Preparation and Analysis of Sheath–Core Intelligent Thermo-Regulating Fiber

Abstract

:1. Introduction

2. Numerical Simulation

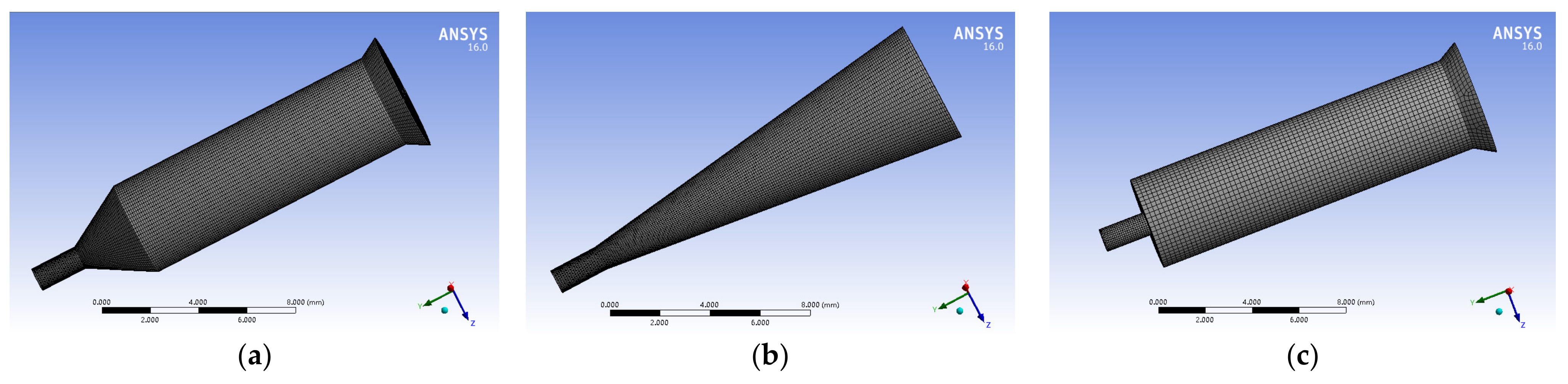

2.1. Modeling

2.2. Material Parameters

2.3. Boundary Conditions

3. Experimental Methods

3.1. Preparation of Sheath–Core Intelligent Thermo-Regulating Fiber

3.2. Performance Characterization Test

3.2.1. Thermal Performance Test

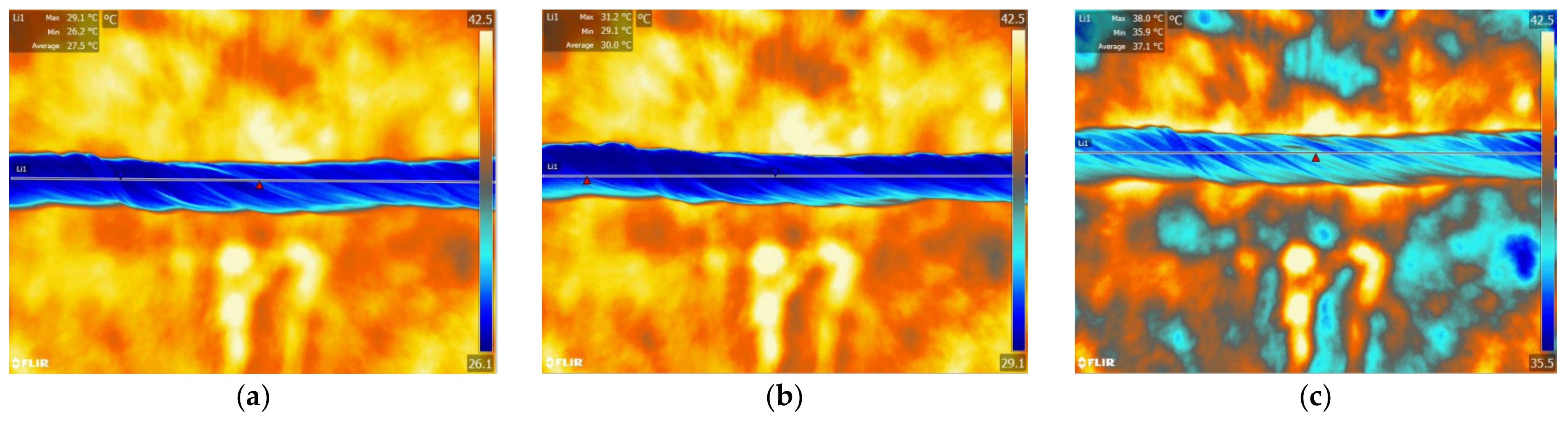

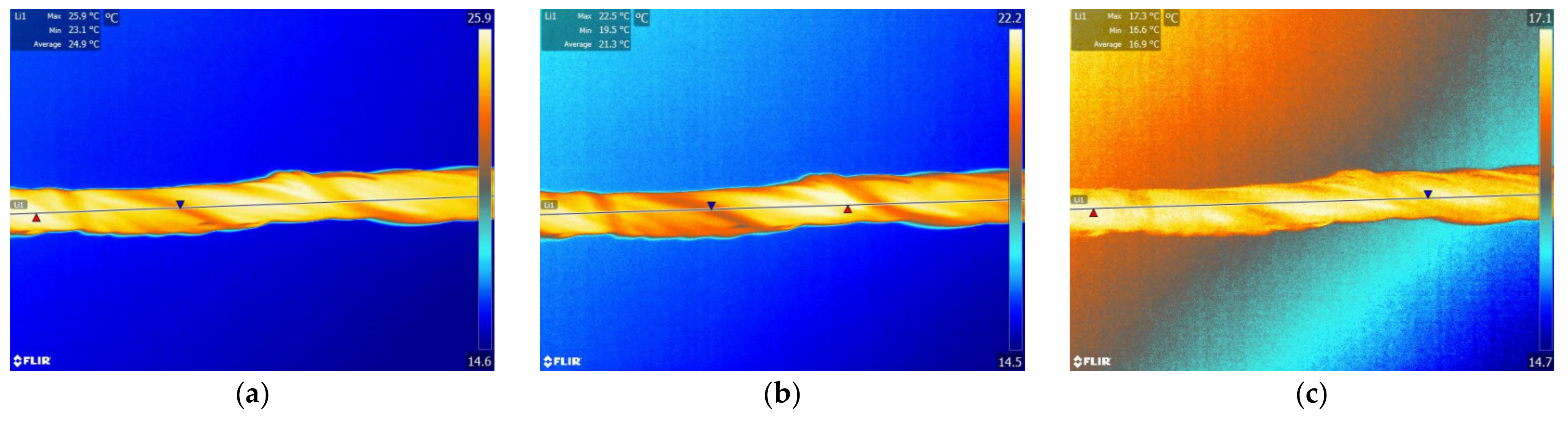

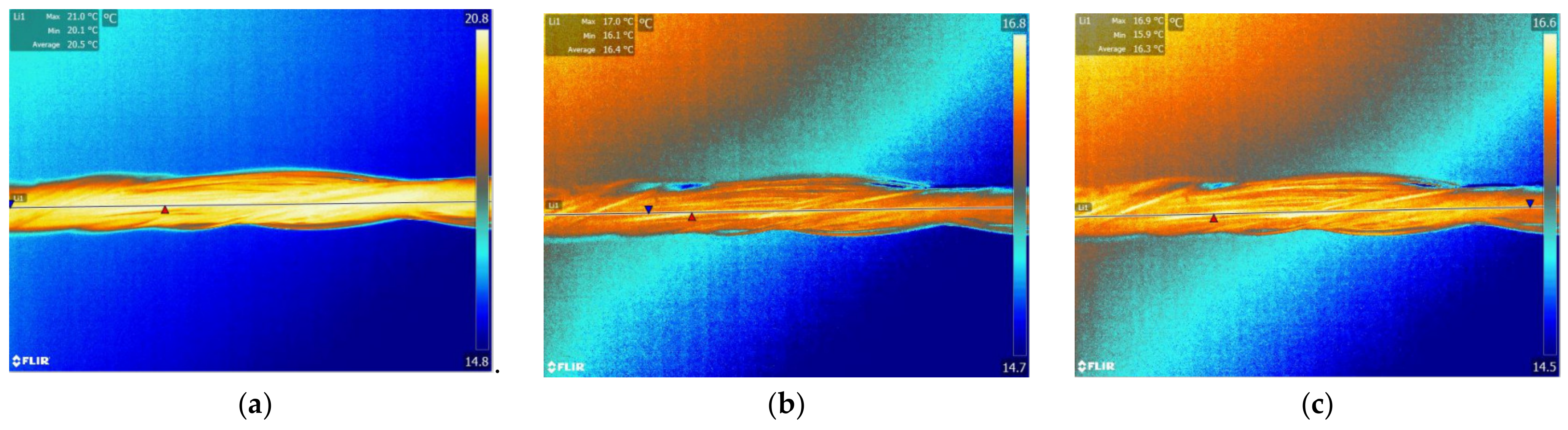

3.2.2. Thermo-Regulating Performance Test

4. Results and Discussion

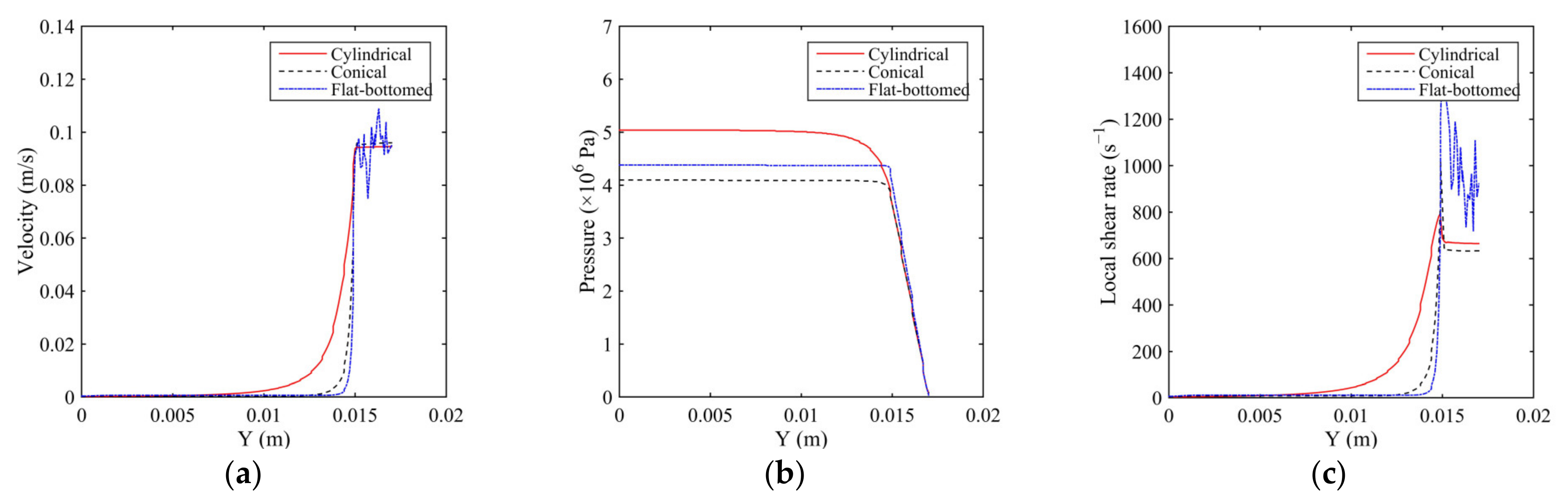

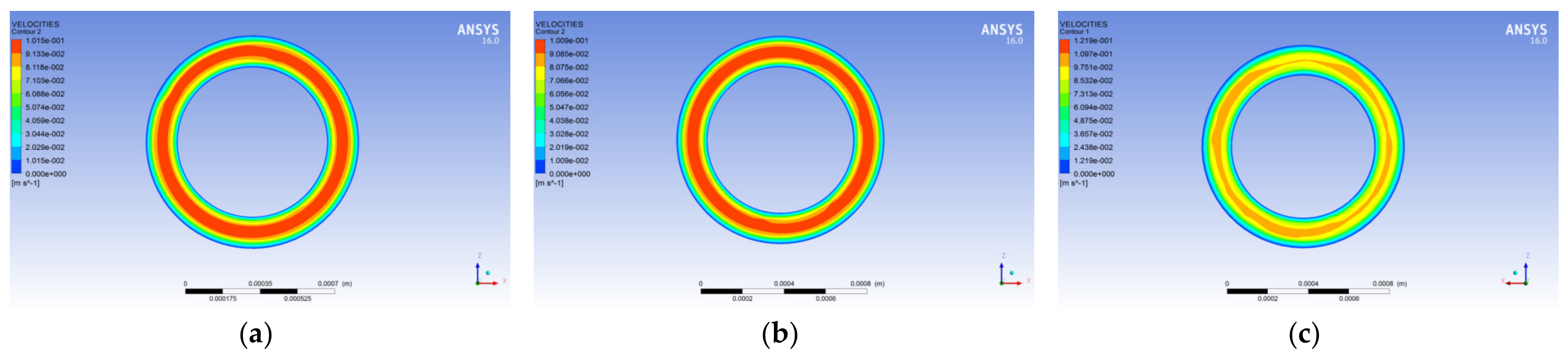

4.1. Numerical Simulation Results

4.1.1. Distribution of Velocity

4.1.2. Distribution of Pressure

4.1.3. Distribution of Shear Rate

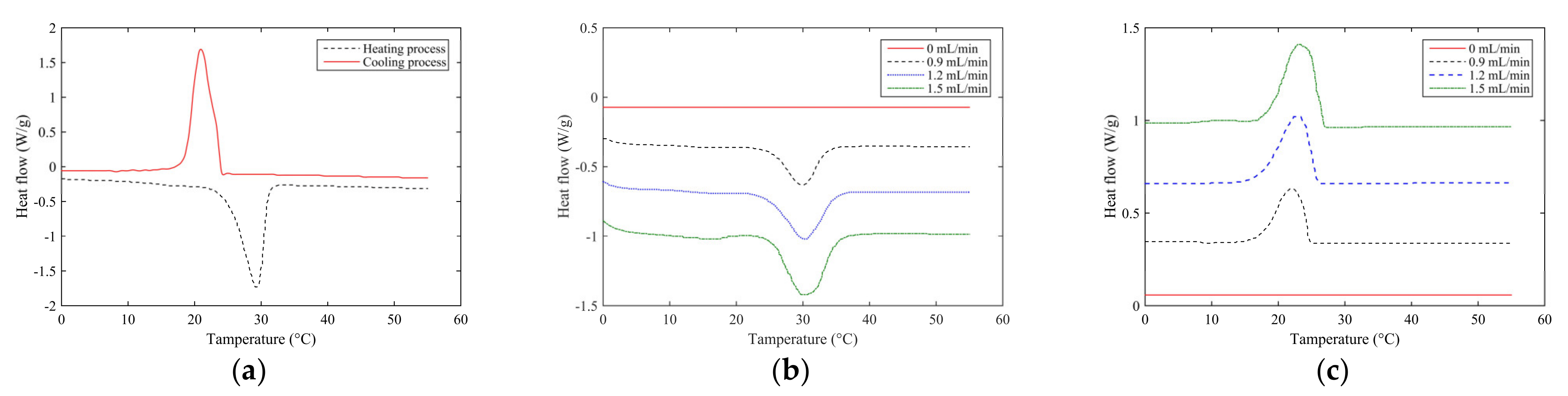

4.2. Thermal Performance

4.3. Thermo-Regulating Performance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iqbal, K.; Khan, A.; Sun, D.; Ashraf, M.; Rehman, A.; Safdar, F.; Basit, A.; Maqsood, H.S. Phase change materials, their synthesis and application in textiles—A review. J. Text. Inst. 2019, 110, 625–638. [Google Scholar] [CrossRef] [Green Version]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Isaza-Ruiz, M.; Xu, X.; Vignarooban, K.; Phelan, P.; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transf. 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Sarier, N.; Onder, E. Organic phase change materials and their textile applications: An overview. Thermochim. Acta 2012, 540, 7–60. [Google Scholar] [CrossRef]

- Fan, L.; Khodadadi, J.M. Thermal conductivity enhancement of phase change materials for thermal energy storage: A review. Renew. Sustain. Energy Rev. 2011, 15, 24–46. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles–An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Gao, T.; Yang, Z.; Chen, C.; Li, Y.; Fu, K.; Dai, J.; Hitz, E.M.; Xie, H.; Liu, B.; Song, J. Three-dimensional printed thermal regulation textiles. ACS Nano 2017, 11, 11513–11520. [Google Scholar] [CrossRef]

- Zhao, L.; Luo, J.; Li, Y.; Wang, H.; Song, G.; Tang, G. Emulsion-electrospinning n-octadecane/silk composite fiber as environmental-friendly form-stable phase change materials. J. Appl. Polym. Sci. 2017, 134, 45538. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Q.; Zhao, Z.; Zhang, J.; Sun, Y.; Sun, L.; Xu, F.; Sawada, Y. Preparation and thermal performance of gypsum boards incorporated with microencapsulated phase change materials for thermal regulation. Sol. Energy Mater. Sol. Cells 2012, 102, 93–102. [Google Scholar] [CrossRef]

- Zhu, W.; Wang, Y.; Song, S.; Ai, H.; Qiu, F.; Li, D.; Dong, L. Environmental-friendly electrospun phase change fiber with exceptional thermal energy storage performance. Sol. Energy Mater. Sol. Cells 2021, 222, 110939. [Google Scholar] [CrossRef]

- Abdalkarim, S.Y.H.; Ouyang, Z.; Yu, H.-Y.; Li, Y.; Wang, C.; Asad, R.A.; Lu, Y.; Yao, J. Magnetic cellulose nanocrystals hybrids reinforced phase change fiber composites with highly thermal energy storage efficiencies. Carbohydr. Polym. 2021, 254, 117481. [Google Scholar] [CrossRef]

- Tian, B.; Yang, W.; Luo, L.; Wang, J.; Zhang, K.; Fan, J.; Wu, J.; Xing, T. Synergistic enhancement of thermal conductivity for expanded graphite and carbon fiber in paraffin/EVA form-stable phase change materials. Sol. Energy 2016, 127, 48–55. [Google Scholar] [CrossRef]

- Mengjin, J.; Xiaoqing, S.; Jianjun, X.; Guangdou, Y. Preparation of a new thermal regulating fiber based on PVA and paraffin. Sol. Energy Mater. Sol. Cells 2008, 92, 1657–1660. [Google Scholar] [CrossRef]

- Pervez, M.N.; Khan, A.; Khan, I.A. Investigation on the thermo-regulating fabric by using phase change material for modern textile practical application. Am. J. Polym. Sci. Eng. 2015, 3, 90–99. [Google Scholar]

- Shin, Y.; Yoo, D.I.; Son, K. Development of thermoregulating textile materials with microencapsulated phase change materials (PCM). II. Preparation and application of PCM microcapsules. J. Appl. Polym. Sci. 2005, 96, 2005–2010. [Google Scholar] [CrossRef]

- Shim, H.; McCullough, E.; Jones, B. Using phase change materials in clothing. Text. Res. J. 2001, 71, 495–502. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.; Fu, J.; Huan, C.; Qi, S.; Zhan, Y.; Zhu, Y.; Xu, G. Novel smart textile with phase change materials encapsulated core-sheath structure fabricated by coaxial electrospinning. Chem. Eng. J. 2019, 355, 532–539. [Google Scholar] [CrossRef]

- Luo, D.; Xiang, L.; Sun, X.; Xie, L.; Zhou, D.; Qin, S. Phase-change smart lines based on paraffin-expanded graphite/polypropylene hollow fiber membrane composite phase change materials for heat storage. Energy 2020, 197, 117252. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Liu, W. Electrospun polyethylene glycol/cellulose acetate phase change fibers with core–sheath structure for thermal energy storage. Renew. Energy 2013, 60, 222–225. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.; Mo, J.; Huan, C.; Qi, S.; Zhan, Y.; Zhu, Y.; Xu, G. Green nano-encapsulation technique for preparation of phase change nanofibers mats with core-sheath structure. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 501–506. [Google Scholar] [CrossRef]

- Wen, G.-Q.; Xie, R.; Liang, W.-G.; He, X.-H.; Wang, W.; Ju, X.-J.; Chu, L.-Y. Microfluidic fabrication and thermal characteristics of core–shell phase change microfibers with high paraffin content. Appl. Therm. Eng. 2015, 87, 471–480. [Google Scholar] [CrossRef]

- Yi, L.; Wang, Y.; Fang, Y.; Zhang, M.; Yao, J.; Wang, L.; Marek, J. Development of core–sheath structured smart nanofibers by coaxial electrospinning for thermo-regulated textiles. RSC Adv. 2019, 9, 21844–21851. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Xiao, X.; Zhan, Y.; Huan, C.; Qi, S.; Cheng, H.; Xu, G. Core-sheath paraffin-wax-loaded nanofibers by electrospinning for heat storage. ACS Appl. Mater. Interfaces 2018, 10, 12759–12767. [Google Scholar] [CrossRef]

- Wang, S.; Yi, L.; Wang, L.; Yao, J.; Militky, J.; Venkataramam, M.; Wiener, J.; Zhang, M. Preparation of core-sheath nanofibers with high latent heat by thermal cross-linking and coaxial electrospinning. Polymer 2021, 228, 123958. [Google Scholar] [CrossRef]

- Iqbal, K.; Sun, D. Development of thermo-regulating polypropylene fibre containing microencapsulated phase change materials. Renew. Energy 2014, 71, 473–479. [Google Scholar] [CrossRef]

- Van Do, C.; Nguyen, T.T.T.; Park, J.S. Fabrication of polyethylene glycol/polyvinylidene fluoride core/shell nanofibers via melt electrospinning and their characteristics. Sol. Energy Mater. Sol. Cells 2012, 104, 131–139. [Google Scholar] [CrossRef]

- Naeimirad, M.; Zadhoush, A.; Kotek, R.; Esmaeely Neisiany, R.; Nouri Khorasani, S.; Ramakrishna, S. Recent advances in core/shell bicomponent fibers and nanofibers: A review. J. Appl. Polym. Sci. 2018, 135, 46265. [Google Scholar] [CrossRef]

| Material | Polypropylene Melt |

|---|---|

| Non-Newtonian exponents (n) | 0.46 |

| Relaxation time (s) | 0.003 |

| Zero shear viscosity (Pa·s) | 115 |

| Density (kg/m3) | 900 |

| Thermal conductivity (w/m/k) | 0.21 |

| Heat capacity (J · kg/k) | 2550 |

| Spinning temperature (°C) | 210 |

| Items | Process Parameters | |

|---|---|---|

| Screw extruder | Zone 1 (°C) | 190 |

| Zone 2 (°C) | 195 | |

| Zone 3 (°C) | 200 | |

| Zone 4 (°C) | 205 | |

| Melt temperature before the pump (°C) | 208 | |

| Melt temperature after pump (°C) | 210 | |

| Spin pack temperature (°C) | 210 | |

| Paraffin temperature (°C) | 50 | |

| Flow rate of polypropylene melt (m3/s) | 2.8 × 10−8 | |

| Paraffin delivery pressure (MPa) | 0.08 | |

| Cooling air temperature (°C) | 15 | |

| Paraffin Flow (mL/min) | Melting Process | Crystallization Process | ||||||

|---|---|---|---|---|---|---|---|---|

| Tp (°C) | ΔHm (J/g) | Onset (°C) | Endset (°C) | Tp (°C) | ΔHc (J/g) | Onset (°C) | Endset (°C) | |

| 0.9 | 29.89 | 43.37 | 25.79 | 34.85 | 22.12 | 44.86 | 24.75 | 14.78 |

| 1.2 | 30.26 | 54.13 | 26.22 | 35.76 | 22.52 | 55.59 | 25.21 | 15.55 |

| 1.5 | 31.02 | 65.93 | 26.53 | 36.38 | 23.16 | 66.15 | 25.85 | 16.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Feng, P.; Yang, C. Preparation and Analysis of Sheath–Core Intelligent Thermo-Regulating Fiber. Polymers 2022, 14, 1665. https://doi.org/10.3390/polym14091665

Zhang R, Feng P, Yang C. Preparation and Analysis of Sheath–Core Intelligent Thermo-Regulating Fiber. Polymers. 2022; 14(9):1665. https://doi.org/10.3390/polym14091665

Chicago/Turabian StyleZhang, Ronggen, Pei Feng, and Chongchang Yang. 2022. "Preparation and Analysis of Sheath–Core Intelligent Thermo-Regulating Fiber" Polymers 14, no. 9: 1665. https://doi.org/10.3390/polym14091665

APA StyleZhang, R., Feng, P., & Yang, C. (2022). Preparation and Analysis of Sheath–Core Intelligent Thermo-Regulating Fiber. Polymers, 14(9), 1665. https://doi.org/10.3390/polym14091665