Structure and Mechanical Properties of a Porous Polymer Material via Molecular Dynamics Simulations

Abstract

1. Introduction

2. Methods and Simulation

3. Results and discussion

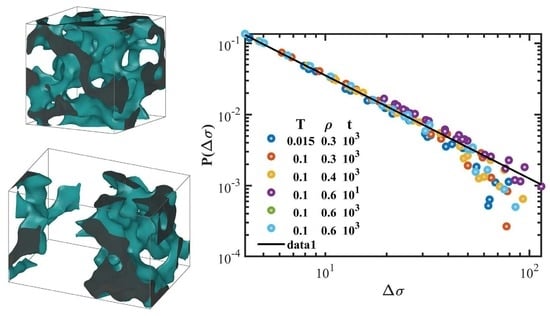

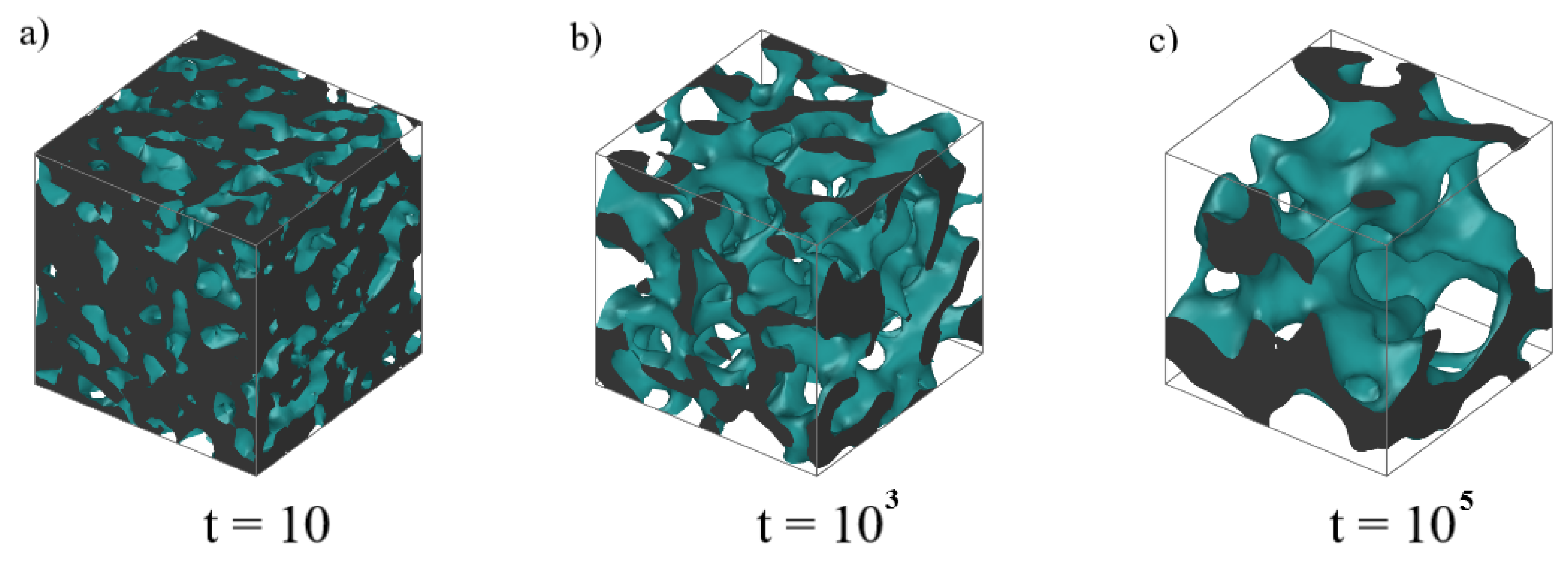

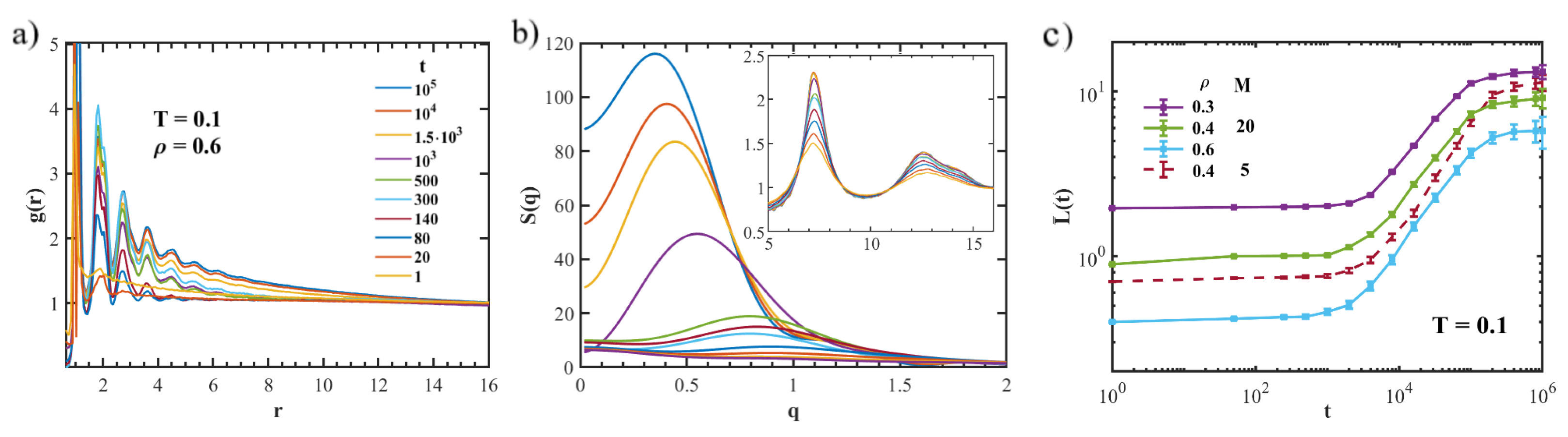

3.1. Structural Analysis

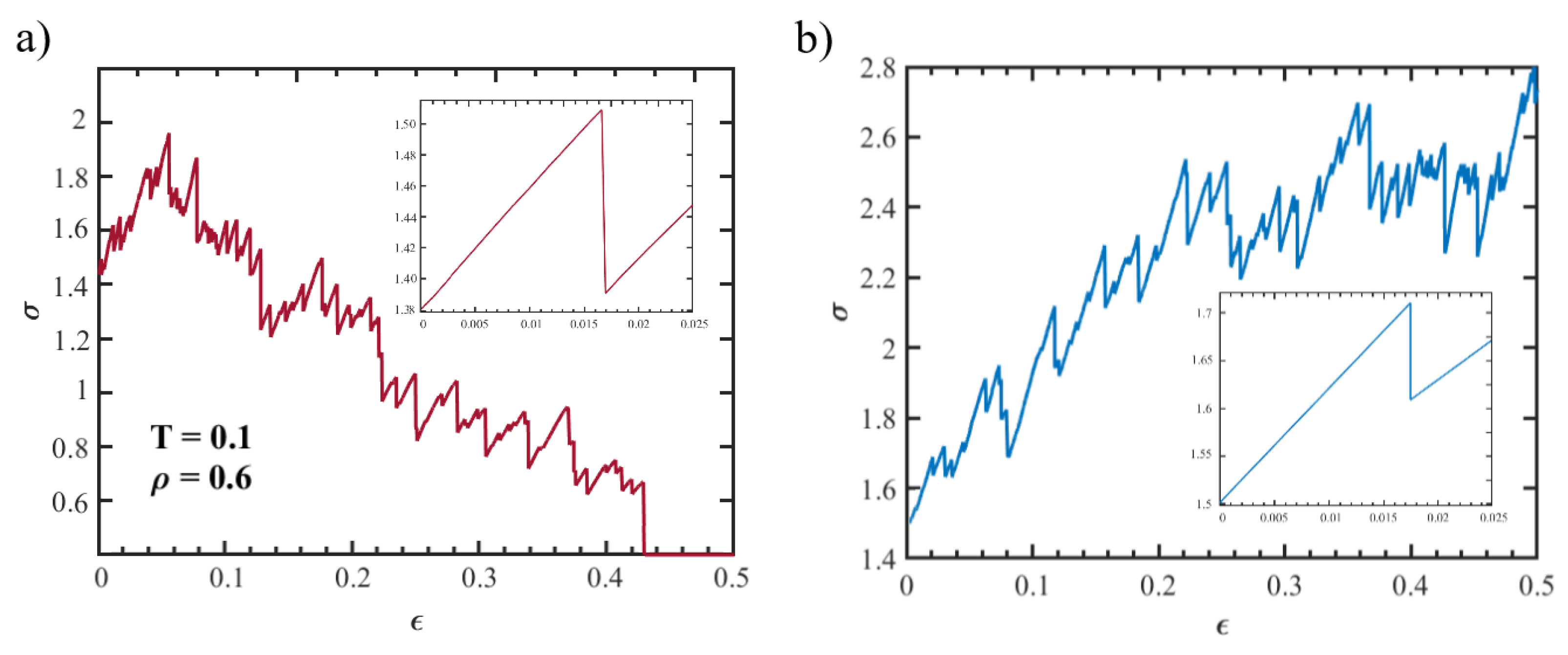

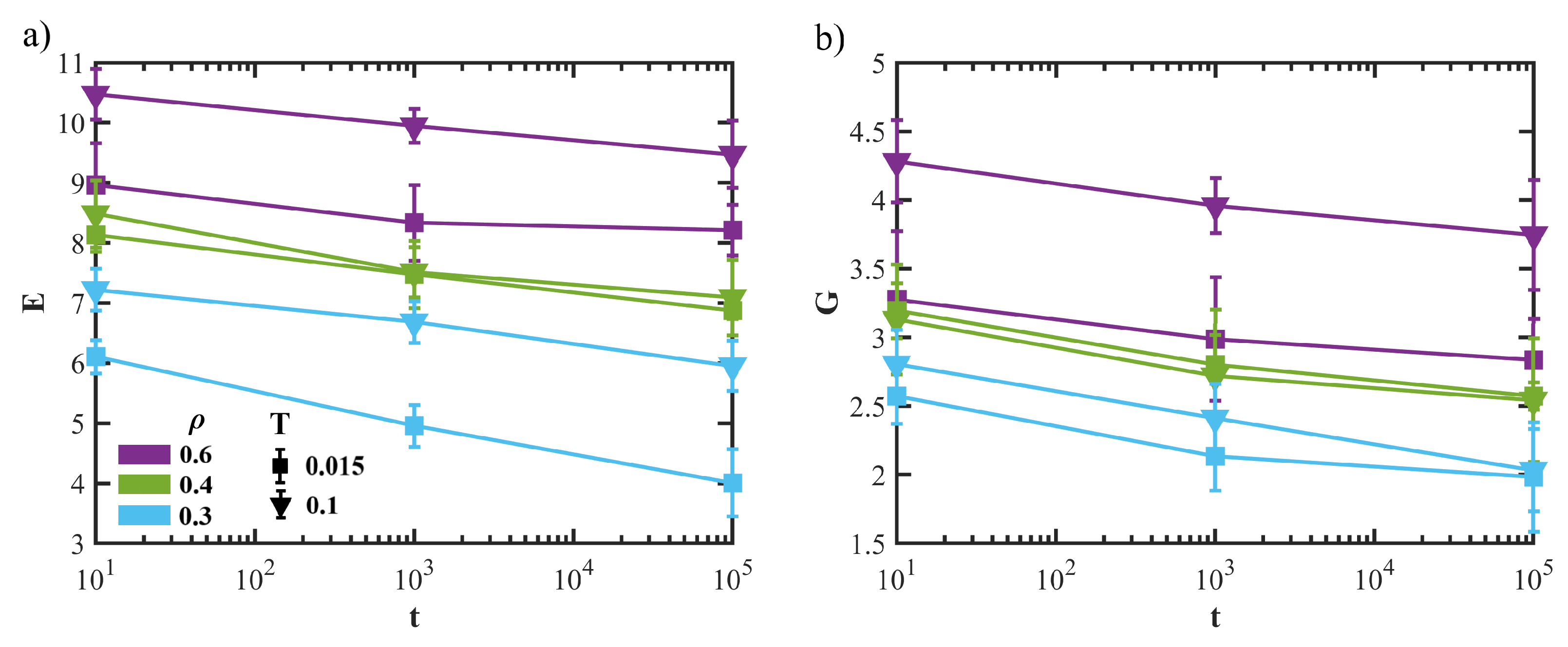

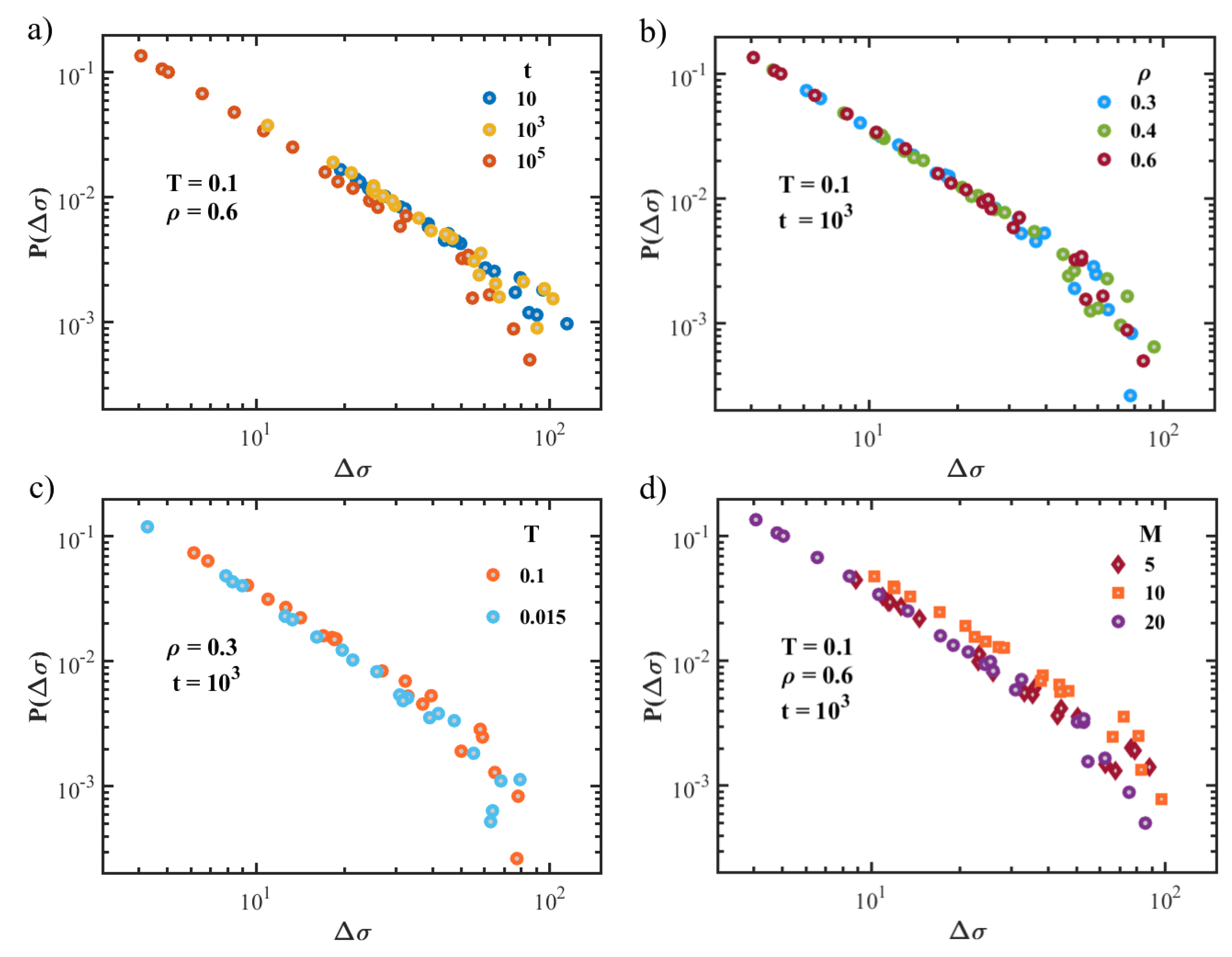

3.2. Mechanical Response

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schnell, B.; Meyer, H.; Fond, C.; Wittmer, J.; Baschnagel, J. Simulated glass-forming polymer melts: Glass transition temperature and elastic constants of the glassy state. Eur. Phys. J. E Soft Matter 2011, 34, 97. [Google Scholar] [CrossRef]

- Samitsu, S.; Zhang, R.; Peng, X.; KRISHNAN, M.R.; Fujii, Y.; Ichinose, I. Flash freezing route to mesoporous polymer nanofibre networks. Nat. Commun. 2013, 4, 2653. [Google Scholar] [CrossRef]

- Lee, J.T.; Jo, C.; De Volder, M. Bicontinuous phase separation of lithium-ion battery electrodes for ultrahigh areal loading. Proc. Natl. Acad. Sci. USA 2020, 117, 21155–21161. [Google Scholar] [CrossRef]

- Sun, Y.; Andrews, W.; Thornton, K.; Voorhees, P. Self-Similarity and the Dynamics of Coarsening in Materials. Sci. Rep. 2018, 8, 17940. [Google Scholar] [CrossRef]

- Tateno, M.; Tanaka, H. Power-law coarsening in network-forming phase separation governed by mechanical relaxation. Nat. Commun. 2021, 12, 912. [Google Scholar] [CrossRef]

- Araki, T.; Tanaka, H. Three-Dimensional Numerical Simulations of Viscoelastic Phase Separation: Morphological Characteristics. Macromolecules 2001, 34, 1953–1963. [Google Scholar] [CrossRef]

- Testard, V.; Berthier, L.; Kob, W. Intermittent dynamics and logarithmic domain growth during the spinodal decomposition of a glass-forming liquid. J. Chem. Phys. 2014, 140, 164502. [Google Scholar] [CrossRef]

- Priezjev, N.V.; Makeev, M.A. Strain-induced deformation of the porous structure in binary glasses under tensile loading. Comput. Mater. Sci. 2018, 150, 134–143. [Google Scholar] [CrossRef]

- Priezjev, N.V.; Makeev, M.A. Structural transformations and mechanical properties of porous glasses under compressive loading. J. Non-Cryst. Solids 2018, 500, 1–10. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; in ’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comp. Phys. Comm. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef]

- Hoover, W.G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 1985, 31, 1695–1697. [Google Scholar] [CrossRef]

- Izaguirre, J.A.; Catarello, D.P.; Wozniak, J.M.; Skeel, R.D. Langevin stabilization of molecular dynamics. J. Chem. Phys. 2001, 114, 2090–2098. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Gelb, L.D.; Gubbins, K.E. Characterization of Porous Glasses: Simulation Models, Adsorption Isotherms and the Brunauer-Emmett-Teller Analysis Method. Langmuir 1998, 14, 2097–2111. [Google Scholar] [CrossRef]

- Koch, S.W.; Desai, R.C.; Abraham, F.F. Dynamics of phase separation in two-dimensional fluids: Spinodal decomposition. Phys. Rev. A 1983, 27, 2152–2167. [Google Scholar] [CrossRef]

- Yamamoto, R.; Nakanishi, K. Computer simulation of vapor-liquid phase separation in two- and three-dimensional fluids: Growth law of domain size. Phys. Rev. B 1994, 49, 14958–14966. [Google Scholar] [CrossRef]

- Tanaka, H. Viscoelastic phase separation. J. Phys. Condens. Matter 2000, 12, R207. [Google Scholar] [CrossRef]

- Singh, M.K.; Hu, M.; Cang, Y.; Hsu, H.P.; Therien-Aubin, H.; Koynov, K.; Fytas, G.; Landfester, K.; Kremer, K. Glass Transition of Disentangled and Entangled Polymer Melts: Single-Chain-Nanoparticles Approach. Macromolecules 2020, 53, 7312–7321. [Google Scholar] [CrossRef]

- Yamamoto, R.; Nakanishi, K. Computer simulation of vapor-liquid phase separation in two- and three-dimensional fluids. II. Domain structure. Phys. Rev. B 1995, 51, 2715–2722. [Google Scholar] [CrossRef]

- Majumder, S.; Das, S.K. Universality in fluid domain coarsening: The case of vapor-liquid transition. Europhys. Lett. 2011, 95, 46002. [Google Scholar] [CrossRef]

- Tanaka, H.; Nishikawa, Y.; Koyama, T. Network-forming phase separation of colloidal suspensions. J. Phys. Condens. Matter 2005, 17, L143. [Google Scholar] [CrossRef]

- Tanaka, H.; Nishikawa, Y. Viscoelastic Phase Separation of Protein Solutions. Phys. Rev. Lett. 2005, 95, 078103. [Google Scholar] [CrossRef]

- Maloney, C.E.; Lemaître, A. Amorphous systems in athermal, quasistatic shear. Phys. Rev. E 2006, 74, 016118. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Mokshin, A.V. Mechanical response of mesoporous amorphous NiTi alloy to external deformations. Int. J. Solids Struct. 2021, 224, 111047. [Google Scholar] [CrossRef]

- Nicolas, A.; Ferrero, E.E.; Martens, K.; Barrat, J.L. Deformation and flow of amorphous solids: Insights from elastoplastic models. Rev. Mod. Phys. 2018, 90, 045006. [Google Scholar] [CrossRef]

- Soto-Parra, D.; Vives, E.; Botello-Zubiate, M.E.; Matutes-Aquino, J.A.; Planes, A. Acoustic emission avalanches during compression of granular manganites. Appl. Phys. Lett. 2018, 112, 251906. [Google Scholar] [CrossRef]

- Ribeiro, H.V.; Costa, L.S.; Alves, L.G.A.; Santoro, P.A.; Picoli, S.; Lenzi, E.K.; Mendes, R.S. Analogies Between the Cracking Noise of Ethanol-Dampened Charcoal and Earthquakes. Phys. Rev. Lett. 2015, 115, 025503. [Google Scholar] [CrossRef]

| M, , T | Exponent | Time Window |

|---|---|---|

| 5, , | [1000–16,000] | |

| 10, , | [500–16,000] | |

| 20, , | [500–16,000] | |

| 5, , | [500–16,000] | |

| 10, , | [500–16,000] | |

| 20, , | [500–16,000] | |

| 5, , | [2000–100,000] | |

| 10, , | [4000–100,000] | |

| 20, , | [2000–100,000] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volpe, S.C.; Leporini, D.; Puosi, F. Structure and Mechanical Properties of a Porous Polymer Material via Molecular Dynamics Simulations. Polymers 2023, 15, 358. https://doi.org/10.3390/polym15020358

Volpe SC, Leporini D, Puosi F. Structure and Mechanical Properties of a Porous Polymer Material via Molecular Dynamics Simulations. Polymers. 2023; 15(2):358. https://doi.org/10.3390/polym15020358

Chicago/Turabian StyleVolpe, Sharon Carol, Dino Leporini, and Francesco Puosi. 2023. "Structure and Mechanical Properties of a Porous Polymer Material via Molecular Dynamics Simulations" Polymers 15, no. 2: 358. https://doi.org/10.3390/polym15020358

APA StyleVolpe, S. C., Leporini, D., & Puosi, F. (2023). Structure and Mechanical Properties of a Porous Polymer Material via Molecular Dynamics Simulations. Polymers, 15(2), 358. https://doi.org/10.3390/polym15020358