenging task. Consequently, researchers are compelled to continually explore novel materials and innovative techniques, with the aim of optimizing MRE composites for a diverse array of applications.

In recent years, researchers have embarked on an exploration of the untapped potential within hybrid matrix magnetorheological elastomer (MRE) composites, aiming to conquer the persistent challenges posed by nanofillers and the relatively modest mechanical properties inherent in conventional MREs. This innovative approach has opened up a promising pathway for addressing the challenges associated with nanofillers and the relatively low mechanical properties observed in conventional MREs [

22,

23,

24].

Researchers aimed to find a balance between the mechanical performance and magnetorheological (MR) effect by using NR and PBR by addressing a common challenge in MRE development. NR-based MREs excel in terms of their mechanical properties but often fall short in terms of the required MR effect for industrial applications. In contrast, PBR-based MREs exhibit a high MR effect but suffer from inferior mechanical properties. The synergy between NR’s excellent synthetic mechanical performance and PBR’s desirable characteristics, including high elasticity, low heat buildup, cold resistance, and flex fatigue resistance, allows for the development of hybrid matrices that capitalize on the strengths of both materials. This harmonious blend results in improved compatibility, as NR and PBR share active cross-linking spots and possess similar vulcanization mechanisms and curing rates [

25]. Song et al.’s research reveals that increasing polybutadiene rubber (PBR) content from 10% to 50% results in a minor decrease in the zero-field modulus, accompanied by a substantial enhancement in the magneto-rheological (MR) effect, ranging from 31.25% to 44.19% [

25]. This work underscores the trade-off between these critical material properties in hybrid MREs, with implications for future applications. Several works on matrix materials incorporating blends of NR/styrene–butadiene rubber (SBR) and NR/nitrile butadiene rubber (NBR) reveals improved mechanical properties when compared to a matrix composed of only NR or NBR [

26]. Pal et al. showed that blends of urethane rubber (UR)/NR and PBR/NR exhibited a 35–40% enhancement in mechanical properties [

27]. The study by Ge et al. revealed that the incorporation of rosin glycerin ester into natural rubber/rosin glycerin hybrid-matrix-based MREs resulted in an increase in the zero-field modulus (G

0) at a 9% concentration, but this effect diminished at higher concentrations. Furthermore, an increase in carbon iron (CI) content led to a substantial 575% improvement in G

0 at 80 wt%. Additionally, the application of a magnetic field intensified interparticle forces within CI-based MREs, highlighting the potential for tailoring the mechanical properties of these materials for diverse engineering applications [

28].

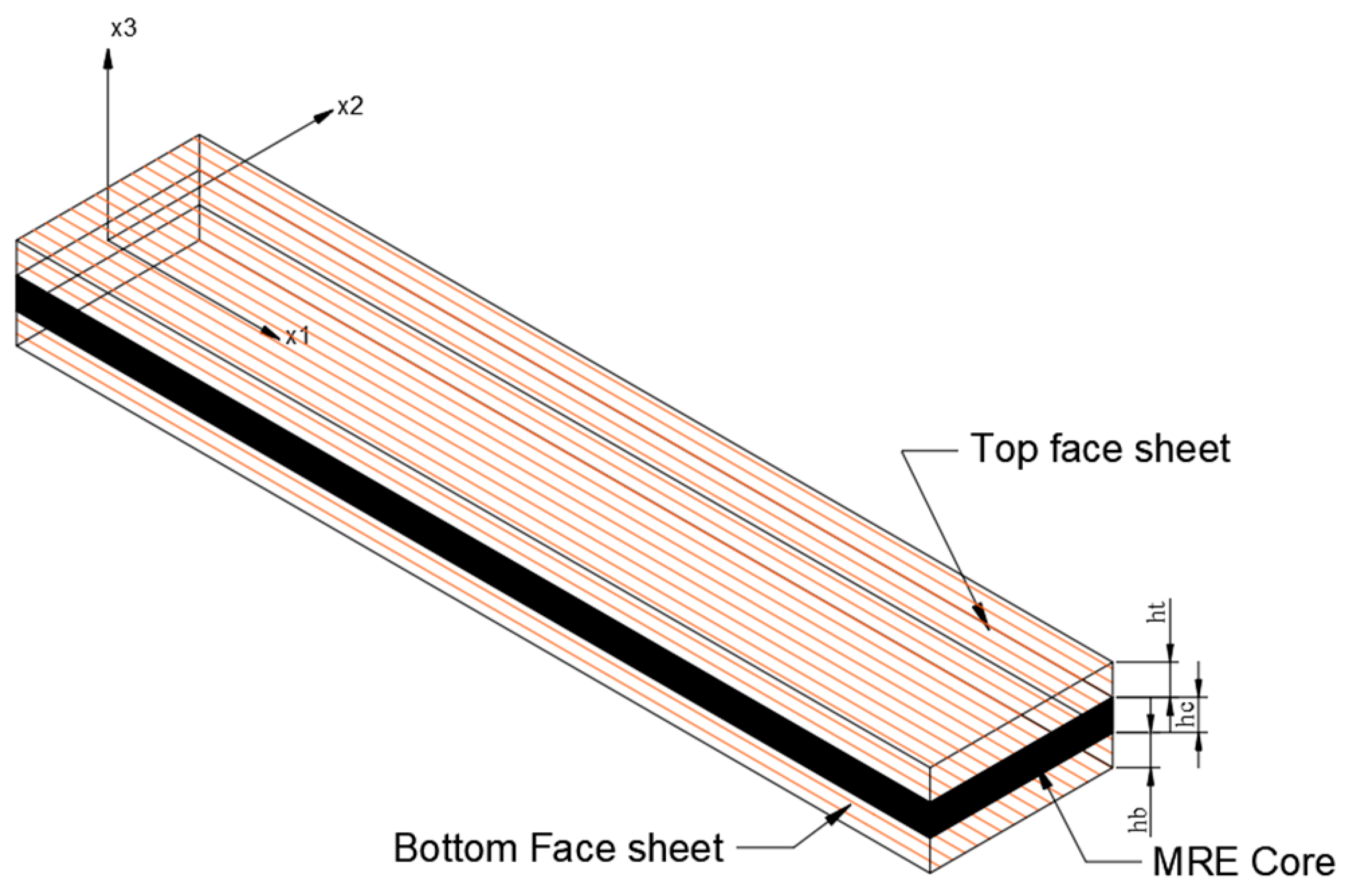

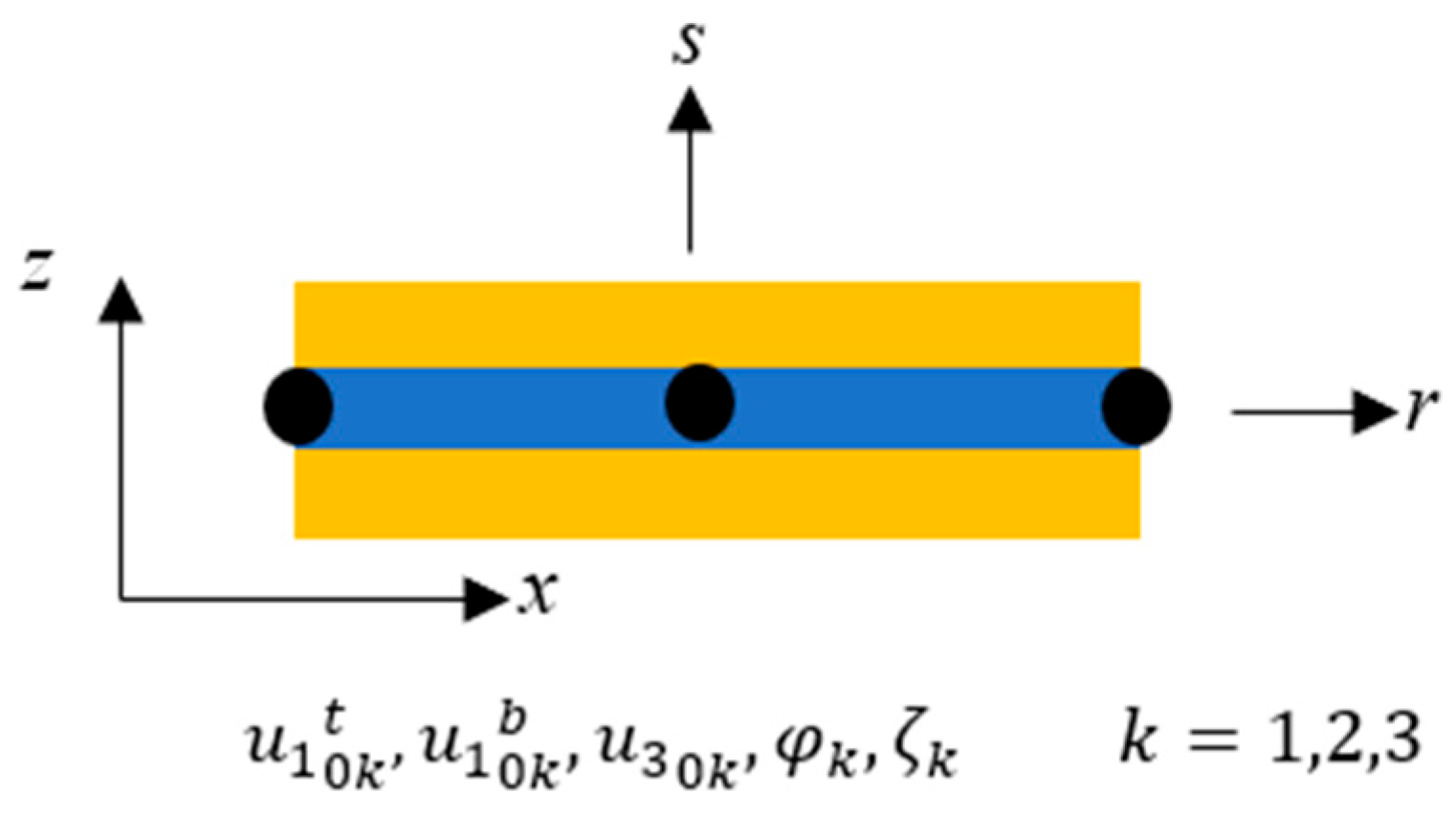

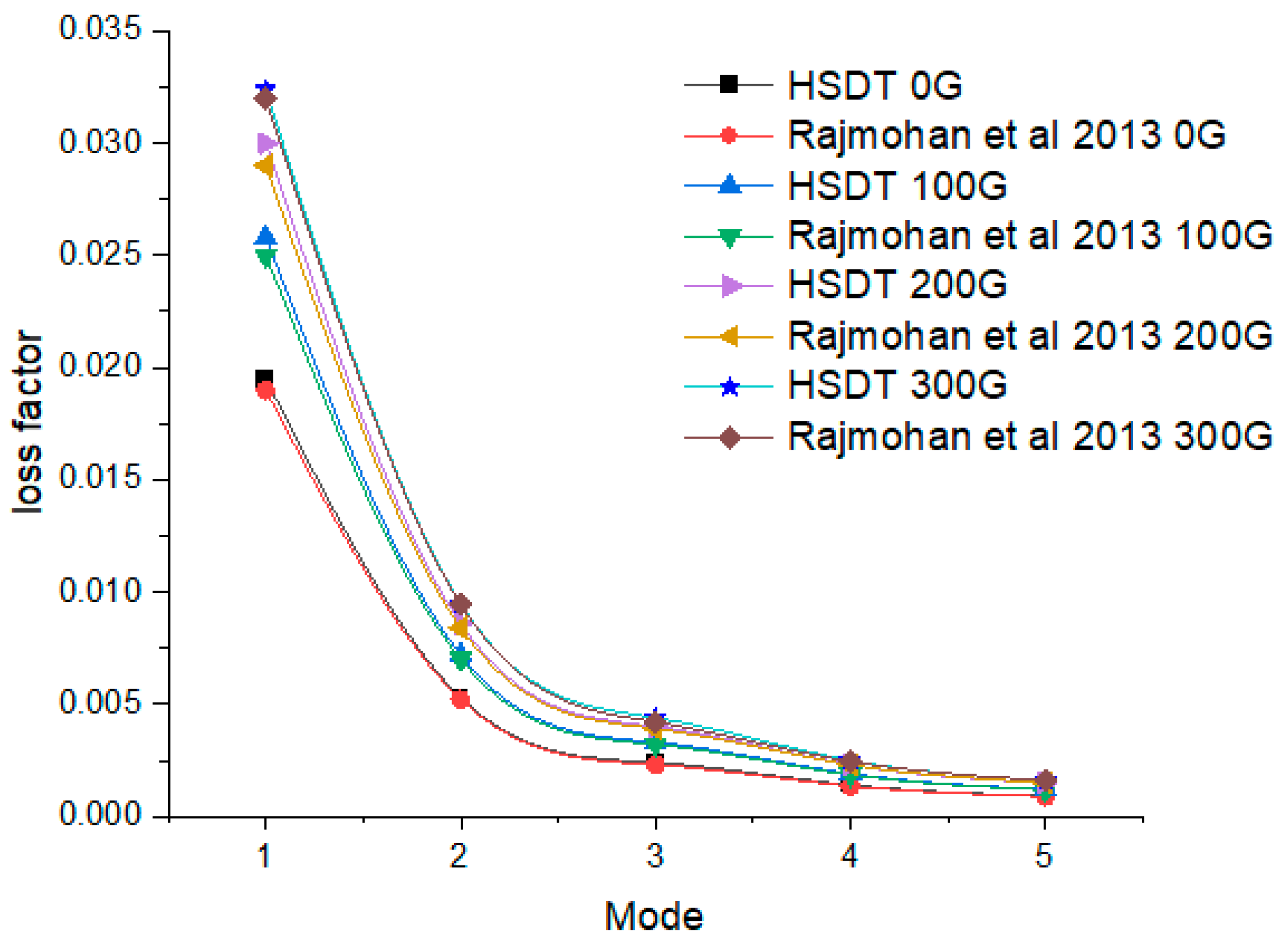

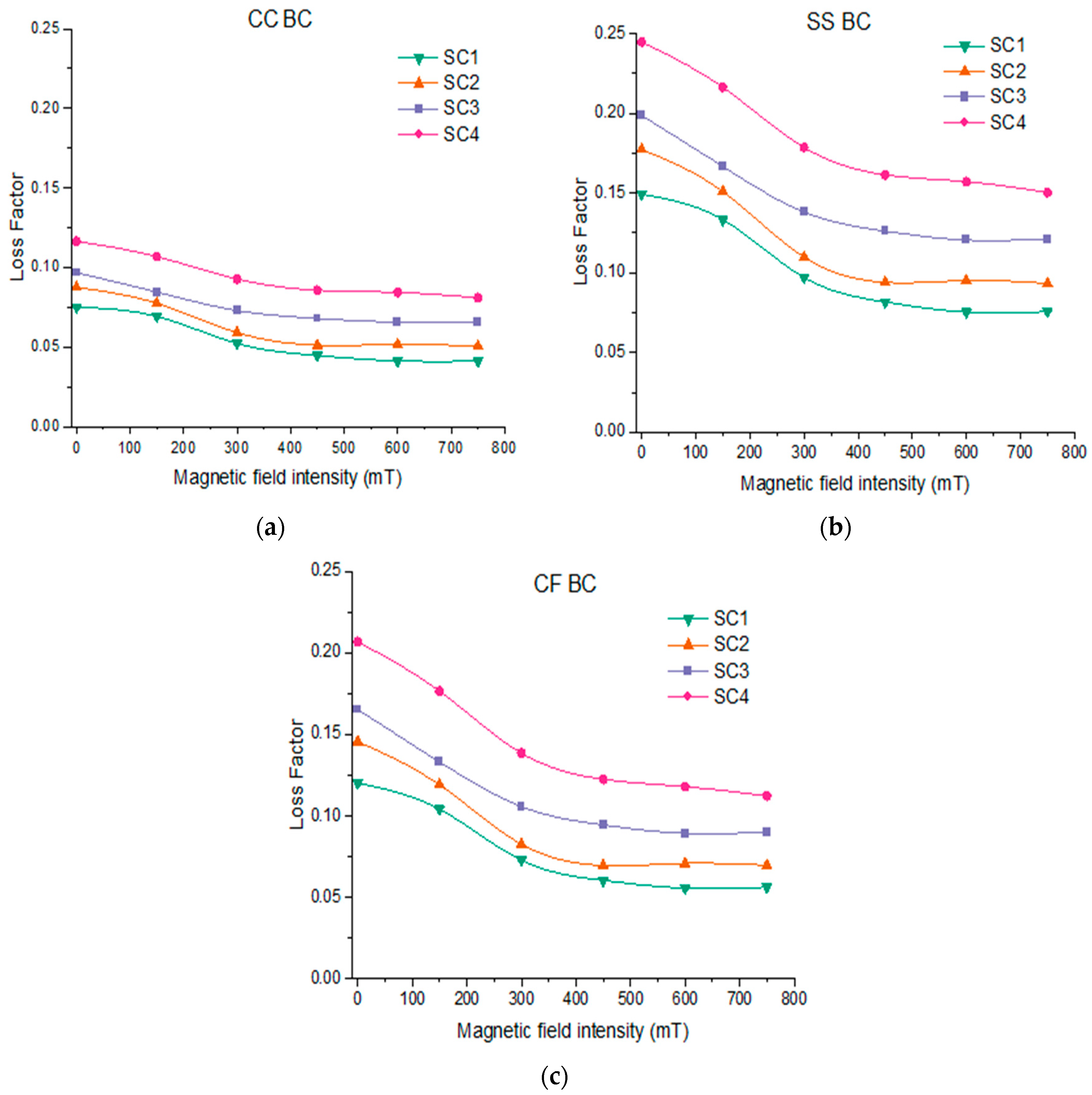

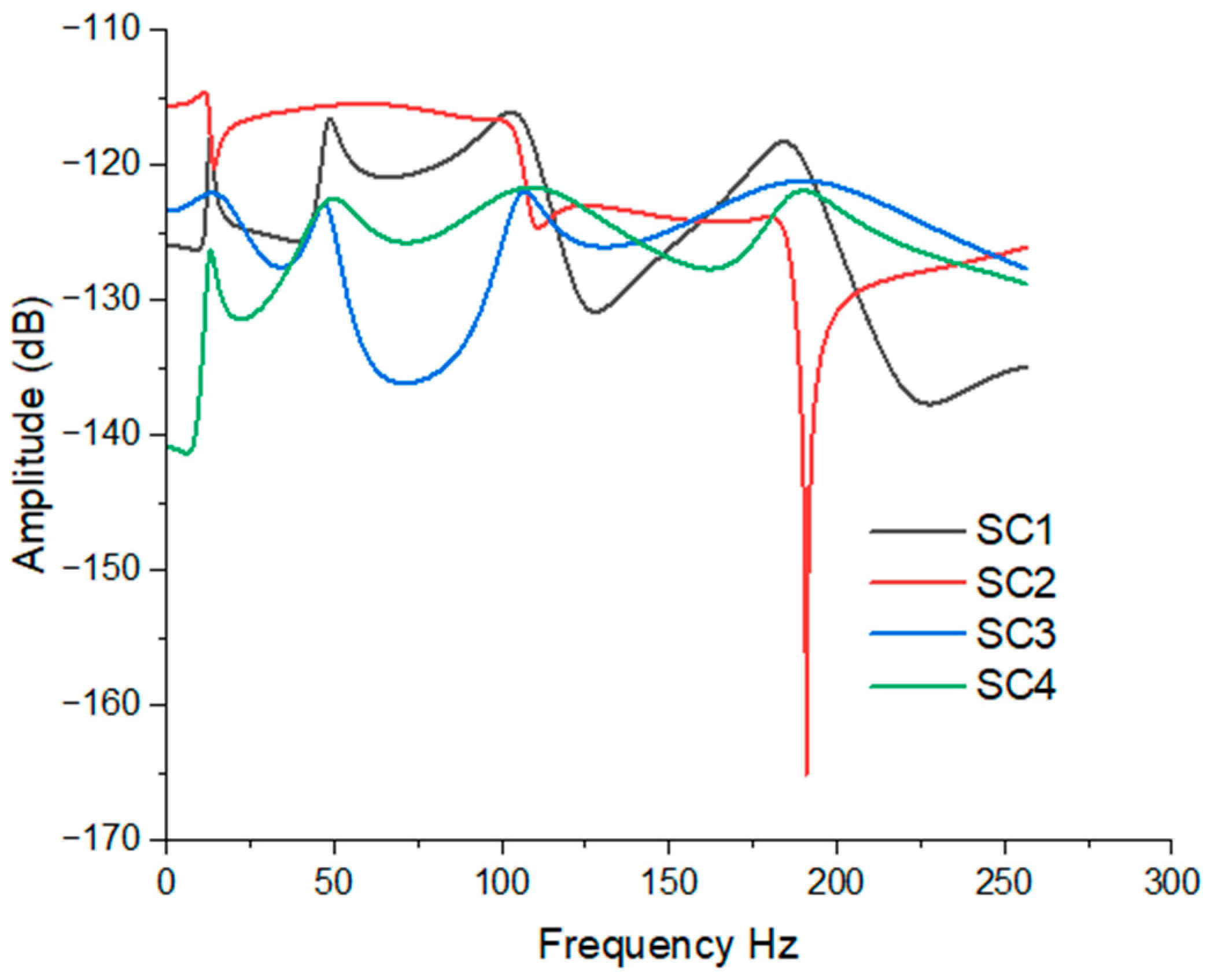

Previous research into the hybrid matrix MREs has made limited progress in comprehending their mechanical properties, rheological properties and dynamic behavior. There is a clear absence of both mathematical approaches and experimental investigations analyzing the dynamic behavior of hybrid MRE composites. In the present study, the dynamic characteristics of NR/PBR-based hybrid magnetorheological (MR) elastomer sandwich composite beams are investigated using numerical simulations. This investigation considers various compositions of NR and PBR to develop finite element equations for the sandwich composite beam. The potential energy and kinetic energy equations for the hybrid elastomer sandwich composite beam with FRP face sheets, employing Reddy’s third-order shear deformation theory, are derived. Remarkably, there is a lack of research on the dynamic study of hybrid MRE sandwich composite structures. To address this gap, the governing differential equations of motion for the hybrid MRE sandwich composite beam are established, considering various compositions of the NR/PBR matrix. These equations are presented using a three-node line element with five degrees of freedom at each node. To validate the finite element simulations, the results are compared with the existing data on MR fluids that are available in the literature. Additionally, the study examines the dynamic characteristics of various configurations of hybrid MRE sandwich composite beams under the influence of magnetic field intensity, ply orientation, core thickness, and boundary conditions.

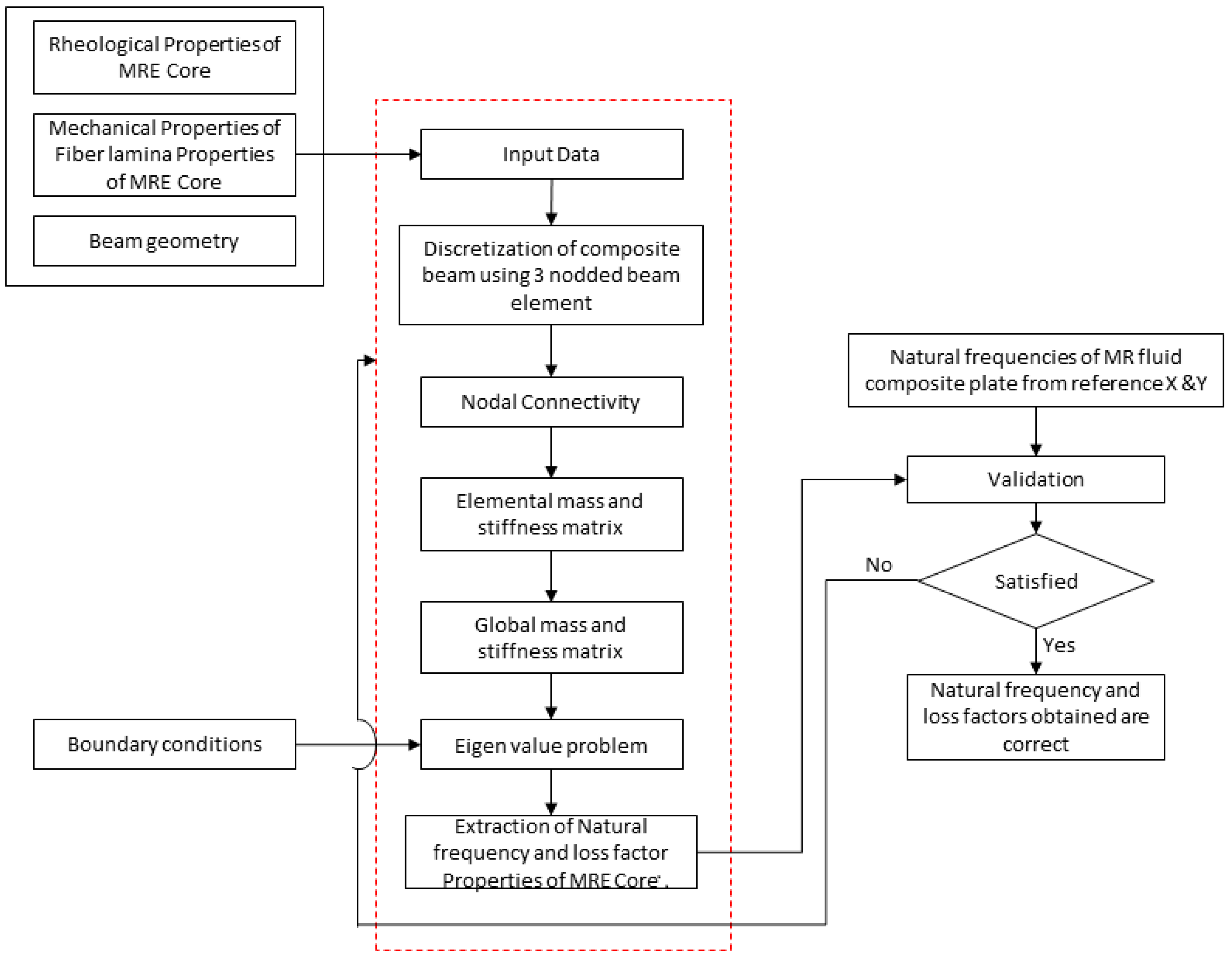

Figure 1 outlines the various steps involved in the numerical simulation of hybrid MRE sandwich composites, representing a concerted effort to gain a deeper understanding of the characteristics of these structures.