Sustainability Assessment of the End-of-Life Technologies for Biocomposite Waste in the Aviation Industry

Abstract

1. Introduction

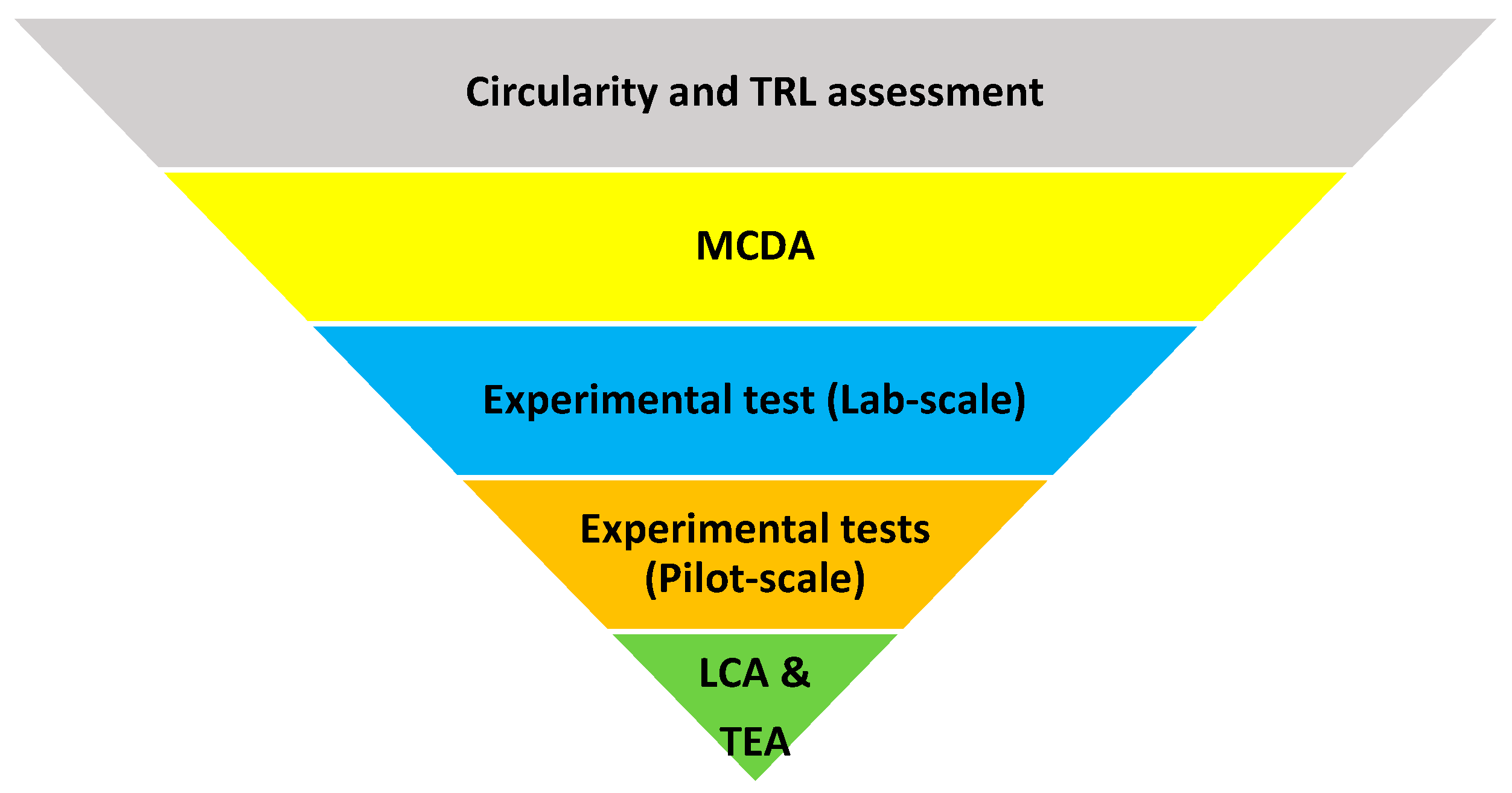

2. Methods

2.1. Circularity and TRL Assessments

2.2. Multi-Criteria Decision Analysis (MCDA)

2.3. Experimental Testing

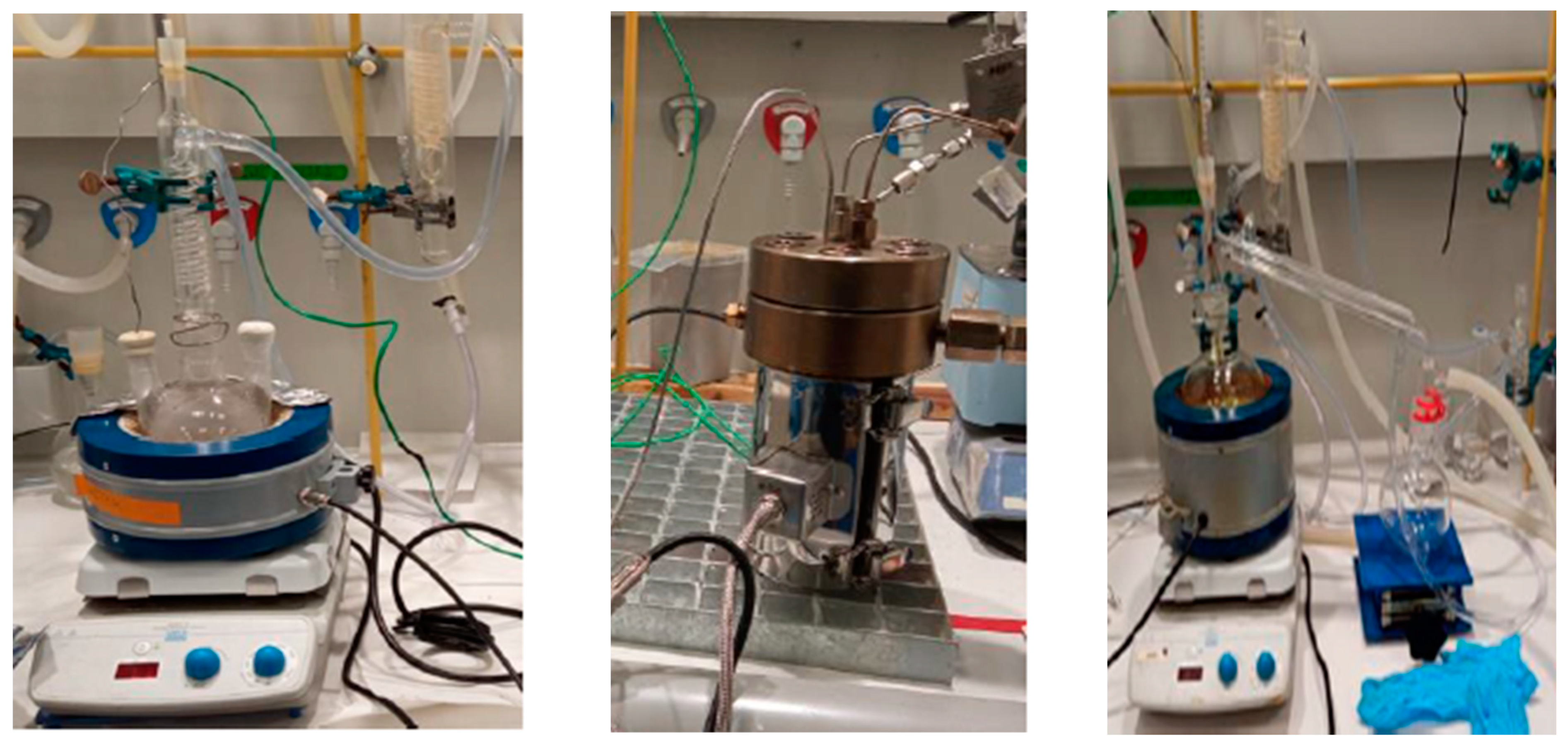

2.3.1. Laboratory Scale Testing

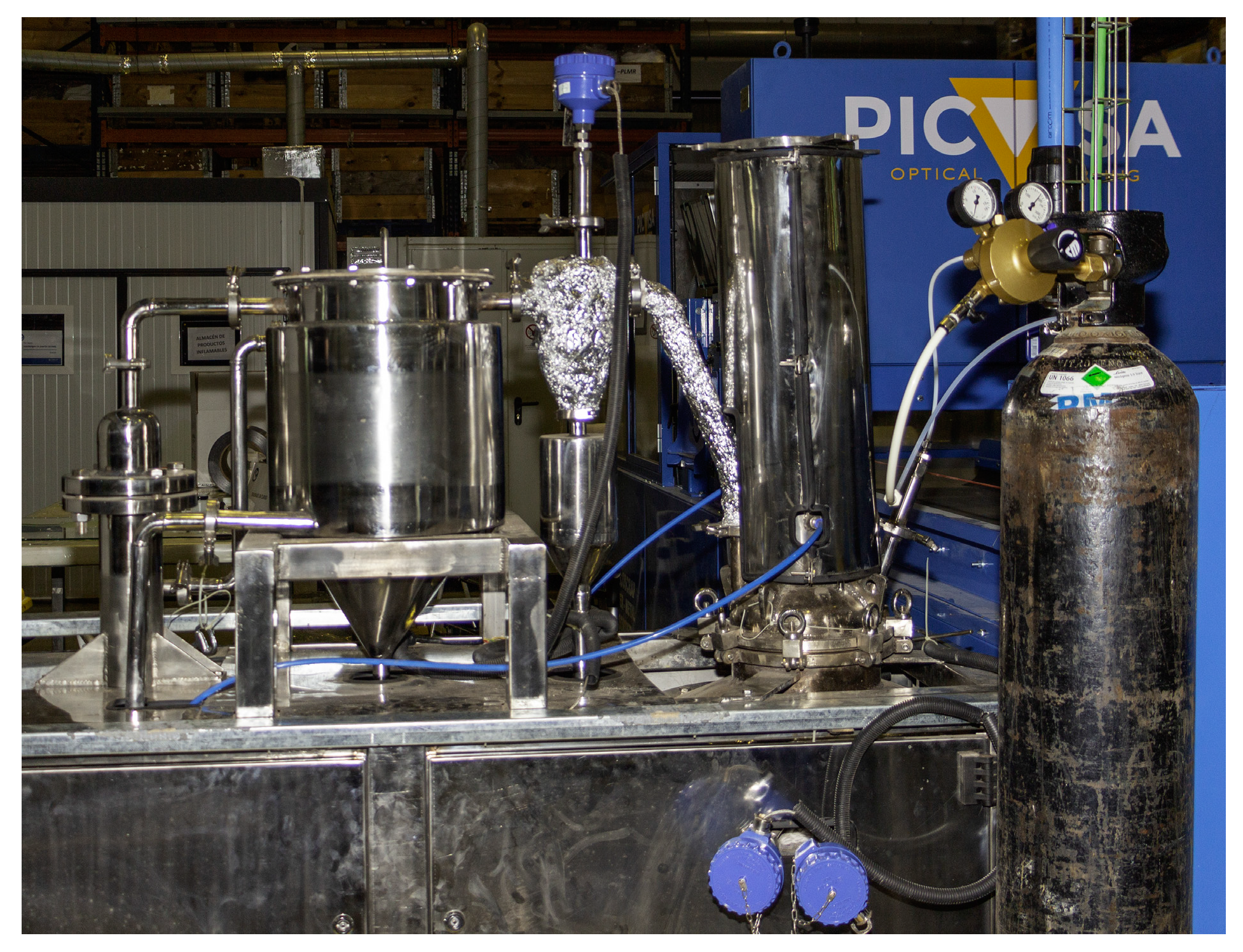

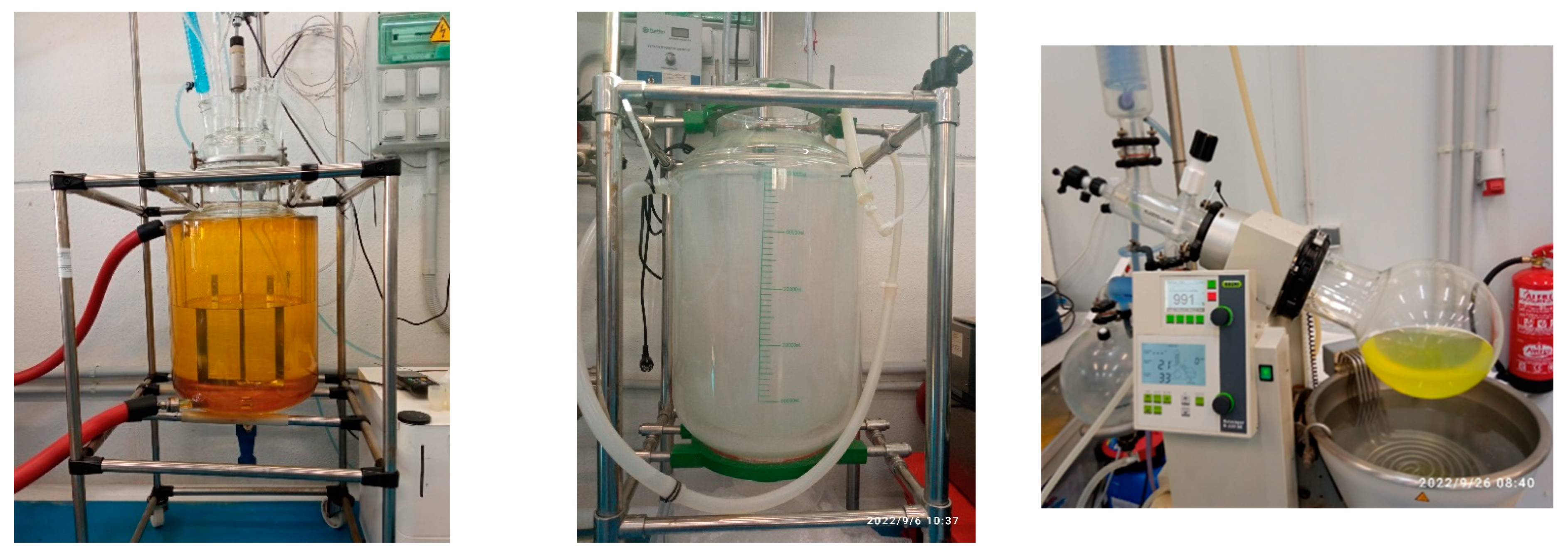

2.3.2. Pilot Scale Testing

2.4. Sustainability Assessment

2.4.1. Life Cycle Assessment (LCA)

2.4.2. Techno-Economic Analysis (TEA)

3. Results and Discussion

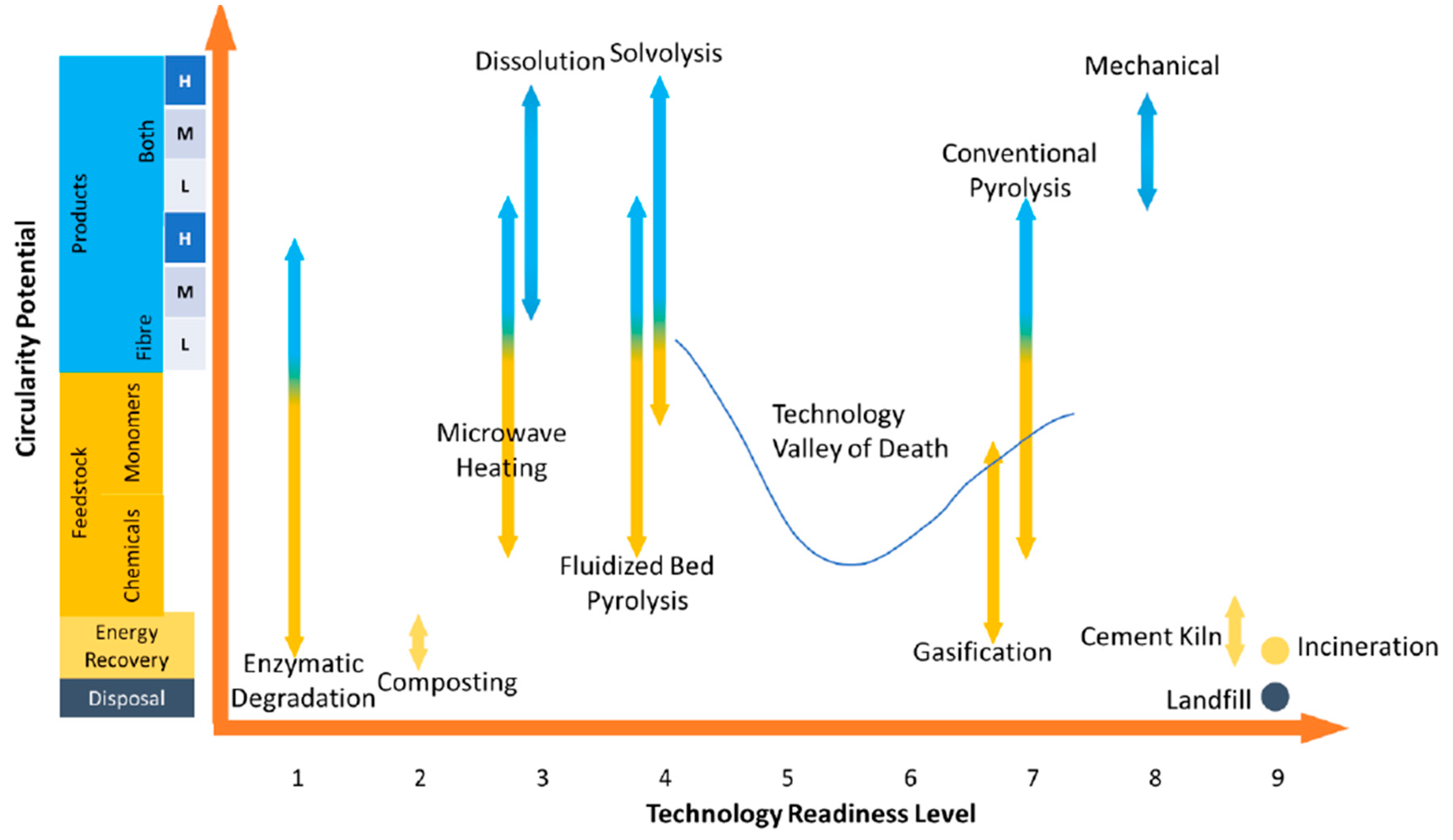

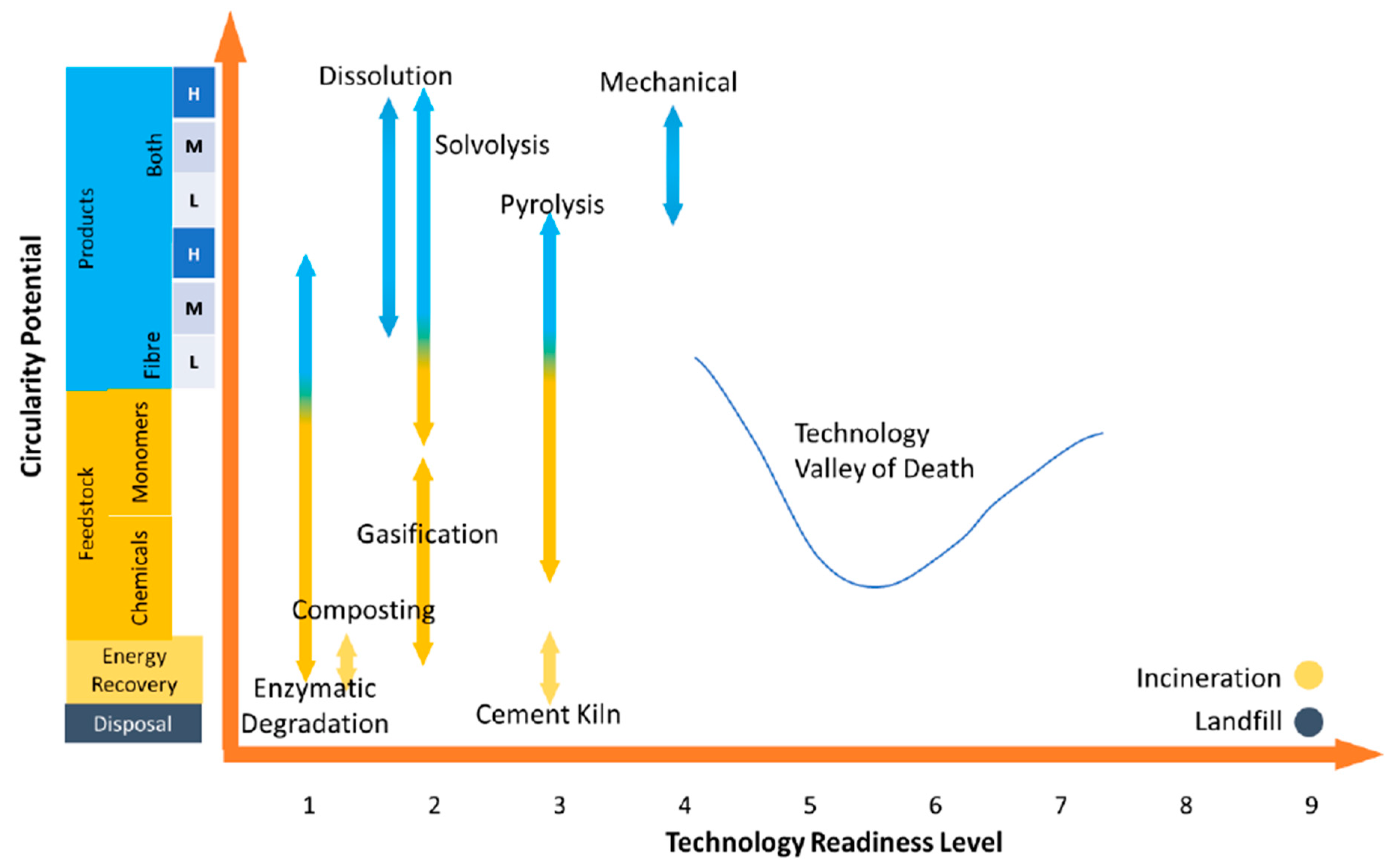

3.1. Circularity and TRL Assessments

3.1.1. Mechanical Recycling

3.1.2. Combustion in Cement Kiln

3.1.3. Classic Pyrolysis

3.1.4. Fluidised-Bed Pyrolysis

3.1.5. Microwave-Assisted Pyrolysis

3.1.6. Gasification

3.1.7. Enzymatic Degradation

3.1.8. Composting

3.1.9. Solvolysis

3.1.10. Dissolution

3.1.11. Comparison

3.2. MCDA

3.3. Experimental Testing

3.3.1. Laboratory Scale Testing

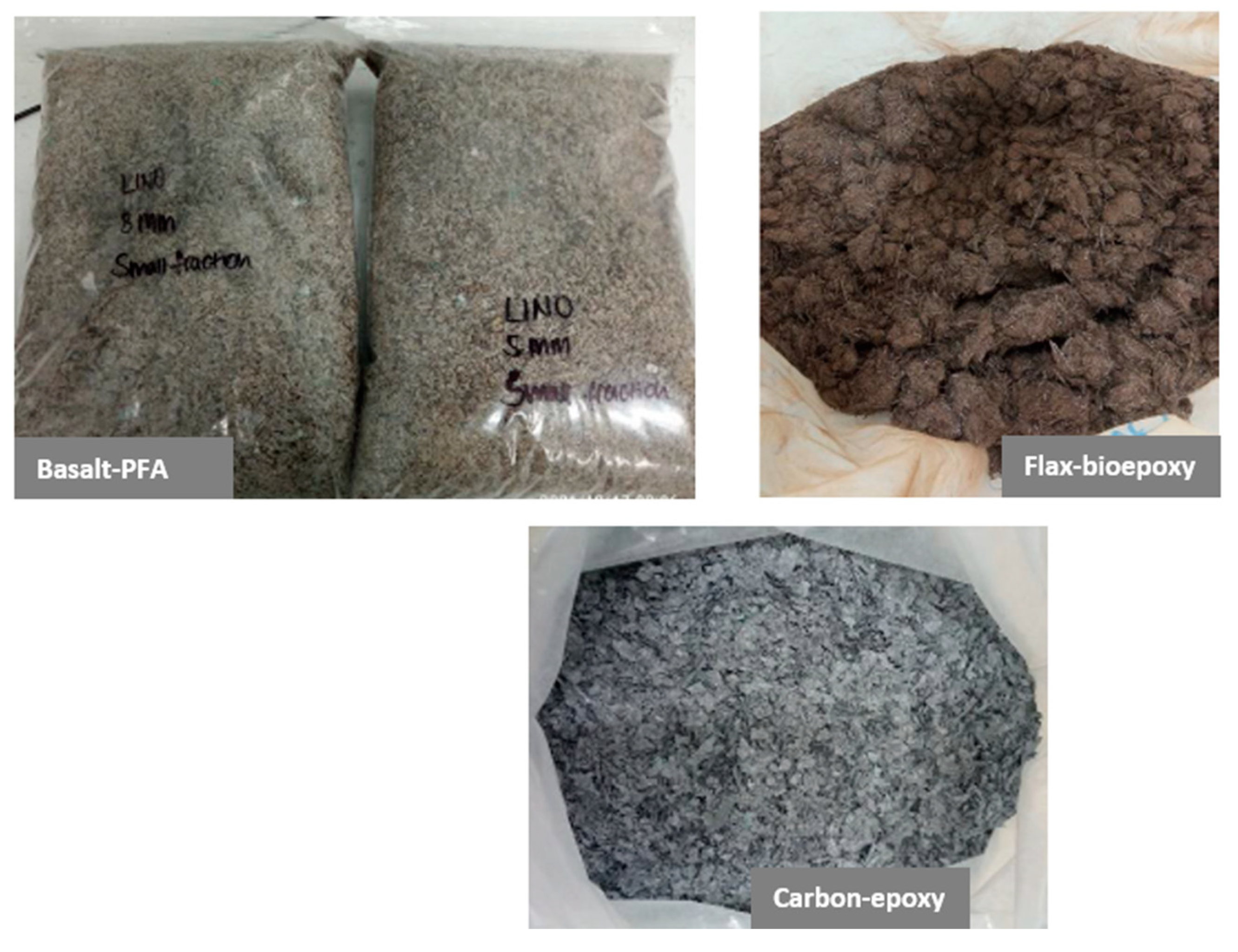

Mechanical Recycling

Dissolution

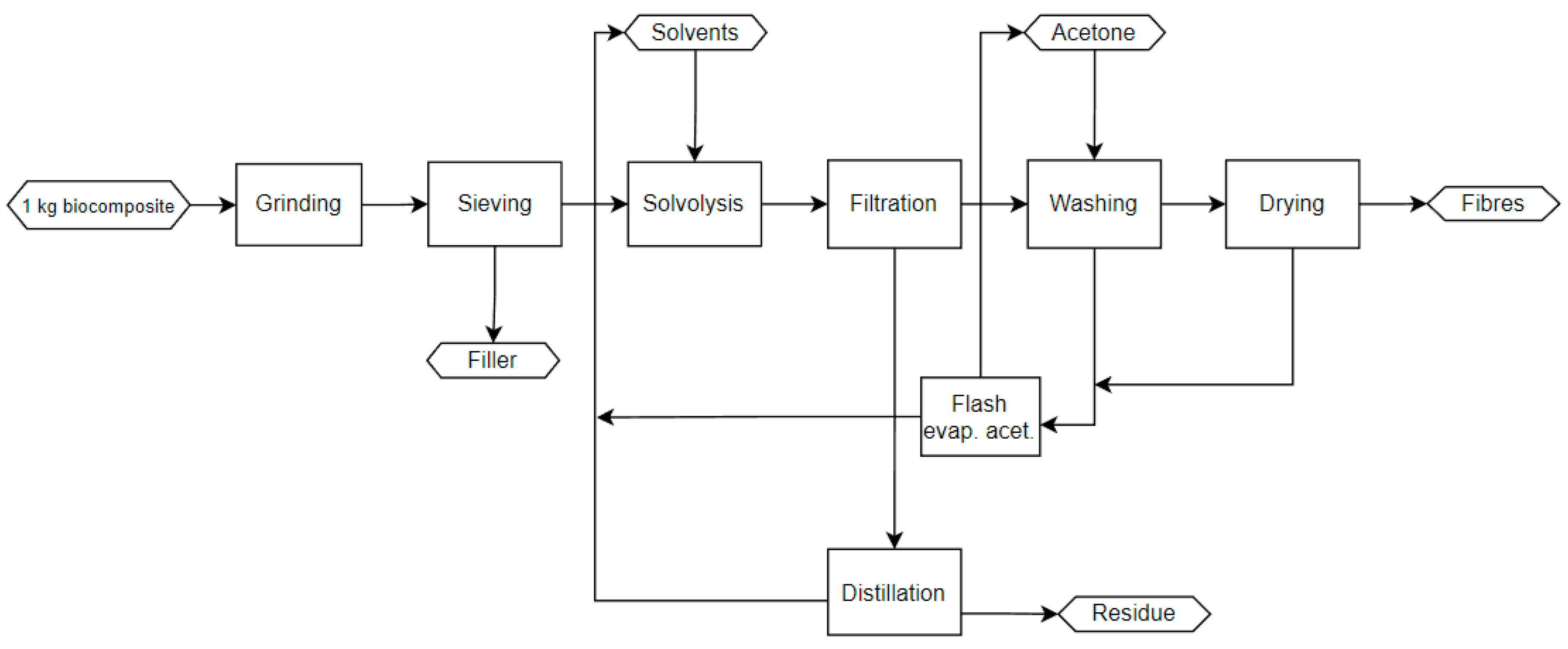

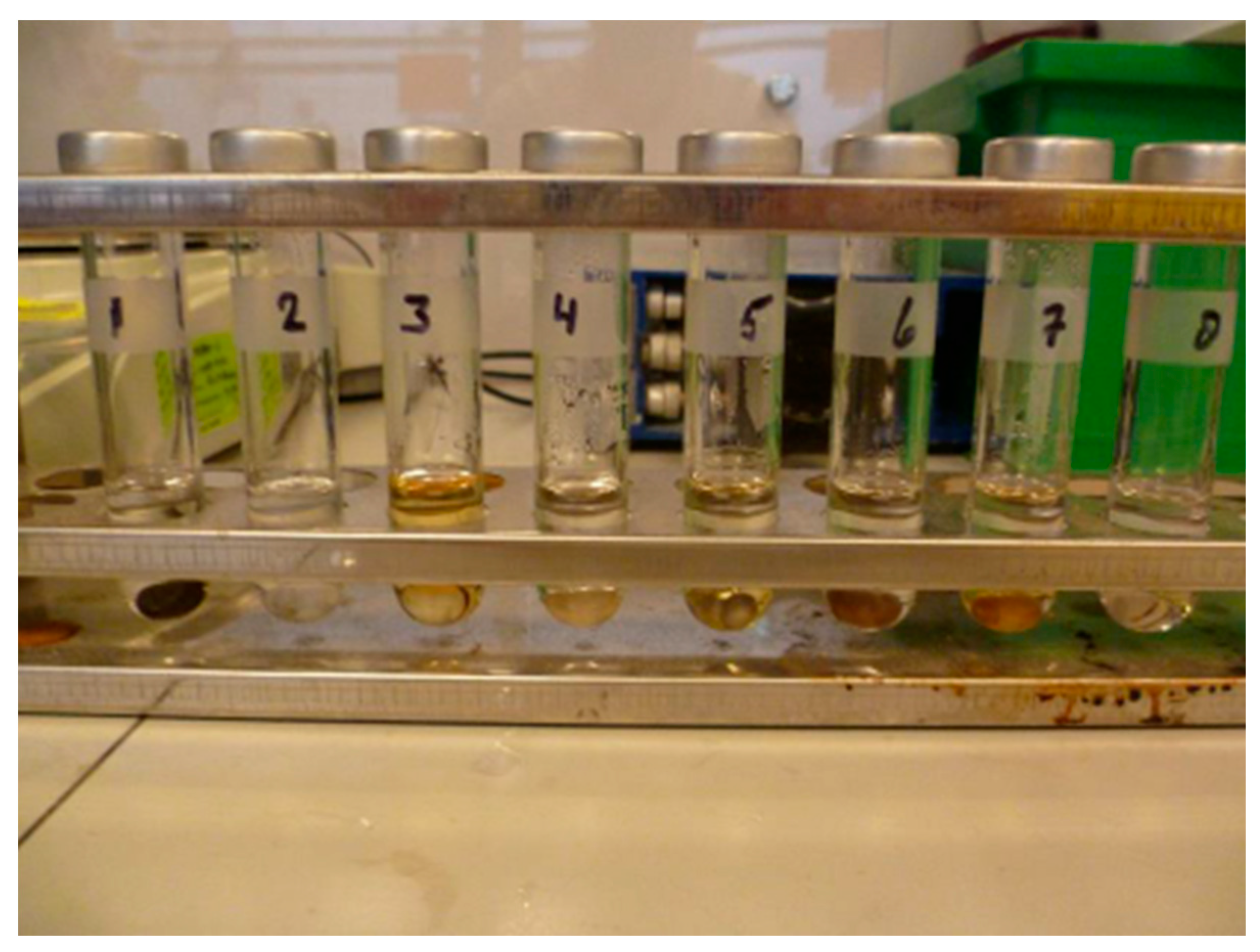

Solvolysis

3.3.2. Pilot Scale Testing

3.4. Sustainability Assessment

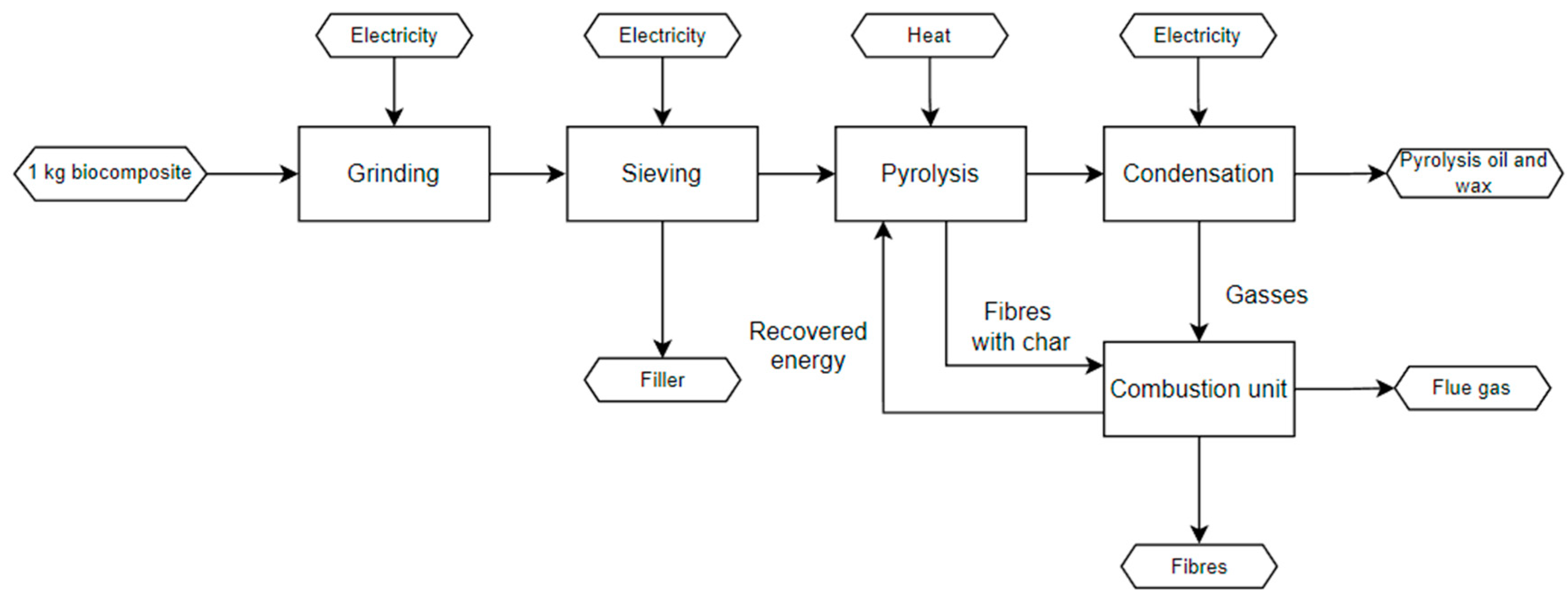

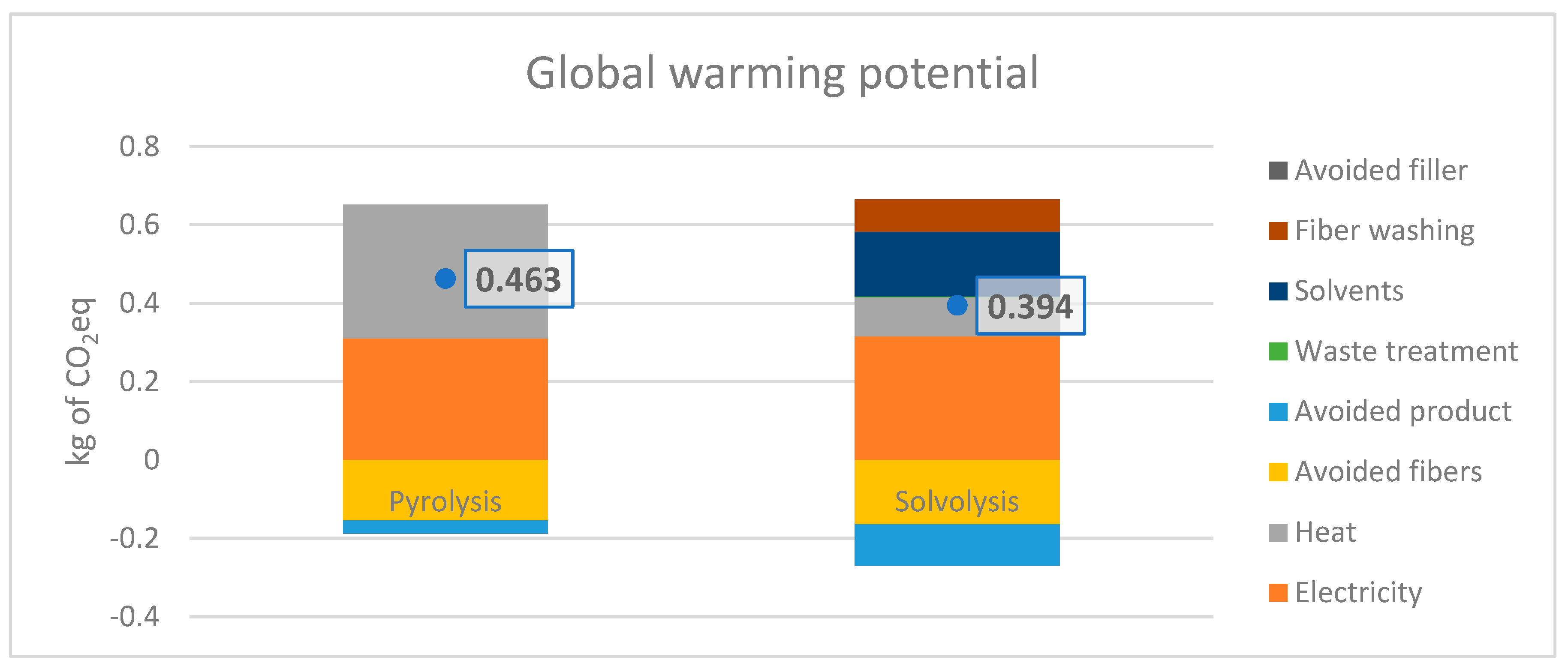

3.4.1. Life Cycle Assessment (LCA)

3.4.2. Techno-Economic Analysis (TEA)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Input Element | Value | Unit | Ecoinvent Dataset | Source |

|---|---|---|---|---|

| Energy consumption for grinding | 0.94 | kWh/kg input | Electricity, medium voltage, Europe (Eurostat) | Primary data |

| Energy consumption for sieving | 0.15 | kWh/kg input | Electricity, medium voltage, Europe (Eurostat) | Secondary data [17] |

| Energy consumption for pyrolysis | 6.64 | MJ/kg input | Heat, district or industrial, natural gas {RER}|market group for|APOS, U | Primary data |

| Recovered basalt fibres | 0.83 | kg/kg input | Basalt fibres | Primary data |

| Avoided product-pyrolysis oil | 0.008 | kg/kg input | Heavy fuel oil {Europe without Switzerland}| | Primary data |

| Avoided product—Wax | 0.03 | kg/kg input | Petroleum slack wax {Europe without Switzerland}| | Primary data |

| Avoided product—fillers | 0.02 | kg/kg input | Lime {Europe without Switzerland}|lime production, milled, loose | Primary data |

| CO2 emissions, biogenic | 0.19 | kg/kg input | Calculated |

| Input Element | Value | Unit | Ecoinvent Dataset | Source |

|---|---|---|---|---|

| Energy consumption for grinding | 0.94 | kWh/kg input | Electricity, medium voltage, Europe (Eurostat) | Primary data |

| Energy consumption for sieving | 0.15 | kWh/kg input | Electricity, medium voltage, Europe (Eurostat) | Secondary data [17] |

| Solvolysis heat consumption | 0.53 | kWh/kg input | Heat, district or industrial, natural gas {RER} | Primary data |

| Glacial acetic acid solvent | 8.03 | kg/kg input | Acetic acid, without water, in 98% solution state {GLO} | Primary data |

| Hydrogen peroxide solvent | 1.02 | kg/kg input | Hydrogen peroxide, without water, in 50% solution state {RER} | Primary data |

| Water (additive to solvolysis) | 4.15 | kg/kg input | Water, deionised {Europe without Switzerland} | Primary data |

| Acetone for washing fibres | 1.84 | kg/kg input | Acetone, liquid {RER}|market for acetone, liquid | Primary data |

| Recovered fibres | 0.84 | kg/kg input | Basalt fibres | Primary data |

| Recovered acetic acid | 8.00 | kg/kg input | Acetic acid, without water, in 98% solution state {GLO} | Primary data |

| Recovered water | 4.15 | kg/kg input | Water, deionised {Europe without Switzerland} | Primary data |

| Recovered hydrogen peroxide | 0.92 | kg/kg input | Hydrogen peroxide, without water, in 50% solution state {RER} | Primary data |

| Recovered acetone | 1.81 | kg/kg input | Acetone, liquid {RER}|market for acetone, liquid | Primary data |

| Waste water treatment of losses | 0.12 | kg/kg input | Wastewater, average {Europe without Switzerland} | Secondary data (Ecoinvent) |

| Incineration of fibre loss | 0.05 | kg/kg input | Waste glass {CH}|treatment of, municipal incineration | Secondary data (Ecoinvent) |

| Recovery of residue | 0.09 | kg/kg input | Petroleum slack wax {Europe without Switzerland}| | Primary data |

| Avoided product—fillers | 0.02 | kg/kg input | Lime {Europe without Switzerland}|lime production, milled, loose | Primary data |

References

- WWF. Cutting Aviation Pollution, (n.d.). Available online: https://www.worldwildlife.org/initiatives/cutting-aviation-pollution (accessed on 15 August 2022).

- Wong, K.; Rudd, C.; Pickering, S.; Liu, X. Composites recycling solutions for the aviation industry. Sci. China Technol. Sci. 2017, 60, 1291–1300. [Google Scholar] [CrossRef]

- IATA. Helping Aircraft Decommissioning, (n.d.). Available online: https://www.iata.org/en/programs/environment/aircraft-decommissioning/ (accessed on 15 August 2022).

- Le Duigou, A.; Bourmaud, A.; Davies, P.; Baley, C. Long term immersion in natural seawater of Flax/PLA biocomposite. Ocean Eng. 2014, 90, 140–148. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Gourier, C.; Baley, C. Multi-scale shear properties of flax fibre reinforced polyamide 11 biocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 123–129. [Google Scholar] [CrossRef]

- Dhakal, H.; Bourmaud, A.; Berzin, F.; Almansour, F.; Zhang, Z.; Shah, D.U.; Beaugrand, J. Mechanical properties of leaf sheath date palm fibre waste biomass reinforced polycaprolactone (PCL) biocomposites. Ind. Crops Prod. 2018, 126, 394–402. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Bennett, N.; Lopez-Arraiza, A.; Vallejo, F. Effects of water immersion ageing on the mechanical properties of flax and jute fibre biocomposites evaluated by nanoindentation and flexural testing. J. Compos. Mater. 2014, 48, 1399–1406. [Google Scholar] [CrossRef]

- Dhakal, H. Mechanical performance of PC-based biocomposites. In Biocomposites; Woodhead Publishing: Sawston, UK, 2015; pp. 303–317. [Google Scholar] [CrossRef]

- A Fowler, P.; Hughes, J.M.; Elias, R.M. Biocomposites: Technology, environmental credentials and market forces. J. Sci. Food Agric. 2006, 86, 1781–1789. [Google Scholar] [CrossRef]

- Bourmaud, A.; Mérotte, J.; Siniscalco, D.; Le Gall, M.; Gager, V.; Le Duigou, A.; Pierre, F.; Behlouli, K.; Arnould, O.; Beaugrand, J.; et al. Main criteria of sustainable natural fibre for efficient unidirectional biocomposites. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105504. [Google Scholar] [CrossRef]

- Skrifvars, M.; Dhakal, H.; Zhang, Z.; Gentilcore, J.; Åkesson, D. Study on the mechanical properties of unsaturated polyester sandwich biocomposites composed of uniaxial warp-knitted and non-woven viscose fabrics. Compos. Part A Appl. Sci. Manuf. 2019, 121, 196–206. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.-E.; Beaugrand, J. Development of sustainable biodegradable lignocellulosic hemp fiber/polycaprolactone biocomposites for light weight applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef]

- Bourmaud, A.; Åkesson, D.; Beaugrand, J.; Le Duigou, A.; Skrifvars, M.; Baley, C. Recycling of L-Poly-(lactide)-Poly-(butylene-succinate)-flax biocomposite. Polym. Degrad. Stab. 2016, 128, 77–88. [Google Scholar] [CrossRef]

- Samani, P.; Mendes, A.; Leal, V.; Guedes, J.M.; Correia, N. A sustainability assessment of advanced materials for novel housing solutions. Build. Environ. 2015, 92, 182–191. [Google Scholar] [CrossRef]

- ISO—ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework, (n.d.). ISO: Geneva, Switzerland. Available online: https://www.iso.org/standard/37456.html (accessed on 26 February 2023).

- ISO—ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guide-Lines, (n.d.). ISO: Geneva, Switzerland, 2006.

- Zhang, M.; Song, X.; Deines, T.W.; Pei, Z.J.; Wang, D. Biofuel Manufacturing from Woody Biomass: Effects of Sieve Size Used in Biomass Size Reduction. J. Biomed. Biotechnol. 2012, 2012, 581039. [Google Scholar] [CrossRef]

| Aspect | Criterium | Unit | Range | Weight |

|---|---|---|---|---|

| Technical | Efficiency of the main product(s) | % | 8.2 | |

| Scalability of the technology | - | Very high–very low | 8.1 | |

| Quality of the main product(s) | - | Very high–very low | 7.6 | |

| Amount of hazardous waste | kg/ton | 7.1 | ||

| Robustness of the operation | - | Very high–very low | 6.9 | |

| Complexity of the technology | - | Very high–very low | 6.6 | |

| Technology readiness level (TRL) | - | 1 to 9 | 6.1 | |

| Economic | CAPEX | EUR/ton | 6.5 | |

| Recovered fibre price | EUR/ton | 6.9 | ||

| Recovered resin percentage | % | 7.0 | ||

| Recovered fibre percentage | % | 6.9 | ||

| Revenues other products (energy, by-products) | EUR/ton | 6.4 | ||

| OPEX utilities and consumables | EUR/ton | 6.4 | ||

| Recovered resin price | EUR/ton | 6.6 | ||

| Resource | Recovered fibre percentage | % | 7.6 | |

| Recovered fibre quality | - | Very high–very low | 7.0 | |

| Additional heat consumption | MJ/ton | 6.9 | ||

| Recovered resin percentage | % | 7.0 | ||

| Recovered resin quality | - | Very high–very low | 6.4 | |

| External power consumption | kWh/ton | 6.7 | ||

| Environmental | Type of hazardous waste treatment | - | Cement kiln, hazardous waste incineration, landfill | 7.1 |

| External power consumption | kWh/ton | 6.8 | ||

| Recovered fibre percentage | % | 6.9 | ||

| Recovered resin quality | - | Very high–very low | 6.2 | |

| Recovered fibre quality | - | Very high–very low | 6.3 | |

| Additional heat consumption | MJ/ton | 6.4 | ||

| Recovered resin percentage | % | 6.2 | ||

| Type of non-hazardous waste treatment | - | Recycling, cement kiln, incineration, landfill | 5.3 |

| Performance | Weight |

|---|---|

| Technical | 1.10 |

| Economic | 0.93 |

| Resource | 0.94 |

| Environmental | 1.02 |

| Class of Solvent | For Both Bioepoxy and PFA | Only for PFA |

|---|---|---|

| Ketones | Methyl ethyl ketone | Acetone, cyclopentanone |

| Esters | Ethyl acetate, methyl acetate | Dimethyl carbonate, diethyl carbonate, |

| Sulphur compounds | Dimethyl sulfoxide | |

| Nitrogen compounds | N-methyl-2-pyrrolidone, dimethylformamide | |

| Aromatic hydrocarbons | Xylene | Toluene |

| Ethers | THF | |

| Alcohols | Methanol, ethanol, 1-propanol |

| Composite | EoL Technology | Cement Kiln | Dissolution | Energy Recovery (MSWI) | Enzymatic Degradation | Gasification | Mechanical Recycling | Pyrolysis, Classic | Pyrolysis, Fluidised Bed | Pyrolysis, Microwave | Solvolysis | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Basalt twill weave—bio-epoxy | Technical | 2.5 | 2.1 | 2.3 | 1.6 | 2.4 | 2.3 | 2.2 | 1.8 | 1.6 | 2.2 | 2.1 |

| Economic | 1.2 | 2.2 | 0.9 | 0.9 | 1.3 | 0.7 | 1.6 | 1.5 | 1.7 | 1.9 | 1.4 | |

| Resource | 1.6 | 3 | 1.6 | 2.2 | 2.3 | 2.8 | 2.4 | 2.6 | 2.6 | 2.6 | 2.4 | |

| Environmental | 1.5 | 2.7 | 1.7 | 2 | 2 | 2.3 | 2 | 2 | 2.1 | 2.4 | 2.1 | |

| Overall | 1.7 | 2.5 | 1.6 | 1.7 | 2 | 2 | 2.1 | 2 | 2 | 2.3 | 2.0 | |

| Flax tape—bio-epoxy | Technical | 2.1 | 2.2 | 2.3 | 1.3 | 2.1 | 2.3 | 2 | 1.3 | 1.1 | 2.2 | 1.9 |

| Economic | 1.2 | 2.2 | 0.9 | 1 | 0.9 | 0.7 | 1.3 | 1.5 | 1.2 | 1.9 | 1.3 | |

| Resource | 1.6 | 3 | 1.6 | 2.2 | 1.3 | 2.8 | 1.4 | 1.5 | 1.5 | 2.4 | 1.9 | |

| Environmental | 1.5 | 2.7 | 1.7 | 2 | 1.6 | 2.3 | 1.4 | 1.4 | 1.4 | 2.3 | 1.8 | |

| Overall | 1.6 | 2.5 | 1.6 | 1.6 | 1.5 | 2 | 1.5 | 1.4 | 1.3 | 2.2 | 1.7 | |

| Average score | 1.7 | 2.5 | 1.6 | 1.7 | 1.8 | 2.0 | 1.8 | 1.7 | 1.7 | 2.3 | 1.9 |

| Parameter | Unit | Pyrolysis | Solvolysis |

|---|---|---|---|

| Heating | MJ/kg feedstock | 6.450 | 1.910 |

| Electricity | kWh/kg feedstock | 1.092 | 1.115 |

| Energy costs | EUR/kg feedstock | 0.090 | 0.066 |

| Capital Investment | Million euros | 2.726 (alternative) 5.235 (oversized) | 8.021 |

| Total benefit | EUR/kg feedstock | 5.00 | 4.910 |

| Production costs | EUR/kg feedstock | 0.292 (oversized) 0.256 (alternative) | 0.792 |

| Net benefits | EUR/kg feedstock | 4.71 (oversized) 4.74 (alternative) | 4.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferjan, Š.; Jovičić, M.; Lardiés Miazza, N.; Ligthart, T.; Harvey, C.; Fita, S.; Mehta, R.; Samani, P. Sustainability Assessment of the End-of-Life Technologies for Biocomposite Waste in the Aviation Industry. Polymers 2023, 15, 2689. https://doi.org/10.3390/polym15122689

Ferjan Š, Jovičić M, Lardiés Miazza N, Ligthart T, Harvey C, Fita S, Mehta R, Samani P. Sustainability Assessment of the End-of-Life Technologies for Biocomposite Waste in the Aviation Industry. Polymers. 2023; 15(12):2689. https://doi.org/10.3390/polym15122689

Chicago/Turabian StyleFerjan, Špela, Milkica Jovičić, Nora Lardiés Miazza, Tom Ligthart, Clare Harvey, Sergio Fita, Rajesh Mehta, and Pouya Samani. 2023. "Sustainability Assessment of the End-of-Life Technologies for Biocomposite Waste in the Aviation Industry" Polymers 15, no. 12: 2689. https://doi.org/10.3390/polym15122689

APA StyleFerjan, Š., Jovičić, M., Lardiés Miazza, N., Ligthart, T., Harvey, C., Fita, S., Mehta, R., & Samani, P. (2023). Sustainability Assessment of the End-of-Life Technologies for Biocomposite Waste in the Aviation Industry. Polymers, 15(12), 2689. https://doi.org/10.3390/polym15122689