Bamboo-Fiber-Reinforced Thermoset and Thermoplastic Polymer Composites: A Review of Properties, Fabrication, and Potential Applications

Abstract

1. Introduction

1.1. Natural Fibers

1.2. Bamboo Plant

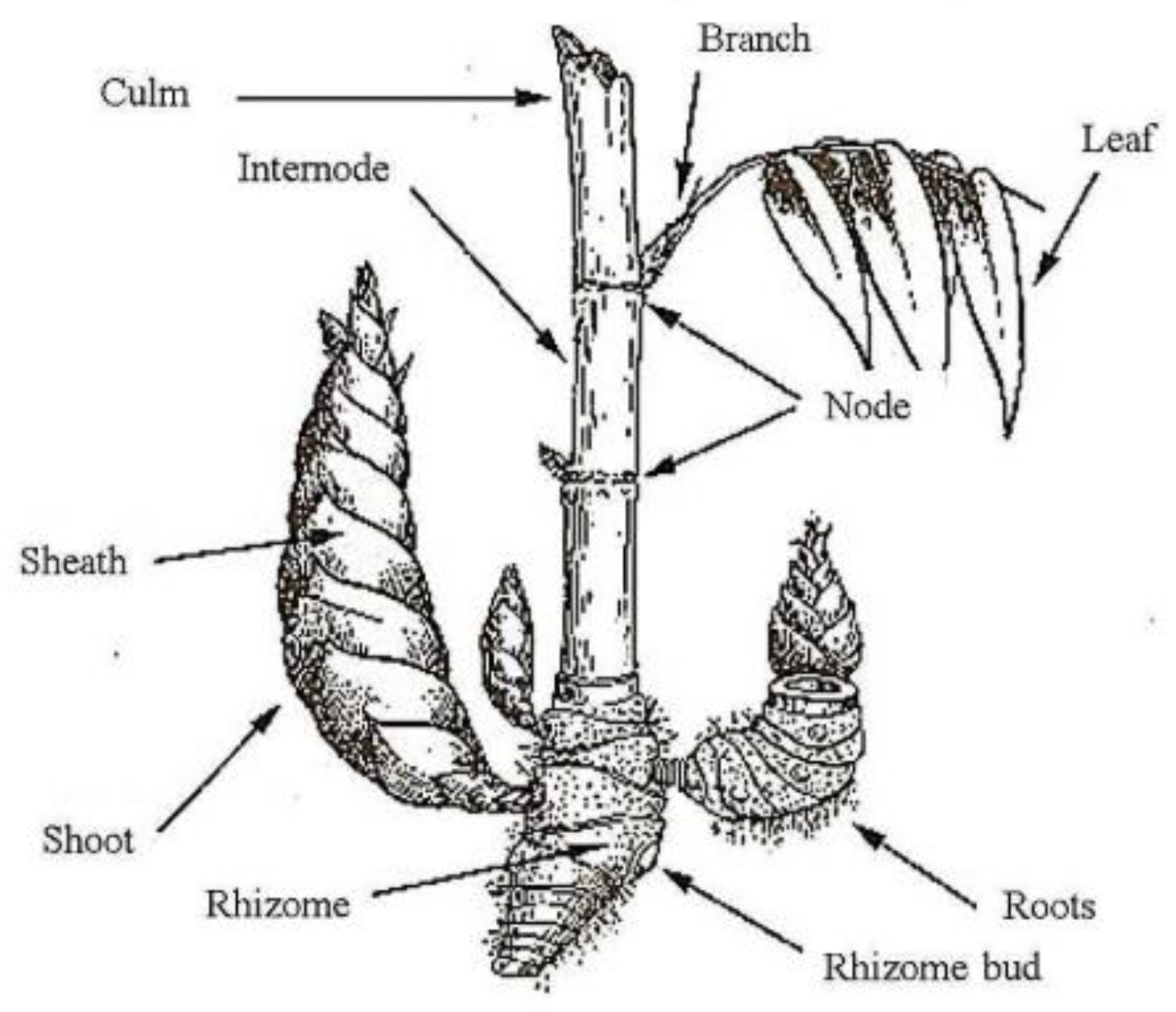

1.3. The Anatomy of the Bamboo Tree

2. Bamboo Plantation in Malaysia

2.1. Bamboo-Based Polymer Composites

2.2. Bamboo-Reinforced Polymer Thermoplastic Composites

2.3. Bamboo-Reinforced Thermosetting Polymer Composites

2.4. Bamboo Fiber Hybrid Composites

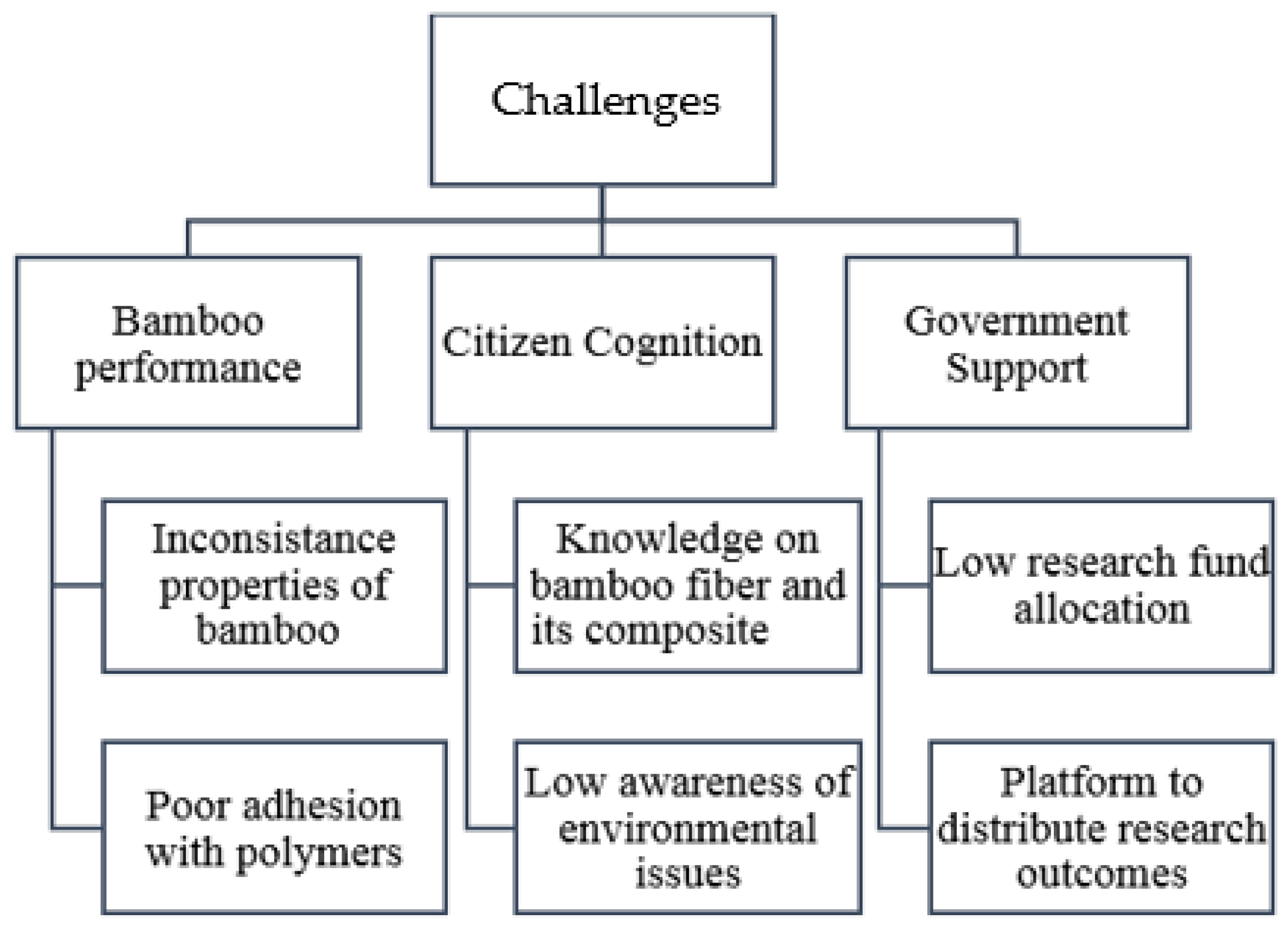

3. Economic Value, Challenges, and Future Perspective for Bamboo-Based Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ilyas, R.A.; Sapuan, S.M.; Radzi, A.M.; Nadlene, R. Roselle: Production, product development, and composites. In Roselle: Production, Product Development, and Composites, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–338. [Google Scholar]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, morphological chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 41, 2917–2932. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M. The Preparation Methods and Processing of Natural Fibre Bio-polymer Composites. Curr. Org. Synth. 2020, 16, 1068–1070. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M. Biopolymers and Biocomposites: Chemistry and Technology. Curr. Anal. Chem. 2020, 16, 500–503. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical Properties of Longitudinal Basalt/Woven-Glass-Fiber-reinforced Unsaturated Polyester-Resin Hybrid Composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef] [PubMed]

- Zia, F.; Zia, K.M.; Zuber, M.; Kamal, S.; Aslam, N. Starch based polyurethanes: A critical review updating recent literature. Carbohydr. Polym. 2015, 134, 784–798. [Google Scholar] [CrossRef] [PubMed]

- Syafiq, R.; Sapuan, S.; Zuhri, M. Antimicrobial activity, physical, mechanical and barrier properties of sugar palm based nanocellulose/starch biocomposite films incorporated with cinnamon essential oil. J. Mater. Res. Technol. 2021, 11, 144–157. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial Activities of Starch-Based Biopolymers and Biocomposites Incorporated with Plant Essential Oils: A Review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef] [PubMed]

- Radzi, A.M.; Sapuan, S.M.; Jawaid, M.; Mansor, M.R. Effect of Alkaline Treatment on Mechanical, Physical and Thermal Properties of Roselle/Sugar Palm Fiber Reinforced Thermoplastic Polyurethane Hybrid Composites. Fibers Polym. 2019, 20, 847–855. [Google Scholar] [CrossRef]

- Nadlene, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Yusriah, L. A Review on Roselle Fiber and Its Composites. J. Nat. Fibers 2016, 13, 10–41. [Google Scholar] [CrossRef]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K.; Siregar, J.P. Siregar, Sugar palm (Arenga pinnata): Its fibres, polymers and composites. Carbohydr. Polym. 2013, 91, 699–710. [Google Scholar] [CrossRef] [PubMed]

- Suhot, M.; Hassan, M.; Aziz, S.; Daud, M.M. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers 2021, 13, 2391. [Google Scholar] [CrossRef] [PubMed]

- Huzaifah, M.R.M.; Sapuan, S.M.; Leman, Z.; Ishak, M.R.; Maleque, M.A. A review of sugar palm (Arenga pinnata): Application, fibre characterisation and composites. Multidiscip. Model. Mater. Struct. 2017, 13, 678–698. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Effect of polybutylene terephthalate (PBT) on impact property improvement of hybrid kenaf/glass epoxy composite. Mater. Lett. 2012, 67, 5–7. [Google Scholar] [CrossRef]

- Radzi, A.M.; Sapuan, S.M.; Jawaid, M.; Mansor, M.R. Mechanical and Thermal Performances of Roselle Fiber-Reinforced Thermoplastic Polyurethane Composites. Polym. Technol. Eng. 2018, 57, 601–608. [Google Scholar] [CrossRef]

- Radzi, A.; Sapuan, S.; Jawaid, M.; Mansor, M. Water absorption, thickness swelling and thermal properties of roselle/sugar palm fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 2019, 8, 3988–3994. [Google Scholar] [CrossRef]

- Sanmuham, V.; Sultan, M.T.H.; Radzi, A.M.; Shamsuri, A.A.; Shah, A.U.M.; Safri, S.N.A.; Basri, A.A. Effect of Silver Nanopowder on Mechanical, Thermal and Antimicrobial Properties of Kenaf/HDPE Composites. Polymers 2021, 13, 3928. [Google Scholar] [CrossRef] [PubMed]

- Huzaifah, M.R.M.; Sapuan, M.S.; Leman, Z.; Ishak, M.R. Comparative Study on Chemical Composition, Physical, Tensile, and Thermal Properties of Sugar Palm Fiber (Arenga pinnata) Obtained from Different Geographical Locations. BioResources 2017, 12, 9366–9382. [Google Scholar]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers 2021, 13, 471. [Google Scholar] [CrossRef] [PubMed]

- Radzi, A.M.; Sapuan, S.M.; Jawaid, M.; Mansor, M.R. Mechanical performance of roselle/sugar palm fiber hybrid reinforced polyurethane composites. BioResources 2018, 13, 6238–6249. [Google Scholar] [CrossRef]

- Ali, M.R.; Salit, M.S.; Jawaid, M.; Mansur, M.R.; Manap, M.F.A. Polyurethane-Based Biocomposites; Elsevier Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.; Zainudin, E.; Asrofi, M.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: A comprehensive approach from macro to nano scale. J. Mater. Res. Technol. 2019, 8, 2753–2766. [Google Scholar] [CrossRef]

- Kasim, F.A.M.; Roslan, S.A.H.; Rasid, Z.A.; Yakub, F.; Hassan, M.Z.; Yahaya, H. Post-buckling of bamboo reinforced composite plates. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 012040. [Google Scholar] [CrossRef]

- Sari, N.H.; Pruncu, C.I.; Sapuan, S.M.; Ilyas, R.A.; Catur, A.D.; Suteja, S.; Sutaryono, Y.A.; Pullen, G. The effect of water immersion and fibre content on properties of corn husk fibres reinforced thermoset polyester composite. Polym. Test. 2020, 91, 106751. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Shah, A.U.M.; Sultan, M.T.H.; Jawaid, M.; Cardona, F.; Abu Talib, A.R. A Review on the Tensile Properties of Bamboo Fiber Reinforced Polymer Composites. BioResources 2016, 11, 10654–10676. [Google Scholar] [CrossRef]

- Hong, C.; Li, H.; Lorenzo, R.; Wu, G.; Corbi, I.; Corbi, O.; Xiong, Z.; Zhang, D.Y.A.H. Review on Connections for Original Bamboo Structures. J. Renew. Mater. 2019, 7, 713–730. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Roslan, S.A.; Sapuan, S.M.; Rasid, Z.A.; Mohd Nor, A.F.; Md Daud, M.Y.; Dolah, R.; Mohamed Yusoff, M.Z. Mercerization Optimization of Bamboo (Bambusa vulgaris) Fiber-Reinforced Epoxy Composite Structures Using a Box–Behnken Design. Polymers 2020, 12, 1367. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T. Thermal stability and dynamic mechanical properties of kenaf/bamboo fibre reinforced epoxy composites. BioResources 2017, 12, 7118–7132. [Google Scholar]

- Ibrahim, I.D.; Jamiru, T.; Sadiku, R.; Kupolati, W.K.; Agwuncha, S.C.; Ekundayo, G. The use of polypropylene in bamboo fibre composites and their mechanical properties—A review. J. Reinf. Plast. Compos. 2015, 34, 1347–1356. [Google Scholar] [CrossRef]

- Kenan Song, L.Z. Green biocomposites. In Green Energy and Technology; No. 9783319493817; Jawaid, M., Salit, M.S., Alothman, O.Y., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 209–246. [Google Scholar]

- Ming, C.Y.T.; Jye, W.K.; Ahmad, H.A.I. Mechanical properties of bamboo and bamboo composites: A Review. J. Adv. Res. Mater. Sci. 2017, 35, 7–26. [Google Scholar]

- van Dam, J.E.; Elbersen, H.W.; Montaño, C.M.D. Bamboo Production for Industrial Utilization; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 175–216. [Google Scholar] [CrossRef]

- Yildizhan, Ş.; Çalik, A.; Özcanli, M.; Serin, H. Bio-composite materials: A short review of recent trends, mechanical and chemical properties, and applications. Eur. Mech. Sci. 2018, 2, 83–91. [Google Scholar] [CrossRef]

- Roslan, S.A.H.; Rasid, Z.A.; Hassan, M. Bamboo reinforced polymer composite—A comprehensive review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 344, 012008. [Google Scholar] [CrossRef]

- Pramudi, G.; Raharjo, W.W.; Ariawan, D.; Arifin, Z. Utilization of Bamboo Fiber in the Development of Environmentally Friendly Composite—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1096, 012038. [Google Scholar] [CrossRef]

- Jawaid, M.; Chee, S.S.; Asim, M.; Saba, N.; Kalia, S. Sustainable kenaf/bamboo fibers/clay hybrid nanocomposites: Properties, environmental aspects and applications. J. Clean. Prod. 2022, 330, 129938. [Google Scholar] [CrossRef]

- Radzi, A.M.; Sapuan, S.M.; Jawaid, M.; Mansor, M.R. Influence of fibre contents on mechanical and thermal properties of roselle fibre reinforced polyurethane composites. Fibers Polym. 2017, 18, 1353–1358. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.A.; Lee, C.H. Characterization Study of Empty Fruit Bunch (EFB) Fibers Reinforcement in Poly(Butylene) Succinate (PBS)/Starch/Glycerol Composite Sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef]

- Halimatul, M.; Sapuan, S.; Jawaid, M. Water absorption and water solubility properties of sago starch biopolymer composite films filled with sugar palm particles. Polimery 2019, 64, 27–35. [Google Scholar] [CrossRef]

- Taj, S.; Munawar, M.A.; Khan, S. Natural Fiber-Reinforced Polymer Composites. Carbon N. Y. 2007, 44, 129–144. [Google Scholar]

- Andrew, J.J.; Dhakal, H.N. Sustainable biobased composites for advanced applications: Recent trends and future—A critical review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Zuhri, M.Y.M.; Asyraf, M.R.M.; Sapuan, S.M.; Zainudin, E.S.; Sharma, S.; Abral, H.; et al. Natural-Fiber-Reinforced Chitosan, Chitosan Blends and Their Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Zuhri, M.Y.M.; Norrrahim, M.N.F.; Misenan, M.S.M.; Jenol, M.A.; Samsudin, S.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Supian, A.B.M.; Bangar, S.P.; et al. Natural Fiber-Reinforced Polycaprolactone Green and Hybrid Biocomposites for Various Advanced Applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.A.B.A.; Omran, A.A.B.; Hasan, Z.; Ilyas, R.A.; Sapuan, S.M. Wheat Biocomposite Extraction, Structure, Properties and Characterization: A Review. Polymers 2021, 13, 3624. [Google Scholar] [CrossRef] [PubMed]

- Jumaidin, R.; Diah, N.; Ilyas, R.; Alamjuri, R.; Yusof, F. Processing and Characterisation of Banana Leaf Fibre Reinforced Thermoplastic Cassava Starch Composites. Polymers 2021, 13, 1420. [Google Scholar] [CrossRef] [PubMed]

- Diyana, Z.; Jumaidin, R.; Selamat, M.; Ghazali, I.; Julmohammad, N.; Huda, N.; Ilyas, R. Physical Properties of Thermoplastic Starch Derived from Natural Resources and Its Blends: A Review. Polymers 2021, 13, 1396. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Tawakkal, I.S.M.A.; Ilyas, R.A. Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly (lactic acid) blend bionanocomposites. Nanotechnol. Rev. 2022, 11, 86–95. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Tawakkal, I.S.M.A.; Ilyas, R.A. Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites. Nanotechnol. Rev. 2021, 10, 431–442. [Google Scholar] [CrossRef]

- Syafiq, R.M.O.; Sapuan, S.M.; Zuhri, M.Y.M.; Othman, S.H.; Ilyas, R.A. Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films. Nanotechnol. Rev. 2022, 11, 423–437. [Google Scholar] [CrossRef]

- Huzaifah, M.R.M.; Sapuan, S.M.; Leman, Z.; Ishak, M.R. Effect of Fibre Loading on the Physical, Mechanical and Thermal Properties of Sugar Palm Fibre Reinforced Vinyl Ester Composites. Fibers Polym. 2019, 20, 1077–1084. [Google Scholar] [CrossRef]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of seaweed on mechanical, thermal, and biodegradation properties of thermoplastic sugar palm starch/agar composites. Int. J. Biol. Macromol. 2017, 99, 265–273. [Google Scholar] [CrossRef] [PubMed]

- Shamsuri, A.A.; Zolkepli, M.N.M.; Ariff, A.H.M.; Sudari, A.K.; Abu Zarin, M. A Preliminary Investigation on Processing, Mechanical and Thermal Properties of Polyethylene/Kenaf Biocomposites with Dolomite Added as Secondary Filler. J. Compos. 2015, 2015, 760909. [Google Scholar] [CrossRef][Green Version]

- Norhasnan, N.; Hassan, M.; Nor, A.; Zaki, S.; Dolah, R.; Jamaludin, K.; Aziz, S. Physicomechanical Properties of Rice Husk/Coco Peat Reinforced Acrylonitrile Butadiene Styrene Blend Composites. Polymers 2021, 13, 1171. [Google Scholar] [CrossRef] [PubMed]

- Latif, R.; Wakeel, S.; Khan, N.Z.; Siddiquee, A.N.; Verma, S.L.; Khan, Z.A. Surface treatments of plant fibers and their effects on mechanical properties of fiber-reinforced composites: A review. J. Reinf. Plast. Compos. 2019, 38, 15–30. [Google Scholar] [CrossRef]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and renewable bio-based natural fibres and its application for 3d printed concrete: A review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Odesanya, K.O.; Ahmad, R.; Jawaid, M.; Bingol, S.; Adebayo, G.O.; Wong, Y.H. Natural Fibre-Reinforced Composite for Ballistic Applications: A Review. J. Polym. Environ. 2021, 29, 3795–3812. [Google Scholar] [CrossRef]

- Mahdavi, M.; Clouston, P.L.; Arwade, S.R. Development of Laminated Bamboo Lumber: Review of Processing, Performance, and Economical Considerations. J. Mater. Civ. Eng. 2011, 23, 1036–1042. [Google Scholar] [CrossRef]

- Lantican, C.B.; Palijon, A.M.; Saludo, C.G. Recent research on bamboos. In Proceedings of the International Bamboo Workshop, Hangzhou, China, 6–14 October 1985; pp. 349–358. [Google Scholar]

- Wong, K.M. Bamboo, the Amazing Grass: A Guide to the Diversity and Study of Bamboos in Southeast Asia. 2004, p. 98. Available online: https://www.bioversityinternational.org/e-library/publications/detail/bamboo-the-amazing-grass-a-guide-to-the-diversity-and-study-of-bamboos-in-southeast-asia/ (accessed on 3 January 2022).

- Siam, N.A.; Uyup, M.K.A.; Husain, H.; Mohmod, A.L.; Awalludin, M.F. Anatomical, physical, and mechanical properties of thirteen Malaysian bamboo species. BioResources 2019, 14, 3925–3943. [Google Scholar] [CrossRef]

- Anwar, U.; Hiziroglu, S.; Hamdan, H.; Latif, M.A. Effect of outdoor exposure on some properties of resin-treated plybamboo. Ind. Crop. Prod. 2011, 33, 140–145. [Google Scholar] [CrossRef]

- Chen, M.; Weng, Y.; Semple, K.; Zhang, S.; Hu, Y.; Jiang, X.; Ma, J.; Fei, B.; Dai, C. Sustainability and innovation of bamboo winding composite pipe products. Renew. Sustain. Energy Rev. 2021, 144, 110976. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Ghavami, K.; Savastano, H. Densification of Bamboo: State of the Art. Materials 2020, 13, 4346. [Google Scholar] [CrossRef] [PubMed]

- Chaowana, P. Bamboo: An Alternative Raw Material for Wood and Wood-Based Composites. J. Mater. Sci. Res. 2013, 2, 90. [Google Scholar] [CrossRef]

- Kumar, S.; Shukla, K.; Dev, T.; Dobriyal, P. Bamboo Preservation Techniques: A Review; INBAR and ICFRE: Dehra Dun, India, 1994.

- Bahari, S.A.; Krause, A. Utilizing Malaysian bamboo for use in thermoplastic composites. J. Clean. Prod. 2016, 110, 16–24. [Google Scholar] [CrossRef]

- Mohamed, A.H.; Hall, J.B.; Sulaiman, O.; Wahab, R. Quality management of the bamboo resource and its contribution to environmental conservation in Malaysia. Manag. Environ. Qual. Int. J. 2007, 18, 643–656. [Google Scholar] [CrossRef]

- Noh, H.M.; Sukri, N.H.A.; Kasim, N.; Zainal, R.; Musa, S.M.S. Utilisation of Bamboo as Reinforcement Material in Concrete. Res. Manag. Technol. Bus. 2021, 2, 905–920. [Google Scholar]

- Darus, S.A.A.Z.M.; Ghazali, M.J.; Azhari, C.H.; Zulkifli, R.; Shamsuri, A.A. Mechanical properties of gigantochloa scortechinii bamboo particle reinforced semirigid polyvinyl chloride composites. J. Teknol. 2020, 82, 15–22. [Google Scholar] [CrossRef]

- Thakur, A.; Purohit, R.; Rana, R.; Bandhu, D. Characterization and Evaluation of Mechanical Behavior of Epoxy-CNT-Bamboo Matrix Hybrid Composites. Mater. Today Proc. 2018, 5, 3971–3980. [Google Scholar] [CrossRef]

- Harikumar, R.; Devaraju, A. Evaluation of mechanical properties of bamboo fiber composite with addition of Al2O3 nano particles. Mater. Today Proc. 2020, 39, 606–609. [Google Scholar] [CrossRef]

- Liu, H.; Wu, Q.; Han, G.; Yao, F.; Kojima, Y.; Suzuki, S. Compatibilizing and toughening bamboo flour-filled HDPE composites: Mechanical properties and morphologies. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1891–1900. [Google Scholar] [CrossRef]

- Aji, I.S.; Sapuan, S.M.; Zainudin, E.S.; Abdan, K. Kenaf fibres as reinforcement for polymeric composites: A review. Int. J. Mech. Mater. Eng. 2009, 4, 239–248. [Google Scholar]

- Torres, F.G.; Díaz, R.M. Morphological Characterisation of Natural Fibre Reinforced Thermoplastics (NFRTP) Processed by Extrusion, Compression and Rotational Moulding. Polym. Polym. Compos. 2004, 12, 705–718. [Google Scholar] [CrossRef]

- Torres, F.G.; Cubillas, M. Study of the interfacial properties of natural fibre reinforced polyethylene. Polym. Test. 2005, 24, 694–698. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Chun, S.-J.; Doh, G.-H.; Kang, I.-A.; Lee, S.; Paik, K.-H. Influence of Chemical Modification and Filler Loading on Fundamental Properties of Bamboo Fibers Reinforced Polypropylene Composites. J. Compos. Mater. 2009, 43, 1639–1657. [Google Scholar] [CrossRef]

- Okubo, K.; Fujii, T.; Yamamoto, Y. Development of bamboo-based polymer composites and their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 377–383. [Google Scholar] [CrossRef]

- Zhang, W.; Yao, X.; Khanal, S.; Xu, S. A novel surface treatment for bamboo flour and its effect on the dimensional stability and mechanical properties of high density polyethylene/bamboo flour composites. Constr. Build. Mater. 2018, 186, 1220–1227. [Google Scholar] [CrossRef]

- Ren, W.; Zhang, D.; Wang, G.; Cheng, H. Mechanical and Thermal Properties of Bamboo Pulp Fiber Reinforced Polyethylene Composites. BioResources 2014, 9, 4117–4127. [Google Scholar] [CrossRef]

- Chattopadhyay, S.K.; Khandal, R.K.; Uppaluri, R.; Ghoshal, A.K. Ghoshal, Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J. Appl. Polym. Sci. 2011, 119, 1619–1626. [Google Scholar] [CrossRef]

- Yeh, C.-H.; Yang, T.-C. Utilization of Waste Bamboo Fibers in Thermoplastic Composites: Influence of the Chemical Composition and Thermal Decomposition Behavior. Polymers 2020, 12, 636. [Google Scholar] [CrossRef] [PubMed]

- Mosiewicki, M.A.; Aranguren, M.I. A short review on novel biocomposites based on plant oil precursors. Eur. Polym. J. 2013, 49, 1243–1256. [Google Scholar] [CrossRef]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Thermal, mechanical, and physical properties of seaweed/sugar palm fibre reinforced thermoplastic sugar palm Starch/Agar hybrid composites. Int. J. Biol. Macromol. 2017, 97, 606–615. [Google Scholar] [CrossRef] [PubMed]

- Zuhri, M.; Nasrudin, M.; Nasrodin, M.; Sapuan, S.; Hassan, M. Mechanical properties under quasi-static loading of the core made of flax/poly(lactic acid) composite. Polimery 2021, 66, 193–197. [Google Scholar] [CrossRef]

- Haris, N.I.N.; Ilyas, R.A.; Hassan, M.Z.; Sapuan, S.M.; Afdzaluddin, A.; Jamaludin, K.R.; Zaki, S.A.; Ramlie, F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers 2021, 13, 3343. [Google Scholar] [CrossRef] [PubMed]

- Jarvis, M. Cellulose stacks up. Nature 2003, 426, 611–612. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Lan, T.; Sheng, K.C.; Qian, X.Q.; Chang, R. Role of Alkali Treatment on Mechanical and Thermal Properties of Bamboo Particles Reinforced Polyvinylchloride Composites. Adv. Mater. Res. 2009, 79–82, 545–548. [Google Scholar] [CrossRef]

- Bahari, S.A.; Krause, A. Bamboo Particles-Polyvinyl Chloride Composites: Analysis of Particles Size Distribution and Composites Performance. J. Mater. Sci. Res. 2017, 6, 1. [Google Scholar] [CrossRef]

- Delgado, P.S.; Lana, S.L.B.; Ayres, E.; Patrício, P.O.S.; Oréfice, R.L. The potential of bamboo in the design of polymer composites. Mater. Res. 2012, 15, 639–644. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, R.; Wang, Y.; Wen, X.; Qin, D. The Effect of Bamboo Charcoal on Water Absorption, Contact Angle, and the Physical-Mechanical Properties of Bamboo/Low-Density Polyethylene Composites. BioResources 2016, 11, 9986–10001. [Google Scholar] [CrossRef][Green Version]

- Nahar, S.; Khan, R.; Dey, K.; Sarker, B.; Das, A.; Ghoshal, S. Comparative Studies of Mechanical and Interfacial Properties between Jute and Bamboo Fiber-Reinforced Polypropylene-Based Composites. J. Thermoplast. Compos. Mater. 2012, 25, 15–32. [Google Scholar] [CrossRef]

- Labasan, K.B.; Espinosa, A.J.G.; España, R.C.N. Fabrication and characterization of bamboo fiber- reinforced polyethylene-polystyrene composites using glycerol as plasticizer. World J. Environ. Res. 2015, 5, 137–157. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Igwegbe, C.A.; Adeniyi, A.G.; Abdulkareem, S.A. Artificial Neural Network Modeling of the Water Absorption Behavior of Plantain Peel and Bamboo Fibers Reinforced Polystyrene Composites. J. Macromol. Sci. Part B 2021, 60, 472–484. [Google Scholar] [CrossRef]

- Tokoro, R.; Vu, D.M.; Okubo, K.; Tanaka, T.; Fujii, T.; Fujiura, T. How to improve mechanical properties of polylactic acid with bamboo fibers. J. Mater. Sci. 2008, 43, 775–787. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the tensile strength of natural fibre reinforced thermoplastics. Compos. Sci. Technol. 2007, 67, 2454–2466. [Google Scholar] [CrossRef]

- Morales, A.P.; Güemes, A.; Fernandez-Lopez, A.; Valero, V.C.; Llano, S.D.L.R. Bamboo–Polylactic Acid (PLA) Composite Material for Structural Applications. Materials 2017, 10, 1286. [Google Scholar] [CrossRef] [PubMed]

- Chattopadhyay, S.K.; Khandal, R.K.; Uppaluri, R.; Ghoshal, A.K. Influence of varying fiber lengths on mechanical, thermal, and morphological properties of MA-g-PP compatibilized and chemically modified short pineapple leaf fiber reinforced polypropylene composites. J. Appl. Polym. Sci. 2009, 113, 3750–3756. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, K.K. Tribological behaviour of fibre-reinforced thermoset polymer composites: A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1439–1449. [Google Scholar] [CrossRef]

- Denissen, W.; Rivero, G.; Nicolaÿ, R.; Leibler, L.; Winne, J.M.; Du Prez, F.E. Vinylogous Urethane Vitrimers. Adv. Funct. Mater. 2015, 25, 2451–2457. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J.; Licence, P. Mechanical Property Characterization of Aligned Plant Yarn Reinforced Thermoset Matrix Composites Manufactured via Vacuum Infusion. Polym. Technol. Eng. 2014, 53, 239–253. [Google Scholar] [CrossRef]

- Supian, A.; Sapuan, S.; Zuhri, M.; Zainudin, E.S.; Ya, H. Hybrid reinforced thermoset polymer composite in energy absorption tube application: A review. Def. Technol. 2018, 14, 291–305. [Google Scholar] [CrossRef]

- Albahash, Z.F.A.; Ansari, M. Investigation on energy absorption of natural and hybrid fiber under axial static crushing. Compos. Sci. Technol. 2017, 151, 52–61. [Google Scholar] [CrossRef]

- Huang, J.-K.; Young, W.-B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Lokesh, P.; Kumari, T.S.; Gopi, R.; Loganathan, G.B. A study on mechanical properties of bamboo fiber reinforced polymer composite. Mater. Today Proc. 2020, 22, 897–903. [Google Scholar] [CrossRef]

- Ratna Prasad, A.V.; Mohana Rao, K. Mechanical properties of natural fibre reinforced polyester composites: Jowar, sisal and bamboo. Mater. Des. 2011, 32, 4658–4663. [Google Scholar] [CrossRef]

- Huang, G.C.; Lee, C.H.; Lee, J.K. Thermal and mechanical properties of short fiber-reinforced epoxy composites. Polymer 2009, 33, 530–536. [Google Scholar]

- Shah, A.U.M.; Sultan, M.T.H.; Cardona, F.; Jawaid, M.; Abu Talib, A.R.; Yidris, N. Thermal Analysis of Bamboo Fibre and Its Composites. BioResources 2017, 12, 2394–2406. [Google Scholar] [CrossRef]

- Rao, K.M.M.; Rao, K.M.; Prasad, A.R. Fabrication and testing of natural fibre composites: Vakka, sisal, bamboo and banana. Mater. Des. 2010, 31, 508–513. [Google Scholar]

- Seki, M.; Yashima, Y.; Kiryu, T.; Miki, T.; Tanaka, S.; Kanayama, K. Deformability of bamboo impregnated with thermosetting resin in upset forging. Int. J. Mater. Form. 2021, 14, 261–270. [Google Scholar] [CrossRef]

- Chen, F.; Li, M.; Xin, W.; Zhou, H.; Smith, L.M.; Wang, G.; Fei, B.; Ye, L. Development of bamboo winding composite pipe (BWCP) and its compression properties. BioResources 2019, 14, 5875–5882. [Google Scholar]

- Widodo, T.D.; Raharjo, R.; Bintarto, R.; Pramudia, M.; Sunardi; Mamungkas, M.I.; Wahudiono, A. Effect of Alkalization Treatment on The Tensile Strength and Interface Character Matrix-Fibber of Bamboo Petung (Dendrocalamus Asper) Reinforced Polyester Resin Composite. IOP Conf. Ser. Mater. Sci. Eng. 2019, 494, 012081. [Google Scholar] [CrossRef]

- Rao, F.; Ji, Y.; Li, N.; Zhang, Y.; Chen, Y.; Yu, W. Outdoor bamboo-fiber-reinforced composite: Influence of resin content on water resistance and mechanical properties. Constr. Build. Mater. 2020, 261, 120022. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, Y.; Zhang, Y.; Liu, R.; Meng, F.; Yu, W. The reinforcing mechanism of mechanical properties of bamboo fiber bundle-reinforced composites. Polym. Compos. 2019, 40, 1463–1472. [Google Scholar] [CrossRef]

- Rao, F.; Chen, Y.; Li, N.; Zhao, X.; Bao, Y.; Wu, Z.; Ren, D.; Xu, J.; Cai, H. Preparation and Characterization of Outdoor Bamboo-Fiber-Reinforced Composites with Different Densities. BioResources 2017, 12, 6789–6811. [Google Scholar] [CrossRef]

- Khan, Z.; Yousif, B.; Islam, M. Fracture behaviour of bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2017, 116, 186–199. [Google Scholar] [CrossRef]

- Yu, Y.-L.; Huang, X.-A.; Yu, W.-J. High performance of bamboo-based fiber composites from long bamboo fiber bundles and phenolic resins. J. Appl. Polym. Sci. 2014, 131, 40371. [Google Scholar] [CrossRef]

- Sugiman, S.; Setyawan, P.D.; Anshari, B. Water absorption and impact strength of alkali-treated bamboo fiber/polystyrene-modified unsaturated polyester composites. J. Appl. Sci. Eng. 2020, 23, 9–20. [Google Scholar]

- Sugiman, S.; Setyawan, P.D.; Anshari, B. Effect of fiber length on the mechanical properties and water absorption of bamboo fiber/polystyrene-modified unsaturated polyester composites. IOP Conf. Ser. Mater. Sci. Eng. 2019, 532, 012008. [Google Scholar] [CrossRef]

- Chen, H.; Miao, M.; Ding, X. Chemical treatments of bamboo to modify its moisture absorption and adhesion to vinyl ester resin in humid environment. J. Compos. Mater. 2011, 45, 1533–1542. [Google Scholar] [CrossRef]

- Rassiah, K.; Ahmad, M.M.H.M. Bamboo, thermoplastic, thermosets, and their composites: A review. Appl. Mech. Mater. 2013, 330, 53–61. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, S.; Yang, M.; Chen, Z.; Ran, S. Thermo-Mechanical Performance of Polylactide Composites Reinforced with Alkali-Treated Bamboo Fibers. Polymers 2018, 10, 401. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Yu, Y.; Zhong, T.; Wu, Y.; Li, Y.; Wu, Z.; Fei, B. Effect of alkali treatment on microstructure and mechanical properties of individual bamboo fibers. Cellulose 2017, 24, 333–347. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Nurazzi, N.M.; Norli, A.; Harussani, M.M.; Rafiqah, S.; Aisyah, H.A.; Ramli, N. The Challenges and Future Perspective of Woven Kenaf Reinforcement in Thermoset Polymer Composites in Malaysia: A Review. Polymers 2021, 13, 1390. [Google Scholar] [CrossRef] [PubMed]

- Sathishkumar, T.; Naveen, J.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Jawaid, M.; Awad, S.; Fouad, H.; Asim, M.; Saba, N.; Dhakal, H.N. Improvements in the thermal behaviour of date palm/bamboo fibres reinforced epoxy hybrid composites. Compos. Struct. 2021, 277, 114644. [Google Scholar] [CrossRef]

- Liew, F.K.; Hamdan, S.; Rahman, R.; Rusop, M. Thermomechanical Properties of Jute/Bamboo Cellulose Composite and Its Hybrid Composites: The Effects of Treatment and Fiber Loading. Adv. Mater. Sci. Eng. 2017, 2017, 8630749. [Google Scholar] [CrossRef]

- Bino, P.R.D.; Stanly, J.R.B.; Shukla, M. Analysis of mechanical properties of hybrid bamboo/jute fibers reinforced & vinyl ester composite material. Int. J. Mech. Eng. Technol. 2017, 8, 318–324. [Google Scholar]

- Ismail, A.S.; Jawaid, M.; Naveen, J. Void Content, Tensile, Vibration and Acoustic Properties of Kenaf/Bamboo Fiber Reinforced Epoxy Hybrid Composites. Materials 2019, 12, 2094. [Google Scholar] [CrossRef] [PubMed]

- Rihayat, T.; Suryani, S.; Fauzi, T.; Agusnar, H.; Wirjosentono, B.; Alam, P.N.; Sami, M. Mechanical properties evaluation of single and hybrid composites polyester reinforced bamboo, PALF and coir fiber. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012081. [Google Scholar] [CrossRef]

- Getu, D.; Nallamothu, R.B.; Masresha, M.; Nallamothu, S.K.; Nallamothu, A.K. Production and characterization of bamboo and sisal fiber reinforced hybrid composite for interior automotive body application. Mater. Today Proc. 2020, 38, 2853–2860. [Google Scholar] [CrossRef]

- Abedom, F.; Sakthivel, S.; Asfaw, D.; Melese, B.; Solomon, E.; Kumar, S.S. Development of Natural Fiber Hybrid Composites Using Sugarcane Bagasse and Bamboo Charcoal for Automotive Thermal Insulation Materials. Adv. Mater. Sci. Eng. 2021, 2021, 2508840. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Shenoy, B.S.; Sultan, M.T.B.H.; Kini, C.R.; Shenoy, K.R.; Acharya, A.; Jaideep, J. Influence of stacking sequence on the mechanical properties of 3D E-glass/bamboo non-woven hybrid epoxy composites. Mater. Today Proc. 2020, 38, 2431–2438. [Google Scholar] [CrossRef]

- Zuhudi, N.Z.M.; Lin, R.J.; Jayaraman, K. Flammability, thermal and dynamic mechanical properties of bamboo-glass hybrid composites. J. Thermoplast. Compos. Mater. 2016, 29, 1210–1228. [Google Scholar] [CrossRef]

- Sathish, S.; Kumaresan, K.; Prabhu, L.; Vigneshkumar, N. Experimental Investigation on Volume Fraction of Mechanical and Physical Properties of Flax and Bamboo Fibers Reinforced Hybrid Epoxy Composites. Polym. Polym. Compos. 2017, 25, 229–236. [Google Scholar] [CrossRef]

- Zweben, C. Tensile strength of hybrid composites. J. Mater. Sci. 1977, 12, 1325–1337. [Google Scholar] [CrossRef]

- Thiagamani, S.M.K.; Krishnasamy, S.; Muthukumar, C.; Tengsuthiwat, J.; Nagarajan, R.; Siengchin, S.; Ismail, S.O. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef] [PubMed]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Evaluation of the hybridization effect on the thermal and thermo-oxidative stability of bamboo/kenaf/epoxy hybrid composites. J. Therm. Anal. 2019, 137, 55–63. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.; Alothman, O.Y.; Abdullah, L.C. Accelerated weathering and soil burial effects on colour, biodegradability and thermal properties of bamboo/kenaf/epoxy hybrid composites. Polym. Test. 2019, 79, 106054. [Google Scholar] [CrossRef]

- Bamboos Market Size, Share & Trends Analysis Report, By Application (Raw Materials, Industrial Products, Furniture, Shoots), By Region, And Segment Forecasts, 2019–2025. Grand View Research. 2021. Available online: https://www.grandviewresearch.com/industry-analysis/bamboos-market (accessed on 4 January 2022).

- Javadian, A.; Smith, I.F.C.; Hebel, D.E. Application of Sustainable Bamboo-Based Composite Reinforcement in Structural-Concrete Beams: Design and Evaluation. Materials 2020, 13, 696. [Google Scholar] [CrossRef]

- Global Waste Generation—Statistics & Facts. Statista. 2021. Available online: https://www.statista.com/topics/4983/waste-generation-worldwide/ (accessed on 4 January 2022).

- Ramachandralu, K. Development of surgical clothing from bamboo fibres. In Medical and Healthcare Textiles; Elsevier: Amsterdam, The Netherlands, 2010; pp. 171–180. [Google Scholar] [CrossRef]

| Year | Reference | Remark | Processing Technique | Water Absorption | Tensile Strength | Flexural Strength | Impact Strength | Thermal Test | Hybrid Composites |

|---|---|---|---|---|---|---|---|---|---|

| 2017 | Kenan Song, Xiaofeng Ren and Longhe Zhang [32] | Study on mechanical/thermal and characteristics performance | √ | √ | √ | √ | √ | ||

| 2017 | Calvin Yap Thai Ming, Wong King Jye and Haris Ahmad Israr Ahmad [33] | Study on mechanical performance | √ | √ | √ | ||||

| 2018 | Jan E.G. van Dam, H. Wolter Elbersen and Claudia M. Daza Montaño [34] | Focus on the potential bamboo in biobased economy | √ | ||||||

| 2018 | Yıldızhan et al. [35] | Study on the mechanical and chemical properties | √ | ||||||

| 2018 | S. A. H. Roslan, Z. A. Rasid and M. Z. Hassan [36] | Study on fiber extraction and mechanical properties | √ | √ | √ | ||||

| 2018 | Pramudi et al. [37] | Study on parameter and tensile behavior | √ | ||||||

| 2022 | Jawaid et al. [38] | Investigated on bamboo- and kenaf-reinforced nanocomposites on mechanical and thermal performance | √ | √ | √ | √ |

| Fiber | Annual Production (103 Tons) | Origin |

|---|---|---|

| Abaca | 70 | Leaf |

| Bamboo | 10,000 | Stem |

| Banana | 200 | Stem |

| Coir | 100 | Fruit |

| Cotton Lint | 18,500 | Stem |

| Flax | 810 | Stem |

| Hemp | 215 | Stem |

| Jute | 2500 | Stem |

| Kenaf | 770 | Stem |

| Ramie | 100 | Stem |

| Rice straw | Abundant | Fruit/grain |

| Wood | 1,750,000 | Stem |

| Fibers | Cellulose (wt.%) | Hemicellulose (wt.%) | Lignin (wt.%) | Waxes (wt.%) |

|---|---|---|---|---|

| Abaca | 56–63 | 20–25 | 12–131 | - |

| Bagasse | 55.2 | 16.8 | 25.3 | - |

| Bamboo | 26–43 | 30 | 21–31 | - |

| Banana | 63–64 | - | 5–11 | - |

| Coir | 32–43 | 0.15–0.25 | 40–45 | - |

| Cotton | 85–90 | 5.7 | - | 0.6 |

| Curaua | 7.36 | 9.9 | 7.5 | - |

| Flax | 71 | 18.6–20.6 | 2.2–20.6 | 1.5–1.7 |

| Hemp | 68–74 | 15–22.4 | 3.5–10 | 0.8 |

| Jute | 61–71.5 | 13.6–20.4 | 12–13 | 0.5 |

| Kenaf | 45–72 | 20.3–21.5 | 8–13 | - |

| Pineapple | 80.5 | 17.5 | 8.3 | - |

| Ramie | 68.6–76.2 | 13–16 | 0.6–0.7 | 0.3 |

| Sisal | 65–78 | 10–14 | 9.9–14 | 2 |

| Fibers | Tensile (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | Density (g/cm3) |

|---|---|---|---|---|

| Abaca | 400 | 12 | 3–10 | 1.5 |

| Bagasse | 350 | 22 | 5.8 | 0.89 |

| Bamboo | 290 | 17 | - | 1.25 |

| Banana | 529–914 | 27–32 | 5.9 | 1.35 |

| Coir | 220 | 6 | 15–25 | 1.25 |

| Cotton | 400 | 11.8 | 3–10 | 1.51 |

| Curaua | 550–1150 | 11.8 | 3.7–4.3 | 1.4 |

| Flax | 800–1500 | 60–80 | 1.2–1.6 | 1.4 |

| Hemp | 550–900 | 70 | 1.6 | 1.48 |

| Jute | 410–780 | 26.5 | 1.9 | 1.48 |

| Kenaf | 930 | 53 | 1.6 | - |

| Pineapple | 413–1627 | 60–82 | 14.5 | 1.44 |

| Ramie | 500 | 44 | 2 | 1.5 |

| Sisal | 610–720 | 2–3 | 2–3 | 1.34 |

| E-glass | 2400 | 73 | 3 | 2.55 |

| Bamboo Species | Modulus of Rupture (MPa) | Modulus Elasticity (MPa) | Shear Strength (MPa) | Compression Strength (MPa) |

|---|---|---|---|---|

| Bambusa blumeana | 99.8 | 4100 | 4.5 | 24 |

| Bambusa vulgaris | 62.3 | 6100 | 4 | 25.3 |

| Balanocarpus levis | 122 | 1800 | 13.7 | 69 |

| Dendrocalamus asper | 85.7 | 6300 | 5.4 | 31.5 |

| Gigantochloa scortechinii | 52.4 | 4800 | 4.3 | 27 |

| Gigantochloa levis | 78.5 | 5100 | 4.8 | 40 |

| Koompasia malaccensis | 100 | 1700 | 10 | 54.7 |

| Bamboo (Type) | Polymer Thermoplastic | Manufacturing Methods | Applied Testing Method | Ref. |

|---|---|---|---|---|

| Flour | High-density polyethylene (HDPE) | Twin screw extruders and injection molding | Static mechanical test, dynamic mechanical analyzer (DM), scanning electron microscope (SEM) | [78] |

| Fiber | Polypropylene (PP) | Twin screw extruders and injection molding | Tensile strength, flexural strength, impact strength, water absorption, and thermogravimetric analysis (TGA) | [82] |

| Fiber | PP | Hot press | Tensile strength, SEM, and steam explosion technique | [83] |

| Fiber | HDPE | Melt blending and hot press | Mechanical test and SEM | [84] |

| Fiber | Polyvinyl chloride (PVC) | Hot–cool mixer, twin screw extruders, and hot press | Mechanical test | [72] |

| Fiber | Polyethylene (PE) | Twin screw extruders | Mechanical test and thermal properties | [85] |

| Fiber | PP | Two roll mill and hot press | Mechanical test, physical and SEM | [86] |

| Thermoplastic Matrix | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (kJ/m) | Water Absorption (%) | Ref. |

|---|---|---|---|---|---|

| HDPE | 19–44.7 | 20–36 | 2.4–4.9 | 1.5–10 | [84,85,93,94] |

| LDPE | 9.2–9.5 | 17.57 | 8.35 | - | [95,96] |

| PP | 25.5–63 | 38.8–80 | 2.94–3.13 | 2.07–3.76 | [31,82,86,97] |

| Polystrene | 25–69 | 27–29 | 1.14 | 2.79 | [98,99] |

| PLA | 26–41.4 | 85 | 6 | - | [100,101,102] |

| Samples | T1on (°C) | Tmax (°C) | Residue at 600 °C (%) |

|---|---|---|---|

| 1 | 341.36 | 466.48 | 2.19 |

| 2 | 339.37 | 474.55 | 2.58 |

| 3 | 321.03 | 473.55 | 3.02 |

| 4 | 304.13 | 472.53 | 3.6 |

| 5 | 297.71 | 470.51 | 4.01 |

| 6 | 277.53 | 468.45 | 16.43 |

| Neat HDPE | 427.64 | - | 0.49 |

| Thermoset | Density (g/cm3) | Tensile Strength (MPa) | Young Modulus (GPa) | Elongation (%) | Ref. |

|---|---|---|---|---|---|

| Epoxy | 1.1–1.4 | 35–90 | 2.1–6 | 1.9–3.5 | [104,106,107,108] |

| Phenolic | 1.3 | 55–55 | 2.7–4.1 | - | [104] |

| Polyester | 1.2–1.5 | 61–63 | 1–4 | 2.5–4.7 | [97,98,101] |

| Polyimides | 1.46 | 120 | 3.5–4.5 | - | [104] |

| Vinyl Ester | 1.2–1.4 | 80–120 | 2.9–11.9 | 3–5 | [104,107] |

| Bamboo Type | Polymer Thermoset | Manufacturing Methods | Applied Testing Methods | Ref. |

|---|---|---|---|---|

| Fiber | Epoxy | Resin transfer molding (RTM) | Tensile and flexural test, and hydrothermal ageing test | [109] |

| Fiber | Epoxy | Hand layout | Mechanical test | [110] |

| Fiber | Unsaturated polyester | Hand layout | Mechanical test | [111] |

| Fiber | Epoxy | Hand layout | Flexural, quasi-static fracture toughness, thermal and FTIR test | [112] |

| Powder | Epoxy | Hand layout | Thermal test | [113] |

| Fiber | Polyester | Hand layout | Mechanical test | [114] |

| Solid | Phenol–formaldehyde | Impregnation | Dynamic mechanical test (DMA), compression test, measurement of friction coefficient, and differential scanning calorimetry (DSC) | [115] |

| Strips | Phenol–formaldehyde (PF) | Winding | Compression test | [116] |

| Fiber | Polyester | Vacuum infusion | Fracture and tensile test | [117] |

| Thermoset Matrix | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (kJ/m) | Water Absorption (%) | Ref. |

|---|---|---|---|---|---|

| Epoxy | 142.86–291.67 | 141.39–182.29 | - | 19 | [109,112,121] |

| Phenolic | 114.4–354.78 | - | - | 7.98 | [122] |

| Polyester | 98.4–191.3 | 50–128.5 | 5–20 | 4–12.05 | [111,117,123,124] |

| Vinyl Ester | 48.06–119.39 | 106.81–161.58 | - | 6–14 | [125] |

| Hybrid | Resin | Method | Ref. |

|---|---|---|---|

| Date palm | Epoxy | Hand layout technique | [131] |

| Jute | Low-density polyethylene (LDPE) | Hotpress technique | [132] |

| Jute | Vinyl ester | Hand layout technique | [133] |

| Kenaf | Epoxy | Hand layout technique | [134] |

| Pineapple leaf/coir fiber | Polyester | Hotpress technique | [135] |

| Sisal | Polyester | Hand layout technique | [136] |

| Sugarcane bagasse | Polyurethane (PU) foam | Hand layout and compression molding technique | [137] |

| Carbon nanotubes (CNT) | Epoxy | Hand layout technique | [76] |

| E-glass | Epoxy | Hand layout technique | [138] |

| Glass | PP | Hotpress technique | [139] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radzi, A.M.; Zaki, S.A.; Hassan, M.Z.; Ilyas, R.A.; Jamaludin, K.R.; Daud, M.Y.M.; Aziz, S.A. Bamboo-Fiber-Reinforced Thermoset and Thermoplastic Polymer Composites: A Review of Properties, Fabrication, and Potential Applications. Polymers 2022, 14, 1387. https://doi.org/10.3390/polym14071387

Radzi AM, Zaki SA, Hassan MZ, Ilyas RA, Jamaludin KR, Daud MYM, Aziz SA. Bamboo-Fiber-Reinforced Thermoset and Thermoplastic Polymer Composites: A Review of Properties, Fabrication, and Potential Applications. Polymers. 2022; 14(7):1387. https://doi.org/10.3390/polym14071387

Chicago/Turabian StyleRadzi, A.M., Sheikh Ahmad Zaki, Mohamad Zaki Hassan, R.A. Ilyas, Khairur Rijal Jamaludin, Mohd Yusof Md Daud, and Sa’ardin Abd Aziz. 2022. "Bamboo-Fiber-Reinforced Thermoset and Thermoplastic Polymer Composites: A Review of Properties, Fabrication, and Potential Applications" Polymers 14, no. 7: 1387. https://doi.org/10.3390/polym14071387

APA StyleRadzi, A. M., Zaki, S. A., Hassan, M. Z., Ilyas, R. A., Jamaludin, K. R., Daud, M. Y. M., & Aziz, S. A. (2022). Bamboo-Fiber-Reinforced Thermoset and Thermoplastic Polymer Composites: A Review of Properties, Fabrication, and Potential Applications. Polymers, 14(7), 1387. https://doi.org/10.3390/polym14071387