1. Introduction

Investment casting (IC), also referred to as lost wax casting or precision casting, is a near-net shape process of manufacturing complex metal geometries. IC can be used to cast non-ferrous and ferrous metals and produces parts with high dimensional accuracy and excellent surface finish. IC is widely used in numerous industries including automotive, aerospace, medicine, military, jewelry, and energy sectors [

1].

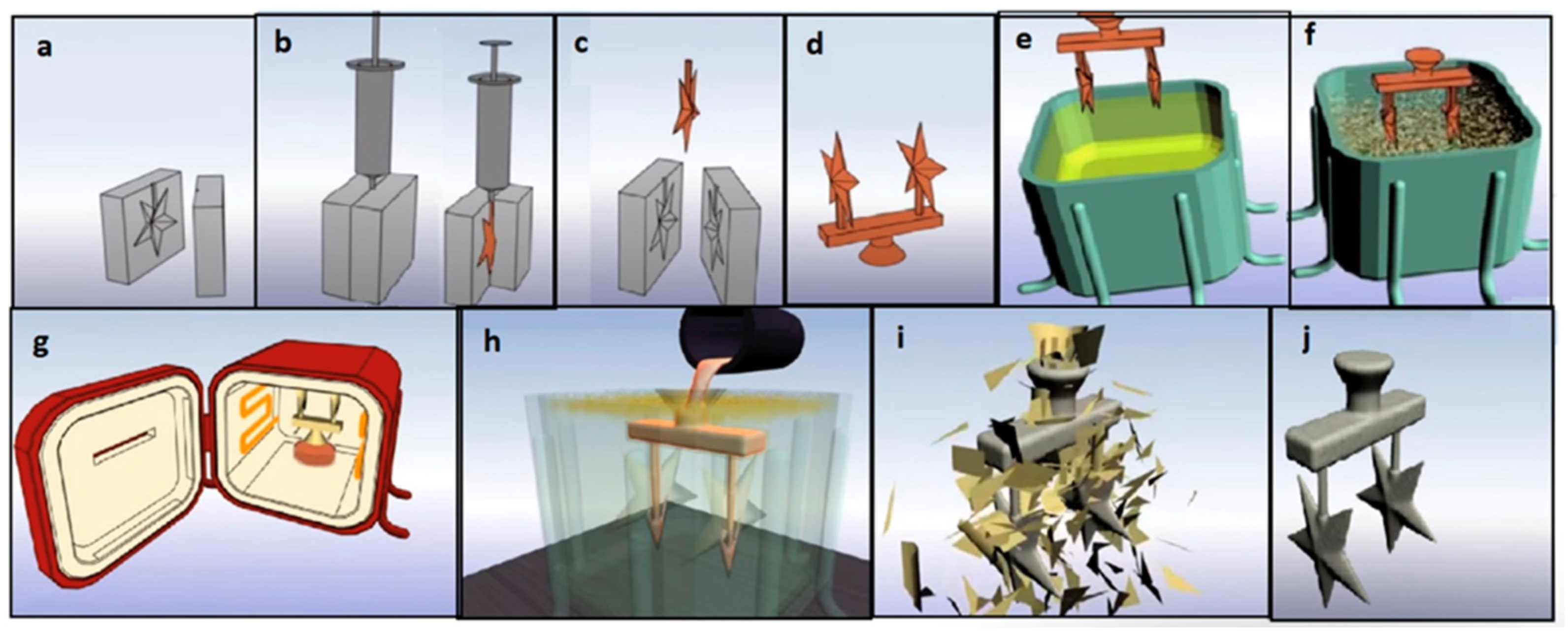

The conventional IC process is shown in

Figure 1. First, a metal mold for a wax pattern is manufactured through the fabrication of a metal die. The molten wax is then injected into the metal mold to create a wax pattern. A casting tree is assembled with multiple wax patterns. Afterward, the casting tree is dipped into a ceramic slurry containing alumina and colloidal silica to create the interior walls of a ceramic mold. The obtained mold is heated in an oven to melt all wax content. The molten metal is poured into the ceramic mold and allowed to solidify and cool before the destruction of the ceramic shell [

2].

One of the issues faced with conventional IC is the manufacturing of wax patterns since it requires a difficult tooling process. The pattern-making stage can be simplified by using additive manufacturing (AM) to replace the IC steps such as the hard tooling of metal molds and wax injection. AM, also known as rapid prototyping, is a layer-by-layer fabrication process that emerged in the 1980s. In recent decades, AM technologies evolved significantly to be used in IC. The AM-assisted IC is called rapid investment casting (RIC) due to the reduced time needed to prepare the patterns for casting [

3].

The AM technologies in RIC are used either through an indirect or direct approach. A 3D-printed mold is used to prepare the wax pattern in the indirect RIC, while the pattern is fabricated using a printer in the direct RIC [

4]. The application of AM-based sacrificial patterns in IC reduces the lead time and cost significantly for individual and small-size productions when compared to the conventional process. The AM processes used for RIC include stereolithography (SLA), fused filament fabrication (FFF), selective laser sintering (SLS), and laminated object manufacturing (LOM). In order to create castings of superior quality, the AM-based patterns are required to have a low melting point, sufficient mechanical strength and toughness, low surface roughness, high dimensional accuracy, and no residual ash following burnout [

5,

6]. SLA is regarded as a very precise method among 3D printing techniques [

7].

SLA is a vat photopolymerization technology that uses ultraviolet (UV) light to cure or solidify liquid resin, a photosensitive thermoset material. The UV radiation initiates the curing reaction of a resin which results in the cross-linking of molecular chains and the polymerization of oligomers and monomers. Depending on the printing device, there might be a bottom-up or top-down method. Indeed, desktop 3D printers, such as Formlabs 3D printers, employ the bottom-up approach, whereas industrial 3D printers use the top-down technique [

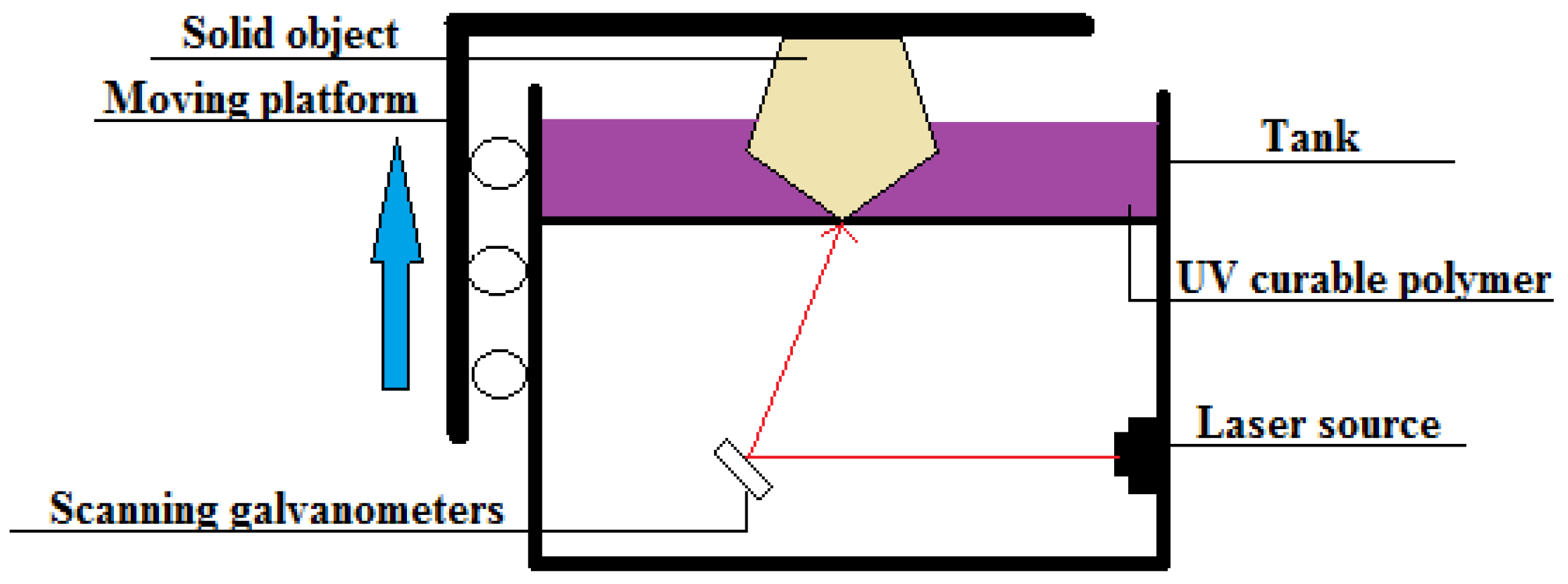

8]. As shown in

Figure 2, the main components of the SLA machines are the laser, mirrors, galvanometers, resin tank, and build platform. A layer of liquid photopolymer is scanned by a laser to harden the resin in the areas specified by the CAD model. After the curing of one layer, the surface is covered with a thin film of resin for further exposure to the laser beam. The platform is raised/moved up along the

z-axis for the curing of each consecutive layer [

1].

There are several benefits of casting with SLA. Firstly, compared to traditional IC, its manufacturing cost and lead time are decreased. Secondly, waste is reduced as a result of the faster machining [

9,

10]. Also, it is possible to implement modifications to the model when designing without affecting the production time [

1].

Most of the SLA studies considered the effect of the layer thickness, position on the build platform, and build angle on surface roughness or dimensional accuracy of SLA parts. A summary of the literature review is given in

Table 1.

Khaledi et al. and Piangsuk et al. have studied the dimensional accuracy of SLA-based RIC and milled copings used in prosthetic dentistry [

22,

23]. According to the outcomes, both SLA-printed and SLA-based RIC components demonstrated higher dimensional accuracy than milled components.

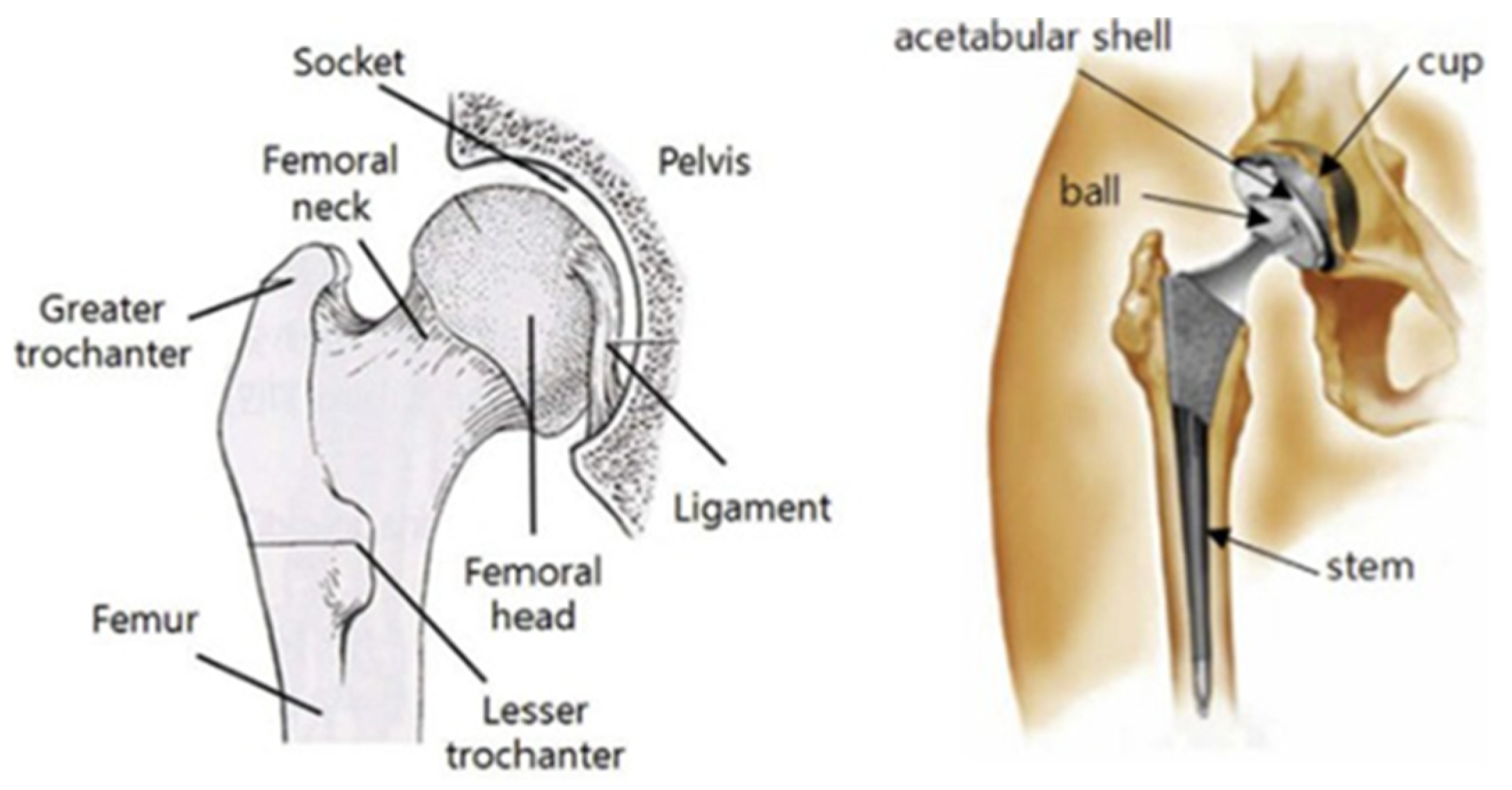

A prosthetic biomedical implant for total hip replacement was selected to be the benchmark model due to its practical significance based on the available literature. A hip implant is used to replace a hip joint, one of the largest ball-and-socket joints in the human body, which allows for the free movement of a leg, supports the upper part of the body, and absorbs the movement impact. As shown in

Figure 3, the hip implant consists of three main parts, such as the cup, ball, and stem. The cup is a replacement for the hip socket in the pelvis bone. The ball placed in the cup is inserted into the acetabular shell, while the stem is put into the femoral canal for stability [

24].

Several researchers have studied the dimensional accuracy and surface roughness of hip implants produced by FFF and FFF-based IC. A study by Singh et al. investigated the effect of IC process parameters such as slurry viscosity, number of slurry layers, and dry time of the primary coating on the surface roughness of hip joints developed by a combination of IC and FFF [

25]. The design was used the femoral ball and shortened stem. It was found that the most influential factor on the quality of a cast hip implant surface is the number of layers. Kumar et al. examined three hip implants with different volume-to-surface (V/A) ratios [

26]. The first model consisted of only a stem, while the other two implants were designed with a femoral ball. Researchers focused on both the printing and casting parameters such as the orientation, density of the pattern, mold thickness, grade of material, type of pattern, and V/A ratio. According to the results, an orientation of 0° angle is recommended for Acrylonitrile Butadiene Styrene (ABS) patterns while a wax layer notably increased the surface quality of cast parts. A simplified model of the hip implant was designed by Tiwary et al., and the printing parameters examined in this article were extrusion speed, infill, number of top and bottom solid layers, and layer thickness [

27]. It was found that the surface roughness of the FFF parts can be decreased by making the top and bottom layers solid and it was suggested that the RIC technique be applied for a low volume of production.

In the RIC, the process parameters used to print the sacrificial patterns can affect the surface roughness and dimensional accuracy of the castings. Hence, the surface finish and accuracy of the printed patterns must be improved by optimizing the printing parameters. According to the literature review, numerous studies focused on the dimensional accuracy and surface roughness of the SLA-printed parts separately. However, there is lack of studies on the effects of the SLA process parameters on the surface roughness and dimensional accuracy of both printed and cast parts and on castable wax resin material. Consequently, this study intends to examine and fill these research gaps. The aim of this work is to investigate the effect of the SLA printing parameters on the dimensional accuracy and surface roughness of the printed patterns and the cast components. The following objectives were defined to attain the aim of this study:

Design a benchmark model of the small-scale prosthetic biomedical hip implant.

Fabricate benchmark patterns using the SLA printing technology and assess their dimensional accuracy and surface roughness.

Cast and measure the dimensional accuracy and surface roughness of the AM-based IC components.

Examine the experimental results and obtain the optimized printing parameters for dimensional accuracy and surface roughness.

Investigate the hardness, microstructure, and composition of the IC parts.

2. Materials and Methods

This section describes the experimental procedure, model design, printing materials, design of experiments, and equipment used in the study.

2.1. Experimental Procedure

This study consists of several stages as shown in

Figure 4. Firstly, the virtual model of the hip implant was created using a computer-aided design software, SolidWorks 2021. The material and printing parameters were selected. Taguchi’s L18 orthogonal array was chosen for the design of experiments (DOE). The SLA printer, FormLabs Form 3 (Formlabs Inc., Somerville, MA, USA), was used to print the specimens. The surface roughness and dimensional accuracy of the printed parts were measured and processed to examine the effect of parameters on these properties. Afterward, the printed samples were used to fabricate the mold for the casting. The IC parts were produced using aluminum. The surface finish and dimensional deviation of these parts were measured. The microhardness and microstructure of the IC parts were characterized.

2.2. Benchmark model design

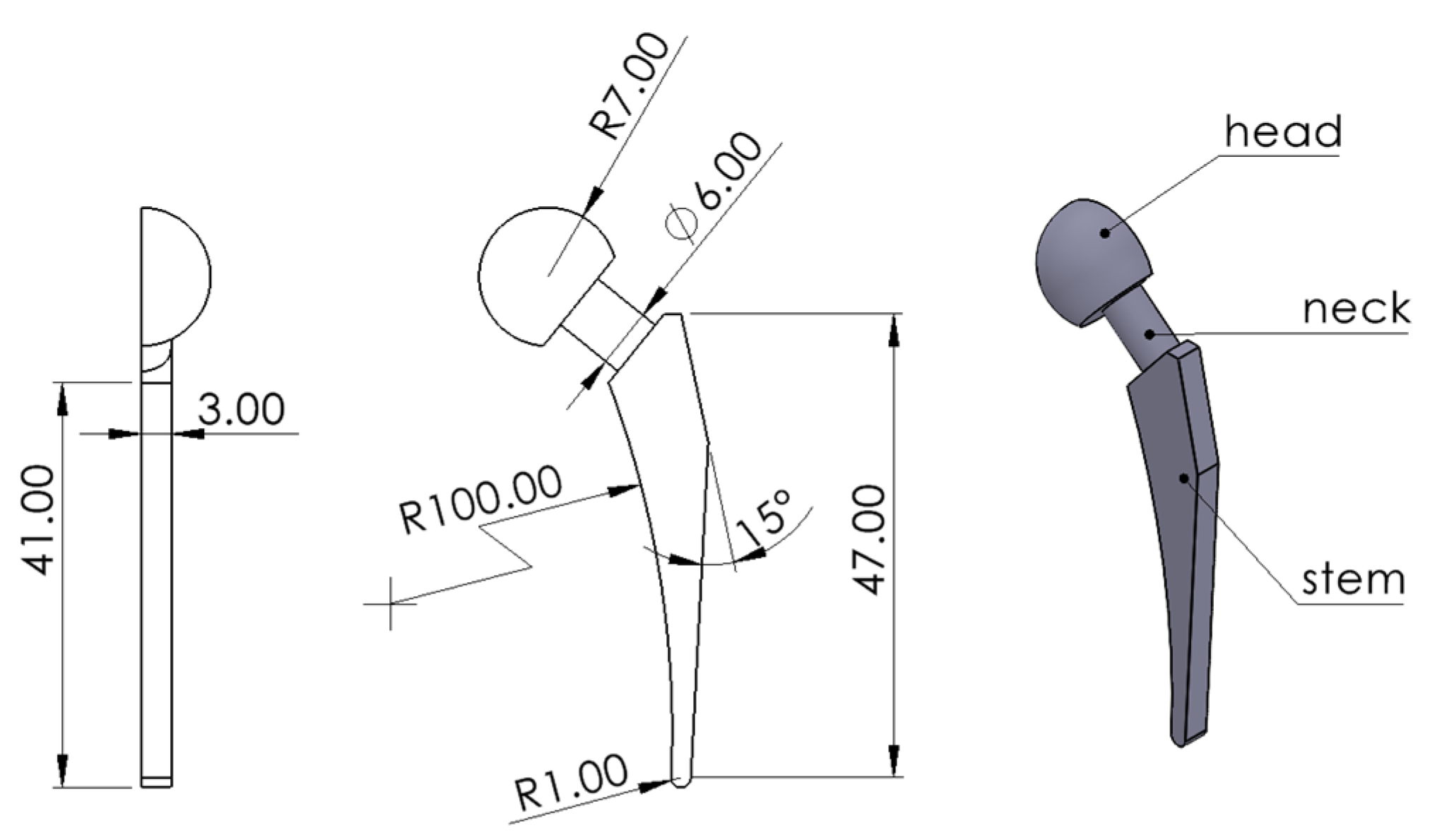

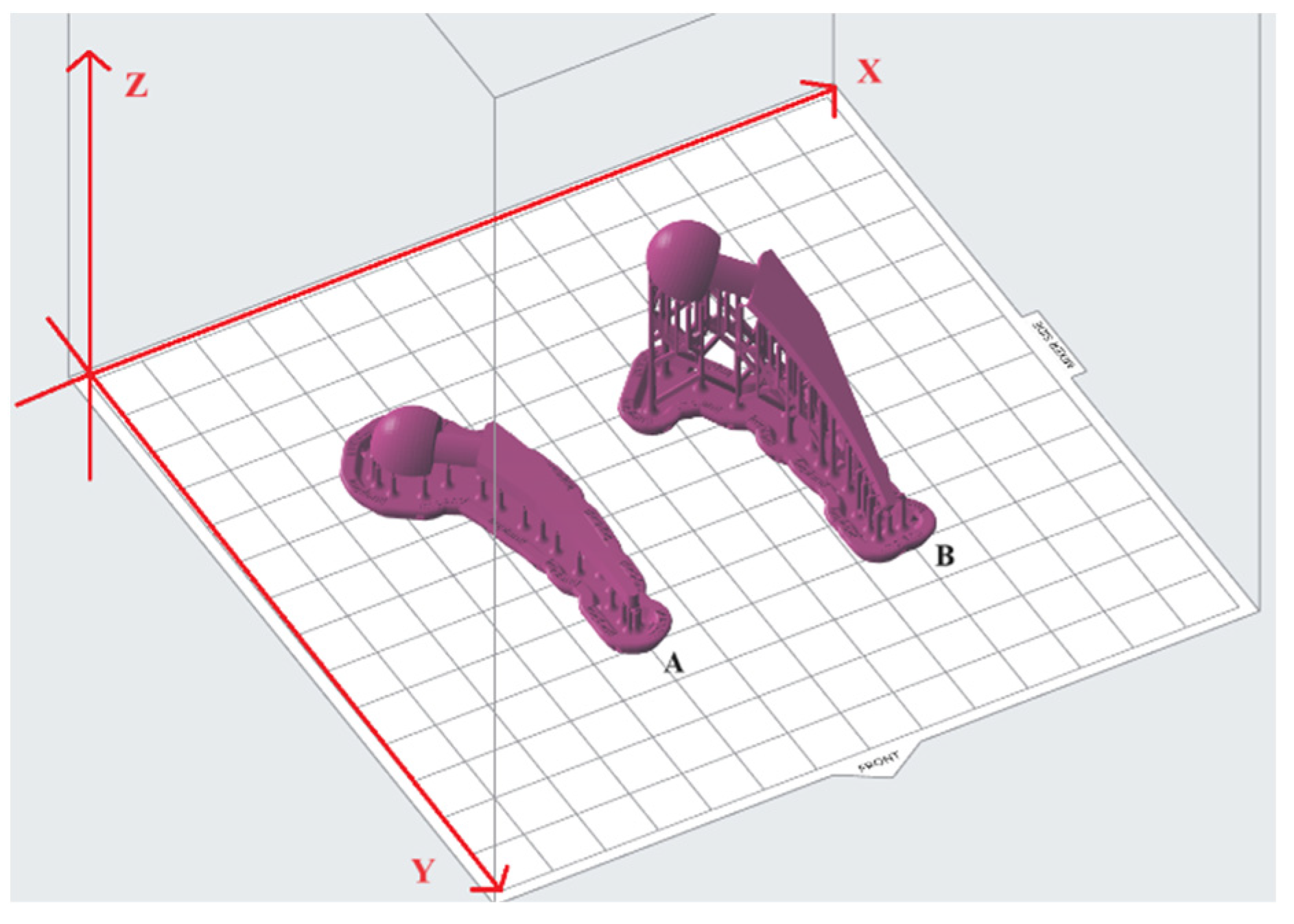

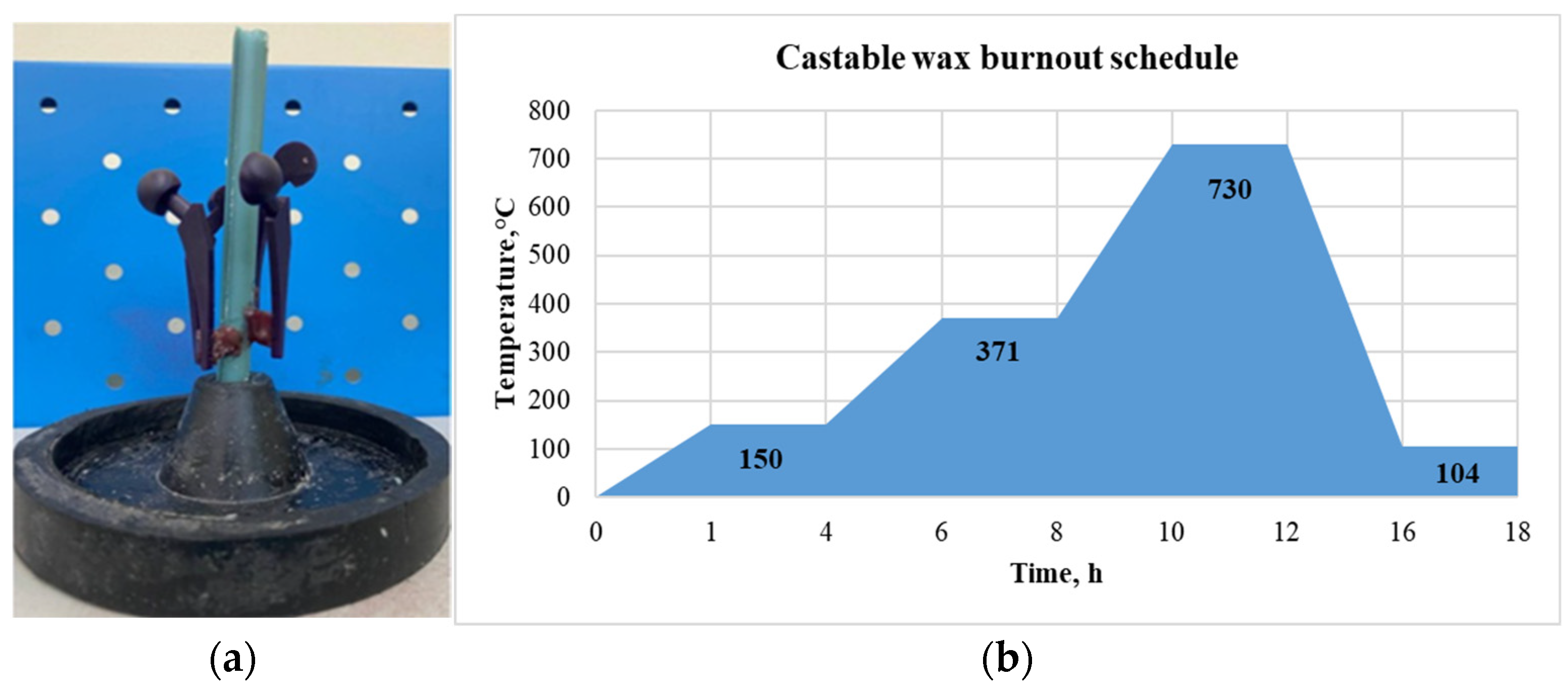

The small-scale prosthetic biomedical hip implant model designed for the experiment is shown in

Figure 5. The model was created using the SolidWorks 2021 software based on the literature review and resized down to an appropriate scale for 3D printing [

22,

23,

24]. The main geometric features of the hip implant are the femoral head, the neck, and the stem. The model was designed to be the half of the implant since the part was required to lie flat on the surface for measurement purposes.

2.3. SLA Printing of Patterns

The SLA patterns were printed using FormLabs Form 3. The printer was equipped with 250 mW laser power and low-force stereolithography (LFS) technology. The size of the laser spot was 85 µm [

28].

The material used for the SLA printing of patterns was FormLabs Castable Wax V1 (FLCWPU01) resin, an acrylate photopolymer with a wax content of 20%. This resin produced the pattern for casting with a high level of detail, with print resolutions of 25 and 50 µm and a superior surface finish. The castable wax resulted in a clean burnout and almost zero ash content. The layer thicknesses that can be printed with this material are 0.025 and 0.05 mm. According to the material specifications, no-post curing is needed for the castable wax [

29]. The characteristics of the resin are given in

Table 2. The Preform 3.27.1 software was used to set up the parts for SLA printing.

2.4. Design of Experiment

The Taguchi method of parametric design of experiment (DOE) was employed to examine the impact of the selected printing parameters (see

Table 3) on the dimensional accuracy and surface roughness of the hip implant model. The Taguchi method allows for a reduction in the number of experiments while still determining the sensitivity and importance of each parameter. In this study, the process parameters of SLA printing were chosen to be layer thickness, build angle (see

Figure 6), support density, and model base orientation (see

Figure 7). In

Figure 6, model base orientations are across the front; build angles are 0° and 30° in part A and B, respectively. To obtain B, the A was rotated along the

x-axis by 30°. Then, the two other cases where the build angle was 30° and model base orientation was diagonal to the front and parallel to the front were obtained by rotating B along the

z-axis by 45° and 90°, respectively. The support density was chosen in the range [0.6, 1.0] because a support density of less than 0.6 was not recommended and showed an error by the Preform software when the checking model for printability while using a support density of more than 1.0; surface finish was considerably reduced due to the footprints of the excess support structures. According to the chosen DOE, there should be 3 levels of support density, therefore, 0.6, 0.8, and 1.0 were chosen.

The Minitab Statistical Software Version 21.1.0 was used to create Taguchi’s experimental design. L18 Orthogonal Array with 18 rows as shown in

Table 4 was created for the chosen factors and levels. There is a setting for the different experimental SLA printing runs in each row. Each experimental run was repeated three times as shown in

Figure 8.

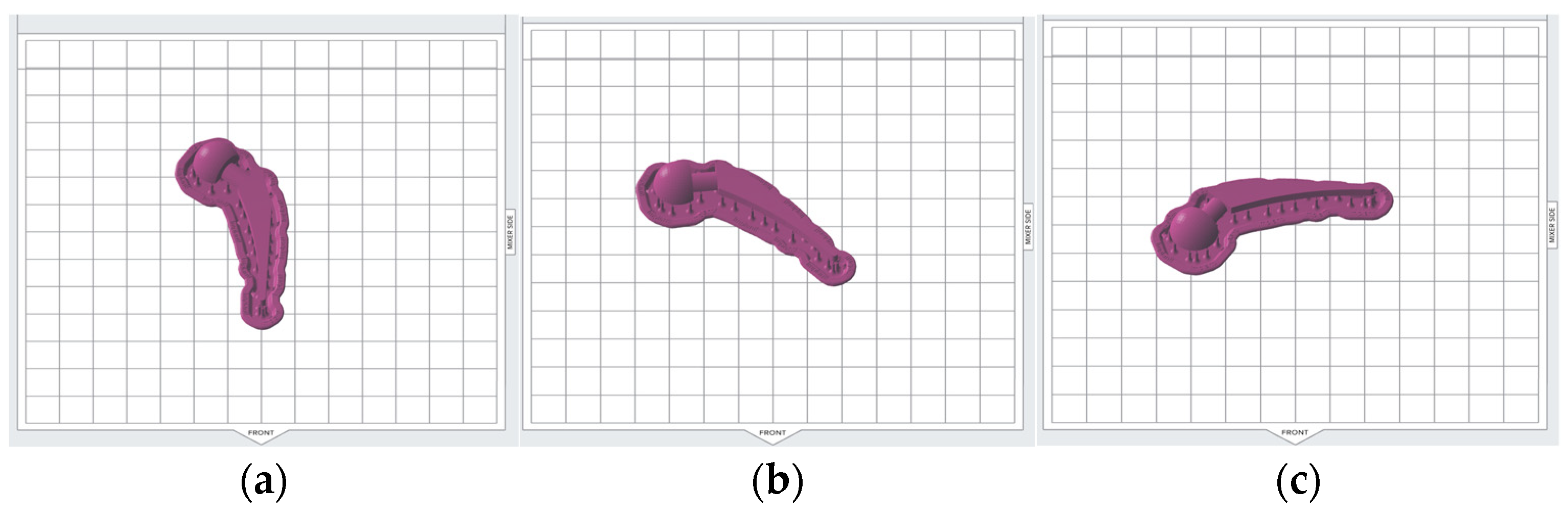

2.5. Investment Casting

Aluminum wrought alloy (AMg3 (1530), Kazakhstan Metal Industrial Company, Astana, Kazakhstan) was chosen as the casting metal for this experiment since it is a lightweight, highly recyclable, inexpensive, and available metal with good strength, stiffness, and high thermal conductivity. The equipment used for casting procedures is shown in

Figure 9.

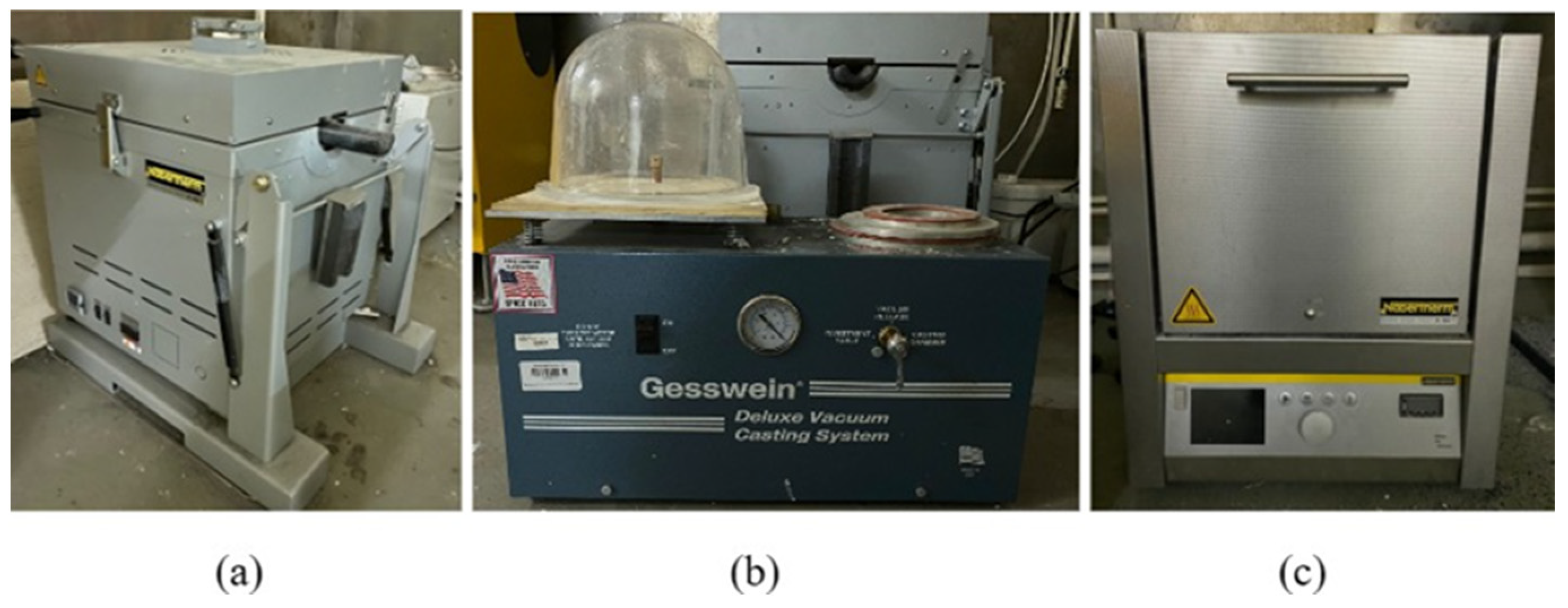

Firstly, wax rods were used to build the patterns in a casting tree, as can be seen in

Figure 10a. Then, the mold creation was carried out using Ultravest investment powder from Ranson and Randolf and distilled water in a 39/100 water to powder ratio. According to the instructions for the investment powder, 690 g of powder and 269.4 g of water were mixed for an investment in a flask with a 10.2 cm height and 8.3 cm diameter. After mixing the powder with water for 2–3 min, the investment table side of the Gesswein Deluxe Vacuum Casting System machine was utilized to remove trapped air from the mixture. The mixture was then added to the flask containing the casting tree, and the vacuum was applied once again. Mold reaches its peak green intensity after 2 h, thus it was left to sit undisturbed for that time period.

For further burnout of the flask with investment, Nabertherm Muffle Furnace L15/11/B410 (Nabertherm GmbH, Lilienthal, Germany) was used. The flask was put into a kiln which was preheated to 150 °C. The burnout cycle for the selected castable wax material was approximately 15 h as illustrated in

Figure 10b. Aluminum bars were placed into a Nabertherm K1/13 (Nabertherm GmbH, Lilienthal, Germany) metal melting furnace and melted at 750 °C during the final two hours of the burnout cycle. The casting parameters used were as follows: casting temperature of 750 °C, mold temperature before casting of 104 °C, pouring speed of 2.5 cm/s, and time before cooling 20 min.

The flask was taken out of the kiln and put into the casting chamber of the Gesswein Deluxe Vacuum Casting System machine (Gesswein, Bridgeport, CT, USA) after 1.5 h of gradually melting the metal. The vacuum was switched on and the molten aluminum metal was poured into the flask. After 15–20 min of metal solidification, the hot flask was cooled with water and the investment casting shells were removed from th e cast parts. Next, the cast hip implant parts were sawed off from the casting tree and no post-processing was carried out. The hip implants produced using IC are shown in

Figure 11.

2.6. Measurements

A Vernier digital caliper was used to measure the dimensional accuracy of the printed components. The features that were measured and checked for accuracy are shown in

Table 5 and

Figure 5.

The surface roughness was measured using a profilometer—Dektak XT Stylus (Bruker, Billerica, MA, USA) profiler. The profilometer was in contact with the sample using a stylus with a single-crystal diamond tip with a radius of 12.5 µm. The sample stage slid the sample underneath the stylus tip to draw a profile while the equipment maintained a steady stylus force. This device assessed the surface roughness by profiling the surface topography. The surface roughness was measured in the stem of the implant. The arithmetical average roughness (

Ra) refers to the arithmetic mean of all the absolute variances from the center line over the total length and is defined by Equation (1).

where

L is a sampling length and

z is a coordinate of the curve profile [

30].

The measurement setup parameters for the profilometer were the following: duration of 20 sec, length of 5000 µm, range of 524 µm, and 7 mg of stylus force. An average of three measurements was taken for each specimen.

The Vickers microhardness of the SLA-based IC was measured using the Microhardness (HV) Tester—Innovatest Falcon 500 (INNOVATEST Europe BV, Maastricht, The Netherlands). The hardness was measured three times for each specimen. A load of 0.5 kg was applied to the specimen with a dwelling time of 10 s. The surface of the parts was polished using the polishing machine before the test.

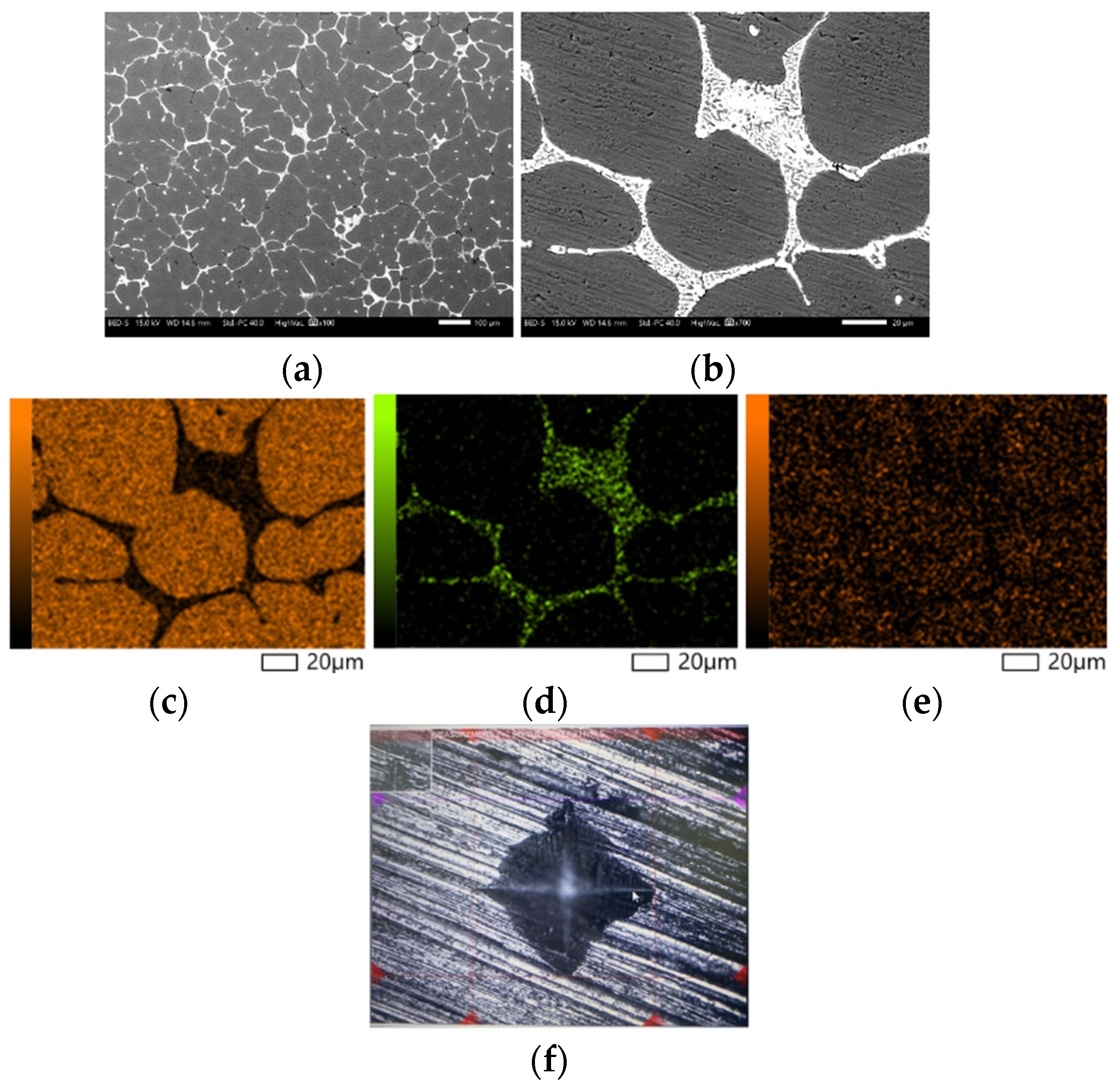

The microstructure was examined using the Scanning Electron Microscope JEOL JSM-IT200 (JEOL Ltd., Tokyo, Japan). The Energy Dispersive Spectroscopy (EDS) analysis was conducted to investigate the chemical composition of the specimen while imaging. The hip implants were cut using a micro wire electrical discharge machine (µWEDM) to prepare the samples for the SEM. The surface of the samples was polished using a polishing machine. The samples also underwent wet etching to remove the material from the surface.

4. Conclusions

This study examined the effect of process parameters on the surface roughness and dimensional accuracy of the SLA patterns by using the small-scale prosthetic hip implant as a benchmark model. The Taguchi L18 array was used for DOE and fifty-four SLA patterns were printed for the measurements. The optimum parameters which reduce the surface roughness and dimensional deviation of the SLA printed parts and the SLA-based IC parts were established. The main findings of the study are as follows:

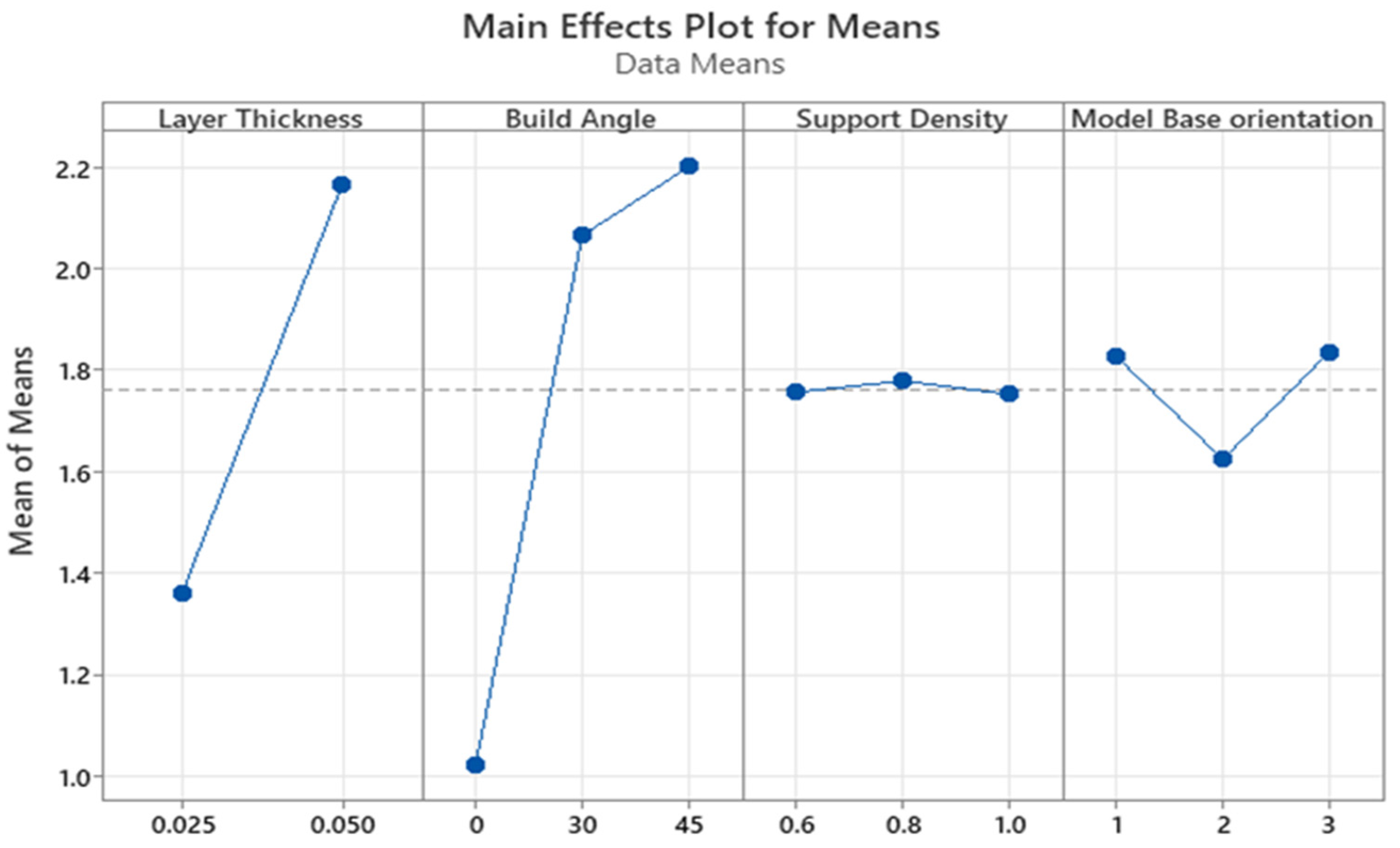

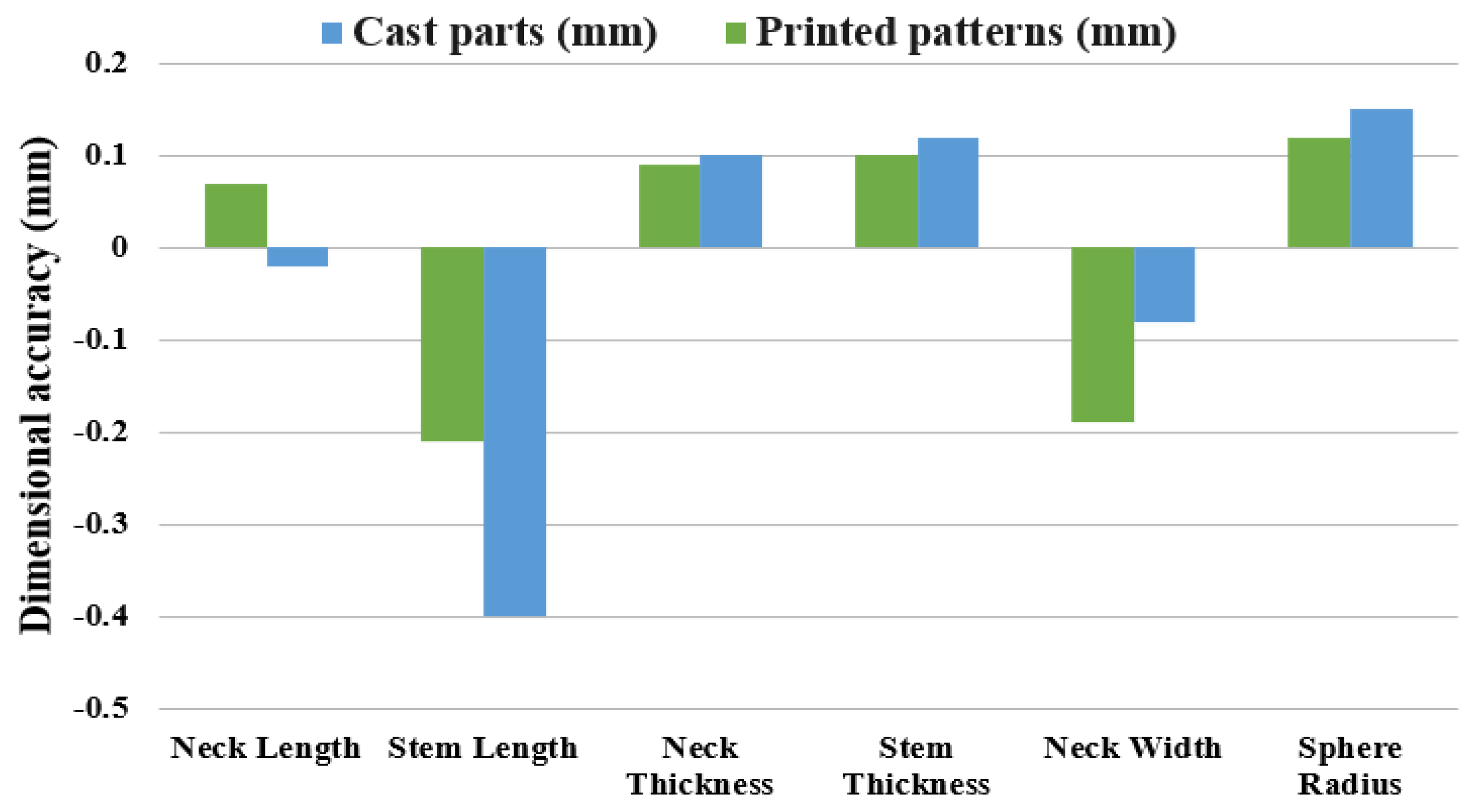

The most influential SLA printing parameter affecting the surface roughness was the build angle, followed by the layer thickness. The optimum values that minimize the surface roughness are 0.025 mm layer thickness, 0° build angle, 1.0 support density, and across the front base orientation. As for the dimensional accuracy, the optimum printing parameters are a 0.025 mm layer thickness, 30° build angle, 0.6 support density, and diagonal to the front base orientation.

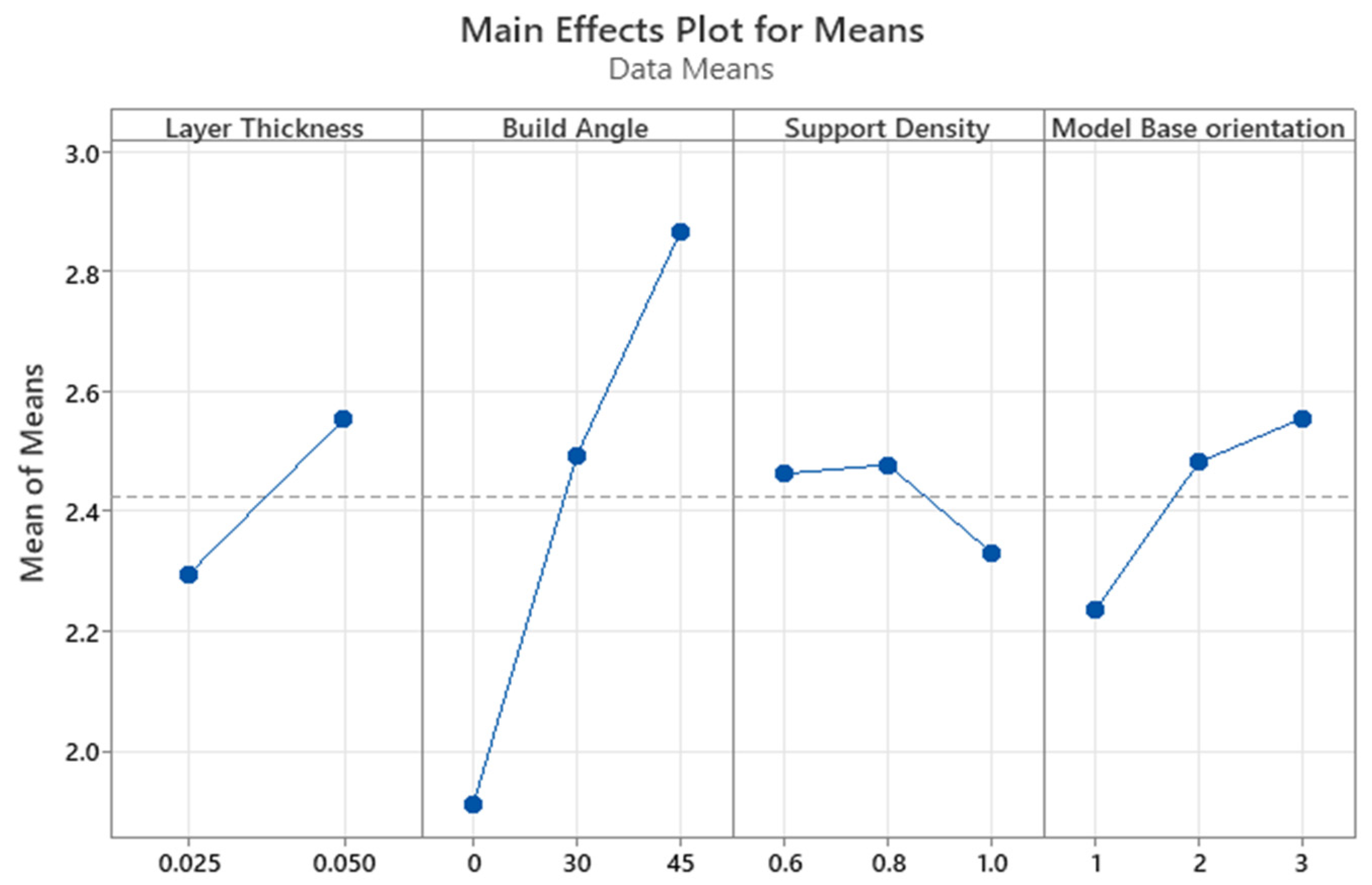

The SLA-based IC components had the optimum values for the surface roughness such as 0.025 mm layer thickness, 0° build angle, 1.0 support density, and parallel to the front base orientation. As for the dimensional accuracy, the optimum printing parameters are 0.050 mm layer thickness, 45° build angle, 0.8 support density, and diagonal to the front base orientation.