Influence of Non-Rubber Components on the Properties of Unvulcanized Natural Rubber from Different Clones

Abstract

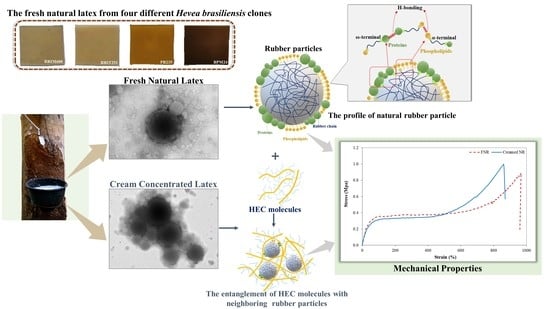

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Creamed Concentrated Latex

2.3. Characterization and Measurements

2.3.1. Analysis and Testing of the Fresh Natural Latex and Creamed Concentrated Latex

2.3.2. The Protein Contents

2.3.3. Molecular Weight and Polydispersity Index

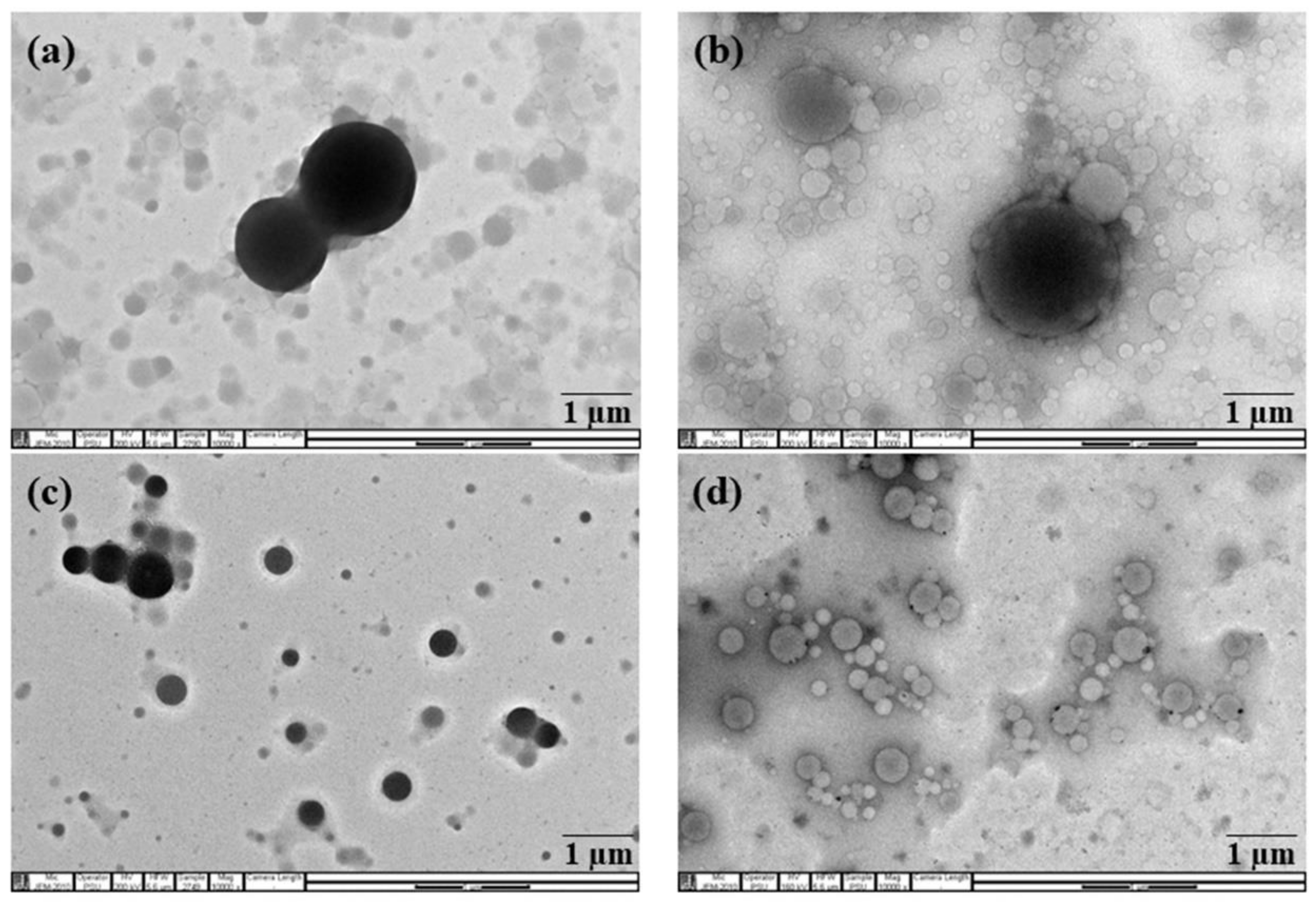

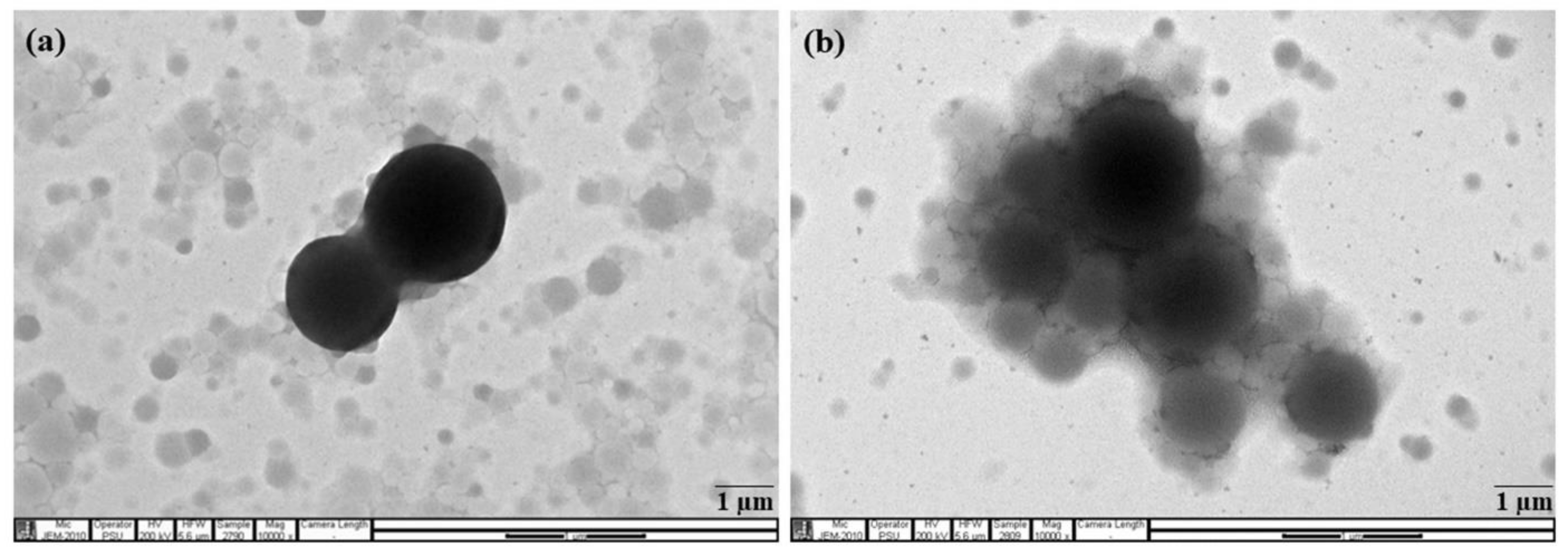

2.3.4. Morphological Properties

2.3.5. Mechanical Properties

3. Results and Discussion

3.1. Characterization of Fresh Natural Latex

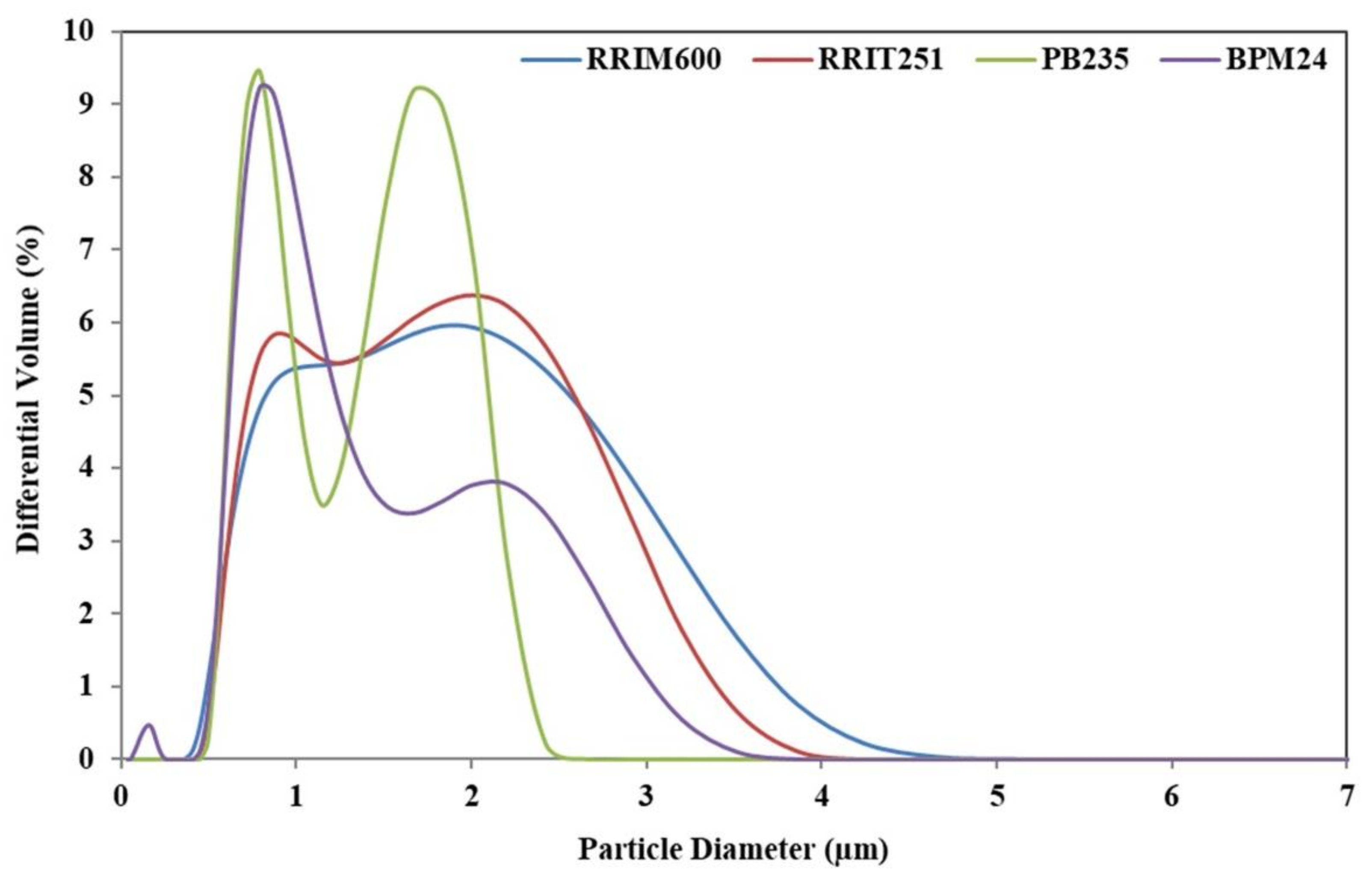

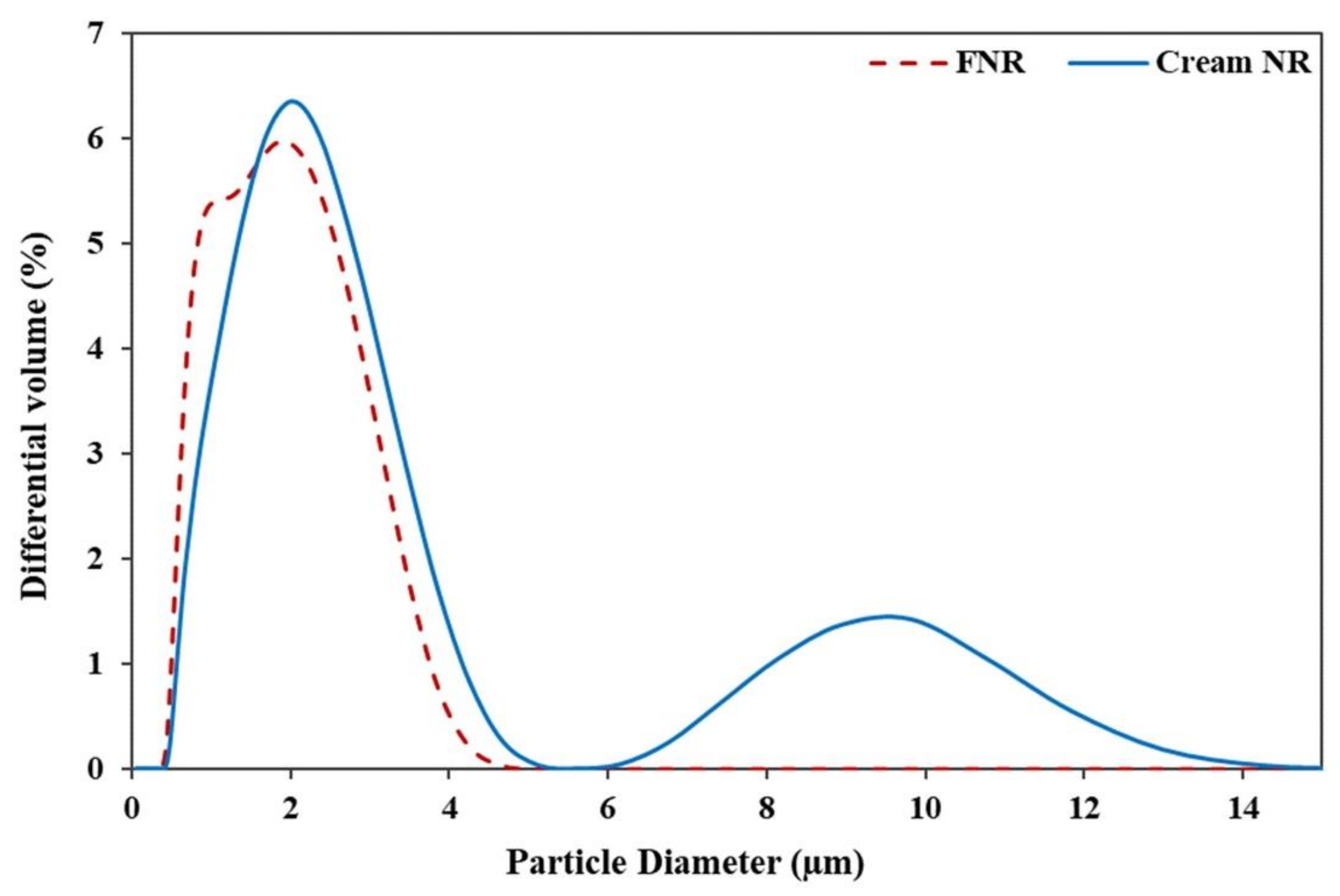

3.2. Rubber Particle Size Distribution of the Fresh Natural Latex

3.3. Molar Mass Distribution of the Fresh Natural Latex

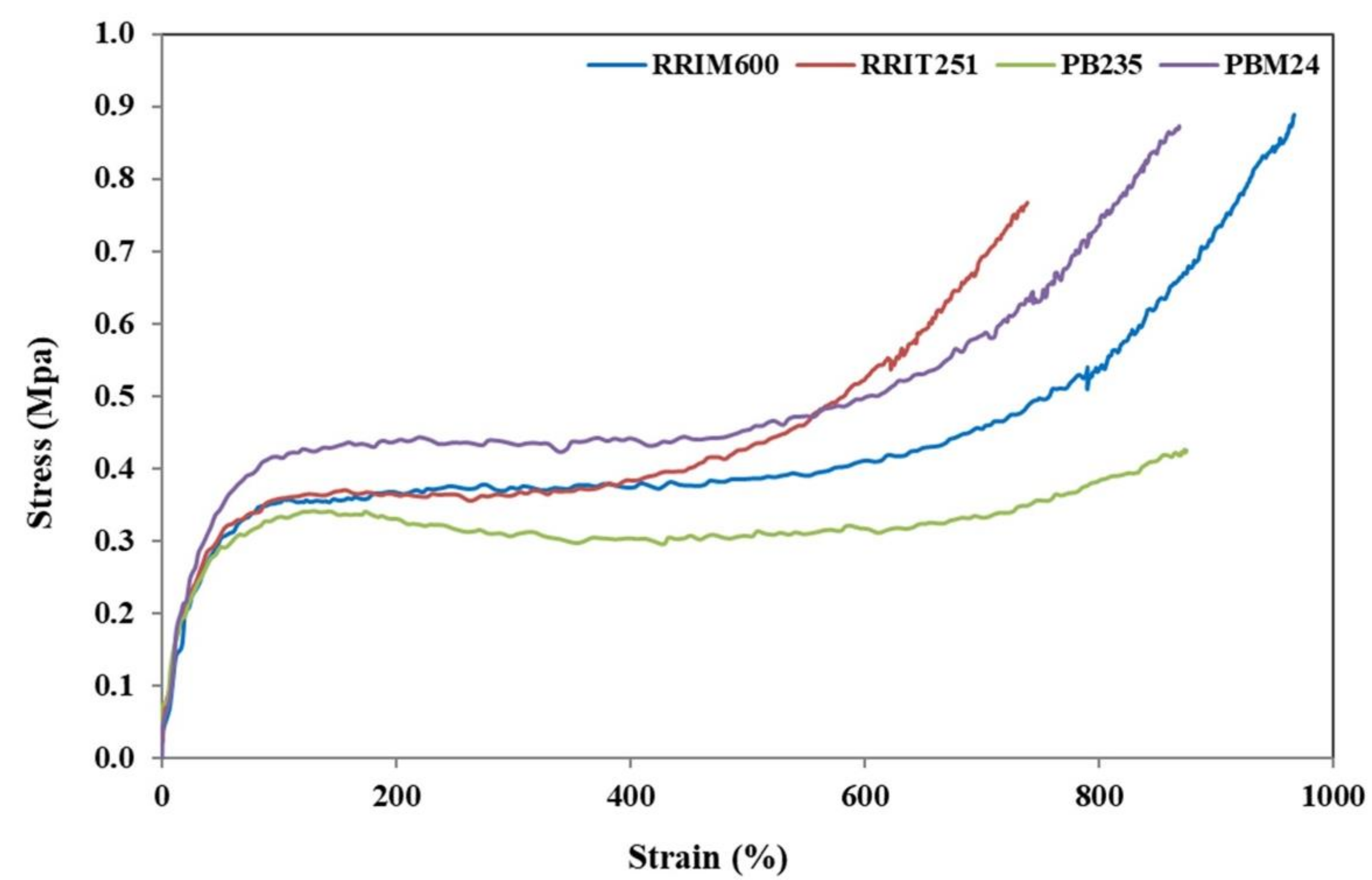

3.4. Mechanical Properties of Fresh Natural Latex

3.5. Characterization of Cream Concentrated Latex from Four Different Hevea Brasiliensis Clones

3.6. Rubber Particle Size Distribution of Fresh Natural Latex and Cream Concentrated Latex from the RRIM600 Clone

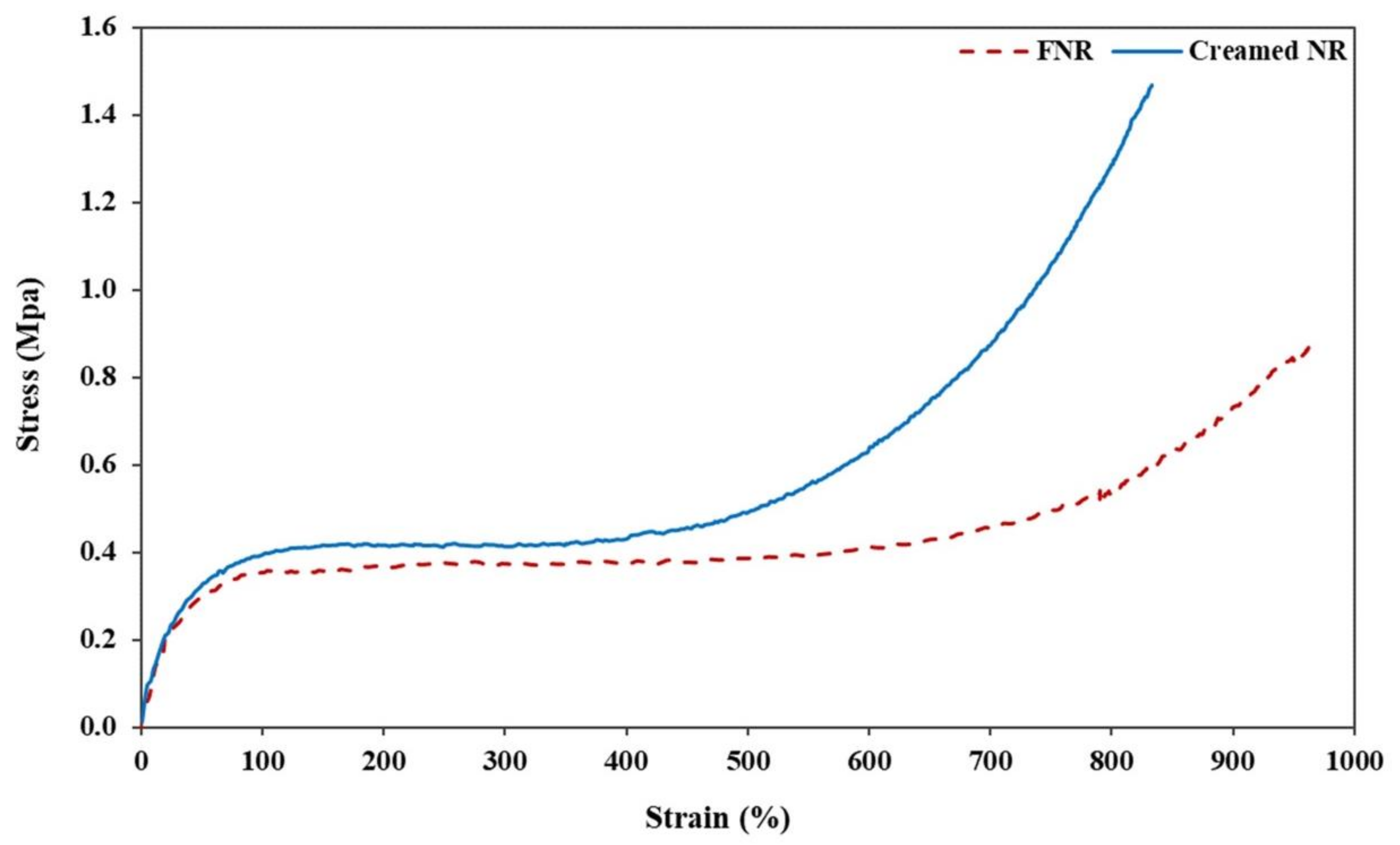

3.7. Comparison between the Mechanical Properties of Fresh Natural Latex and Cream Concentrated Latex fromRRIM600 Clone

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ochigbo, S.S.; Lafia-Araga, R.A.; Suleiman, M.A.T. Comparison of two creaming methods for preparation of natural rubber latex concentrates from field latex. Afr. J. Agric. Res. 2011, 12, 2619–2916. [Google Scholar] [CrossRef]

- Suksup, R.; Imkaew, C.; Smitthipong, W. Cream concentrated latex for foam rubber products. In Proceedings of the 4th International Conference on Mechanical, Materials and Manufacturing (ICMMM 2017), Atlanta, GA, USA, 25–27 October 2017; Volume 272, pp. 1–8. [Google Scholar]

- Riyajan, S.; Santipanusopon, S. Influence of ammonia concentration and storage period on properties field NR latex and skim coagulation. J. Elastomers Plast. 2010, 63, 240–245. [Google Scholar]

- Suksup, R.; Sun, Y.; Sukatta, U.; Smitthipong, W. Foam rubber from centrifuged and creamed latex. J. Polym. Eng. 2019, 39, 1–9. [Google Scholar] [CrossRef]

- Yip, E.; Cacioli, P. The manufacture of gloves from natural rubber latex. J. Allergy Clin. Immunol. 2002, 110, S3–S14. [Google Scholar] [CrossRef] [PubMed]

- Peng, Z.; Kong, L.X.; Li, S.D.; Chen, Y.; Huang, M.F. Self-assembled natural rubber/silica nanocomposites: Its preparation and characterization. Compos. Sci. Technol. 2007, 67, 3130–3139. [Google Scholar] [CrossRef]

- Krainoi, A.; Poomputsa, K.; Kalkornsurapranee, E.; Johns, J.; Songtipya, L.; Nip, R.L.; Nakaramontri, Y. Disinfectant natural rubber films filled with modified zinc oxide nanoparticles: Synergetic effect of mechanical and antibacterial properties. Express Polym. Lett. 2021, 15, 1081–1100. [Google Scholar] [CrossRef]

- Afreen, S.; Haque, R.K.; Huda, M.K. Troubleshooting for the observed problems in processing latex concentrate from natural resource. In Proceedings of the 4th International Conference on Energy and Environment 2013 (ICEE 2013), Putrajaya, Malaysia, 5–6 March 2013; Volume 16, pp. 1–4. [Google Scholar] [CrossRef] [Green Version]

- Rong, J.; Yang, J.; Huang, Y.; Luo, W.; Hu, X. Characteristic tearing energy and fatigue crack propagation of filled natural rubber. Polymers 2021, 13, 3891. [Google Scholar] [CrossRef]

- Nun-anan, P.; Wisunthorn, S.; Pichaiyut, S.; Vennemann, N.; Nakason, C. Novel approach to determine non-rubber content in Hevea brasiliensis: Influence of clone variation on properties of un-vulcanized natural rubber. Ind. Crops Prod. 2018, 118, 38–47. [Google Scholar] [CrossRef]

- Nun-anan, P.; Wisunthorn, S.; Pichaiyut, S.; Nathaworn, C.D.; Nakason, C. Influence of nonrubber components on properties of unvulcanized natural rubber. Polym. Adv. Technol. 2020, 31, 44–59. [Google Scholar] [CrossRef]

- Thongpet, C.; Wisunthorn, S.; Liengprayoon, S.; Vaysse, L.; Bonfils, F.; Nakason, C. Effect of rubber clone on fatty acid composition and properties of air-dried sheet. Adv. Mater. Res. 2014, 844, 194–197. [Google Scholar] [CrossRef]

- Kakubo, T.; Matsuura, A.; Kawahara, S.; Tanaka, Y. Origin of characteristic properties of natural rubber—effect of fatty acids on crystallization of cis-1,4-polyisoprene. Rubber Chem. Technol. 1998, 71, 70–75. [Google Scholar] [CrossRef]

- Moreno, R.M.B.; Ferreira, M.; Souza, P.D.; Henrique, G.L.; Mattoso, C. Technological properties of latex and natural rubber of Hevea brasiliensis clones. Sci. Agric. 2005, 62, 122–126. [Google Scholar] [CrossRef] [Green Version]

- Alam, D.; Yadav, L.; Nath, D.G.; Purushotham, B.B.M.; Kanna, T.R. Determining surface tension of different fluids with the help of tensiometer. Int. Refereed J. Eng. Sci. 2017, 6, 42–45. [Google Scholar]

- Baur, J.F.; Ensminger, G.L. The association of official analytical chemists (AOAC). J. Am. Oil Chem. Soc. 1977, 54, 171–172. [Google Scholar] [CrossRef]

- Thongnuanchan, B.; Ninjan, R.; Kaesaman, A.; Nakason, C. Synthesis of modified natural rubber with grafted poly(acetoacetoxyethyl methacrylate-co-methyl methacrylate) and performance of derived adhesives with GTA crosslinker. Polym. Eng. Sci. 2018, 58, 1610–1618. [Google Scholar] [CrossRef]

- Pethin, D.; Nakkanong, K.; Nualsri, C. Performance and genetic assessment of rubber tree clones in Southern Thailand. J. Agric. Sci. 2015, 72, 306–313. [Google Scholar] [CrossRef] [Green Version]

- Rojruthai, P.; Pareseecharoen, C.; Sakdapipanich, J. Physical decoloration in the concentration process of natural rubber. SPE Polym. 2021, 2, 210–216. [Google Scholar] [CrossRef]

- Wei, O.C.; Bahri, A.R.S. Rubber particles: Size, molecular weight and their distributions detected in wild Hevea species. J. Biol. Agric. Healthc. 2016, 6, 98–103. [Google Scholar]

- Shamsul, B.A.R. Evaluation of possible natural latex substitutes from artificially prepared latex using transmission electron microscope. J. Nat. Sci. Res. 2014, 4, 147–159. [Google Scholar]

- Amnuaypornsri, S.; Sakdapipanich, J.; Tanaka, Y. Green strength of natural rubber: The origin of the stress–strain behavior of natural rubber. J. Appl. Polym. Sci. 2009, 111, 2127–2133. [Google Scholar] [CrossRef]

- Junkong, P.; Cornish, K.; Ikeda, Y. Characteristics of mechanical properties of sulphur cross-linked guayule and dandelion natural rubbers. RSC Adv. 2017, 7, 50739–50752. [Google Scholar] [CrossRef] [Green Version]

- Thuong, N.T.; Nghia, P.T.; Kawahara, S. Factors influencing green strength of commercial natural rubber. Green Process. Synth. 2018, 7, 399–403. [Google Scholar] [CrossRef]

- Jong, L. Modulus enhancement of natural rubber through the dispersion size reduction of protein/fiber aggregates. Ind. Crops Prod. 2014, 55, 25–32. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Chen, X.; Wang, Y.; Zhao, F.; Luo, F.; Liao, S. The role of non-rubber components on molecular network of natural rubber during accelerated storage. Polymers 2020, 12, 2880. [Google Scholar] [CrossRef]

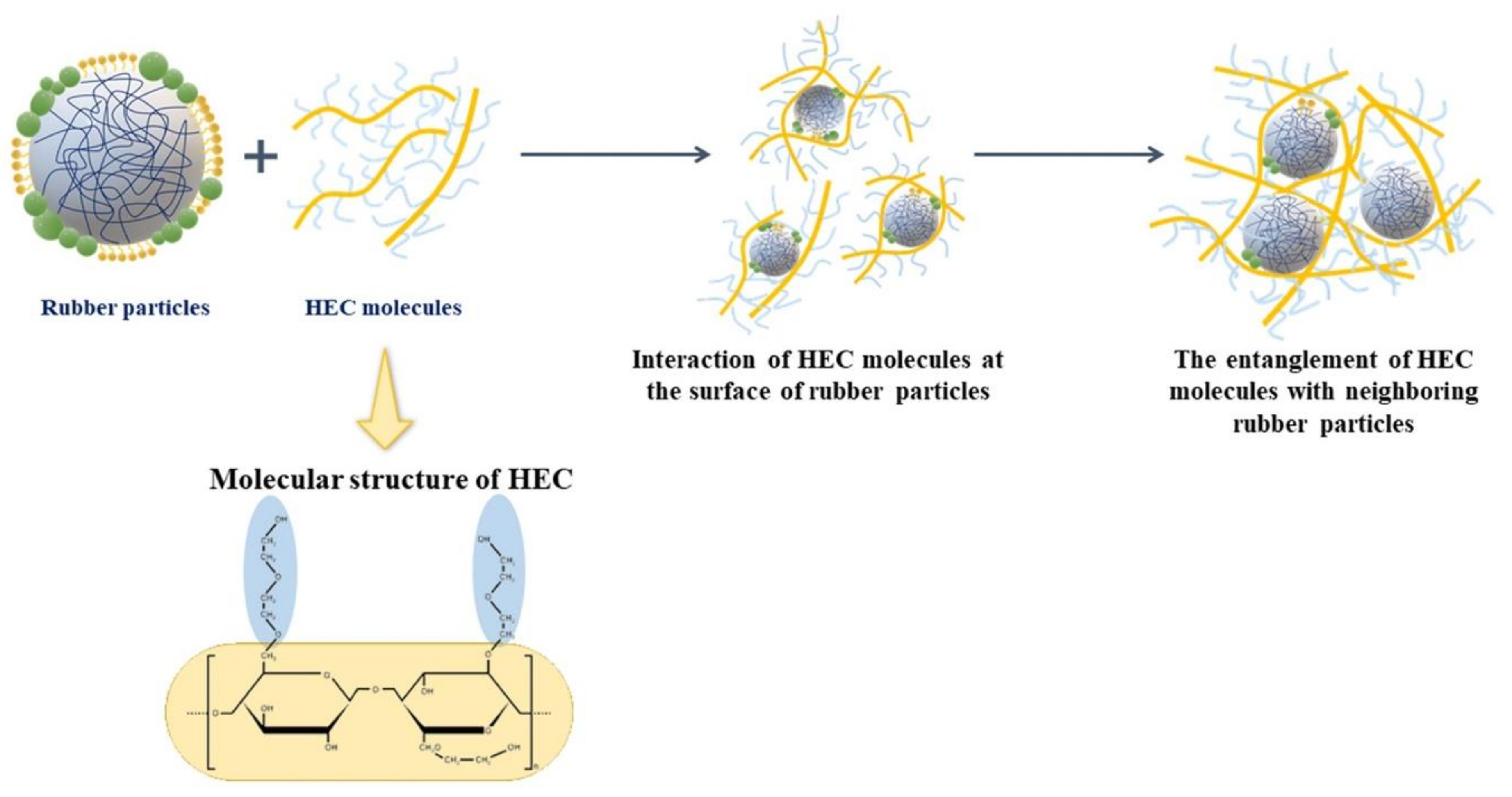

- Yumae, N.; Kaesaman, A.; Rungvichaniwat, A.; Thepchalerm, C.; Nakason, C. Novel creaming agent for preparation of creamed concentrated natural rubber latex. J. Elastomers Plast. 2010, 42, 453–470. [Google Scholar] [CrossRef]

- Jodar-Reyes, A.B.; Martin-Rodriguez, A.; Ortega-Vinuesa, J.L. Effect of the ionic surfactant concentration on the stabilization/destabilization of polystyrene colloidal particles. J. Colloid Interface Sci. 2006, 298, 248–257. [Google Scholar] [CrossRef]

- Promsung, R.; Nakaramontri, Y.; Uthaipan, N.; Kummerlöwe, C.; Johns, J.; Vennemann, N.; Kalkornsurapranee, E. Effects of protein contents in different natural rubber latex forms on the properties of natural rubber vulcanized with glutaraldehyde. Express Polym. Lett. 2021, 15, 308–318. [Google Scholar] [CrossRef]

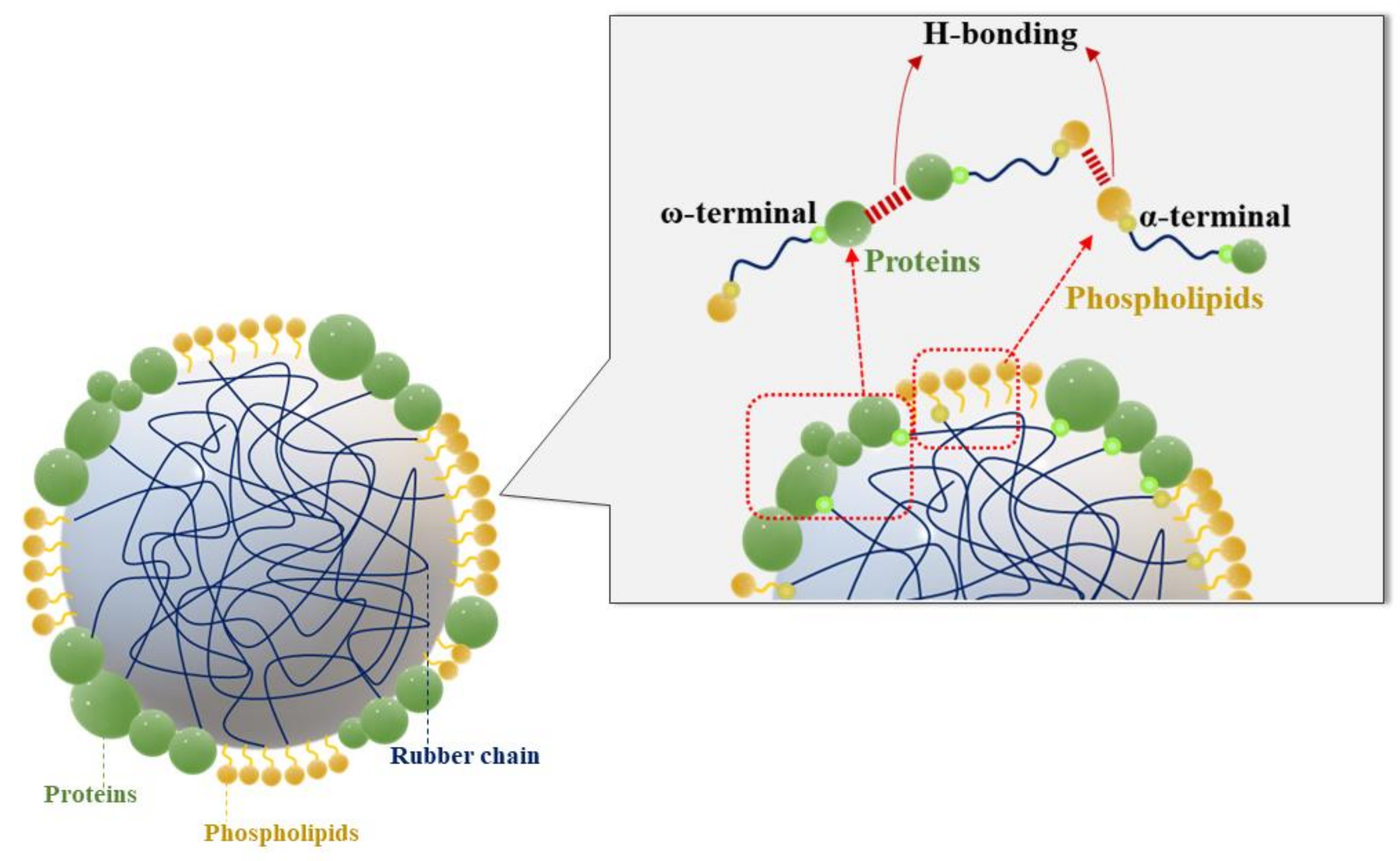

- Sansatsadeekul, J.; Sakdapipanich, J.; Rojruthai, P. Characterization of associated proteins and phospholipids in natural rubber latex. J. Biosci. Bioeng. 2011, 111, 628–634. [Google Scholar] [CrossRef]

- Kawahara, S.; Isono, Y.; Kakubo, T.; Tanaka, Y.; Aik-Hwee, E. Crystallization Behavior and Strength of Natural Rubber Isolated from Different Hevea Clone. Rubber Chem. Technol. 2000, 73, 39–46. [Google Scholar] [CrossRef]

| Constituents | % Composition |

|---|---|

| Rubber particles (cis-1,4-polyisoprene) | 30–40 |

| Protein | 2.0–3.0 |

| Lipids | 0.1–0.5 |

| Resins | 1.5–3.5 |

| Ash | 0.5–1.0 |

| Sugars | 1.0–2.0 |

| Water | 55–65 |

| Chemicals | Quantity, phr |

|---|---|

| Fresh filed NR latex | 100 |

| HEC (1% w/w in water) | 0.4 |

| 20% w/w potassium laurate | 0.3 |

| Properties | Hevea Brasiliensis Clones | |||

|---|---|---|---|---|

| RRIM600 | RRIT251 | PB235 | BPM24 | |

| Total solid content (%) | 45.30 ± 0.16 | 43.47 ± 0.13 | 45.16 ± 0.05 | 28.03 ± 0.03 |

| Dry rubber content (%) | 40.90 ± 3.45 | 40.82 ± 0.28 | 42.47 ± 0.58 | 23.61 ± 1.90 |

| Protein content (wt%) | 3.03 ± 0.009 | 3.33 ± 0.007 | 2.64 ± 0.004 | 3.31 ± 0.002 |

| Viscosity (cps) (Spin no.1/Speed 60 rpm) | 12.50 | 11.50 | 12.00 | 5.00 |

| Surface tension (mN/m) | 45.50 ± 0.70 | 45.00 ± 1.41 | 42.00 ± 0.00 | 45.00 ± 1.41 |

| Lovibond comparator | 2.50–3.00 | 3.00–4.00 | 8.00–10.00 | 12.00–14.00 |

| Particle size (µm) (mean) | 1.66 | 1.59 | 1.27 | 1.24 |

| Hevea Brasiliensis Clones | Mn × 105 (g/mol) | Mw × 106 (g/mol) | Polydispersity Index (PDI) |

|---|---|---|---|

| RRIM600 | 3.81 | 1.96 | 5.14 |

| RRIT251 | 3.71 | 1.68 | 4.53 |

| PB235 | 4.34 | 2.02 | 4.66 |

| BPM24 | 1.37 | 1.09 | 7.92 |

| Properties | Hevea Brasiliensis Clones | |||

|---|---|---|---|---|

| RRIM600 | RRIT251 | PB235 | BPM24 | |

| 100% modulus (MPa) | 0.36 ± 0.01 | 0.37 ± 0.04 | 0.32 ± 0.01 | 0.40 ± 0.02 |

| 300% modulus (MPa) | 0.38 ± 0.01 | 0.39 ± 0.06 | 0.34 ± 0.04 | 0.42 ± 0.02 |

| 500% modulus (MPa) | 0.40 ± 0.02 | 0.42 ± 0.08 | 0.36 ± 0.01 | 0.45 ± 0.04 |

| Green strength (MPa) | 0.86 ± 0.07 | 0.73 ± 0.09 | 0.47 ± 0.07 | 0.89 ± 0.06 |

| Elongation at break (%) | 969 ± 13 | 884 ± 4 | 850 ± 45 | 877 ± 30 |

| Hardness (Shore A) | 15.0 ± 0.8 | 15.5 ± 0.5 | 13.0 ± 0.8 | 14.0 ± 0.5 |

| Properties | Hevea Brasiliensis Clones | |||

|---|---|---|---|---|

| RRIM600 | RRIT251 | PB235 | BPM24 | |

| Total solid content (%) | 56.75 ± 0.02 | 54.46 ± 0.05 | 66.30 ± 0.05 | 49.93 ± 0.15 |

| Dry rubber content (%) | 54.91 ± 0.06 | 51.53 ± 1.27 | 64.80 ± 0.02 | 48.01 ± 1.81 |

| Protein content (wt%) | 2.20 ± 0.002 | 2.93 ± 0.009 | 1.64 ± 0.004 | 2.60 ± 0.001 |

| Viscosity (cps)(Spin no.1/Speed 60 rpm) | 46.00 | 41.00 | 75.50 | 7.00 |

| Surface tension (mN/m) | 41.50 ± 0.71 | 41.00 ± 0.00 | 39.00 ± 0.00 | 38.50 ± 0.70 |

| Lovibond comparator | 2.00–2.50 | 3.50–5.00 | 7.00–8.00 | 5.00–7.00 |

| Particle size (µm) (mean) | 1.90 ± 0.00 | 1.79 ± 0.70 | 1.52 ± 0.70 | 1.22 ± 0.64 |

| Properties | Fresh Natural Latex | Cream Concentrated Latex |

|---|---|---|

| 100% modulus (MPa) | 0.36 ± 0.010 | 0.39 ± 0.005 |

| 300% modulus (MPa) | 0.38 ± 0.010 | 0.42 ± 0.005 |

| 500% modulus (MPa) | 0.40 ± 0.015 | 0.51 ± 0.012 |

| Green strength (MPa) | 0.86 ± 0.070 | 1.47 ± 0.030 |

| Elongation at break (%) | 969 ± 13 | 834 ± 4 |

| Hardness (Shore A) | 13.0 ± 0.8 | 27.0 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lehman, N.; Tuljittraporn, A.; Songtipya, L.; Uthaipan, N.; Sengloyluan, K.; Johns, J.; Nakaramontri, Y.; Kalkornsurapranee, E. Influence of Non-Rubber Components on the Properties of Unvulcanized Natural Rubber from Different Clones. Polymers 2022, 14, 1759. https://doi.org/10.3390/polym14091759

Lehman N, Tuljittraporn A, Songtipya L, Uthaipan N, Sengloyluan K, Johns J, Nakaramontri Y, Kalkornsurapranee E. Influence of Non-Rubber Components on the Properties of Unvulcanized Natural Rubber from Different Clones. Polymers. 2022; 14(9):1759. https://doi.org/10.3390/polym14091759

Chicago/Turabian StyleLehman, Nussana, Akarapong Tuljittraporn, Ladawan Songtipya, Nattapon Uthaipan, Karnda Sengloyluan, Jobish Johns, Yeampon Nakaramontri, and Ekwipoo Kalkornsurapranee. 2022. "Influence of Non-Rubber Components on the Properties of Unvulcanized Natural Rubber from Different Clones" Polymers 14, no. 9: 1759. https://doi.org/10.3390/polym14091759

APA StyleLehman, N., Tuljittraporn, A., Songtipya, L., Uthaipan, N., Sengloyluan, K., Johns, J., Nakaramontri, Y., & Kalkornsurapranee, E. (2022). Influence of Non-Rubber Components on the Properties of Unvulcanized Natural Rubber from Different Clones. Polymers, 14(9), 1759. https://doi.org/10.3390/polym14091759